www.kennametal.com

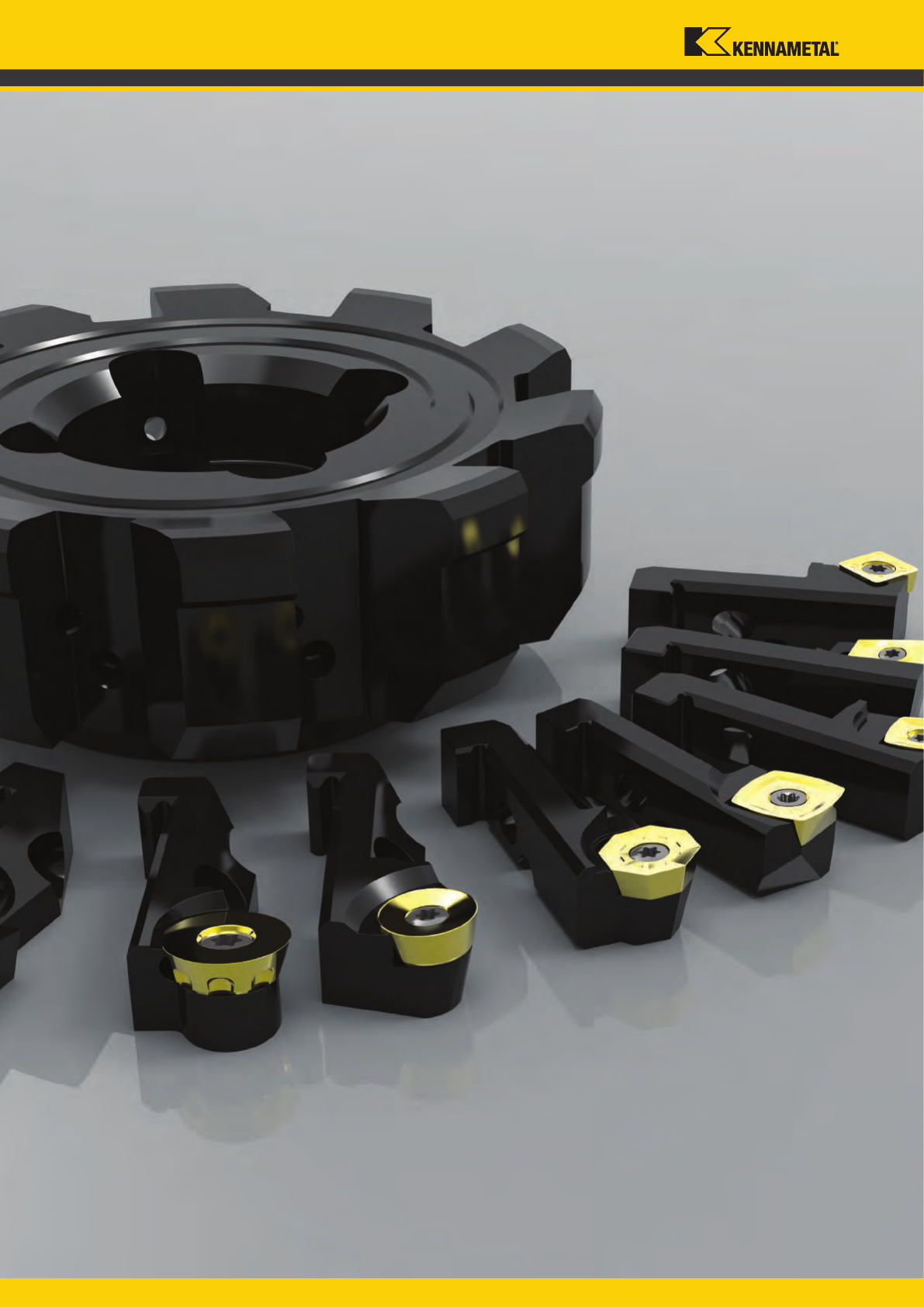

III

MILLING

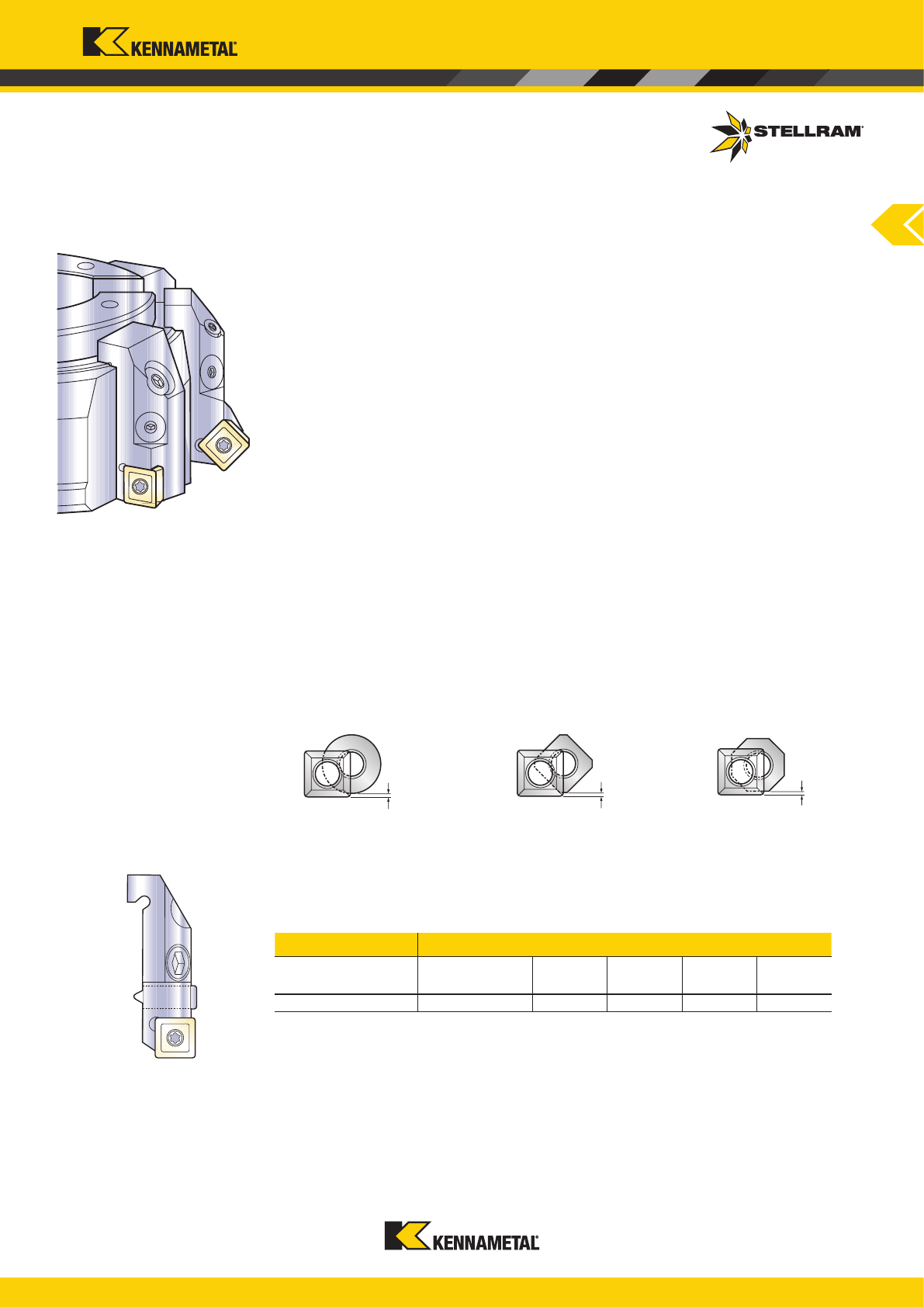

Indexable Milling Solutions

www.kennametal.com

A1

Milling Introduction

Indexable Milling

INTRODUCTION

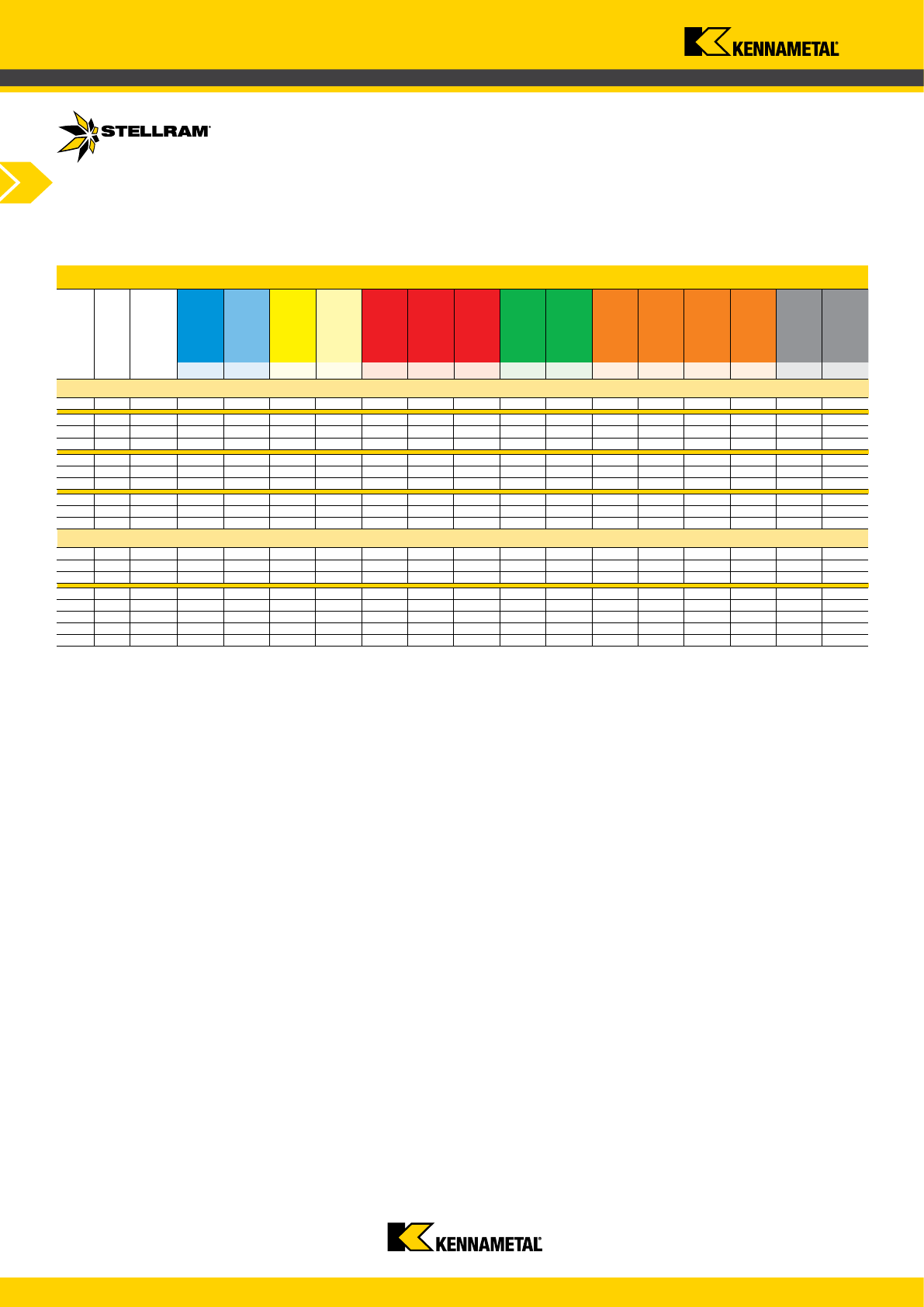

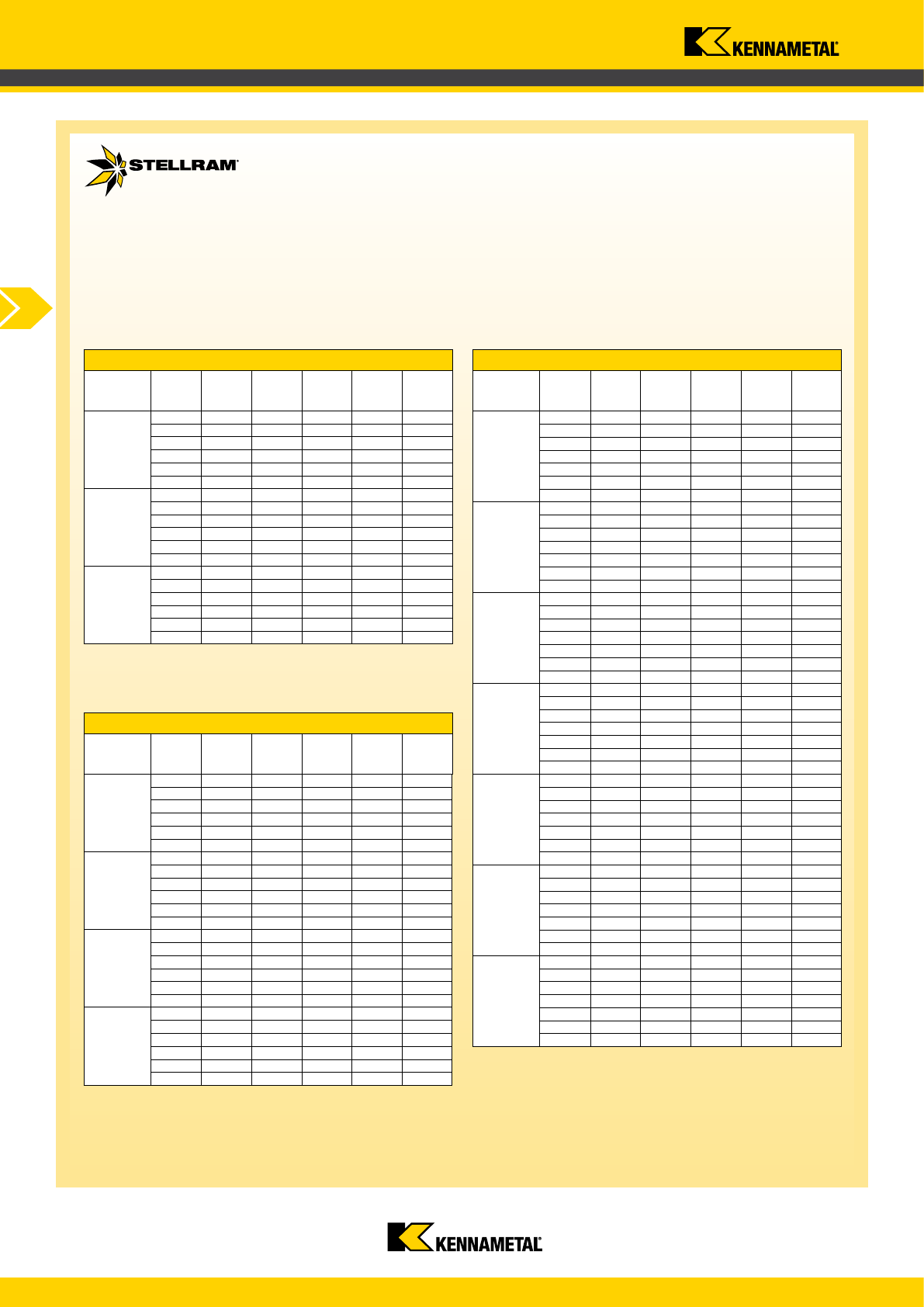

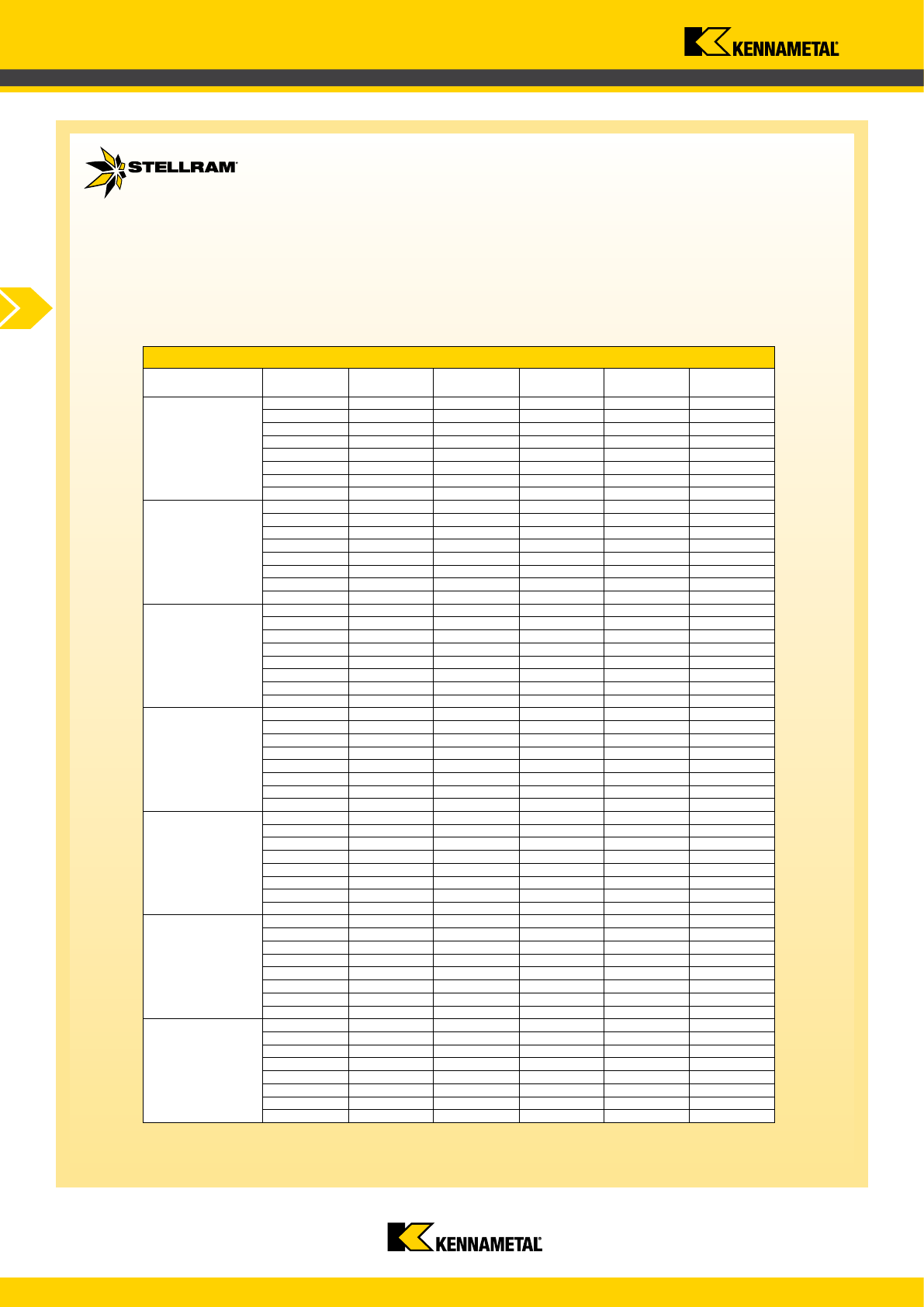

Tooling Selection Guide ....................................................................................................................................................A2 - A5

Application Index .............................................................................................................................................................A6 - A13

Milling Inserts .................................................................................................................................................................A14 - A41

Nomenclature Milling Cutters ........................................................................................................................................ A42 - A43

END MILLS & FACE MILLS

7690VA Series (χ 90°) 09 / 12 / 16 ............................................................................................................................... A45 - A62

7792VX Series (High Feed) 06 / 09 / 12 / 16 ................................................................................................................A63 - A75

Tungsten Cylindrical Shanks for Modular Heads ..................................................................................................................A76

7745VOD Series (χ 42°) 04 / 06.................................................................................................................................... A77 - A86

7745VS Series (χ 45°) 09 / 12....................................................................................................................................... A87 - A94

7745VSE Series (χ 45°) 09 / 12 ...................................................................................................................................A95 -A105

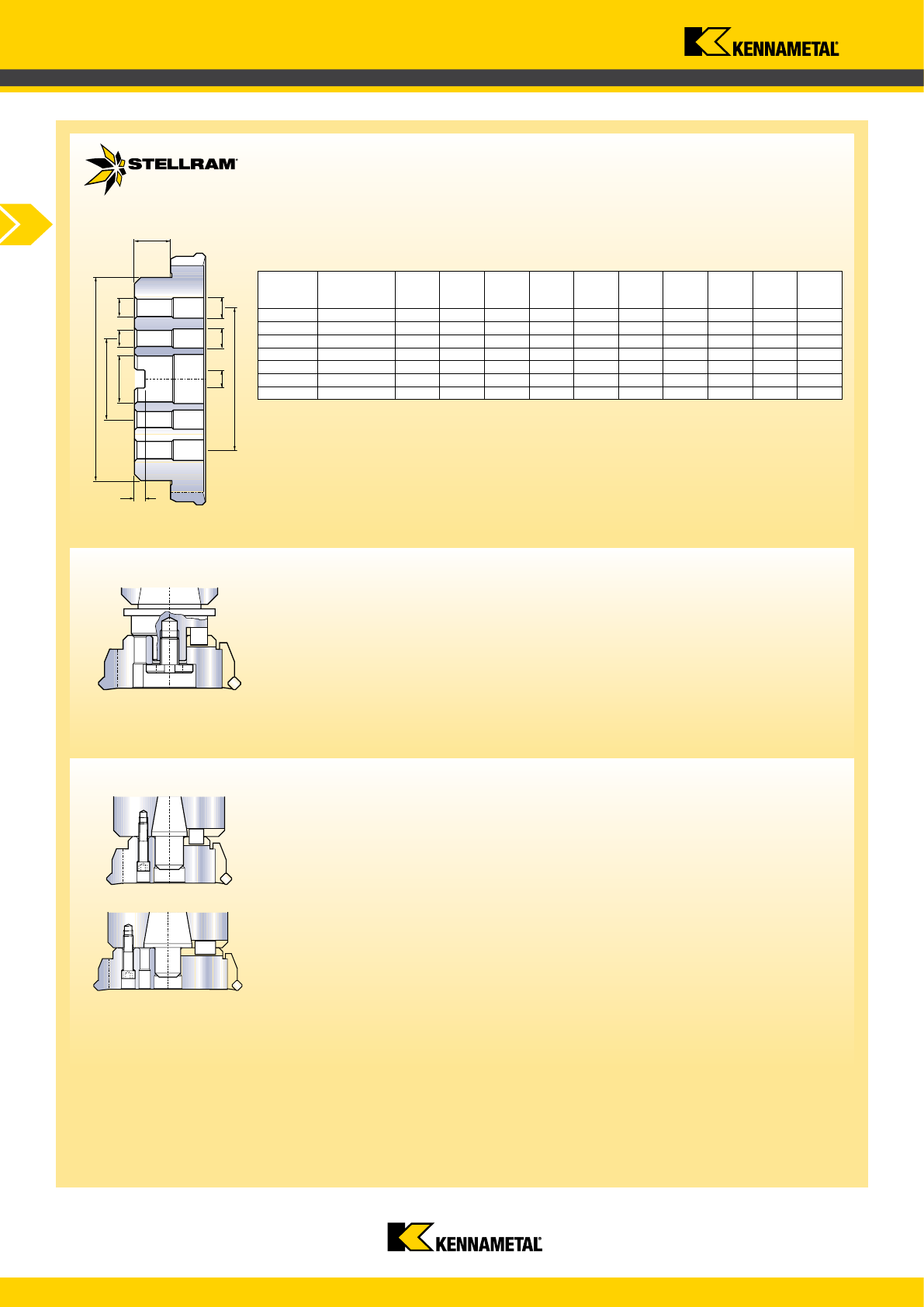

CARTRIDGE FACE MILLS

8000V – 8010V Series .............................................................................................................................................A107 - A110

80_0 VA 90-_R-16 (χ 90°) .........................................................................................................................................A111 - A116

80.0 VX .. 92-_R-12 / _R-16 (High Feed) .................................................................................................................A117 - A124

80.0 VOD 45- (χ 42°) _R-04 / _R-06 ......................................................................................................................... A125 - A134

80.0 VS 45-_R-12 (χ 45°) .......................................................................................................................................... A135 - A140

80.0 VSE 45-_R-12 (χ 45°)........................................................................................................................................ A141 - A148

80.0 VR 00-_R-16 / _R-20 ........................................................................................................................................A149 - A160

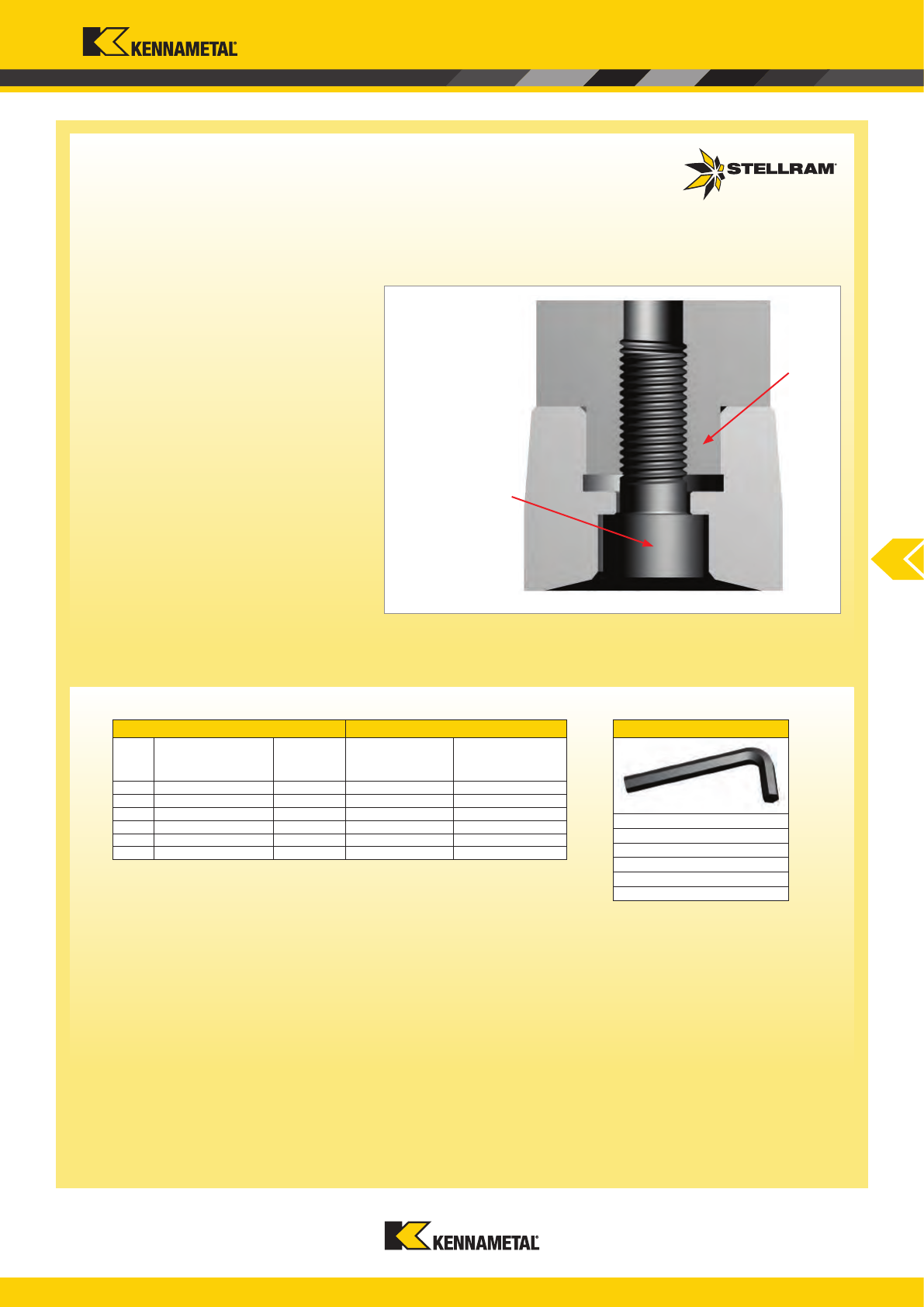

Mounting /Adjusting Cartridges .................................................................................................................................A161 - A164

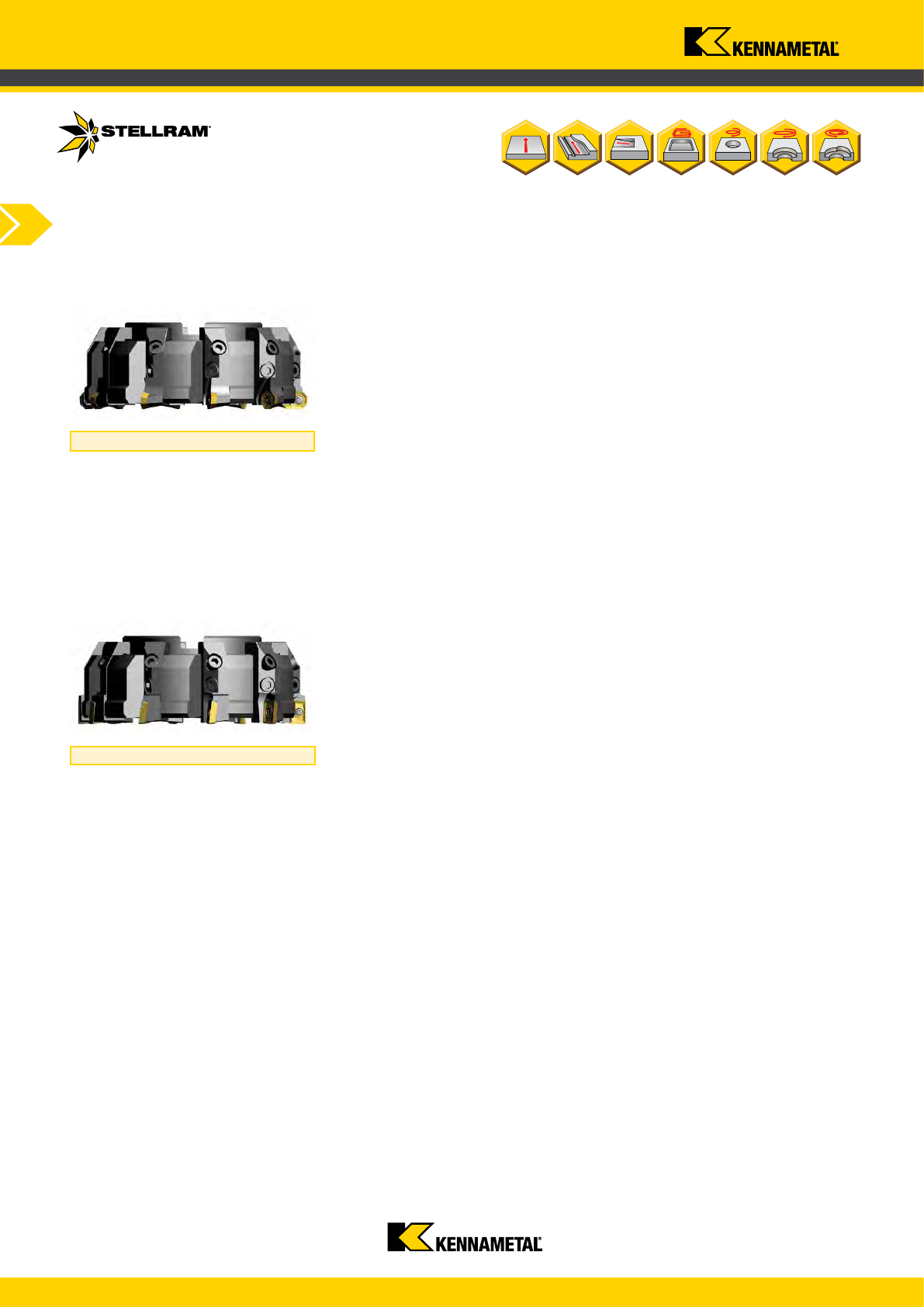

SHOULDER MILLS

5210VS Series 09 / 12 .............................................................................................................................................A165 - A170

5230VS Series 09 / 12 .............................................................................................................................................A171 - A182

5315VA Series 12 / 16 ..............................................................................................................................................A183 - A194

CONTOUR MILLS

5505VX Series 16 / 20 / 25 / 32 / 40 / 50 .................................................................................................................A195 - A200

5500V Series 08 / 10 / 12 / 16 / 20 / 25 .................................................................................................................... A201 - A206

7700VR Series 06 / 08 / 10 ....................................................................................................................................... A207 - A216

7702VRD Series 07 / 10 / 12 / 16 & 7712VRD Series 12 / 16 .................................................................................A217 - A230

7710VRD 20 .............................................................................................................................................................. A231 - A236

7713VR Series 10 / 12 ..............................................................................................................................................A237 - A246

PROFILING & POCKETING MILLS

5702VZD (χ 90°) 14 & 5720VZ (χ 90°) 16 .................................................................................................................A247 - A256

PLUNGING MILLS

7791VS Series 09 / 12 ..............................................................................................................................................A257 - A264

CHAMFERING MILLS

7745VT Series (45°) Series 11 / 16 & 7760VT (60°) 16 ...........................................................................................A265 - A270

T-SLOT MILLS

5400VM Series (χ 90°) 04 / 06 / 08 / 11....................................................................................................................A271 - A277

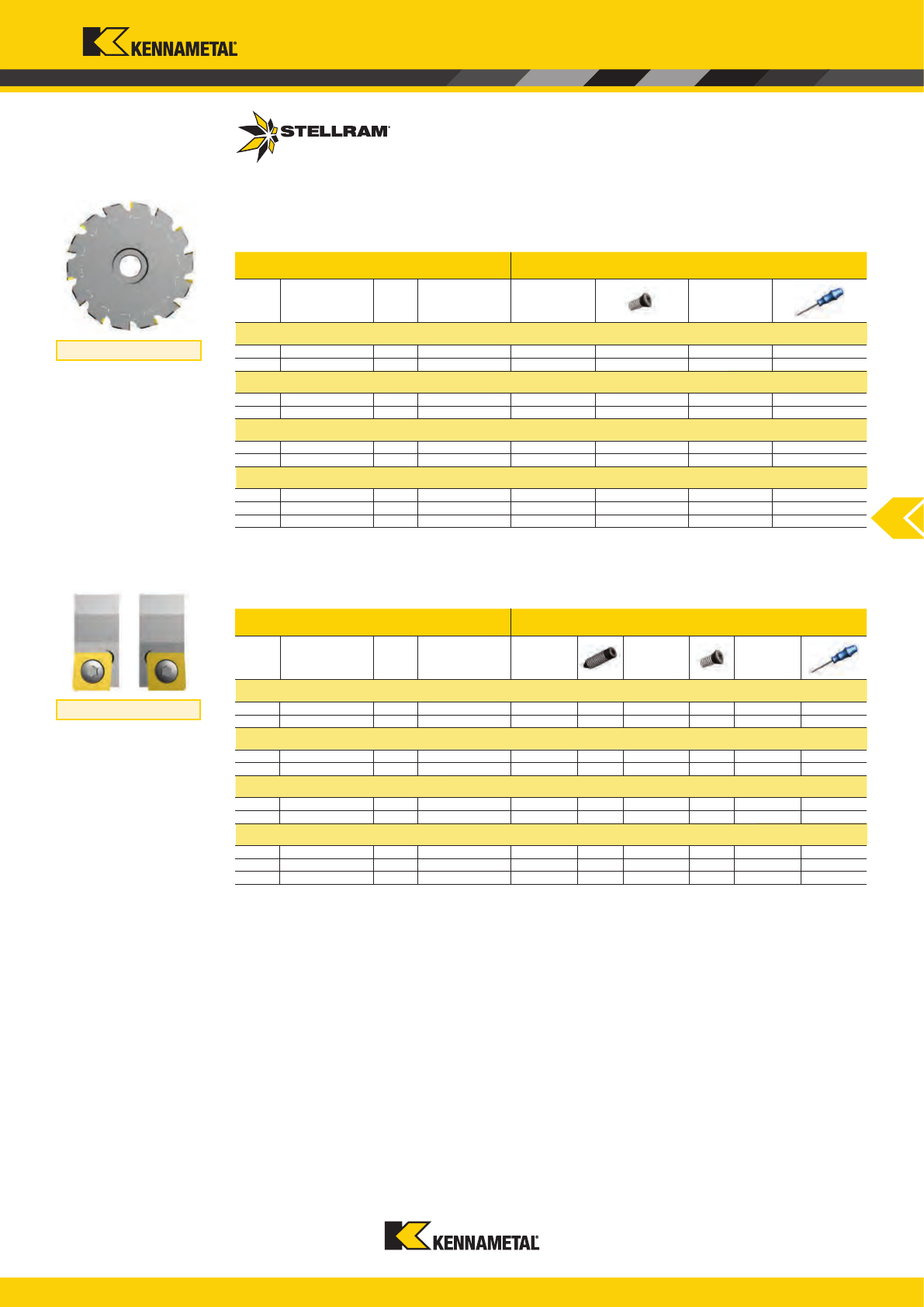

DISC MILLS & CARTRIDGES

7220VM Series (χ 90°) 04 / 06 / 08 / 11 ..................................................................................................................A279 - A288

TECHNICAL

Milling Grade ISO & Speed Charts ...........................................................................................................................A289 - A291

Formulas / Hardness Conversions ............................................................................................................................ A292 - A294

Bolts & Torque Values...........................................................................................................................................................A295

Milling

Contents

www.kennametal.com

A2

www.kennametal.com

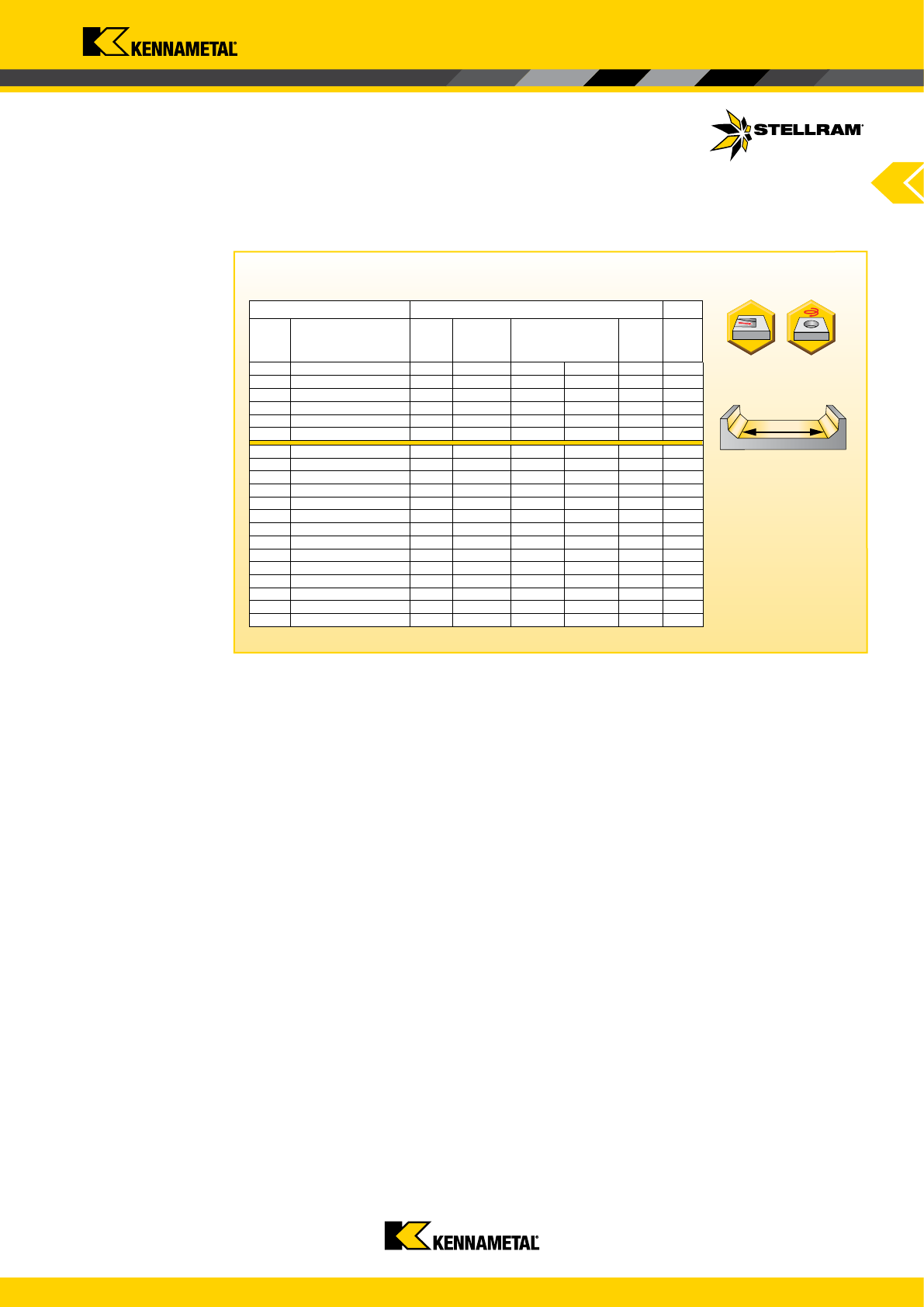

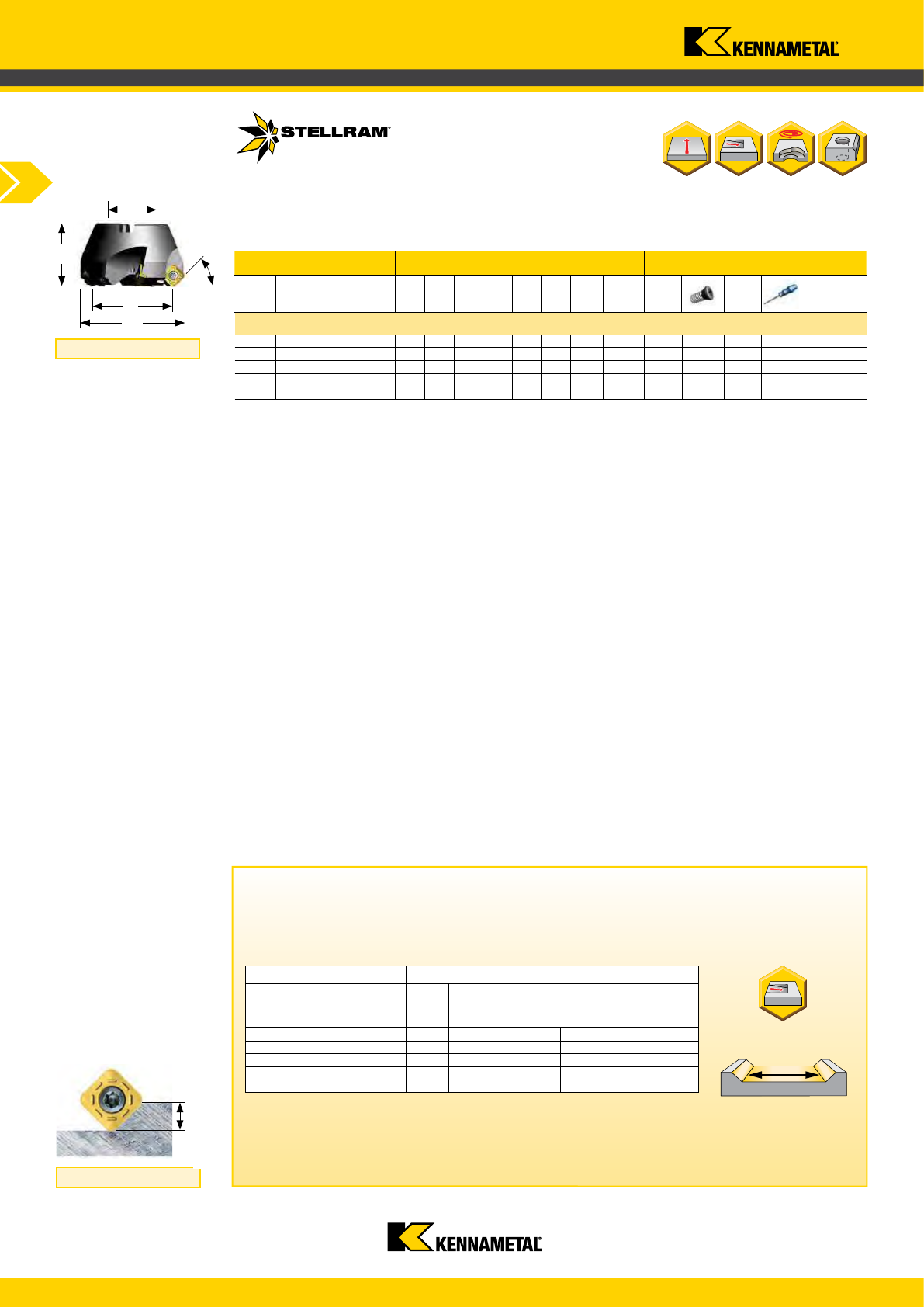

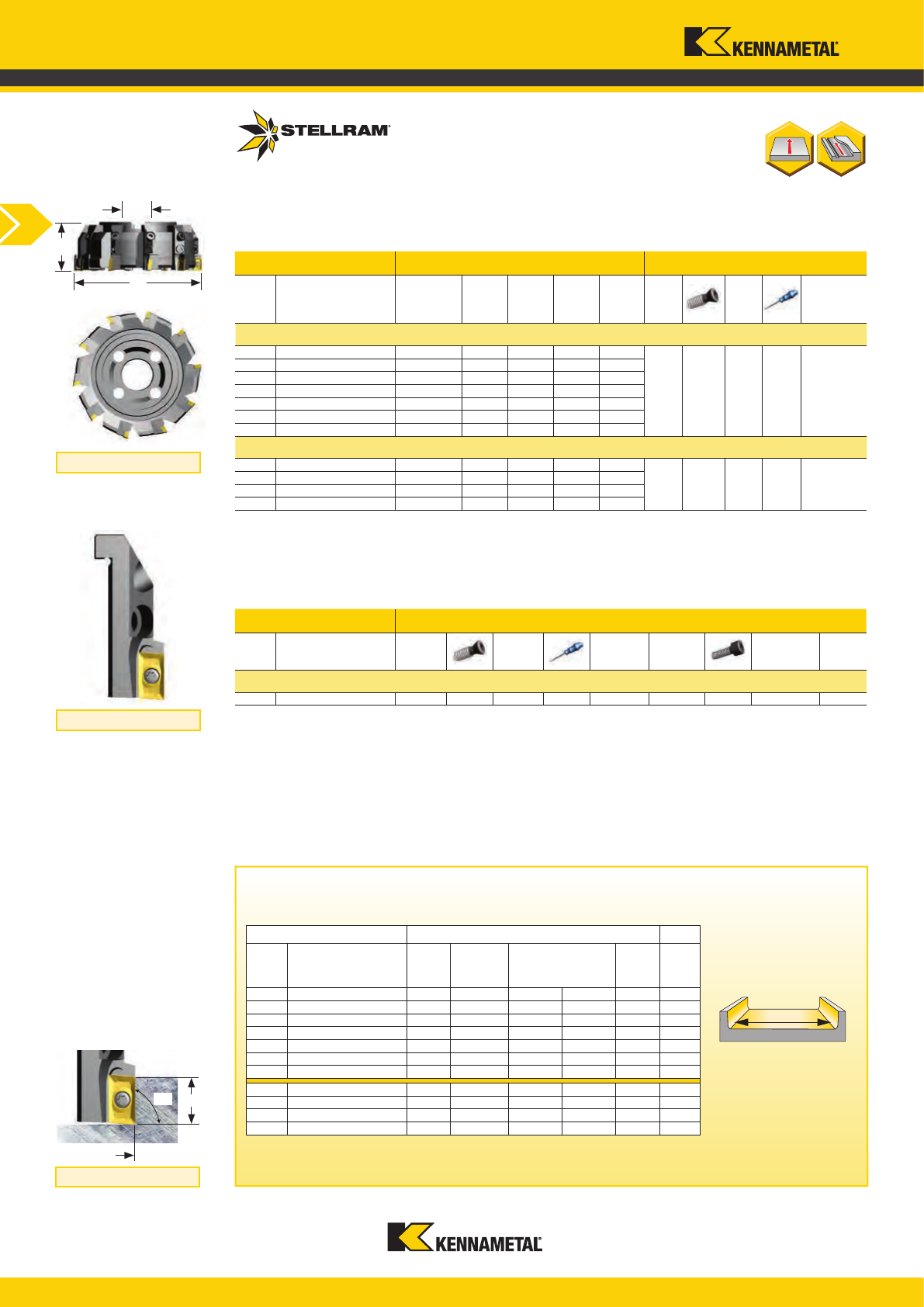

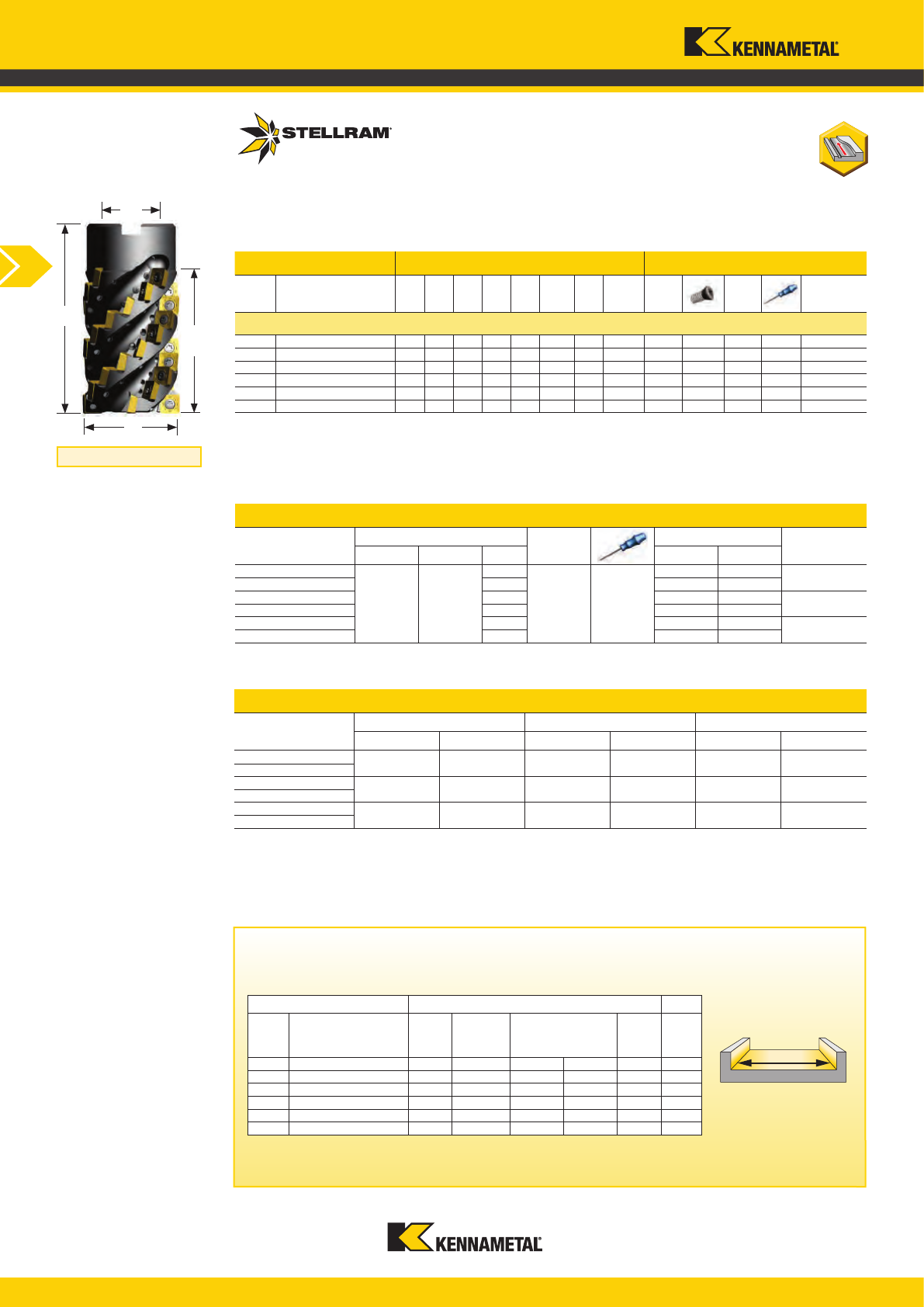

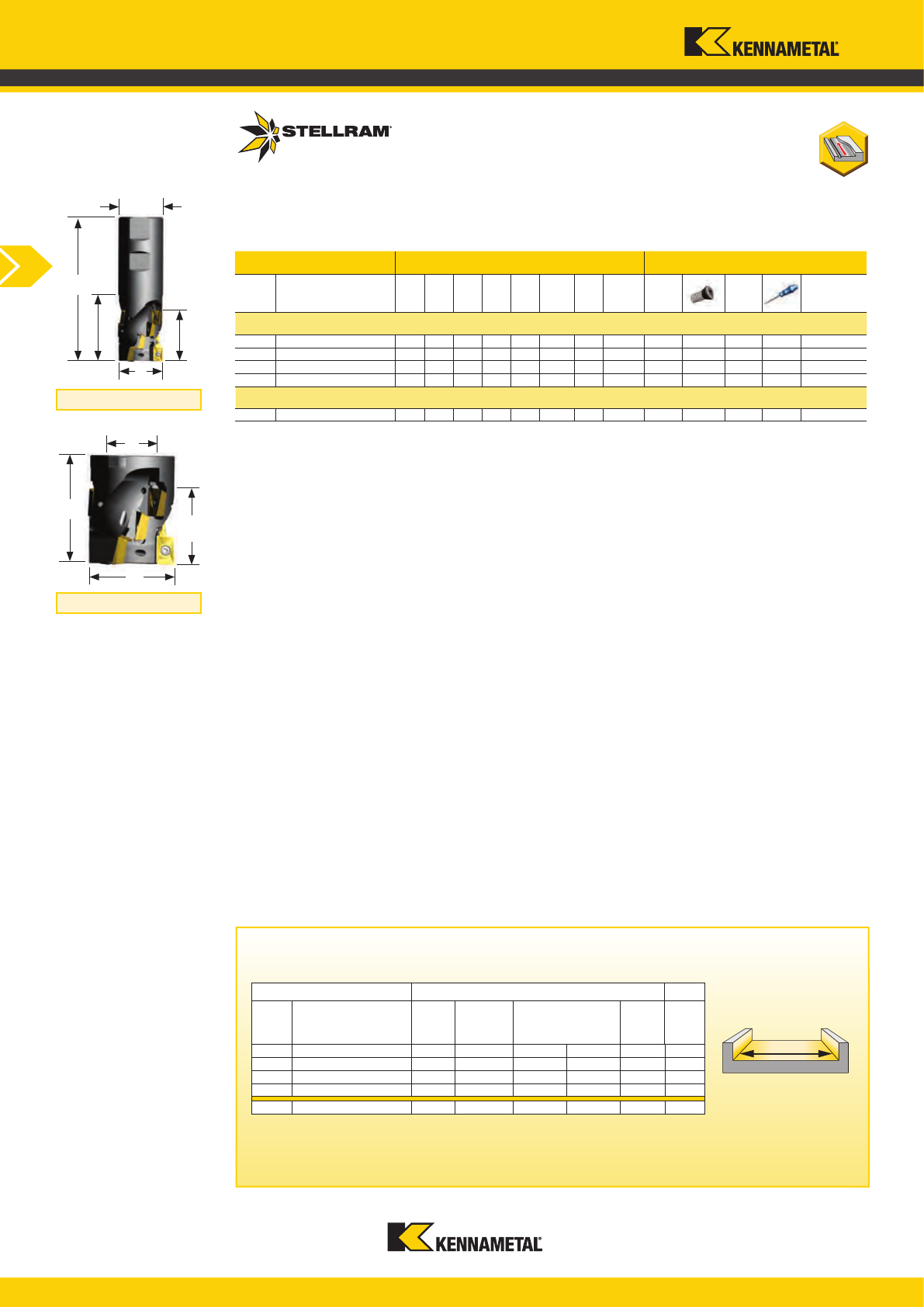

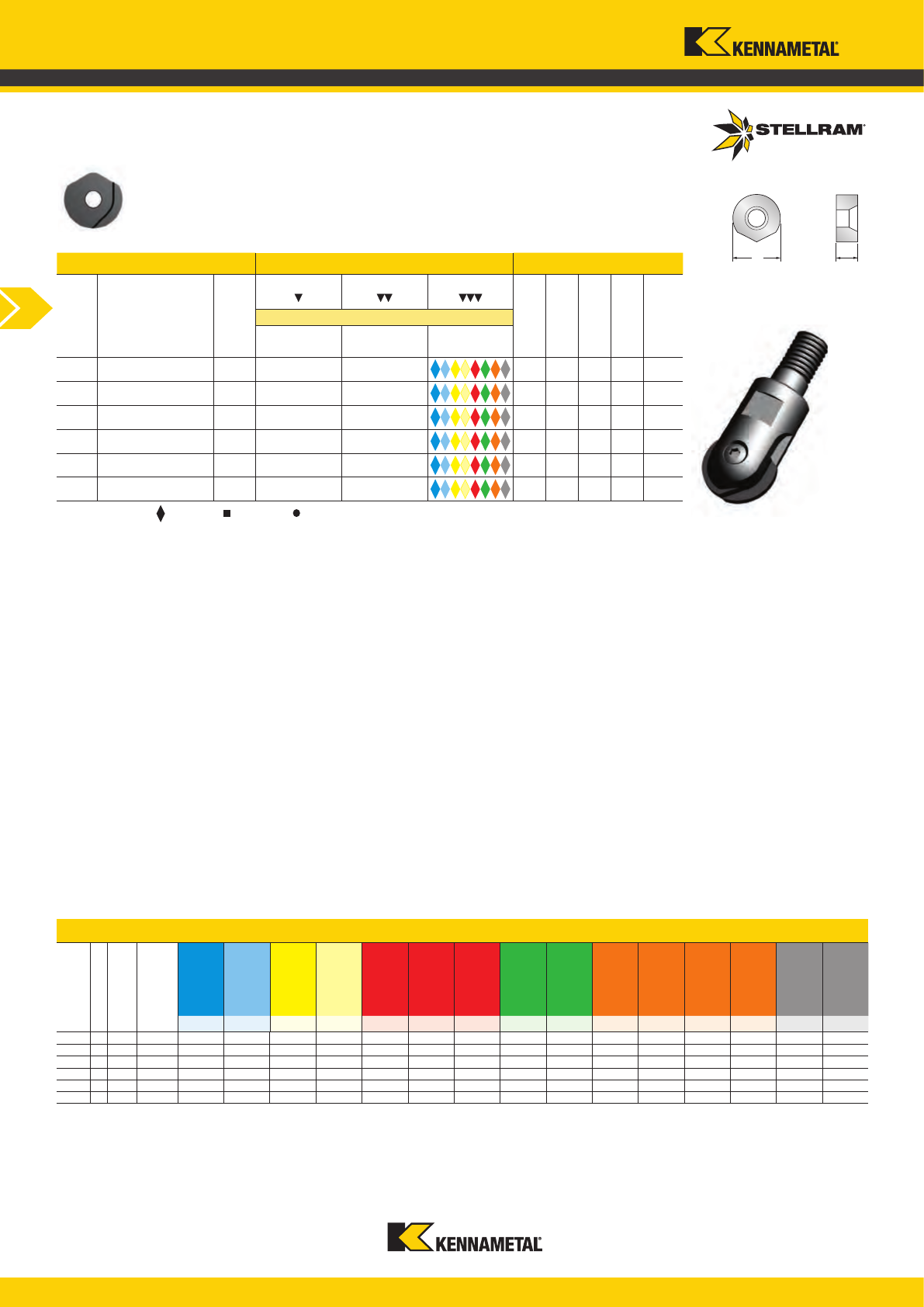

030613 7792VXD09SA025Z2R35 25 35 M1212,50 1,50 2 015269 F3508T 015240 T15 2,10

030614 7792VXD09SA032Z3R43 32 43 M1617,00 1,50 3 015064 F3510T 015240 T15 2,10

029461 7792VXD09WA025Z2R 25 96 40 25 1,50 2 015269 F3508T 015240 T15 2,10

029462 7792VXD09WA032Z3R 32 10040321,503015064 F3510T 015240 T15 2,10

031191 7792VXD09CA025Z2R50 25 20050251,502015064 F3510T 015240 T15 2,10

031192 7792VXD09CA032Z3R70 32 25070321,503015064 F3510T 015240 T15 2,10

029463 7792VXD09-A040Z3R 40 32 -161,503015064 F3510T 015240 T15 2,10

029464 7792VXD09-A040Z4R 40 32 -161,504015064 F3510T 015240 T15 2,10

030434 7792VXD09-A040Z5R 40 32 -161,505015064 F3510T 015240 T15 2,10

030435 7792VXD09-A050Z5R 50 40 -221,505015064 F3510T 015240 T15 2,10

030436 7792VXD09-A050Z6R 50 40 -221,506015064 F3510T 015240 T15 2,10

d

1

H

D

D

L

I

1

d

1

D

L

I

1

d

1

D

029461 7792VXD09WA025Z2R 11,752.806.3034481,006,0048500

029462 7792VXD09WA032Z3R 18,751.505.0048621,006,0040500

031191 7792VXD09CA025Z2R50 11,752.806.3034481,006,0048500

031192 7792VXD09CA032Z3R70 18,751.505.0048621,006,0040500

029463 7792VXD09-A040Z3R 26,750.802.7064781,006,0034500

029464 7792VXD09-A040Z4R 26,750.802.7064781,006,0034500

030434 7792VXD09-A040Z5R 26,750.802.7064781,006,0034500

030435 7792VXD09-A050Z5R 36,750.712.3184981,006,0030000

030436 7792VXD09-A050Z6R 36,750.712.3184981,006,0029500

030613 7792VXD09SA025Z2R35 11,752.806.3034481,006,0048500

030614 7792VXD09SA032Z3R43 18,751.505.0048621,006,0040500

M

L

D

d

1

a

p

A

B

A66

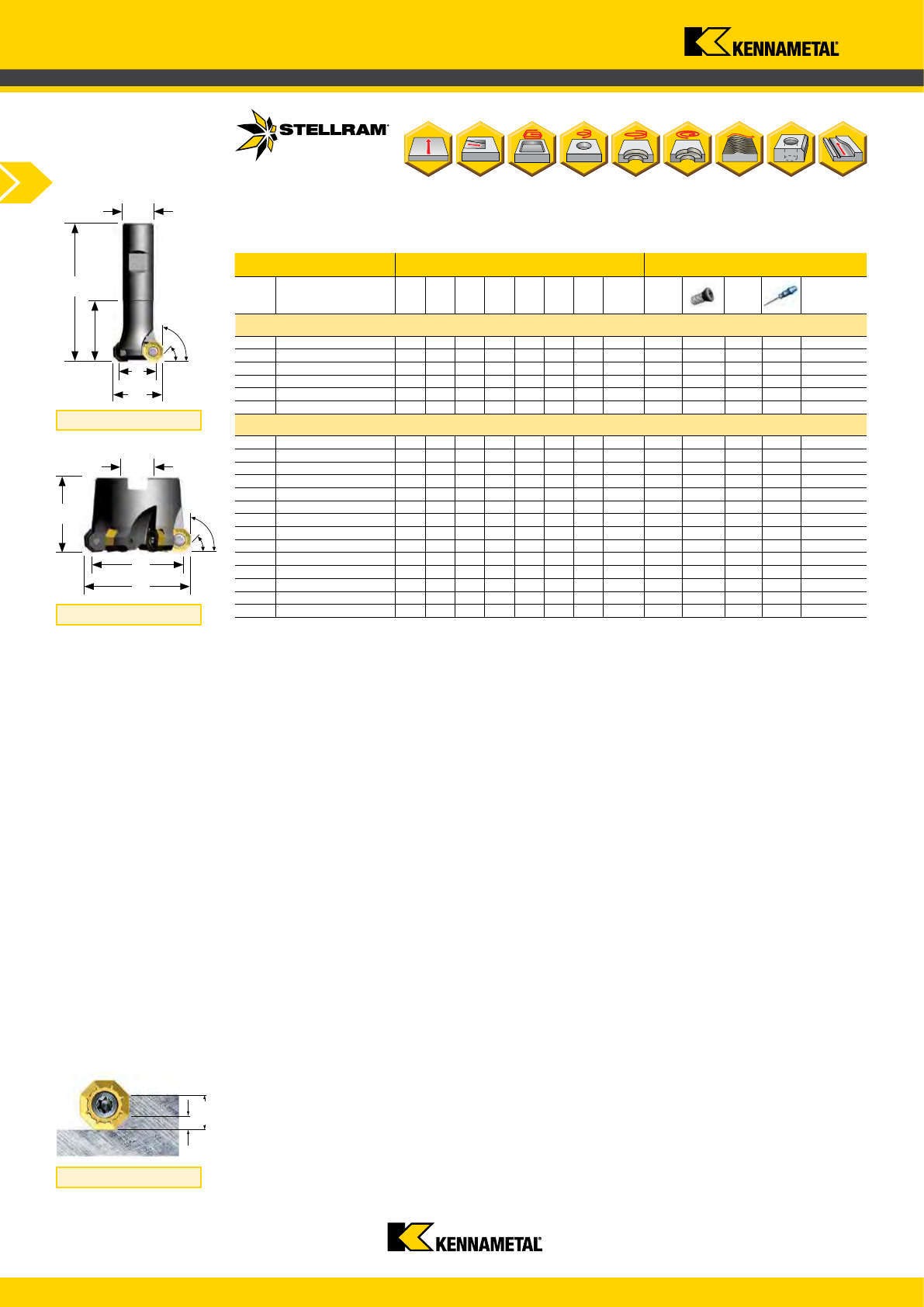

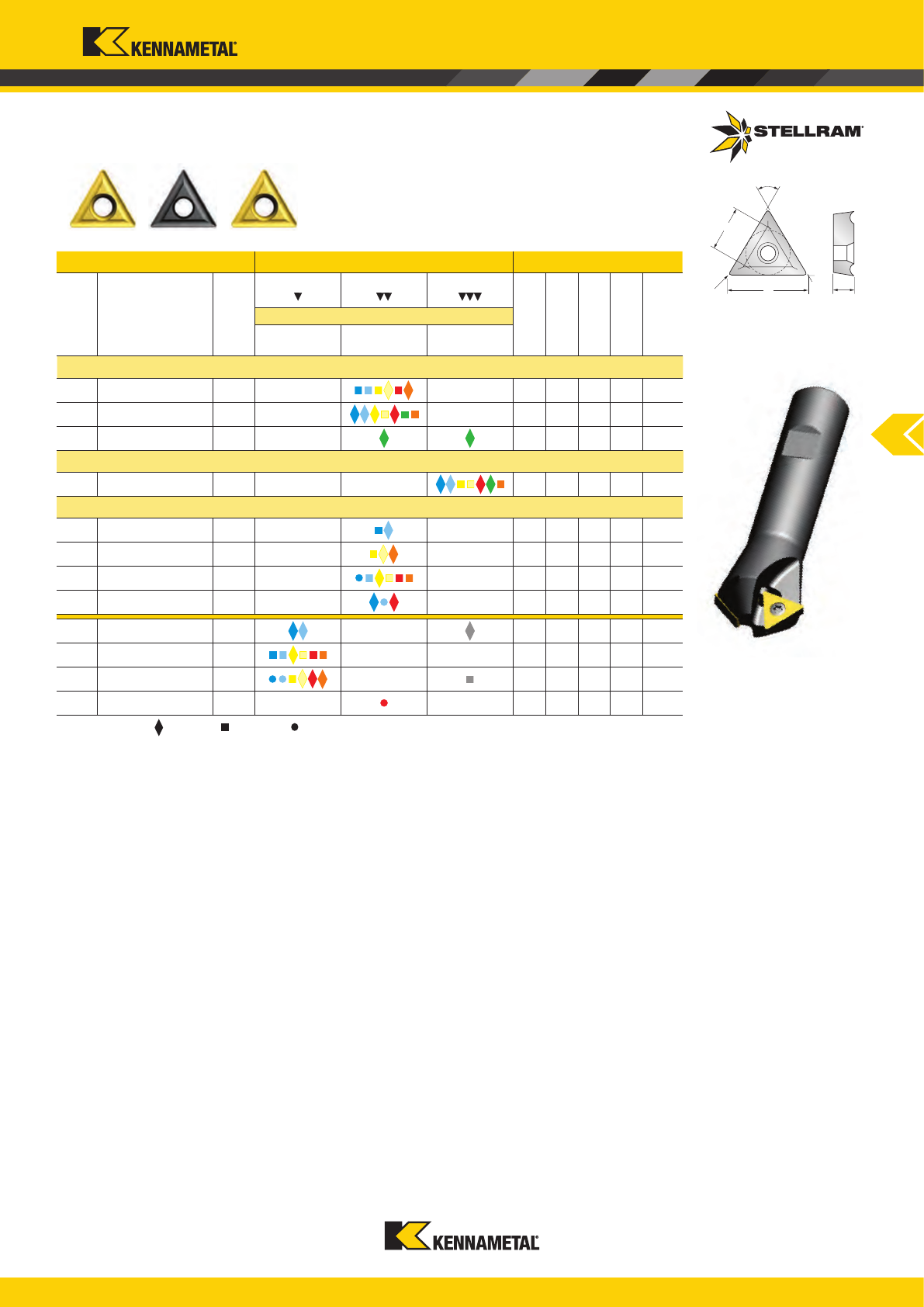

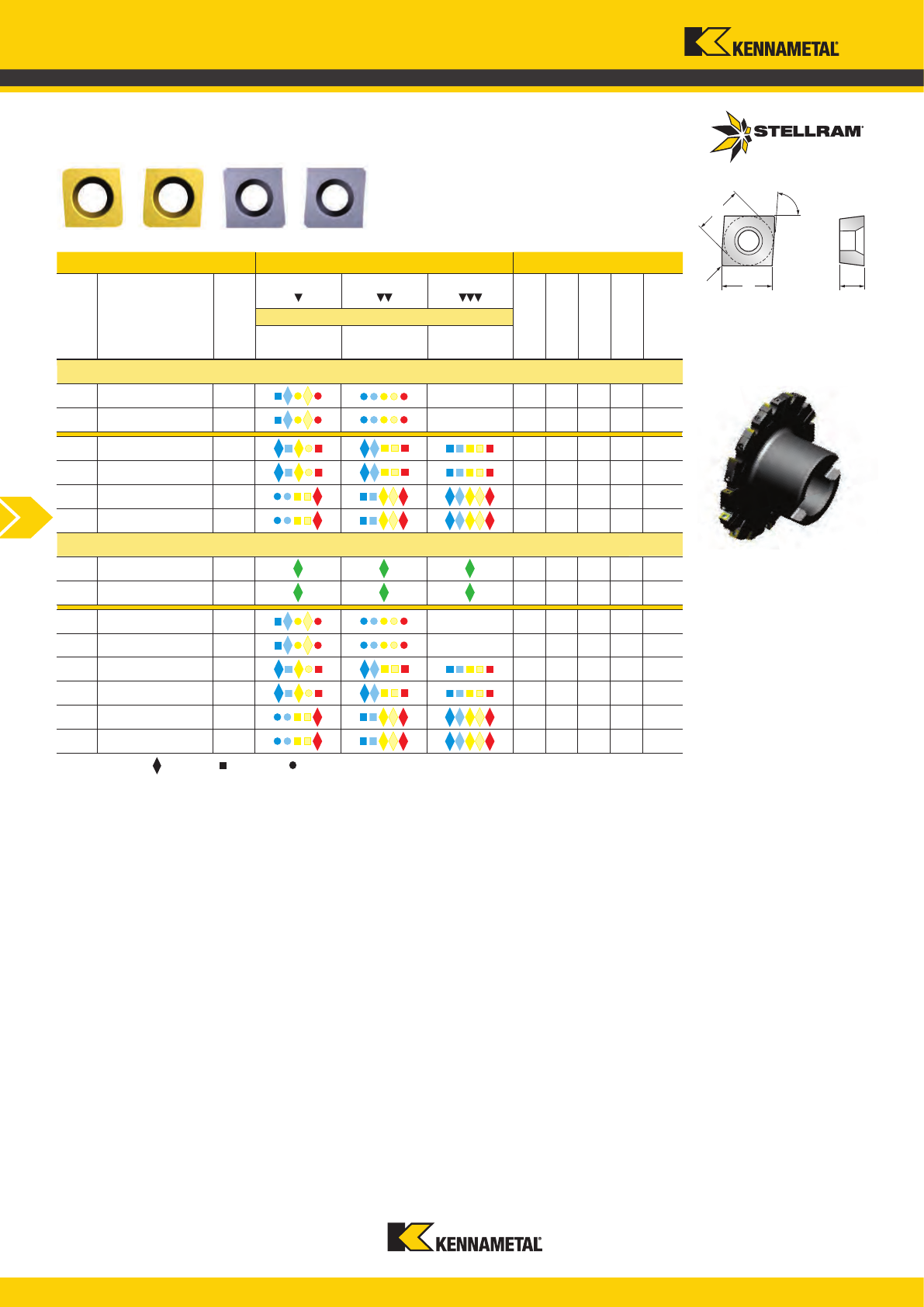

2

1

2.1

2.2

1

• • • • • • • •

•

•

•

• • •

•

•

•

• • • • • • • • •

2

2.1

2.2

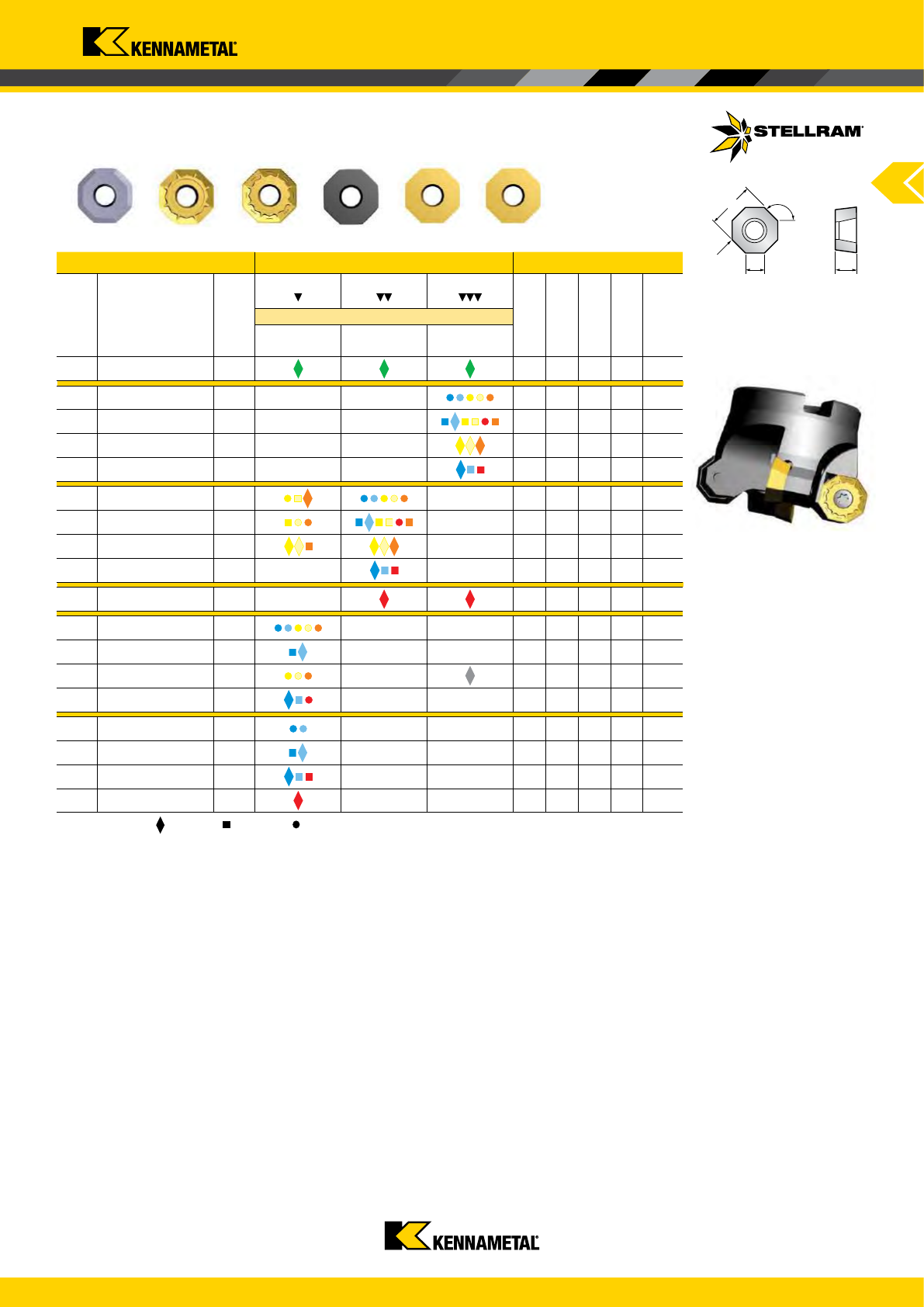

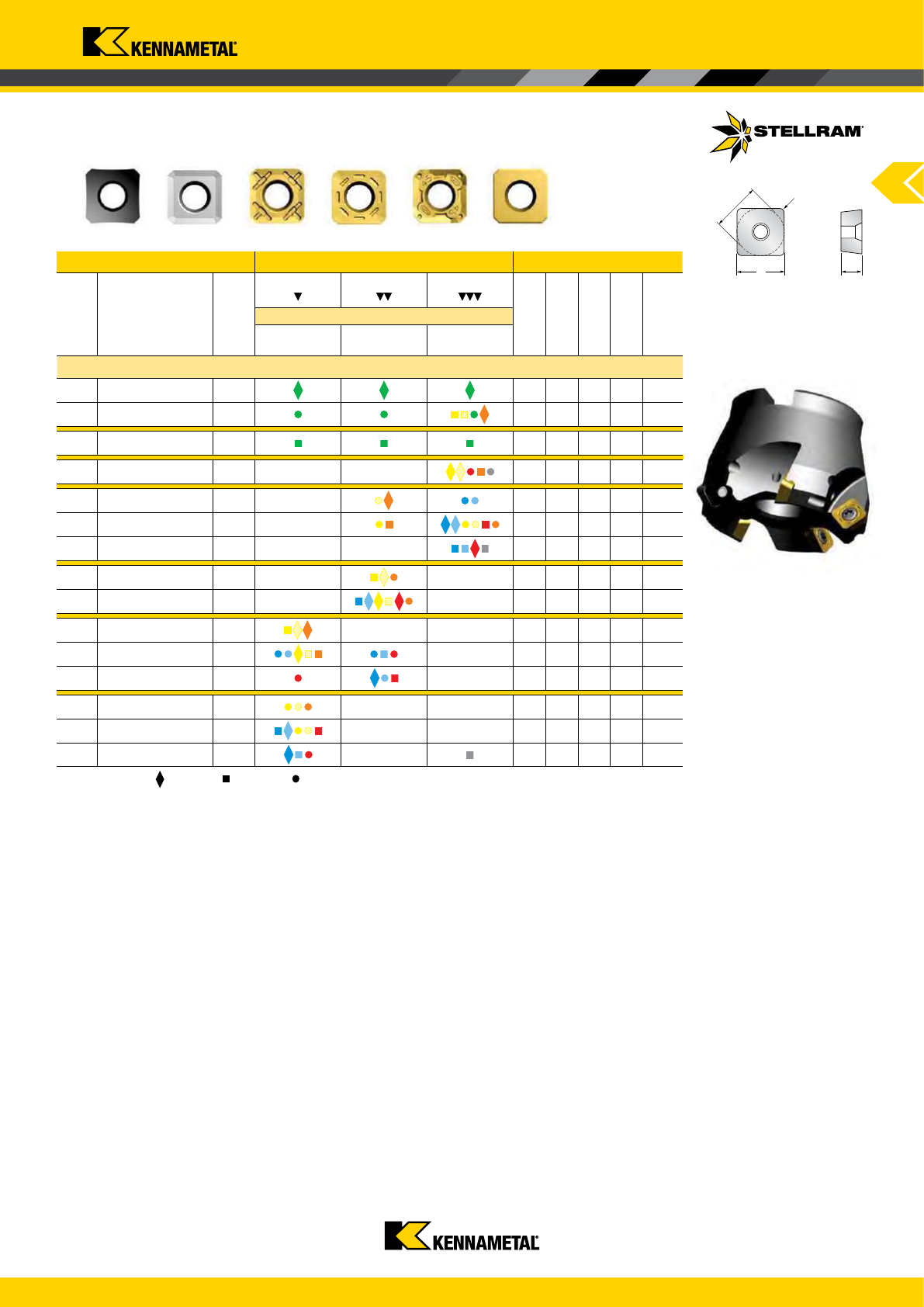

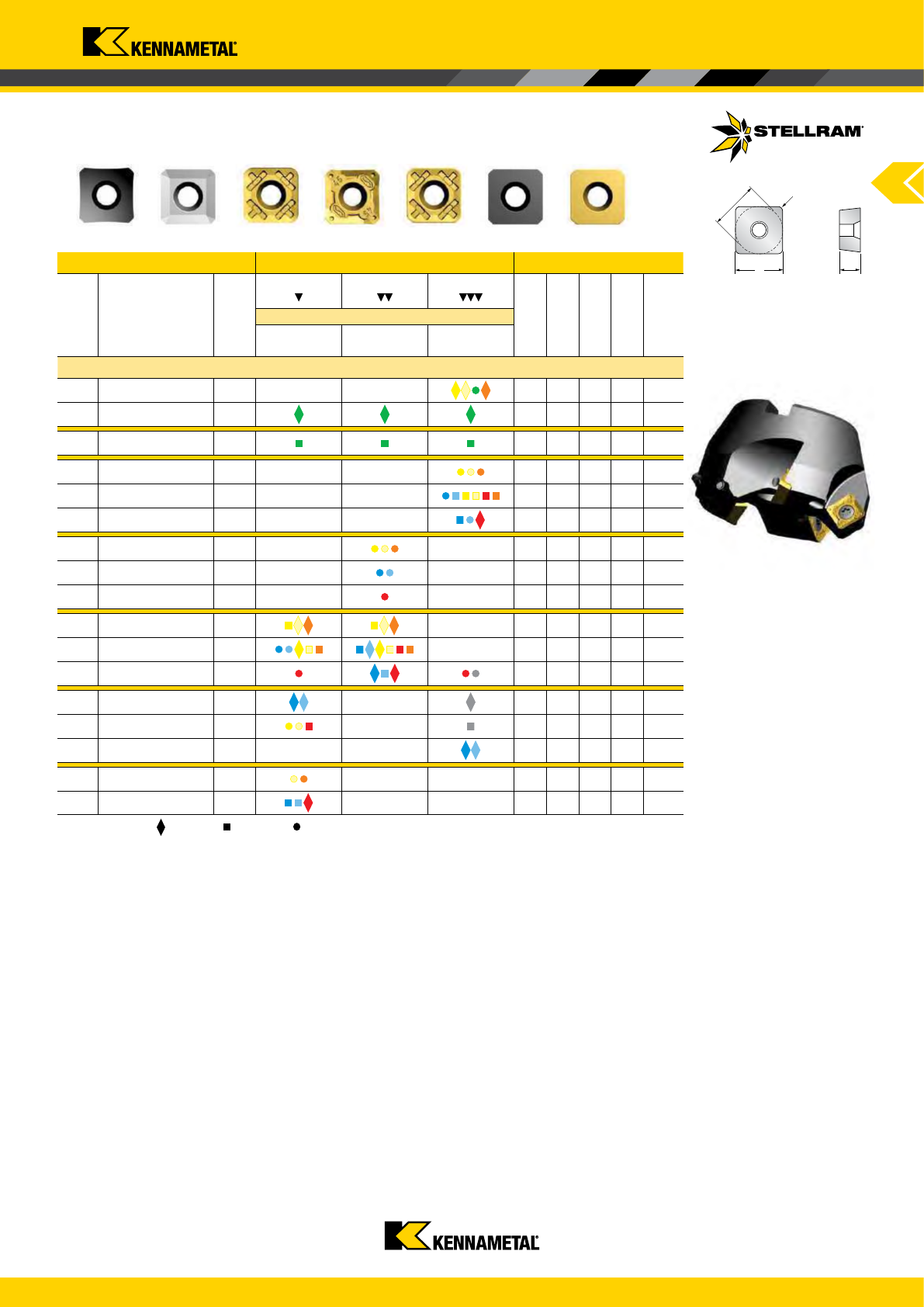

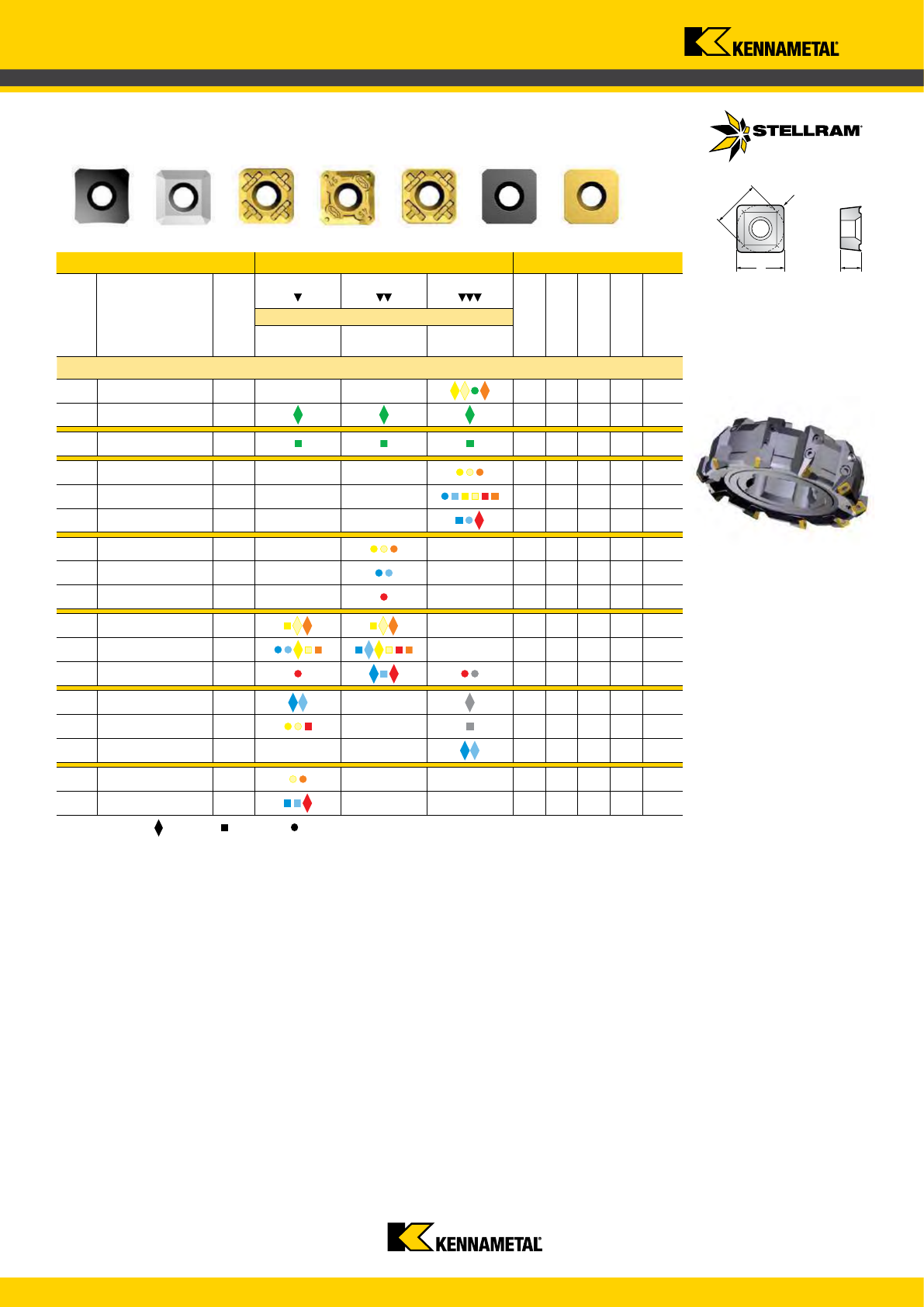

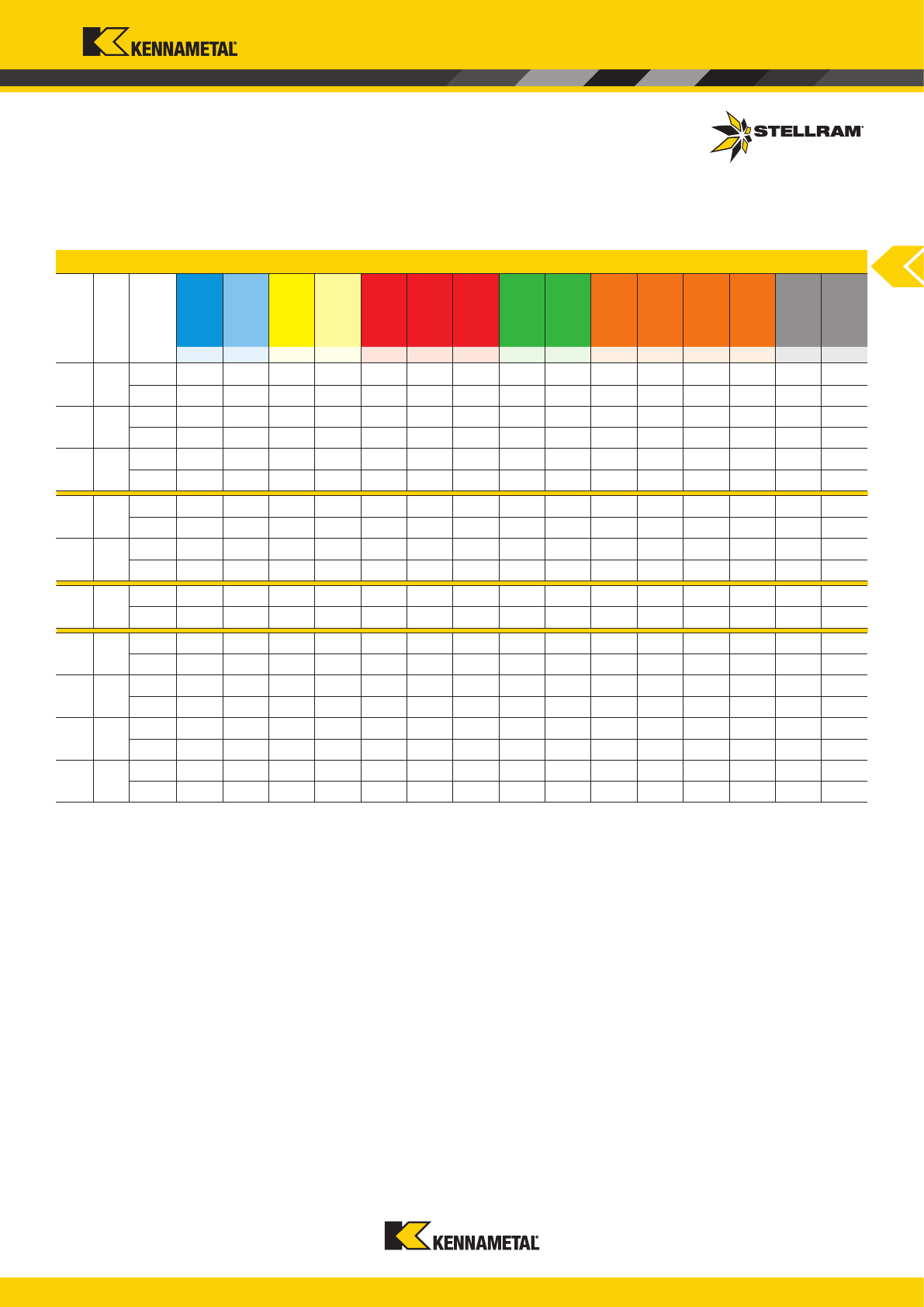

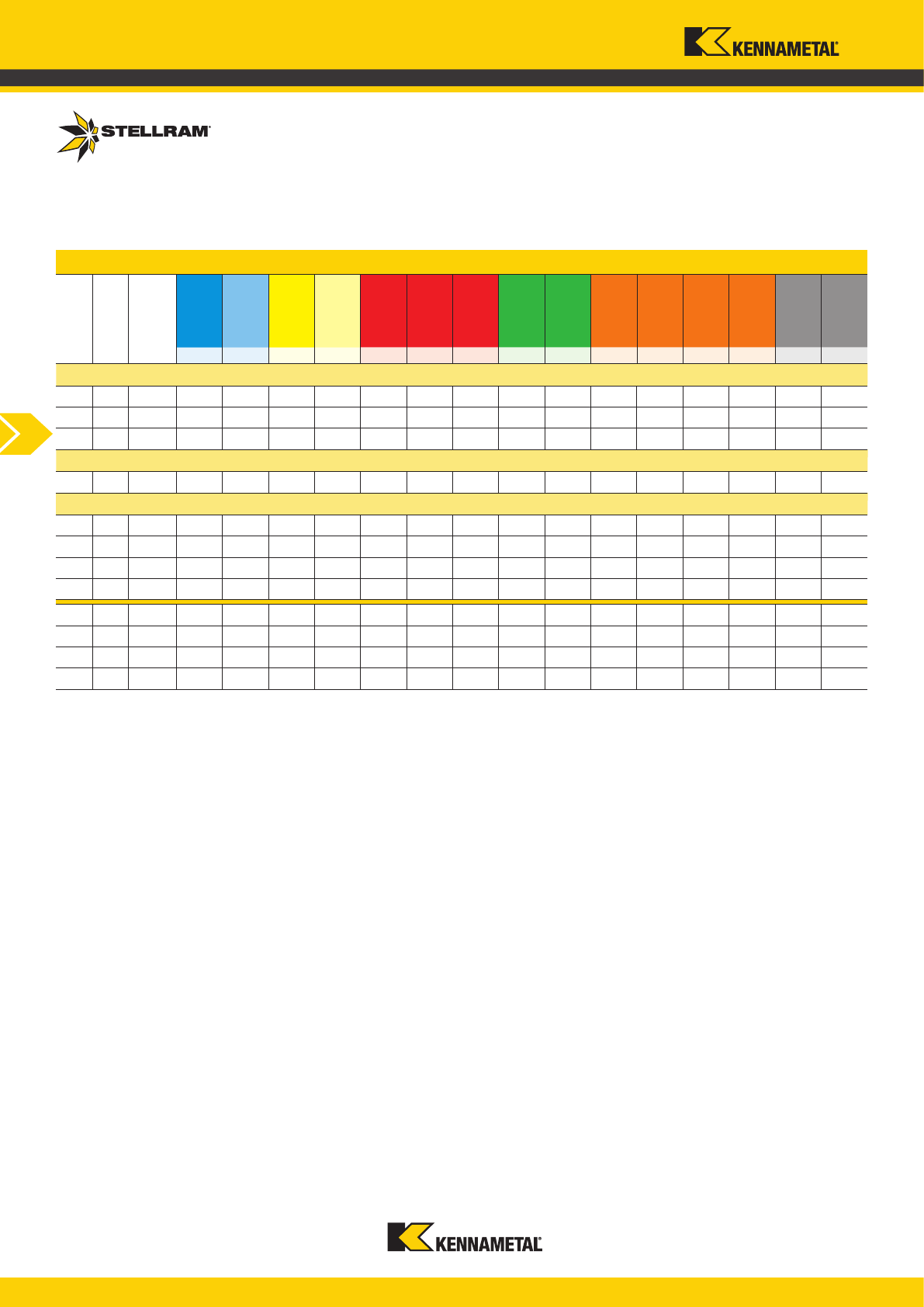

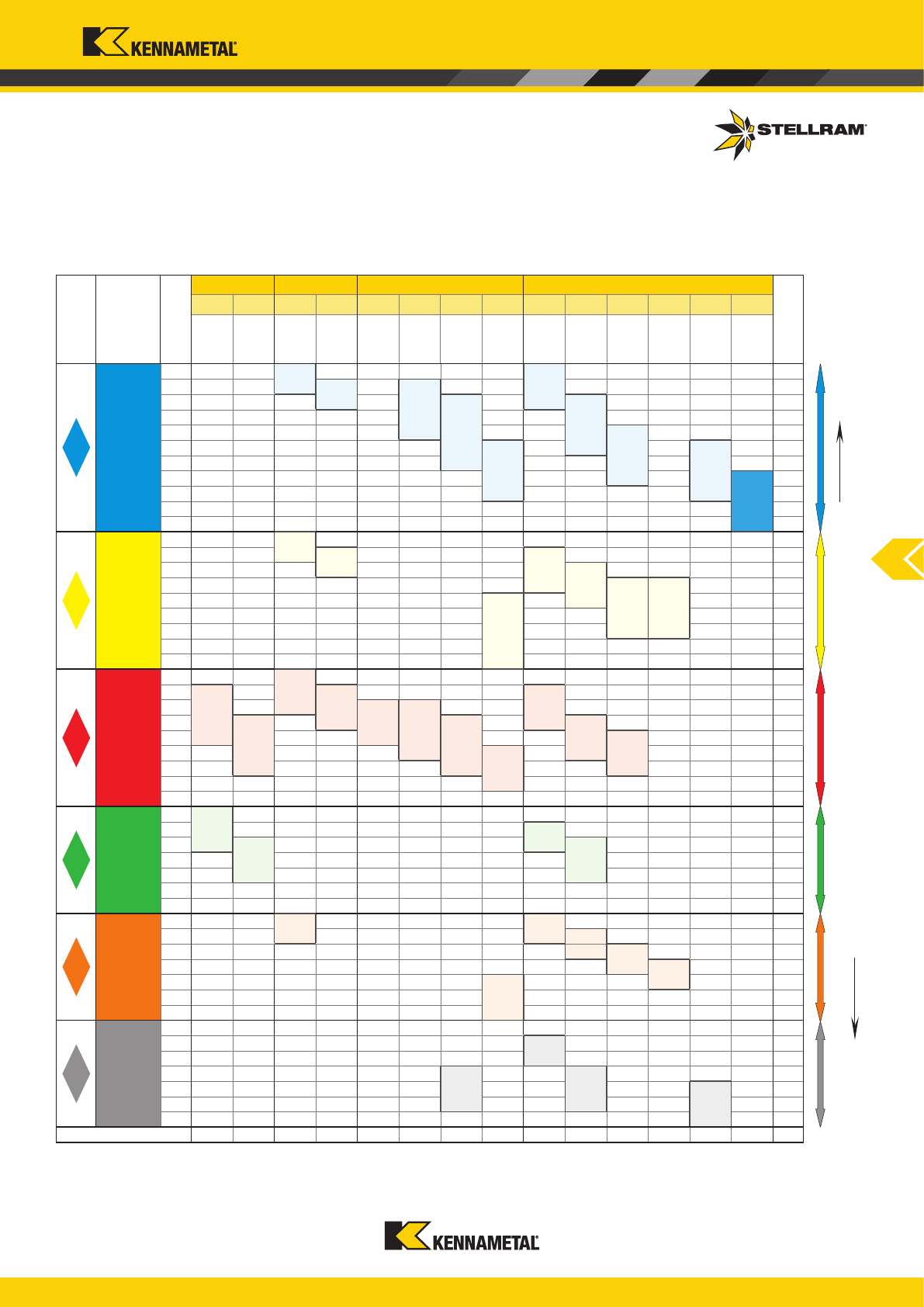

Milling Introduction

Tool Denition

Application

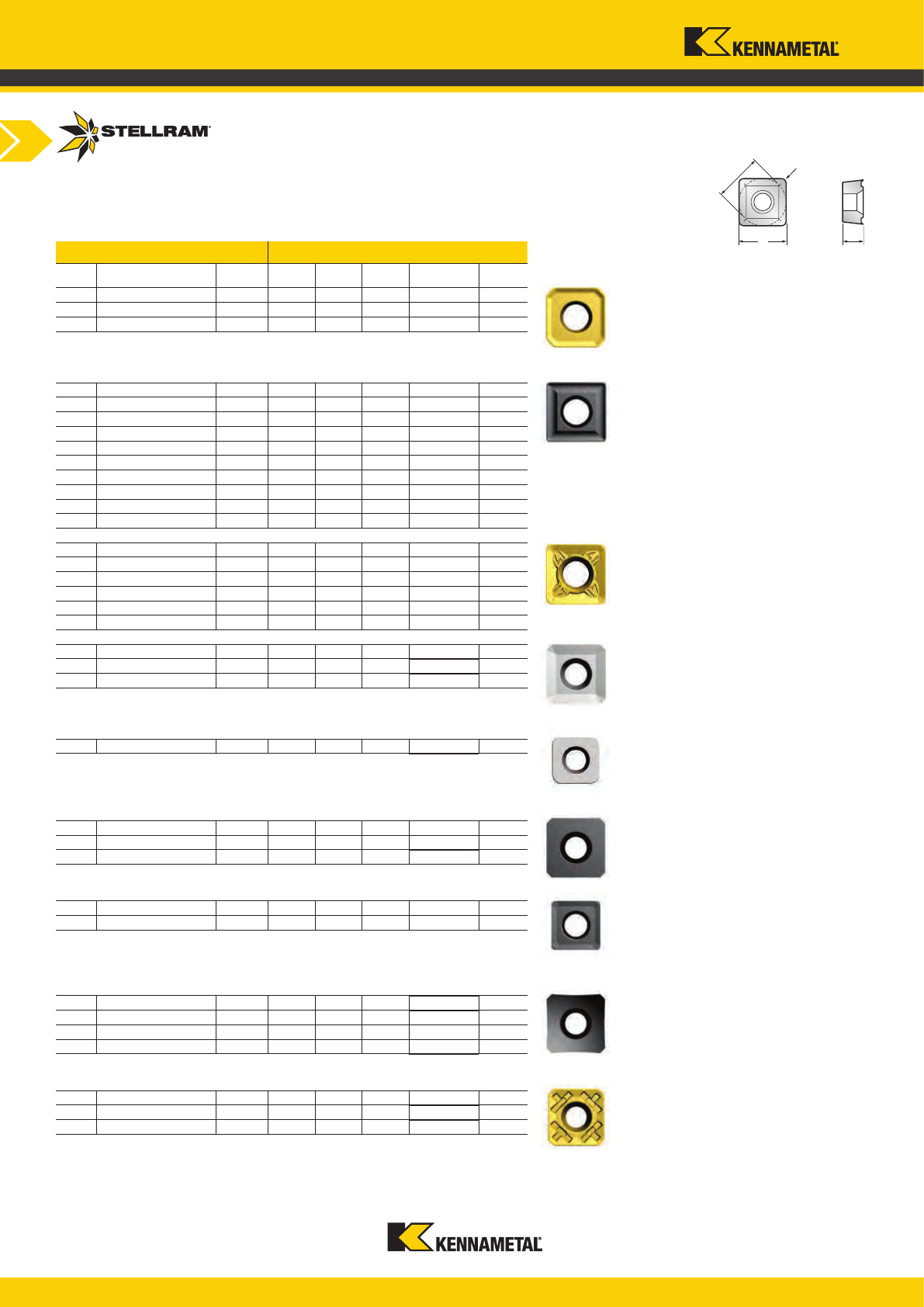

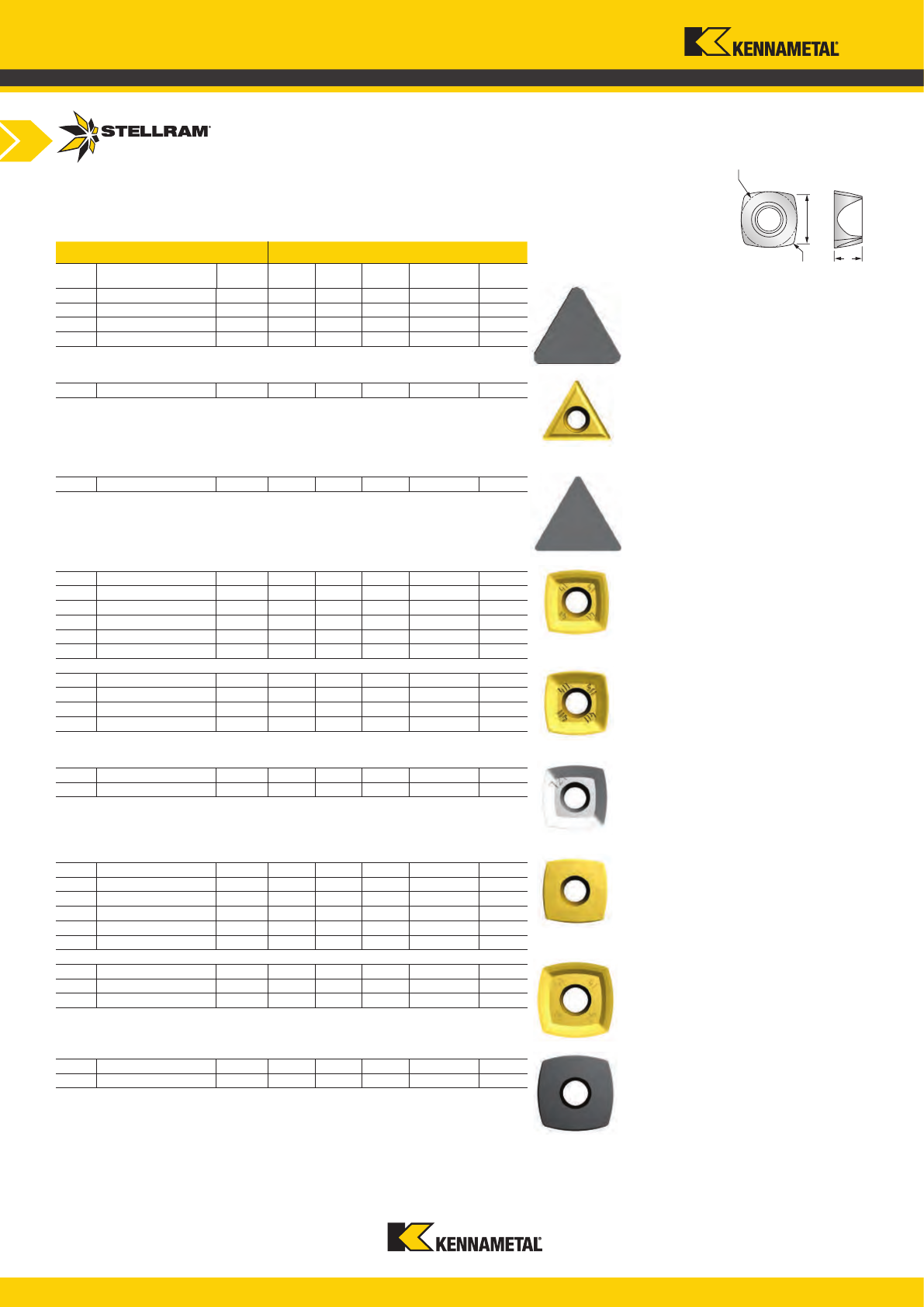

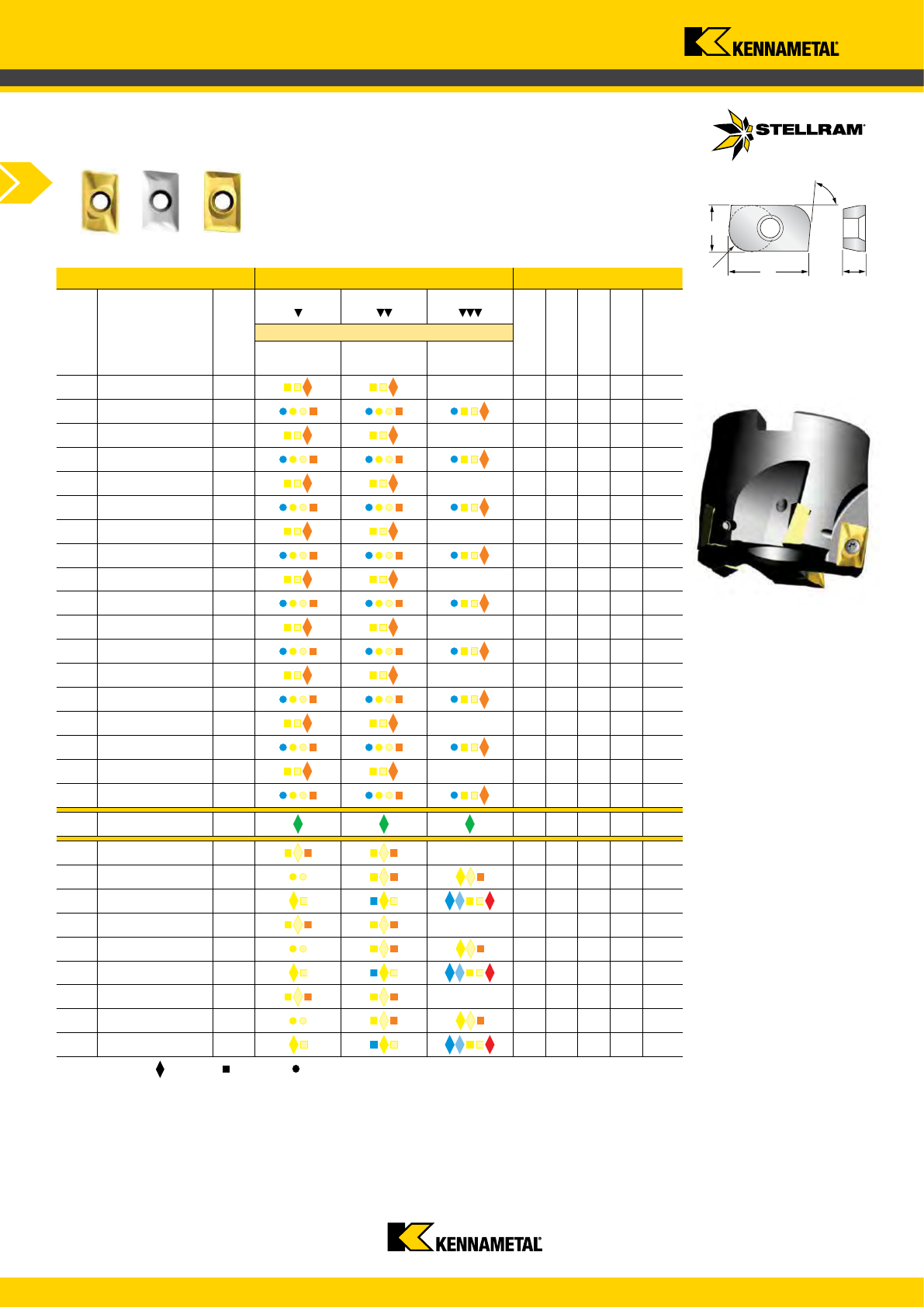

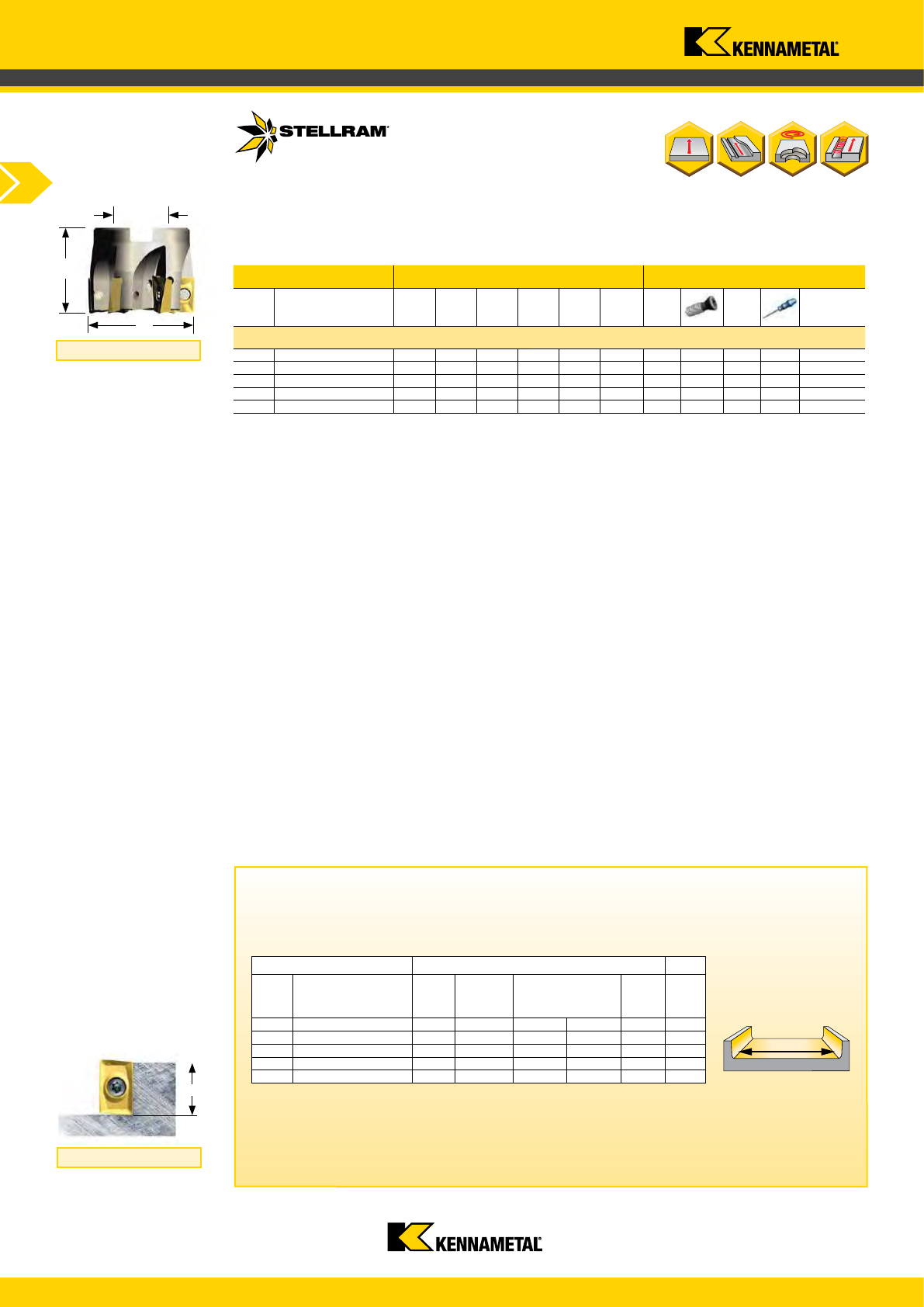

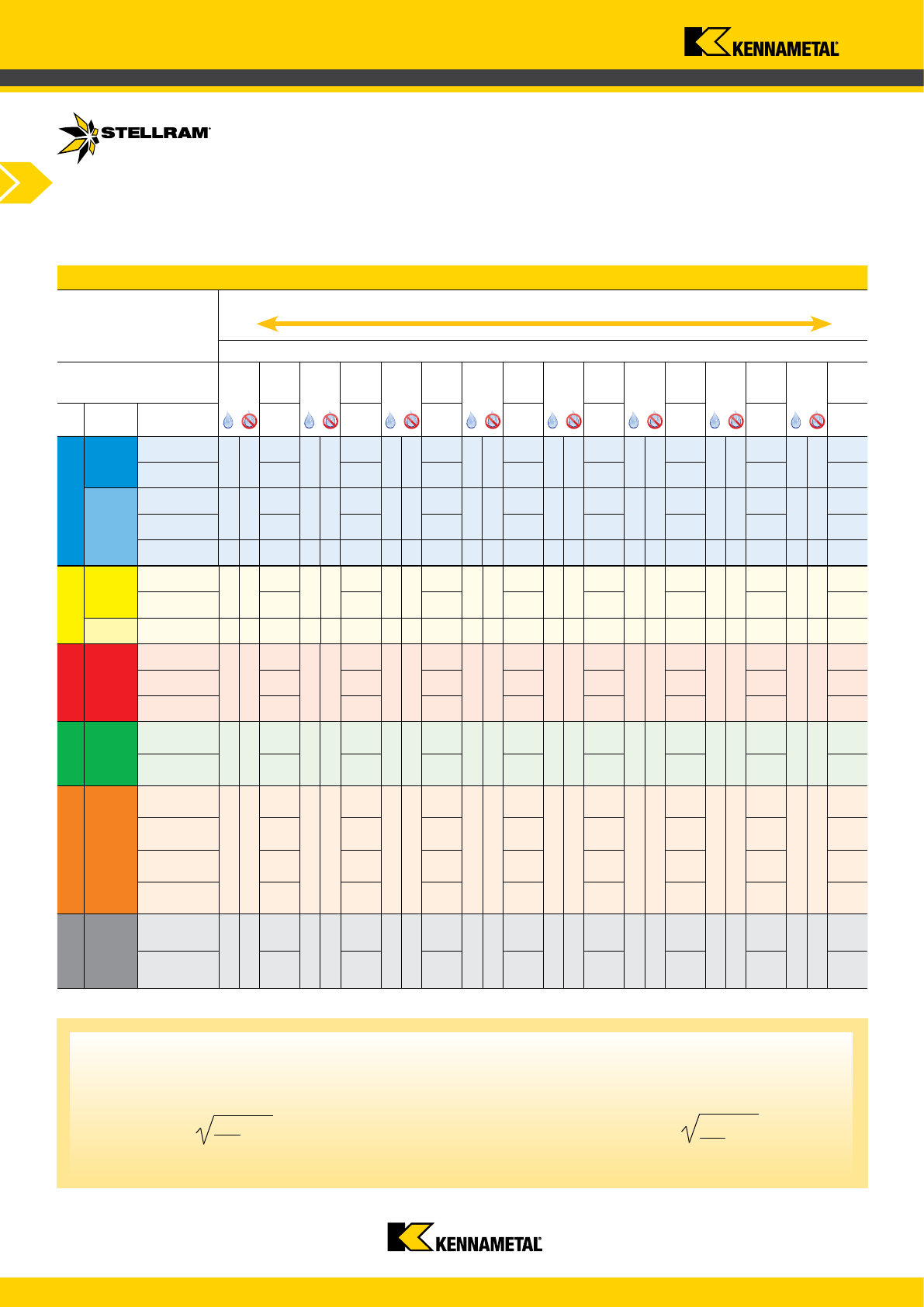

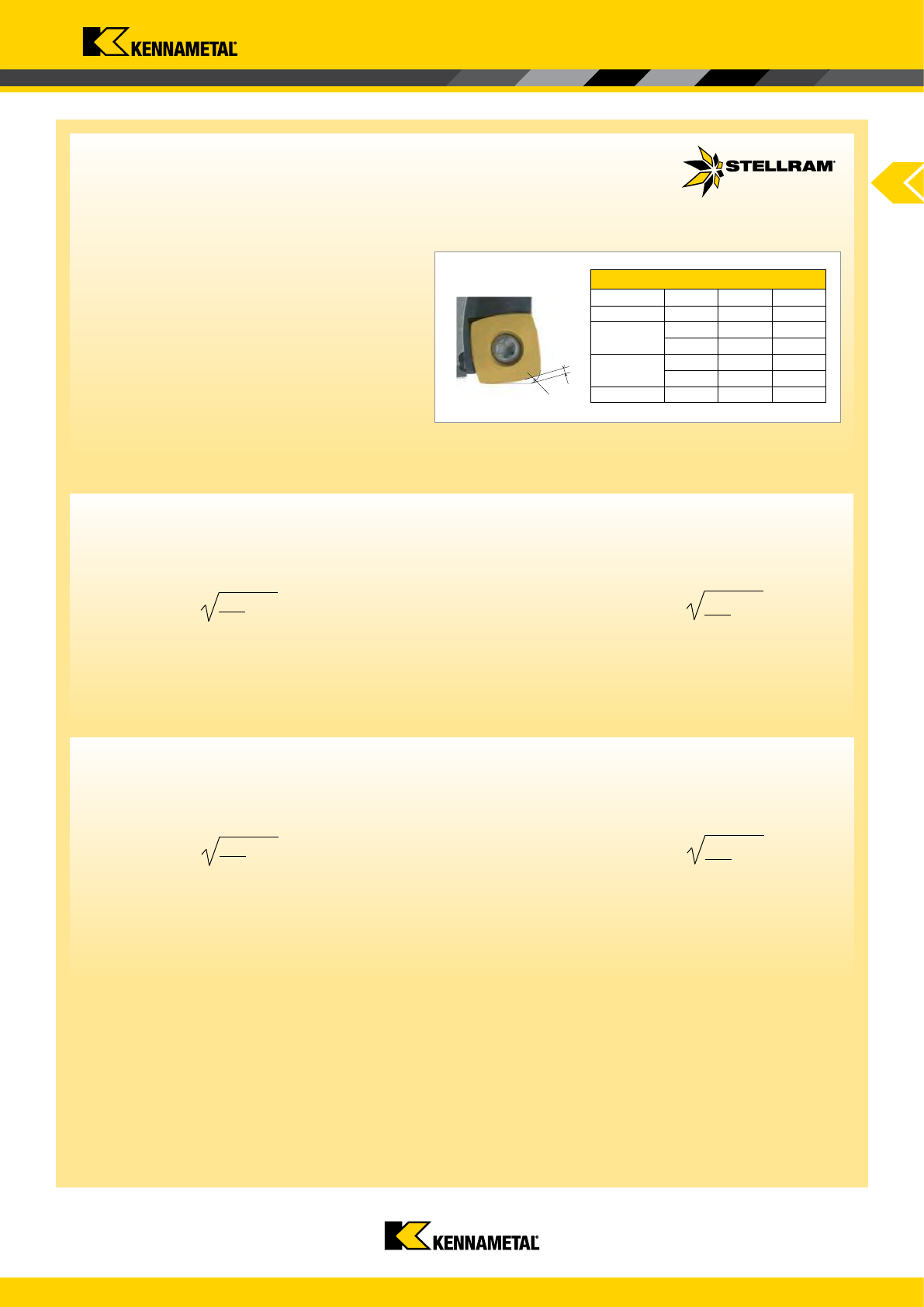

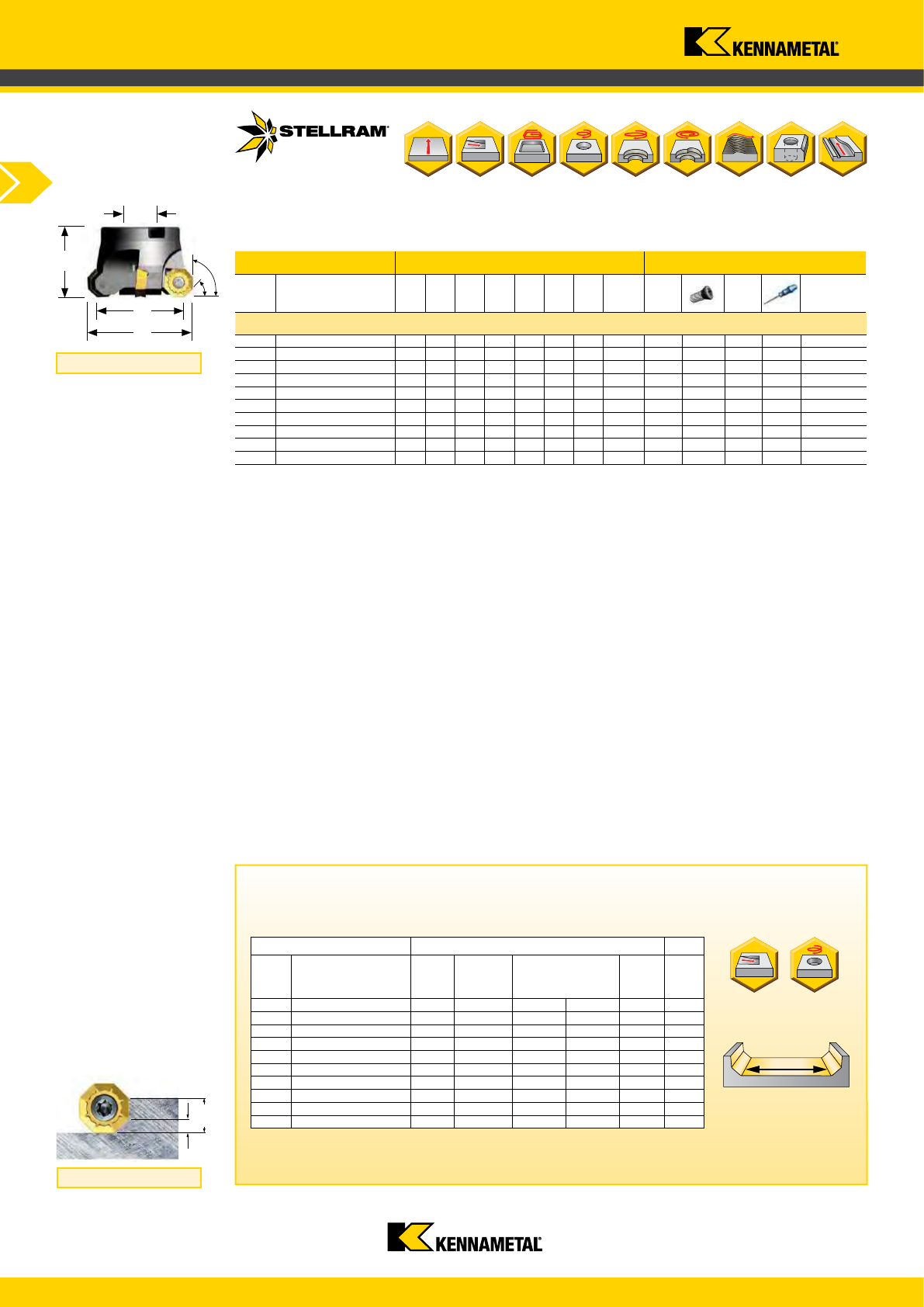

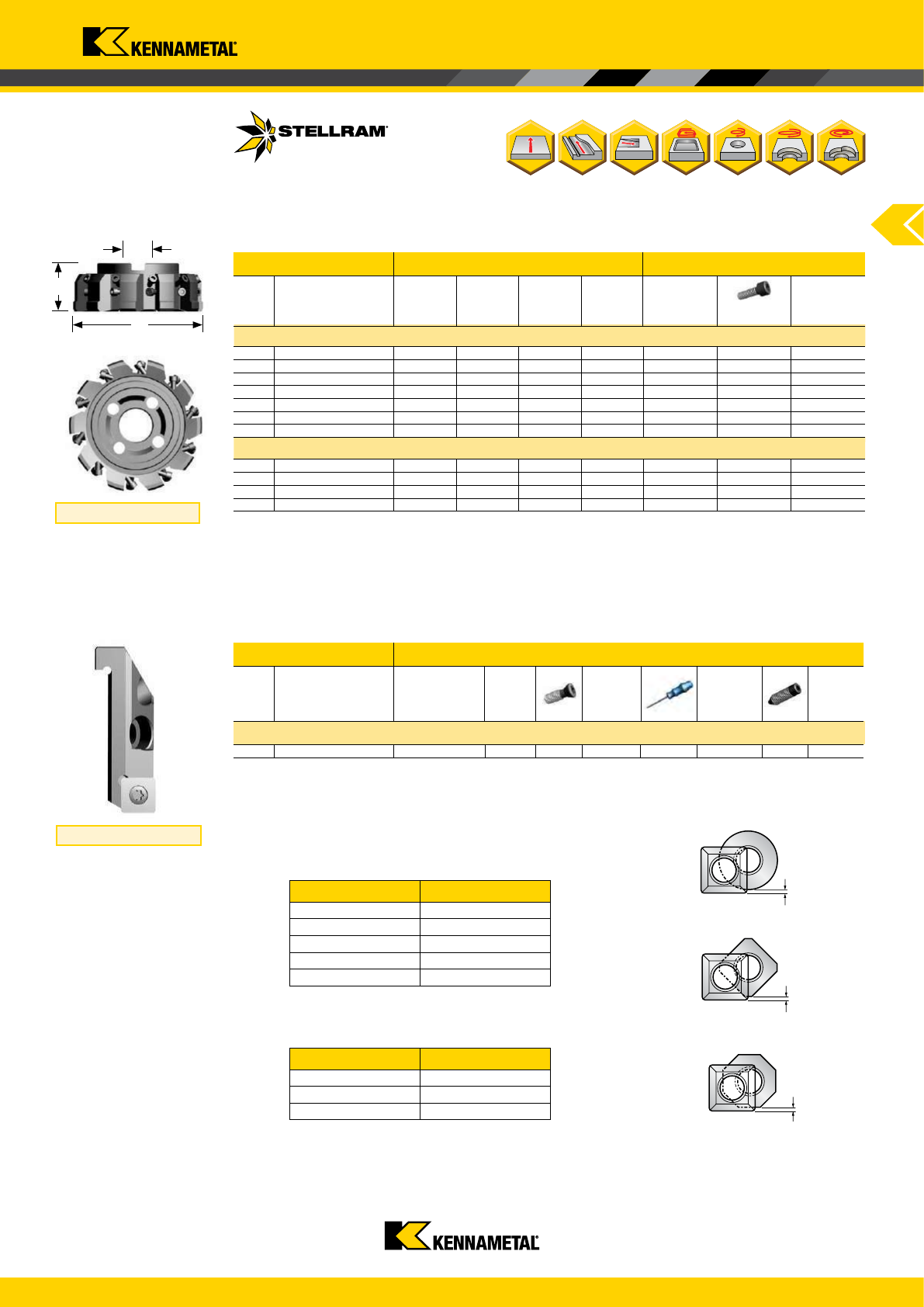

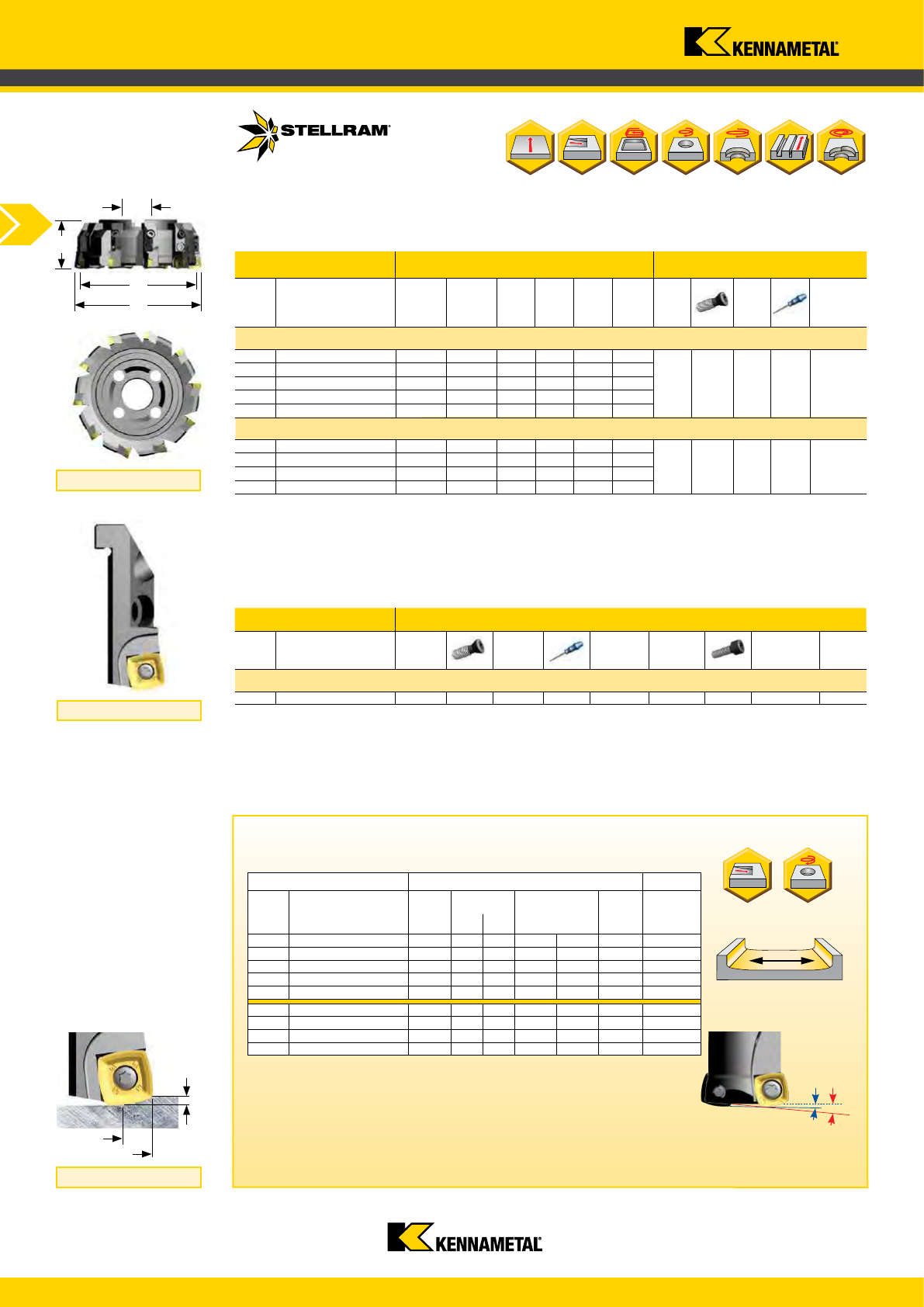

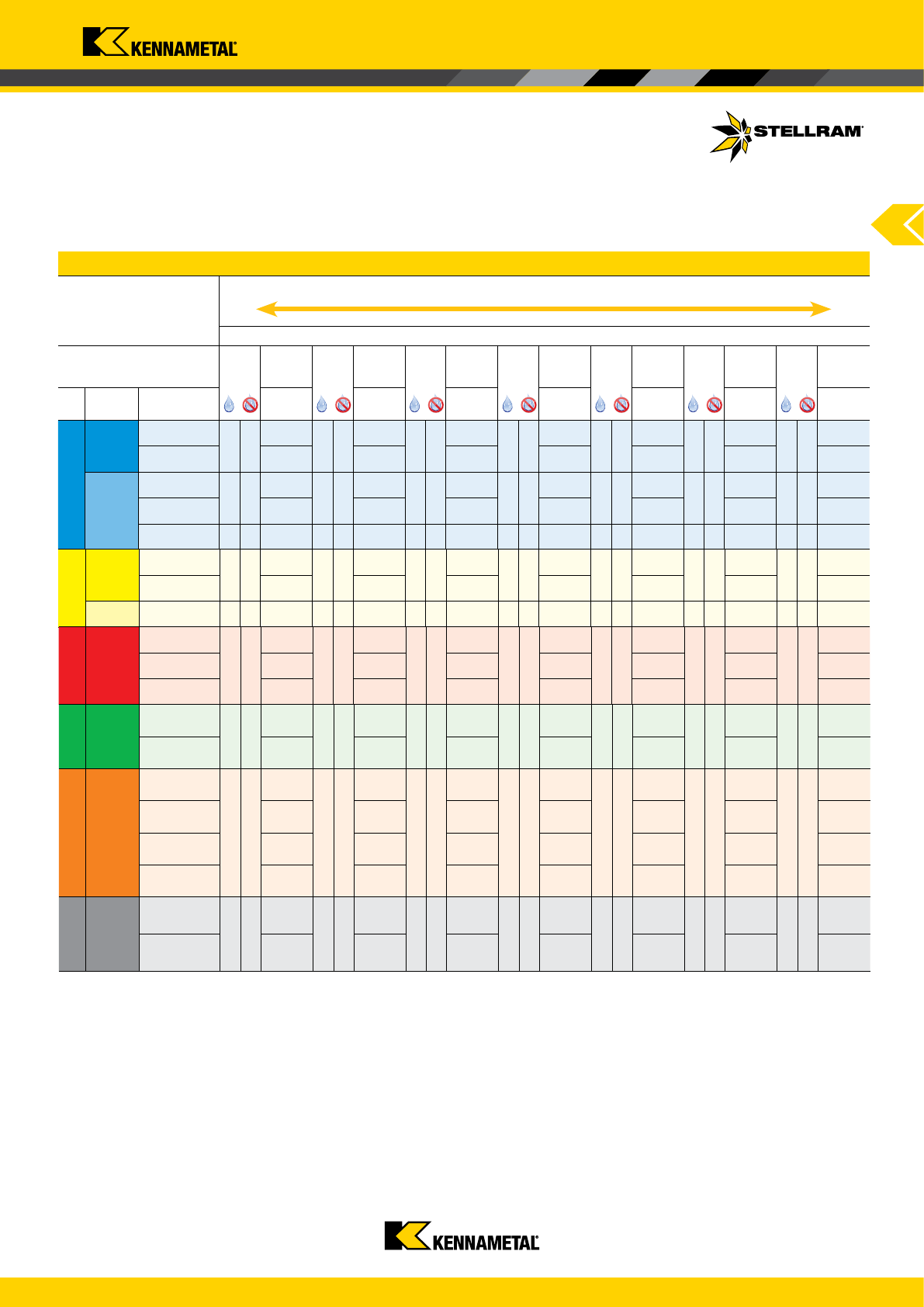

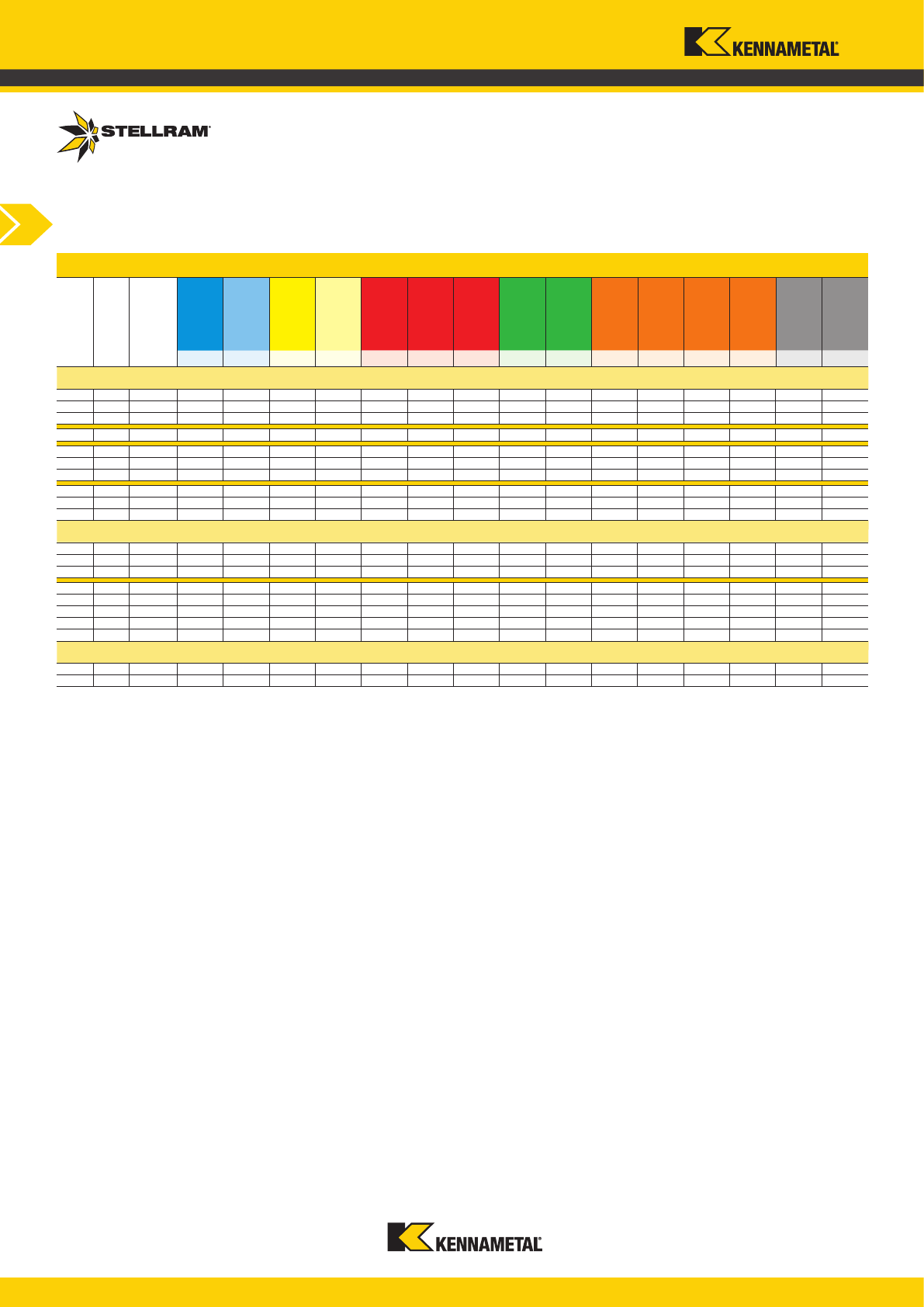

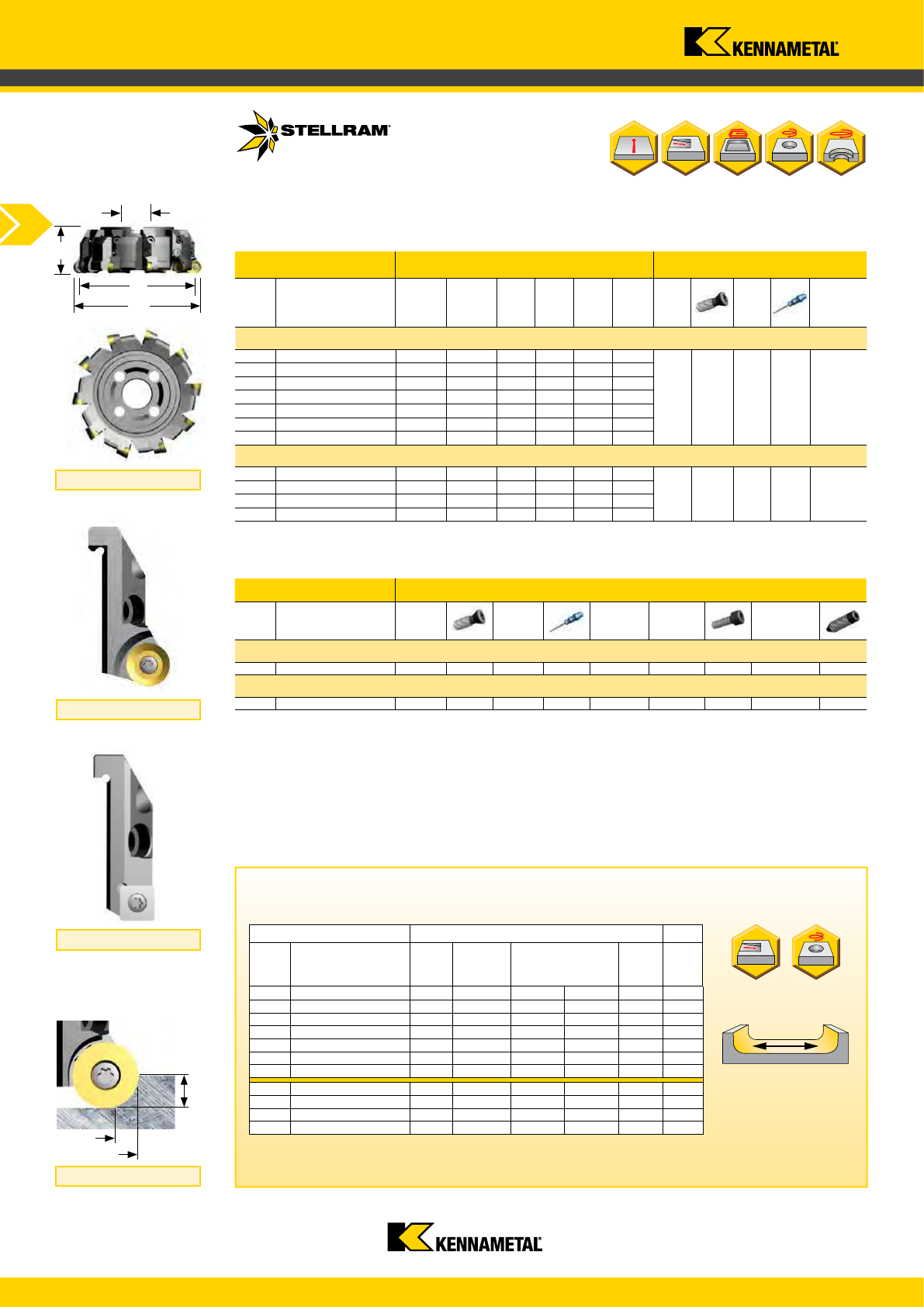

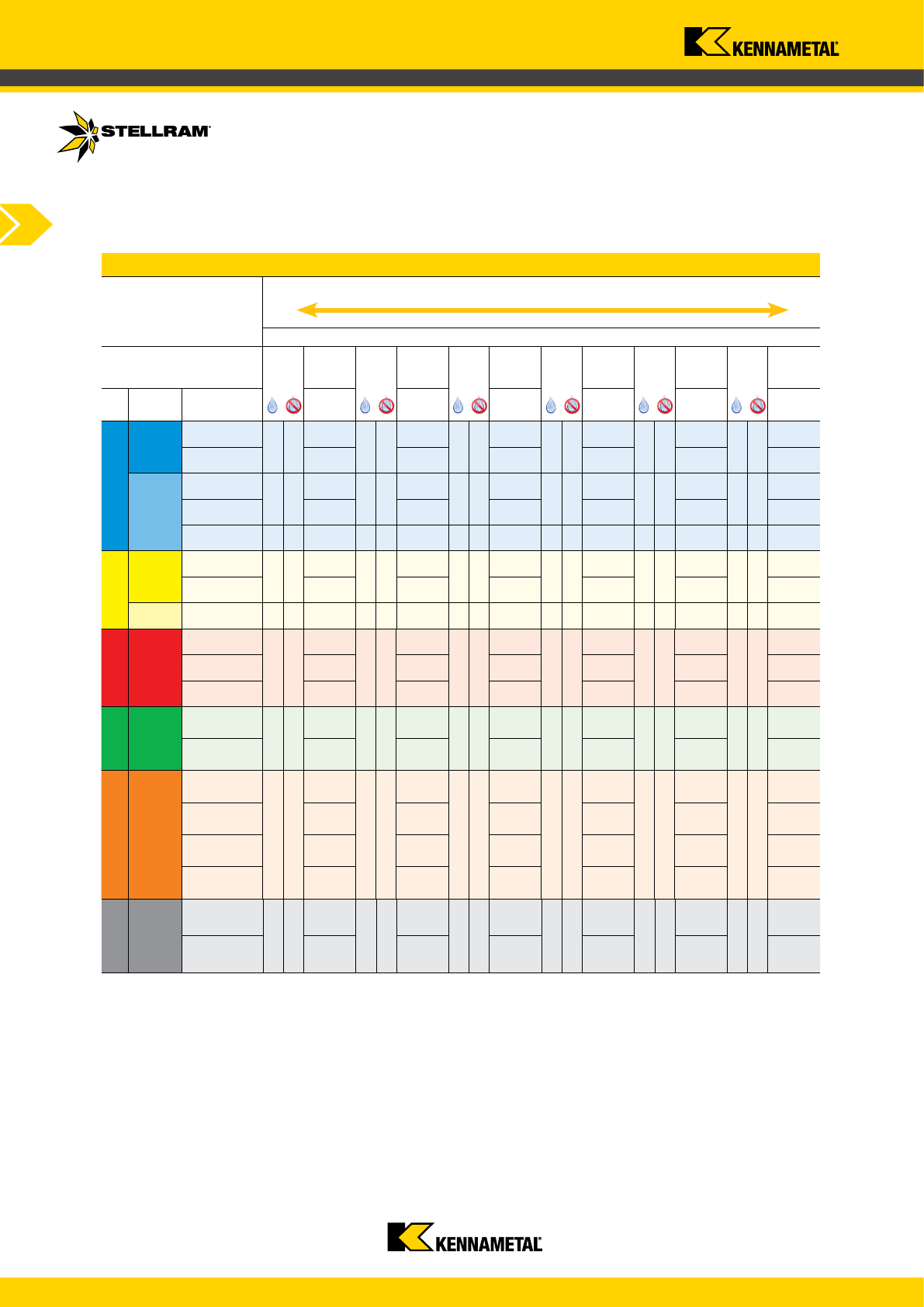

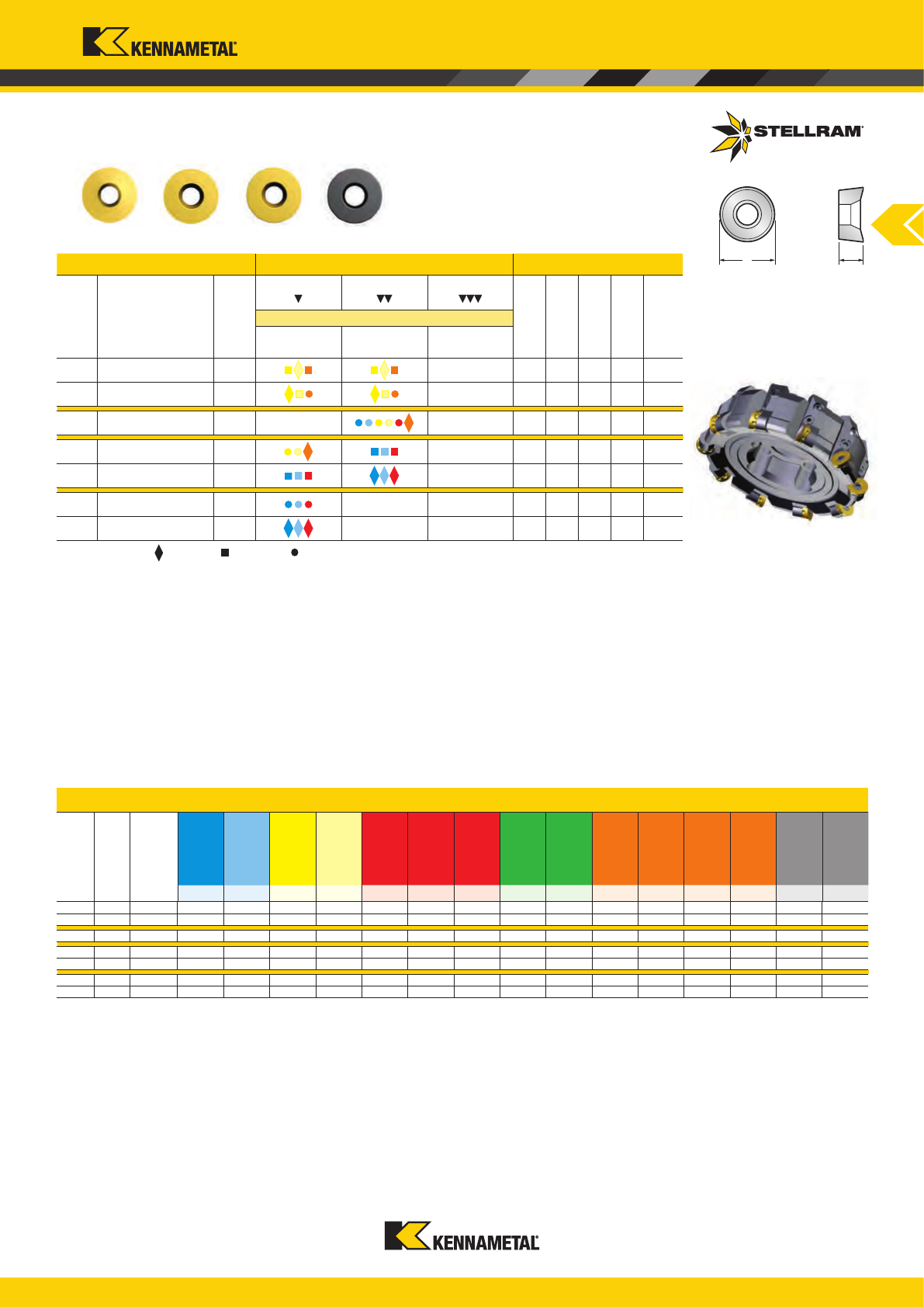

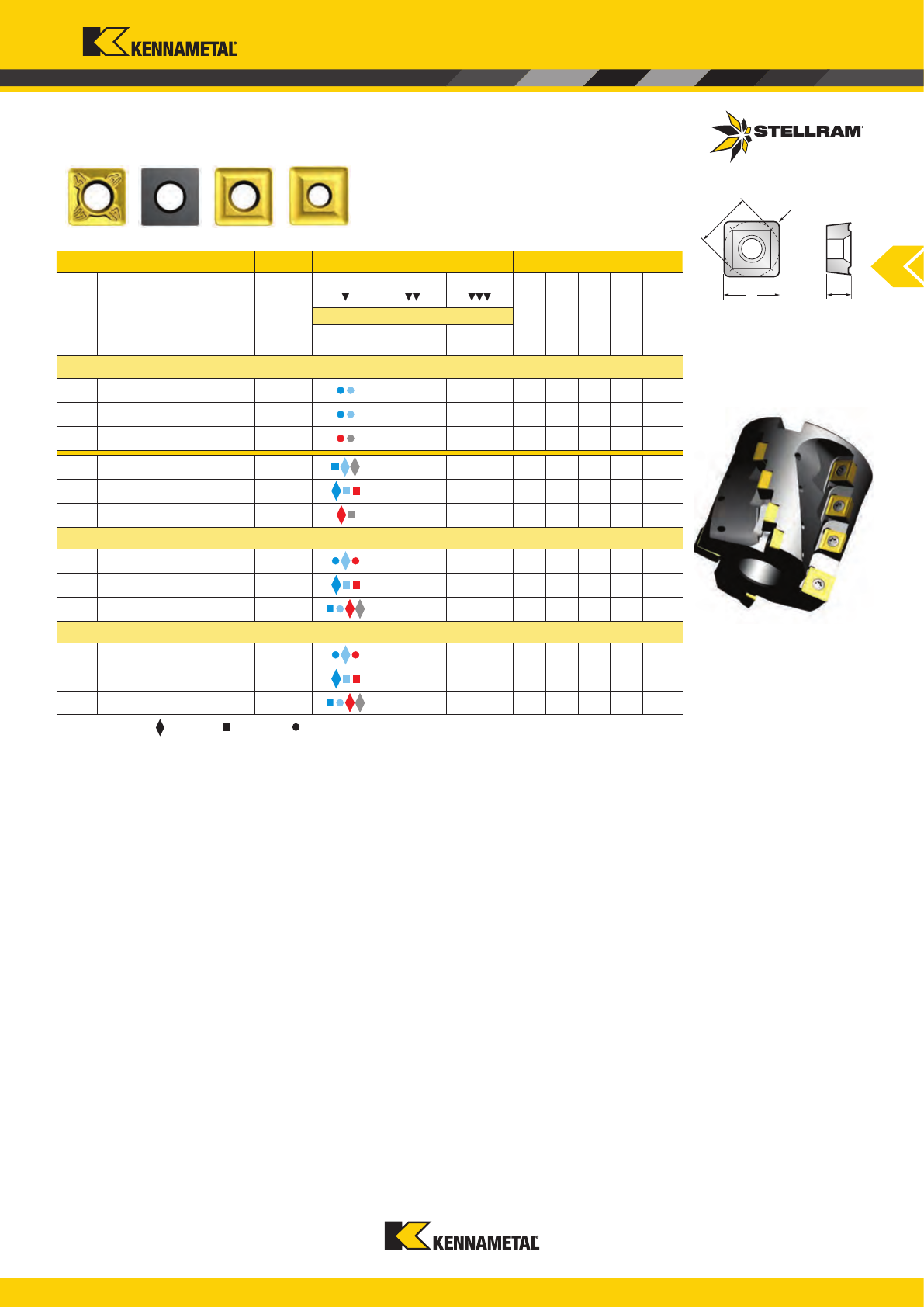

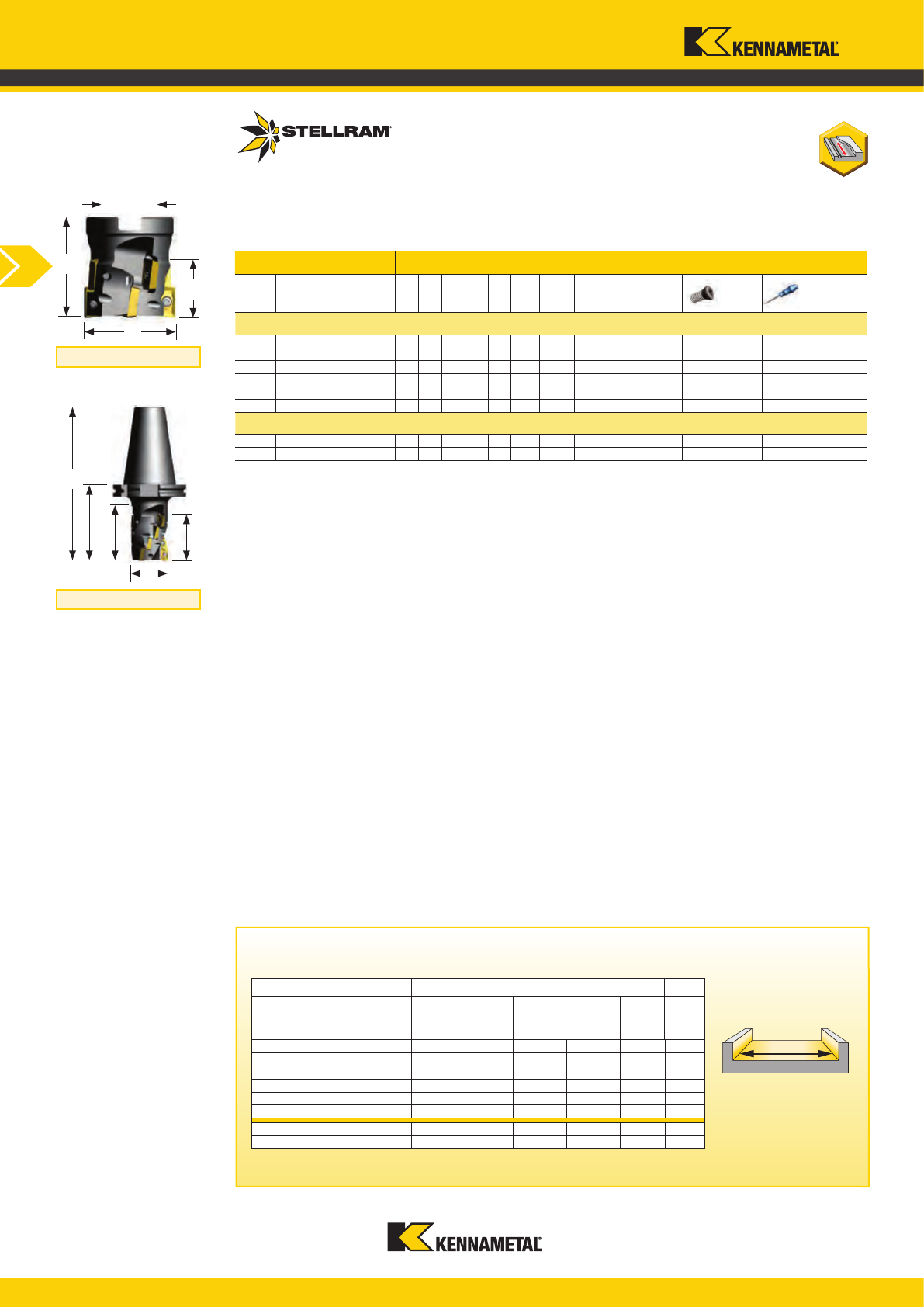

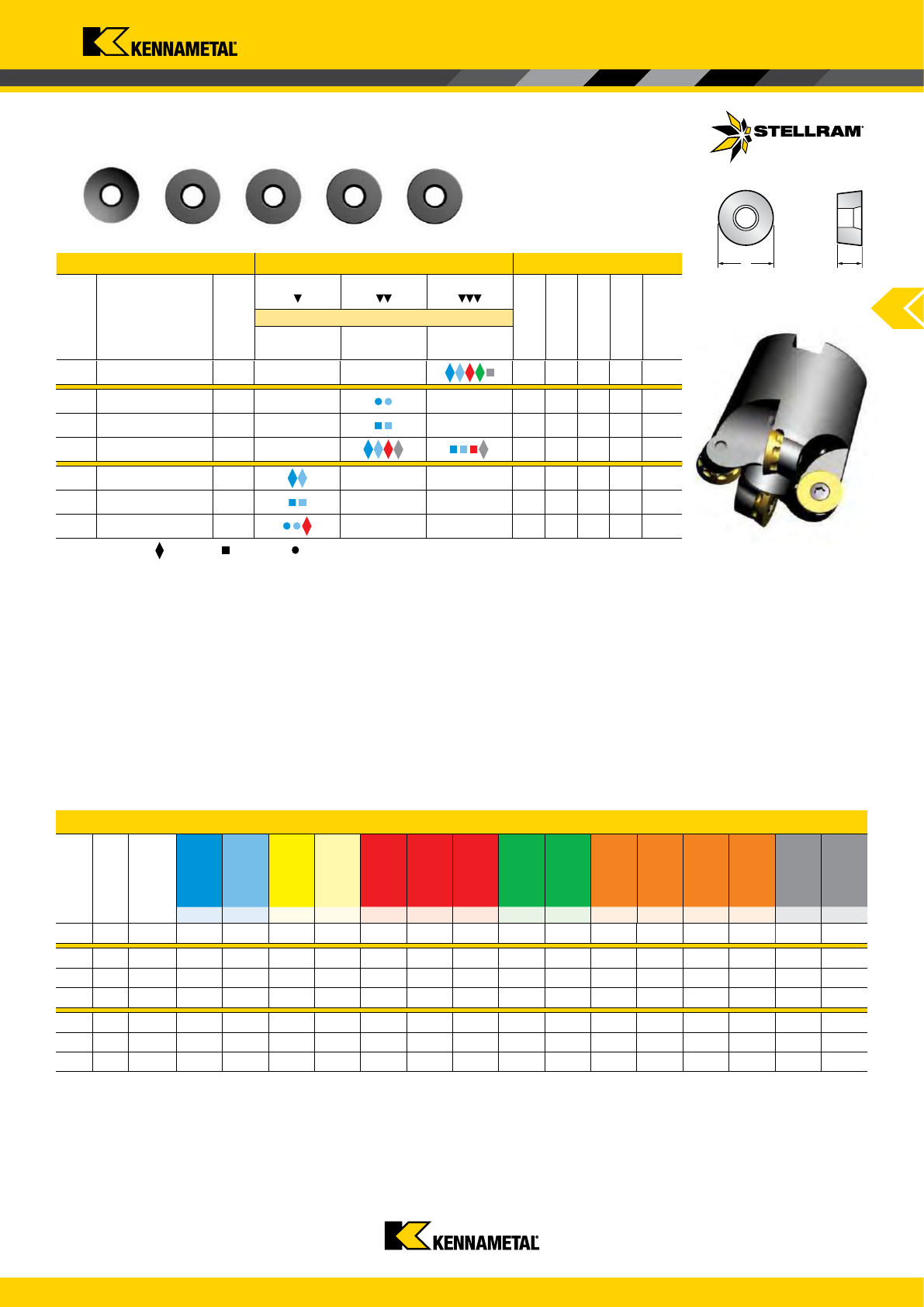

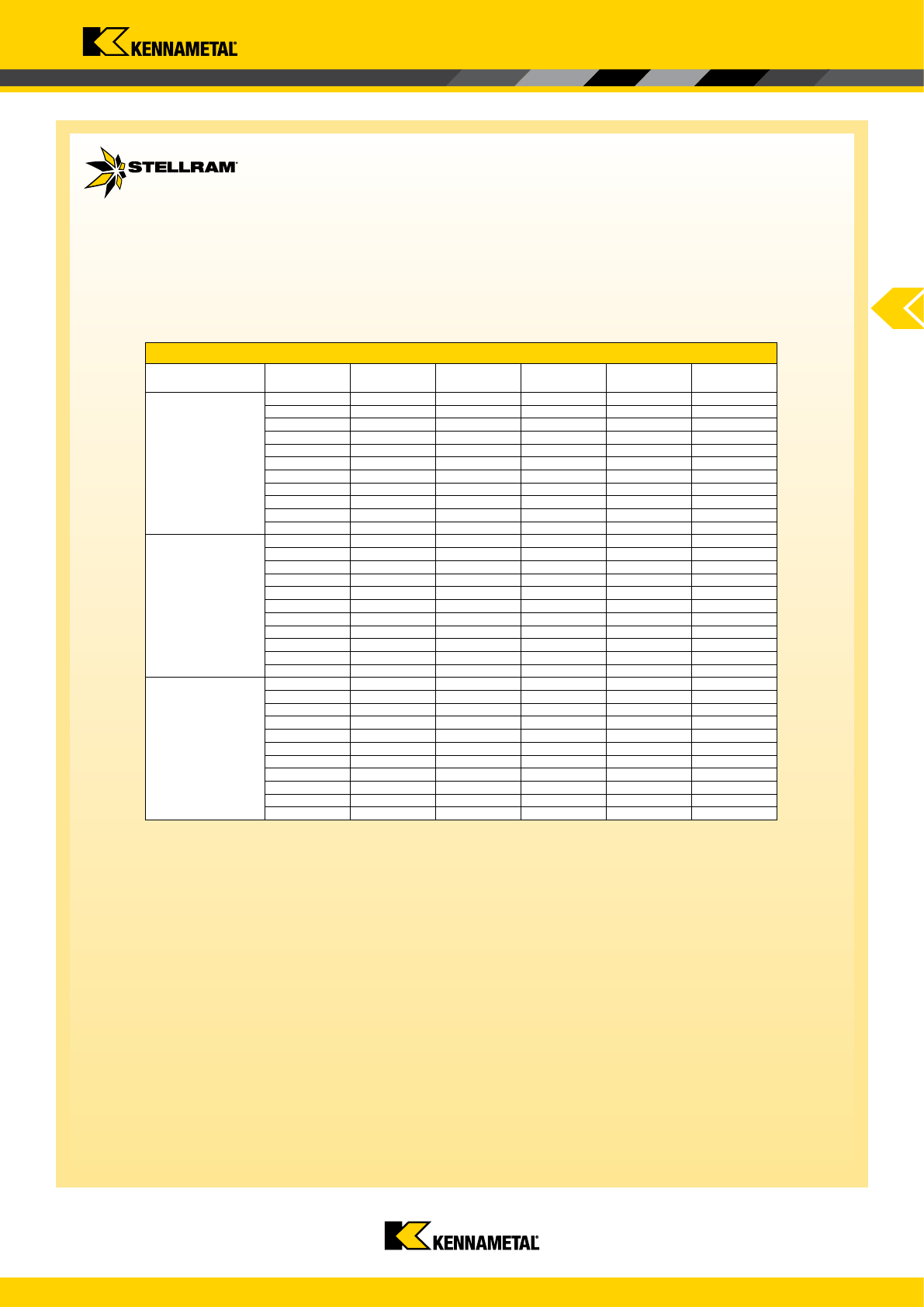

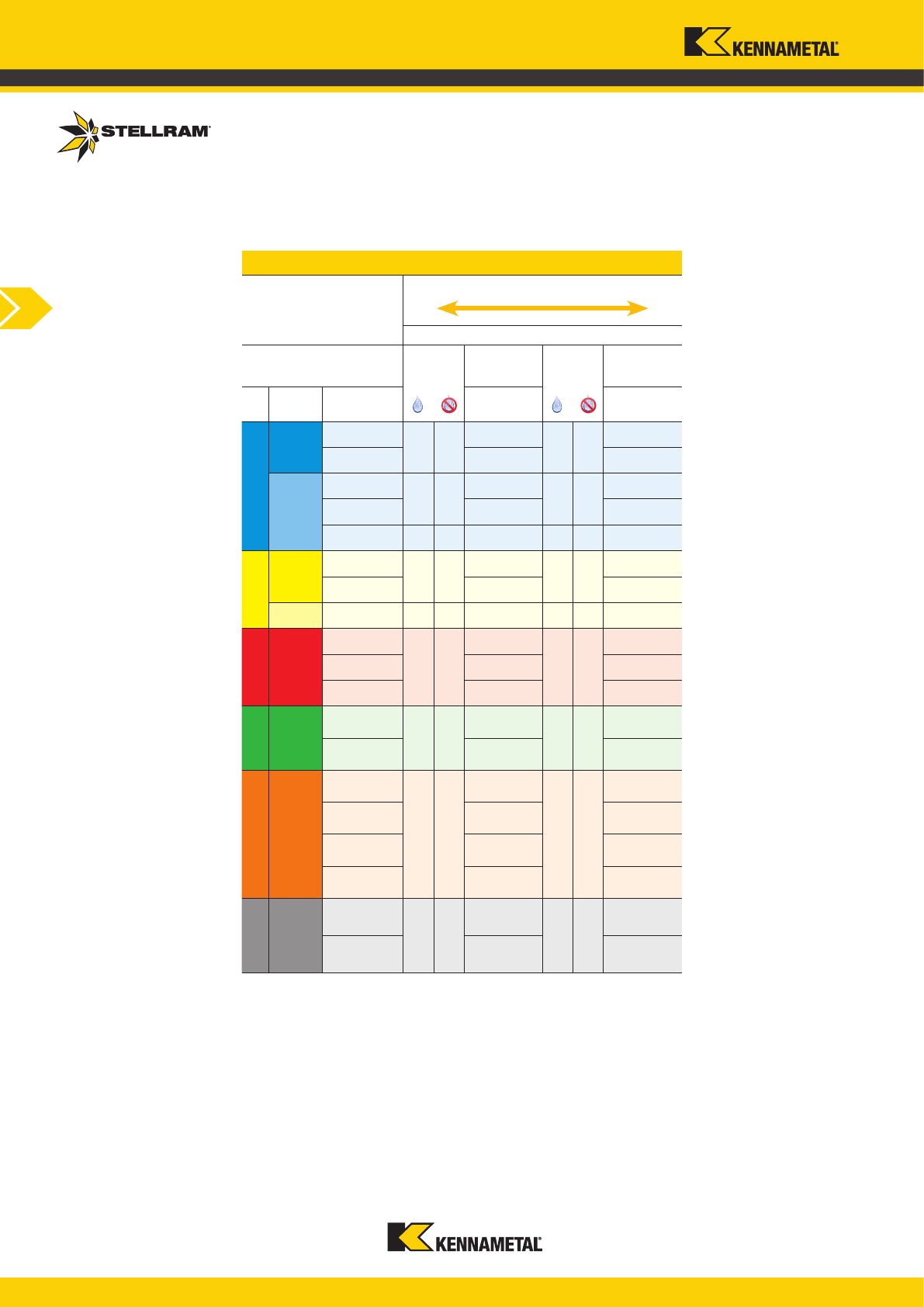

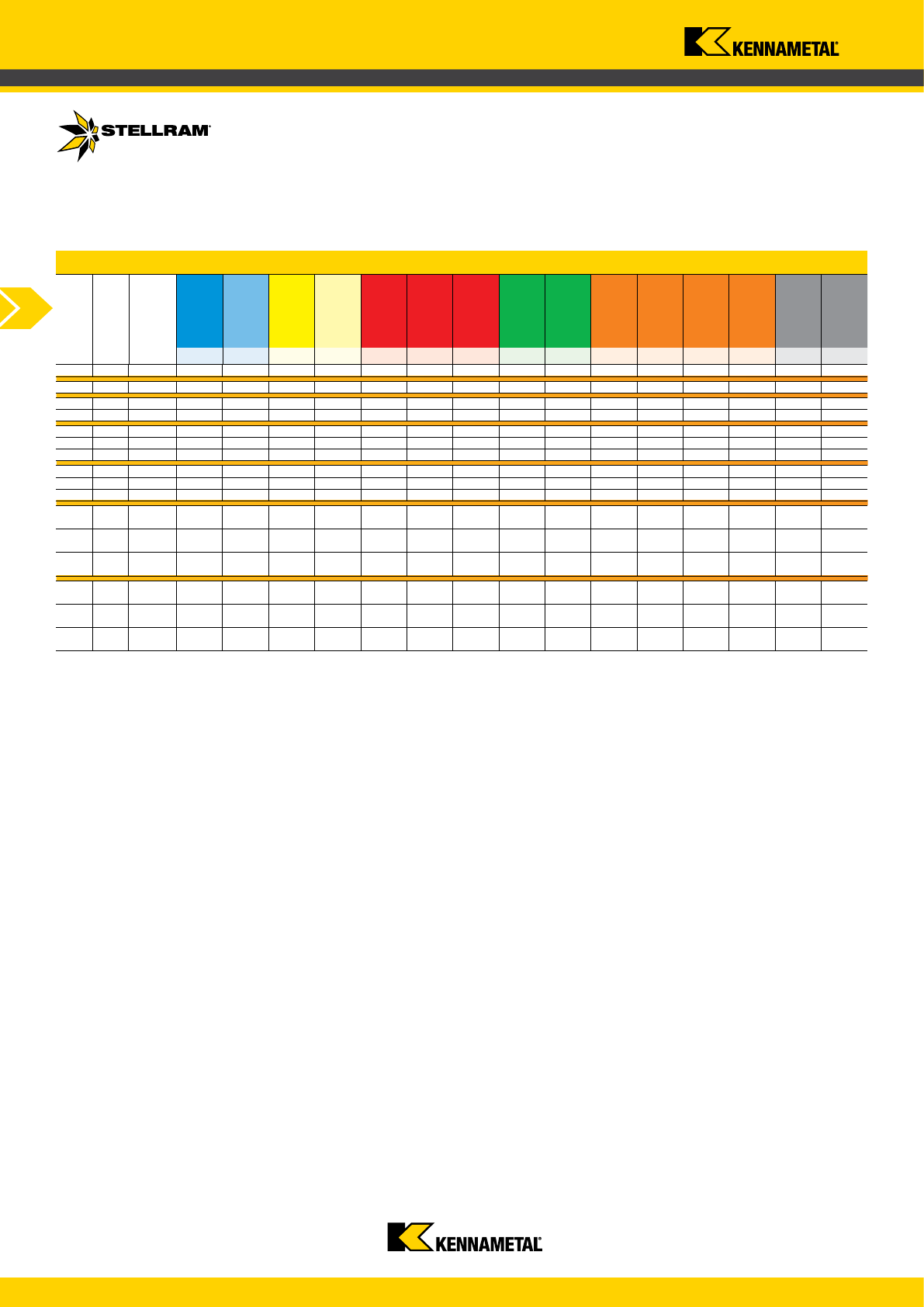

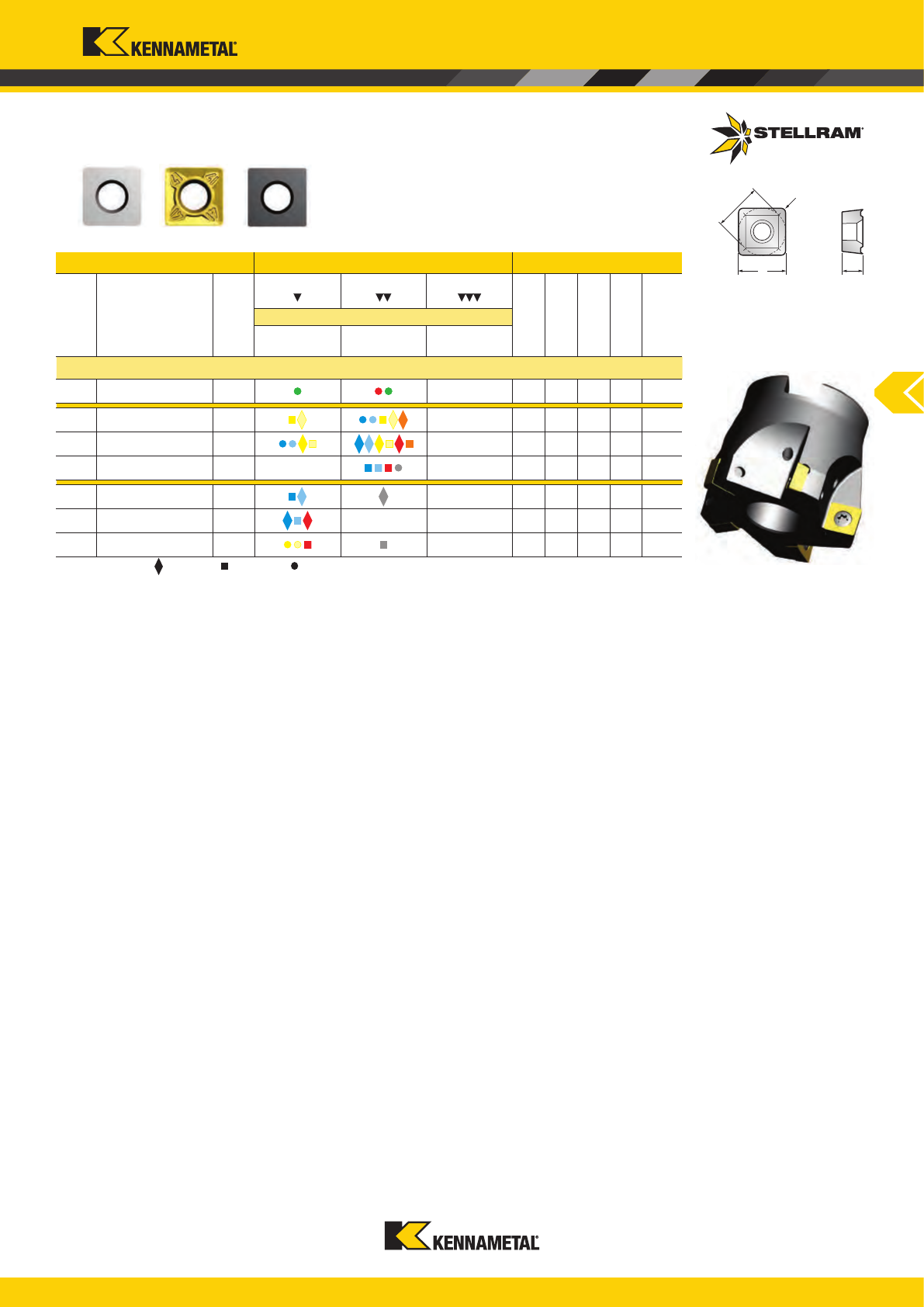

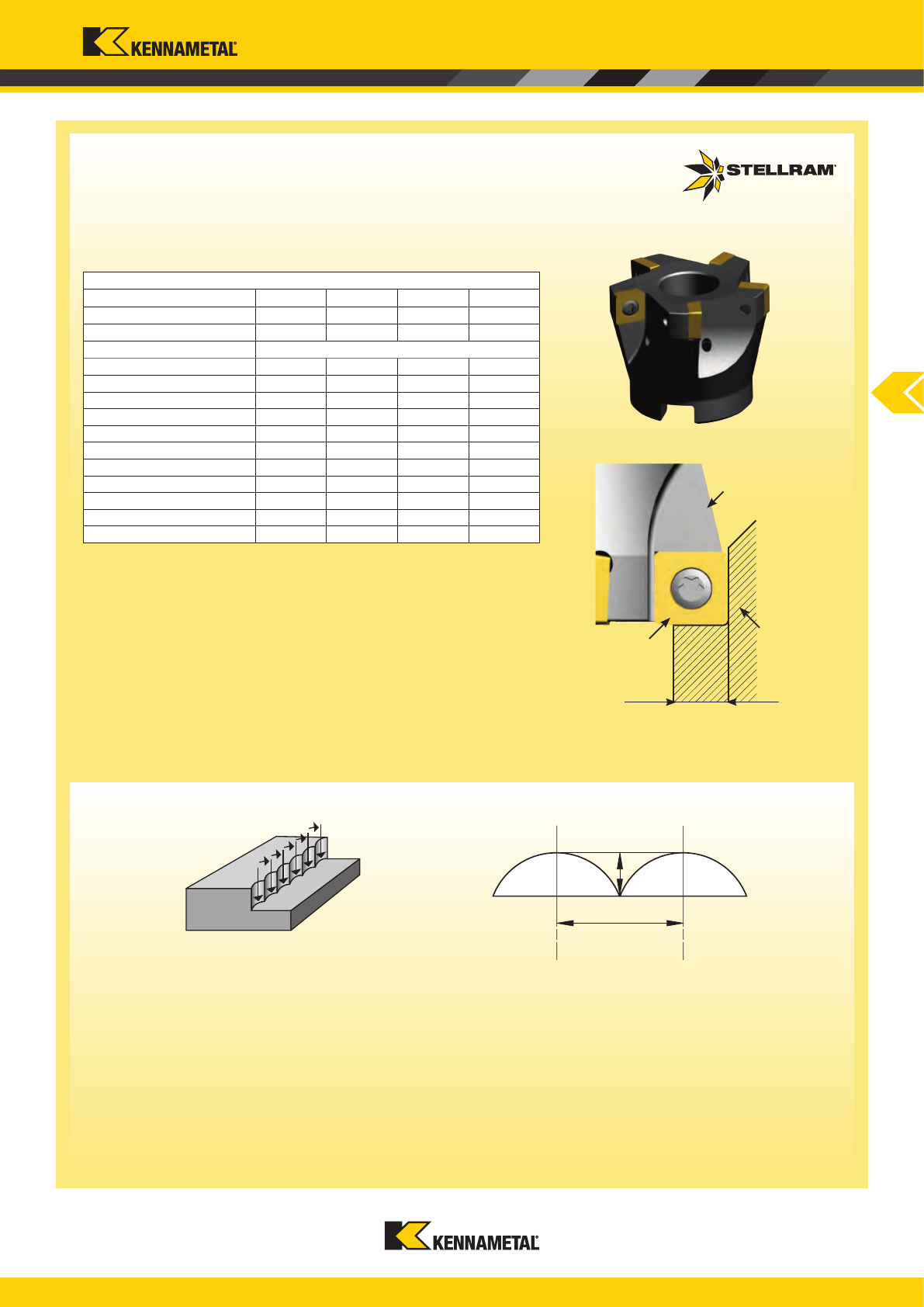

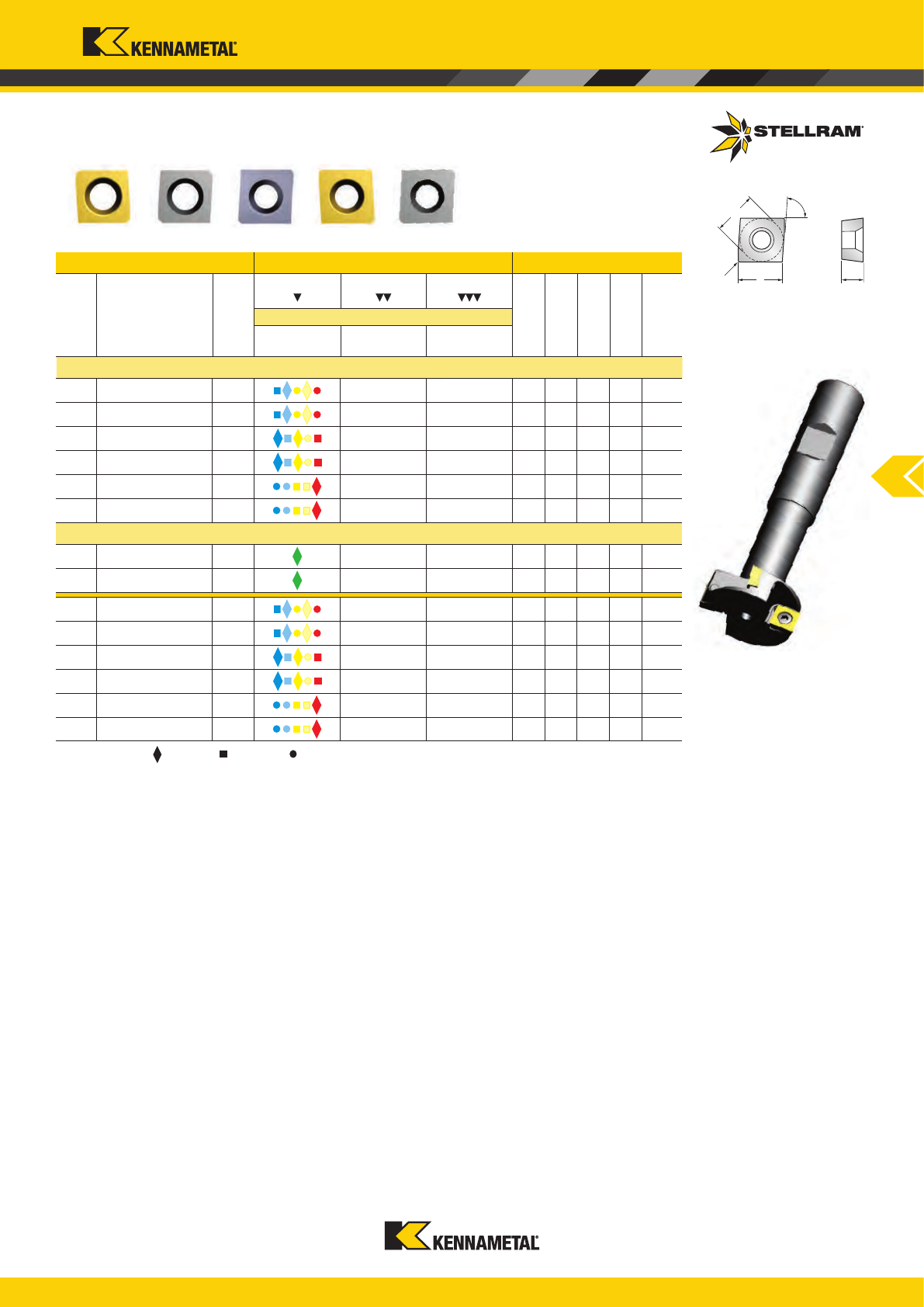

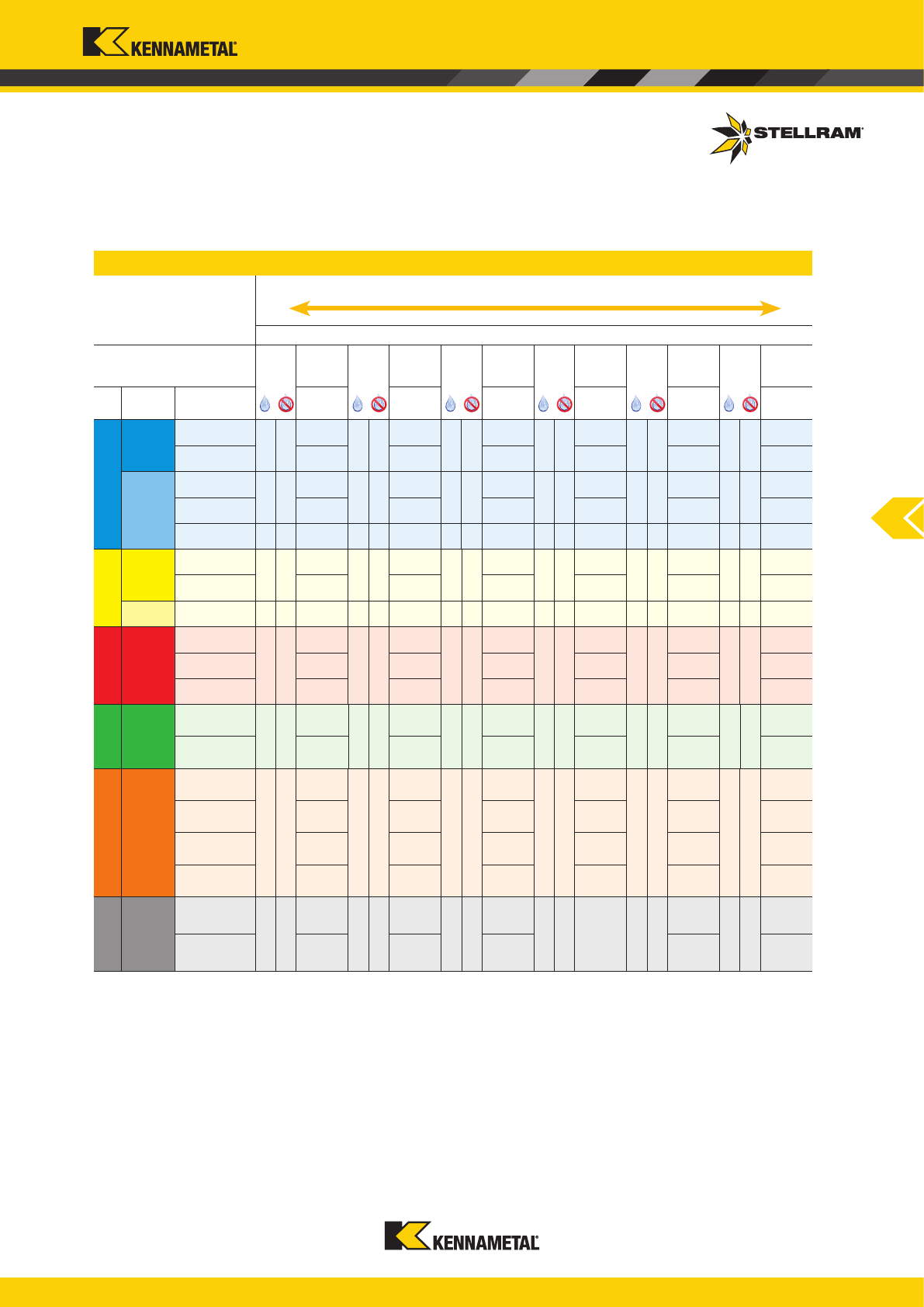

Family Range Dimensions (mm) Body Fixation

Series

Insert Shape

and Size

Angle

Page

a

p

max

Diameter

Range

Modular

Heads

Weldon

Cylindrical

Shell

Mills

Caterpillar

Vee Flange

DIN 69871

Fixation

Taper 50

7745VOD

OD..0404

Facing

42°

A77 -

A86

3,5 25 - 160

• •

OD..0605 4,5 50 - 160

7745VS

SC..09T3

Facing

Chamfering

45°

A87 -

A94

5 16 - 25

• •

SC..12M5 7 40 - 125

7745VSE

SD..09T3

Facing

45°

A95 -

A105

5 16 - 125

• •

SD..1204 7 50 - 125

7745VT

TP..1102

TC..16T3

7,70

6,10 - 11,30

16

20 - 30

Chamfering

45° / 60°

A265 -

A270

•

7760VT TC..16T3 9,50 16 - 25

7791VS

SC..09T3

Plunging

A257 -

A264

a

e

= 8 25 - 50

• •

SC..12M5 a

e

= 11 63 - 80

7792VXP XP..0603 0,90 16 - 32

7792VXD

XD..0904

XD..1205

High Feed

A63 -

A75

1,50

2,50

25 - 50

32 - 160

• • • •

7792VXE XE..1605 3,50 63 - 160

Tungsten

Cylindrical Shank

Extensions

- -

A76

- 16 - 32

•

Facing

Shoulder /

Proling /

Slotting

Ramping

Pocketing

Helical

Interpolation

Helical

Interpolation

with Bore Hole

Copy / 3D

Spiral /

Circular

Trochoidal

Shoulder /

Proling

T-Slotting

Contour

Milling

Slotting

Shoulder

Chamfering

Plunging

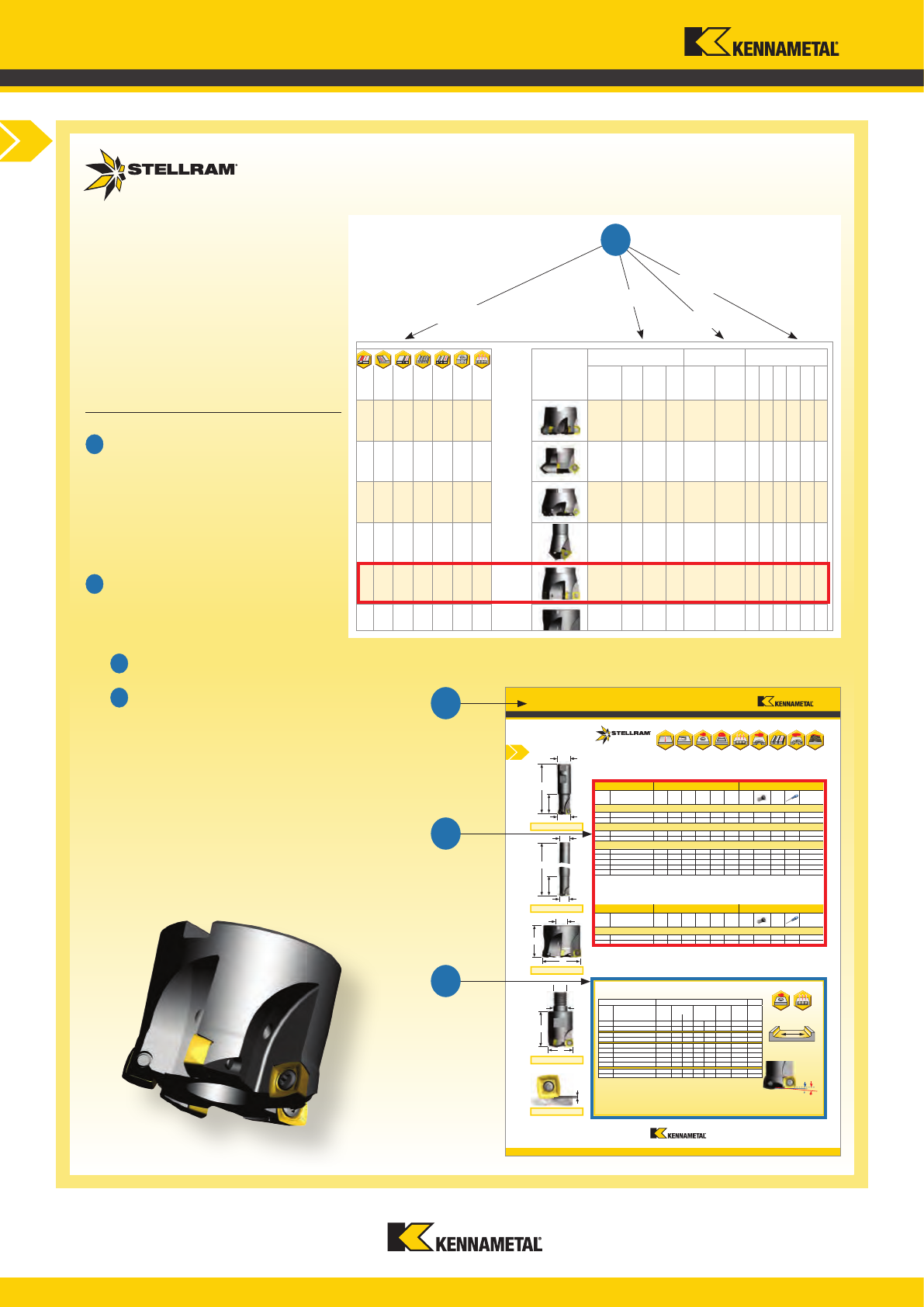

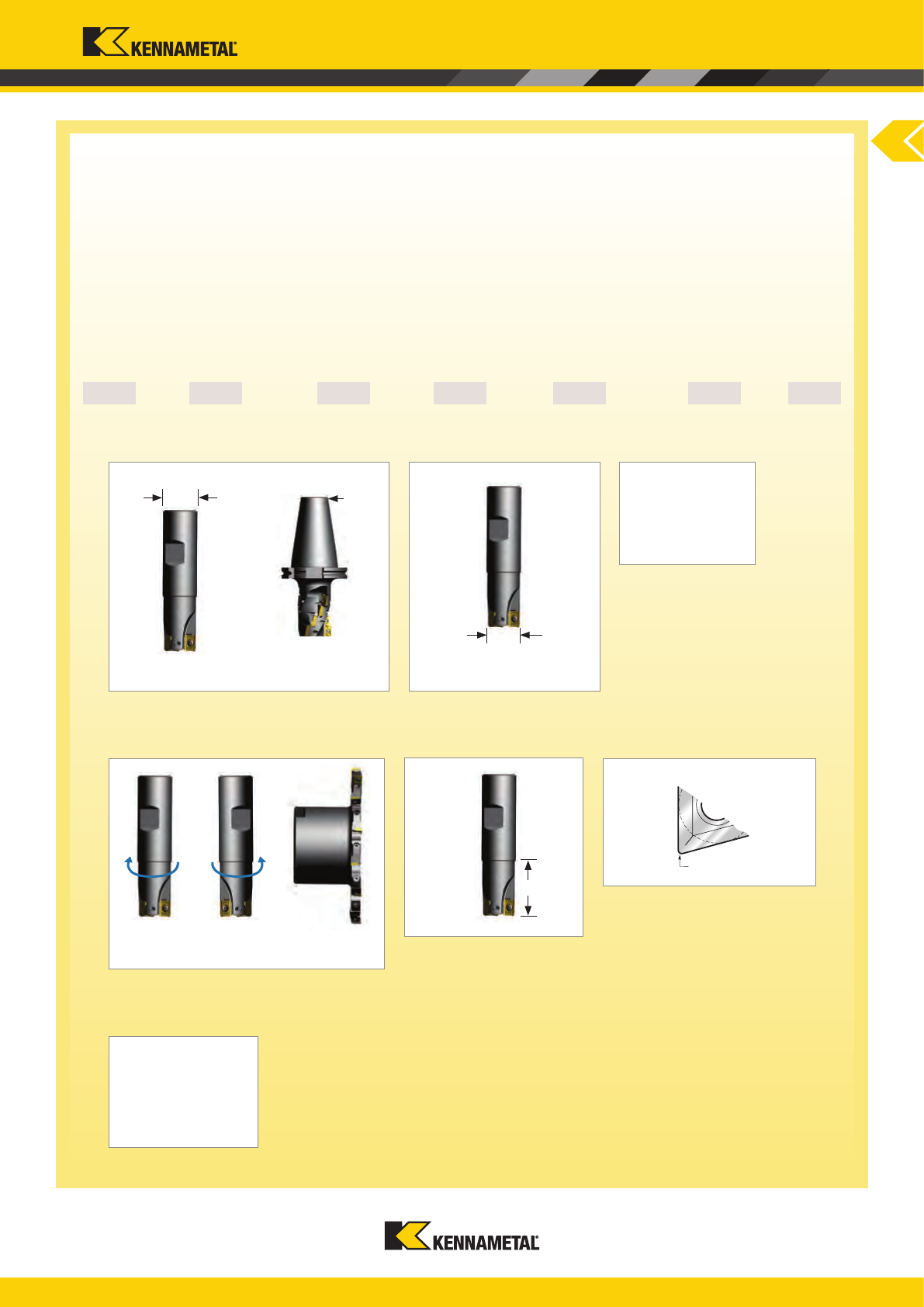

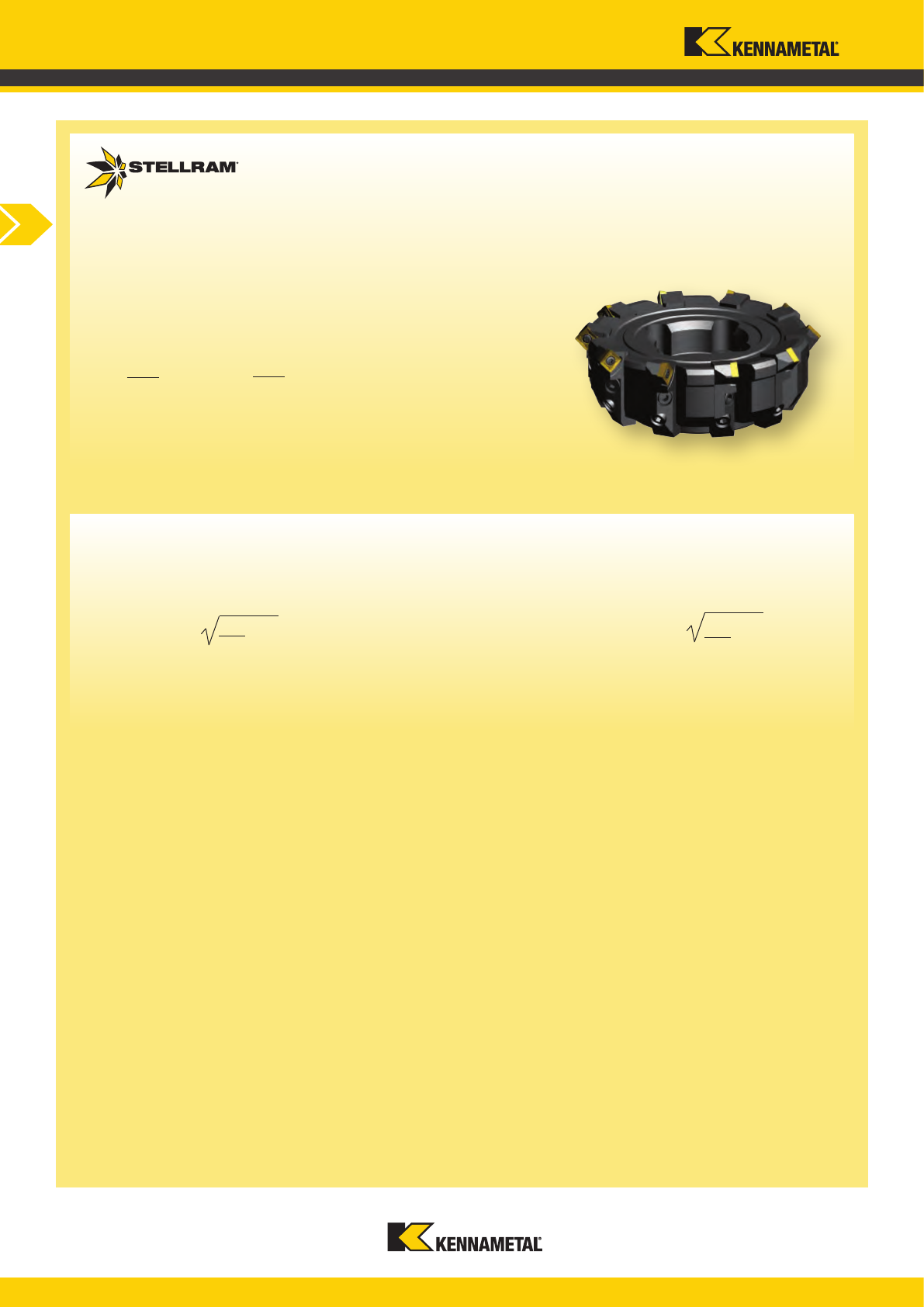

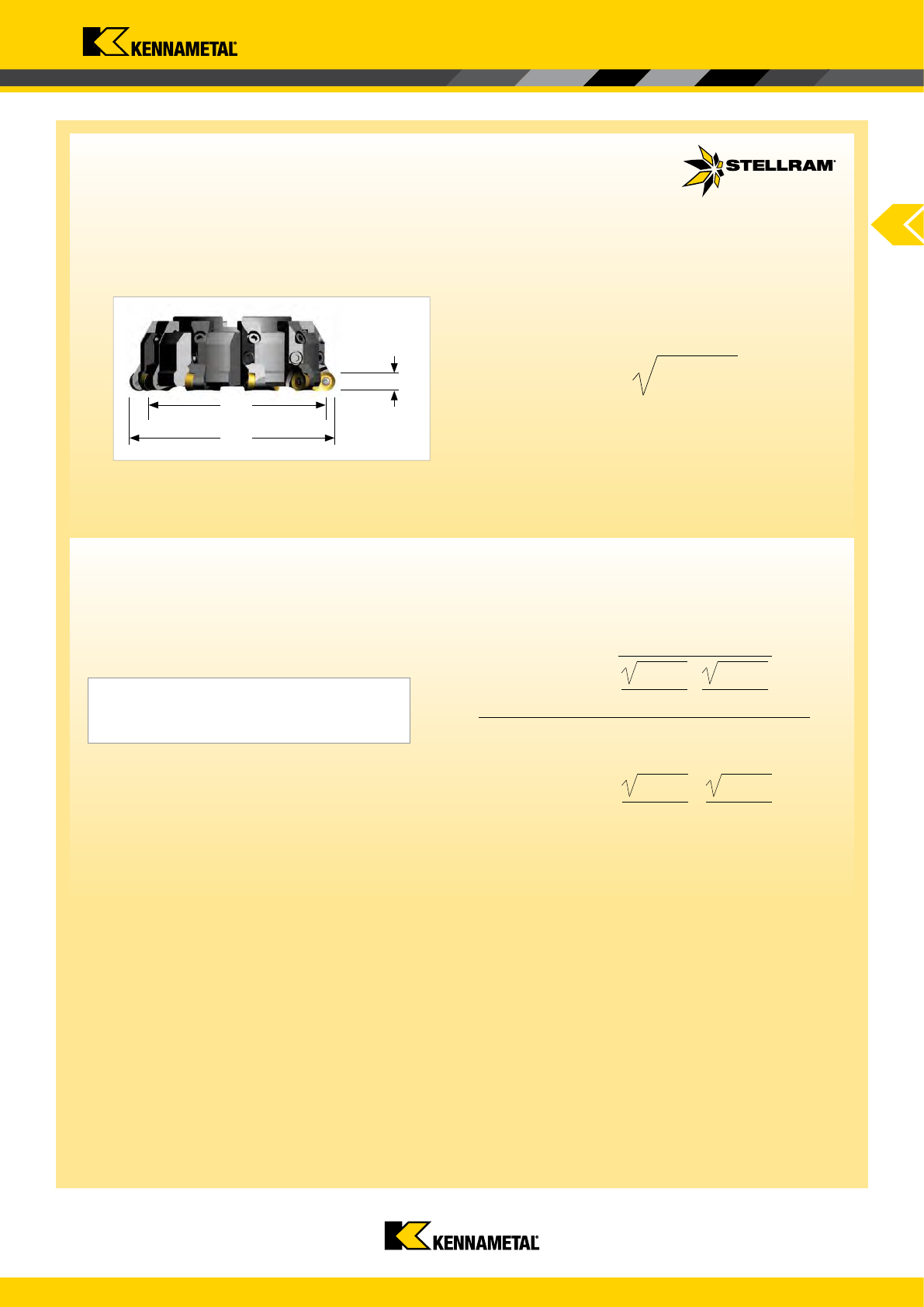

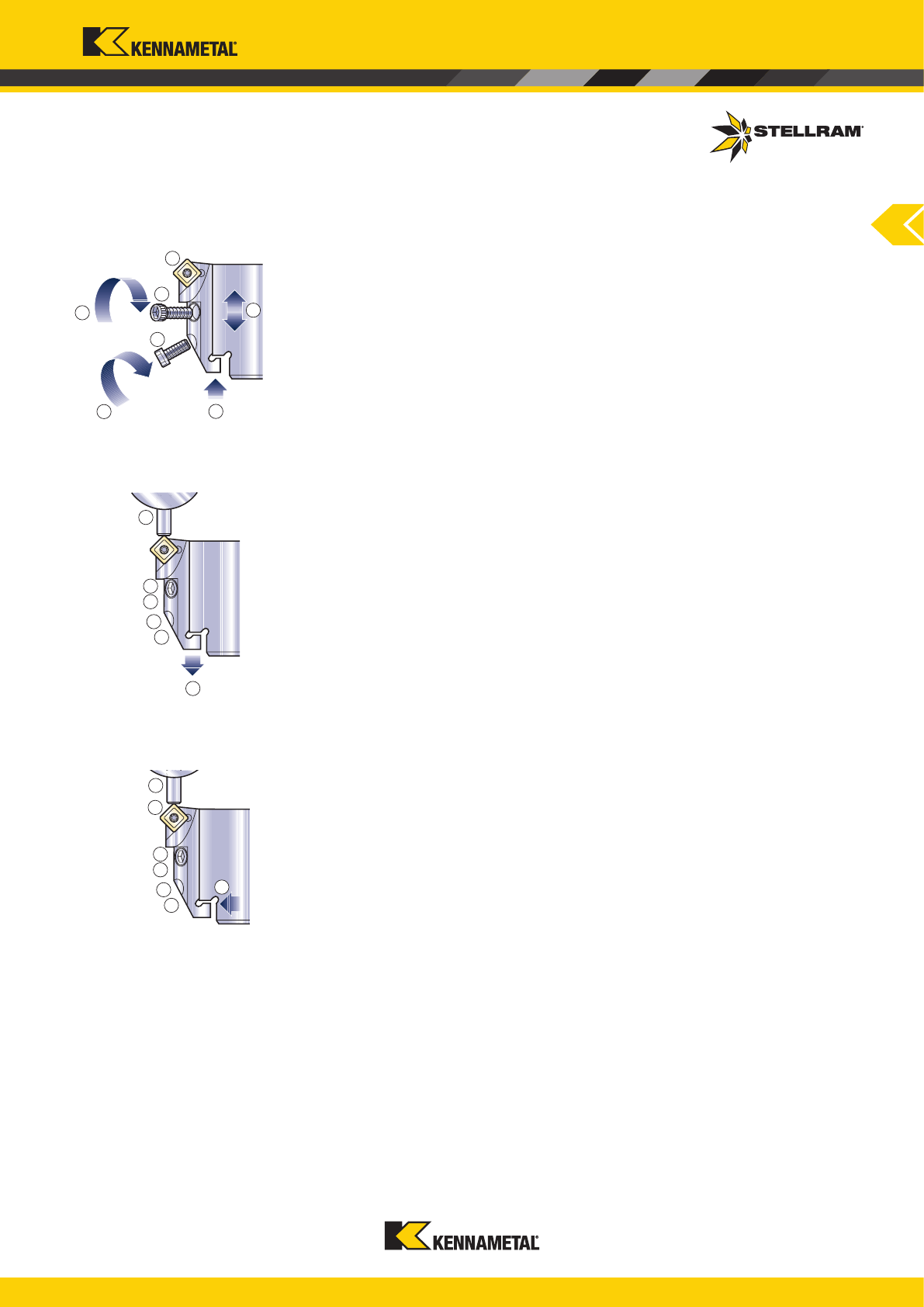

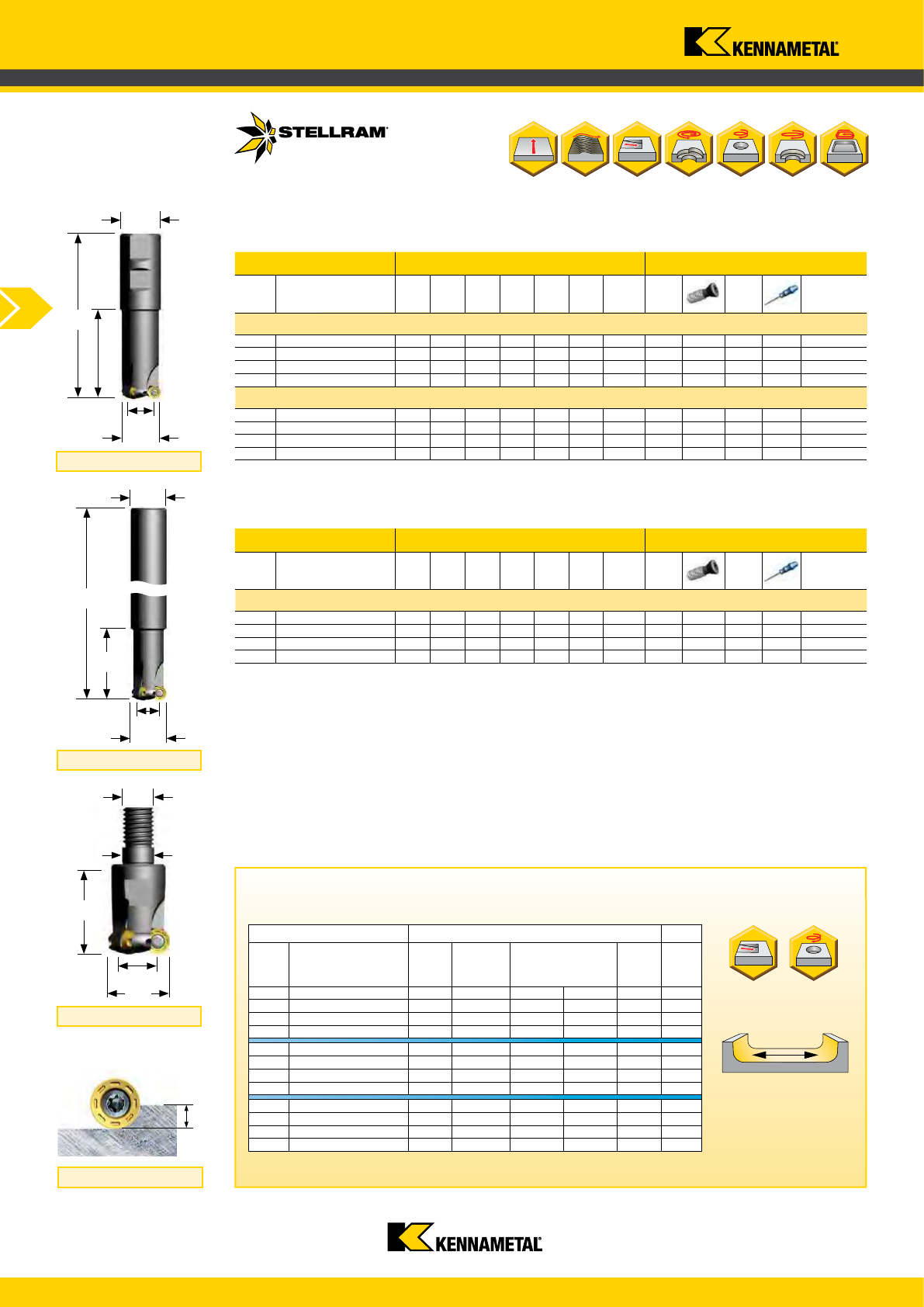

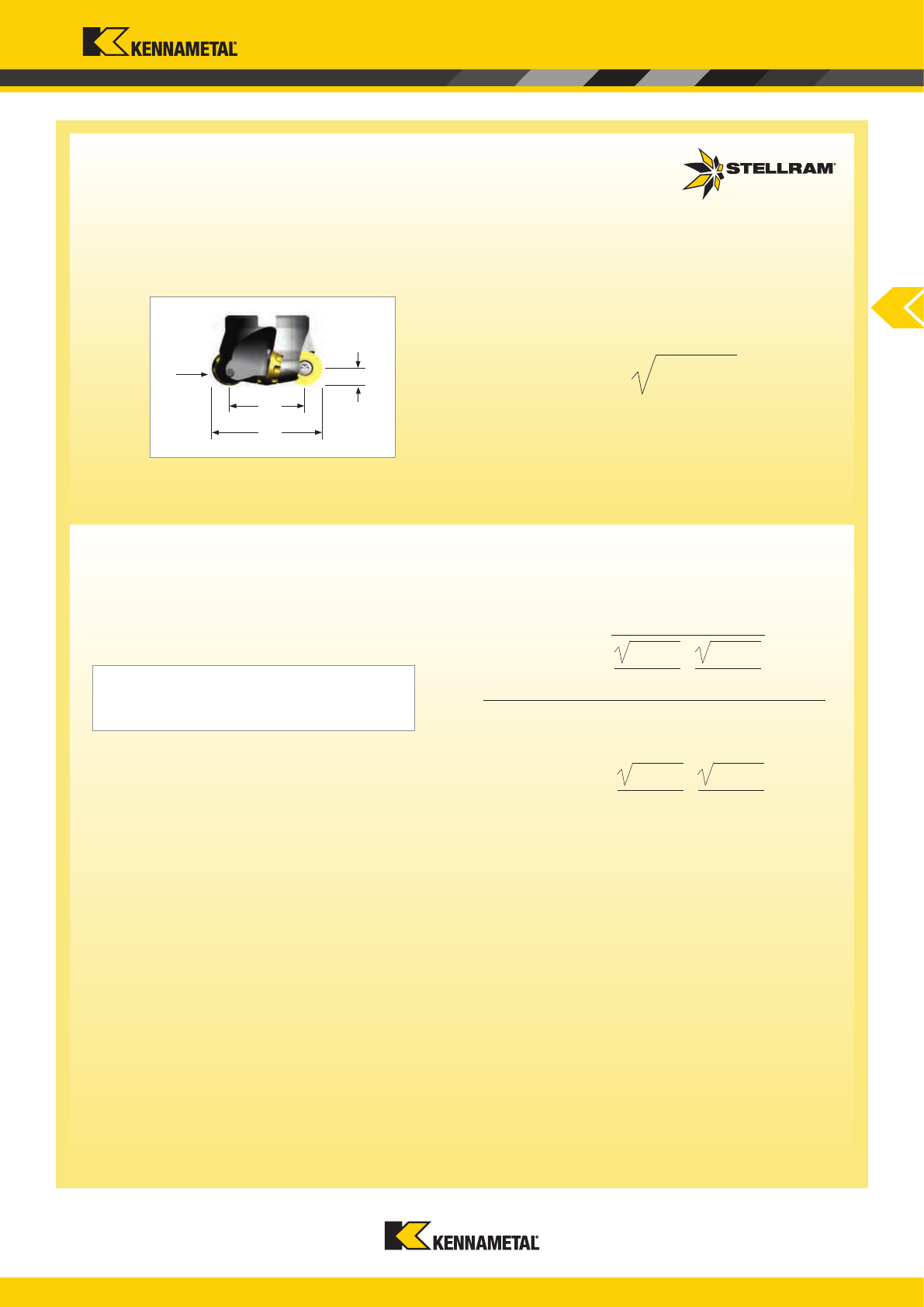

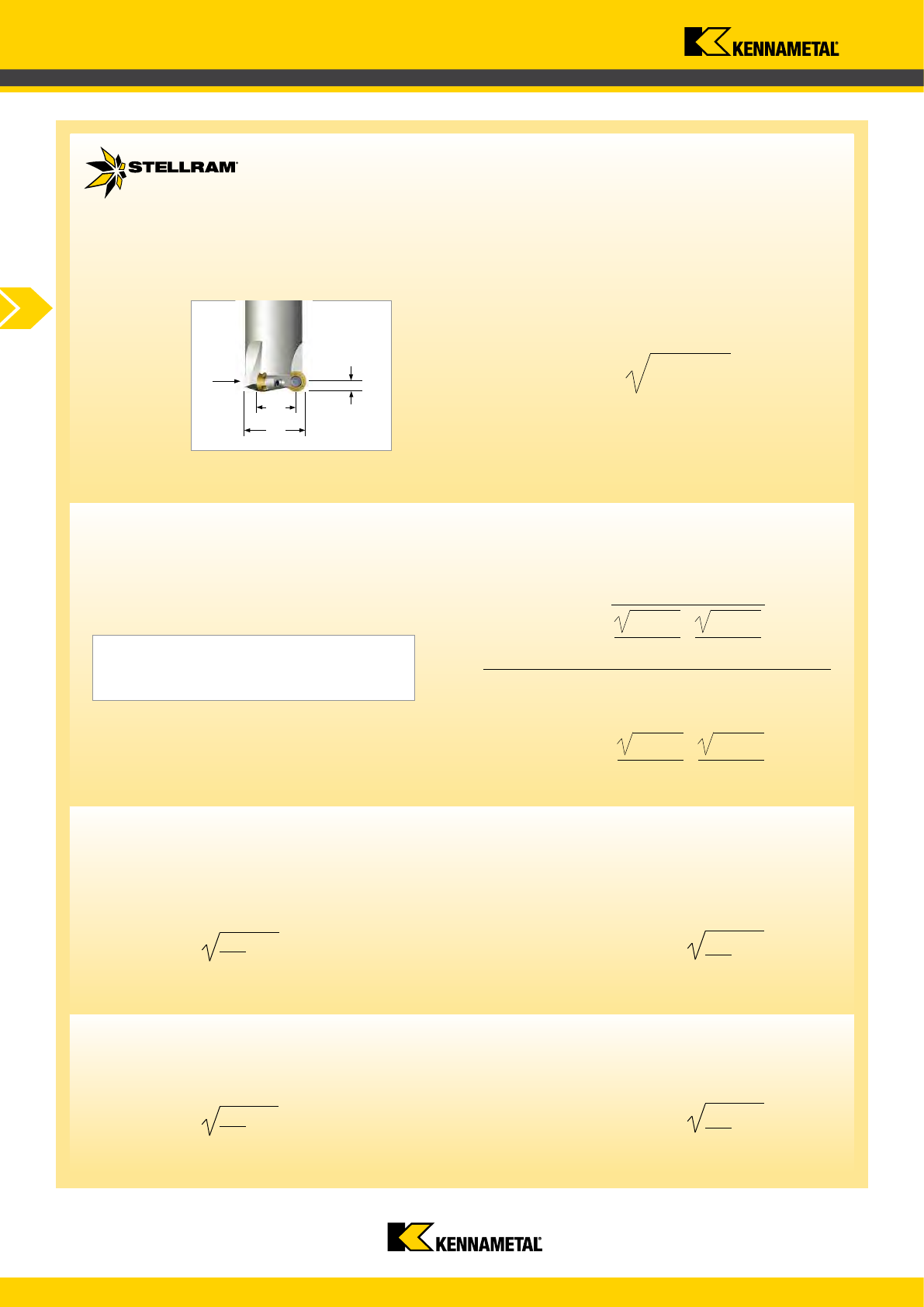

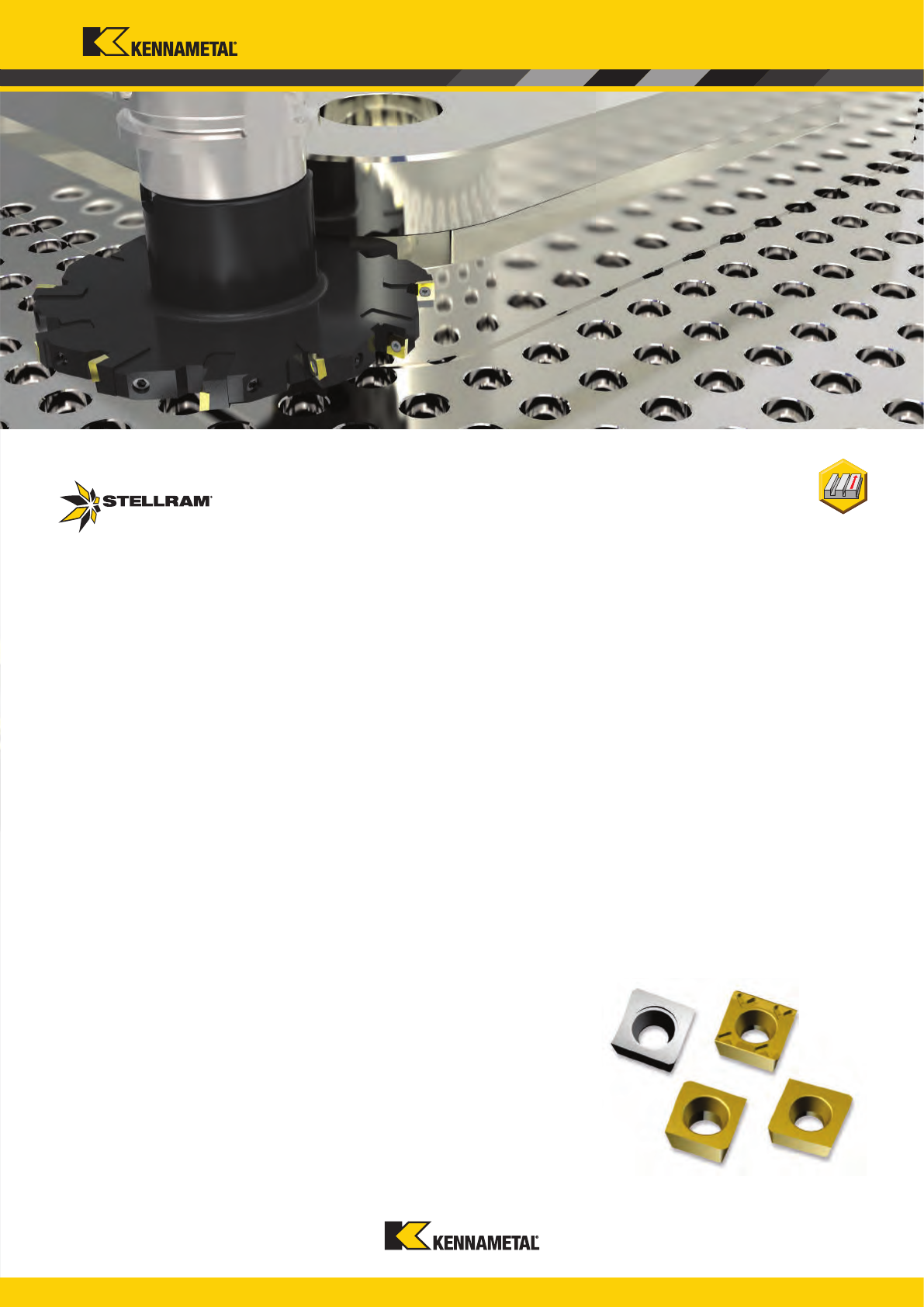

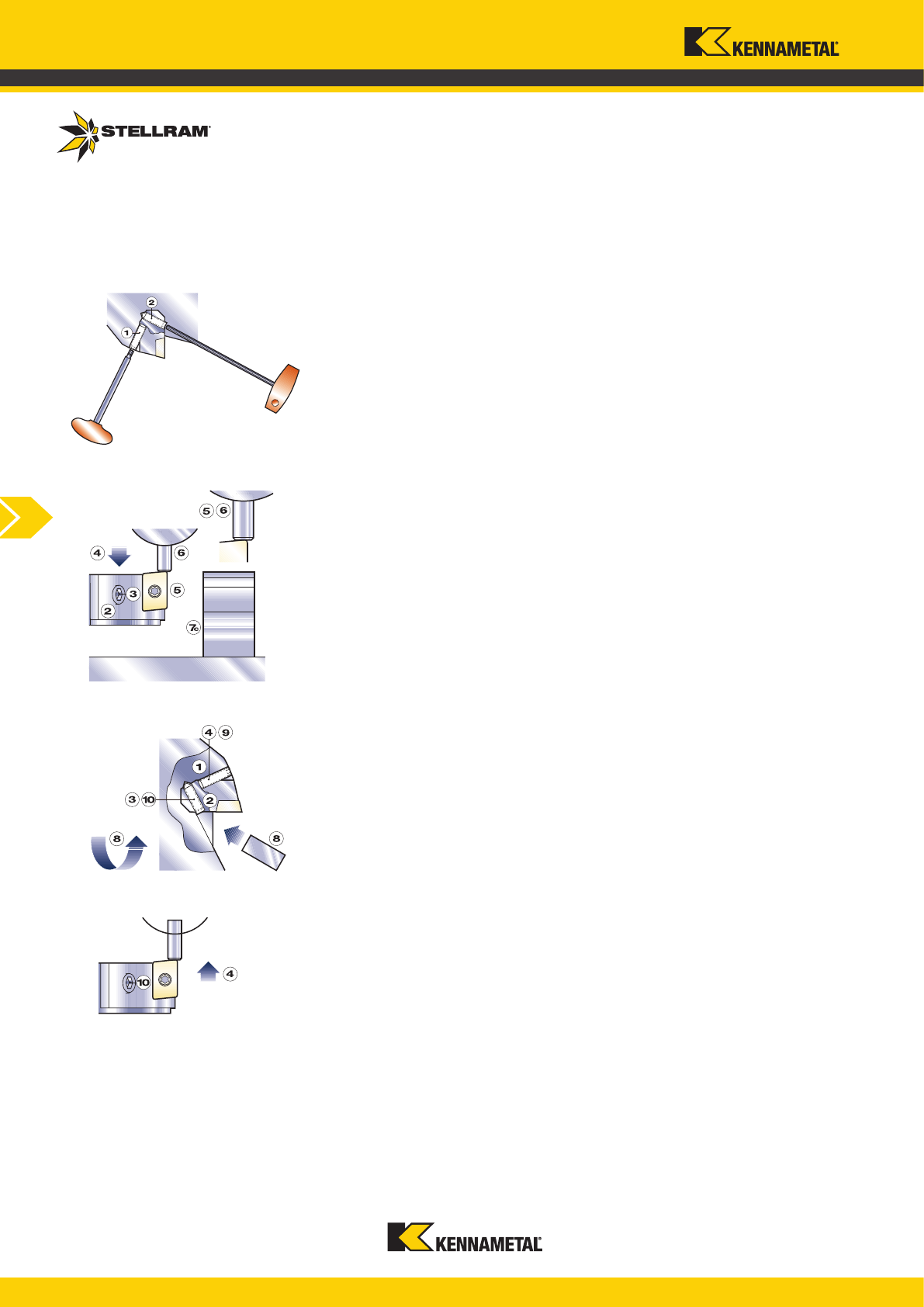

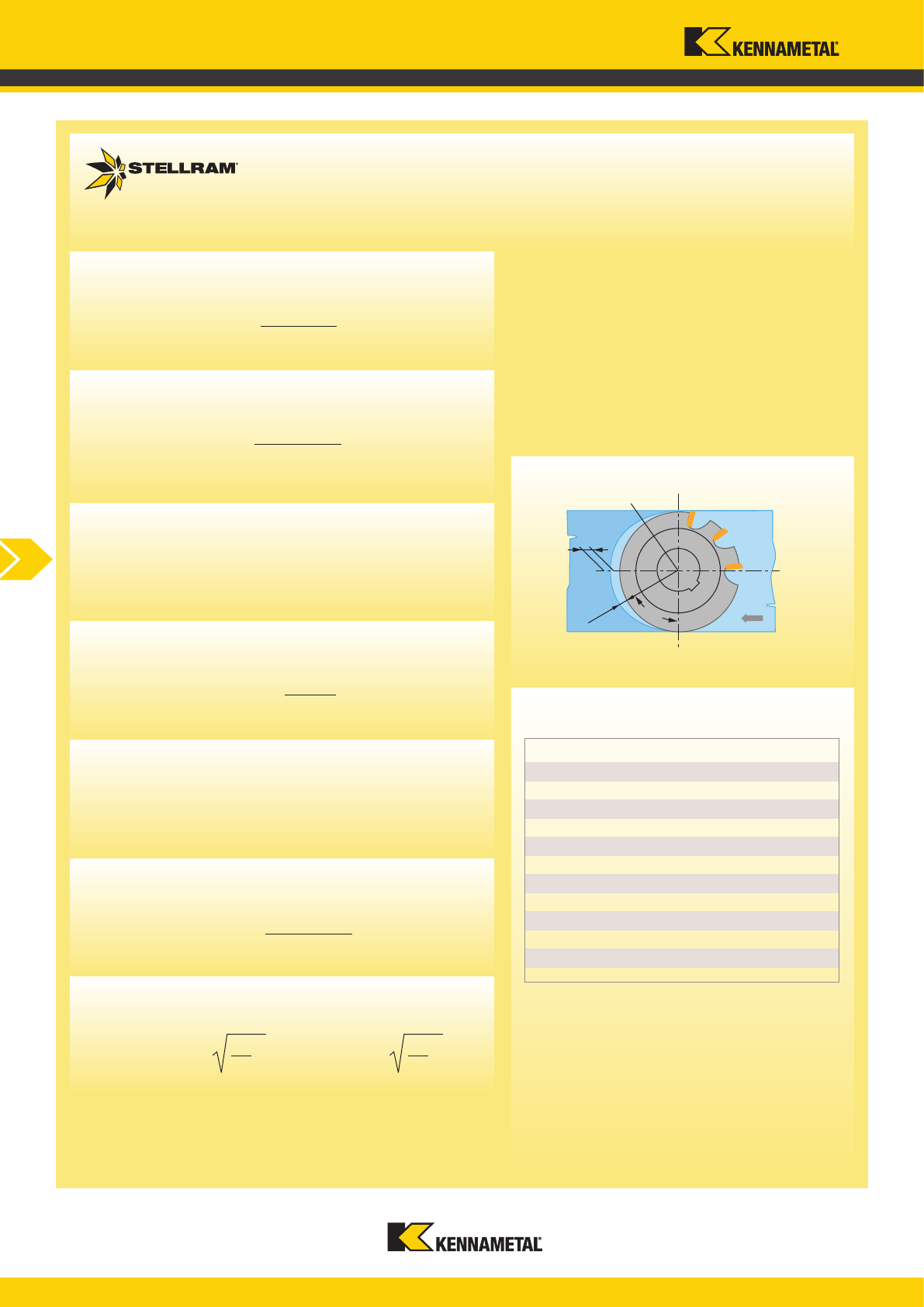

This new Milling Selection Guide leads

you easily to the tool selection and to the

corresponding user information. 6 steps

enable you to select the suitable cutter,

insert geometry and grade in relation with

recommended parameters for Feed and

Speeds.

Go to the Tool guide on pages

A6 - A13. Select the milling family

according to the application.

Available diameters, body fixation

and type of inserts can also be

found. (7792VX family selected)

Go to the referred Family page with

the entire product range and

technical information

Select a Cutter Body Diameter

Technical Information

• Facing pitch

• Ramping angles

• Helical hole (min - max)

• a

p

max Helical / Linear

• a

e

max plunging

(for 7792VX and 7791VS only)

• RPM max

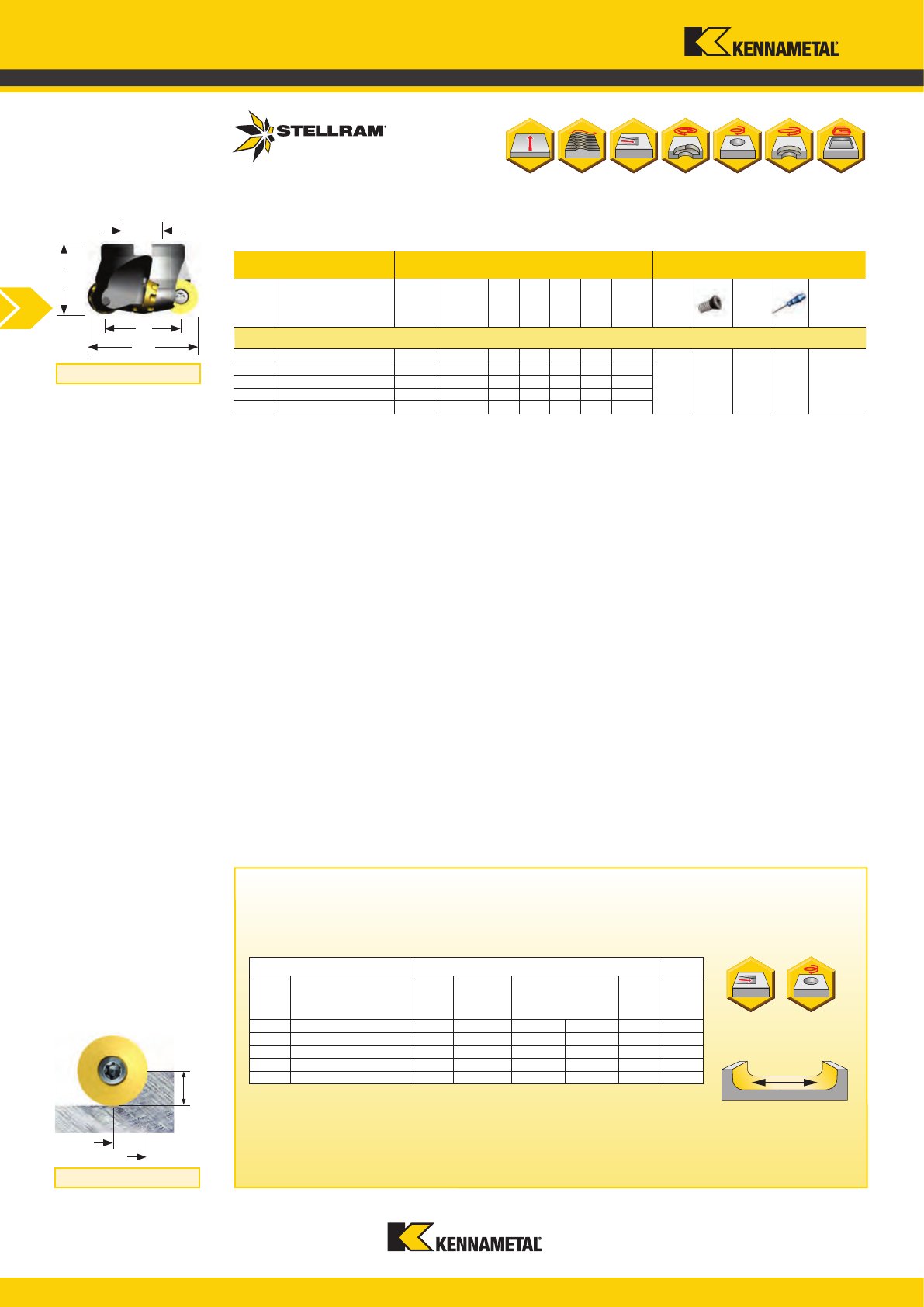

6 Step Tool Selection

Tooling Selection Guide

Cutters, Inserts & Cutting Parameters

Applications

Family Range

Diameter Range

Body Fixation

End Mills & Face Mills

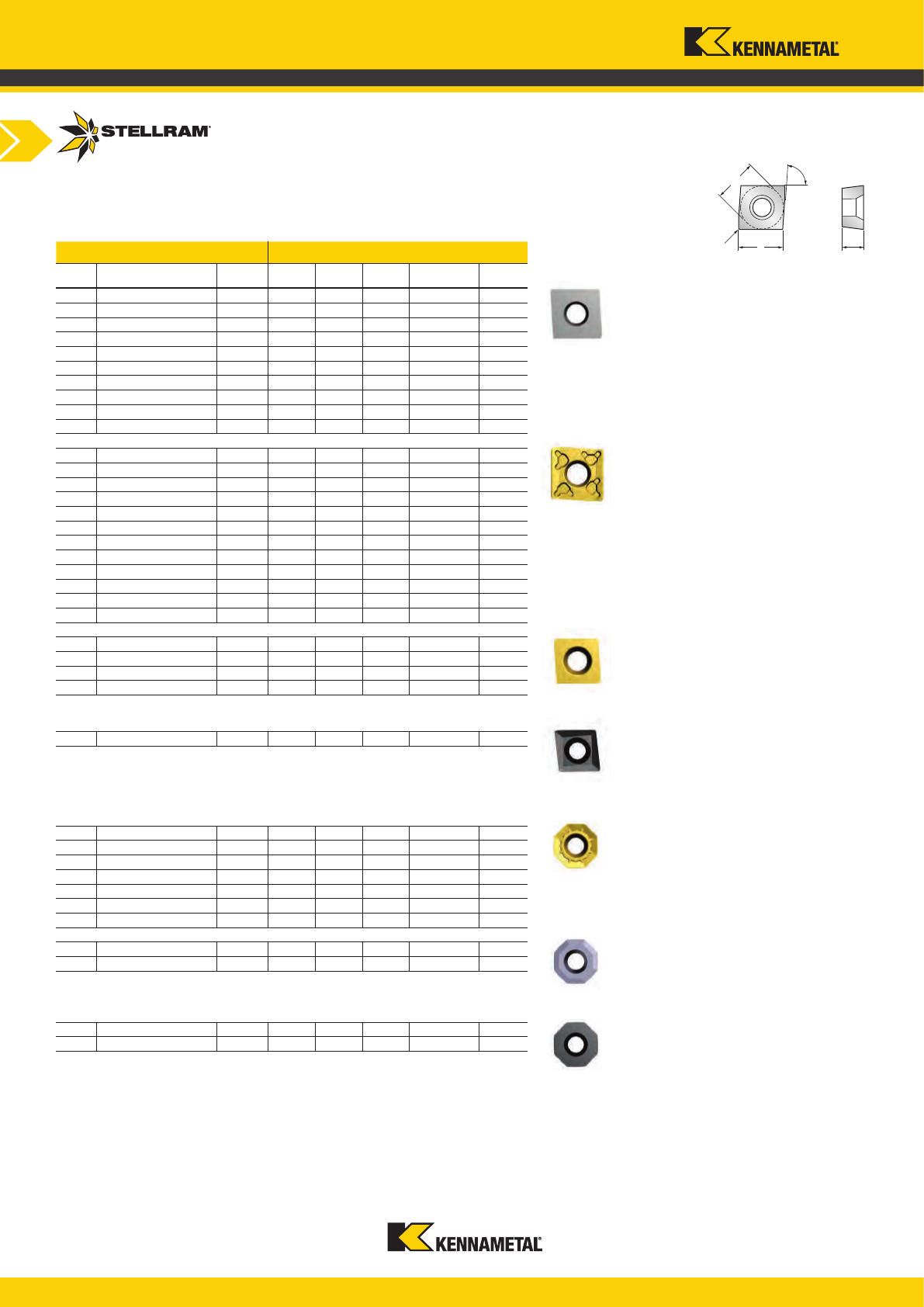

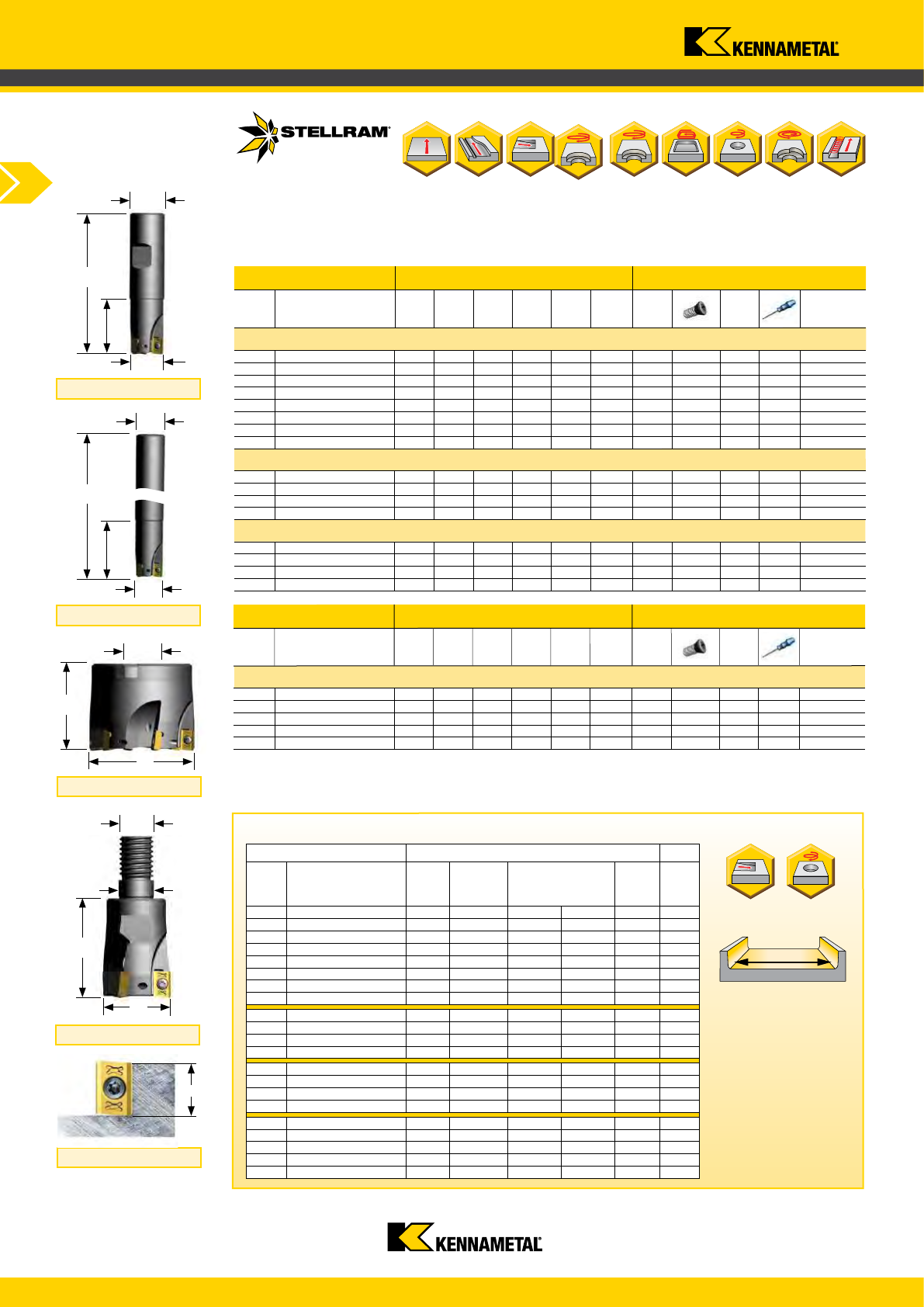

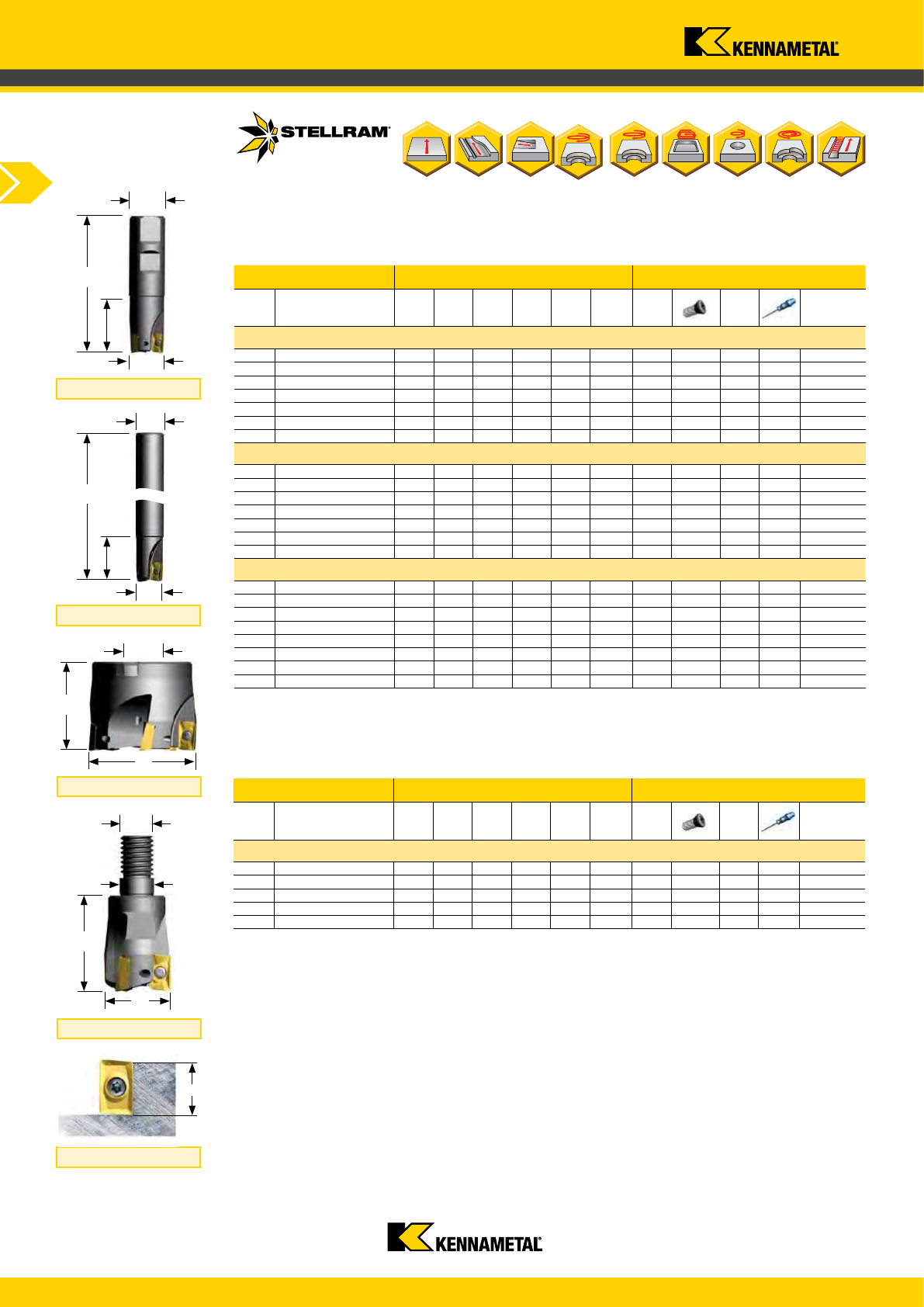

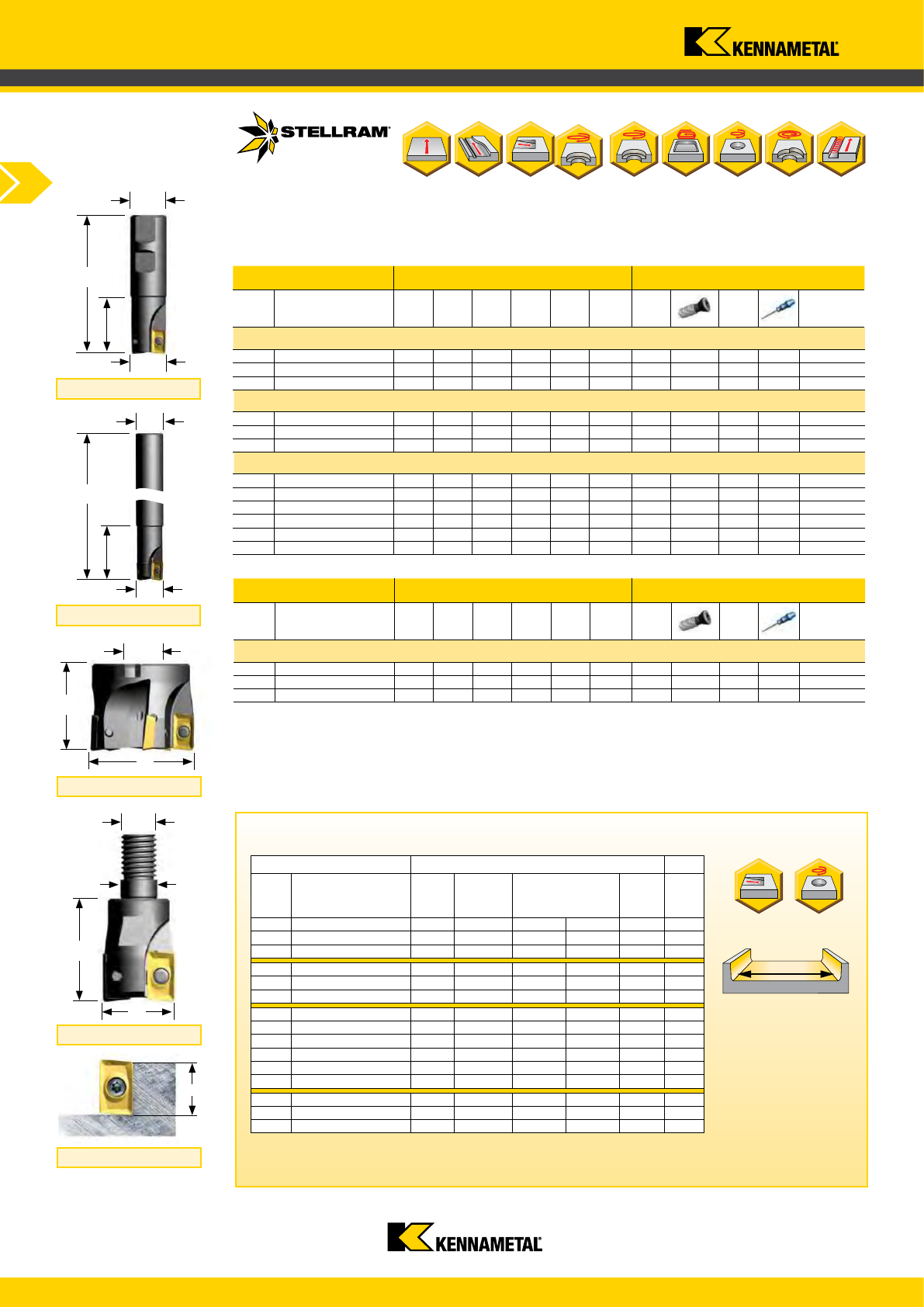

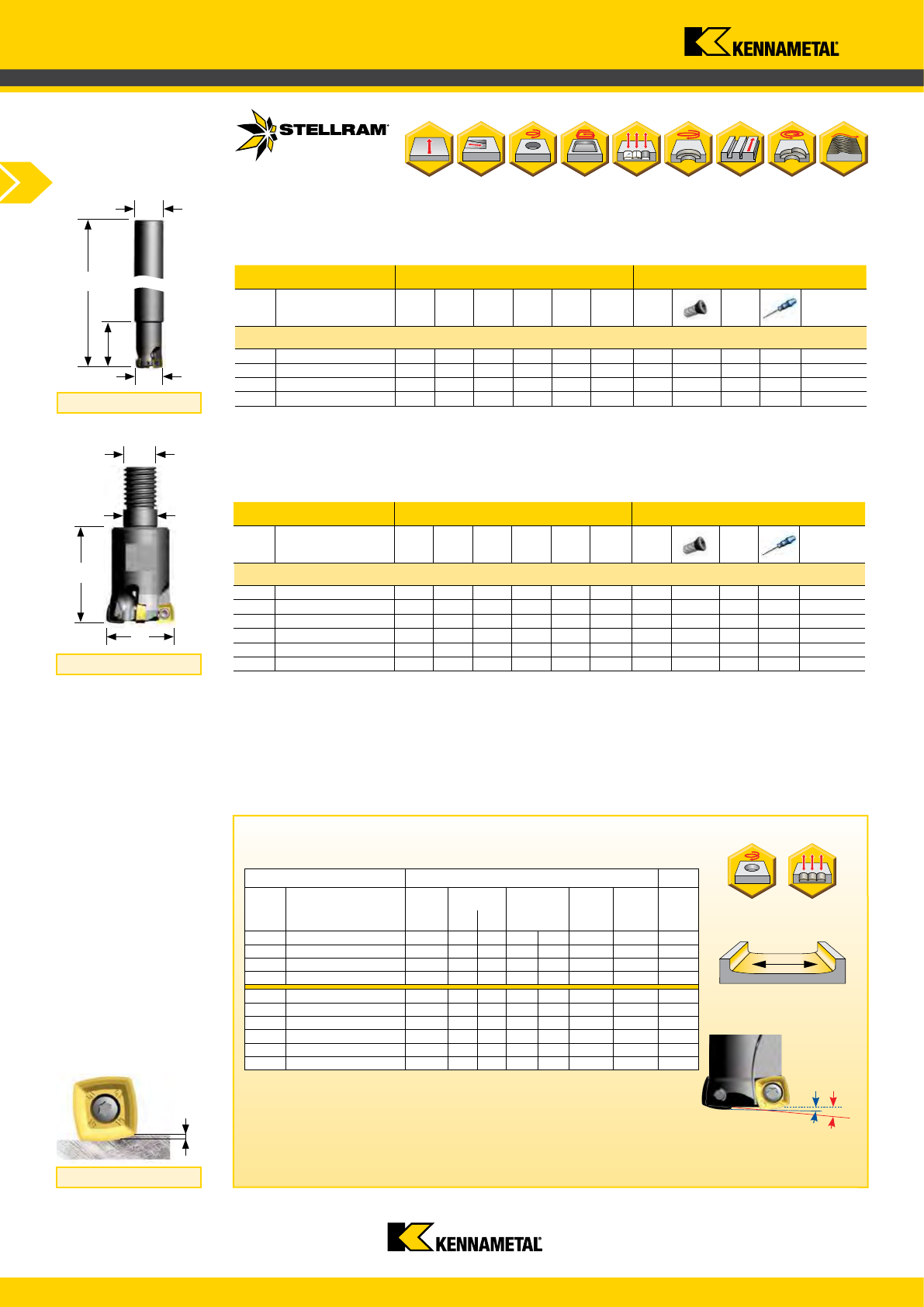

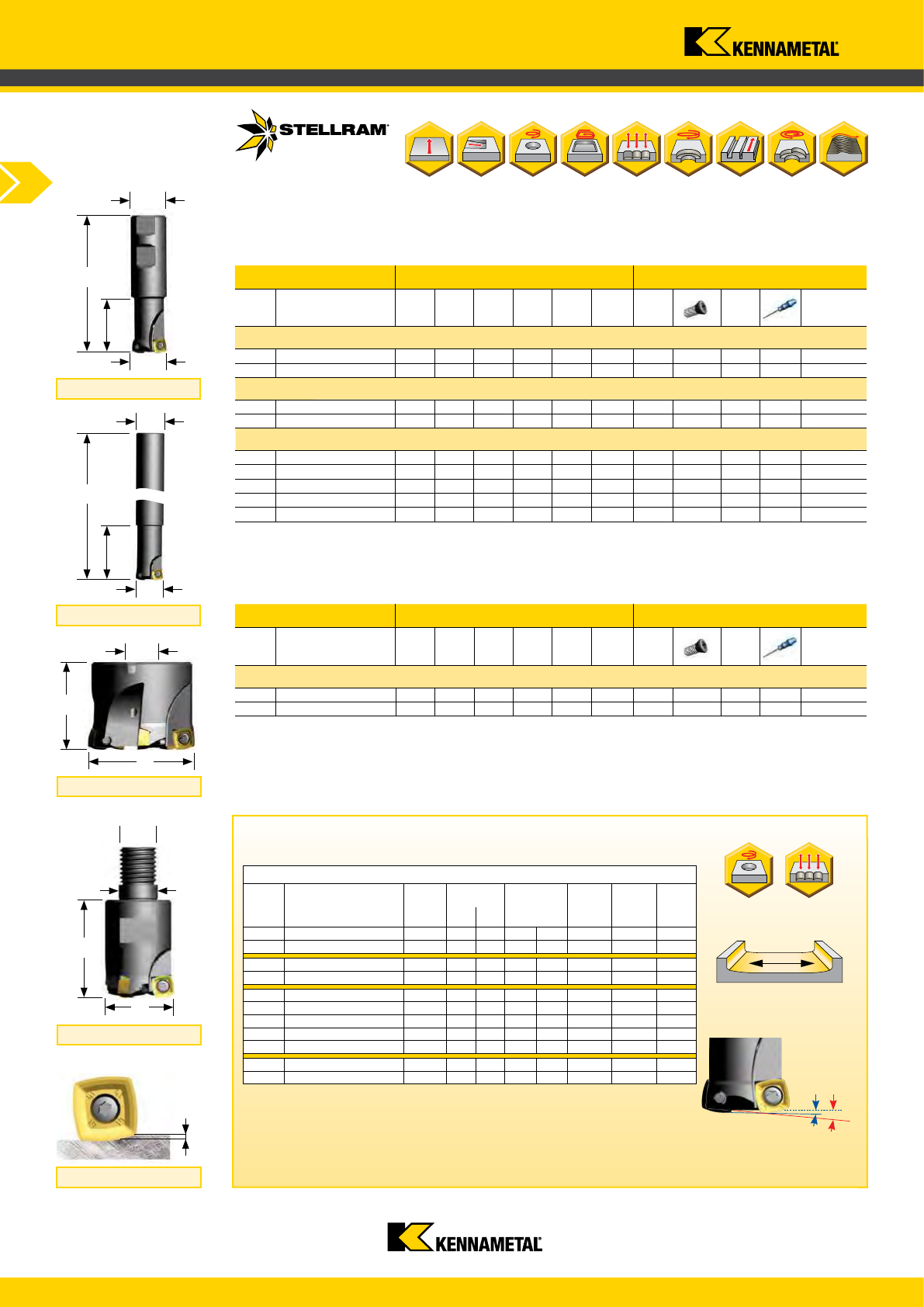

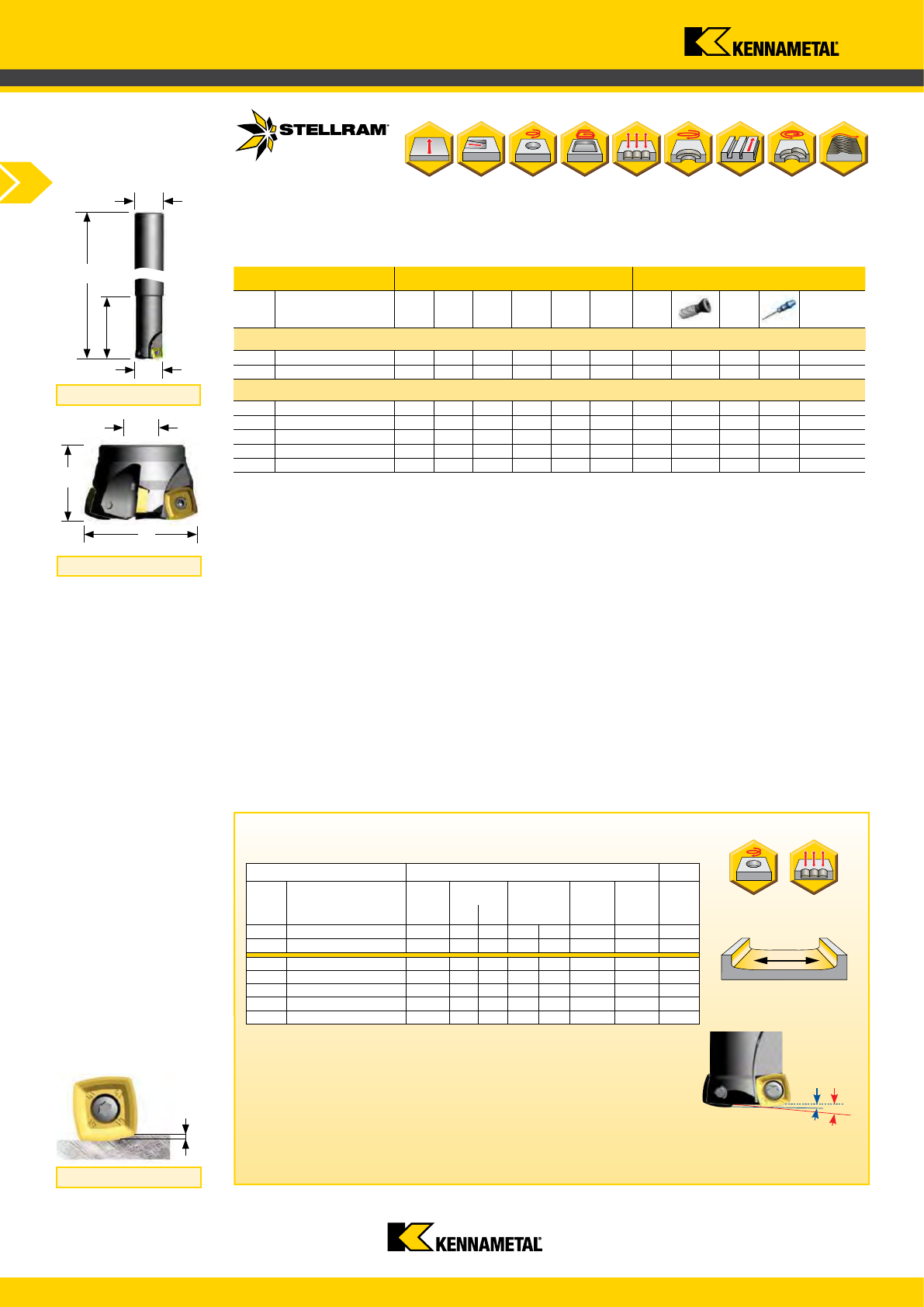

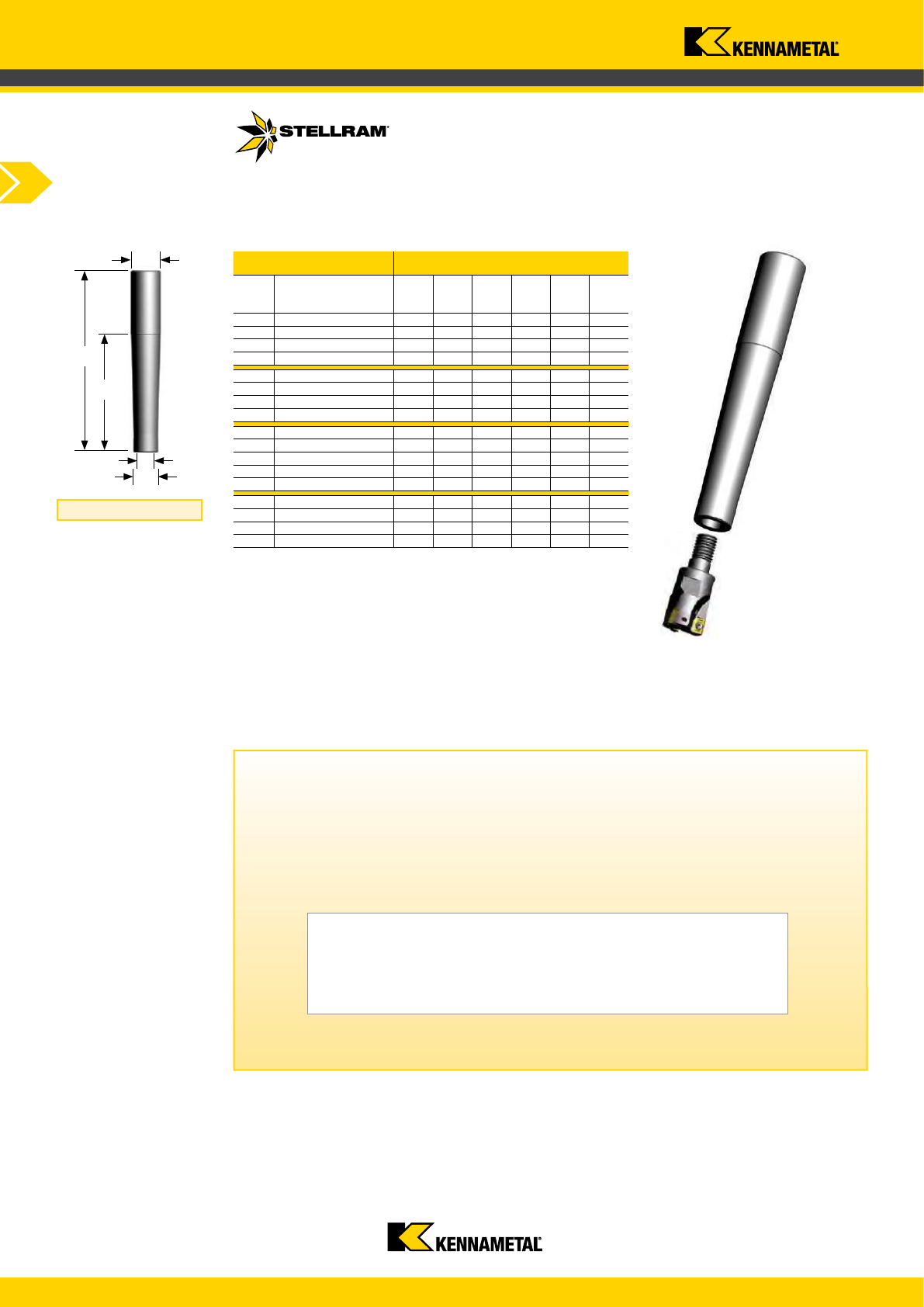

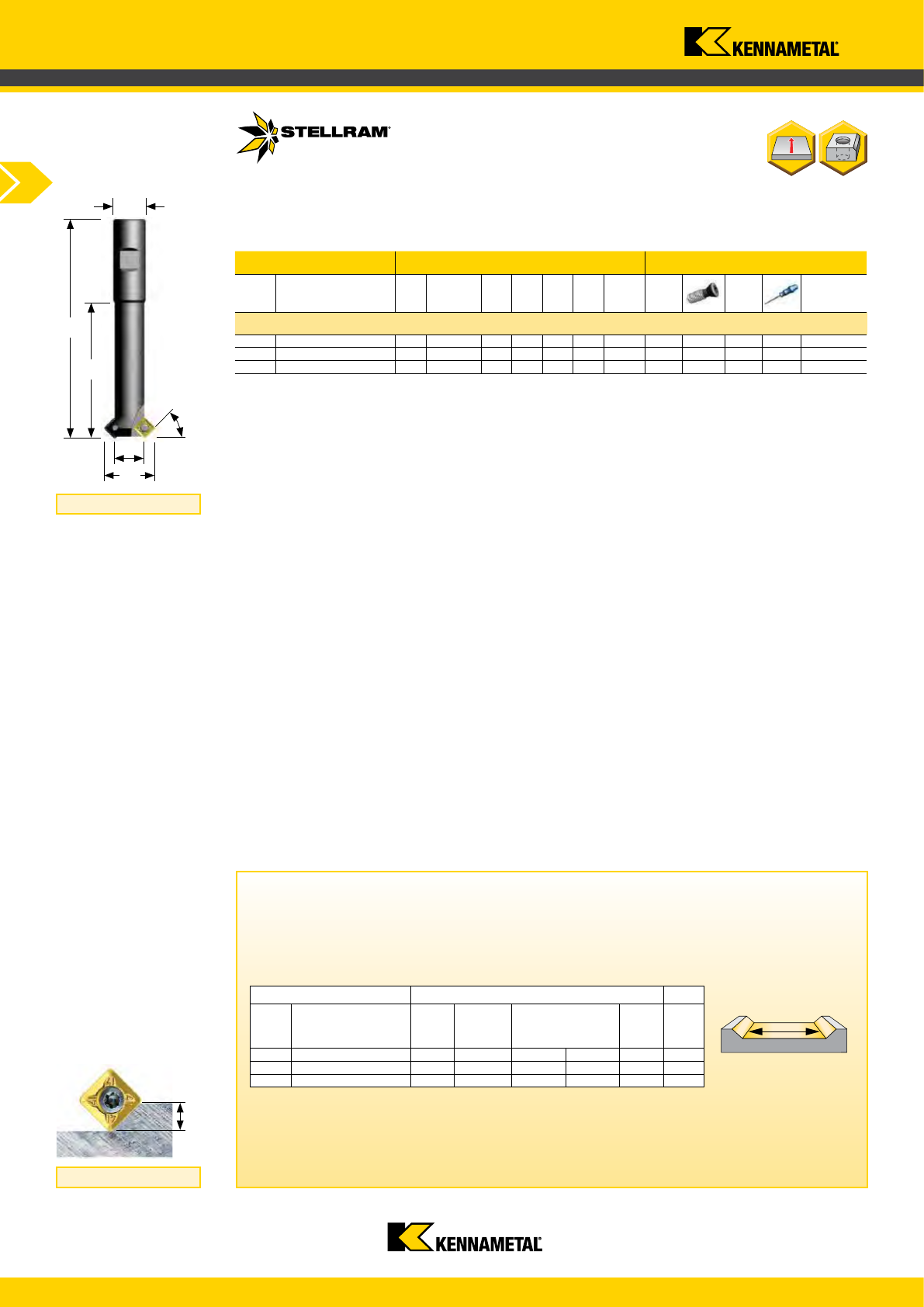

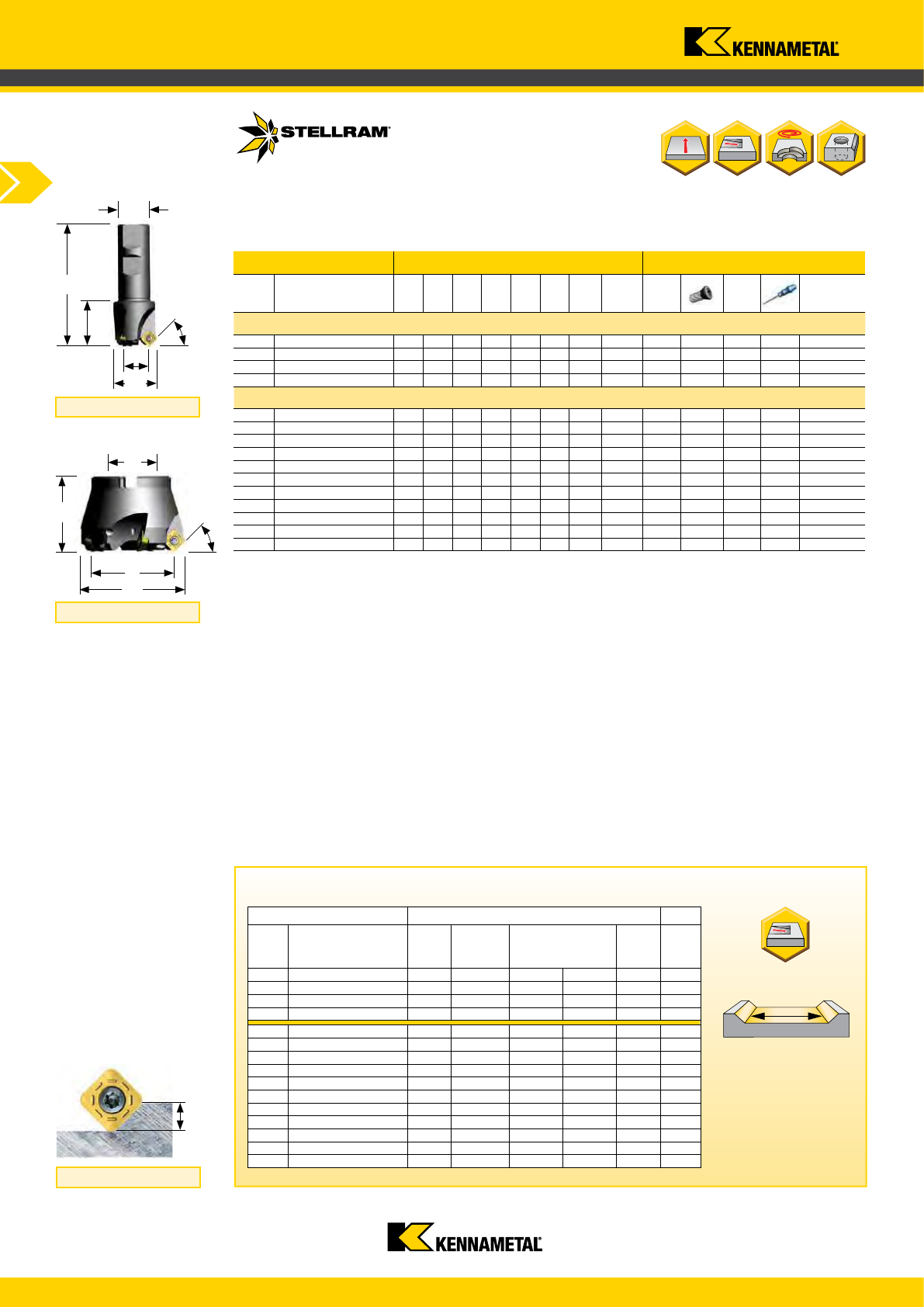

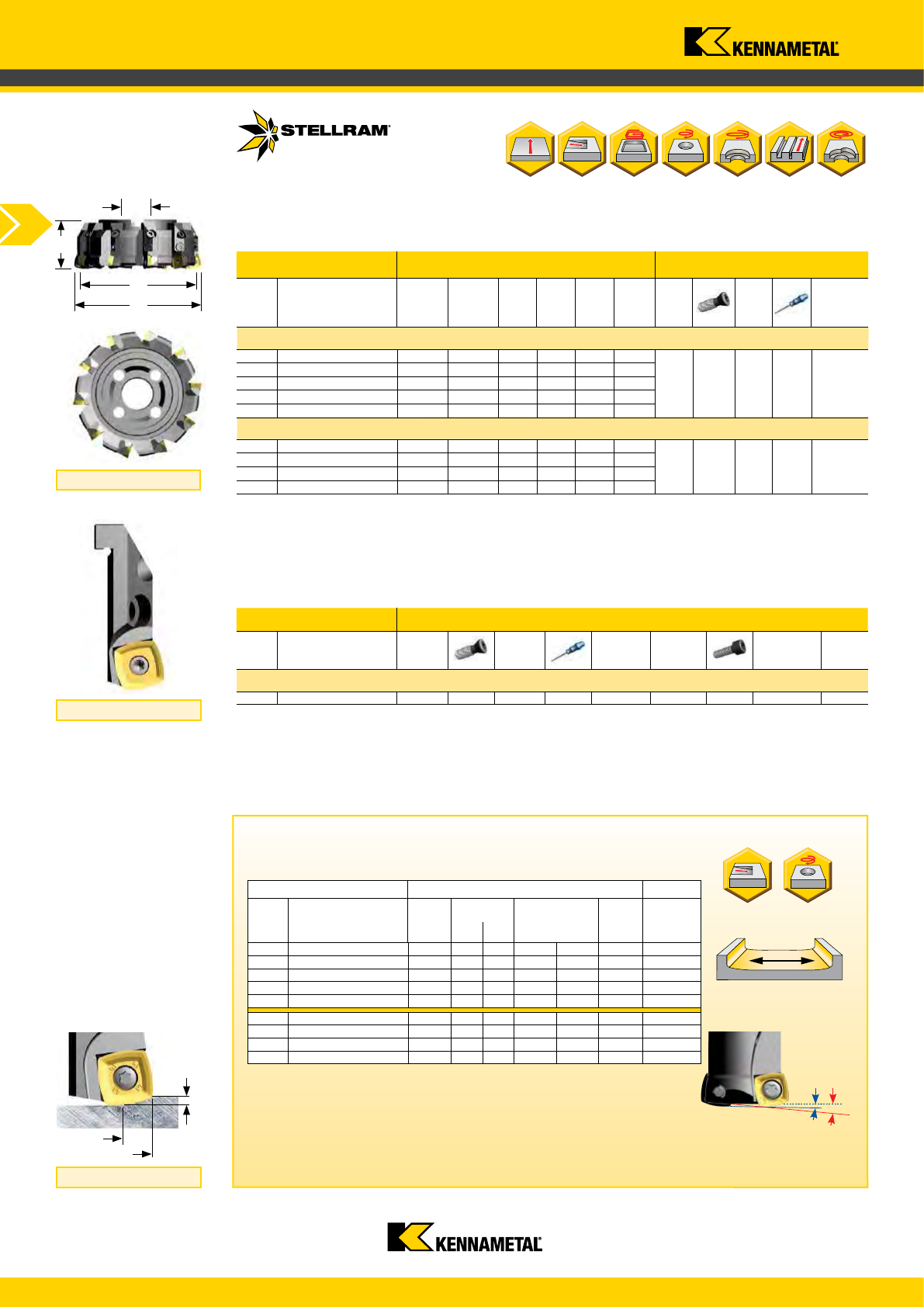

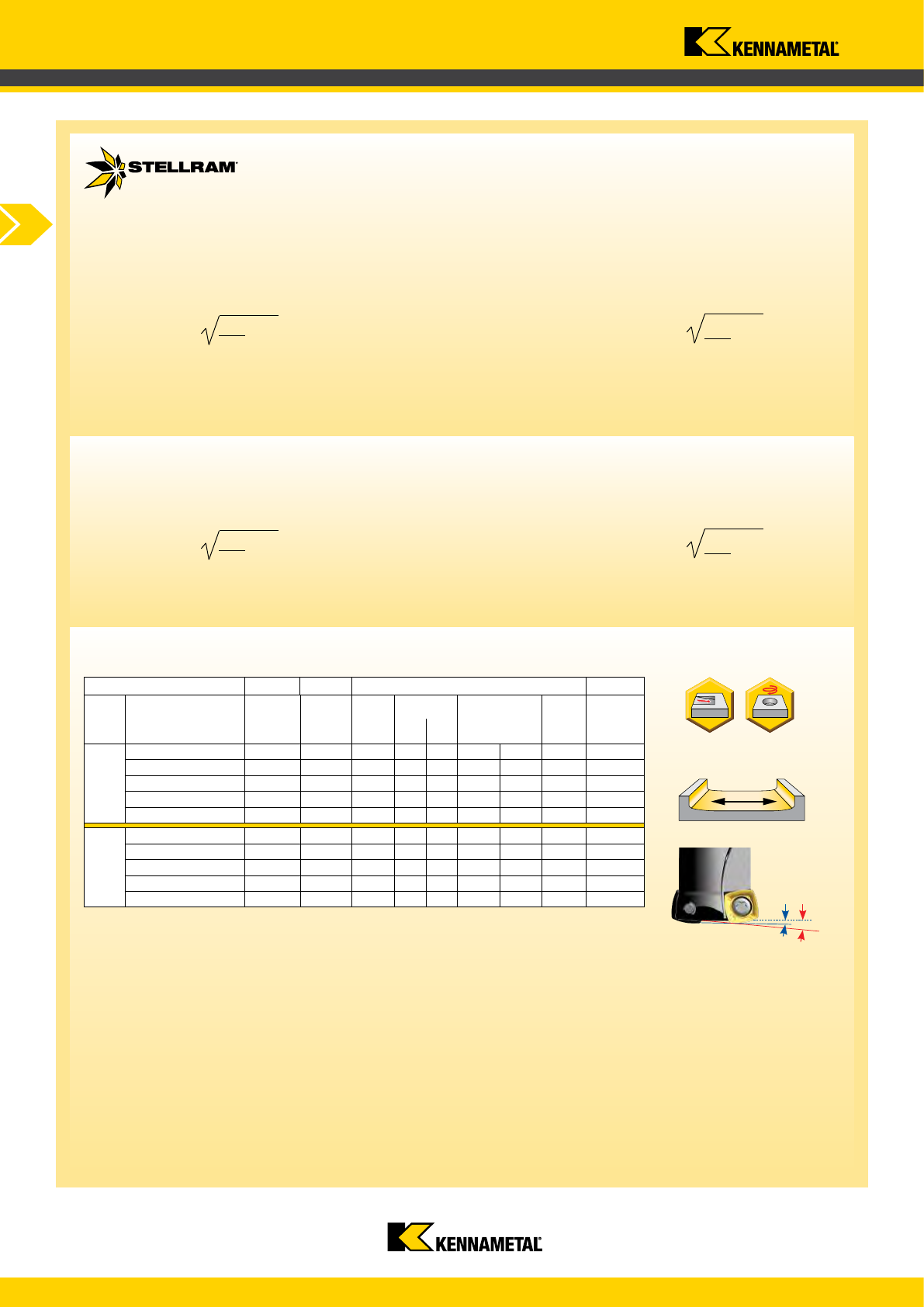

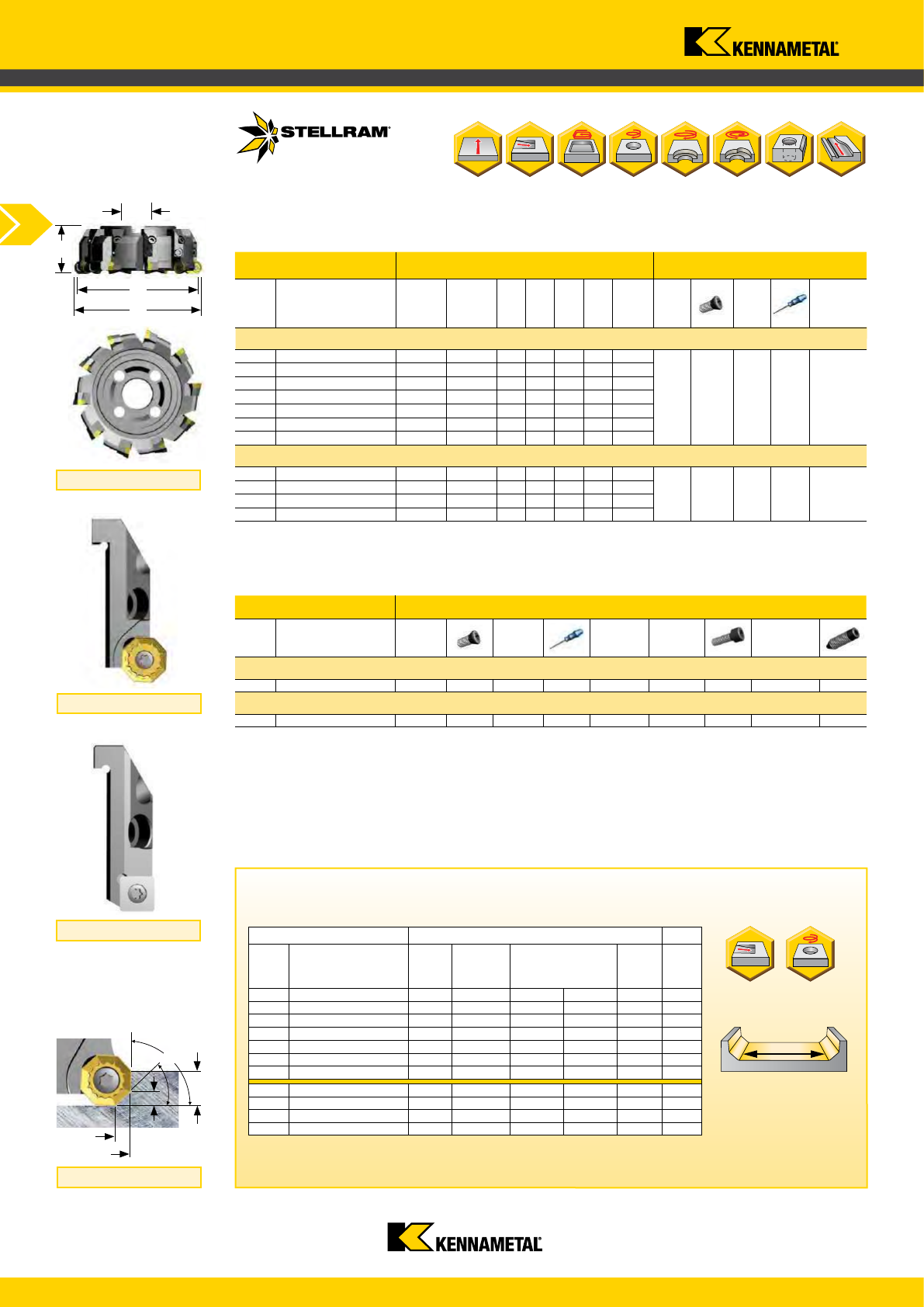

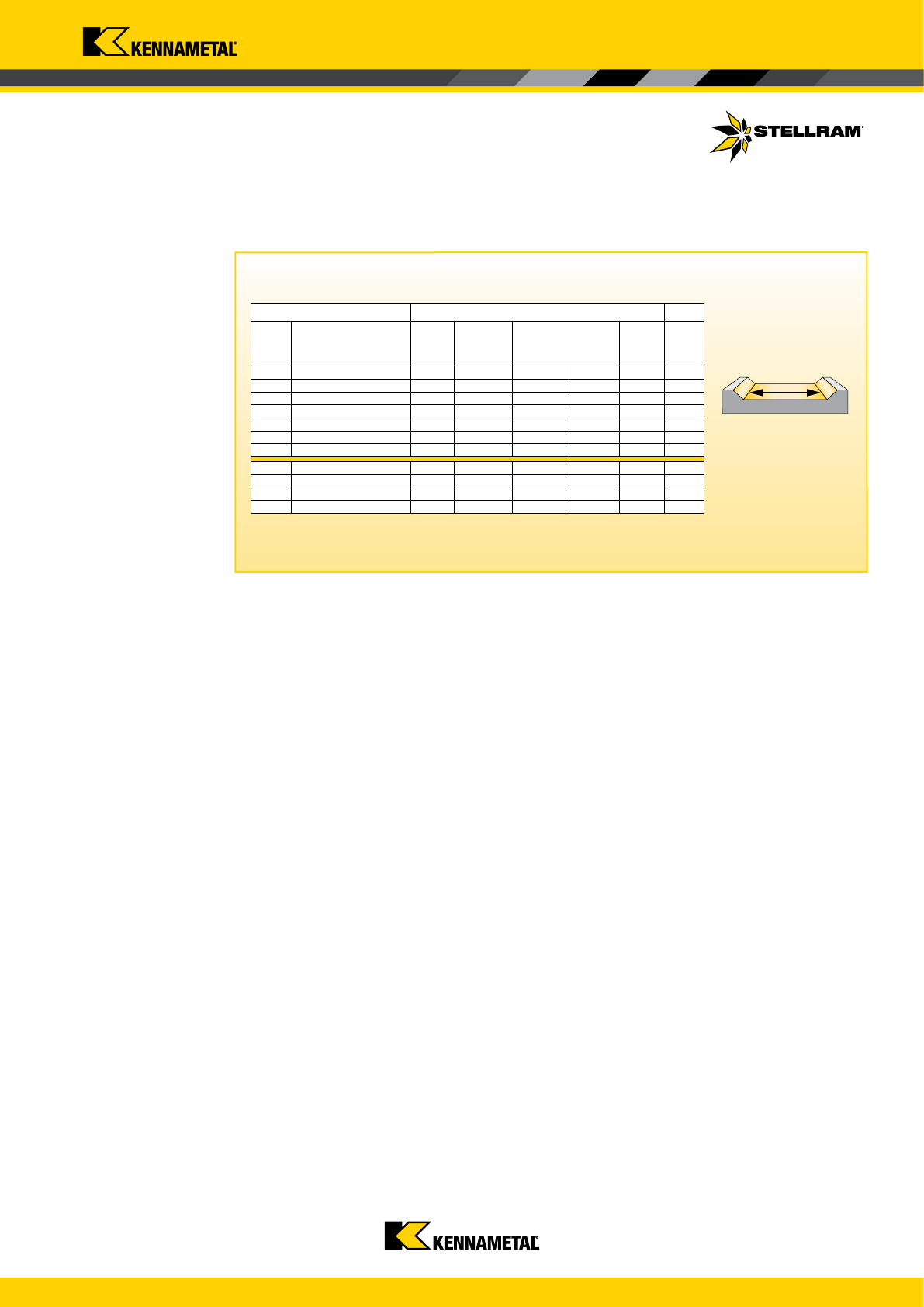

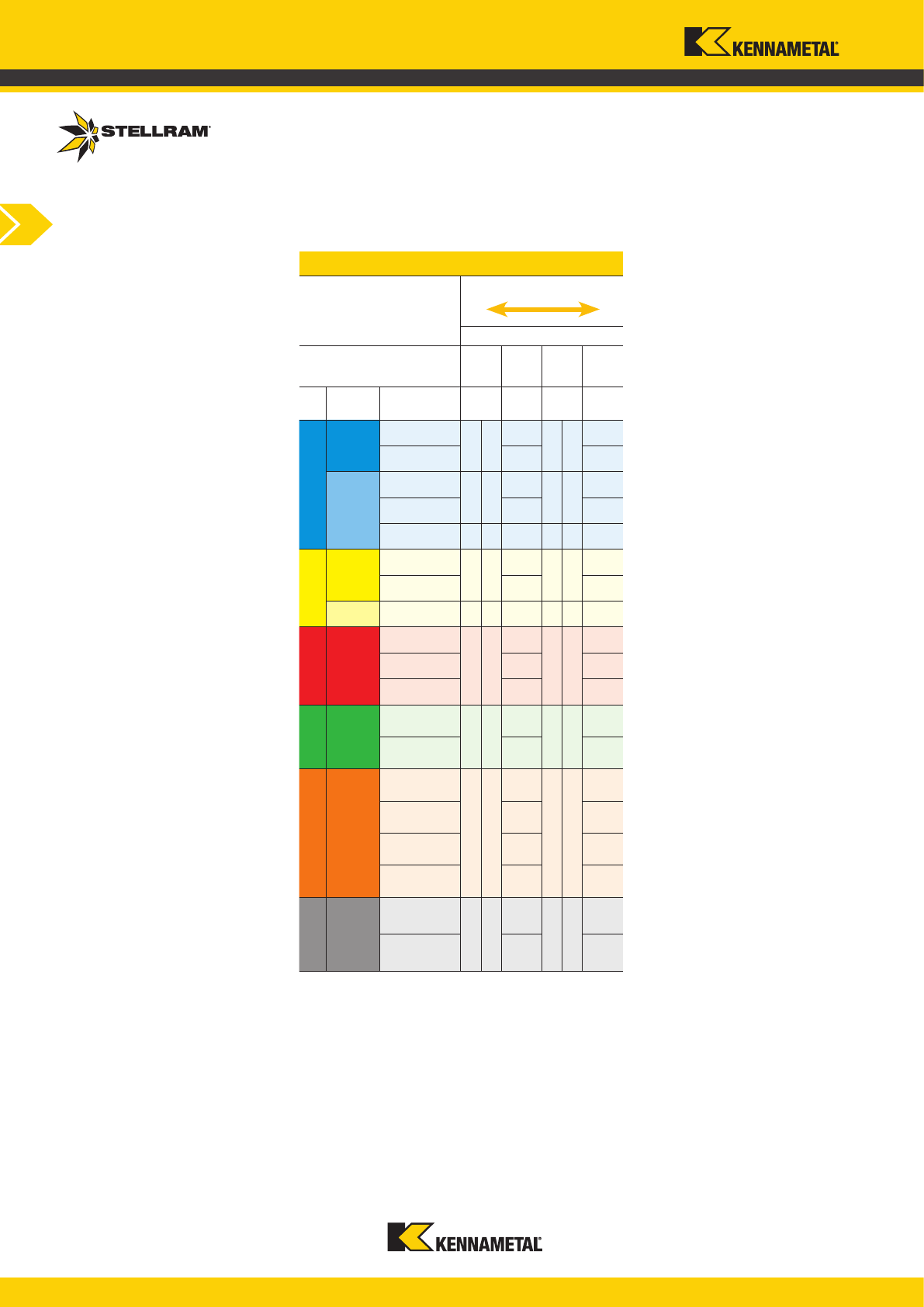

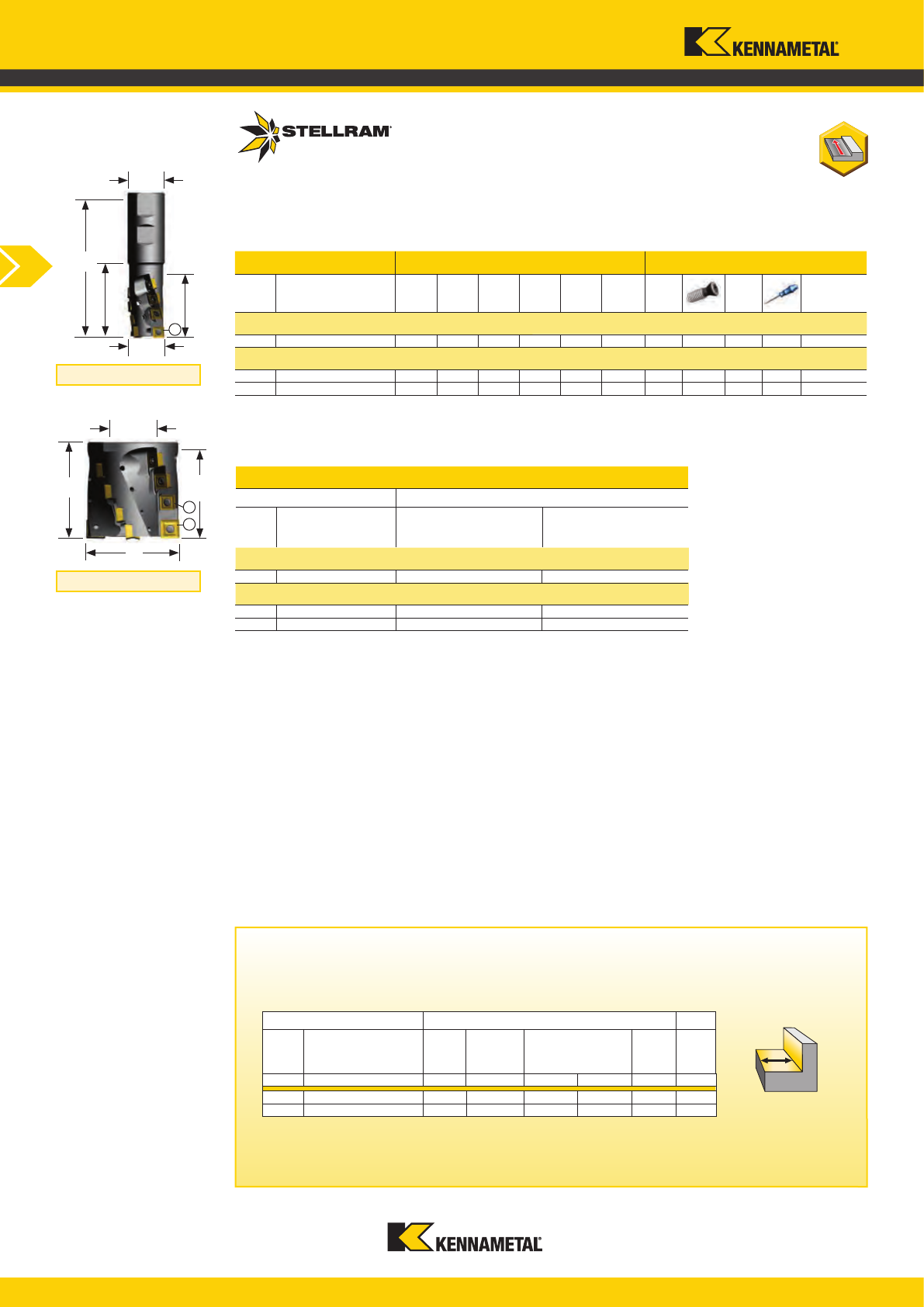

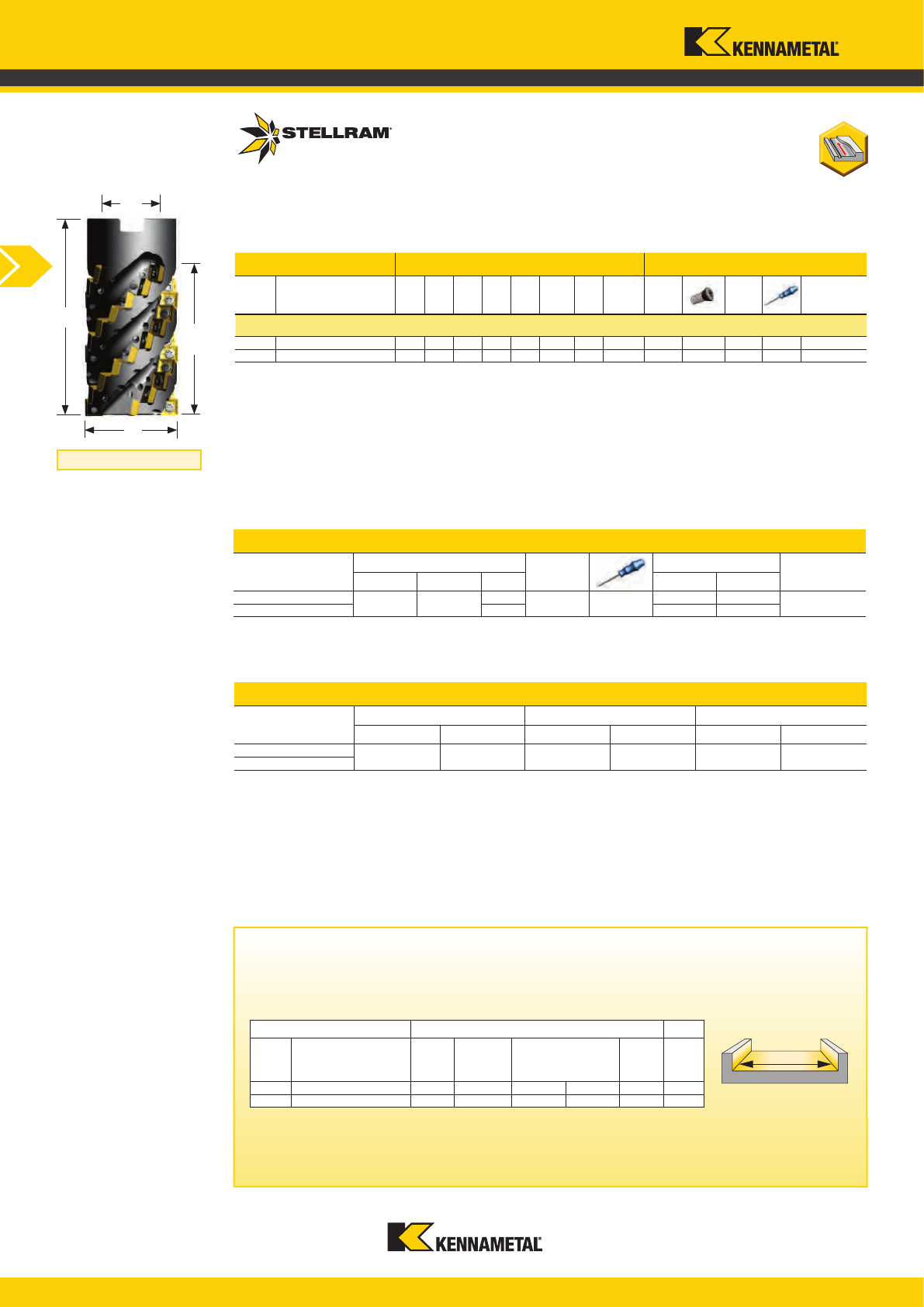

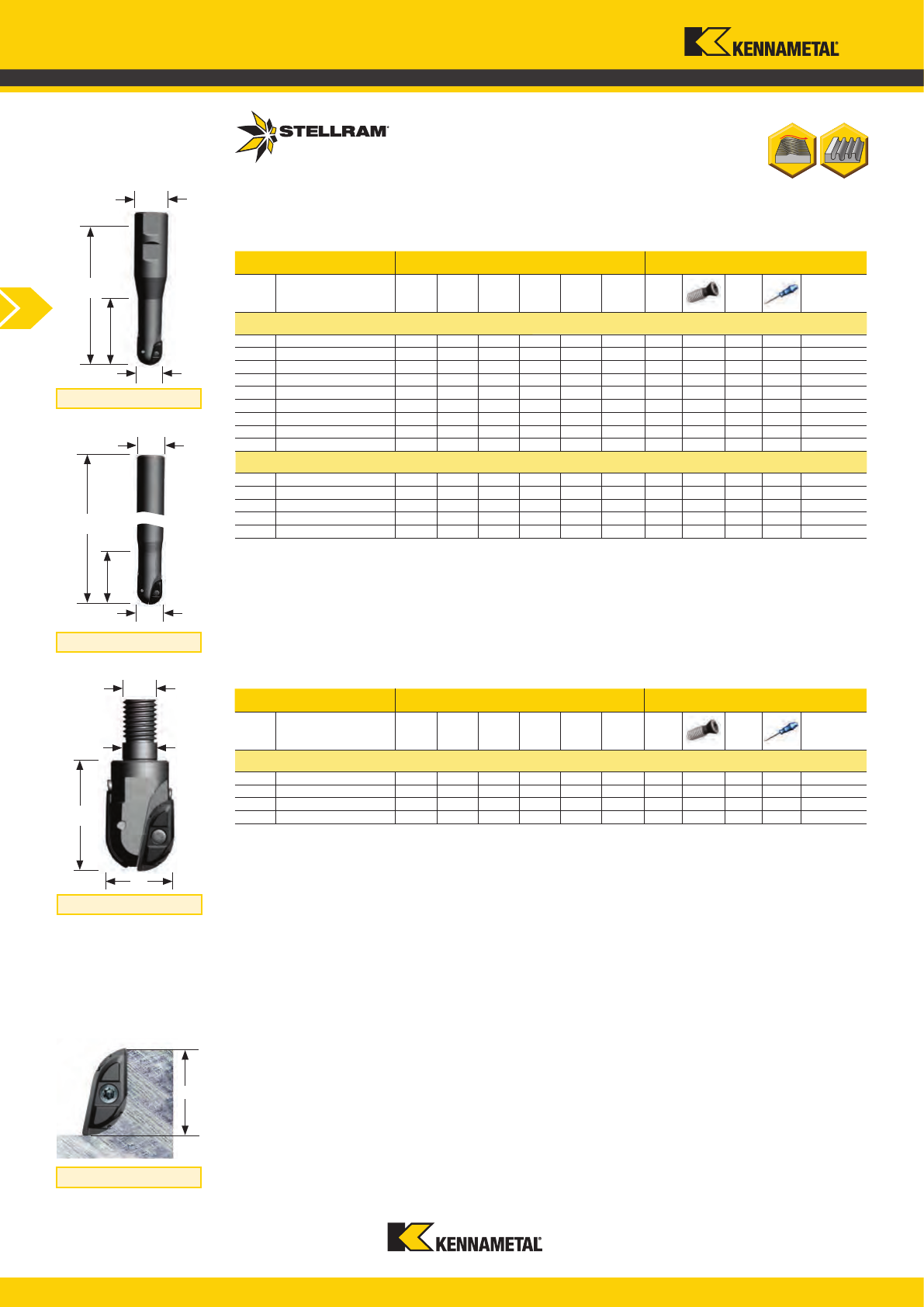

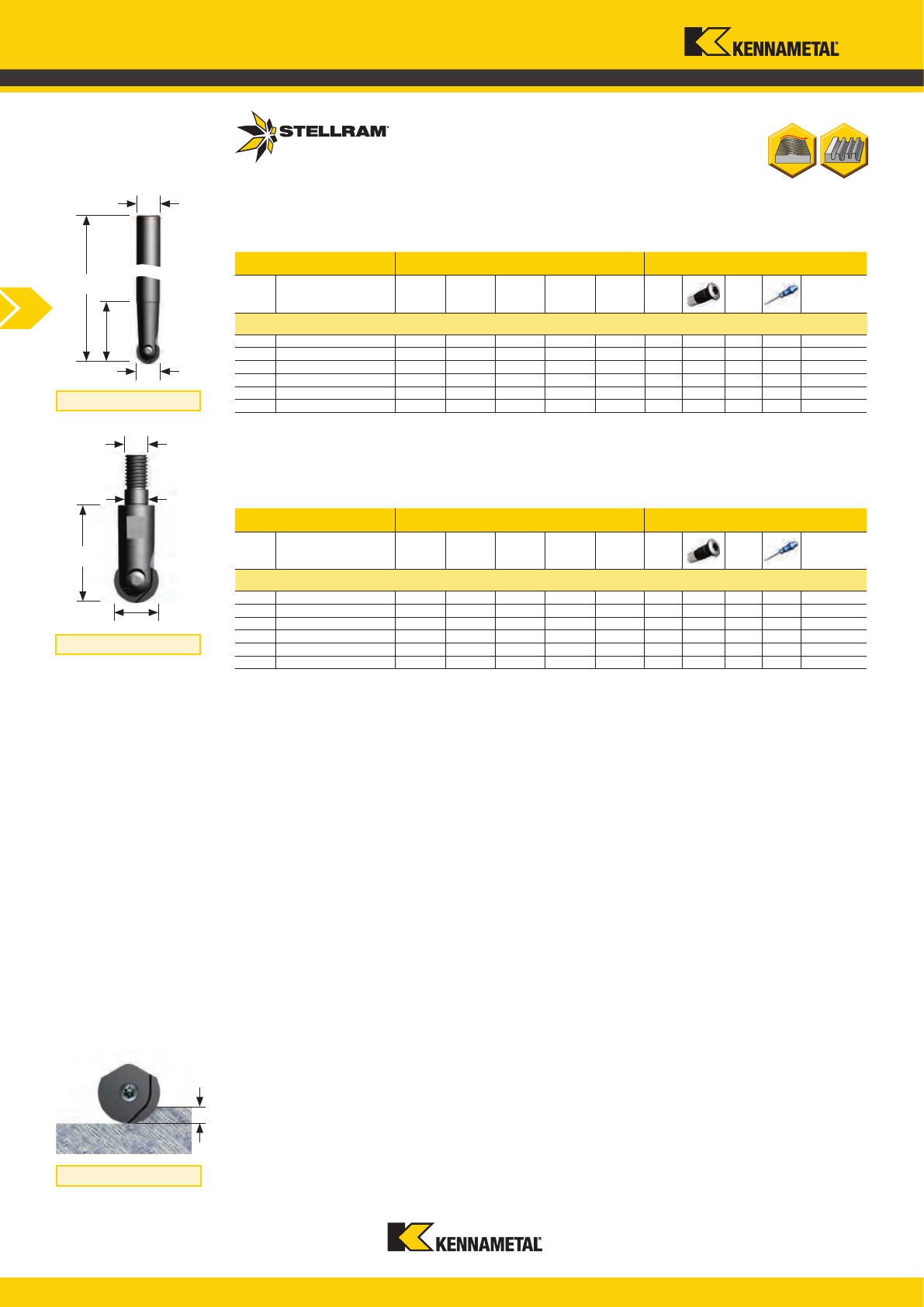

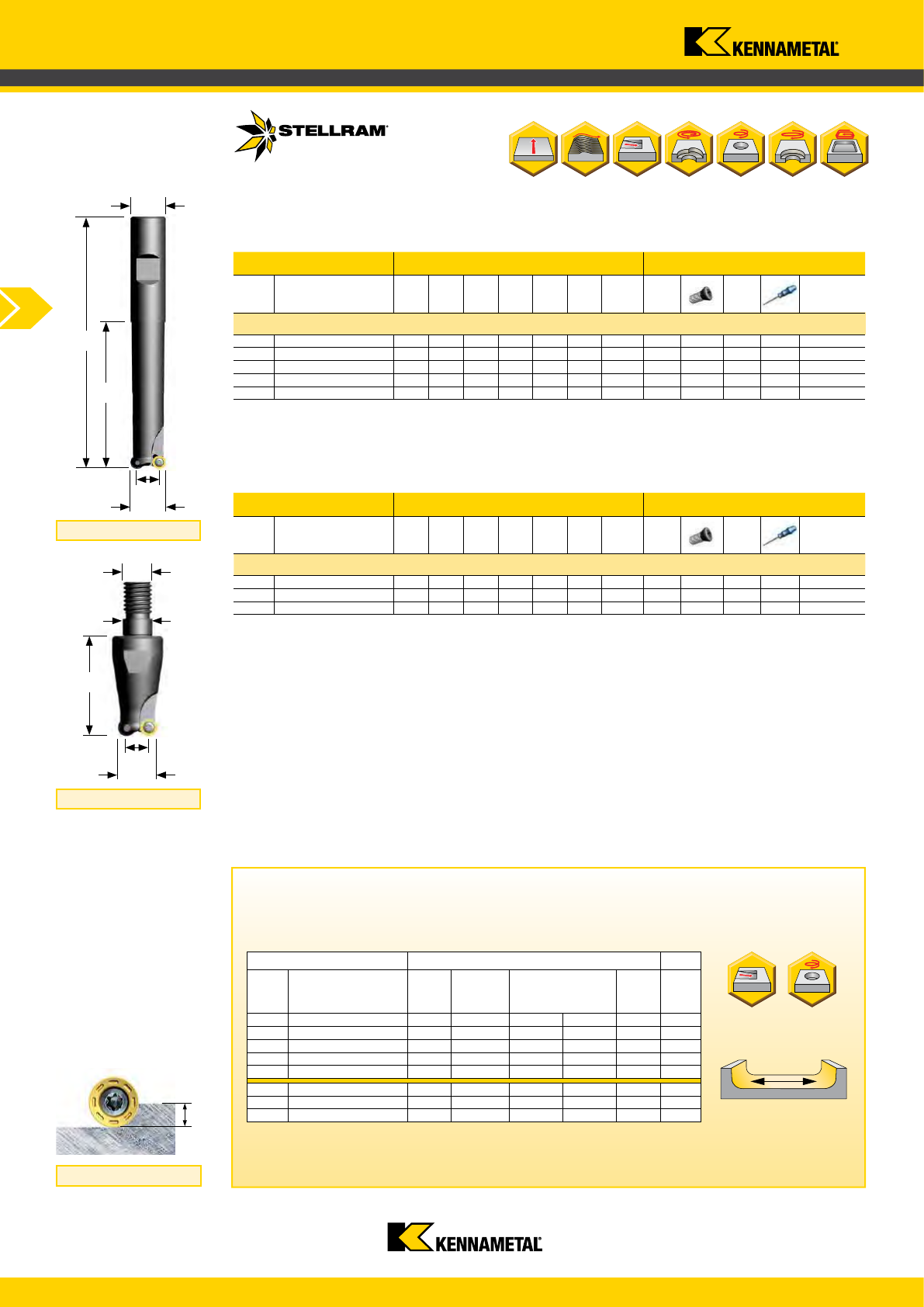

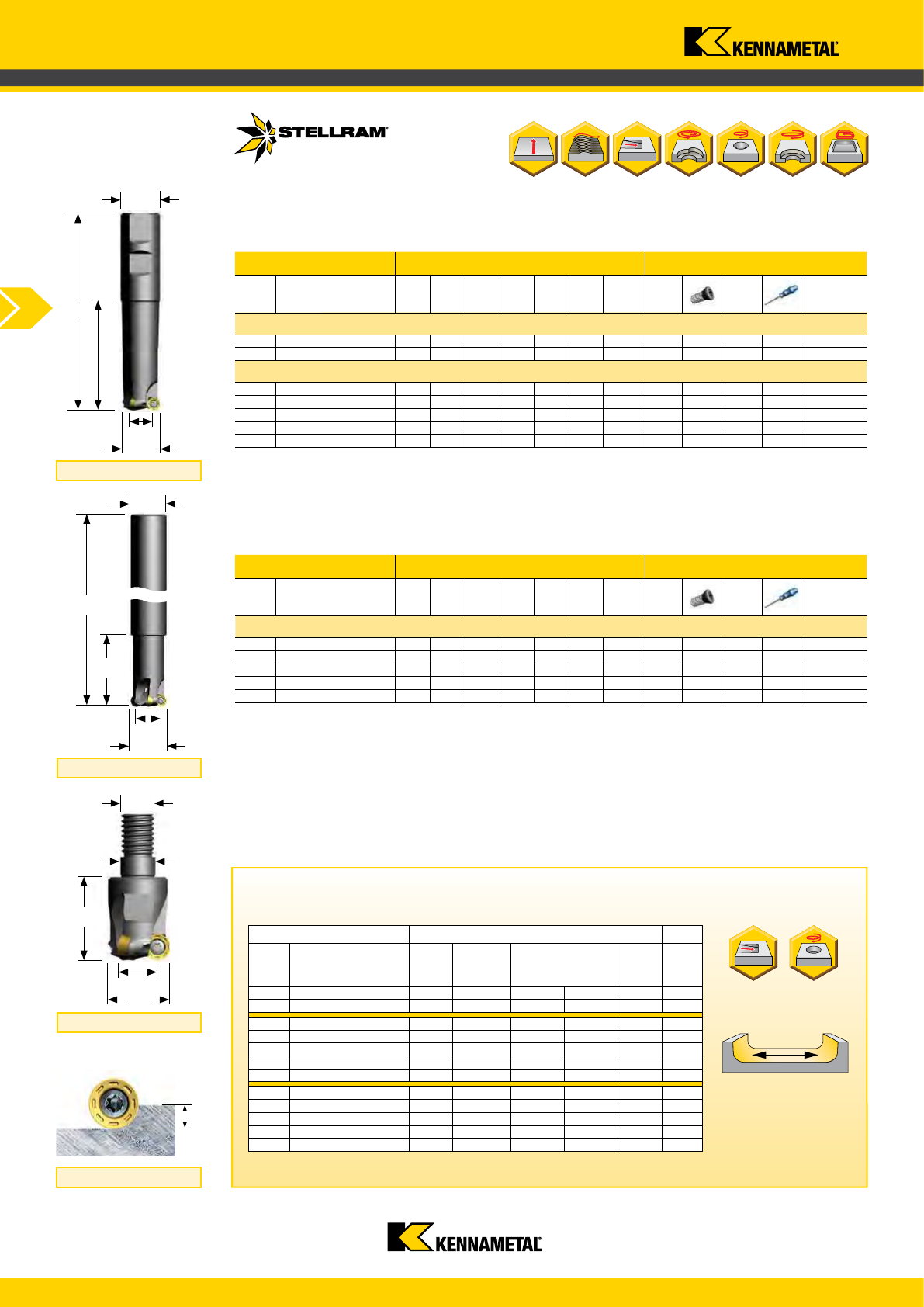

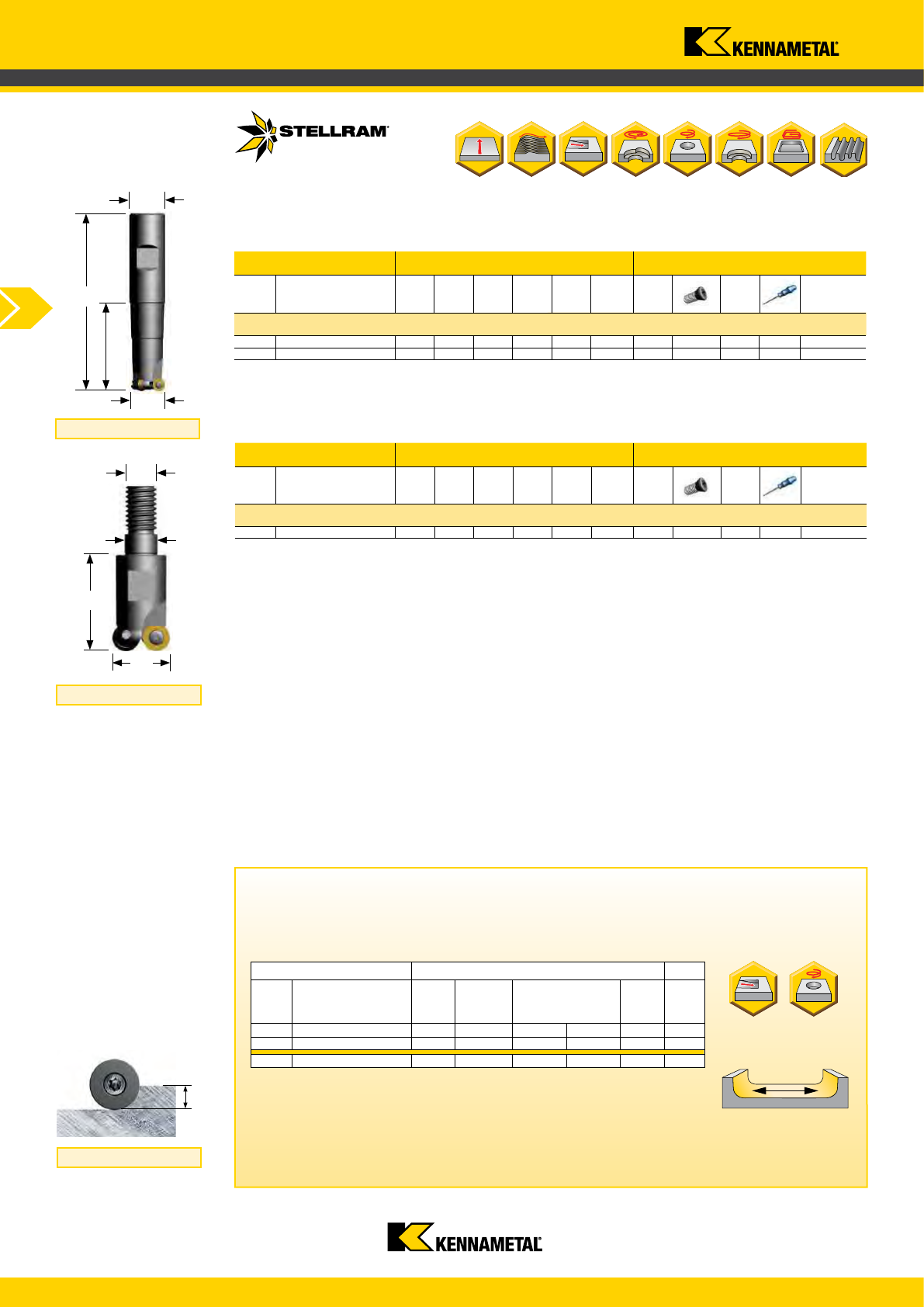

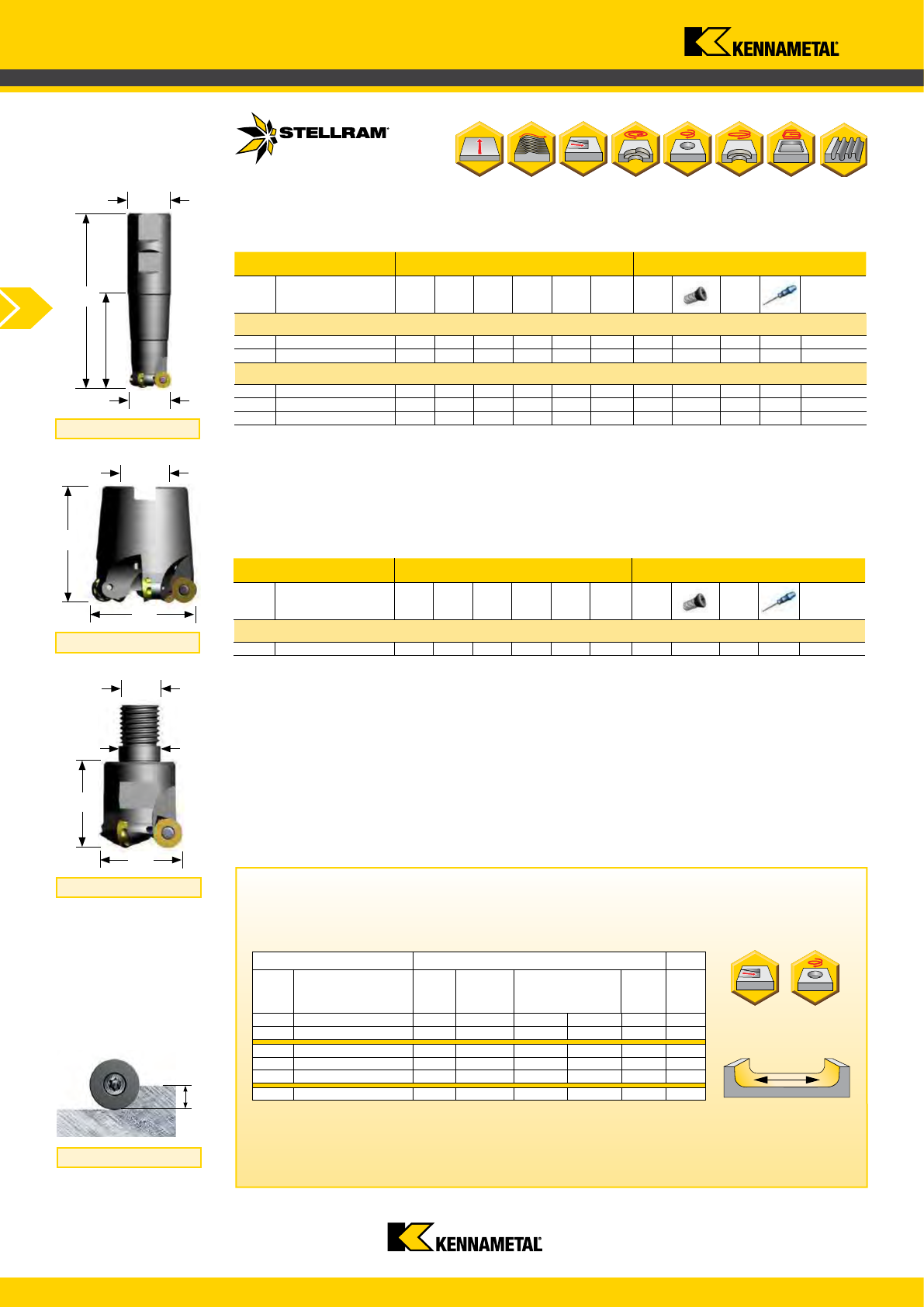

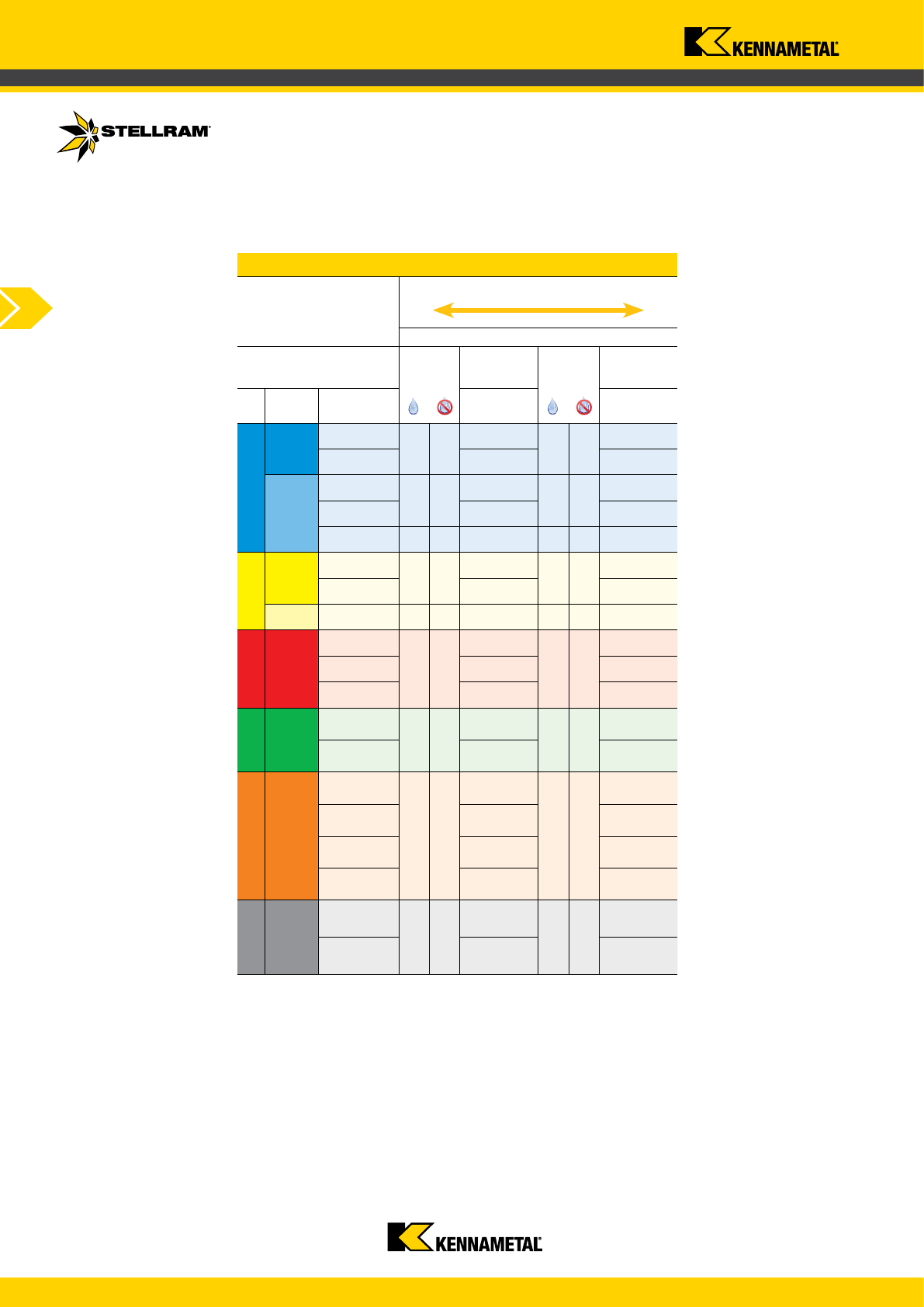

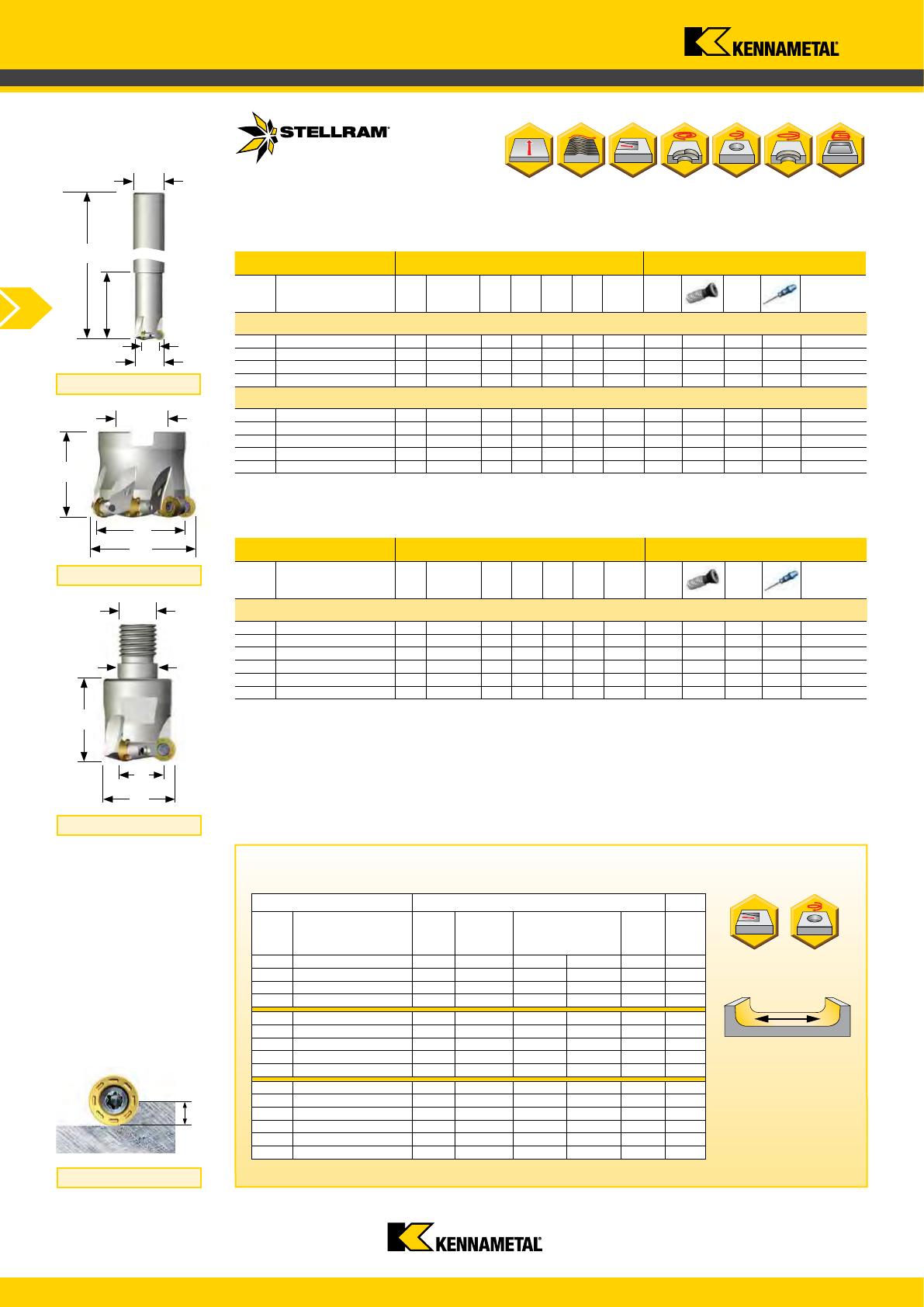

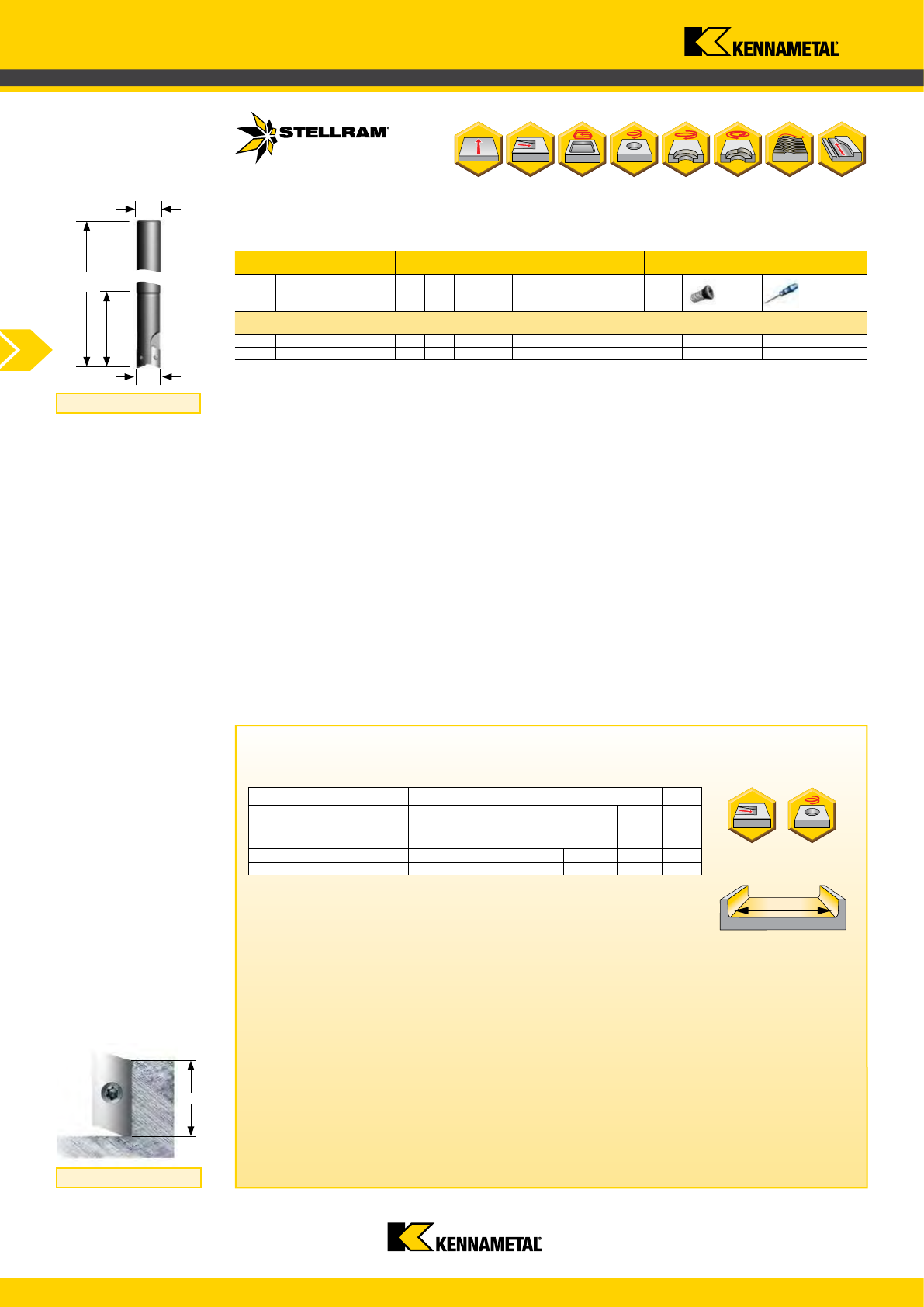

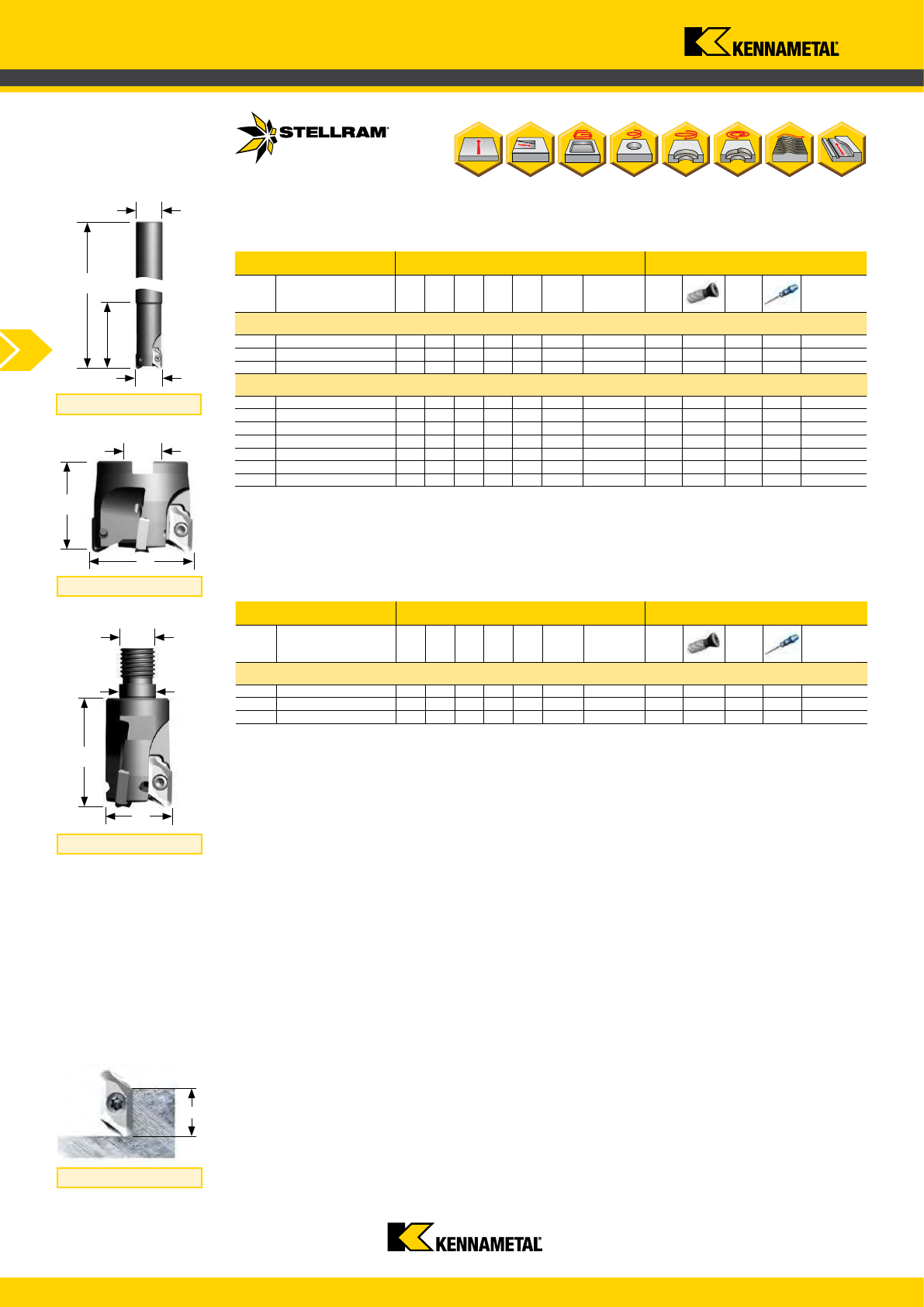

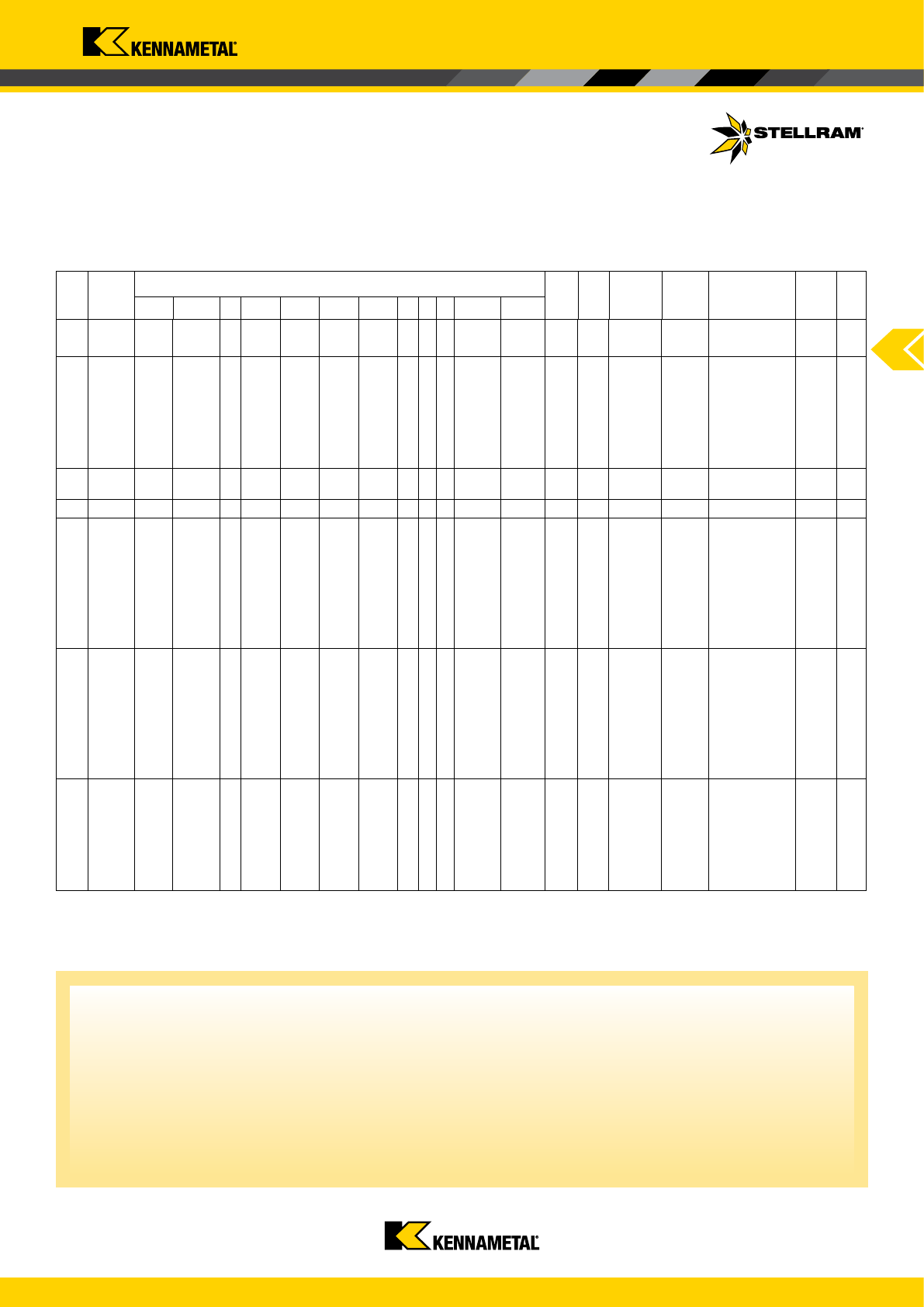

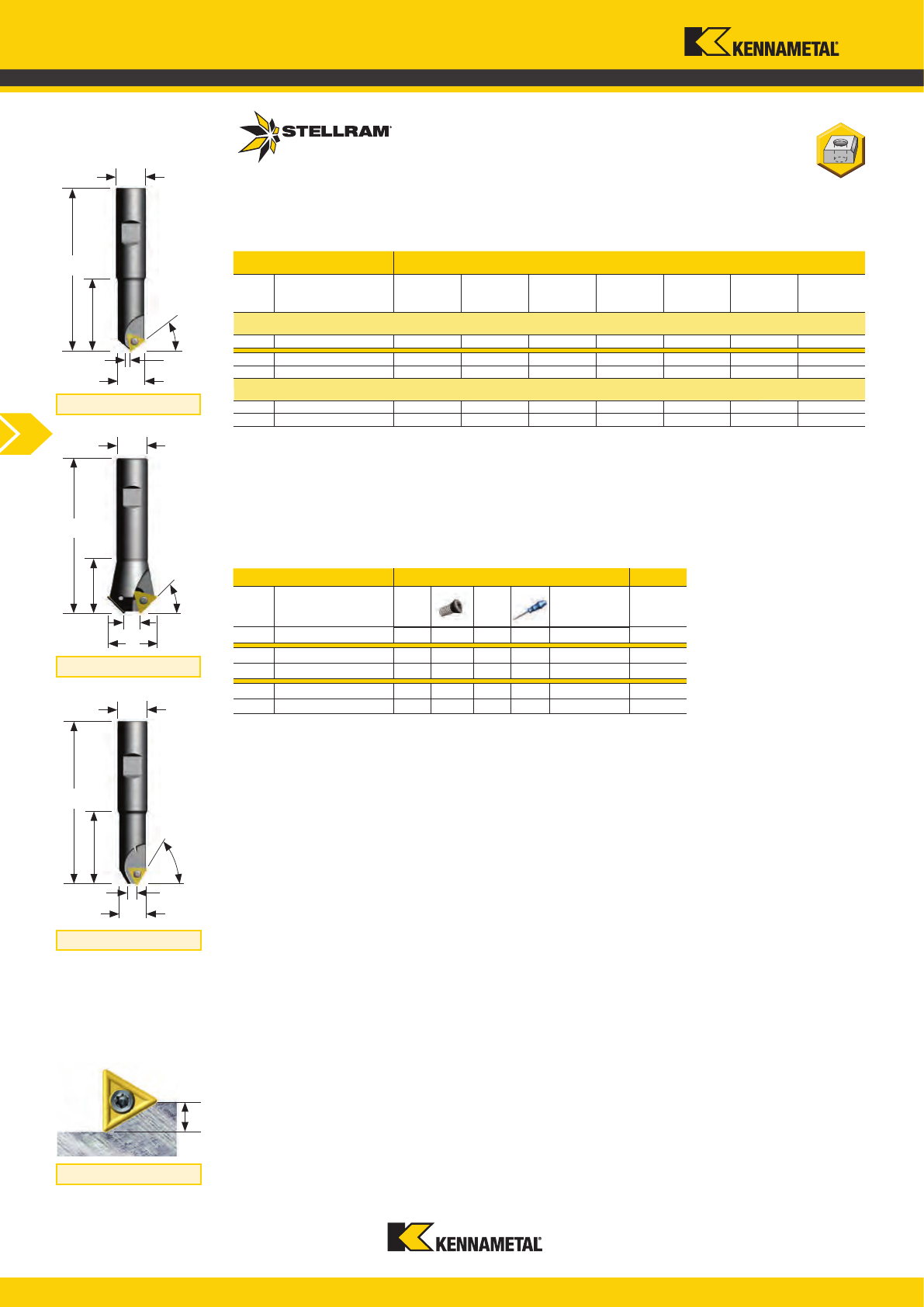

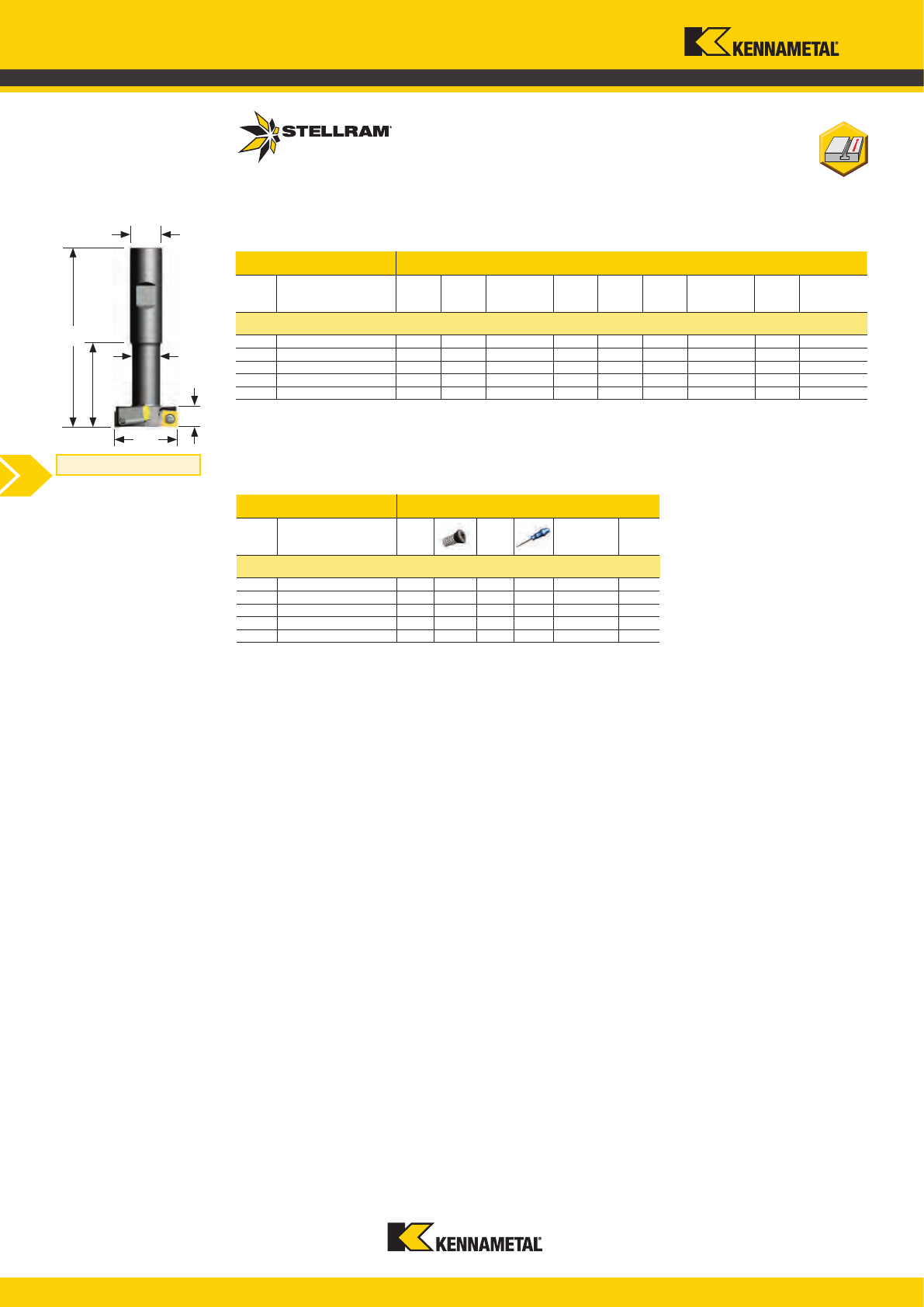

7792VXD09 Technical Information (mm)

Product Dimensions

EDP Item Description

Facing

Pitch

Ramping

Angle

Helical Hole

min. - max

.

a

p

max

Helical /

Linear

a

e

max

Plunging

Max

RPM

A °B °

Product Dimensions (mm) Spares

EDP Item Description DL/H Md

1

a

p

max

No. of

Teeth

EDP EDP

Screw

Tightening

Nm

Product Dimensions (mm) Spares

EDP Item Description DL/H l

1

d

1

a

p

max

No. of

Teeth

EDP EDP

Screw

Tightening

Nm

7792VXD09 Weldon Shank

7792VXD09 Cylindrical Shank

7792VXD09 Shell Mill Fixation - Coarse, Medium and Fine Pitch

7792VXD09 Modular Head

Ramp angle B

uses

two cutting edges

(one outside and

one inside edge).

Ramp angle A uses one

outside cutting edge only.

A = max ramp angle utilising full

face contact

B = max ramp angle utilising full

contact + internal corner radius

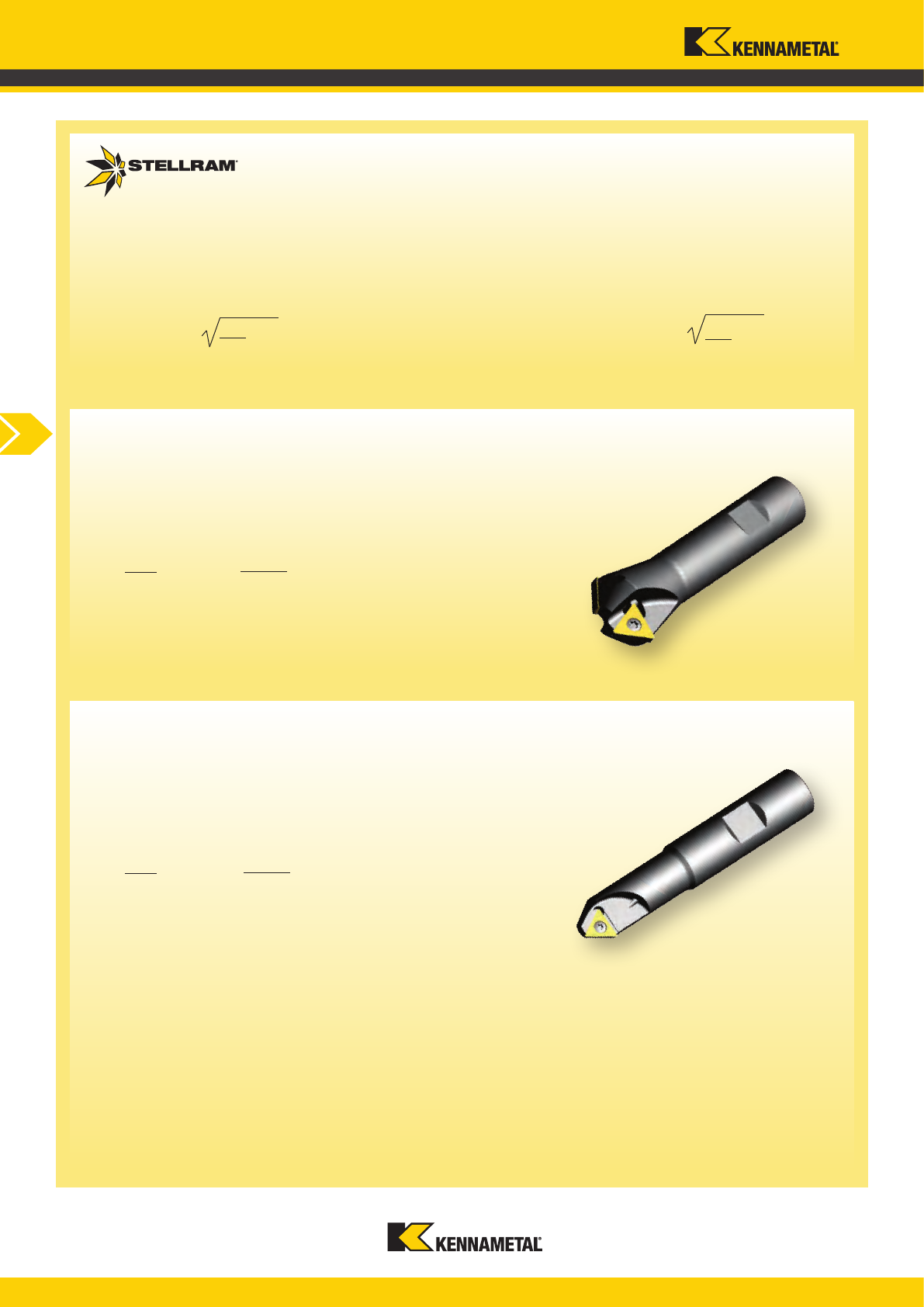

Depth of Cut (

a

p

)

Modular Head

Cylindrical Shank

Weldon Shank

Shell Mill Fixation

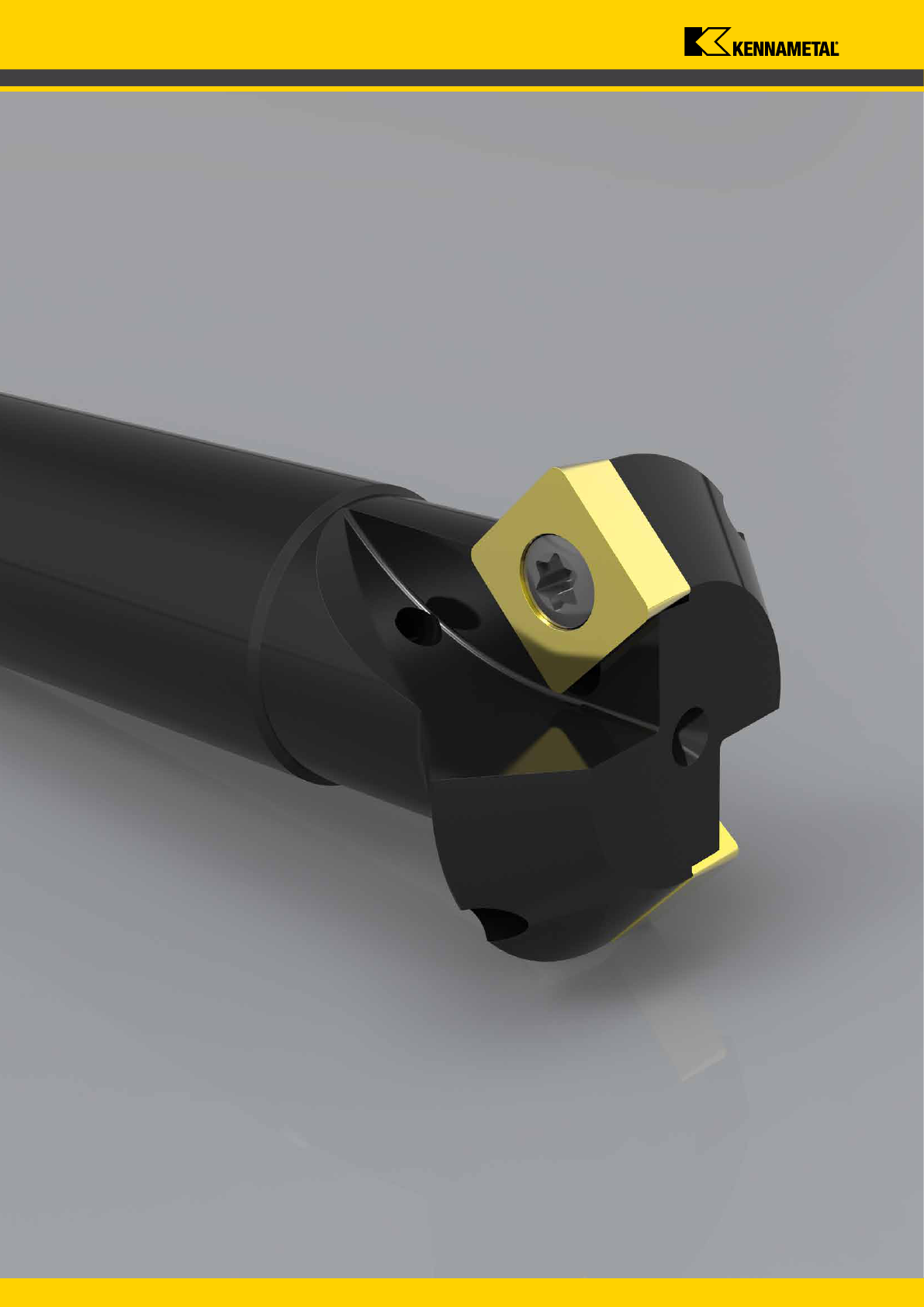

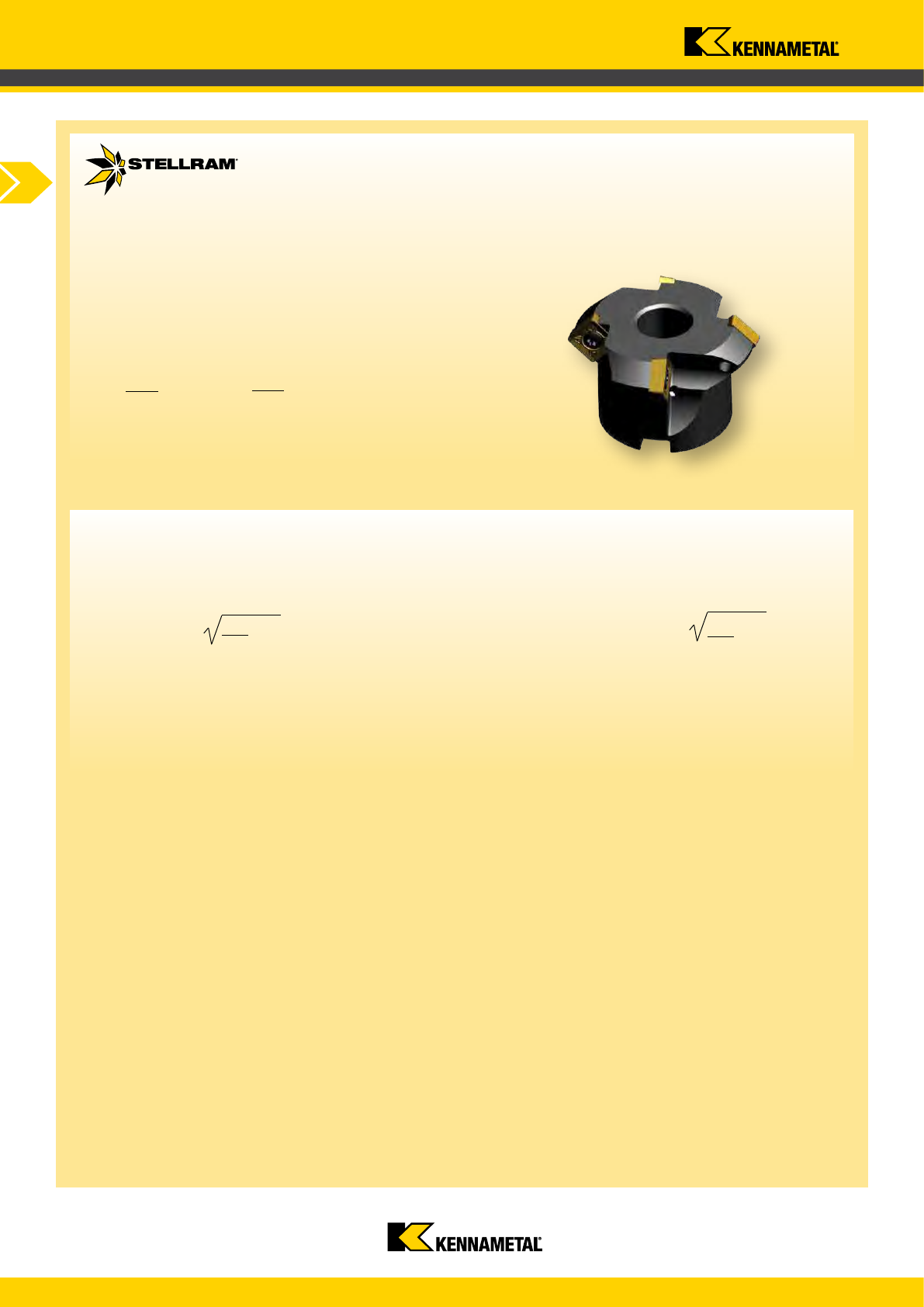

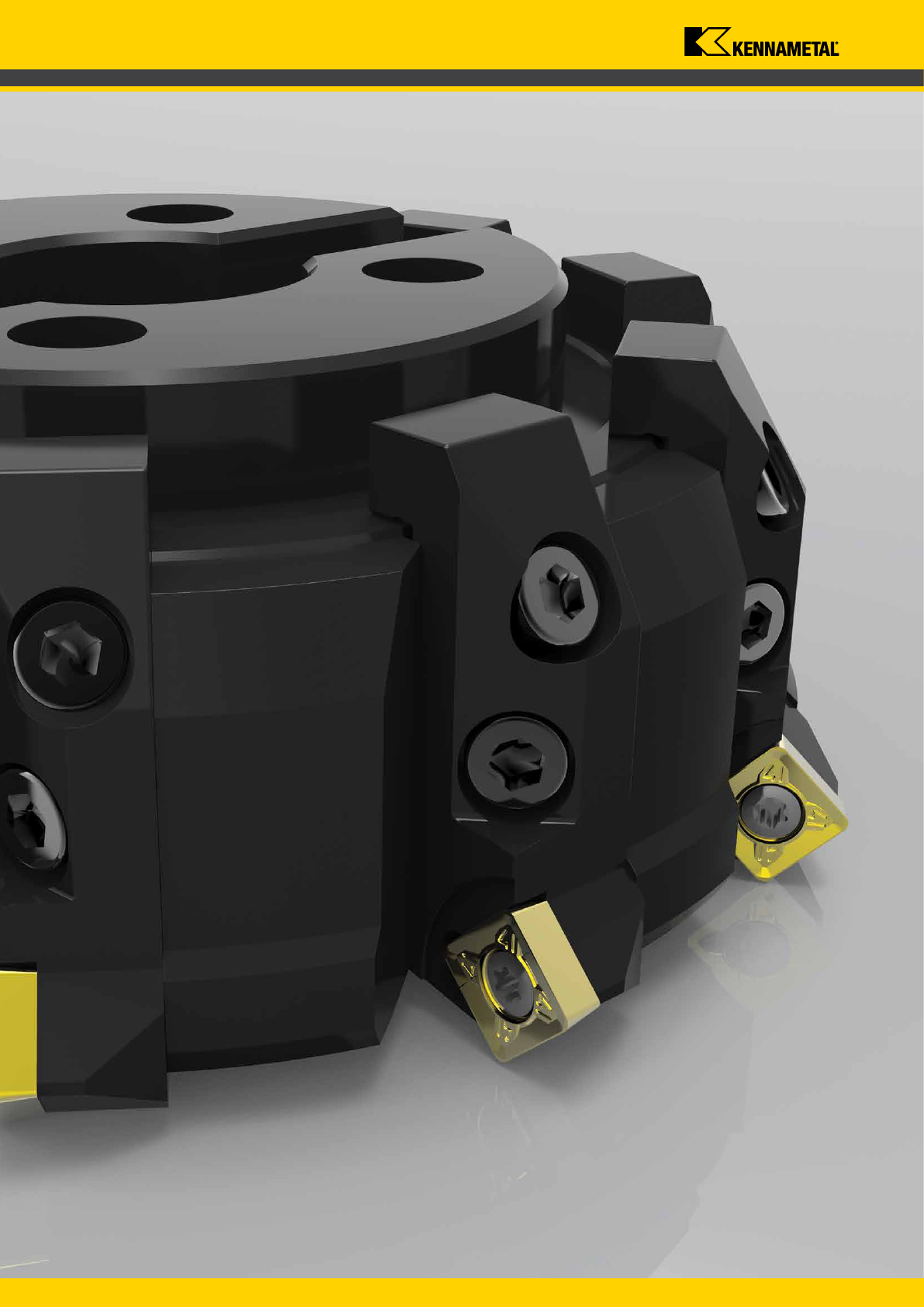

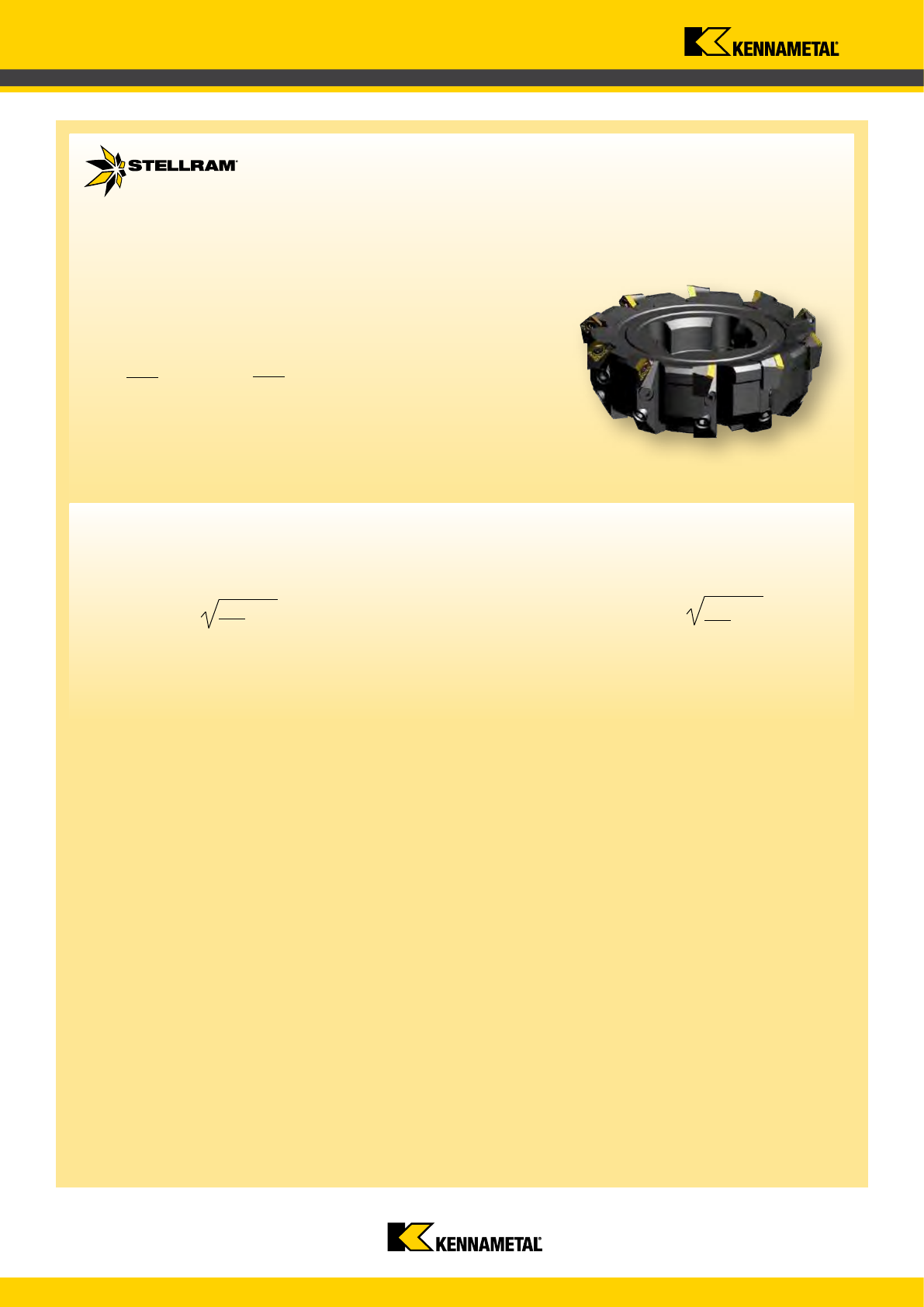

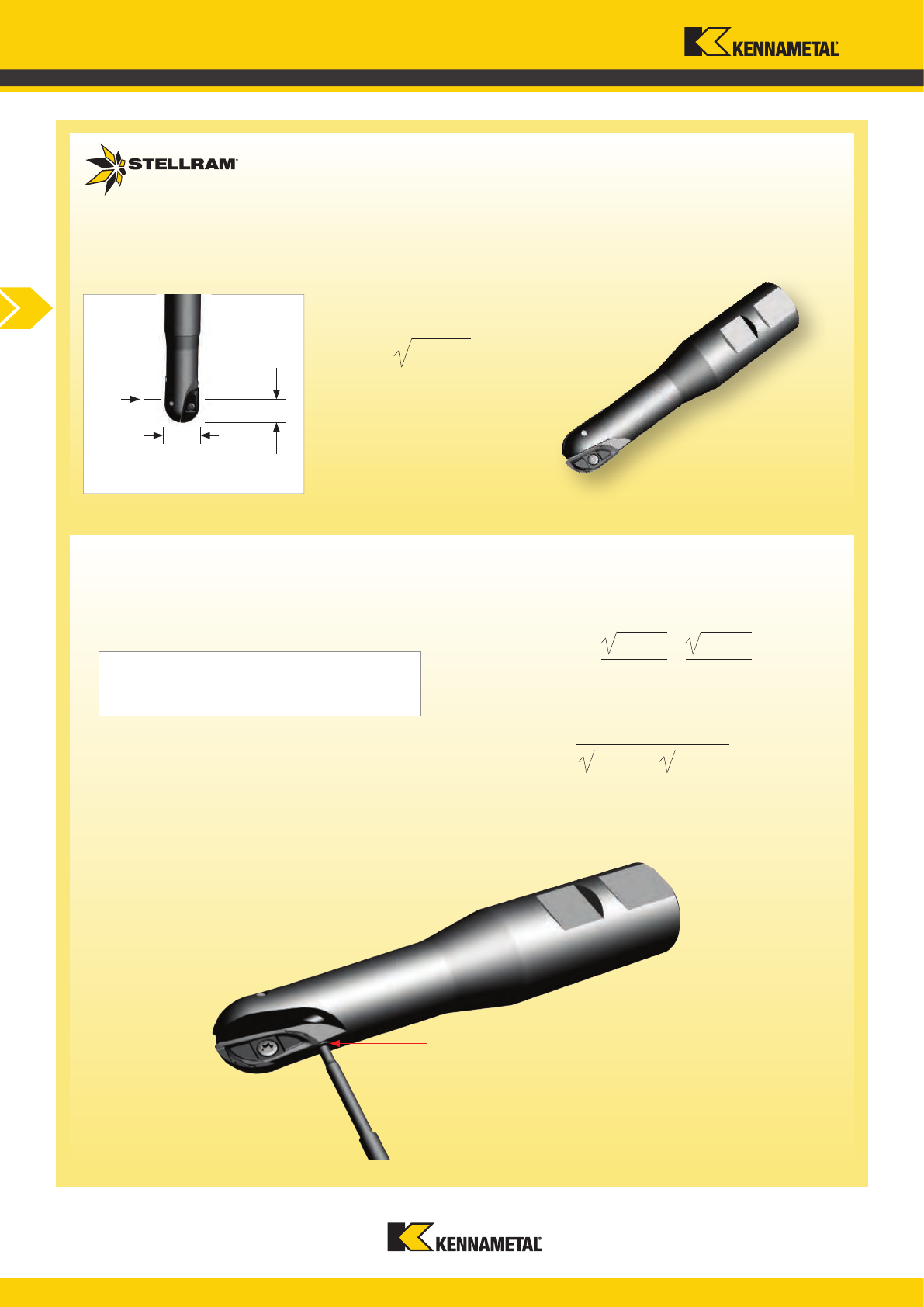

7792VXD09

High Feed Milling Cutter

Flat

Facing Pitch

Helical

Interpolation

Plunging

Note: For cylindrical shank extensions in high density alloy with through coolant refer to page A76.

www.kennametal.com

A3

www.kennametal.com

SR-D X400 0,30 - 2,00 0,30 - 1,90 -----------0,30 - 1,00 0,30 - 1,00

SR-D X400 0,30 - 1,50 0,30 - 1,45- - ---------0,30 - 0,60 0,30 - 0,80

SR-D X400 0,10 - 0,25 0,10 - 0,23- ----------0,10 - 0,12 0,10 - 0,12

SR-D X500-0,30 - 1,90 0,30 - 1,20 0,30 - 1,00 -----------

SR-D X500-0,30 - 1,40 0,30 - 0,90 0,30 - 0,80 -----------

SR-D X500-0,10 - 0,22 0,10 - 0,20 0,10 - 0,15- ----------

SR-DSC3025 ----0,30 - 2,00 0,30 - 1,80 0,30 - 1,50 ------

--

SR-D SC3025 ----0,30 - 1,70 0,30 - 1,50 0,30 - 1,30 - -------

SR-D SC3025 ----0,10 - 0,25 0,10 - 0,22 0,10 - 0,20 ------

--

ER-D41 X500-- 0,20 - 1,00 0,20 - 0,80 -----0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80

--

ER-D41 X500-- 0,20 - 0,80 0,15 - 0,70- ----0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70

--

ER-D41 X500-- 0,10 - 0,16 0,08 - 0,12- - ---0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10

--

ER-D41 SP6519 0,30 - 1,50 0,30 - 1,30 0,20 - 1,00 0,20 - 0,60 0,30 - 1,50 0,30 - 1,30 ---0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80

--

ER-D41 SP6519 0,30 - 1,30 0,30 - 1,00 0,20 - 0,80 0,15 - 0,50 0,30 - 1,30 0,30 - 1,00 ---0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70

--

ER-D41 SP6519 0,10 - 0,20 0,10 - 0,16 0,10 - 0,16 0,05 - 0,08 0,10 - 0,20 0,10 - 0,16- --0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10

--

ER-D41 SC6525 0,30 - 1,45 0,30 - 1,30- - 0,30 - 1,50 0,30 - 1,30 -------

--

ER-D41 SC6525 0,30 - 1,25 0,30 - 1,00- - 0,30 - 1,30 0,30 - 1,00 -------

--

ER-D41 SC6525 0,10 - 0,18 0,10 - 0,16- - 0,10 - 0,20 0,10 - 0,16 -------

--

ER-D721GH2 -------0,30 - 1,50 0,30 - 1,30 ------

ER-D721GH2 -------0,30 - 1,30 0,30 - 1,00 ------

ER-D721GH2 -------0,10 - 0,20 0,10 - 0,16 ------

ER-D411 X500-- 0,20 - 1,00 0,20 - 0,80 -----0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80

--

ER-D411 X500-- 0,20 - 0,80 0,15 - 0,70

- ----0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70

--

ER-D411 X500-- 0,10 - 0,16 0,08 - 0,12 -----0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10

--

ER-D411 SP6519 0,30 - 1,50 0,30 - 1,30 0,20 - 1,00 0,20 - 0,60 0,30 - 1,50 0,30 - 1,30 ---0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80 - -

ER-D411 SP6519 0,30 - 1,30 0,30 - 1,00 0,20 - 0,80 0,15 - 0,50 0,30 - 1,30 0,30 - 1,00- --0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70 - -

ER-D411 SP6519 0,10 - 0,20 0,10 - 0,16 0,10 - 0,16 0,05 - 0,08 0,10 - 0,20 0,10 - 0,16 ---0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10 - -

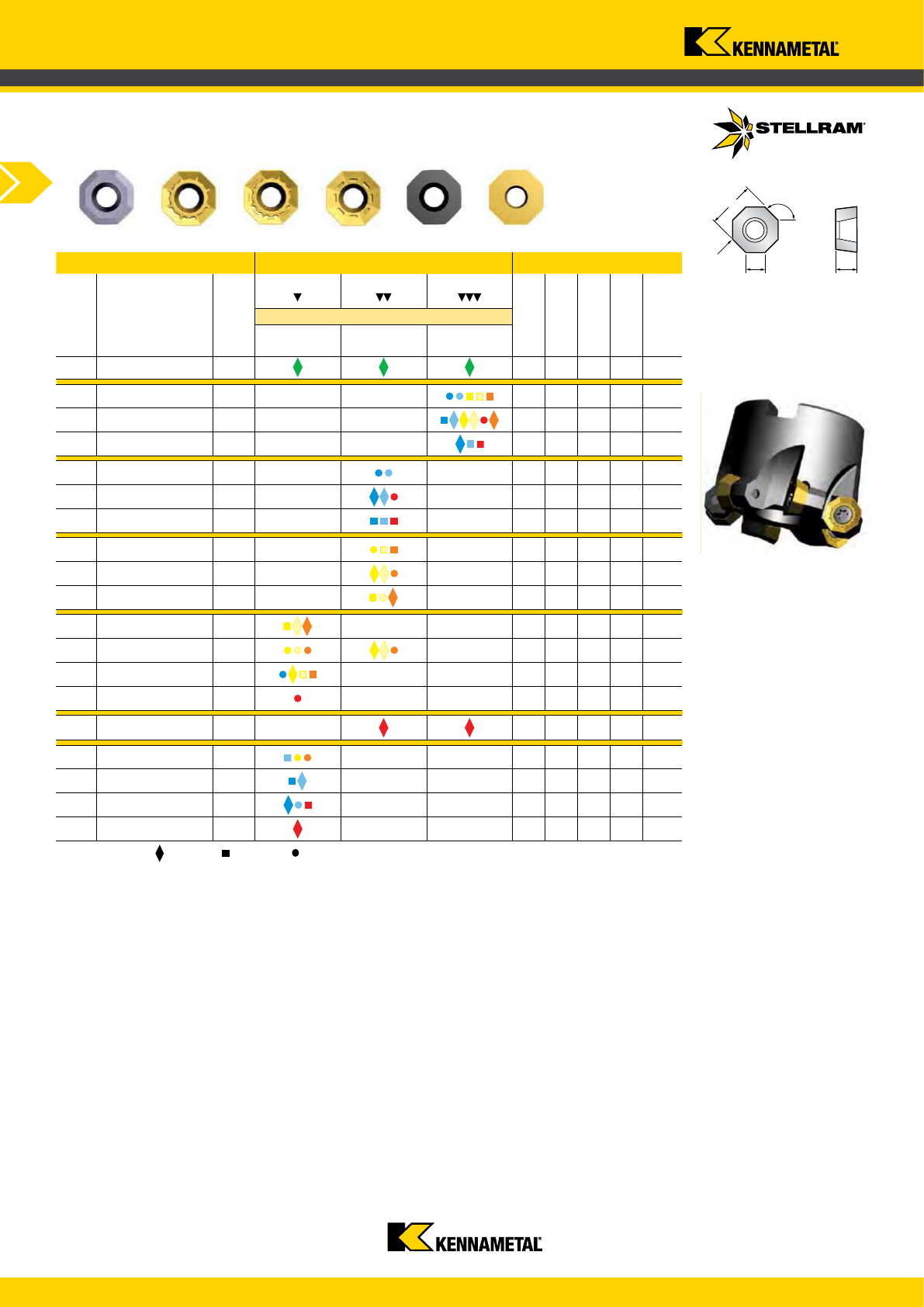

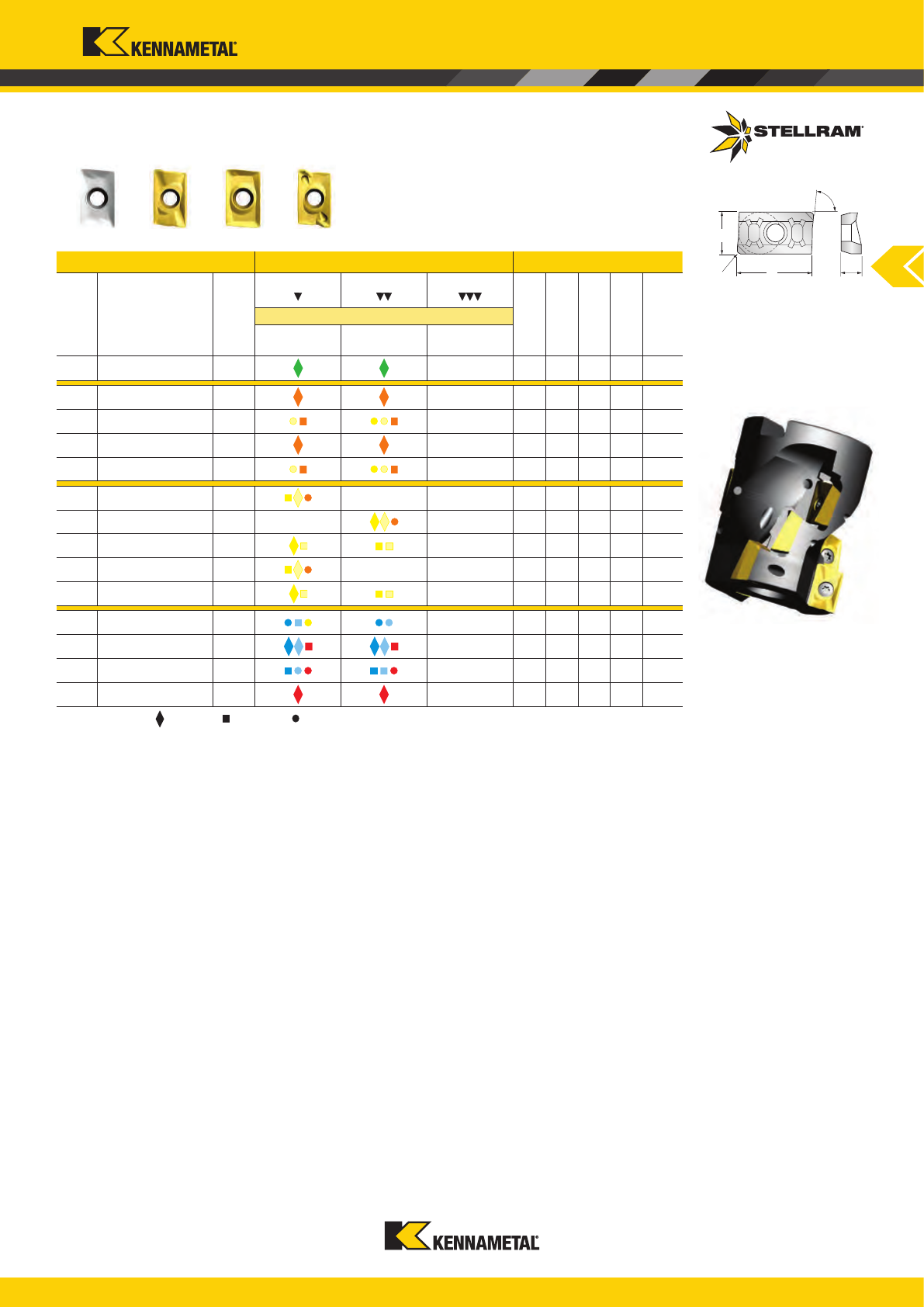

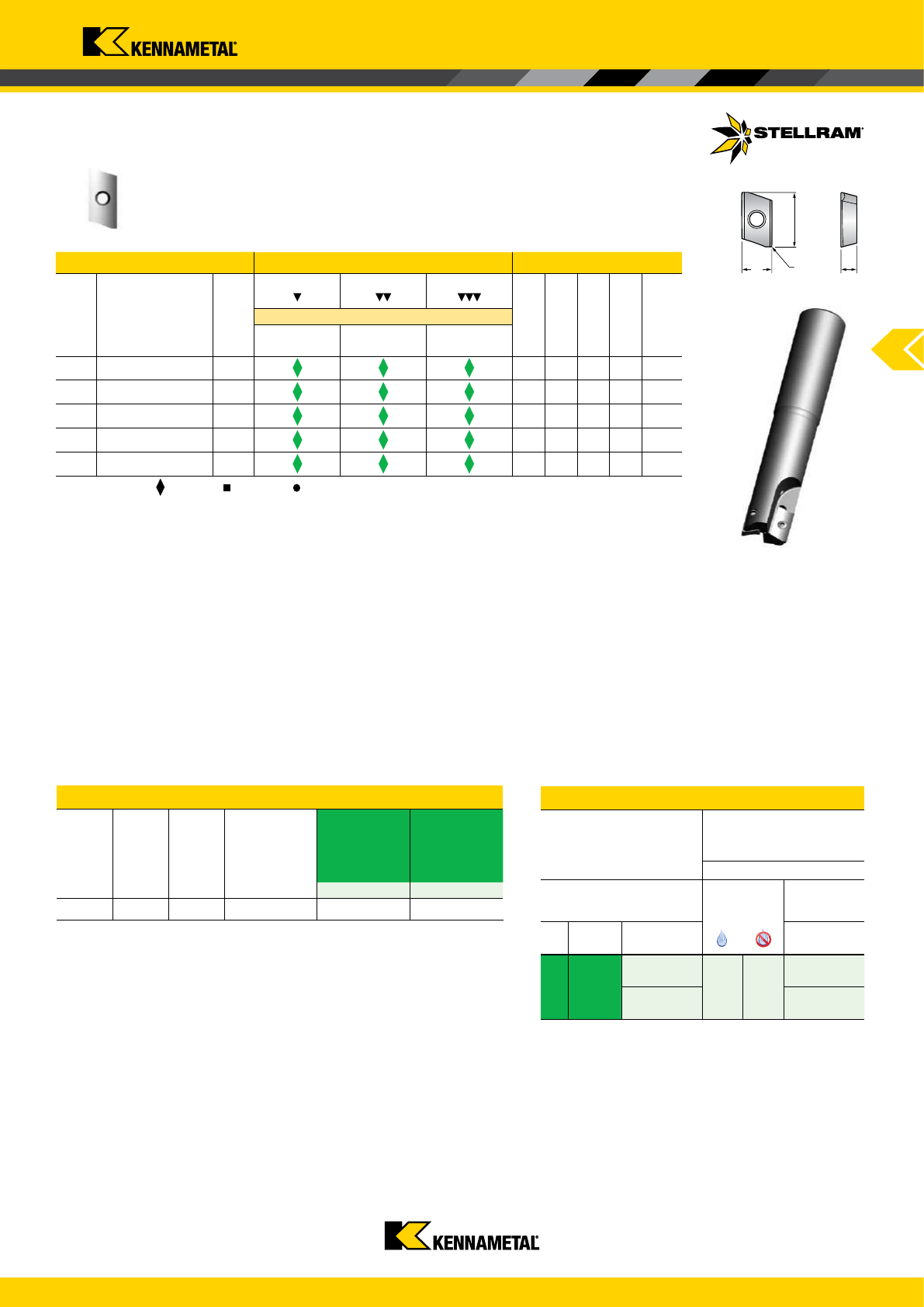

029487 XDLW090408SR-D X400 9,52 9,52 4,76 0,80 0,10

029485 XDLW090408SR-D X500

9,52 9,52 4,76 0,80 0,10

029486 XDLW090408SR-D SC3025

9,52 9,52 4,76 0,80 0,10

029685 XDLT090408ER-D41 X500

9,52 9,52 4,76 0,80 0,05

031535 XDLT090408ER-D41 SP6519

9,52 9,52 4,76 0,80 0,05

033067 XDLT090408ER-D41 SC6525

9,52 9,52 4,76 0,80 0,05

029637 XDLT090408ER-D721 GH2

9,52 9,52 4,76 0,80 0,04

030853 XDLT090412ER-D411 X500

9,52 9,52 4,76 1,20 0,05

030854 XDLT090412ER-D411 SP6519

9,52 9,52 4,76 1,20 0,05

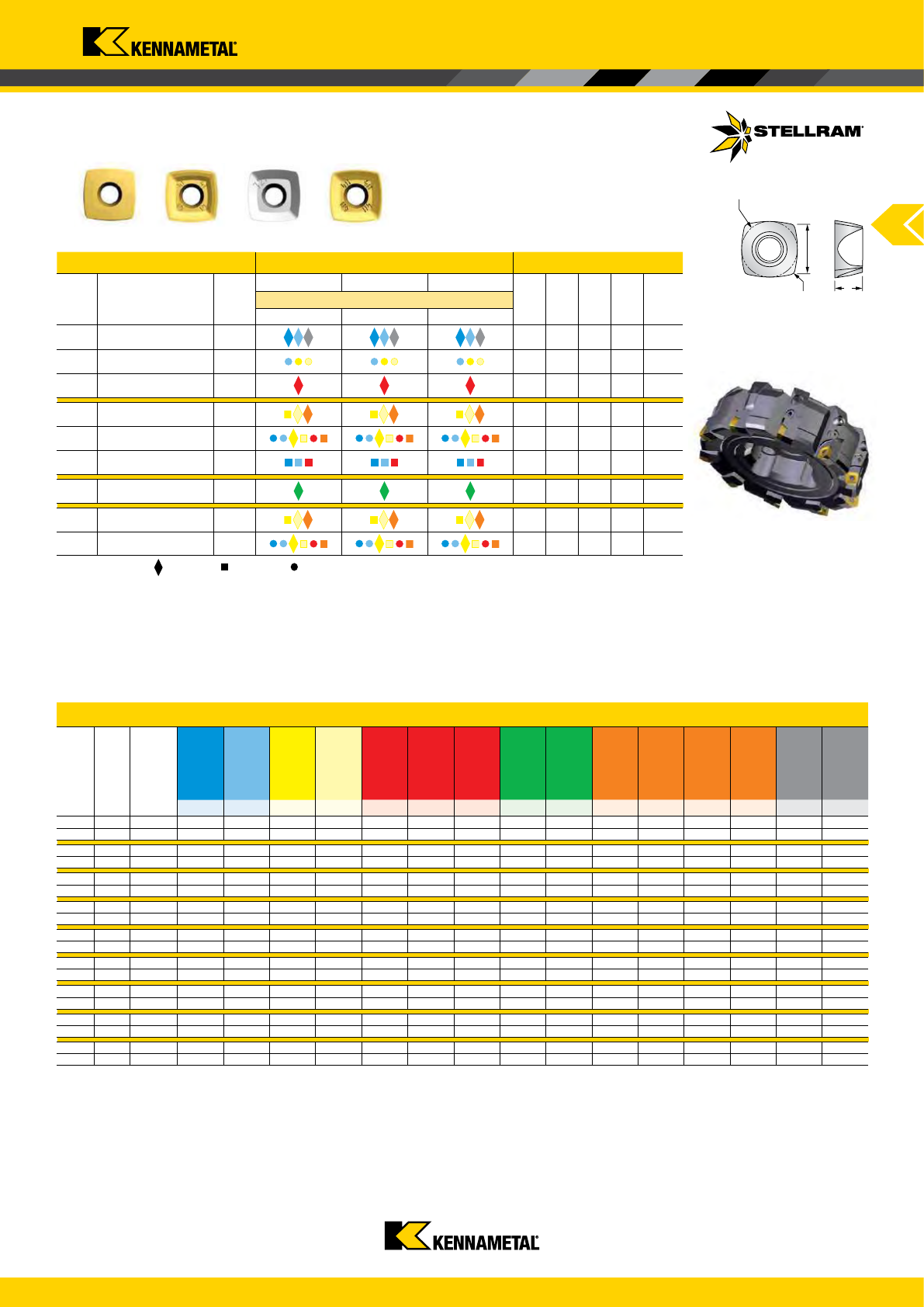

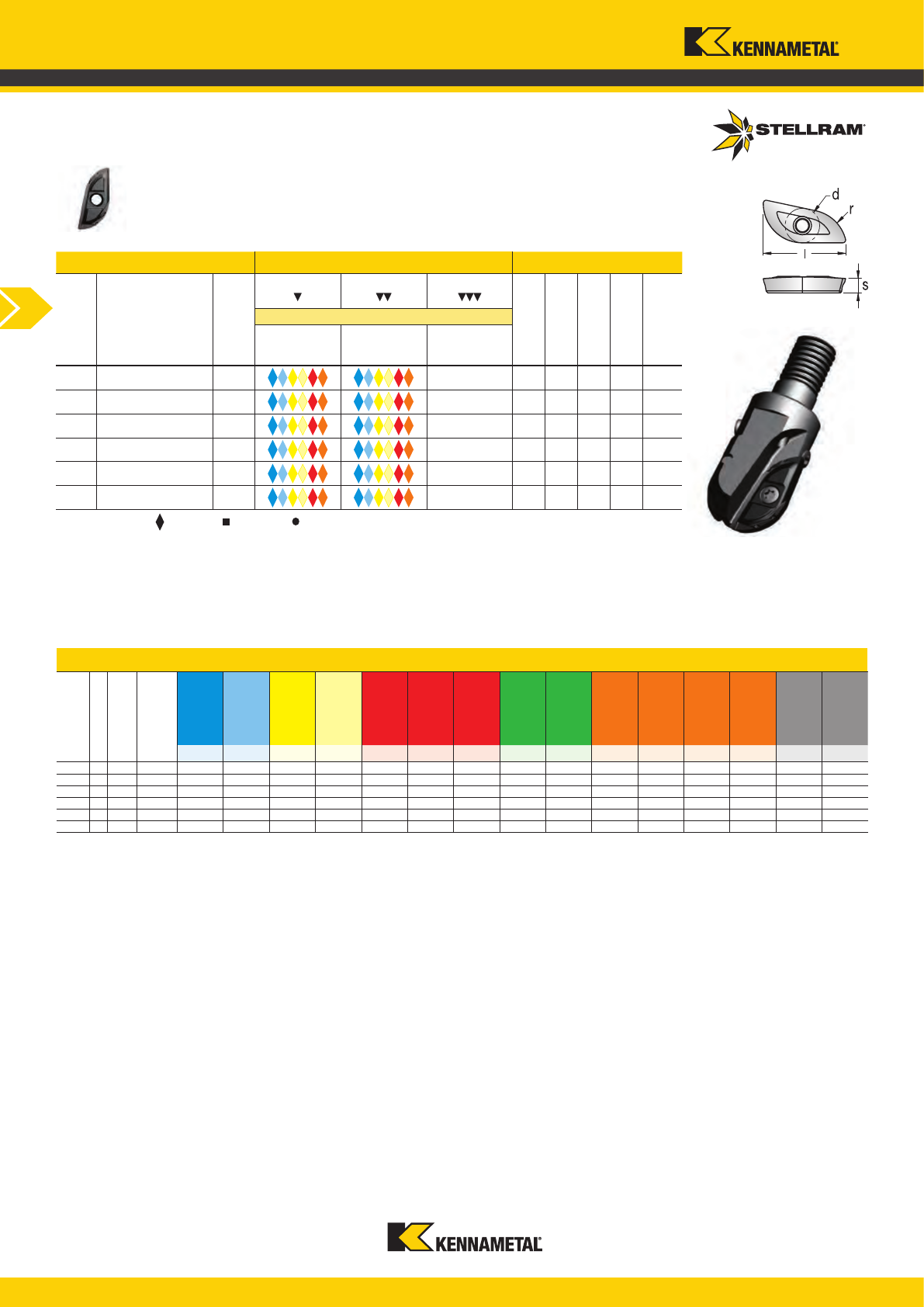

XDLW09-D

XDLT09-D41

XDLT09-D721 XDLT09-D411

d

l

r

s

A67

www.kennametal.com

SR-D X400 0,30 - 2,00 0,30 - 1,90 -----------0,30 - 1,00 0,30 - 1,00

SR-D X400 0,30 - 1,50 0,30 - 1,45- - ---------0,30 - 0,60 0,30 - 0,80

SR-D X400 0,10 - 0,25 0,10 - 0,23- ----------0,10 - 0,12 0,10 - 0,12

SR-D X500-0,30 - 1,90 0,30 - 1,20 0,30 - 1,00 ---------- -

SR-D X500-0,30 - 1,40 0,30 - 0,90 0,30 - 0,80 ---------- -

SR-D X500-0,10 - 0,22 0,10 - 0,20 0,10 - 0,15- ----------

SR-DSC3025 ----0,30 - 2,00 0,30 - 1,80 0,30 - 1,50 --------

SR-D SC3025 ----0,30 - 1,70 0,30 - 1,50 0,30 - 1,30 - ------ -

SR-D SC3025 ----0,10 - 0,25 0,10 - 0,22 0,10 - 0,20 --------

ER-D41 X500-- 0,20 - 1,00 0,20 - 0,80 -----0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80 --

ER-D41 X500-- 0,20 - 0,80 0,15 - 0,70- ----0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70 --

ER-D41 X500-- 0,10 - 0,16 0,08 - 0,12- - ---0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10 --

ER-D41 SP6519 0,30 - 1,50 0,30 - 1,30 0,20 - 1,00 0,20 - 0,60 0,30 - 1,50 0,30 - 1,30 ---0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80 --

ER-D41 SP6519 0,30 - 1,30 0,30 - 1,00 0,20 - 0,80 0,15 - 0,50 0,30 - 1,30 0,30 - 1,00 ---0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70 --

ER-D41 SP6519 0,10 - 0,20 0,10 - 0,16 0,10 - 0,16 0,05 - 0,08 0,10 - 0,20 0,10 - 0,16- --0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10 --

ER-D41 SC6525 0,30 - 1,45 0,30 - 1,30- - 0,30 - 1,50 0,30 - 1,30 ---------

ER-D41 SC6525 0,30 - 1,25 0,30 - 1,00- - 0,30 - 1,30 0,30 - 1,00 ---------

ER-D41 SC6525 0,10 - 0,18 0,10 - 0,16- - 0,10 - 0,20 0,10 - 0,16 ---------

ER-D721GH2 -------0,30 - 1,50 0,30 - 1,30 ------

ER-D721GH2 -------0,30 - 1,30 0,30 - 1,00 ------

ER-D721GH2 -------0,10 - 0,20 0,10 - 0,16 ------

ER-D411 X500-- 0,20 - 1,00 0,20 - 0,80 -----0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80 --

ER-D411 X500-- 0,20 - 0,80 0,15 - 0,70

- ----0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70 --

ER-D411 X500-- 0,10 - 0,16 0,08 - 0,12 -----0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10 --

ER-D411 SP6519 0,30 - 1,50 0,30 - 1,30 0,20 - 1,00 0,20 - 0,60 0,30 - 1,50 0,30 - 1,30 ---0,20 - 0,60 0,20 - 0,60 0,20 - 0,60 0,20 - 0,80 - -

ER-D411 SP6519 0,30 - 1,30 0,30 - 1,00 0,20 - 0,80 0,15 - 0,50 0,30 - 1,30 0,30 - 1,00- --0,10 - 0,50 0,10 - 0,50 0,10 - 0,50 0,10 - 0,70 - -

ER-D411 SP6519 0,10 - 0,20 0,10 - 0,16 0,10 - 0,16 0,05 - 0,08 0,10 - 0,20 0,10 - 0,16 ---0,05 - 0,08 0,05 - 0,08 0,05 - 0,08 0,05 - 0,10 - -

029487 XDLW090408SR-D X400 9,52 9,52 4,76 0,80 0,10

029485 XDLW090408SR-D X500

9,52 9,52 4,76 0,80 0,10

029486 XDLW090408SR-D SC3025

9,52 9,52 4,76 0,80 0,10

029685 XDLT090408ER-D41 X500

9,52 9,52 4,76 0,80 0,05

031535 XDLT090408ER-D41 SP6519

9,52 9,52 4,76 0,80 0,05

033067 XDLT090408ER-D41 SC6525

9,52 9,52 4,76 0,80 0,05

029637 XDLT090408ER-D721 GH2

9,52 9,52 4,76 0,80 0,04

030853 XDLT090412ER-D411 X500

9,52 9,52 4,76 1,20 0,05

030854 XDLT090412ER-D411 SP6519

9,52 9,52 4,76 1,20 0,05

XDLW09-D

XDLT09-D41

XDLT09-D721 XDLT09-D411

d

l

r

s

A67

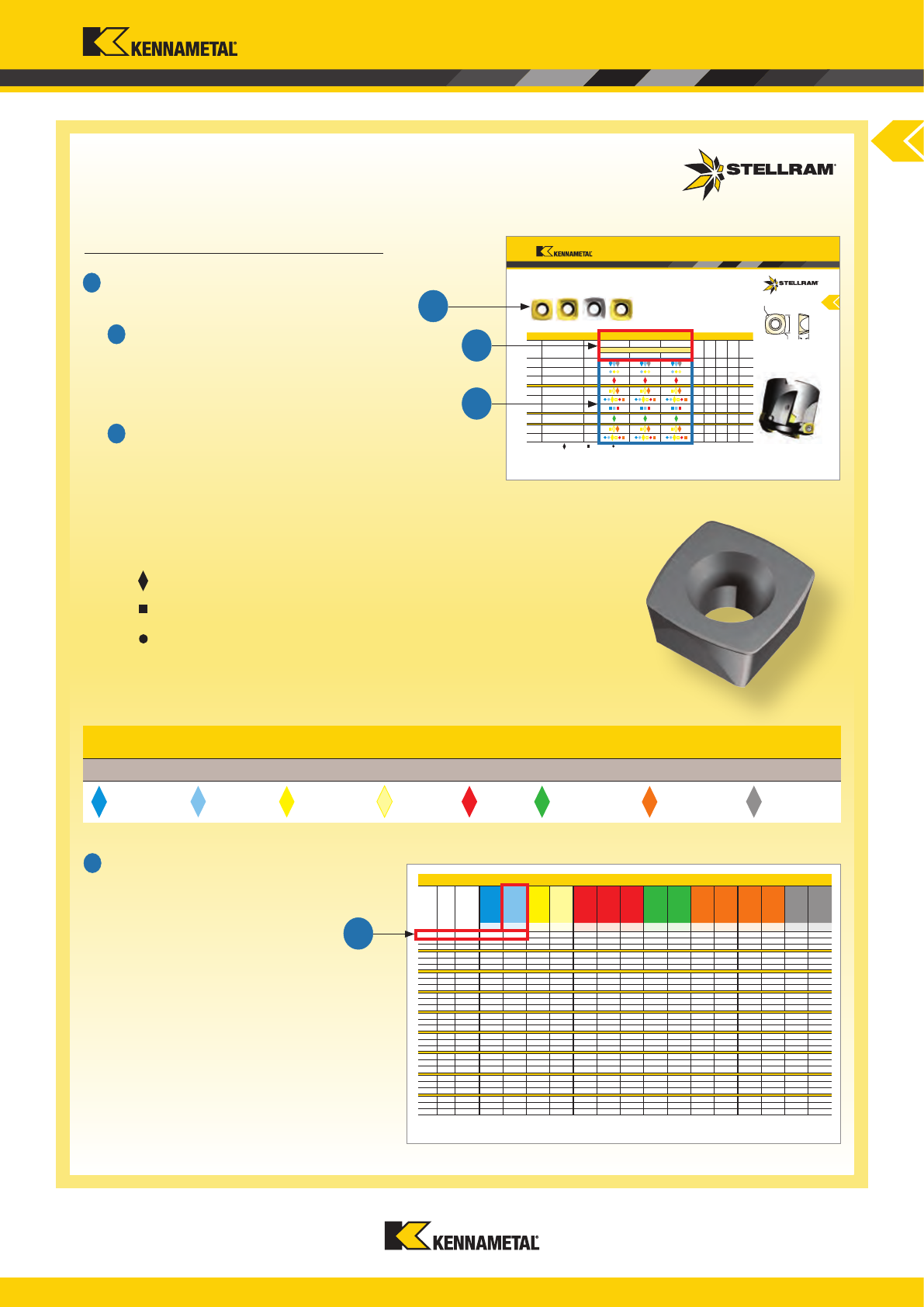

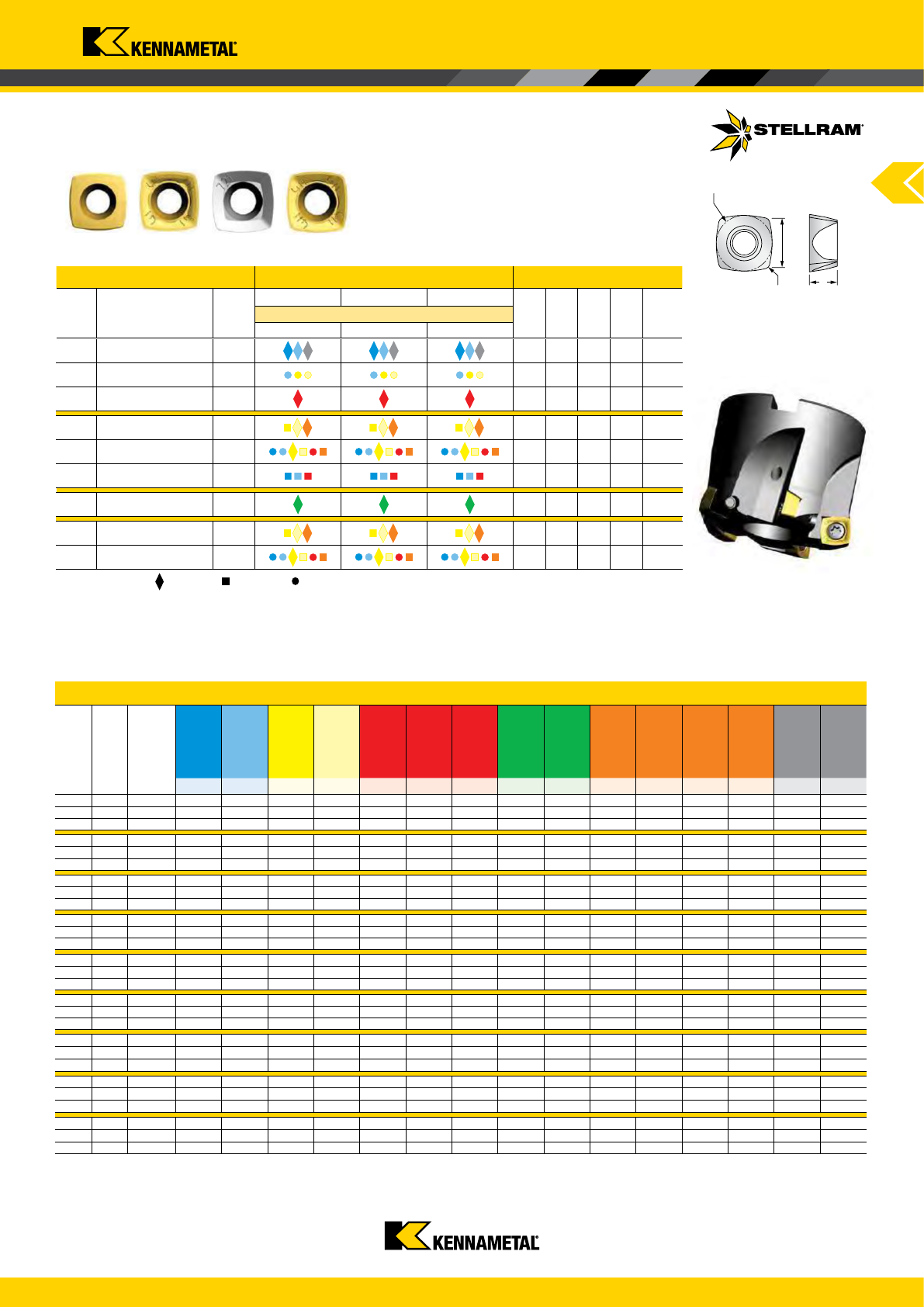

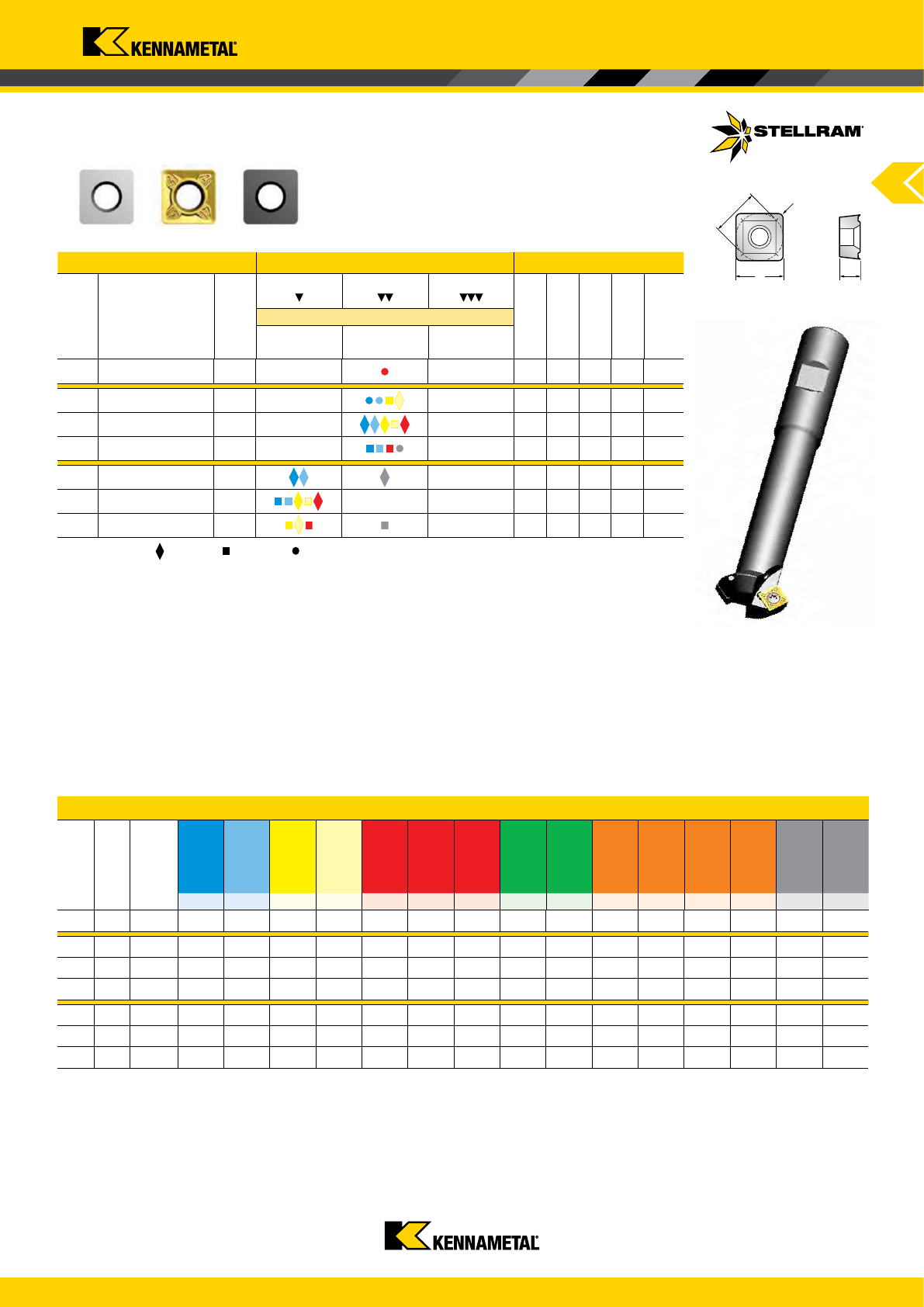

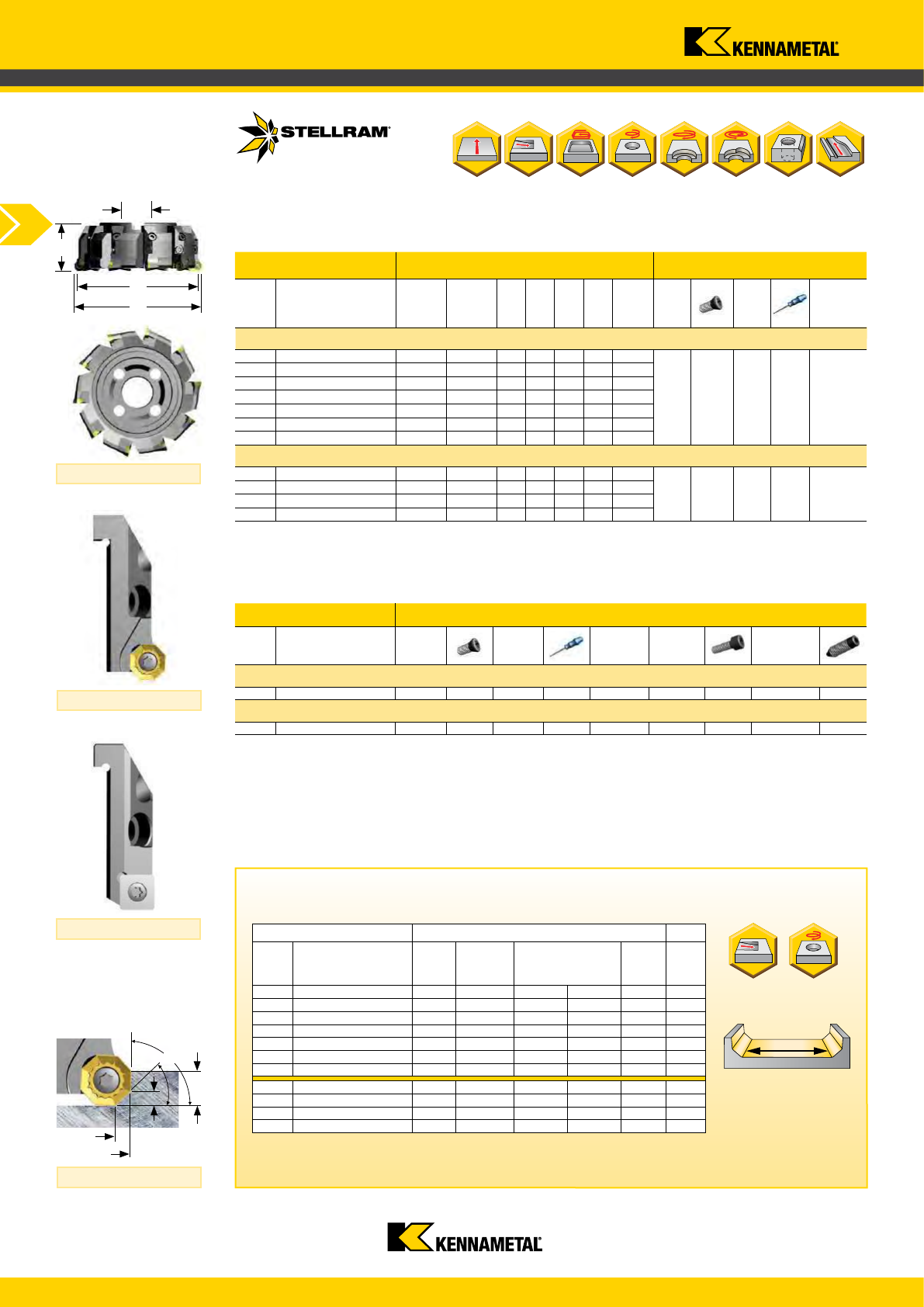

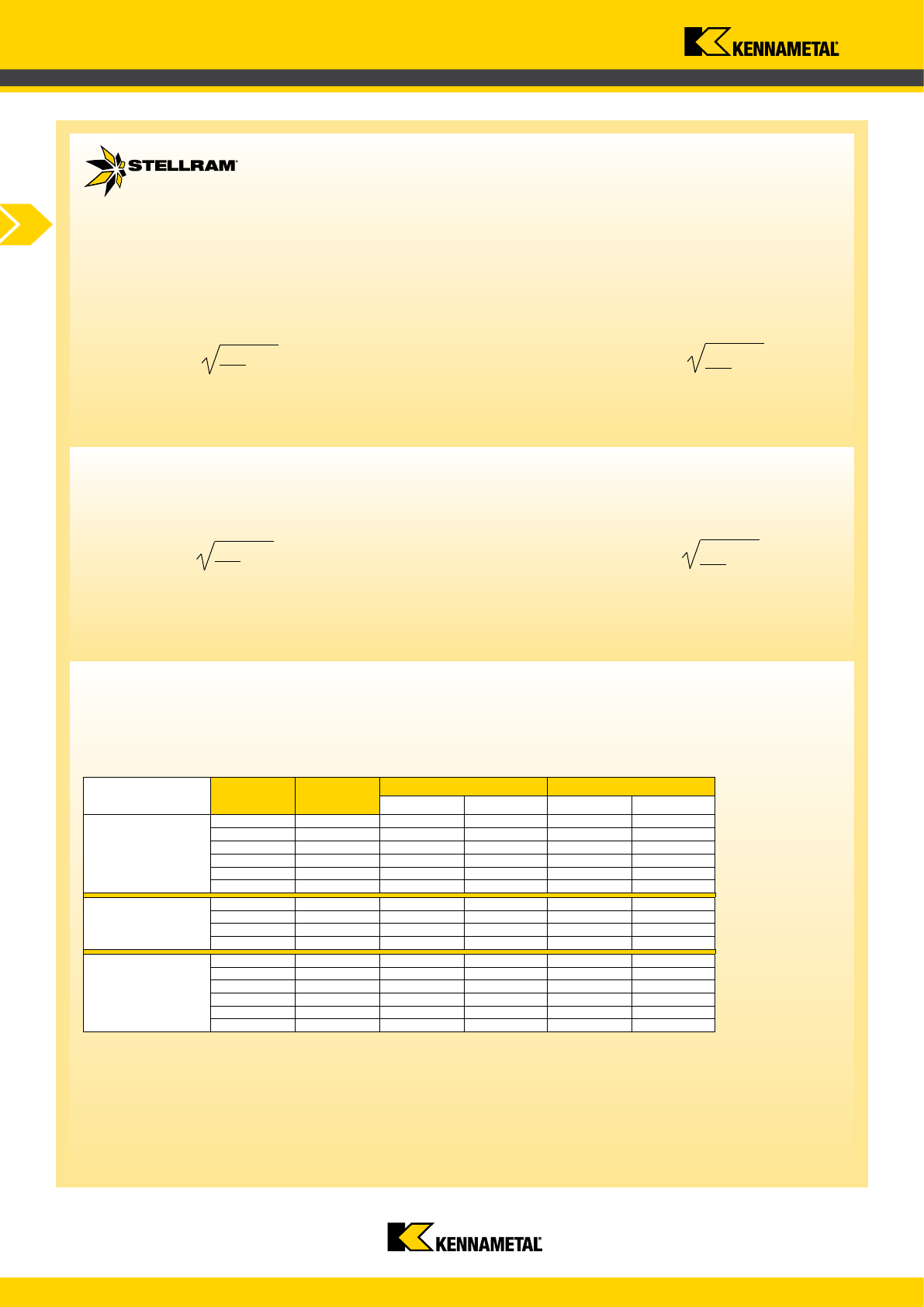

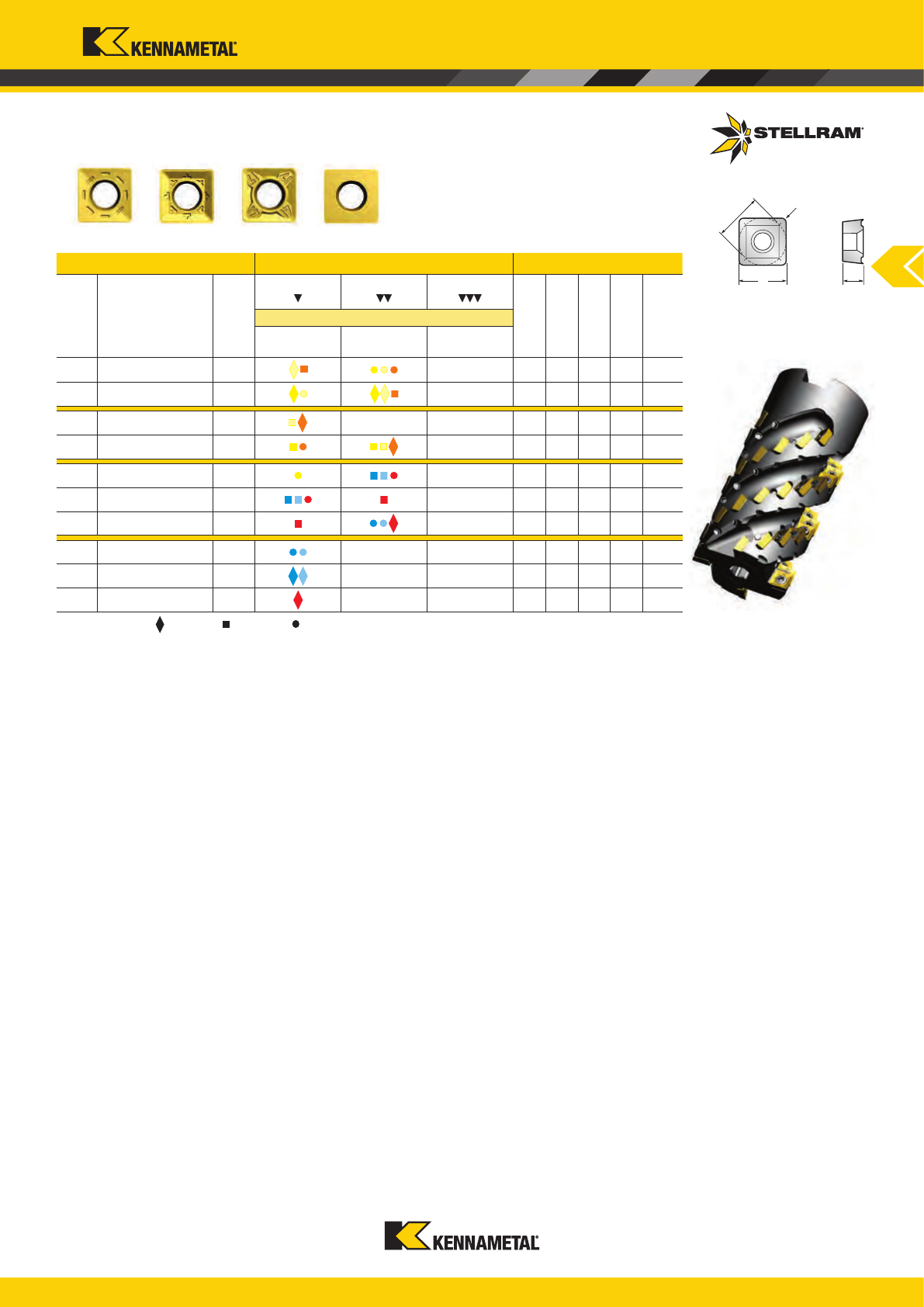

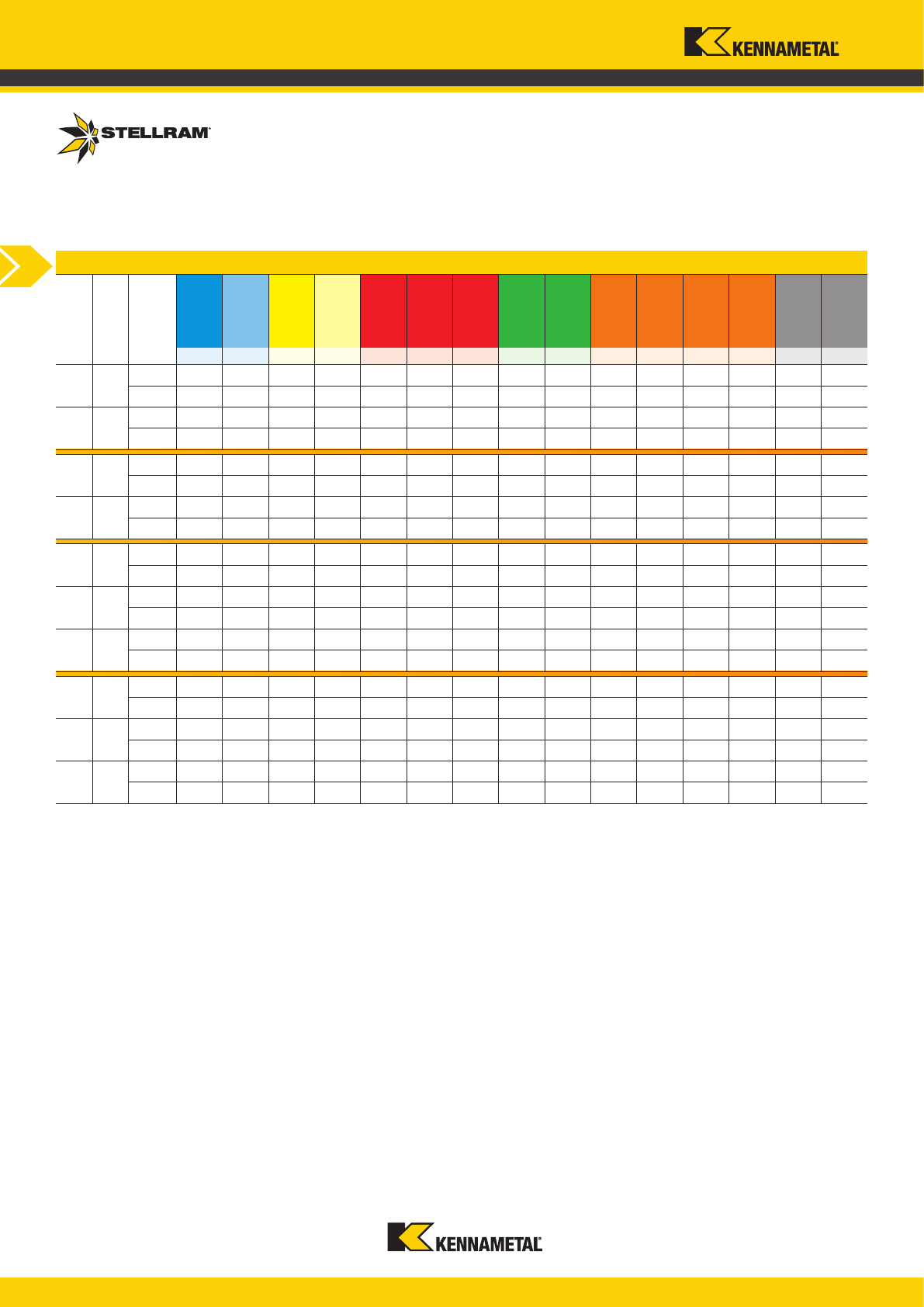

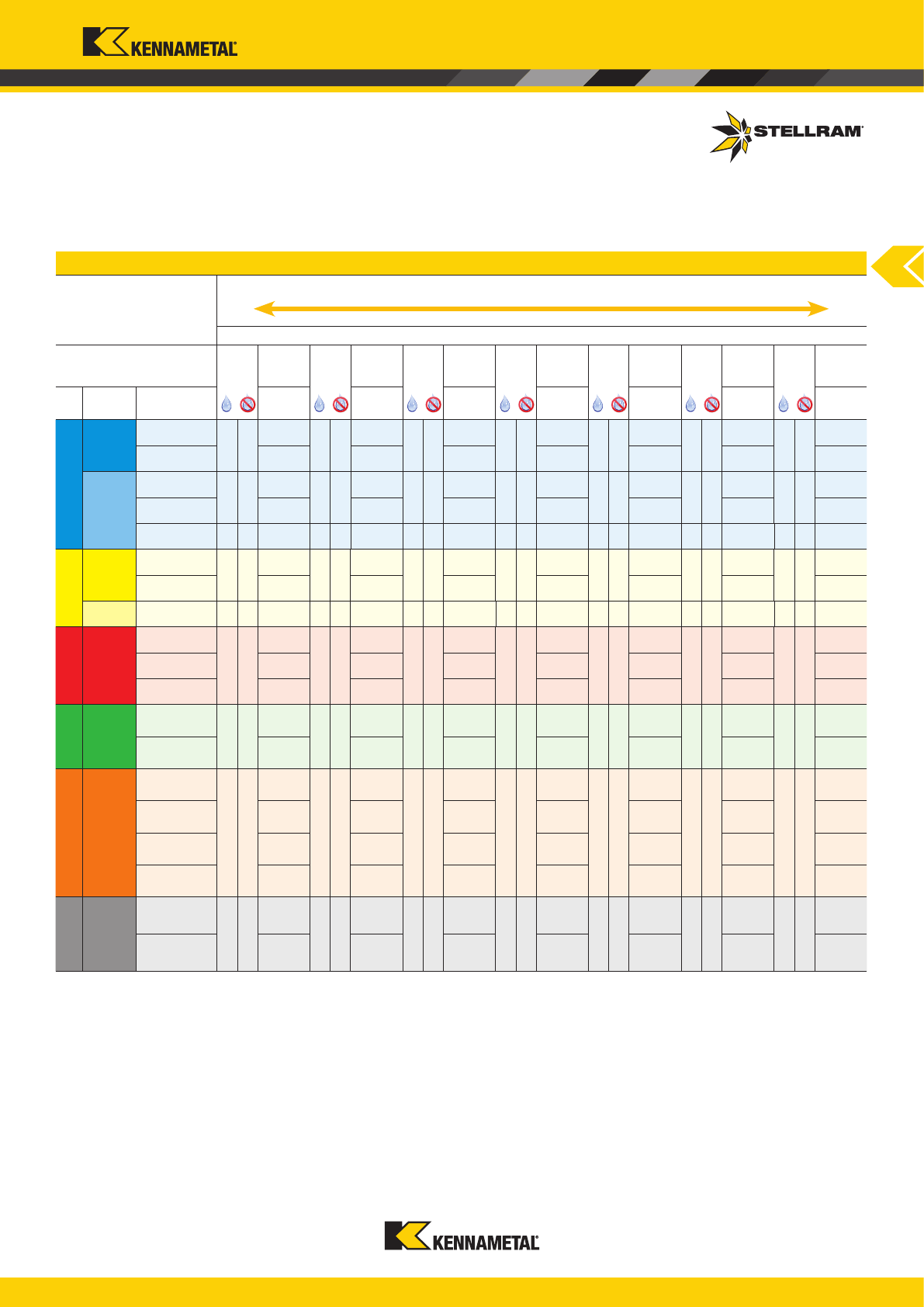

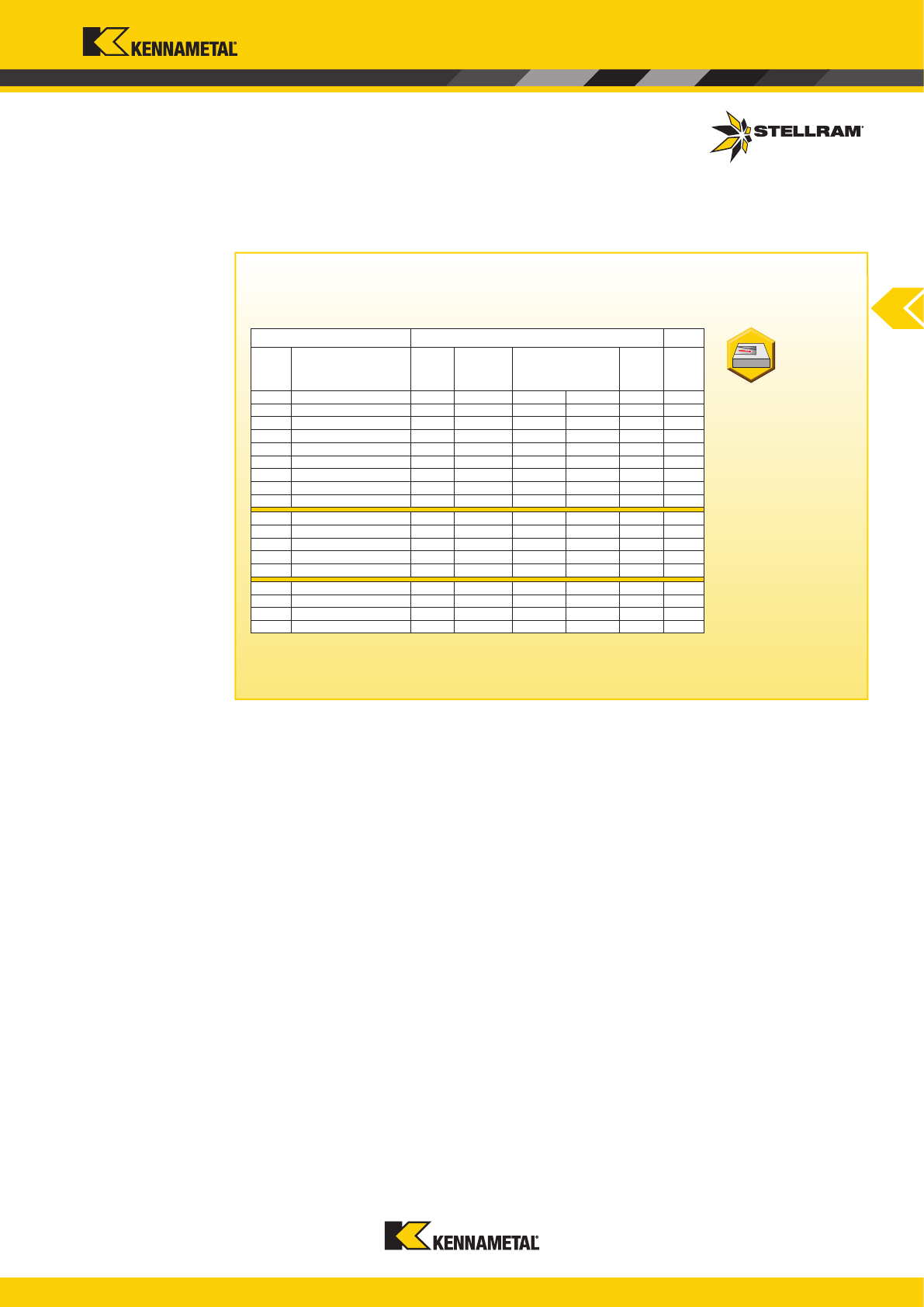

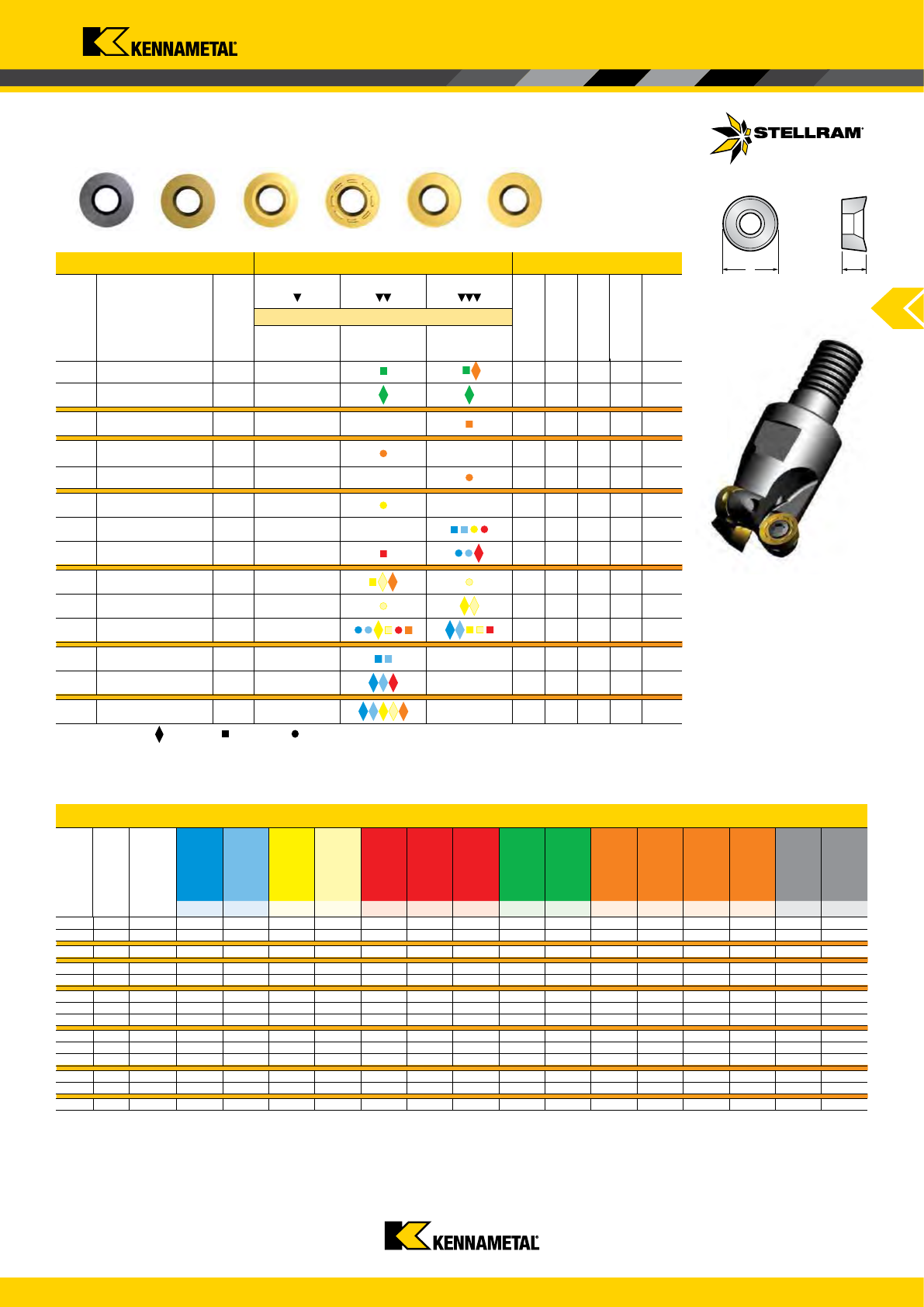

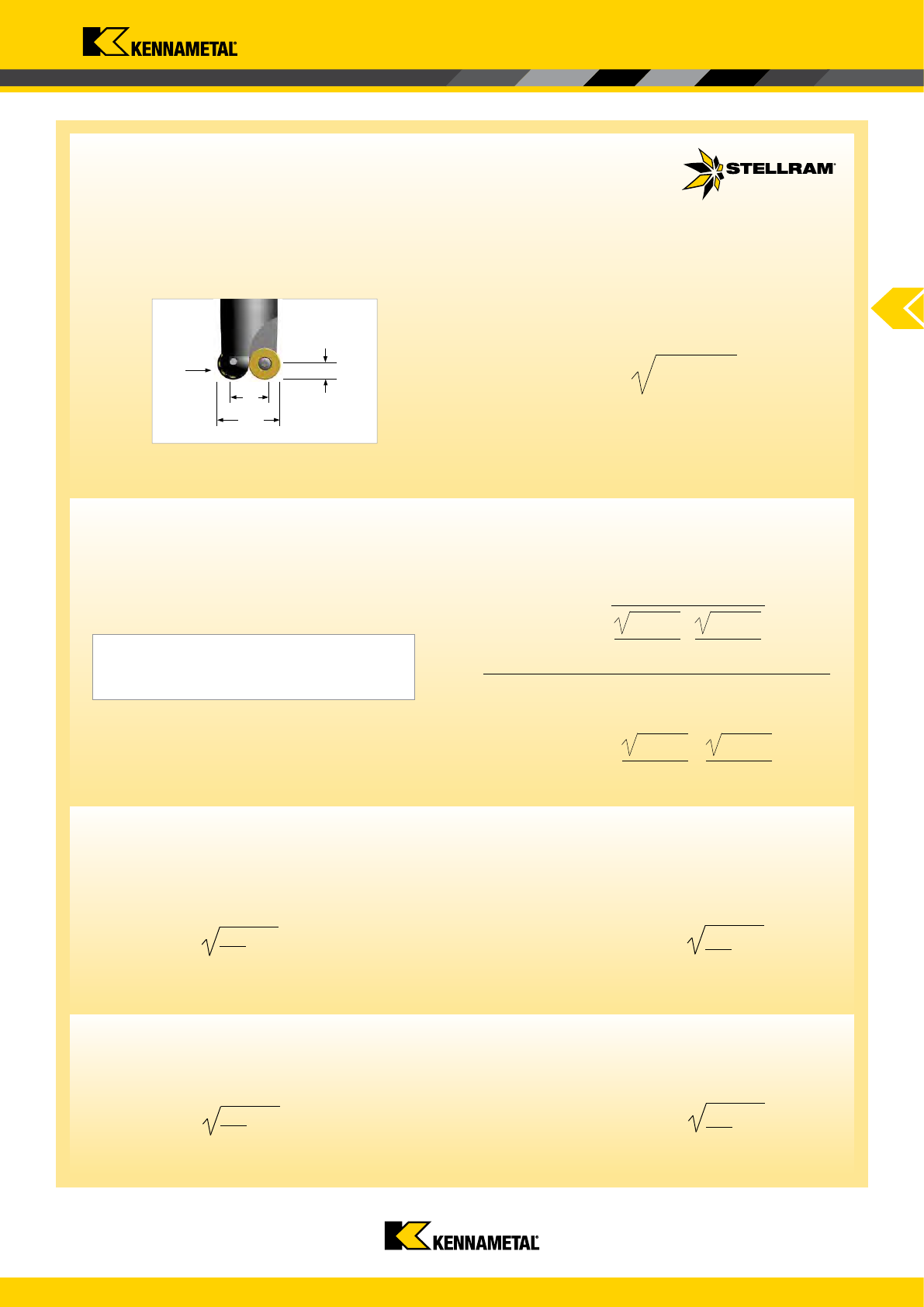

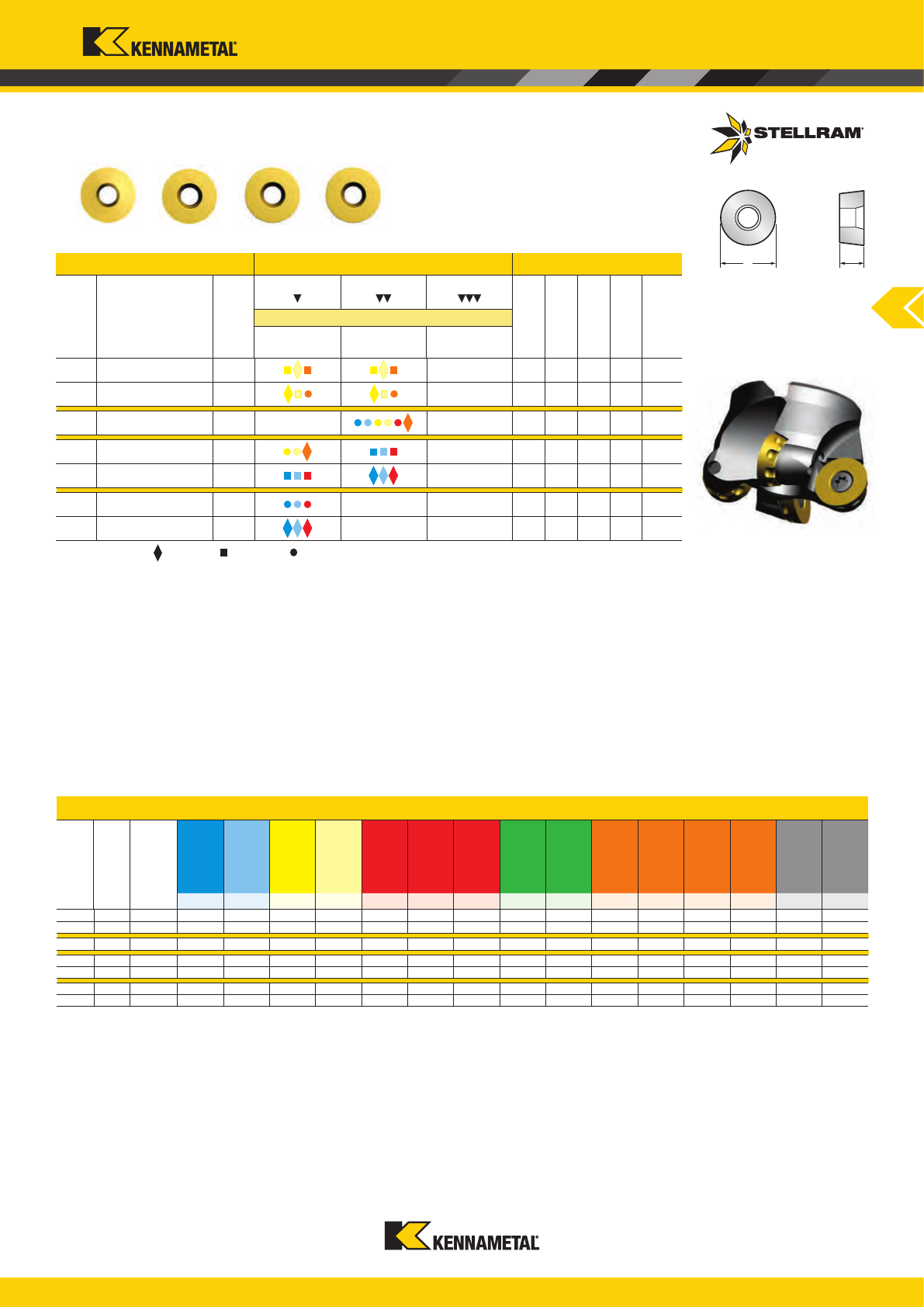

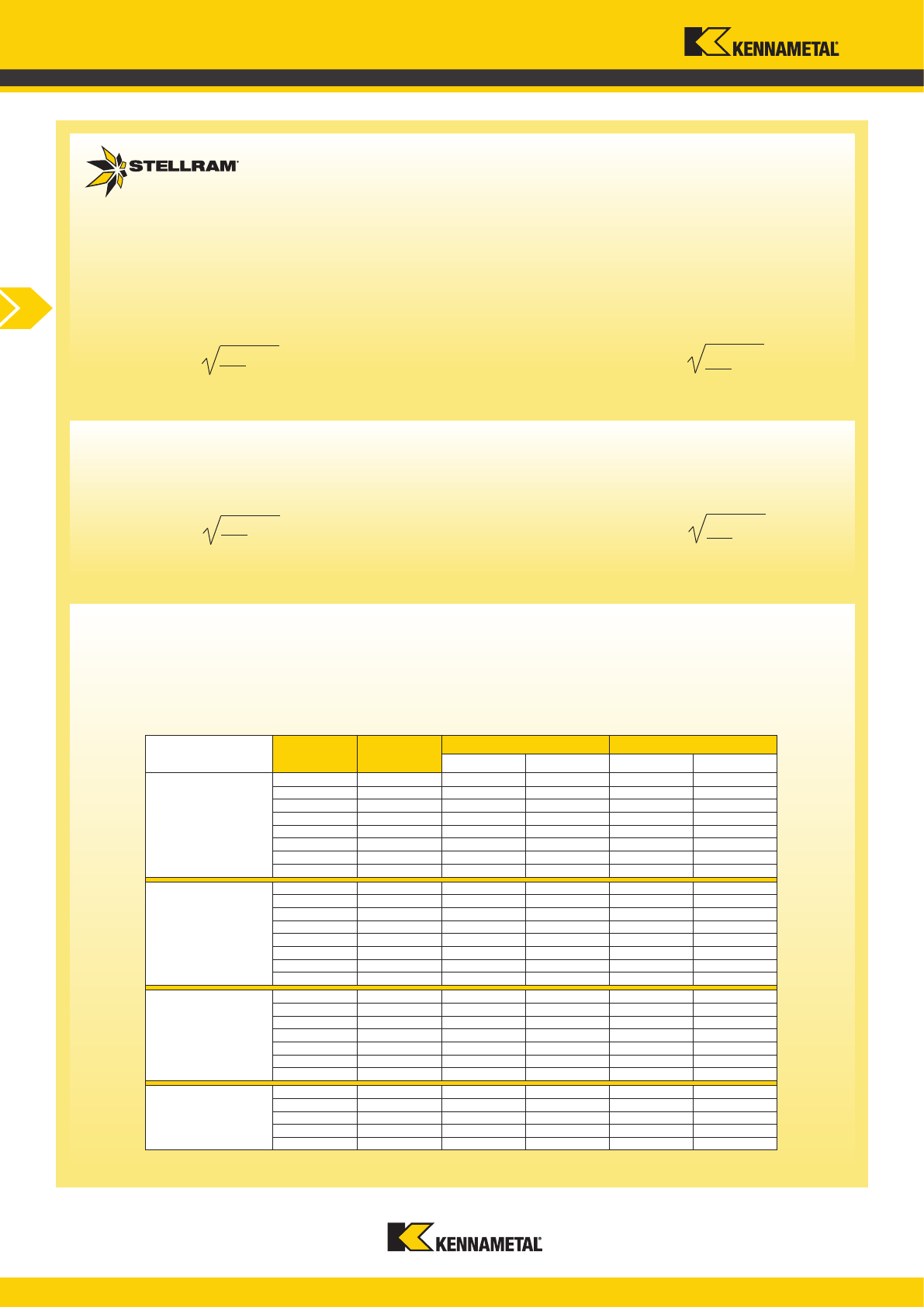

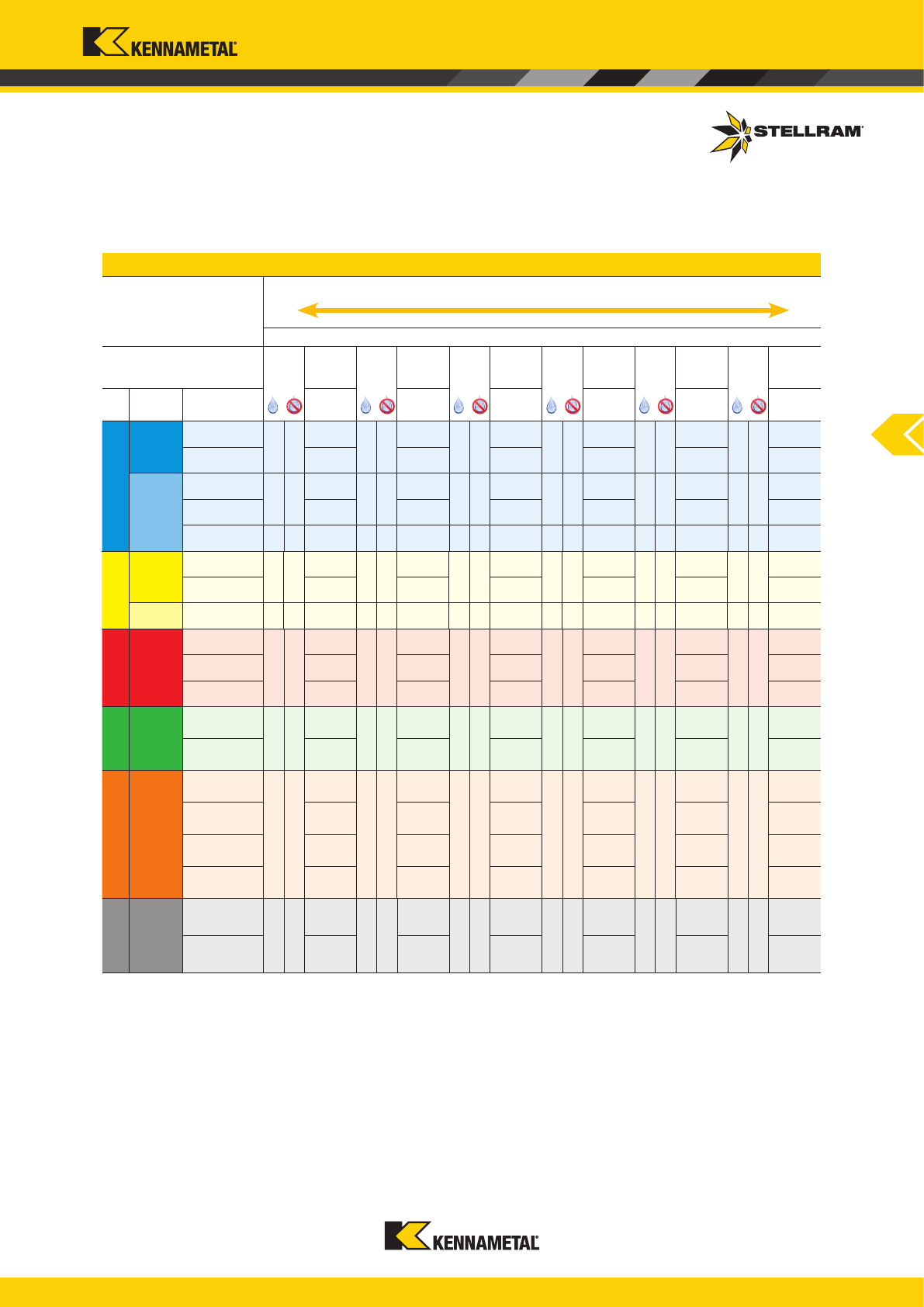

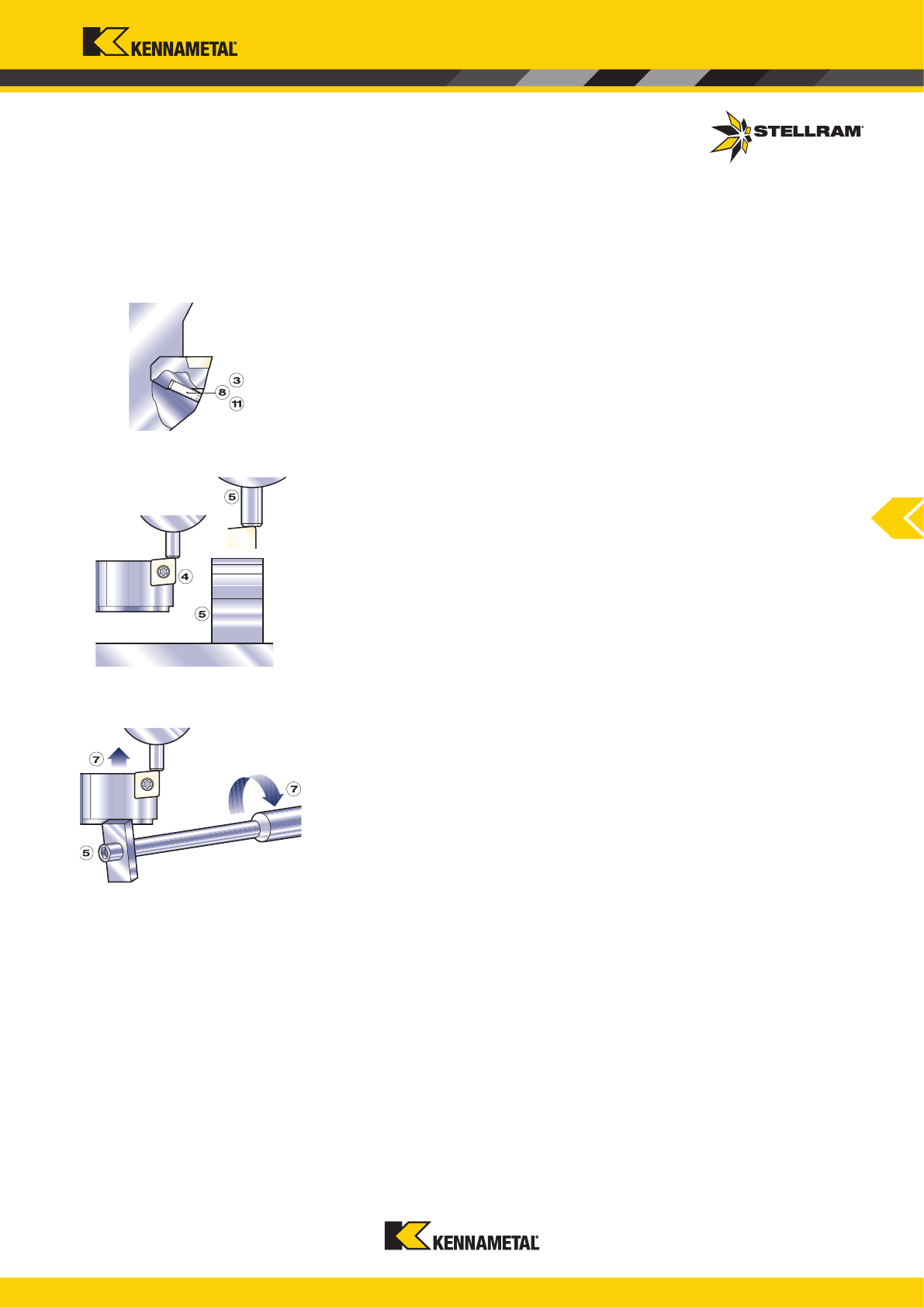

3

3.1

3.2

3

3.1

3.2

4

4

P

P

M

M

K N

S

H

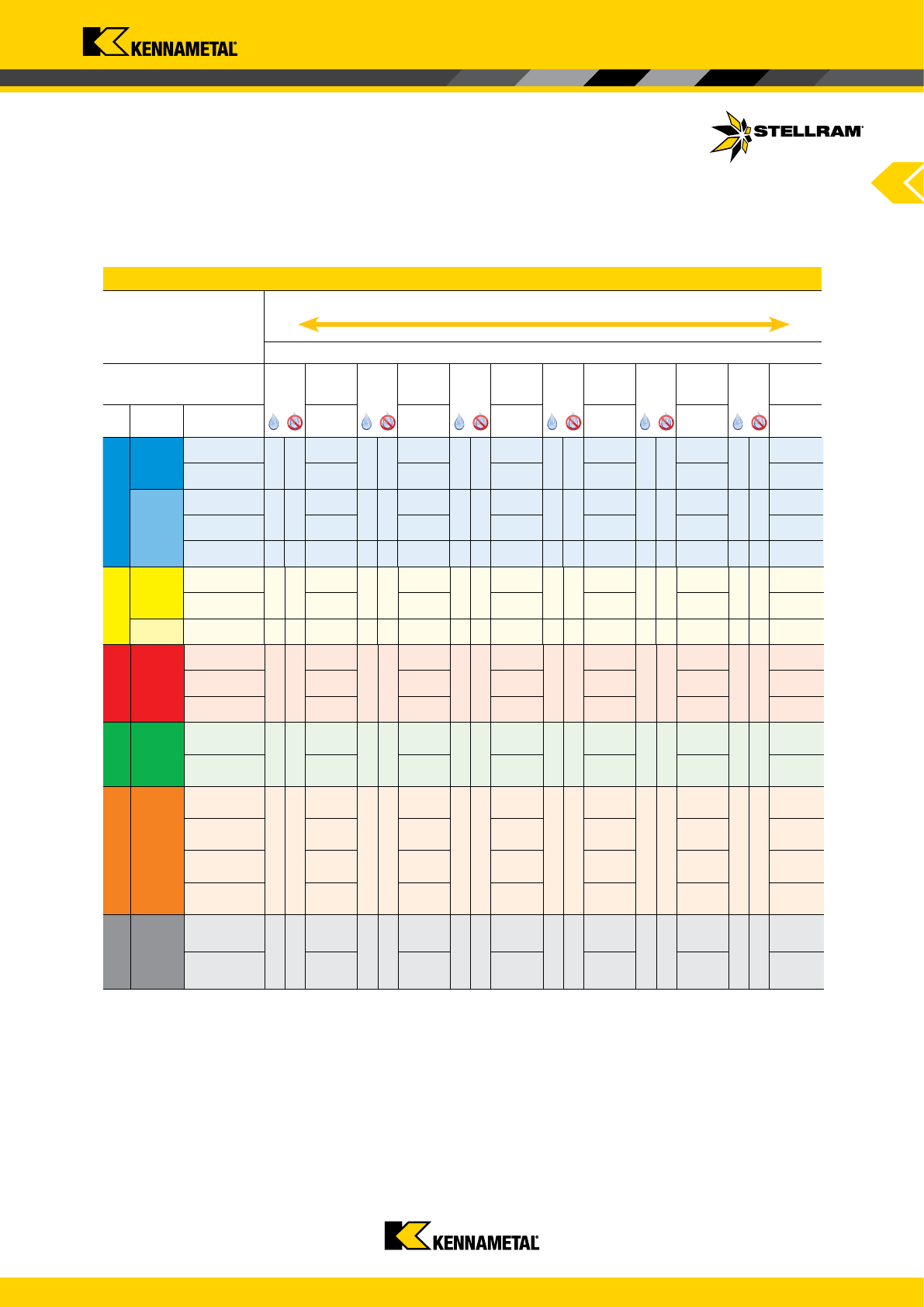

Milling Introduction

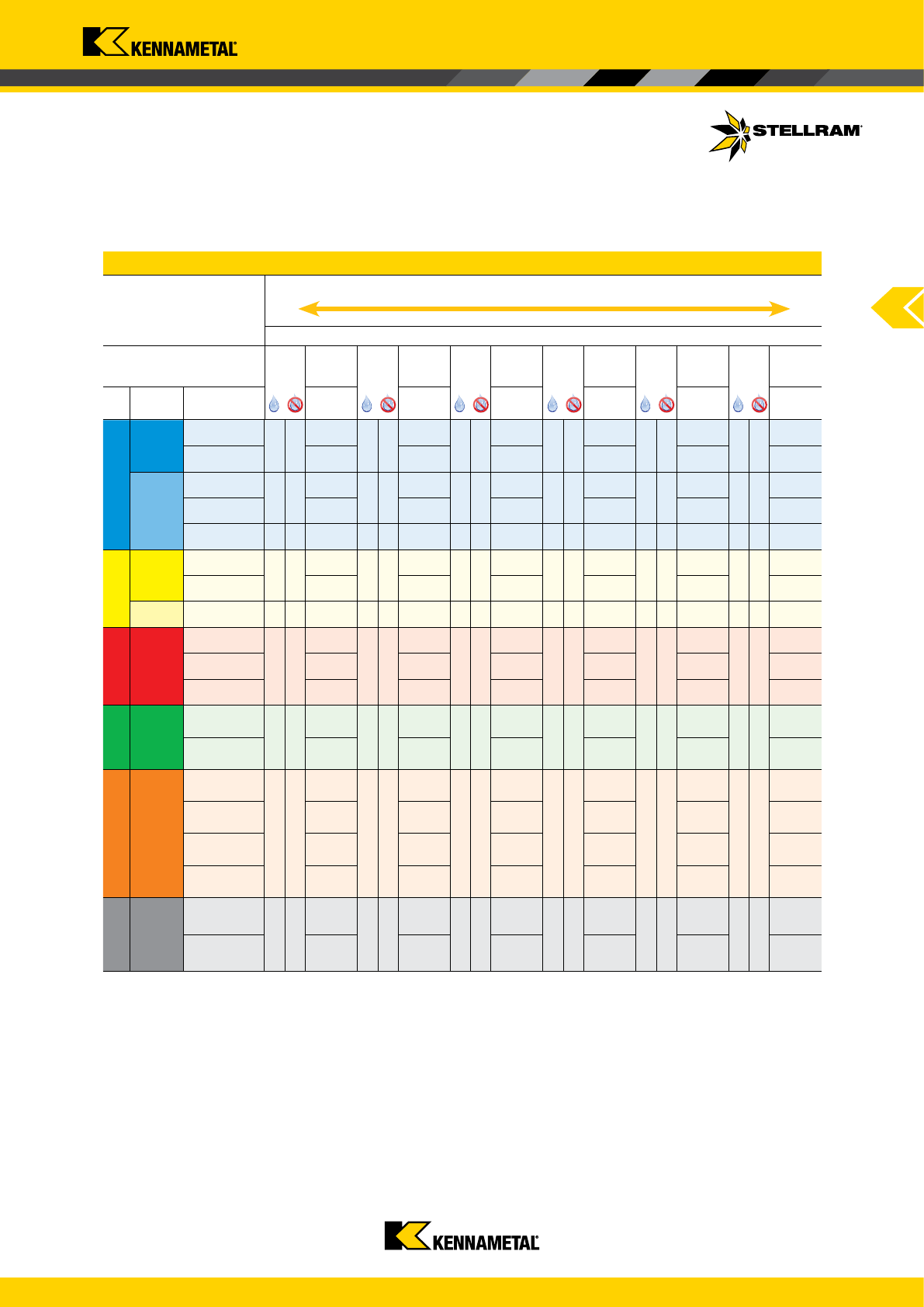

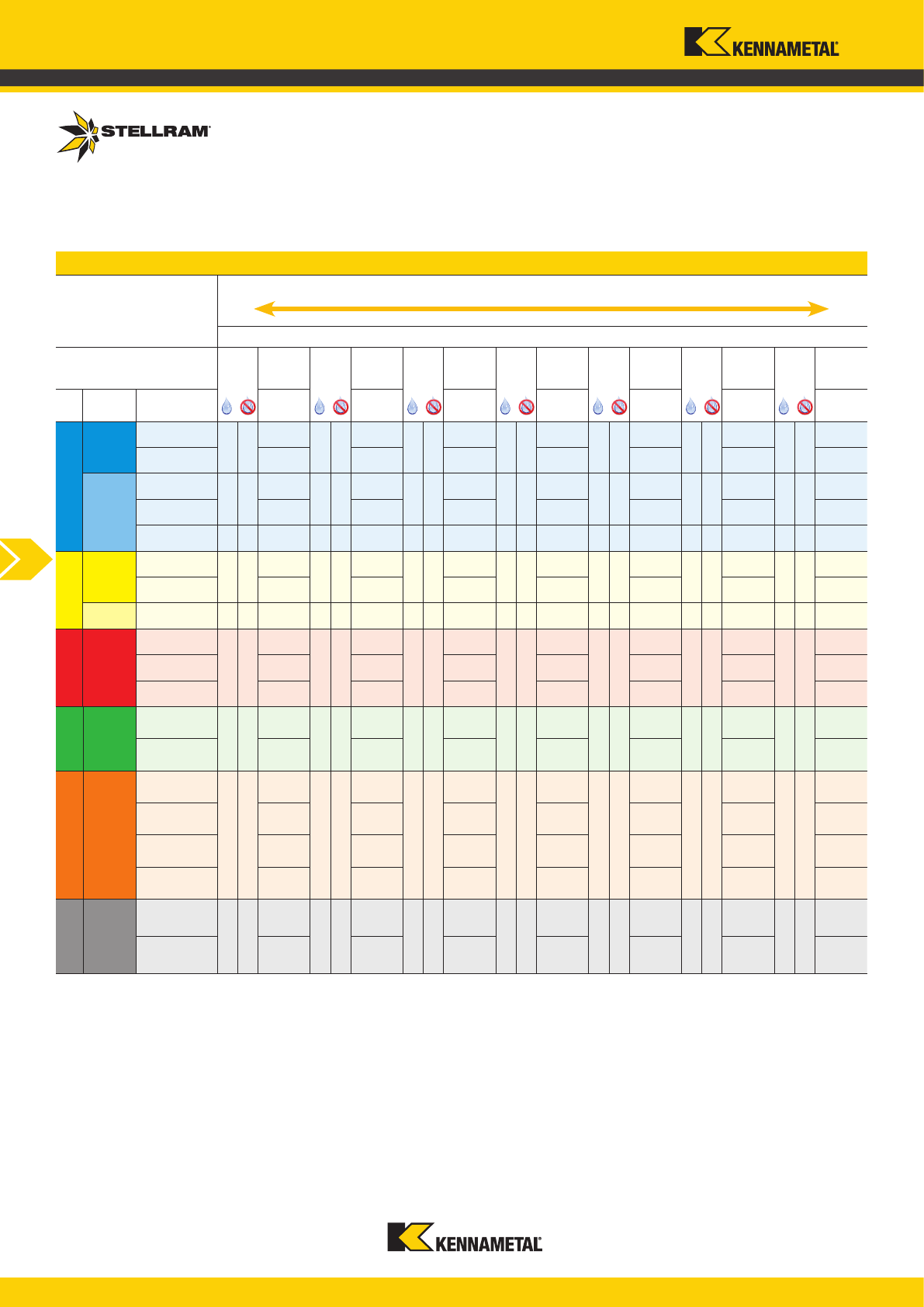

End Mills & Face Mills

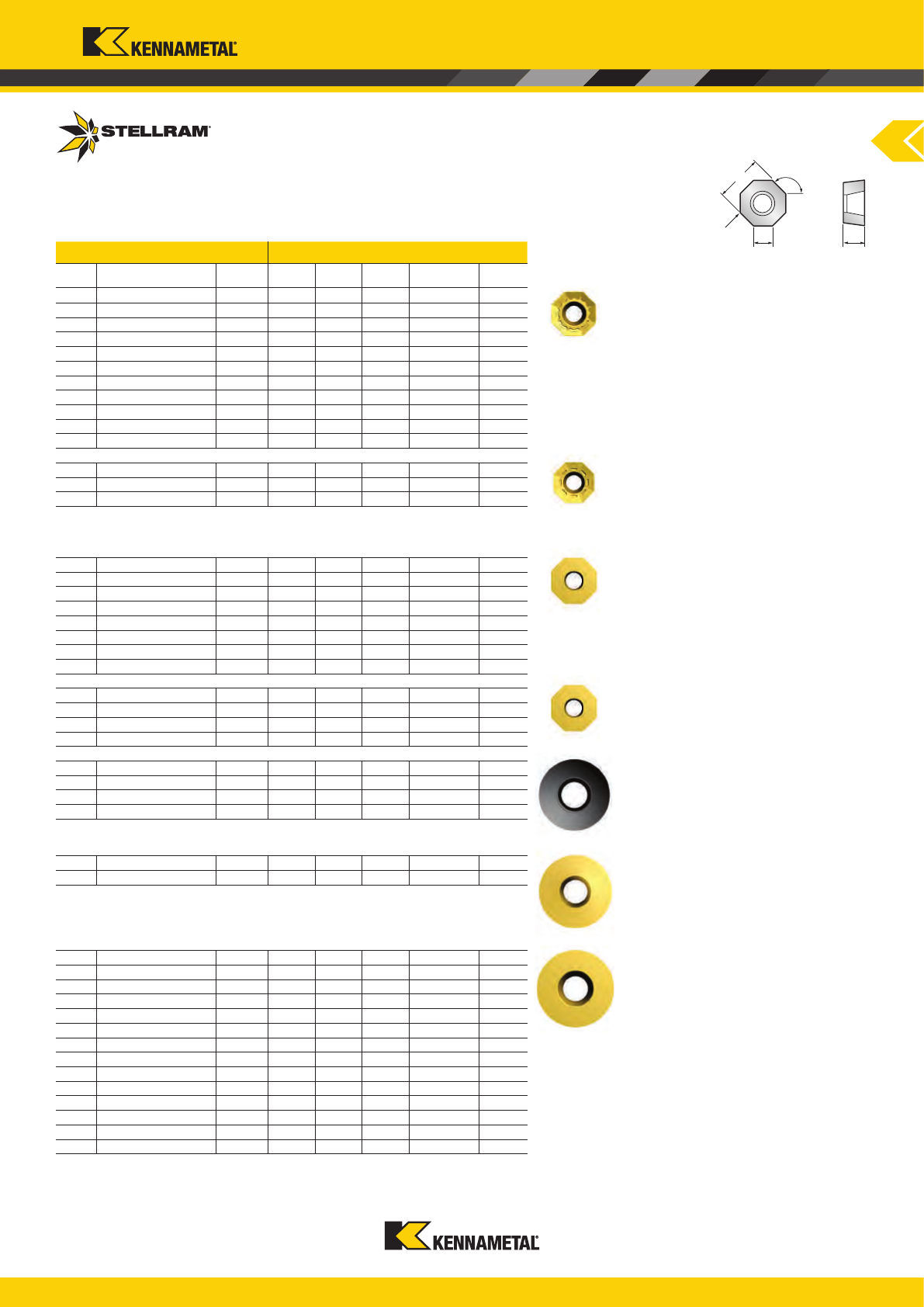

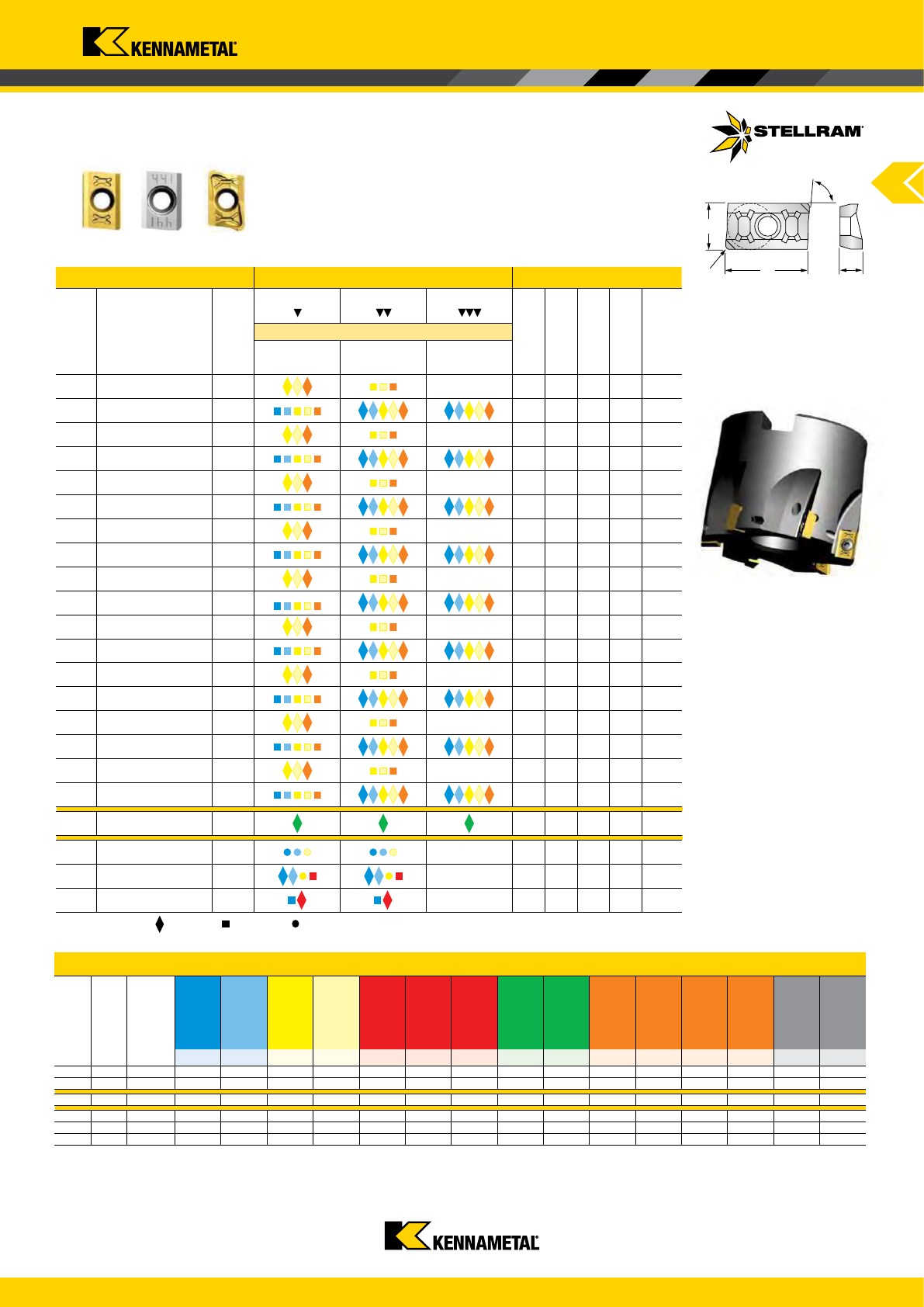

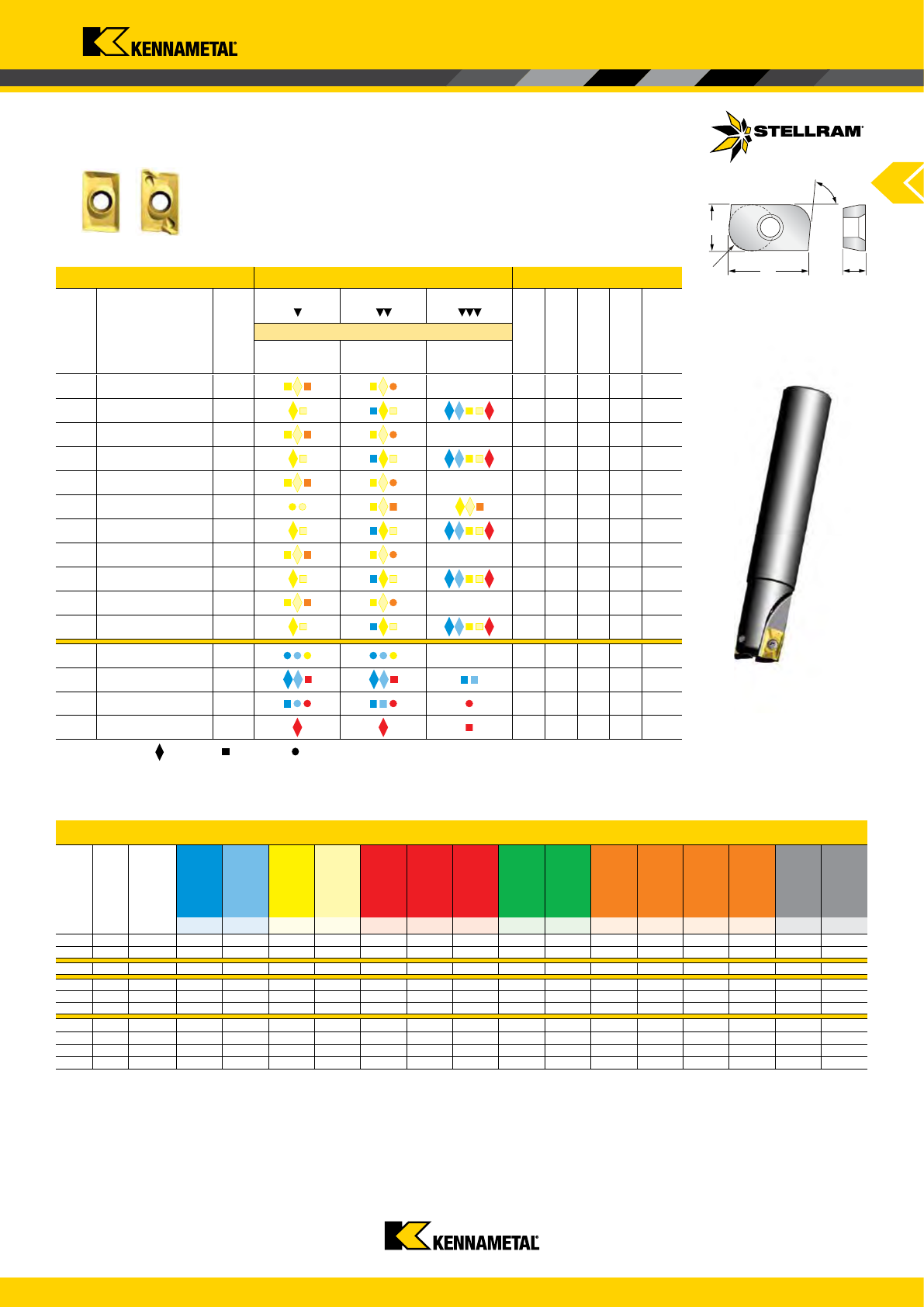

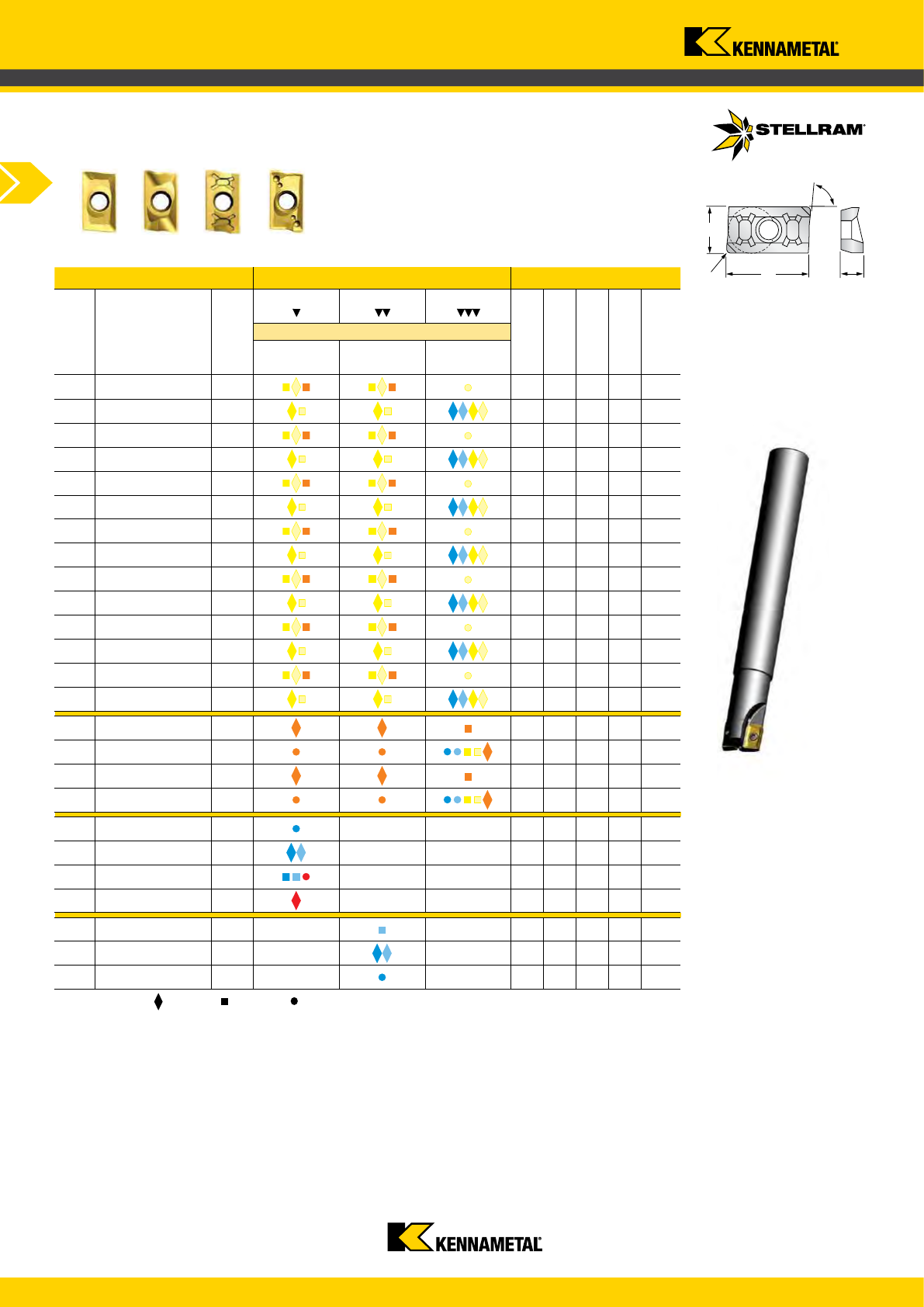

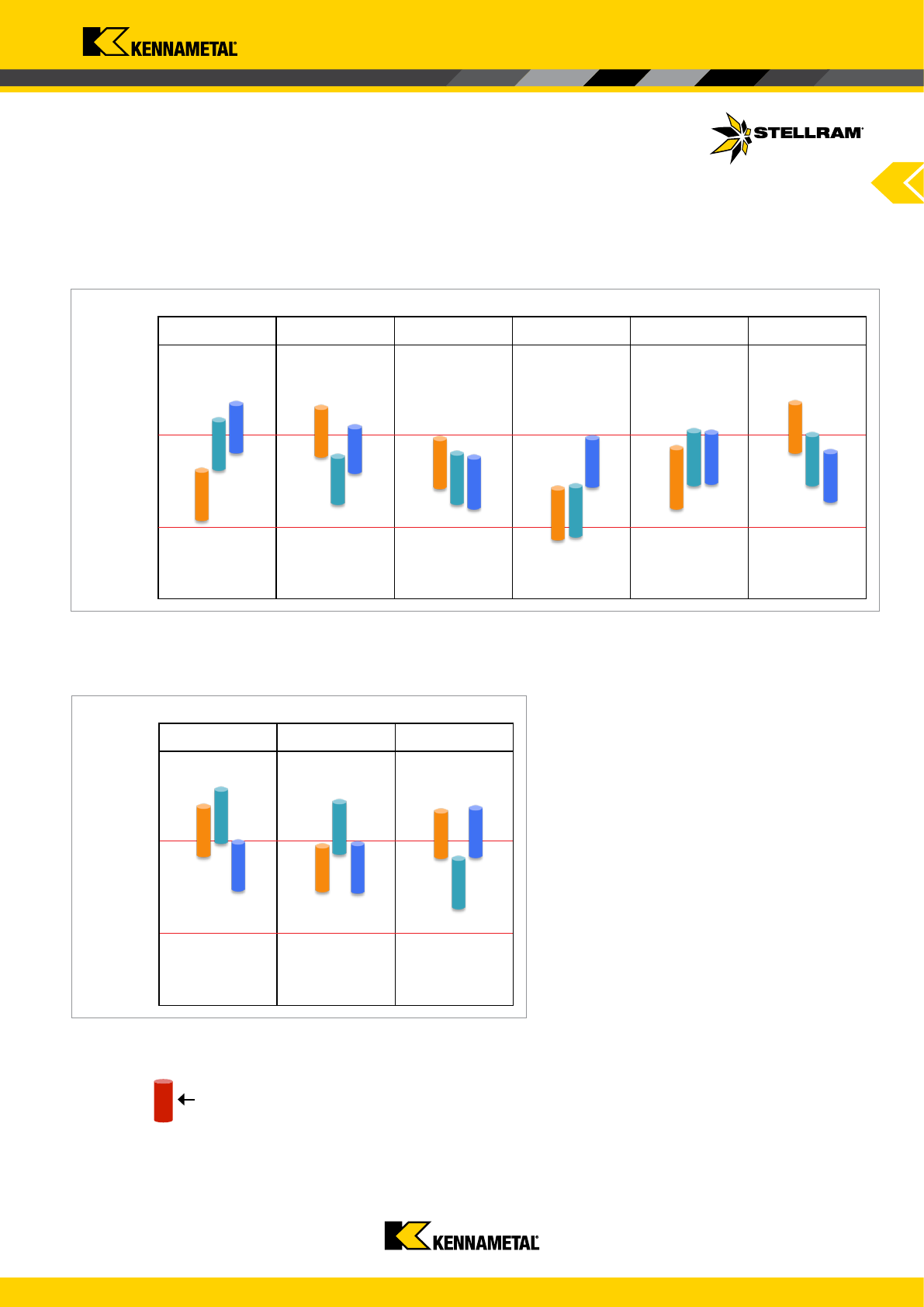

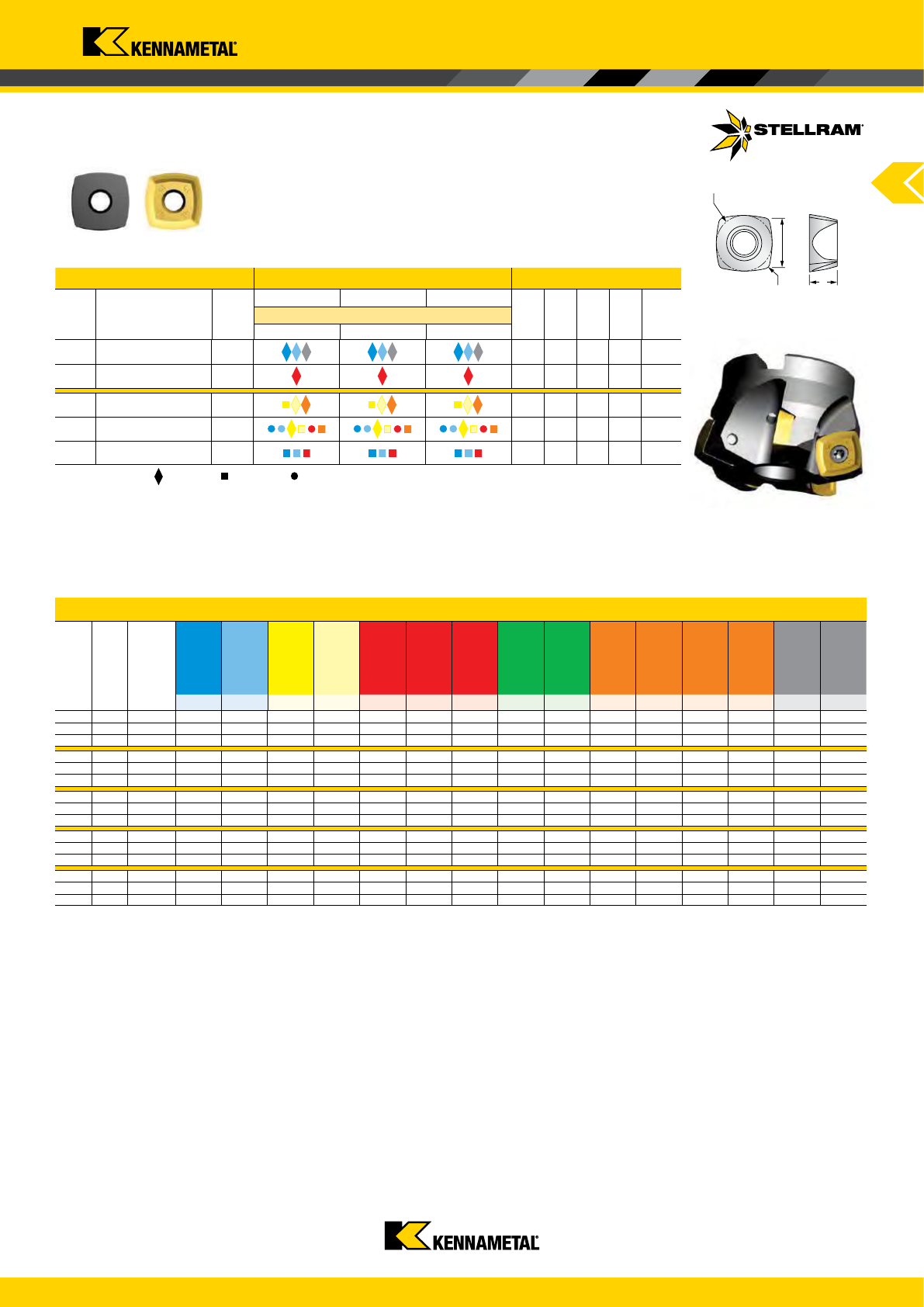

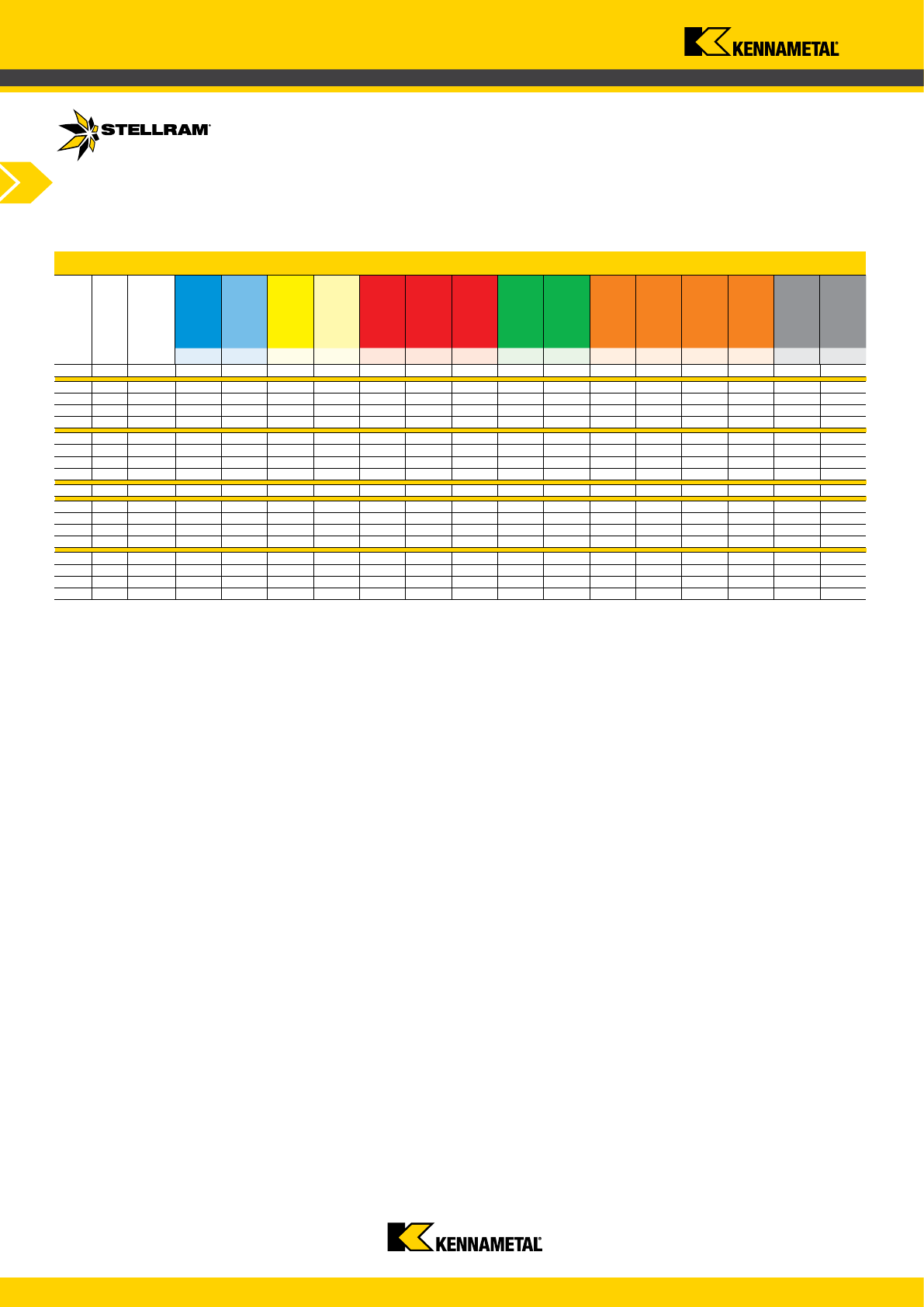

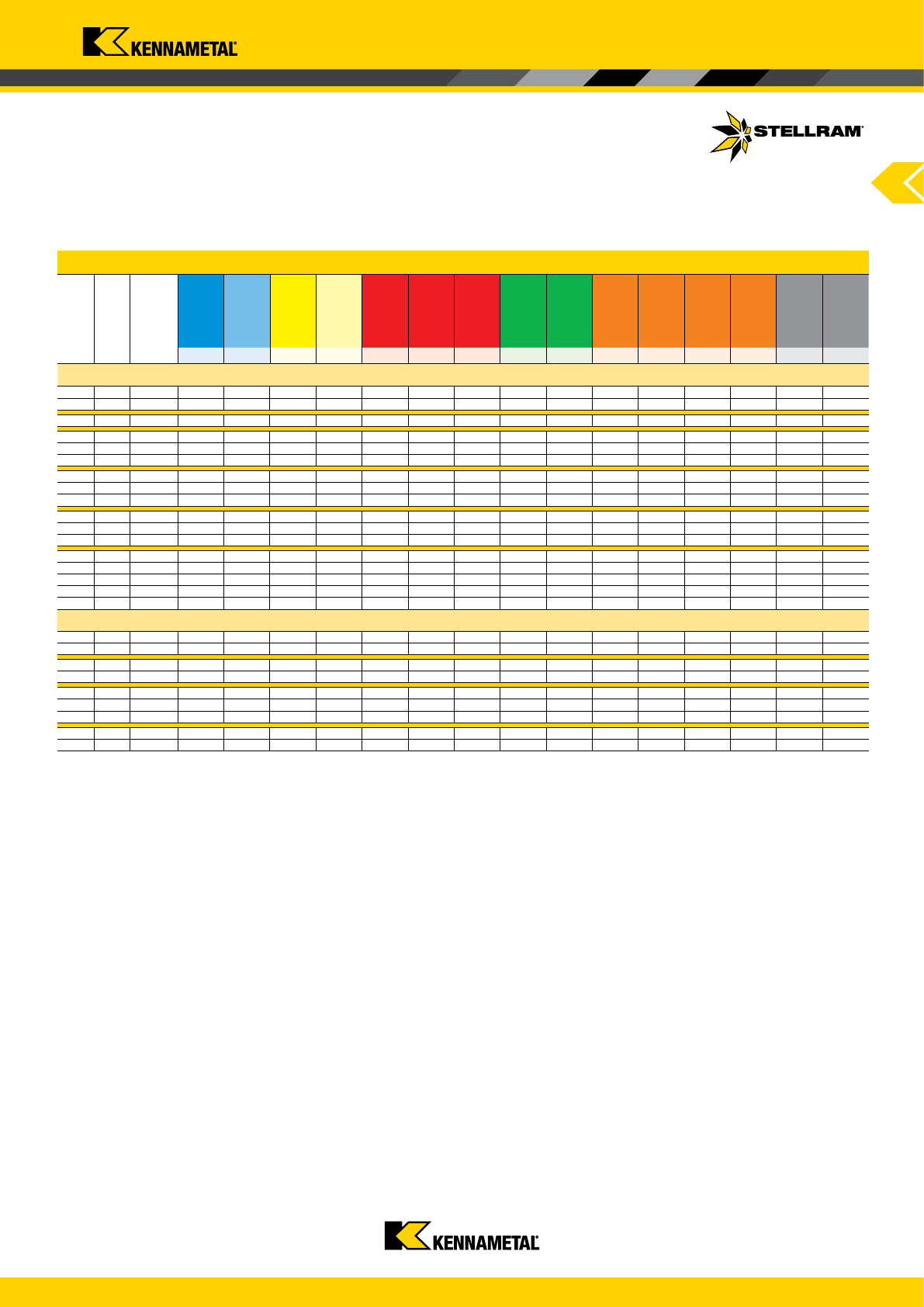

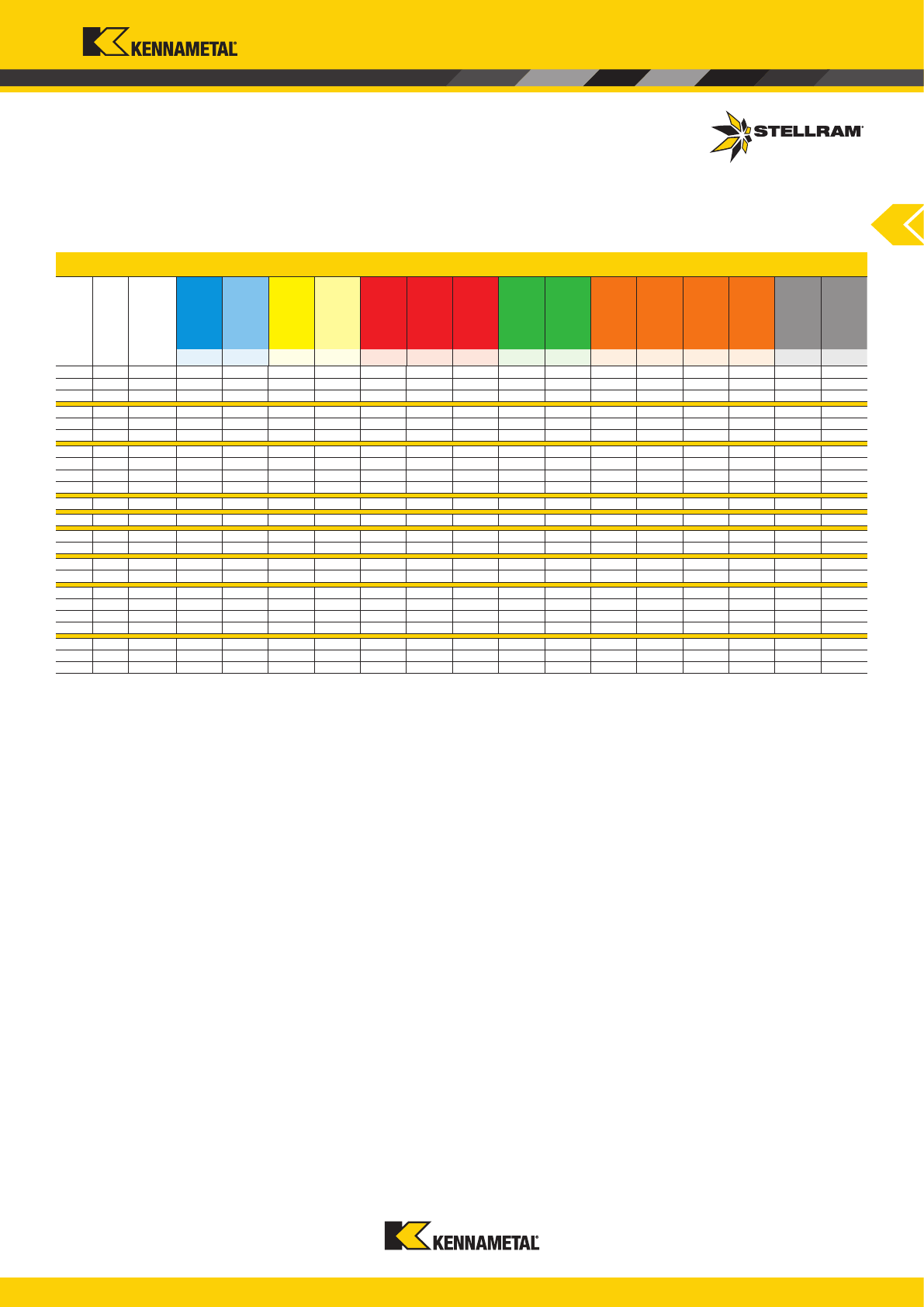

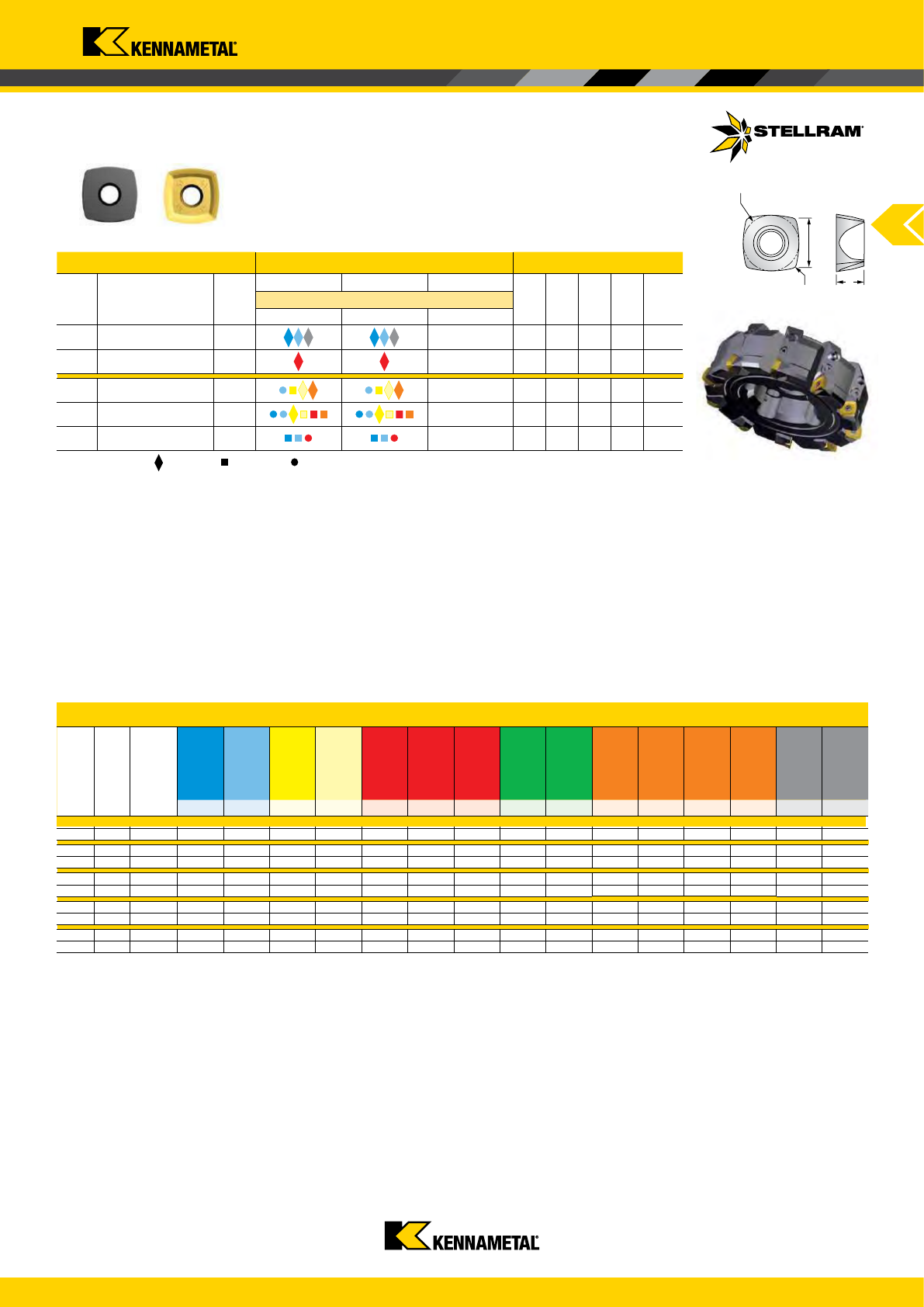

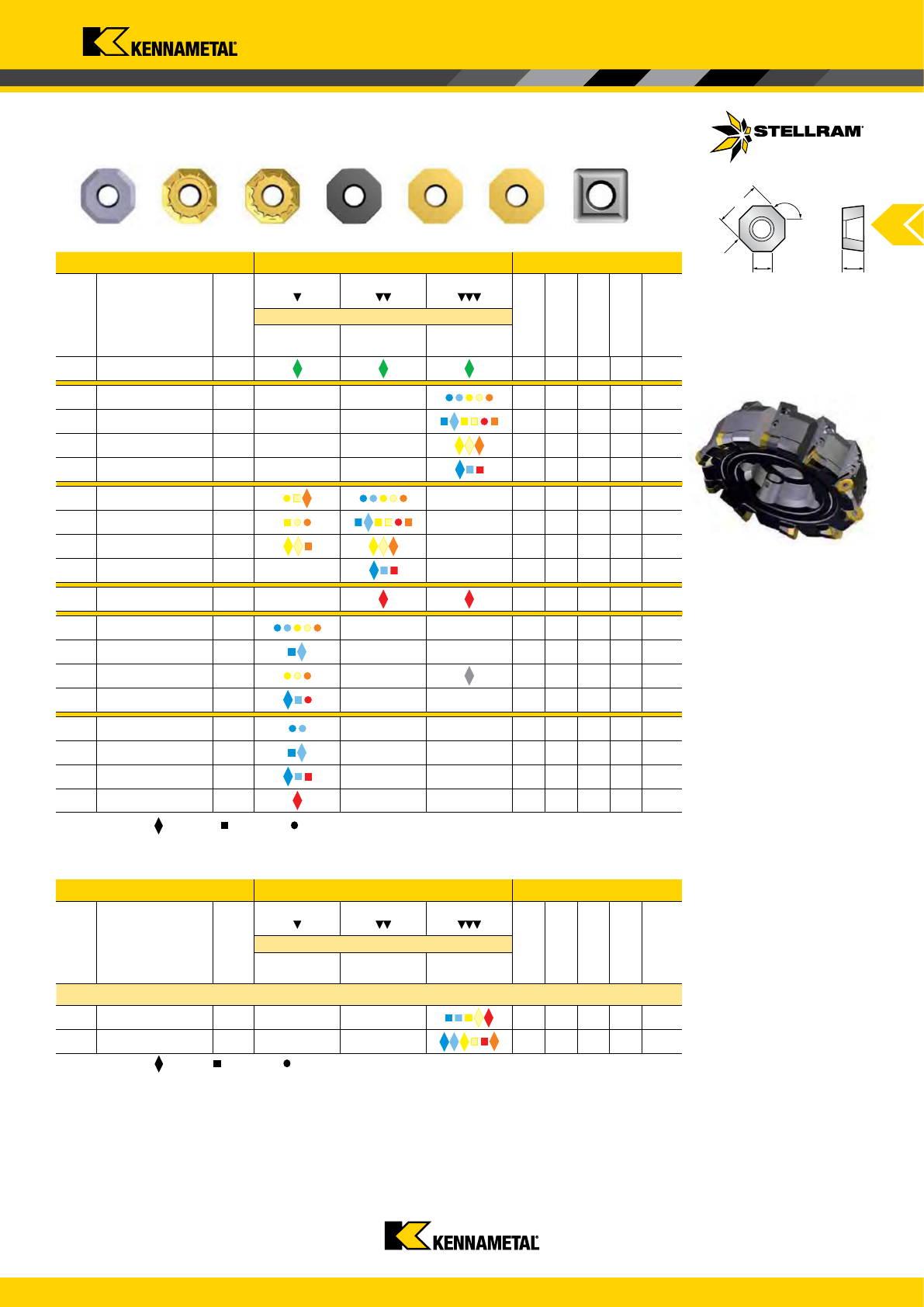

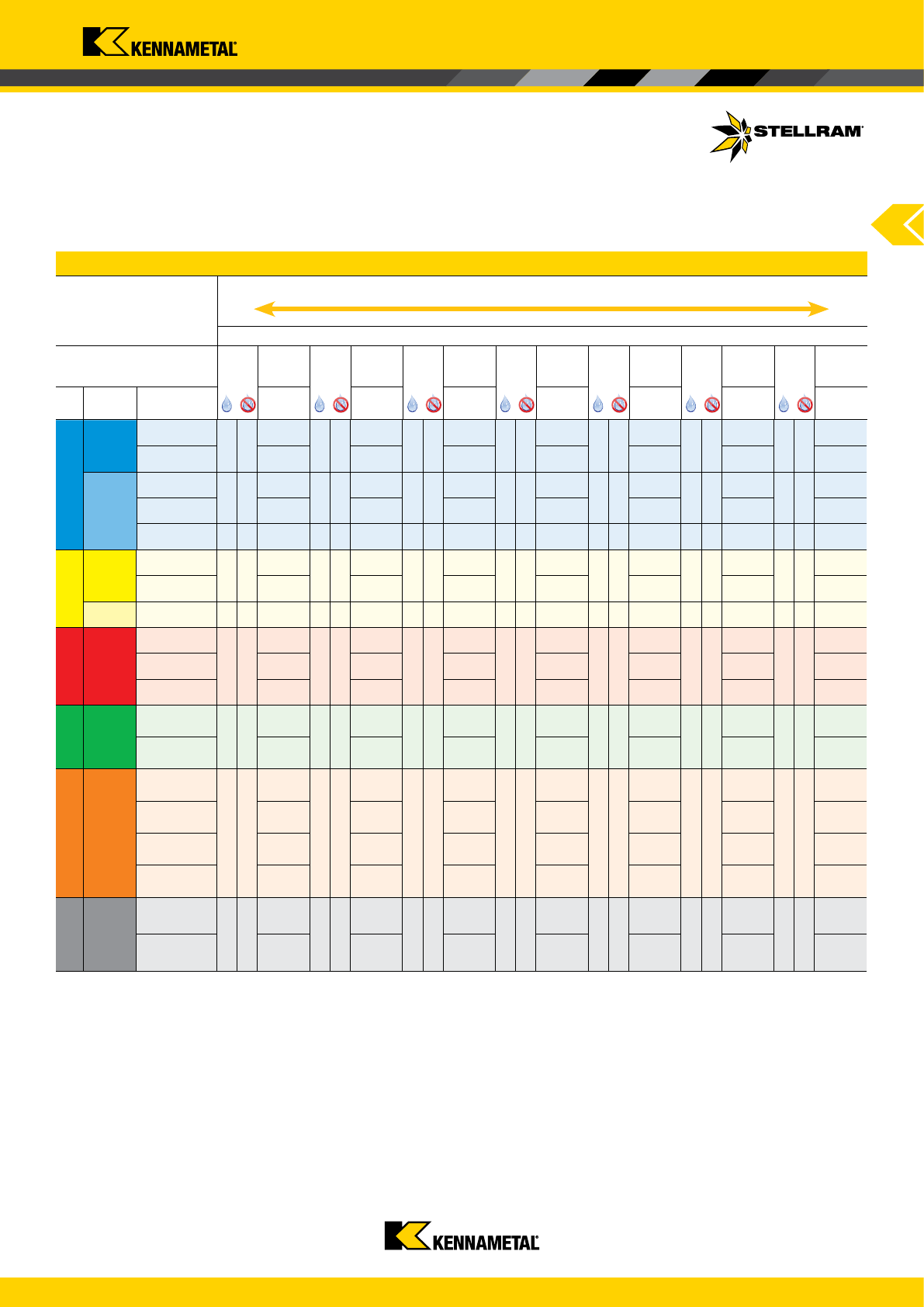

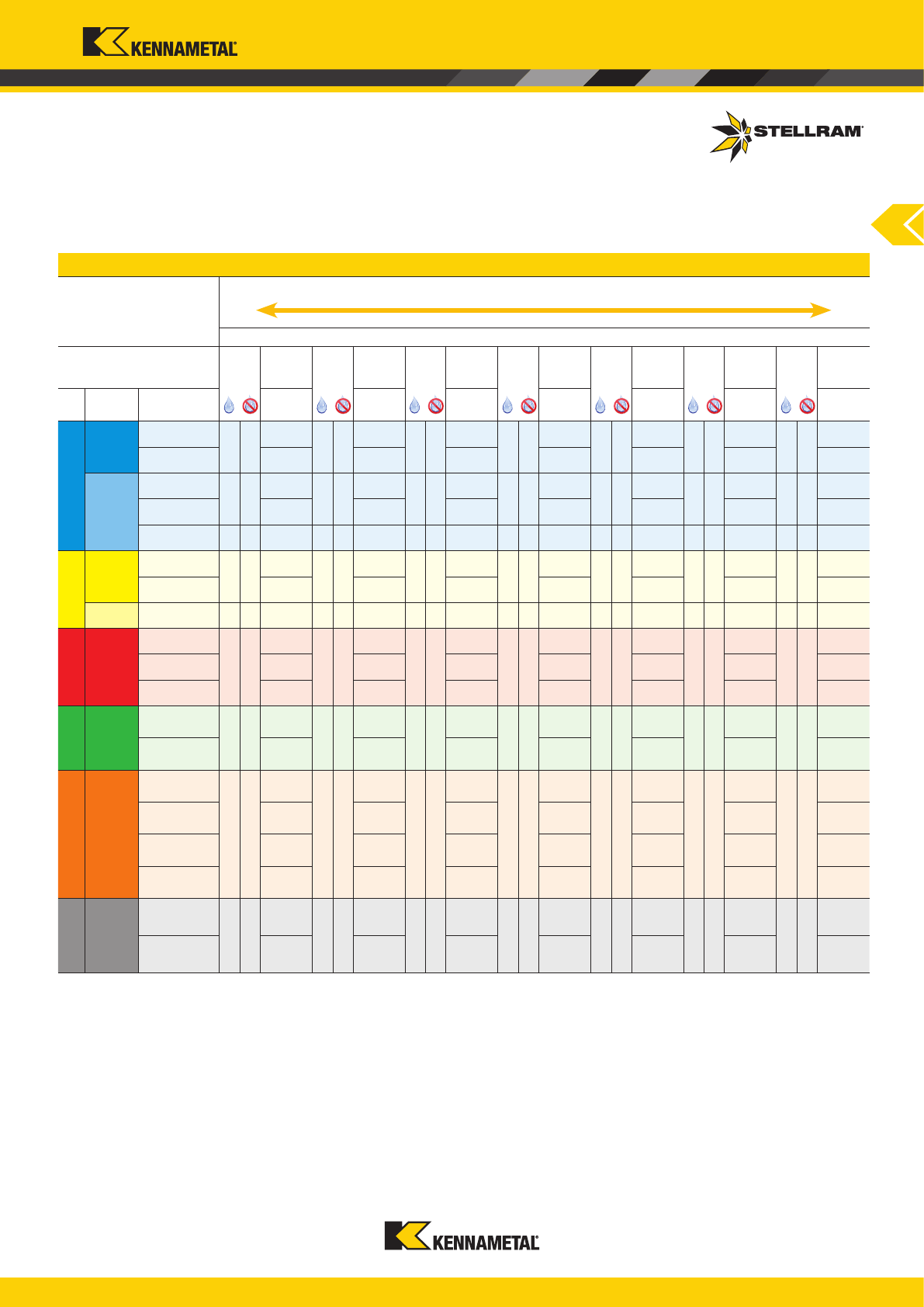

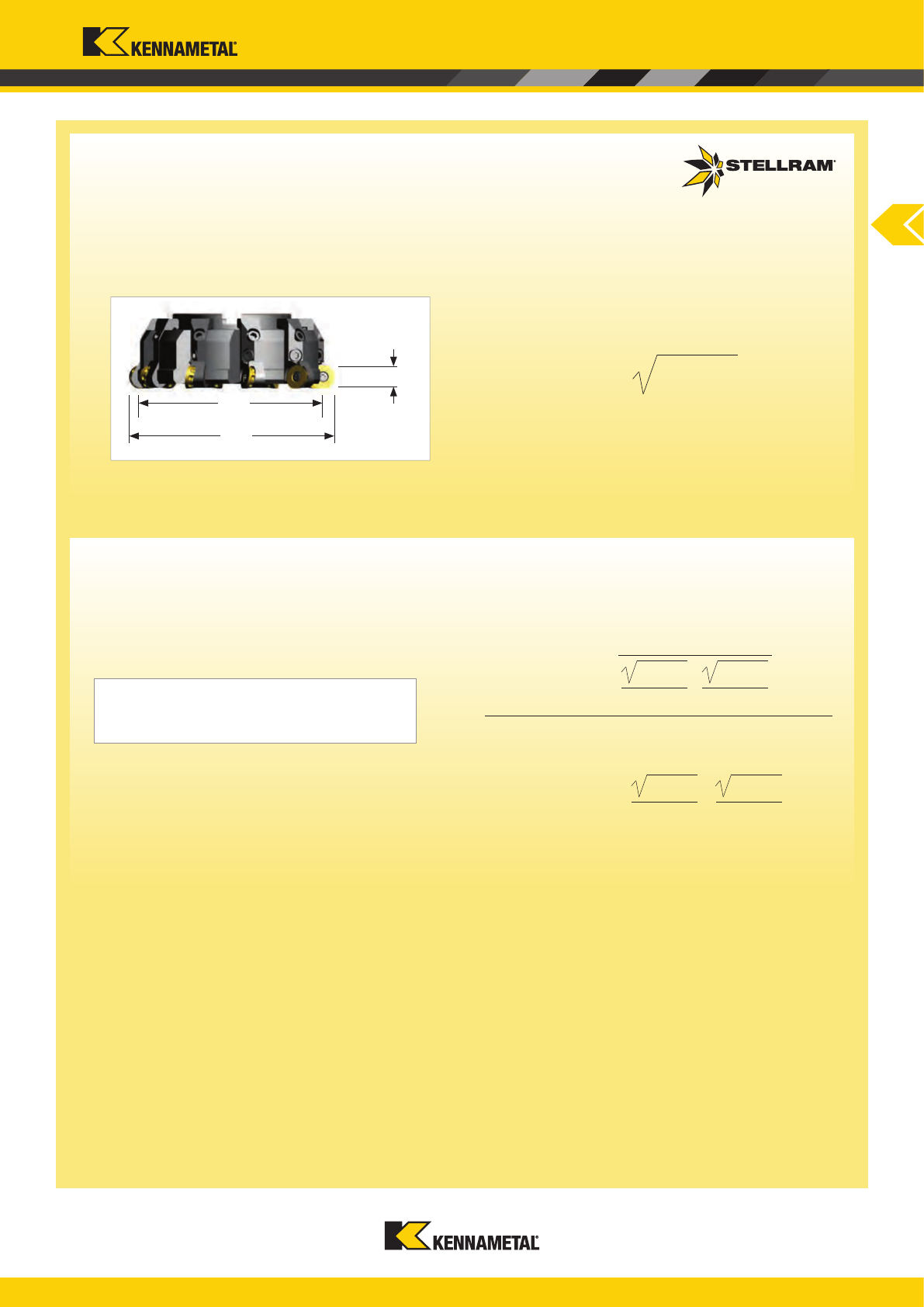

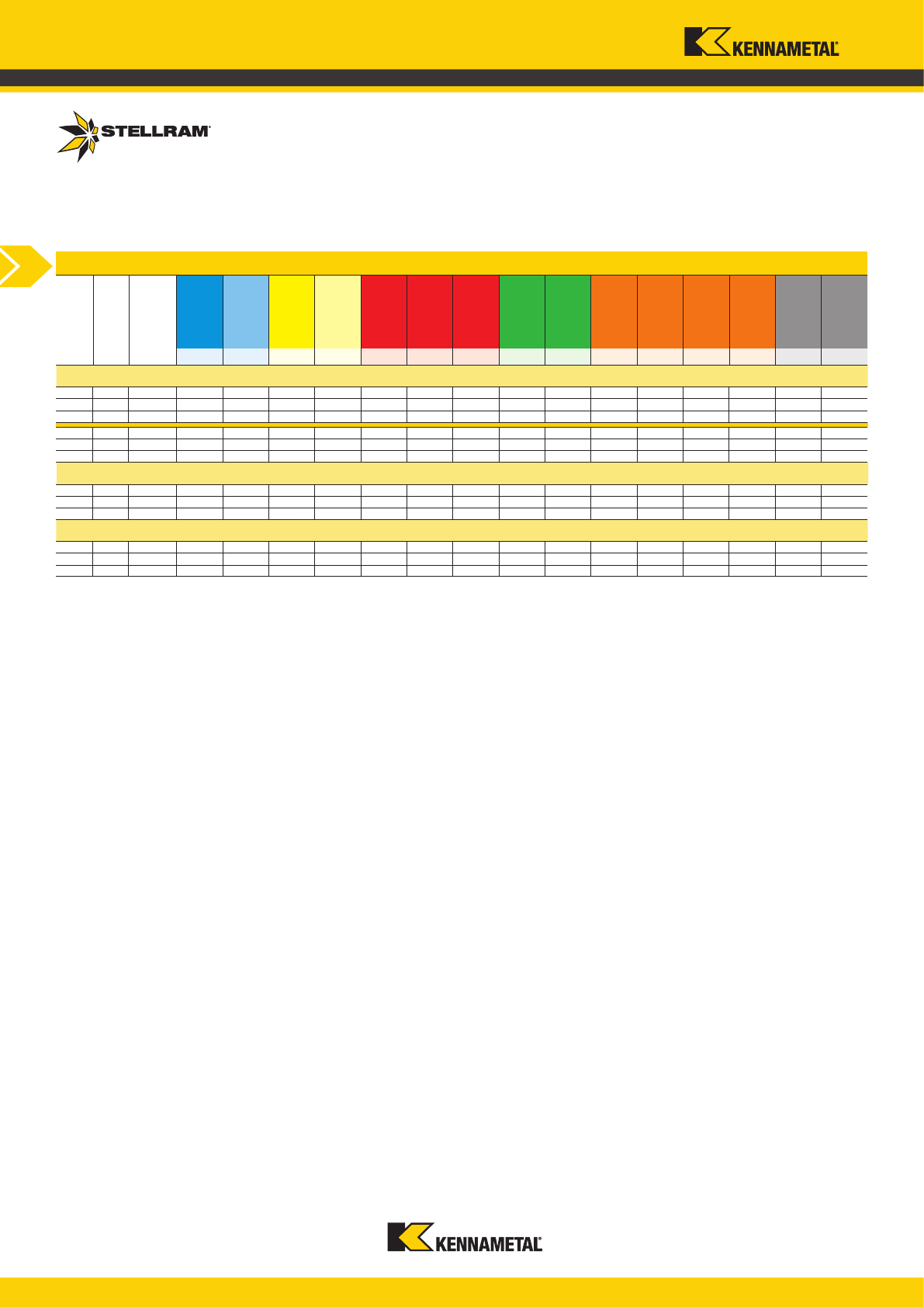

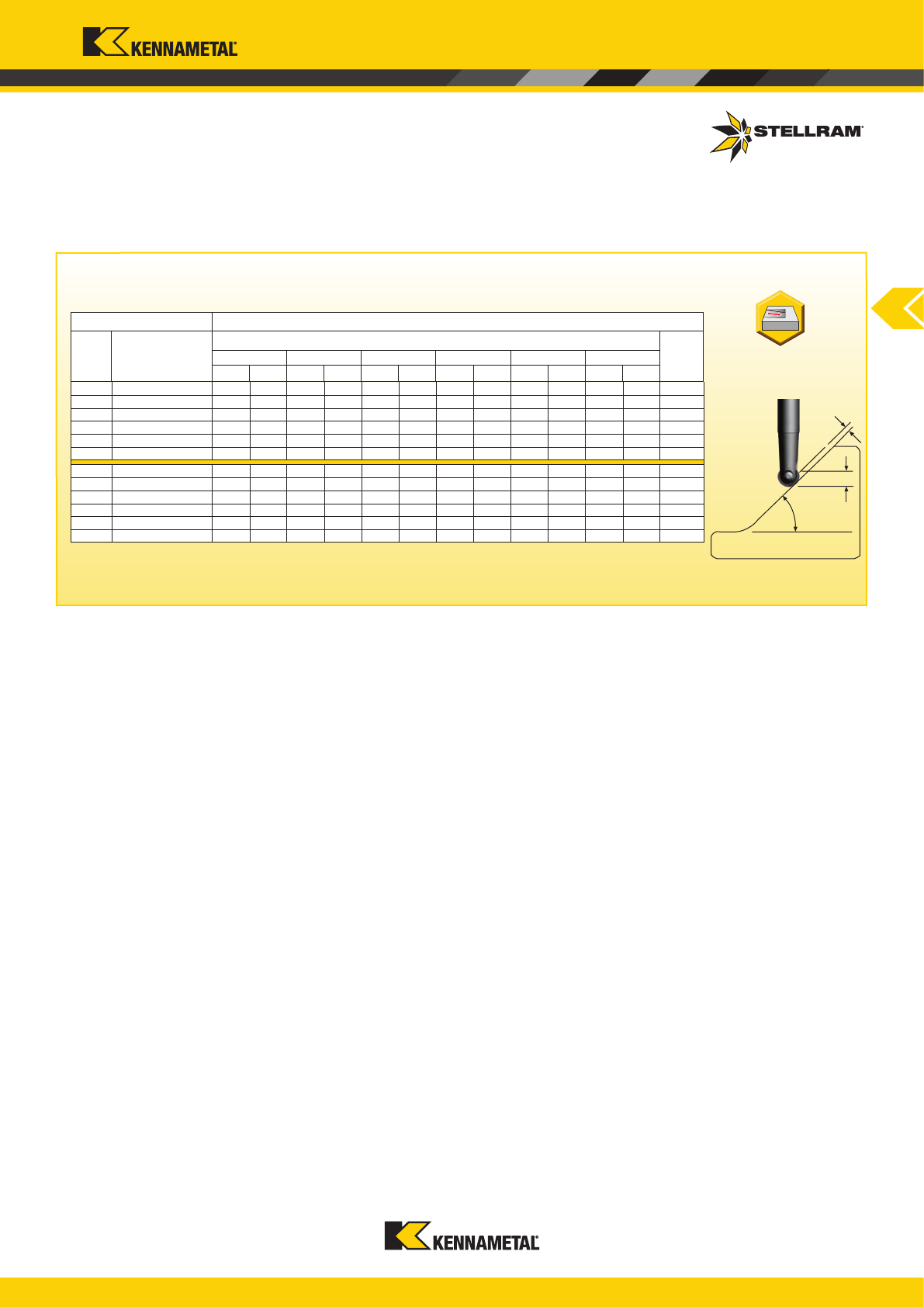

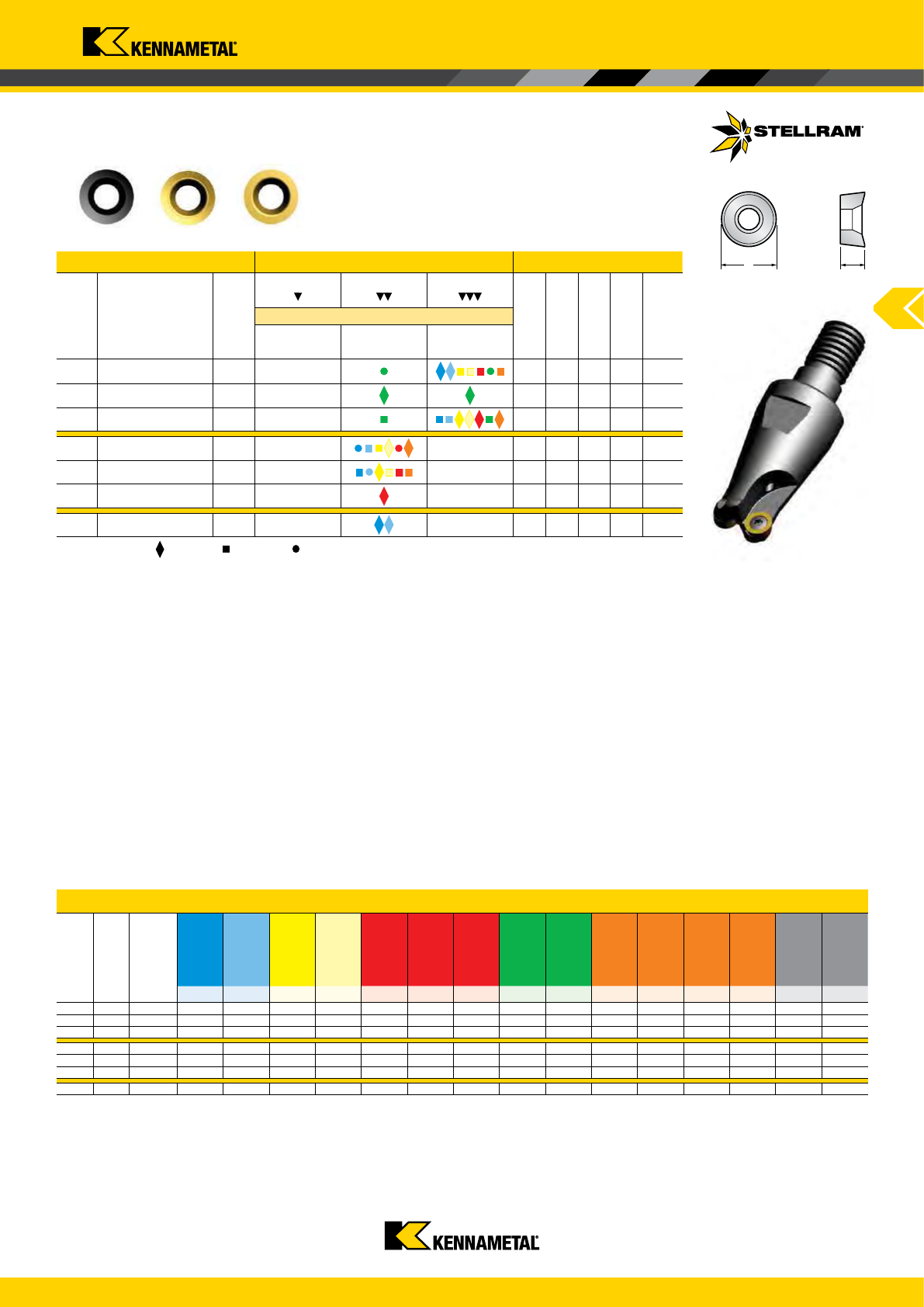

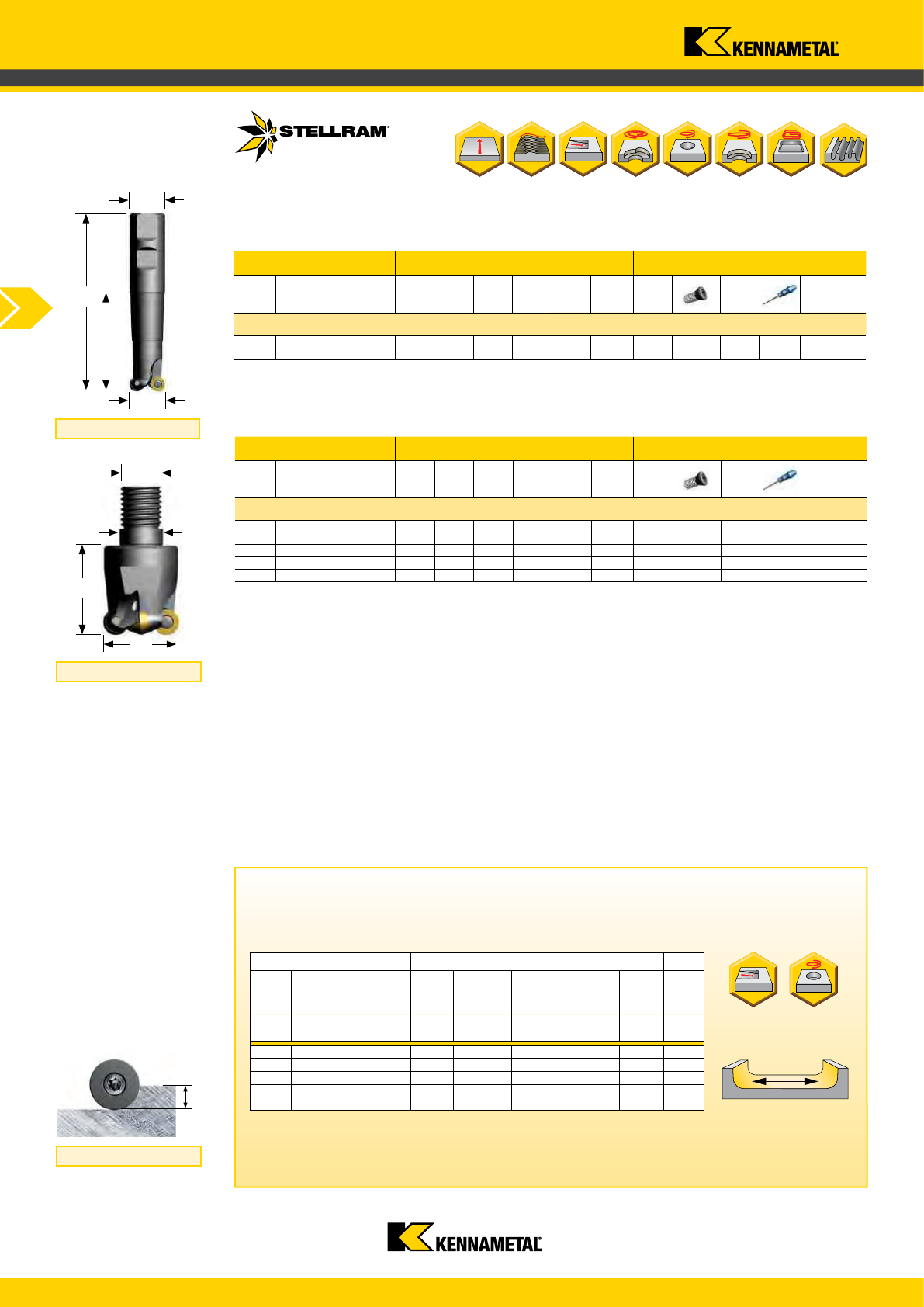

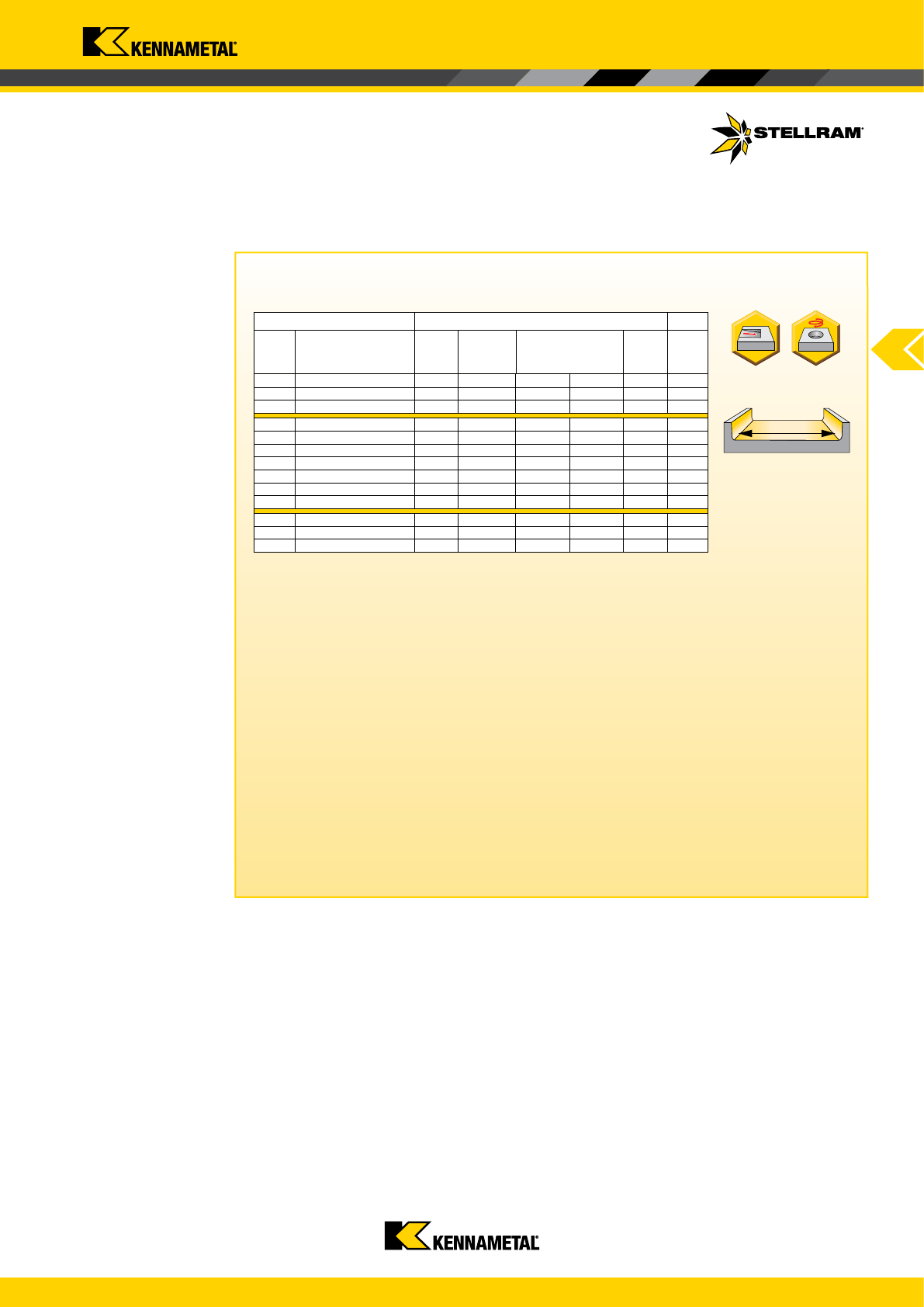

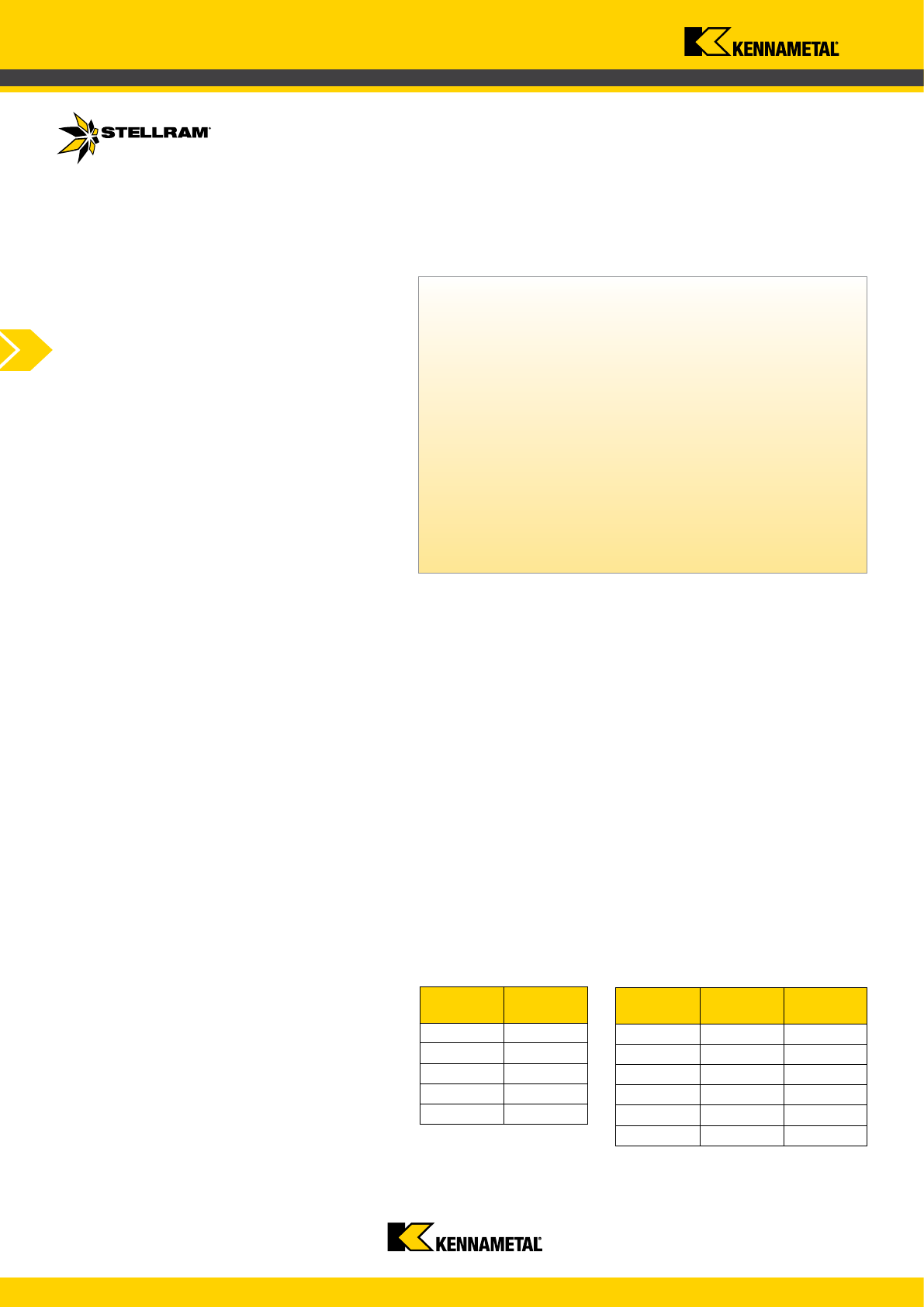

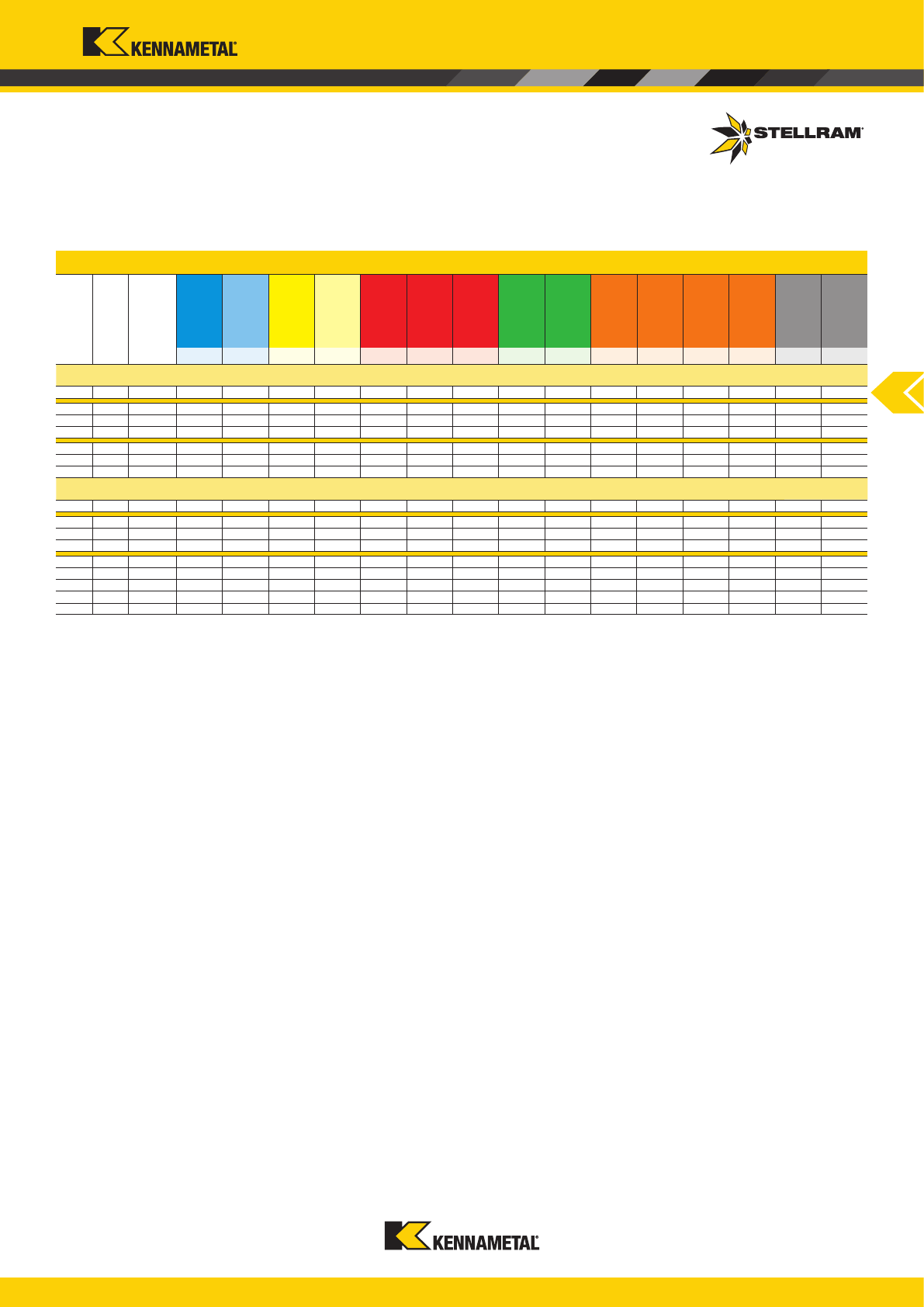

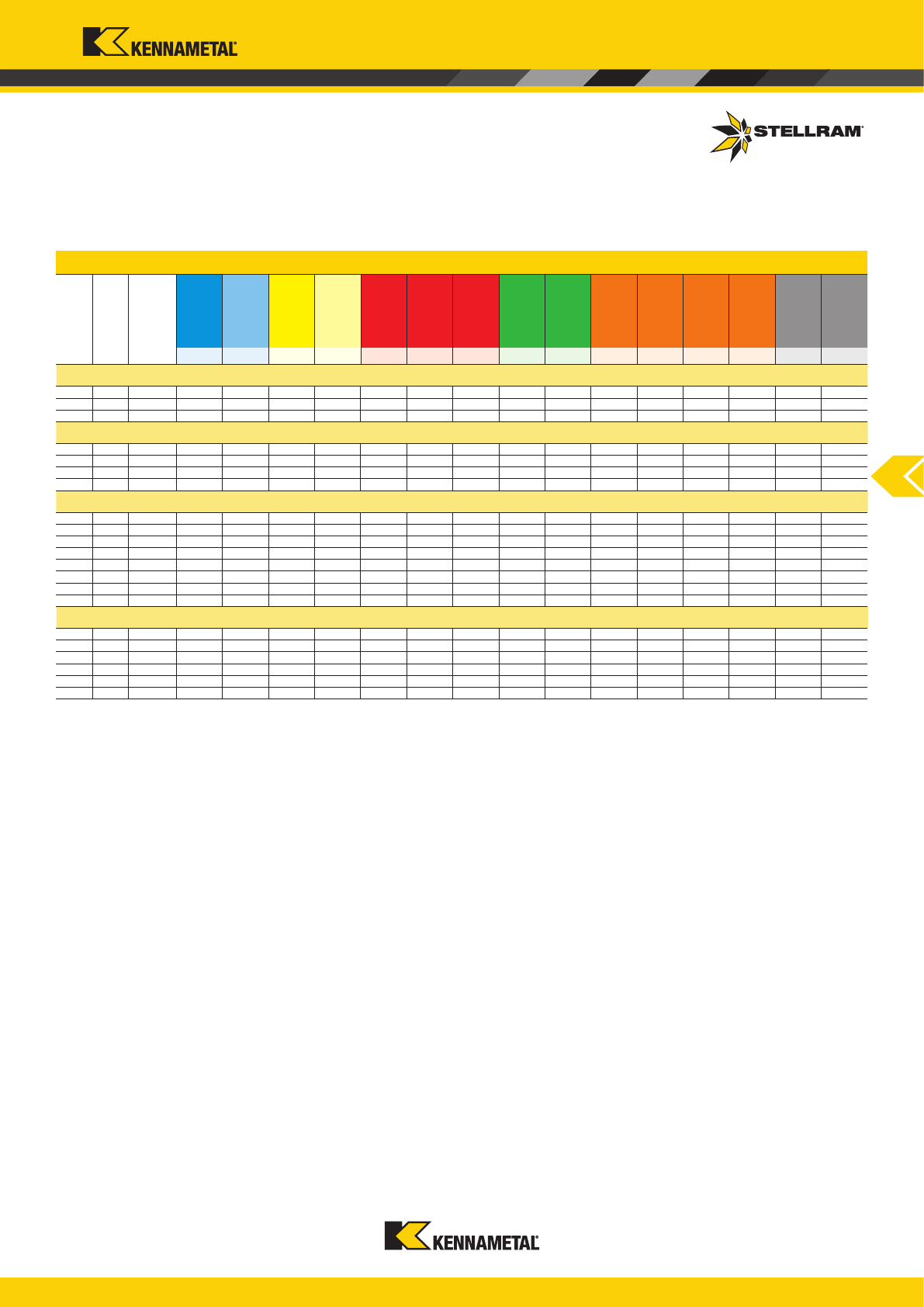

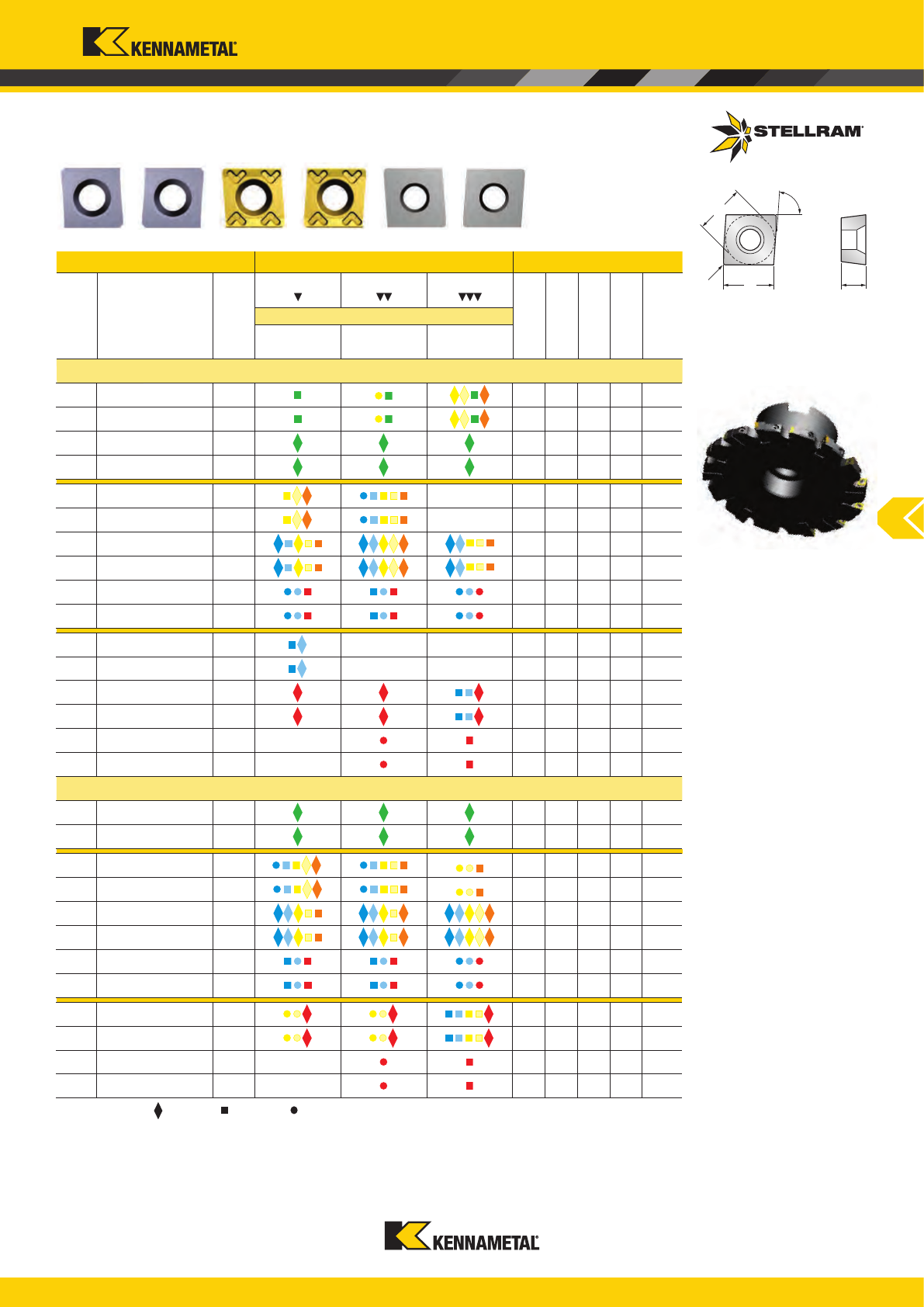

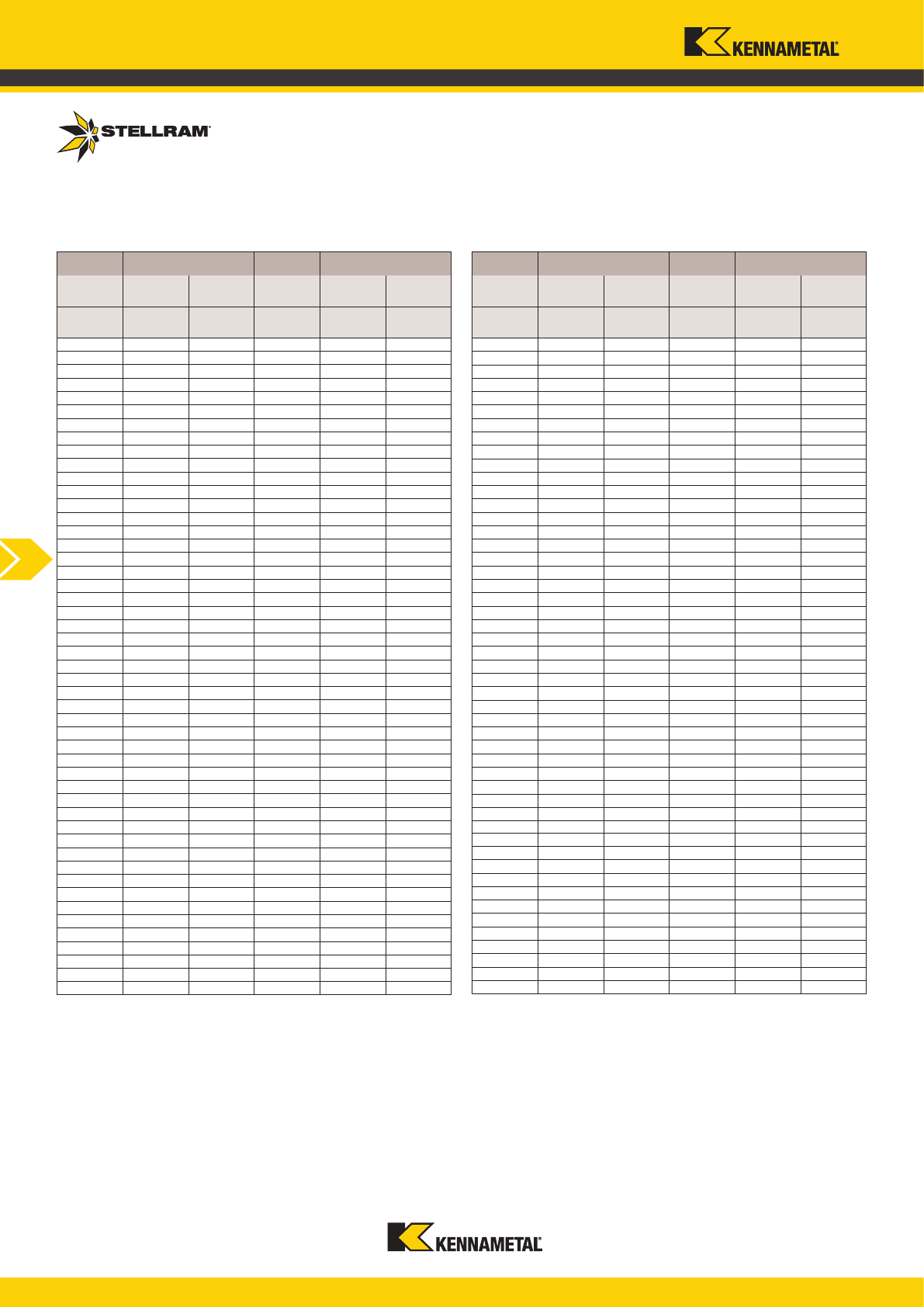

Product Application & Material Dimensions (mm)

EDP Item DescriptionGrade

Facing Slotting Plunging

d (IC)l srh

m

min

Depth of Cut (mm)

a

p

max. 1,50 a

p

max. 1,50 a

e

max. 6,00

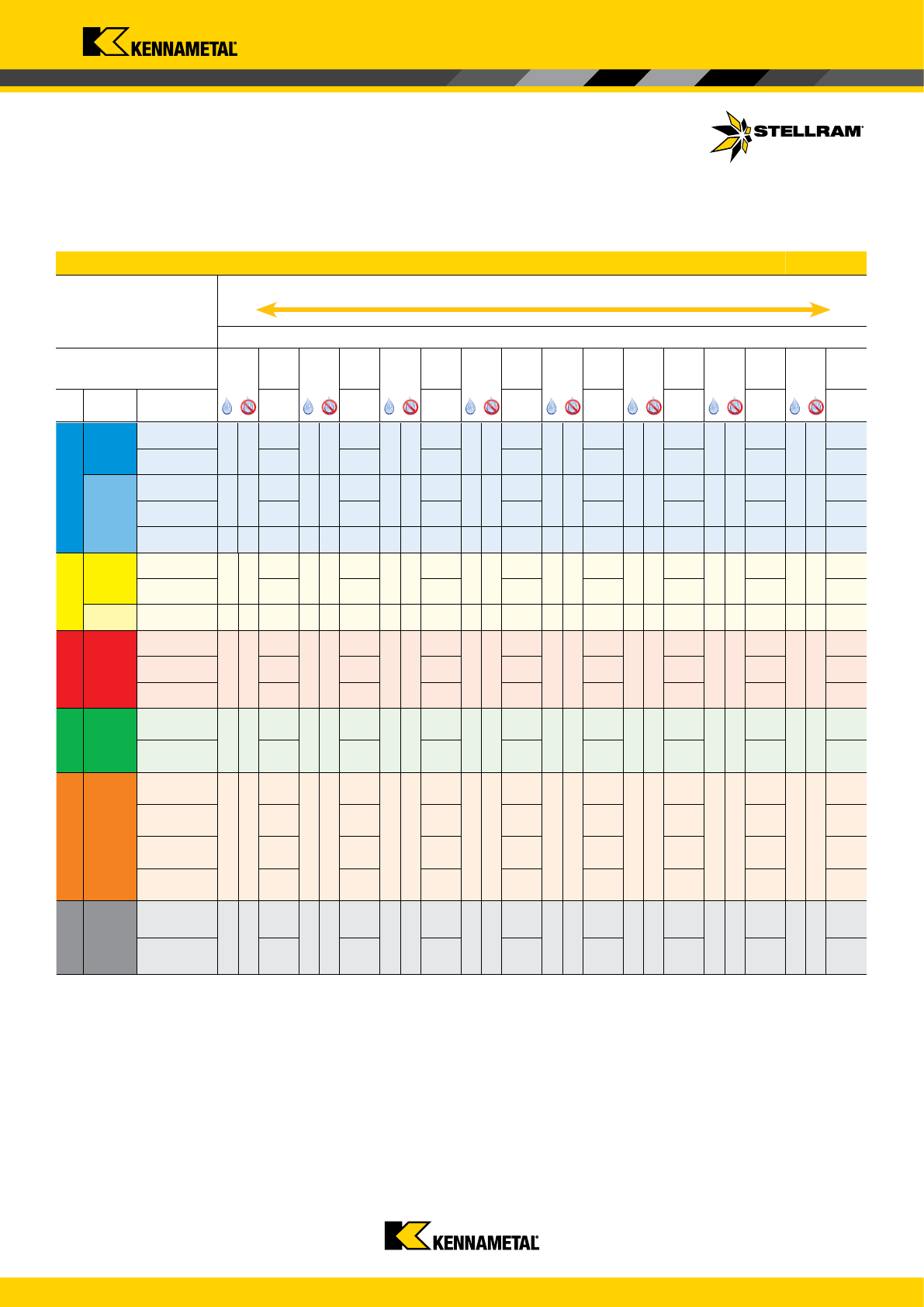

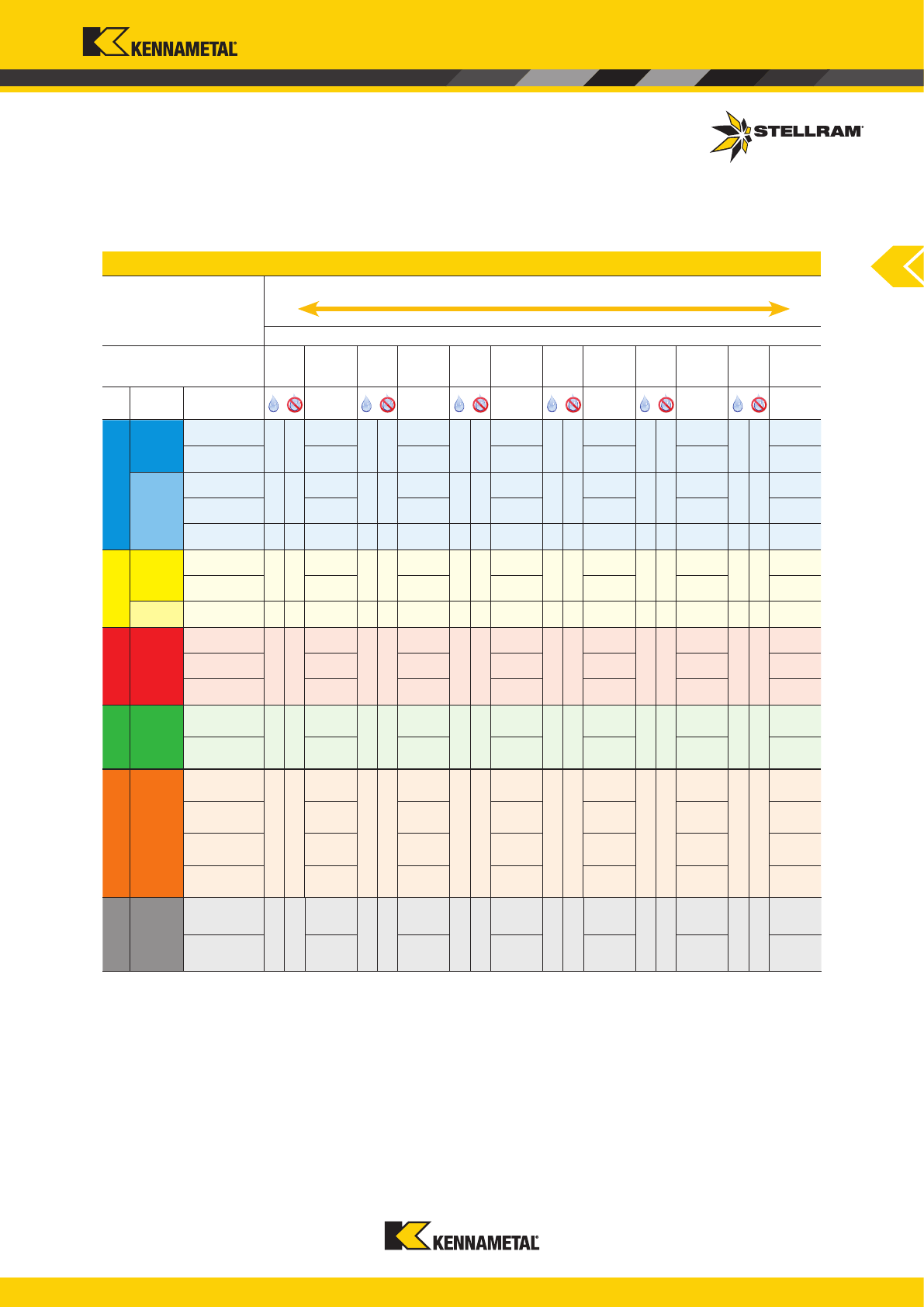

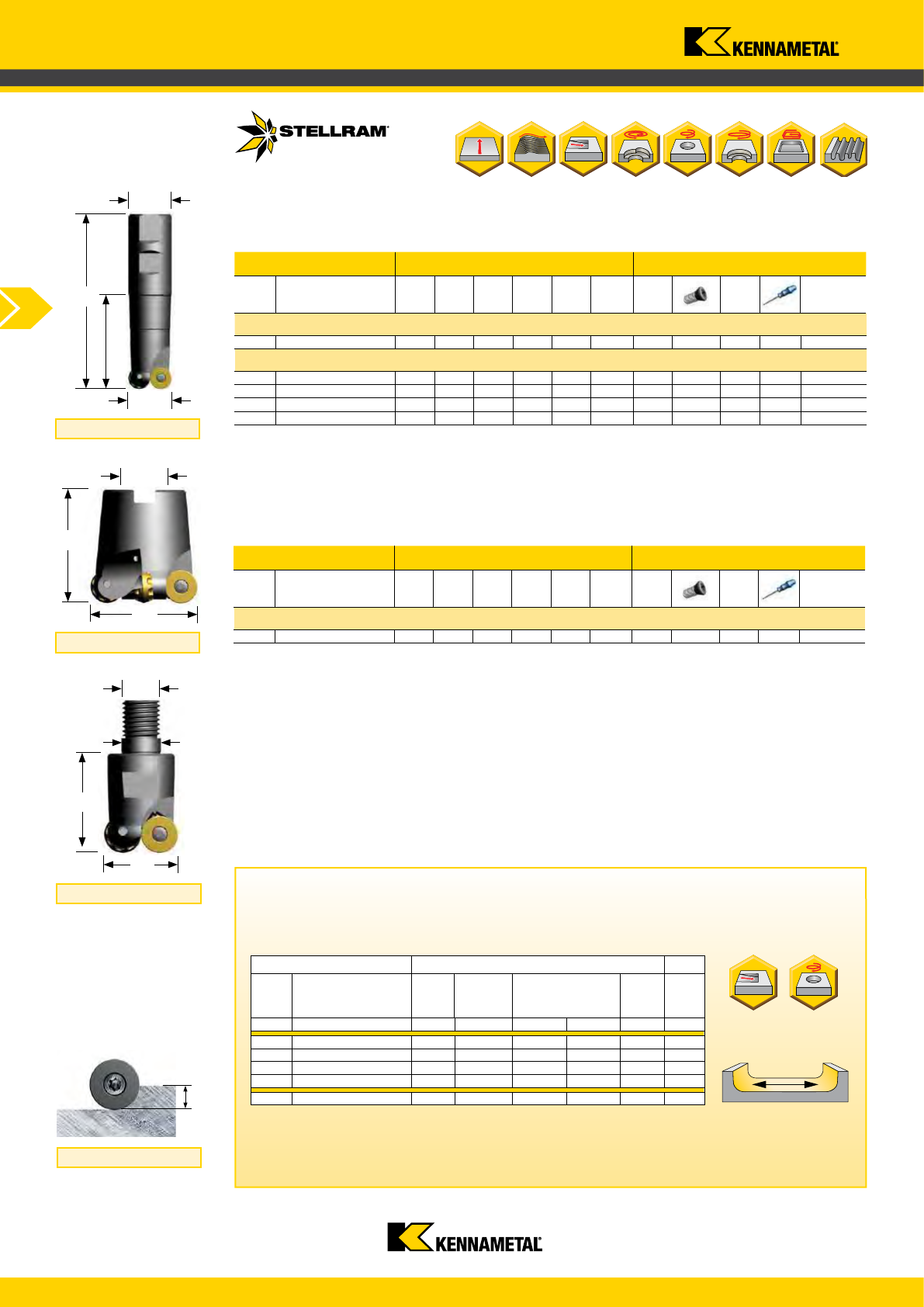

7792VXD09 Feeds f

z

(mm/tooth)

Geometry

Grade

Operation

Unalloyed

Steel

Alloyed

Steel

Stainless

Steel

Stainless Steel

Refractory PH

Gray

Iron

Spheroidal-

Ductile Iron

Malleable

Iron

Aluminium &

Alloys

<16% Si 116 HBN

Aluminium &

Silicon

>16% Si 92 HBN

HTA Iron

Based Alloys

HTA Cobalt

Based Alloys

HTA Nickel

Based Alloys

HTA Titanium

Based Alloys

Hard Steel

>1400 N/mm

2

>415 HBN

Chilled Cast Iron

>1400 N/mm

2

>400 HBN

Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max.

Note: HTA = High Temperature Alloys

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Machining Choice: 1

st

Choice 2

nd

Choice 3

rd

Choice | Material Guide Key descriptions found on page A5.

Note: Speed recommendations can be found on page A72.

XDLW090408SR-D X500 should be used for Alloyed Steel and Stainless Steel with heavy scale.

XDLT090412ER-D411 is a more positive geometry than the -D-41 with a larger radius which increases performance during

smaller radial engagements or where chipping may occur when using the -D-41 geometry.

XDLT090412ER-D411 uses less power than the -D-41 geometry.

7792VXD09

Milling Inserts & Recommended Feeds

Example:

Material: Alloyed Steel

facing operation

XDLW090408SR-D X400

1st Choice grade /

geometry

Select the recommended Feed range

according to the operation and the

material to be machined.

Example:

Feed range for

XDLW090408SR-D X400

for Facing in Alloyed Steel

0,30 – 1,90 mm/tooth

Select the Insert according to the

application and material to be machined.

Application Section

• Facing, Semi-Finishing and Finishing

Or

• Facing, Slotting and Plunging

(7792VX series)

Material to be machined

For each insert, a colored symbol will

advise you about the performance, as well

as the materials which can be machined.

The color of the symbol corresponds to

the ISO Material designation.

Symbol explanation:

1st choice: Excellent performance

2nd choice: Good performance

3rd choice: Alternative option

ISO Material designation:

6 Step Tool Selection (continued)

Tooling Selection Guide

Cutters, Inserts & Cutting Parameters

Material Guide – Key to Recommended Inserts

Material Designation

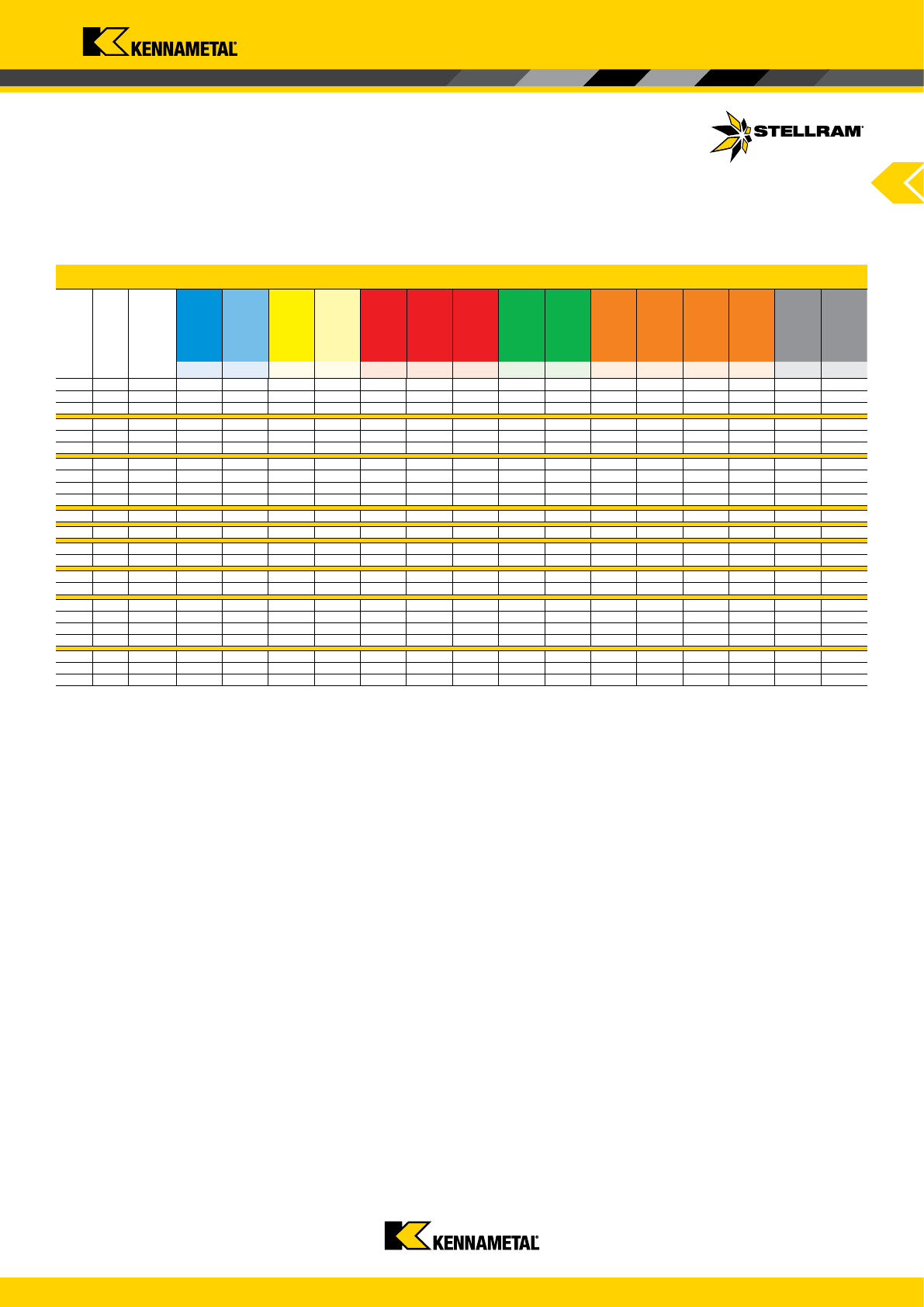

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

End Mills & Face Mills

Product Application & Material Dimensions (mm)

EDP Item DescriptionGrade

Facing Slotting Plunging

d (IC)l srh

m

min

Depth of Cut (mm)

a

p

max. 1,50 a

p

max. 1,50 a

e

max. 6,00

7792VXD09 Feeds f

z

(mm/tooth)

Geometry

Grade

Operation

Unalloyed

Steel

Alloyed

Steel

Stainless

Steel

Stainless Steel

Refractory PH

Gray

Iron

Spheroidal-

Ductile Iron

Malleable

Iron

Aluminium &

Alloys

<16% Si 116 HBN

Aluminium &

Silicon

>16% Si 92 HBN

HTA Iron

Based Alloys

HTA Cobalt

Based Alloys

HTA Nickel

Based Alloys

HTA Titanium

Based Alloys

Hard Steel

>1400 N/mm

2

>415 HBN

Chilled Cast Iron

>1400 N/mm

2

>400 HBN

Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max. Min. - Max.

Note: HTA = High Temperature Alloys

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

Facing

Slotting

Plunging

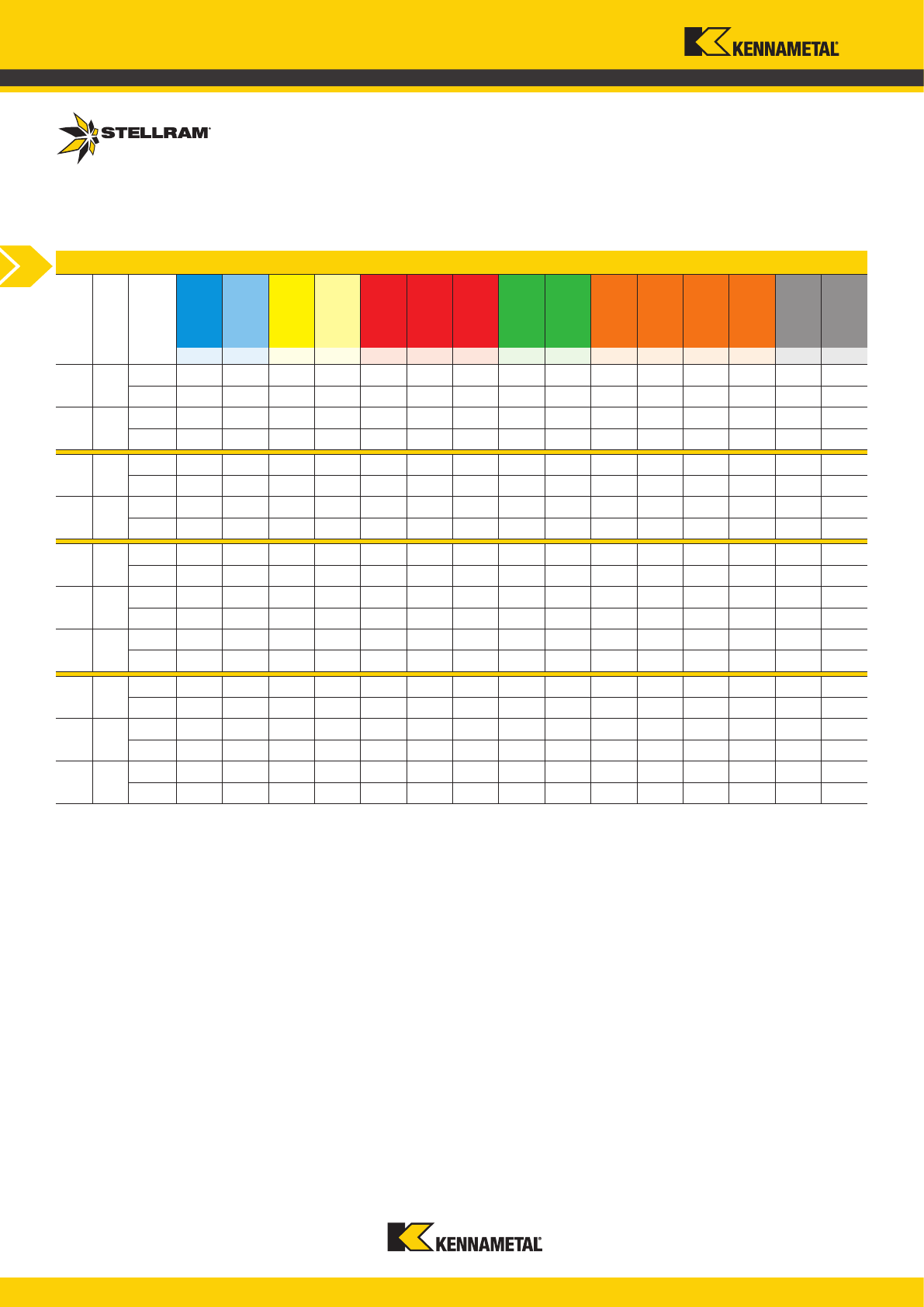

Machining Choice: 1

st

Choice 2

nd

Choice 3

rd

Choice | Material Guide Key descriptions found on page A5.

Note: Speed recommendations can be found on page A72.

XDLW090408SR-D X500 should be used for Alloyed Steel and Stainless Steel with heavy scale.

XDLT090412ER-D411 is a more positive geometry than the -D-41 with a larger radius which increases performance during

smaller radial engagements or where chipping may occur when using the -D-41 geometry.

XDLT090412ER-D411 uses less power than the -D-41 geometry.

7792VXD09

Milling Inserts & Recommended Feeds

www.kennametal.com

A4

www.kennametal.com

A74

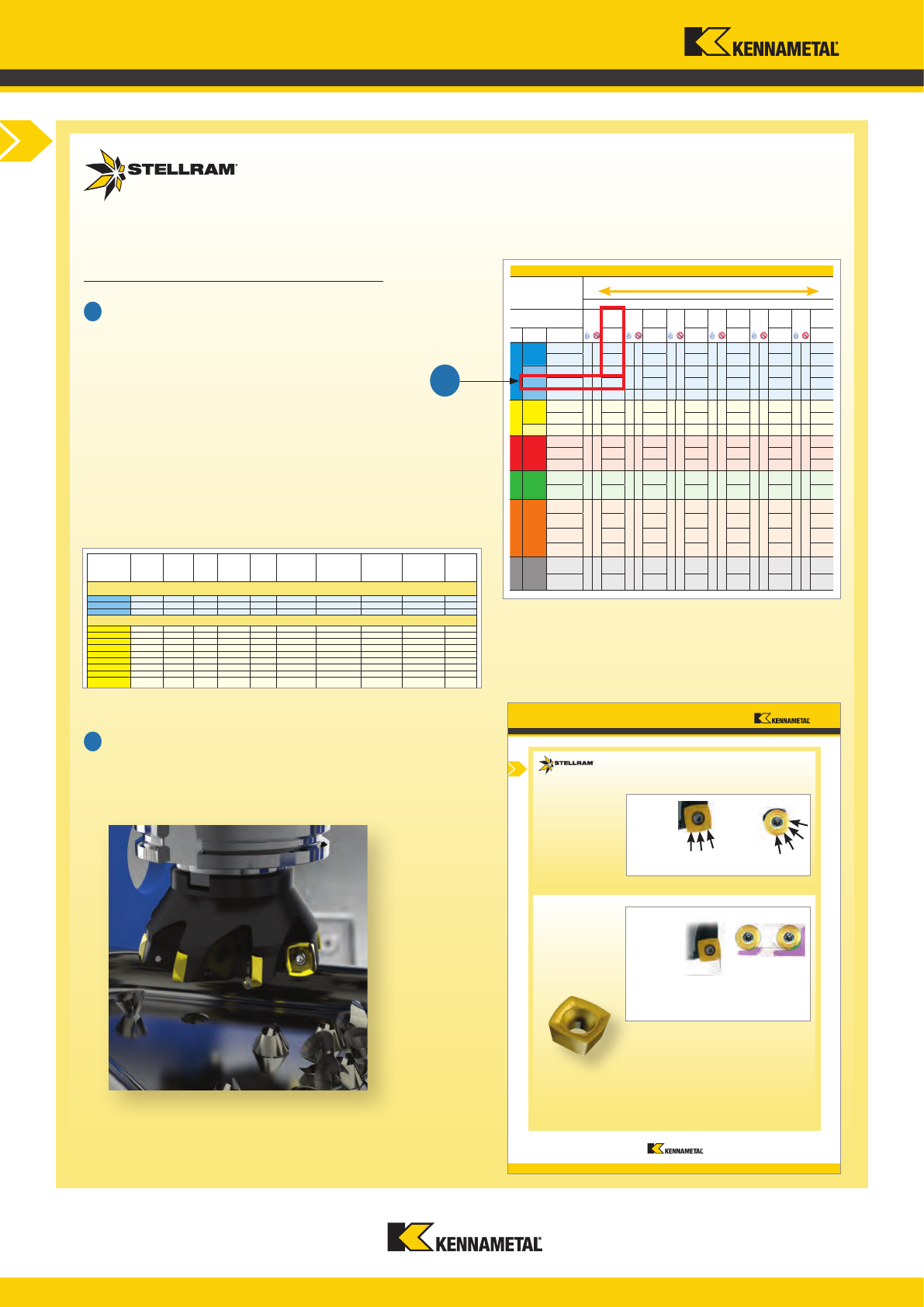

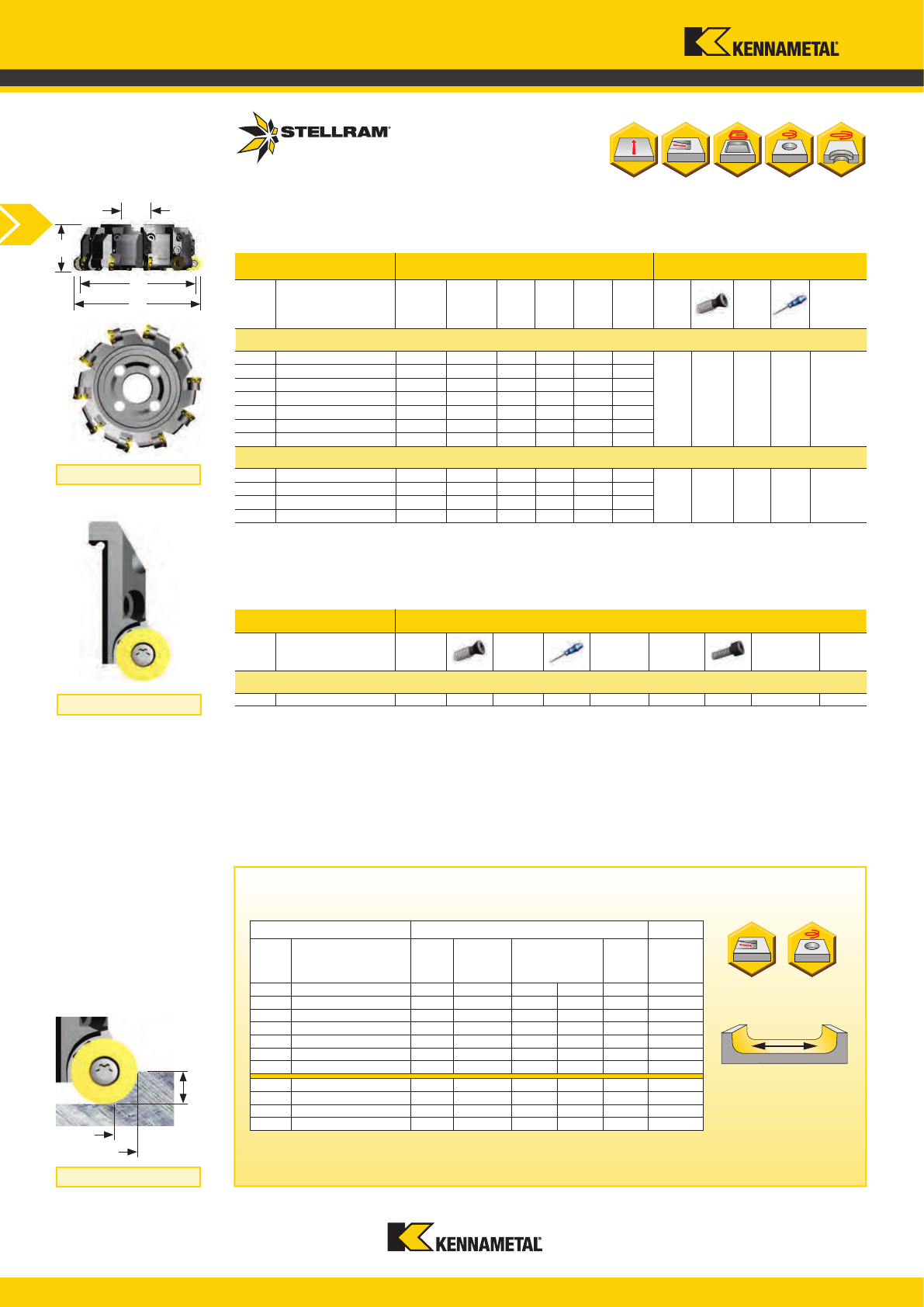

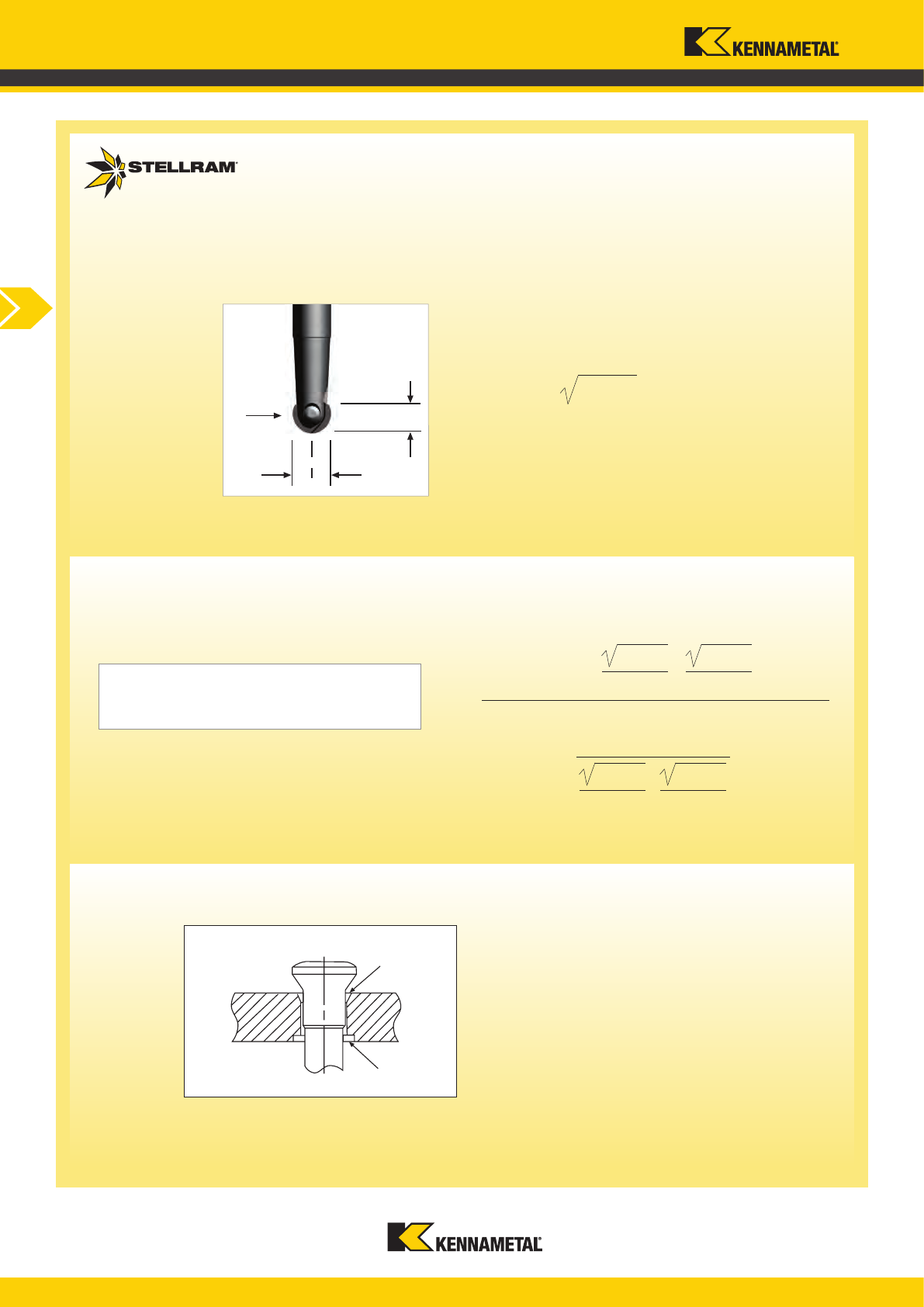

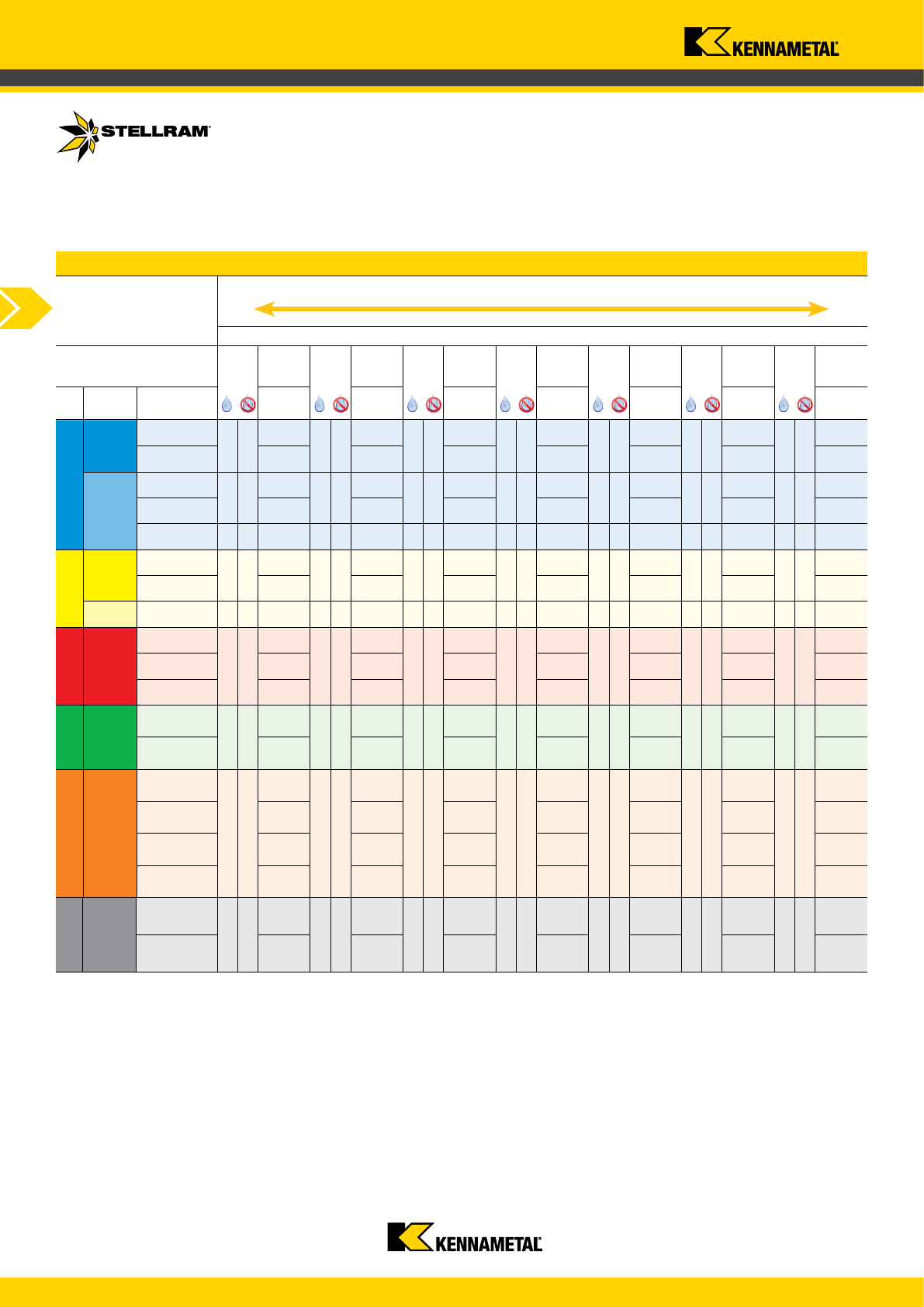

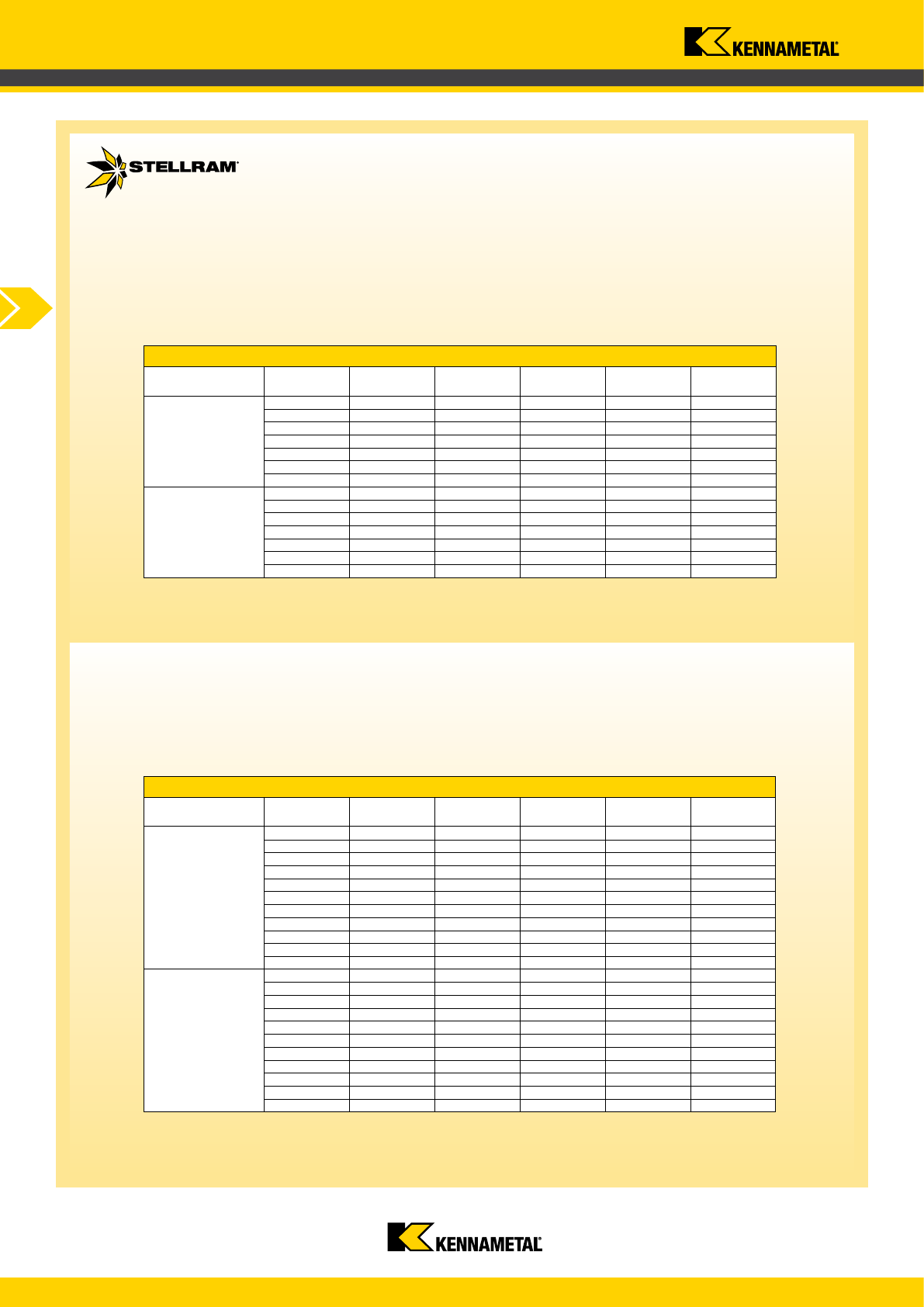

5

5

6

T4 / Z80WKCV18050401 BT4 T4 1.3255 S18.1.2.5 Z80WKCV18050401 X78WCo1805KU HS18.1.1.5 SKH3

Z2NKDT18-10-5 1.2709 X3NiCoMoTi18.9.5 Z2NKDT18-10-5

Z38CDV5-3 1.2367 X40CrMoV53 Z38CDV5-3 Z155CVD12-1

50 UNS S20910

202 284S16 202 1.4371 X3CrMnNiN18-8-7 Z8CMN18.08.05

215

284

301 2331 301 1.4310 X12CrNi17-7 Z12CN17.07 X12CrNi17 07 F.3517 SUS301

302 302S31 2330 302 1.4319 X12CrNi18-9 Z10CN18.09 X10CrNi18 09 F.314

303 303S21, 58M 2346 303 1.4305 X8CrNiS18-9 Z10CNF18.09 X10CrNiS 18.09 F.3508 SUS303

304 304S31, 58E 2332/2333 304 1.4350 X5CrNi18-9 Z6CN18.09 X5CrNi18 10 F.3551;F.3541;F.3504 SUS304

305 305S19 305 1.4312 X8CrNi18-12 X8CrNi1910 F.3503

311

315

316 316S33, 58J 2343 316 1.4401 X5CrNiMo17-13-3 Z6CND19.12.03 X5CrNiMo1713 F.3543 SUS316

317 317S16 317 1.4449 X5CrNiMo17-13

318 318 1.4583 X10CrNiMoNb18-12 Z6CNDNb17.13B X6CrNiMoNb17 13

320

321 UNS S32100 321S12, 58B 2337 321 1.4541 X10CrNiTi18-9 Z6CNT18.10 X6CrNiTi18 11 F.3553;F.3523 SUS321

325

326

329 2324 329 1.4460 X8CrNiMo27-5 Z5CND27.05AZ SUS329L

331

332

334 70334 X8CrNiAlTi20-20

347 UNS S34700 347S17, 58F 2338 347 1.4550 X10CrNiNb18-9 Z6CNNb18.10 X6CrNiNb18 11 F.3552;F.3524 SUS347

348 UNS S34800 1.4546 X5CrNiNb18-10 Z10CrNiNb18 10

394

403 403S17 2301 403 1.4000 X7Cr13 Z6C13 X6Cr13 F.3110 SUS403

409 409S19 409 1.4510 X6CrTi12 Z6CT12 X6CrTi12

410 410S21, 56A 2302 410 1.4006 X10Cr13 Z10C14 X12Cr13 F.3401 SUS410

416 416S21 2380 41600 1.4005 X12CrS13 Z11CF13 X12CrS13 F.3411 SUS416

420 420S37 2303 420 1.4021 X20Cr13 Z20C13 X20Cr13 F.5261

425

430 430S15, 60 2320 430 1.4016 X8Cr17 Z8C17 X8Cr17 F.3113 SUS430

431 431S29, 57 2321 431 1.4057

X22CrNi17 Z15CNi16.02 X16CrNi16 F.3427 SUS431

433

434 434S17 2325 434 1.4113 X6CrMo17 Z8CD17.01 X8CrMo17 SUS434

441

444 UNS S44400 2326 444 1.4521 Z3CDT18 02

452

455 UNS S45500

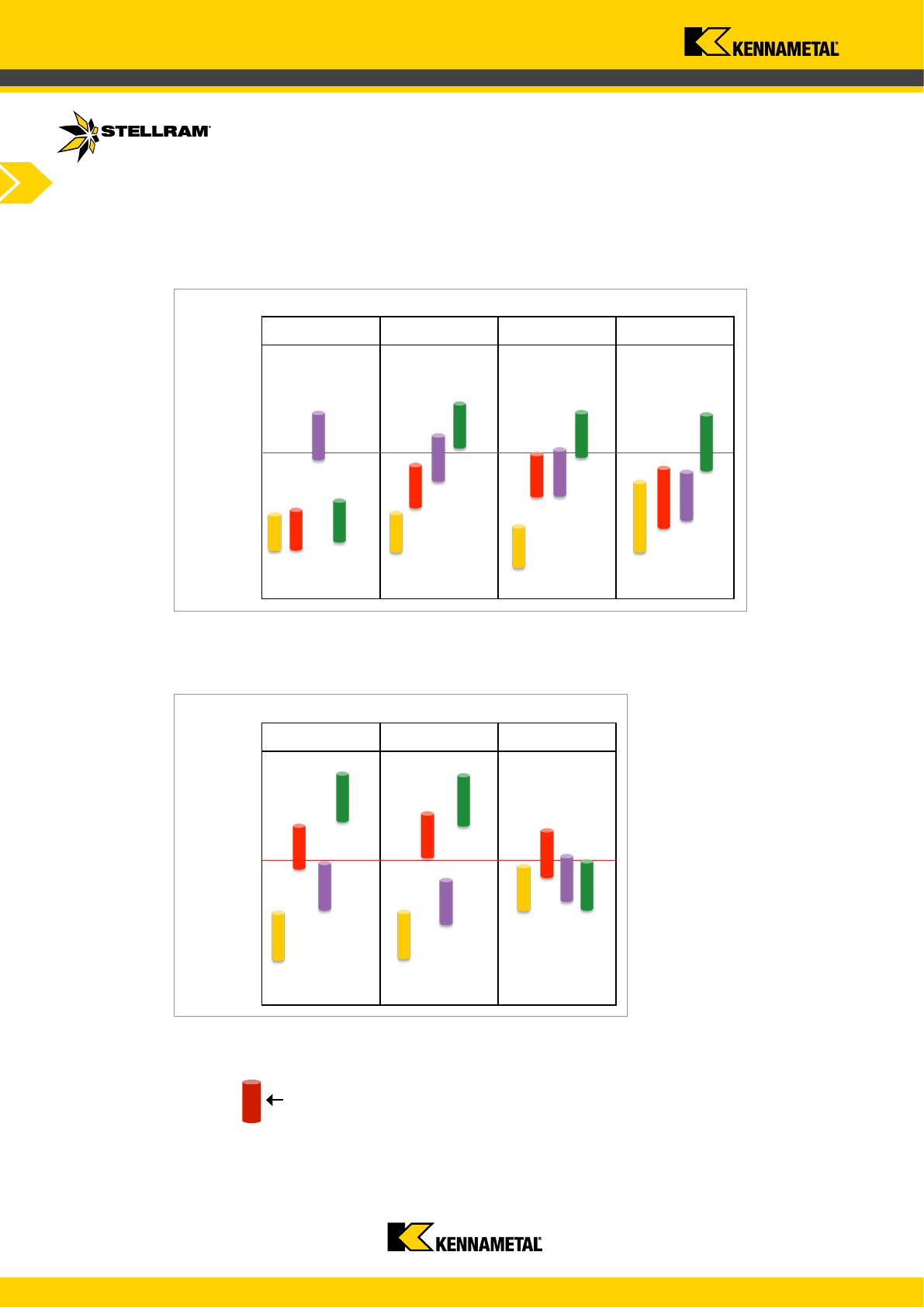

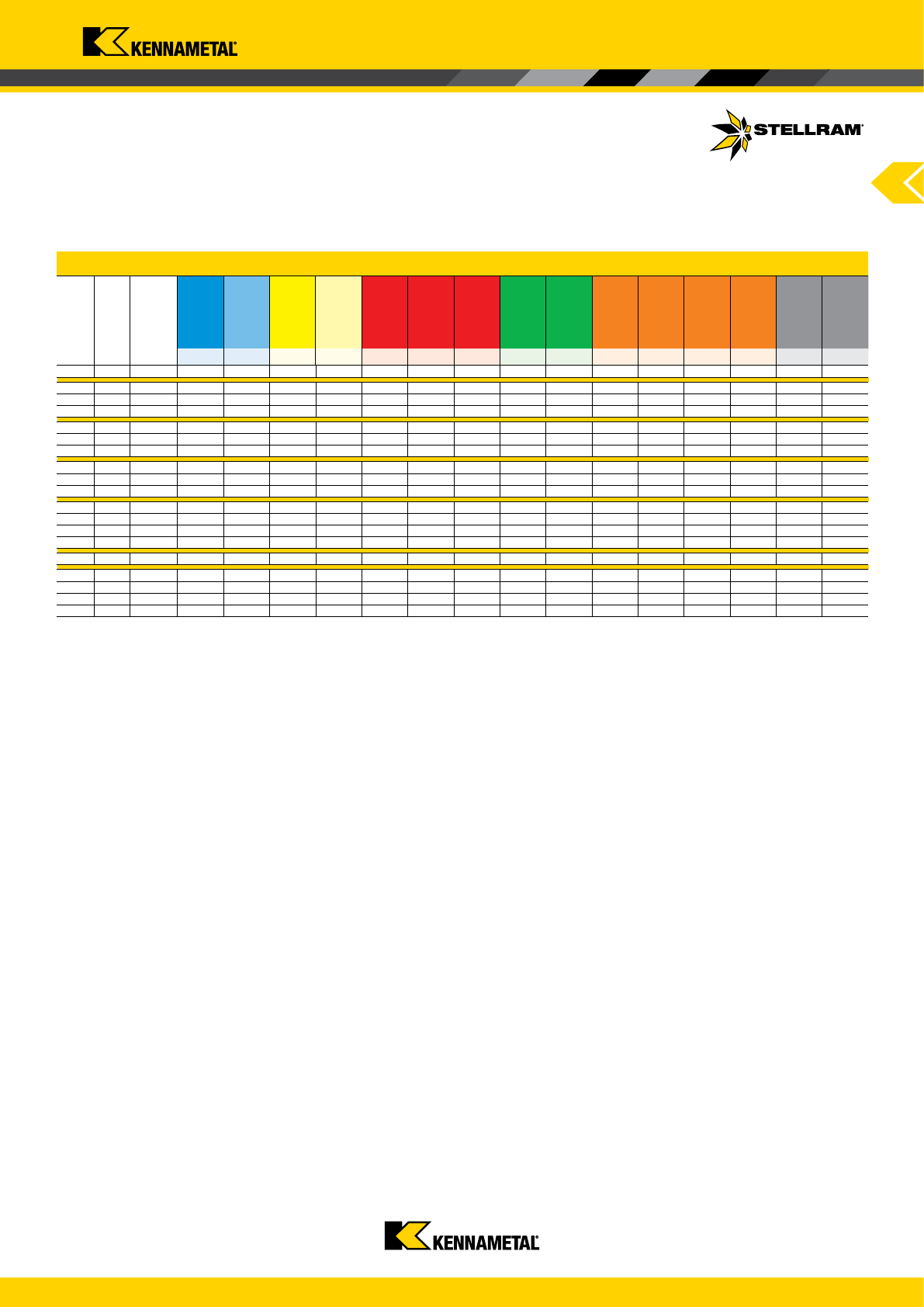

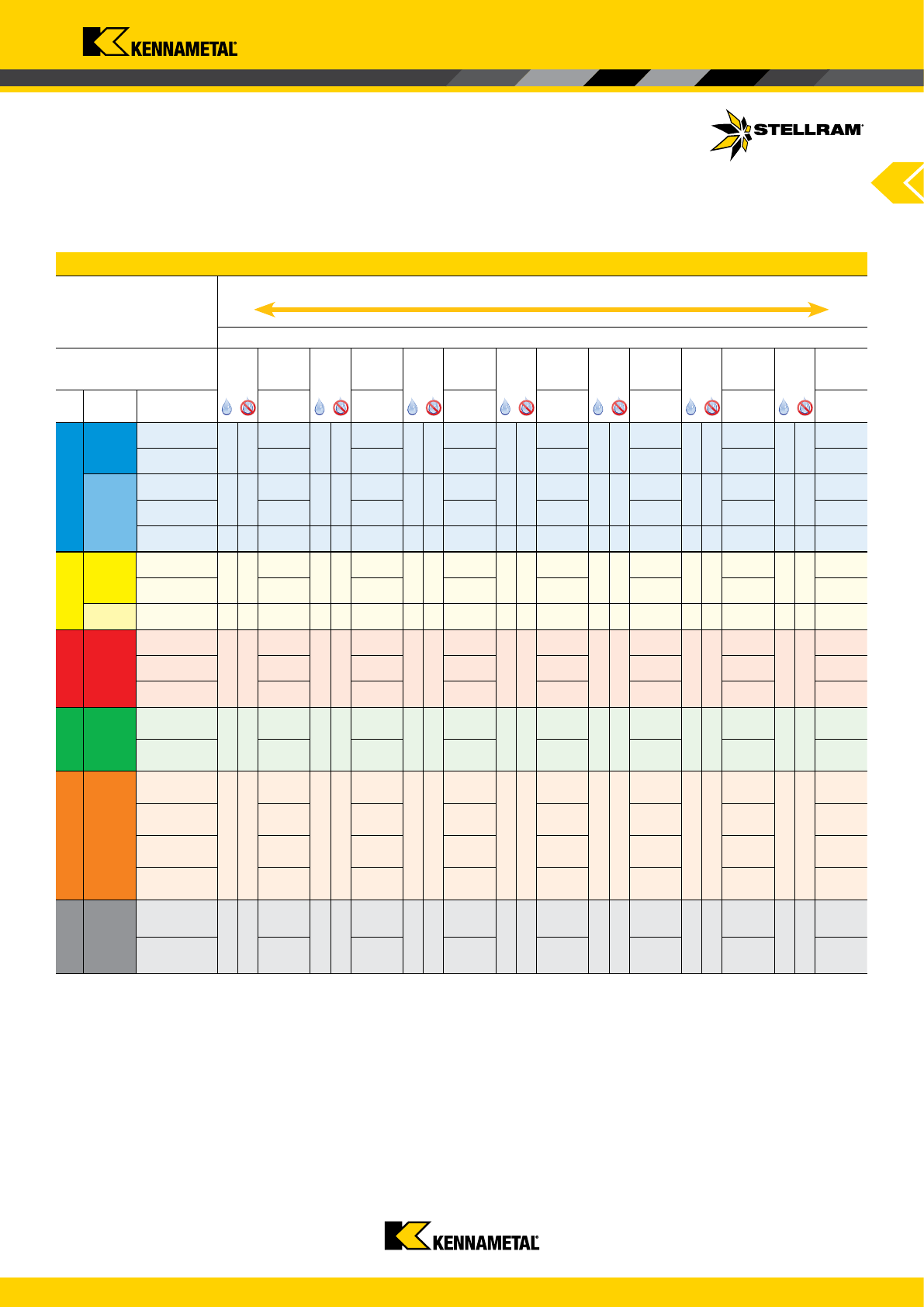

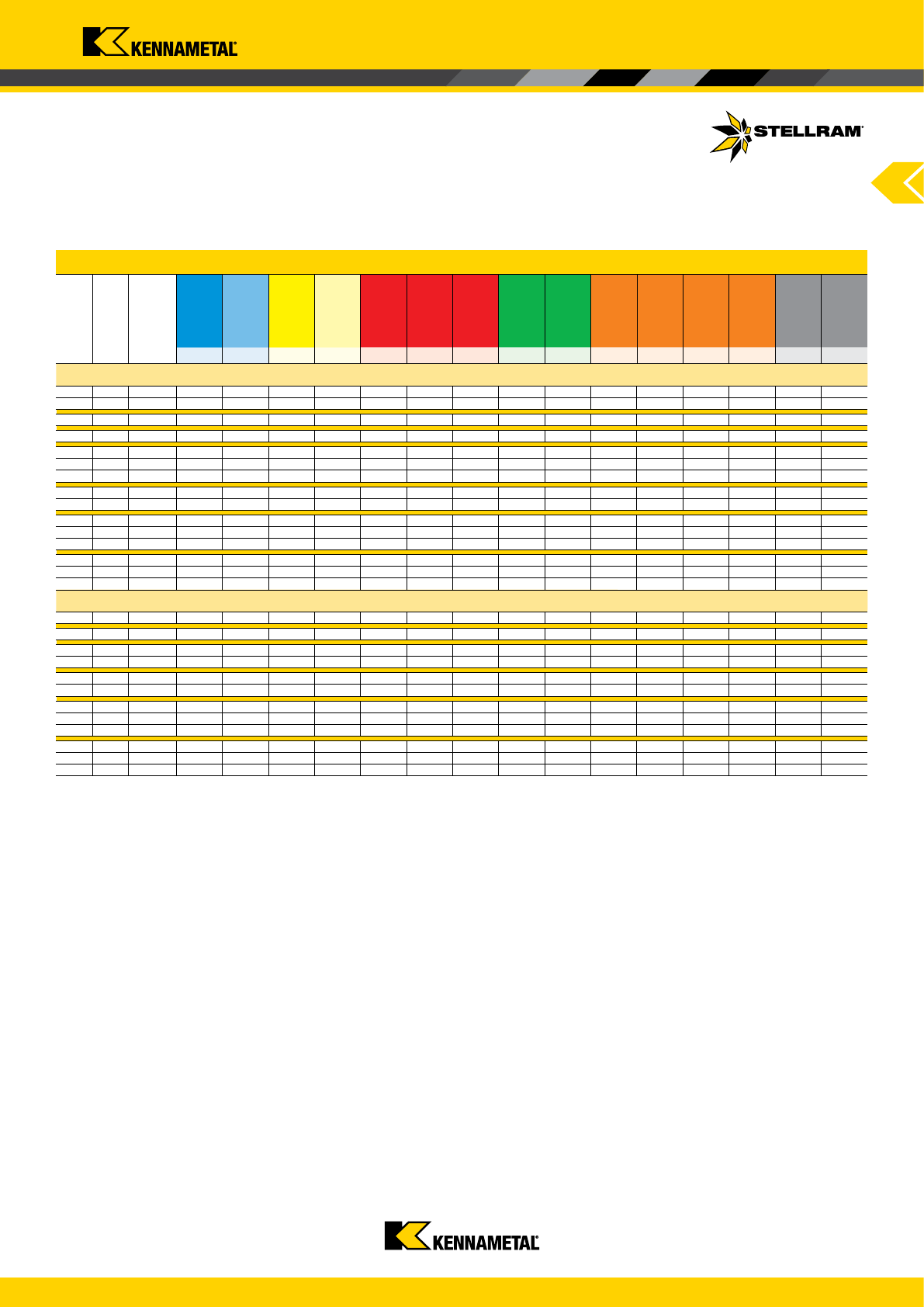

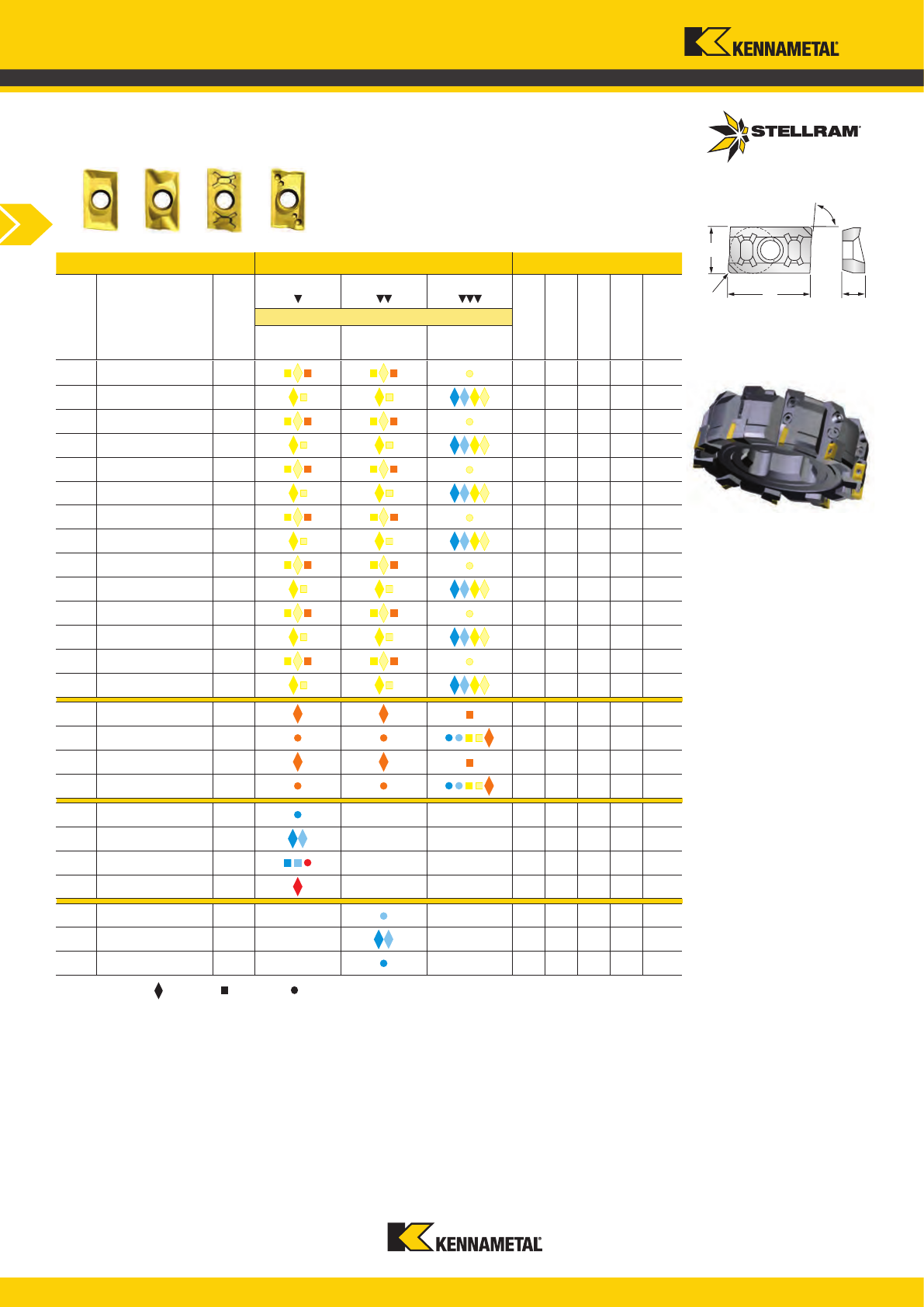

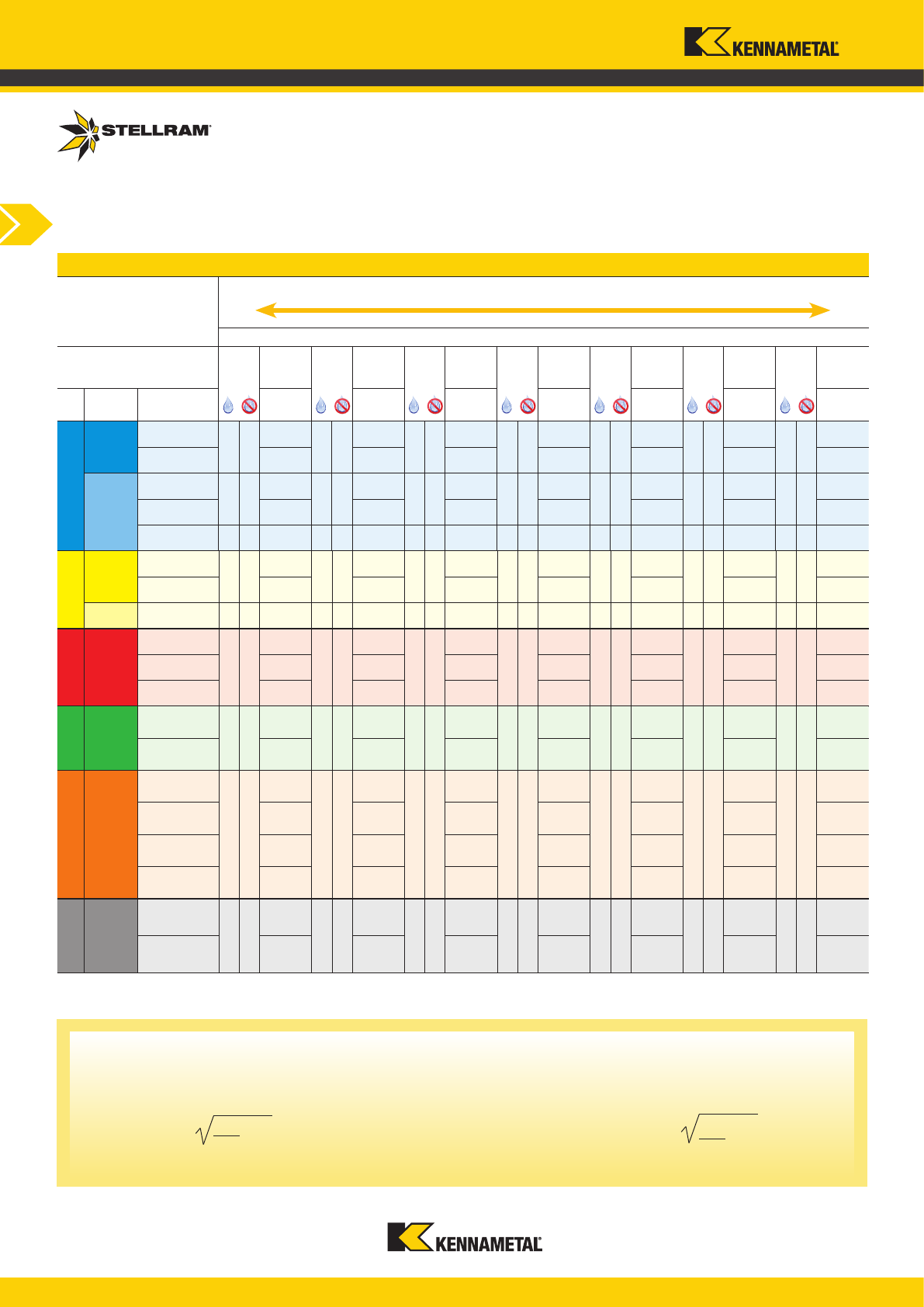

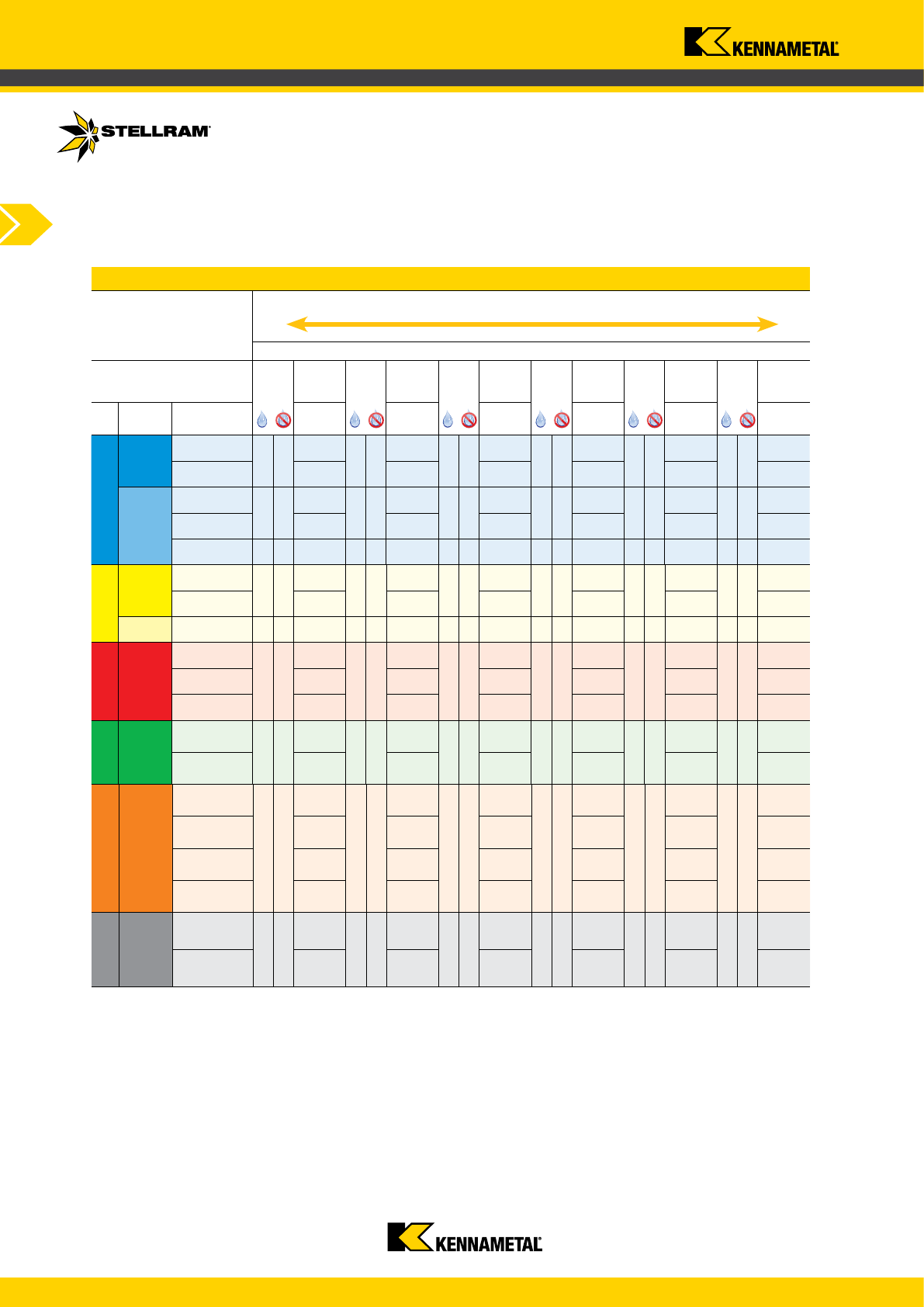

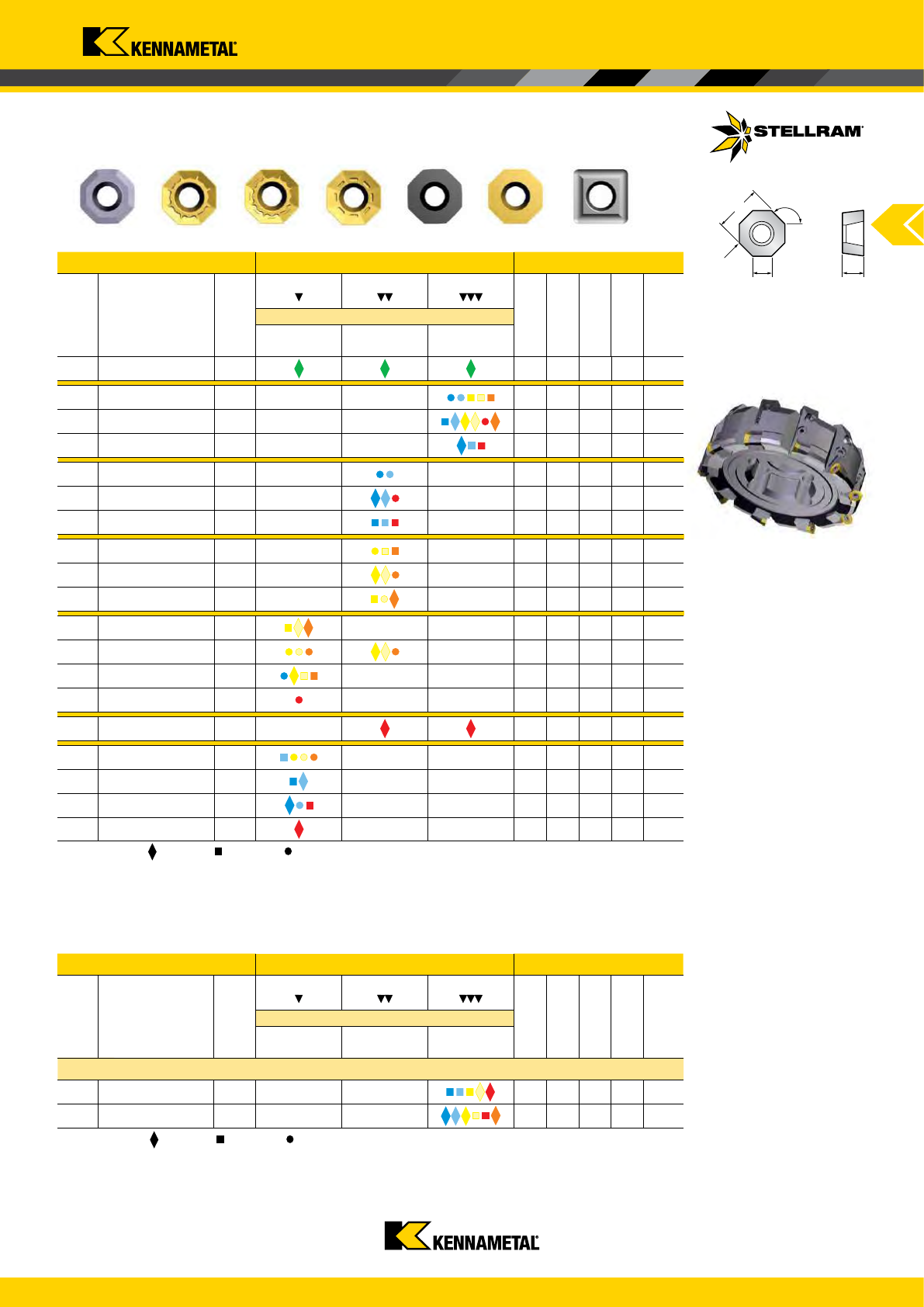

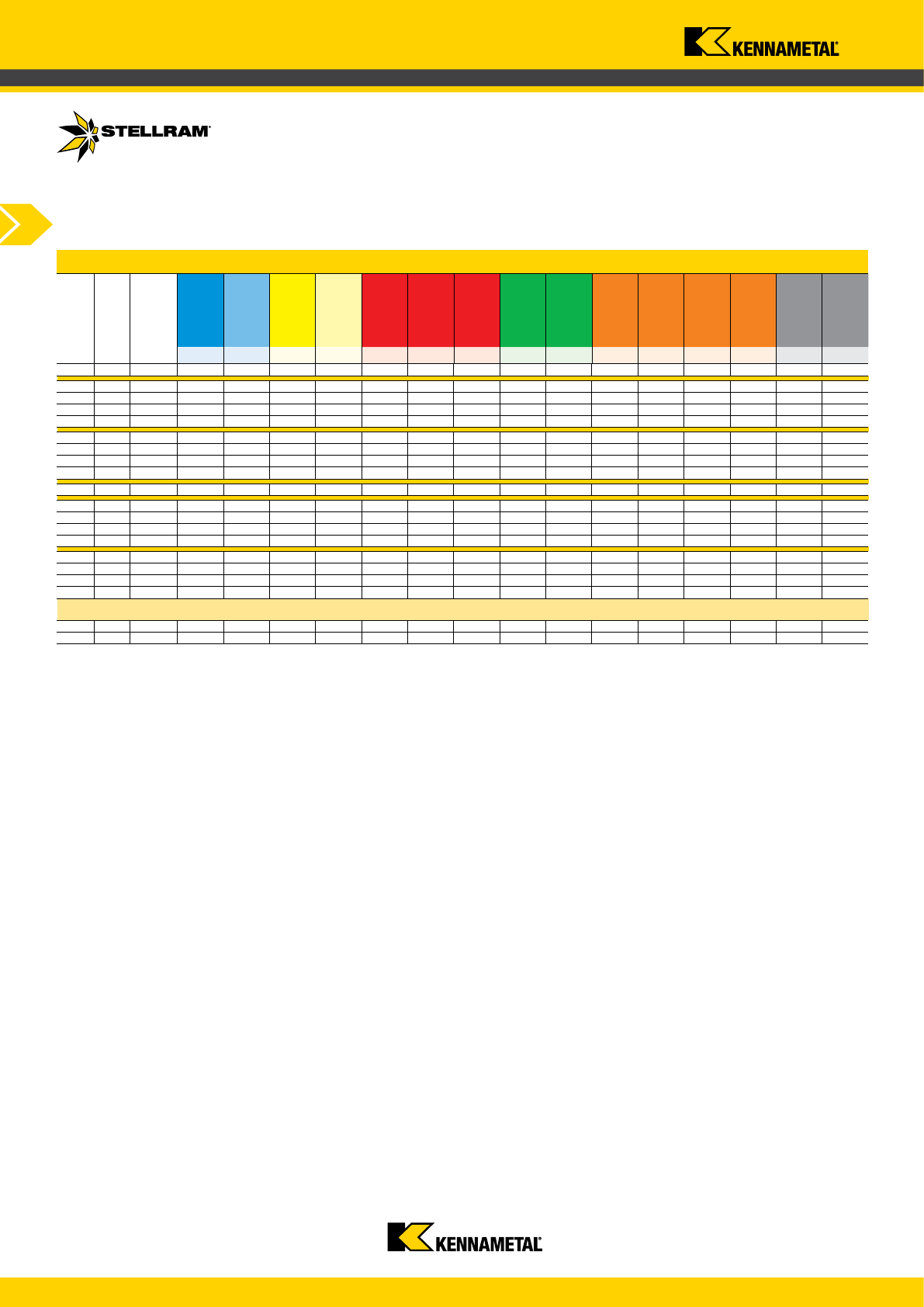

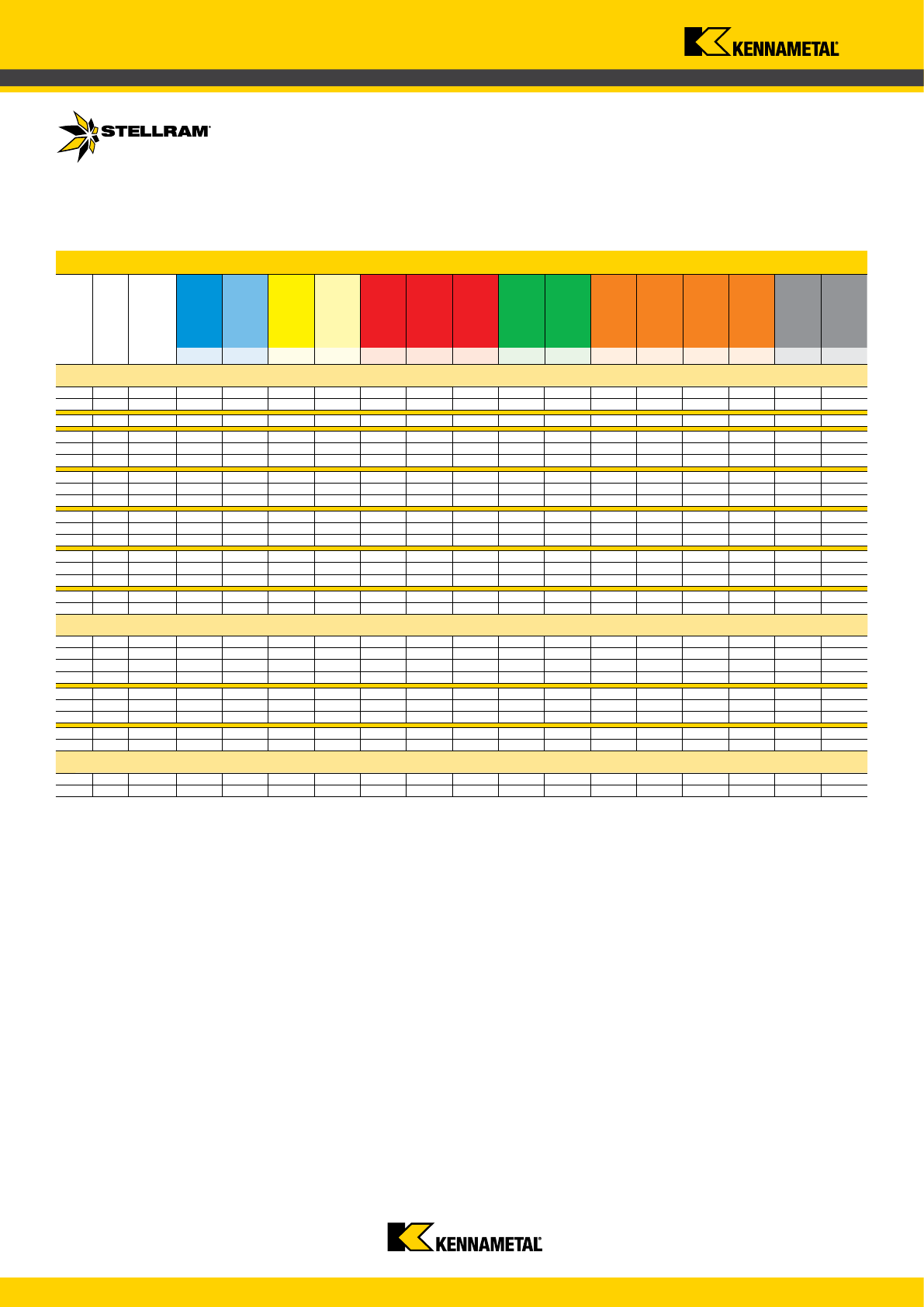

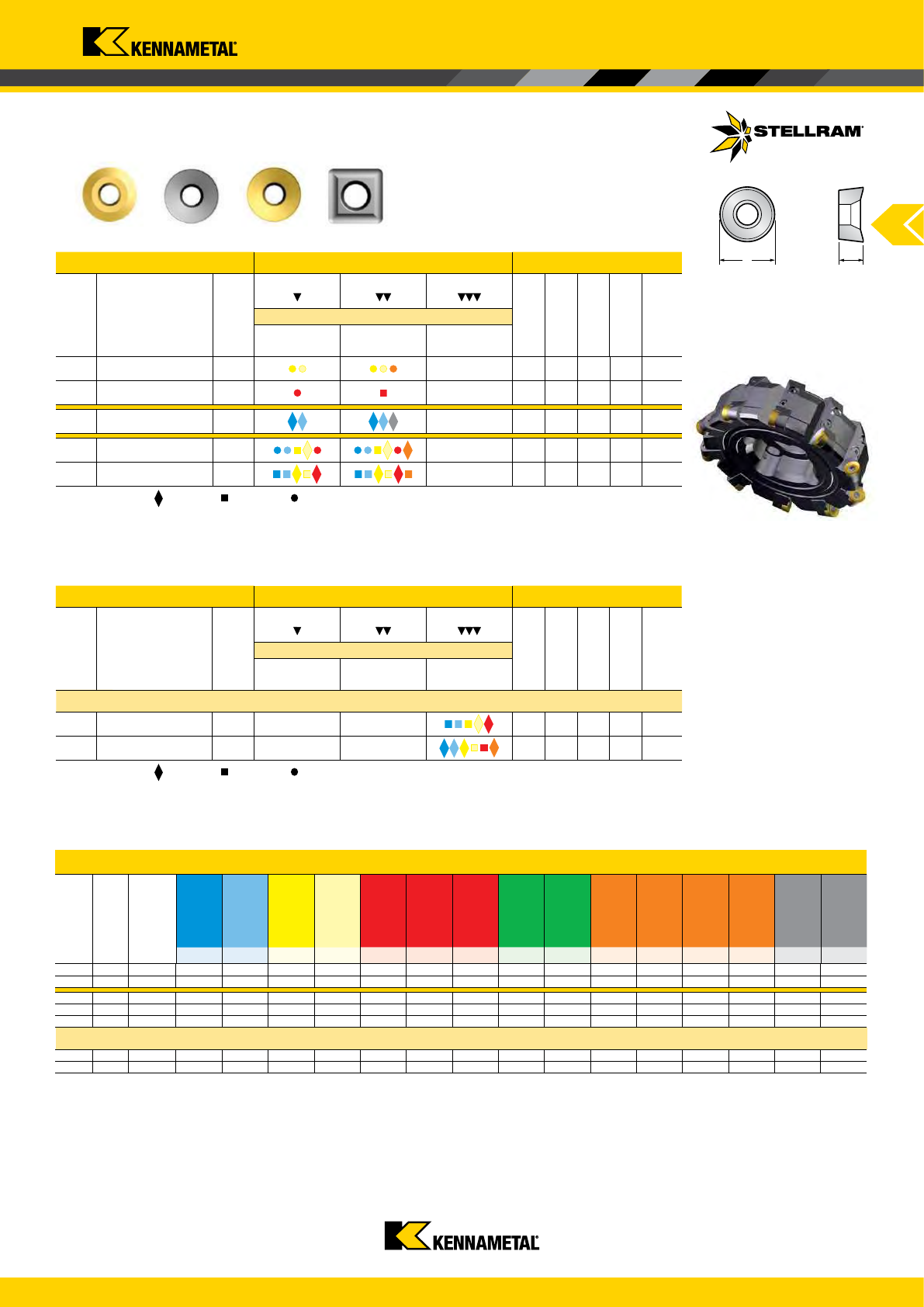

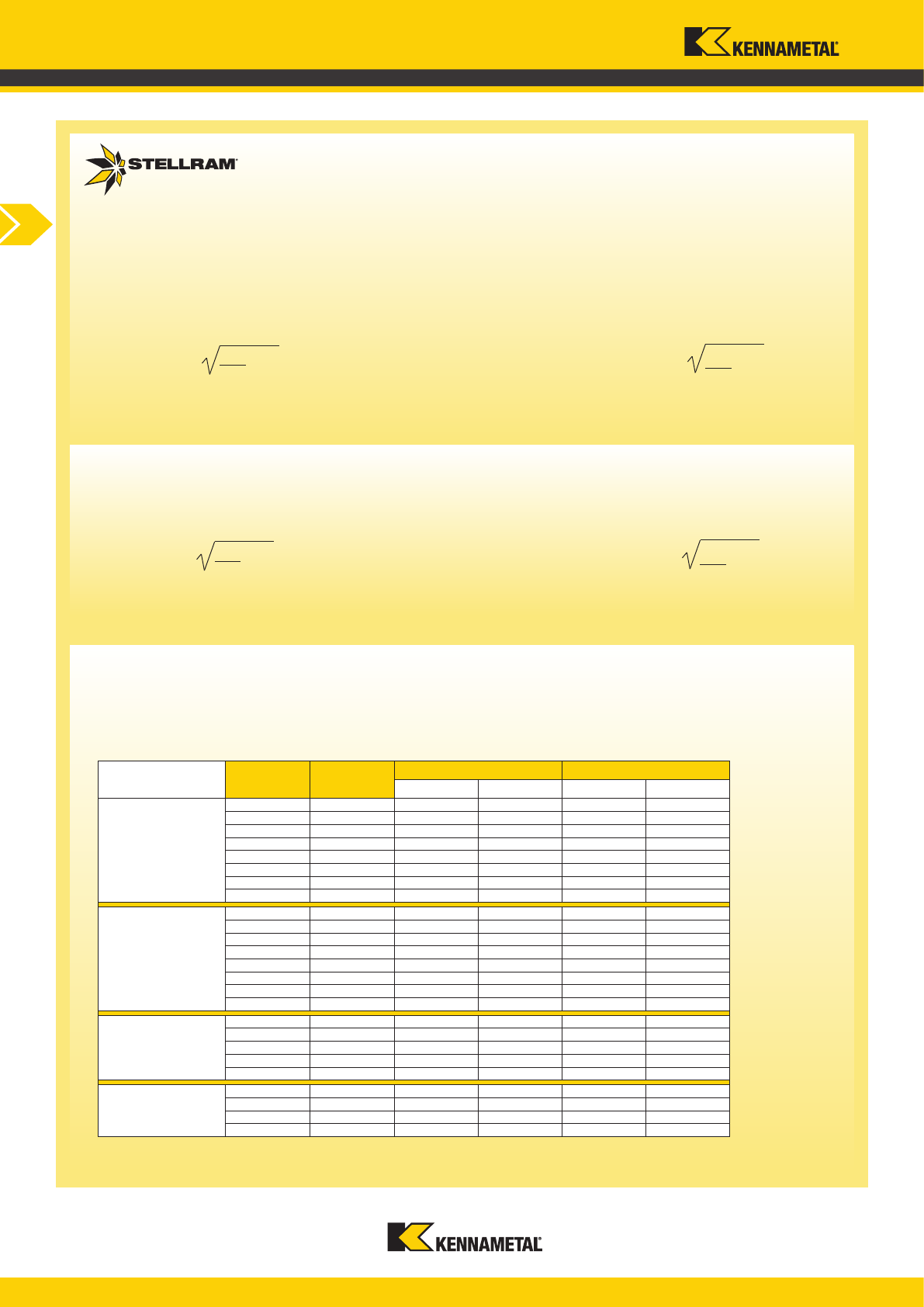

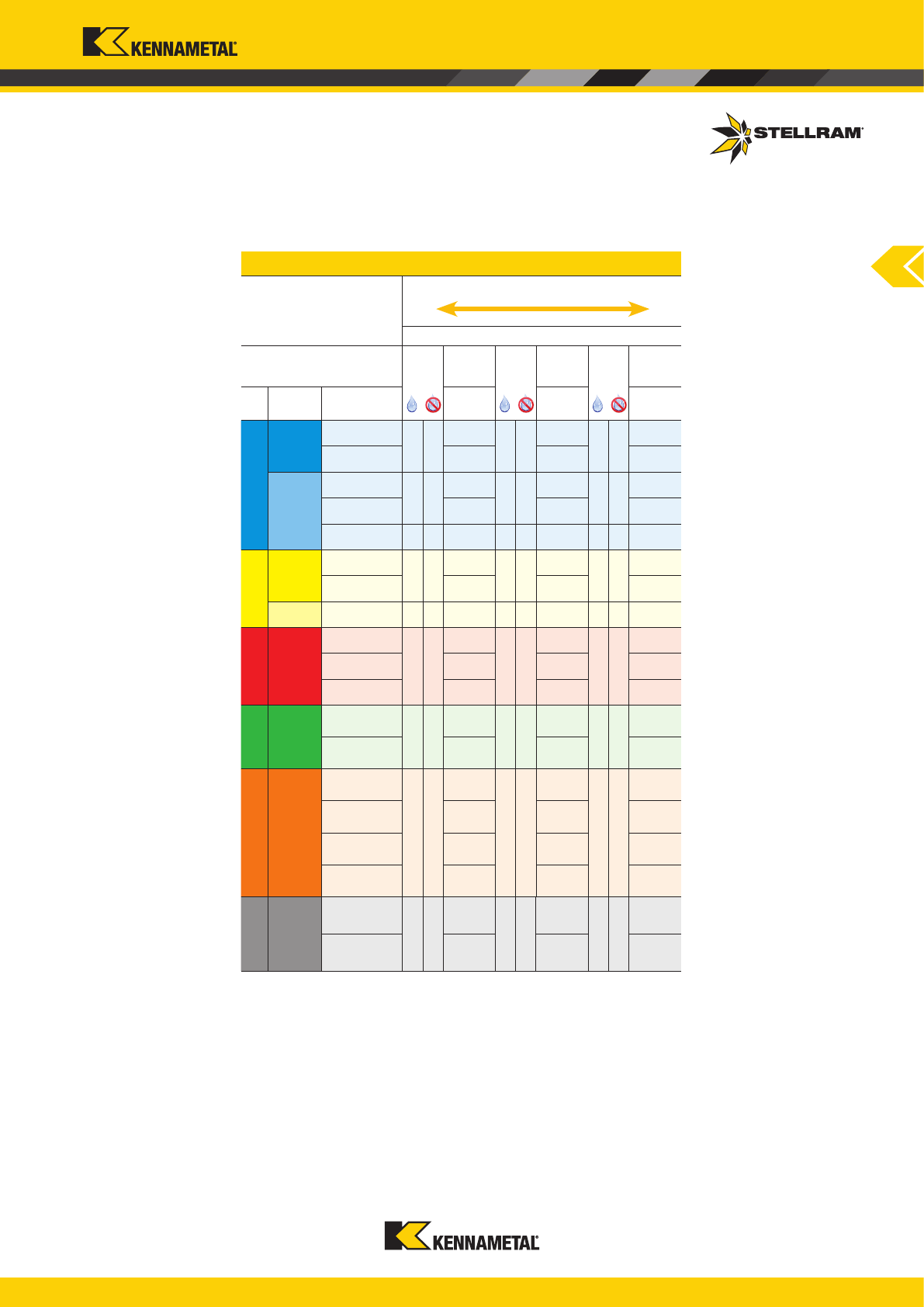

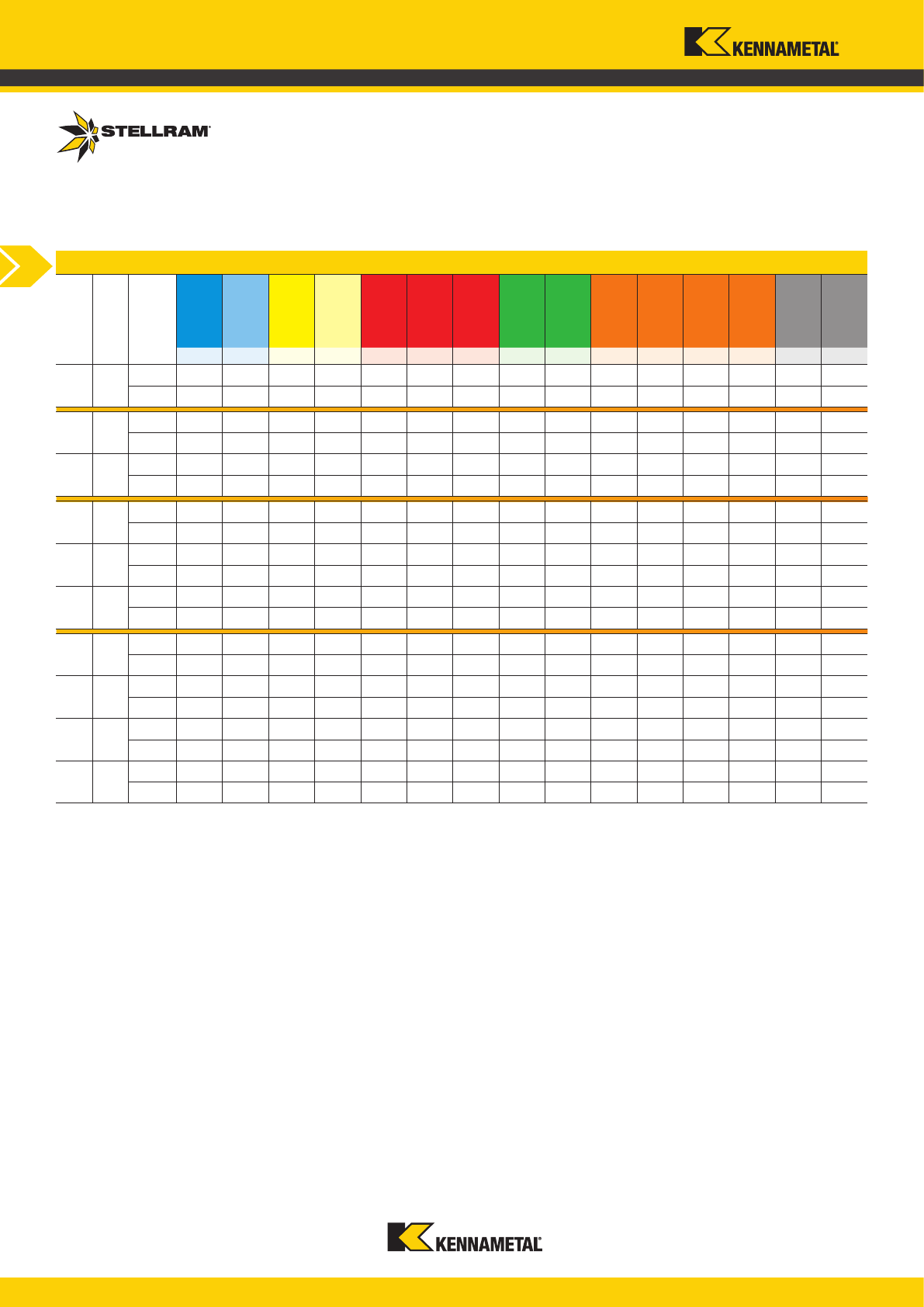

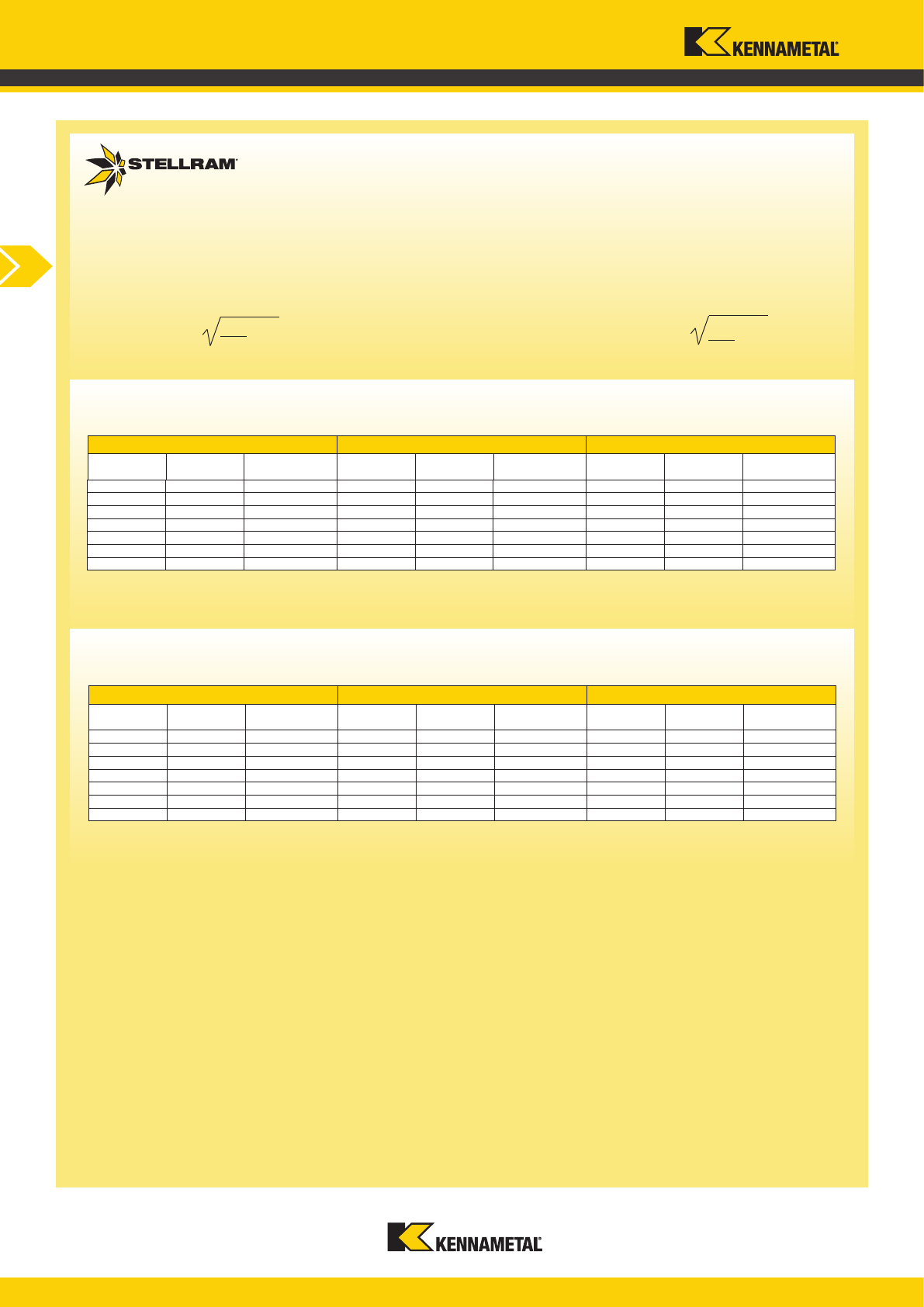

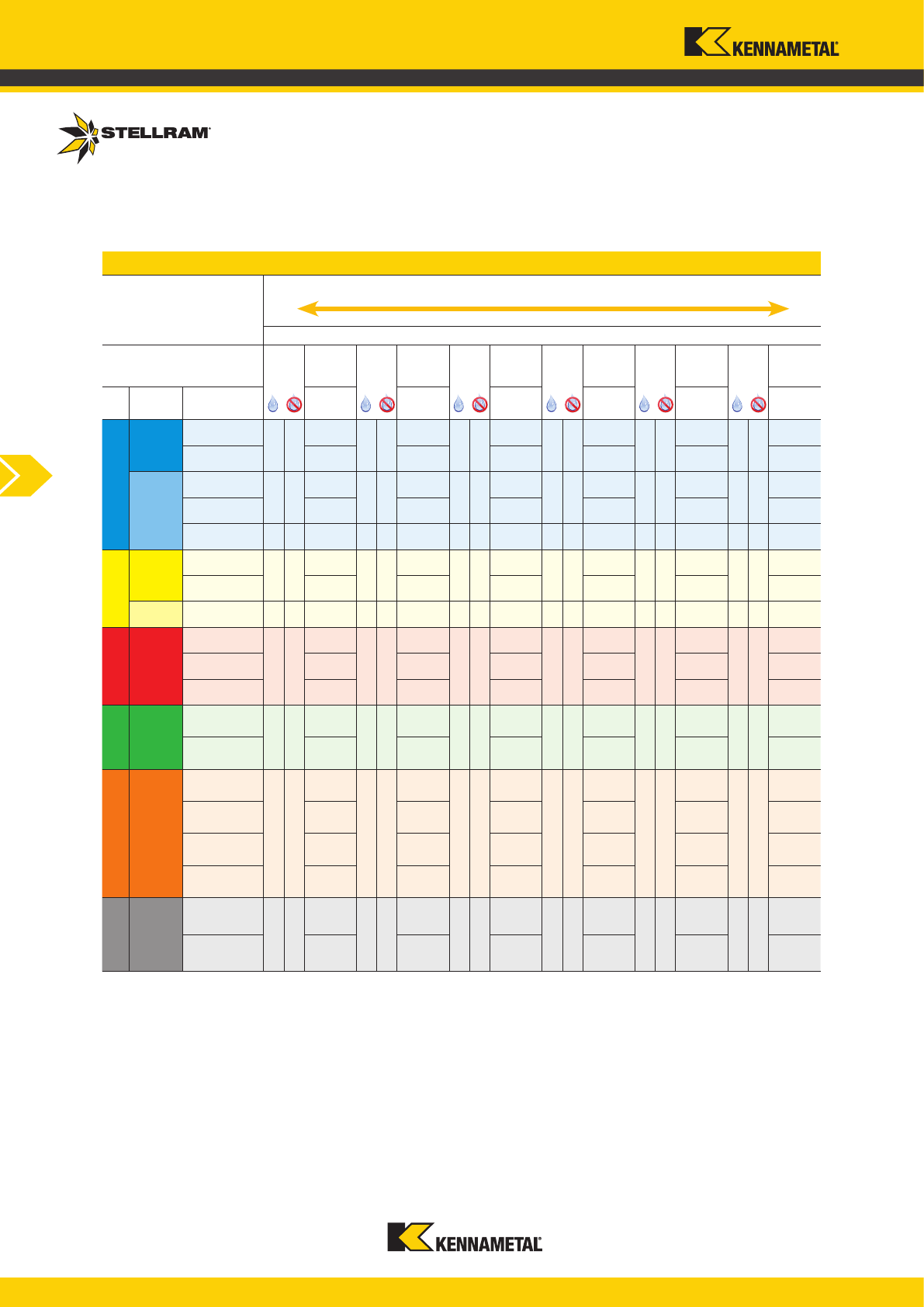

P

120 - 260

130 - 295

140 - 370

105 - 230 115 - 260 120 - 325

95 - 200

100 - 210

100 - 230

105 - 290

70 - 150 75 - 160 75 - 175 80 - 210

45 - 95

50 - 100

50 - 110

50 - 140

--

+

M

115 - 250

115 - 270

100 - 220 105 - 235

50 - 110

50 - 120

K

140 - 295

145 - 390

150 - 395

110 - 240 115 - 305 120 - 335

100 - 220 105 - 275

N

305 - 2130

400 - 2745

245 - 1760 295 - 2135

S

23 - 48

23 - 55

21 - 44 22 - 48

24 - 51 25 - 55

35 - 73 36 - 79

H

45 - 95

35 - 80

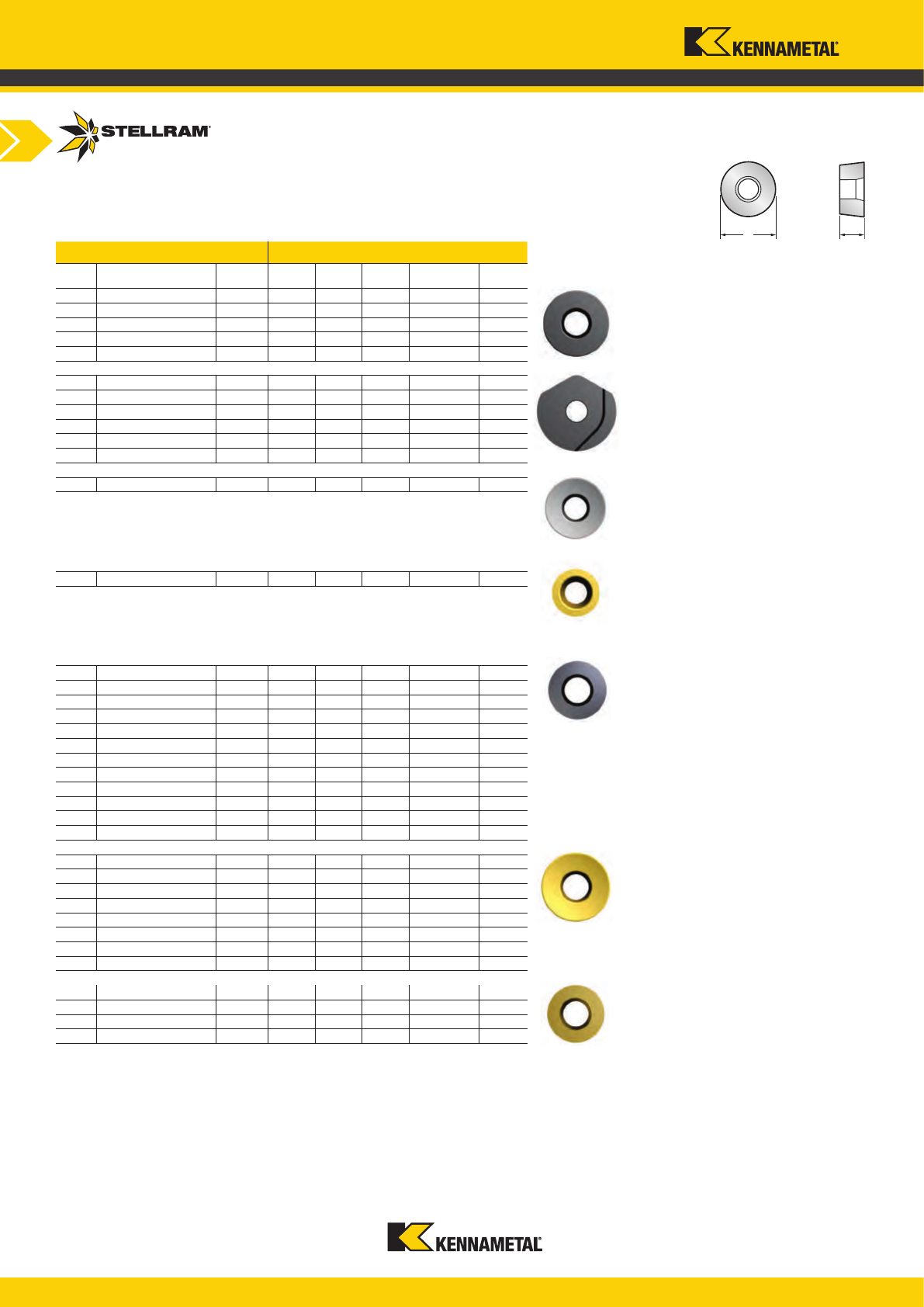

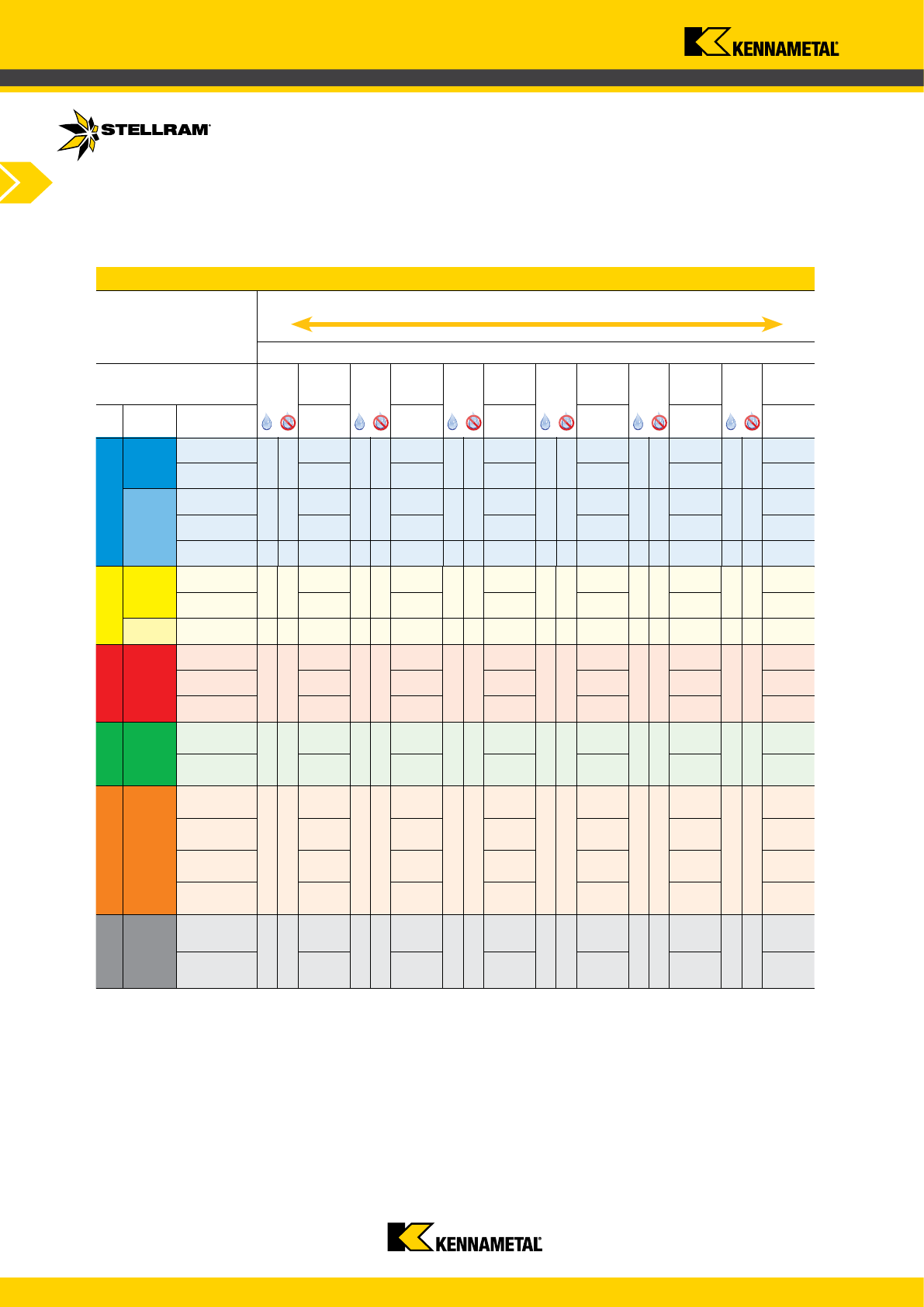

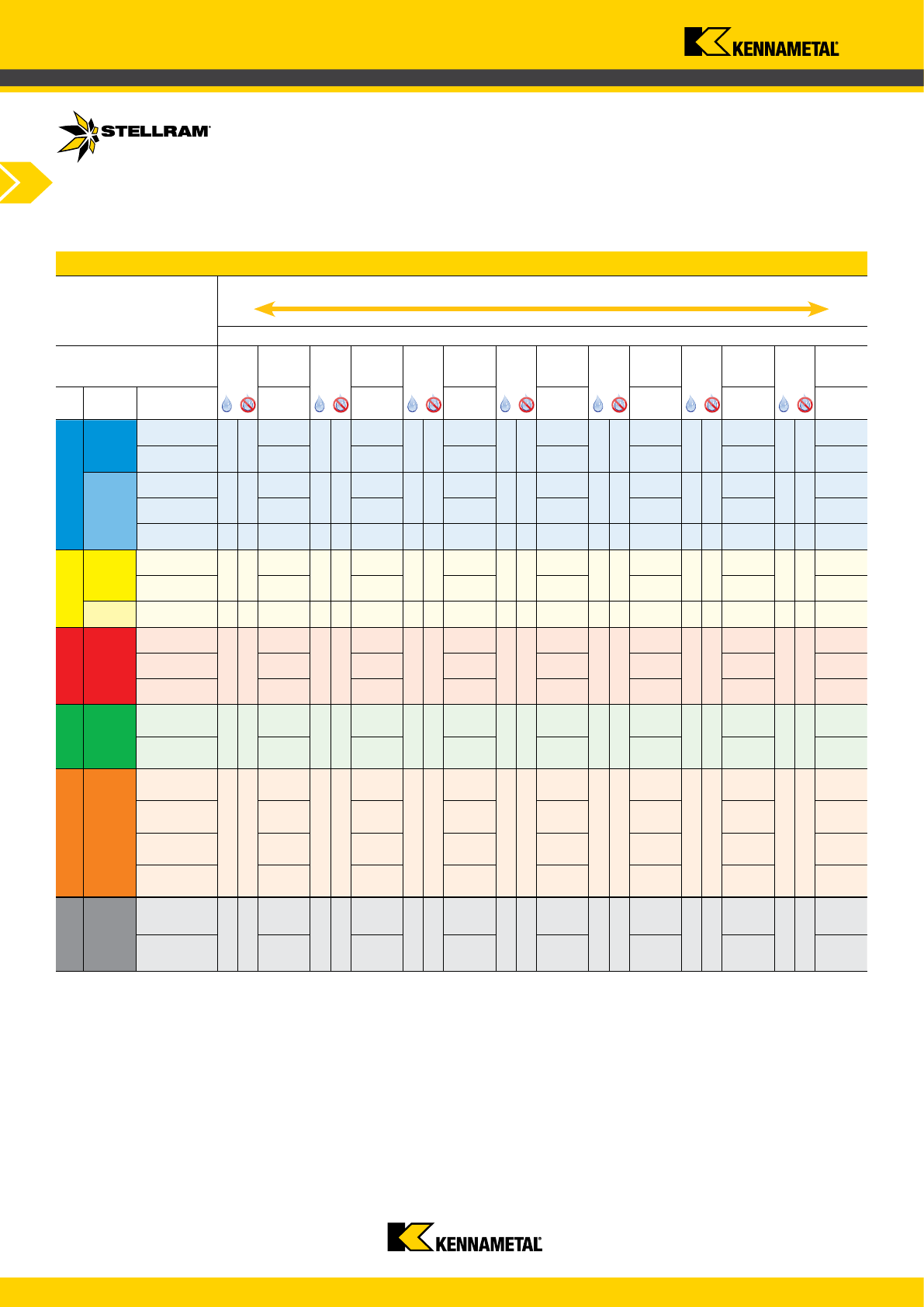

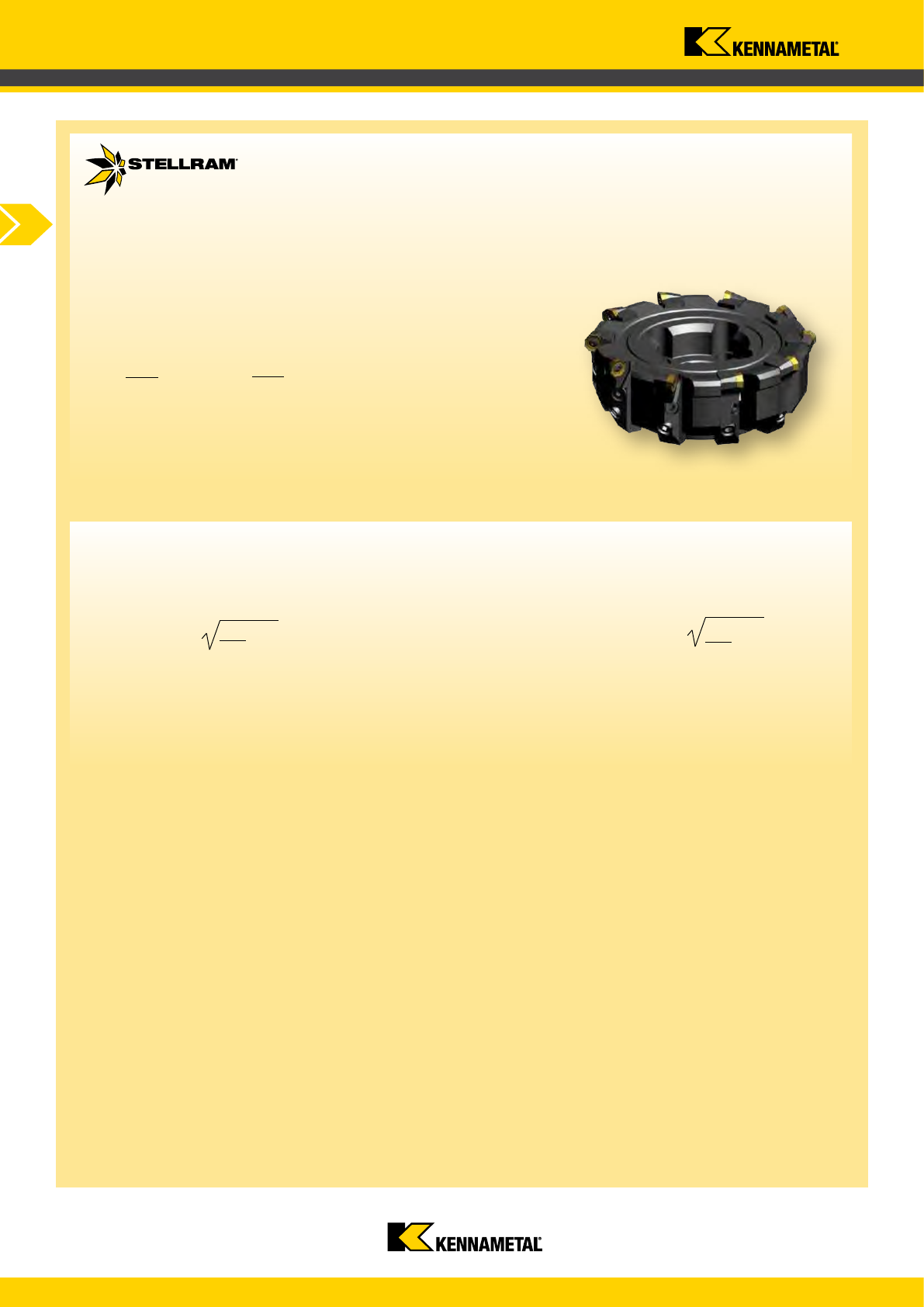

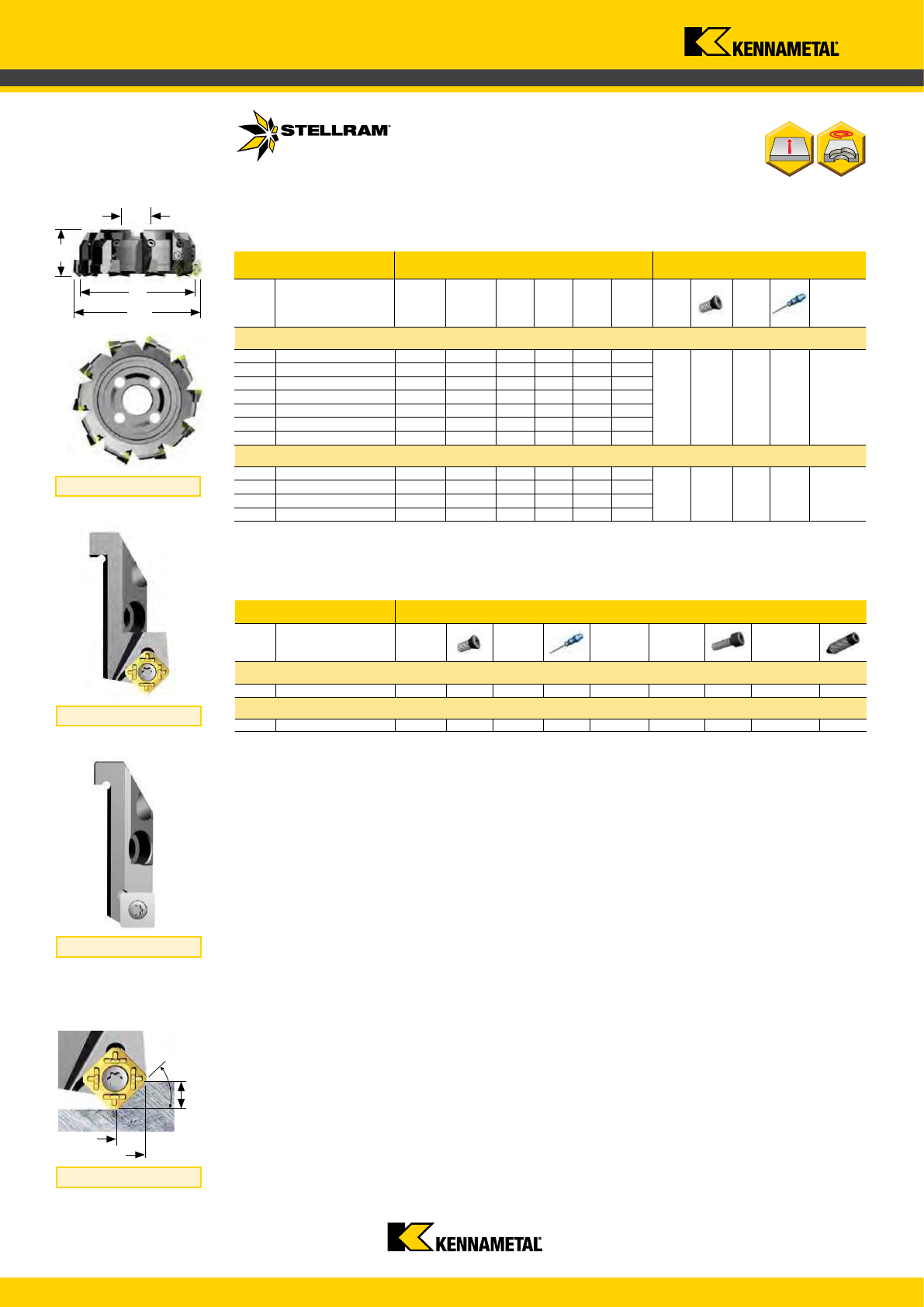

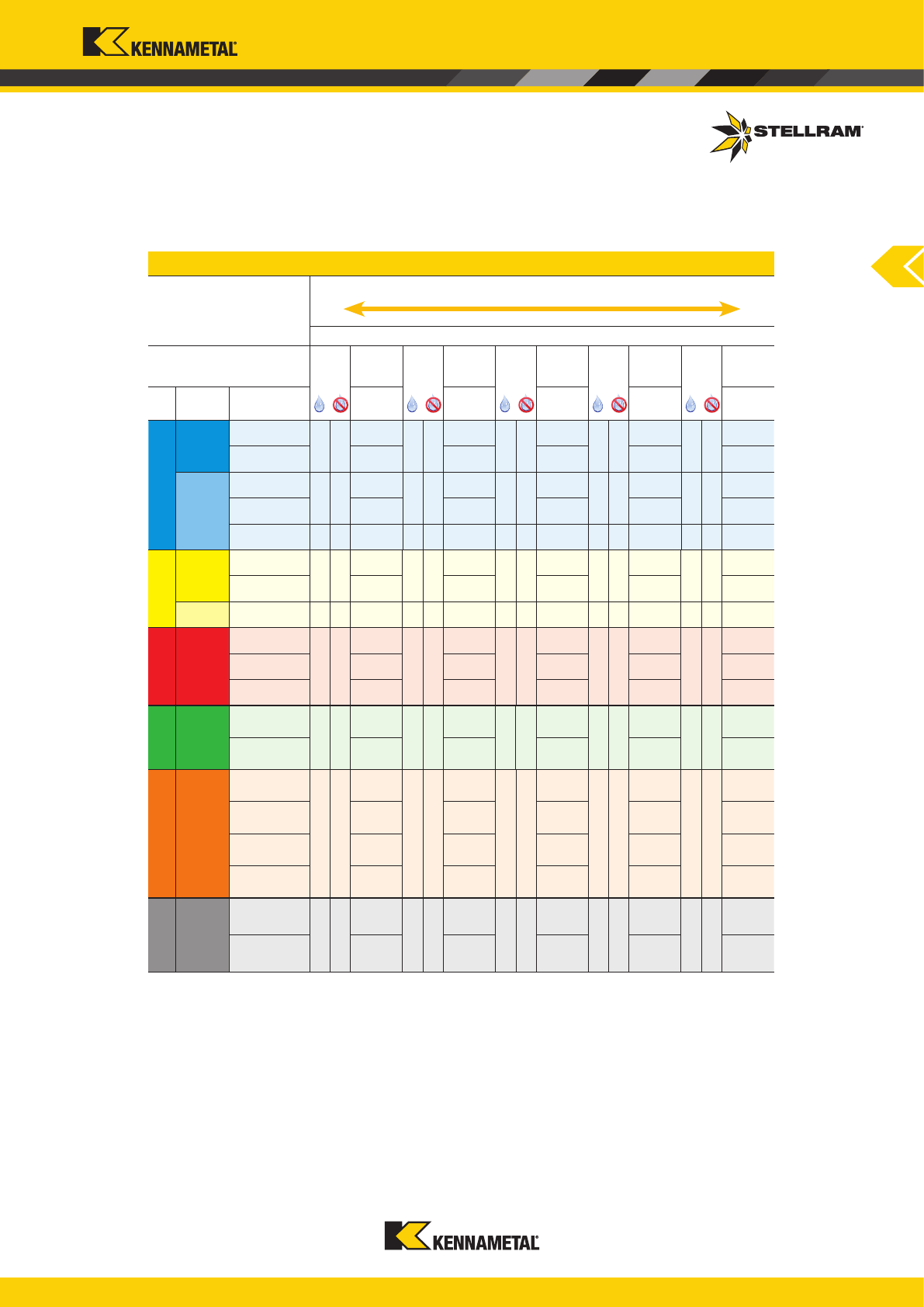

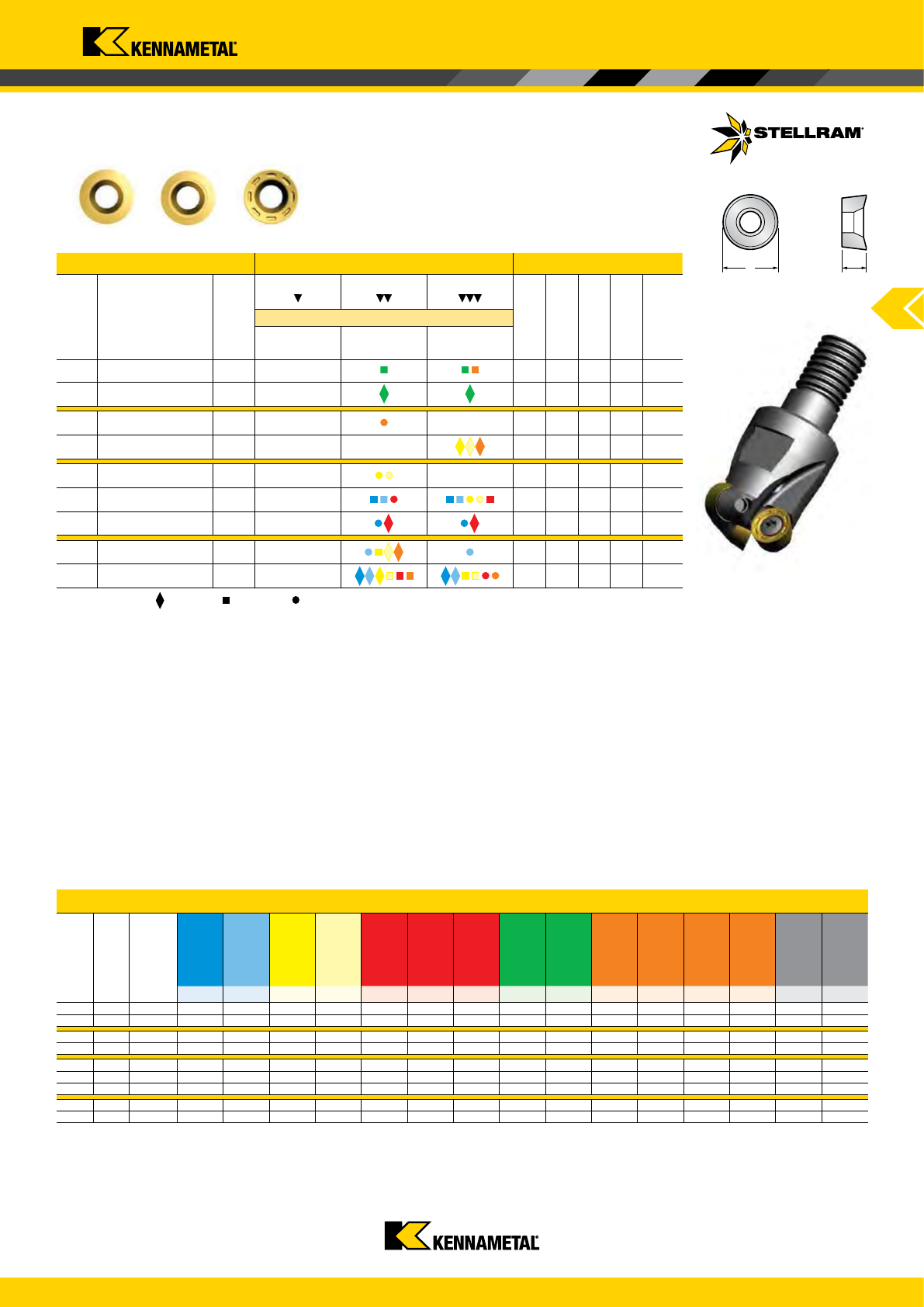

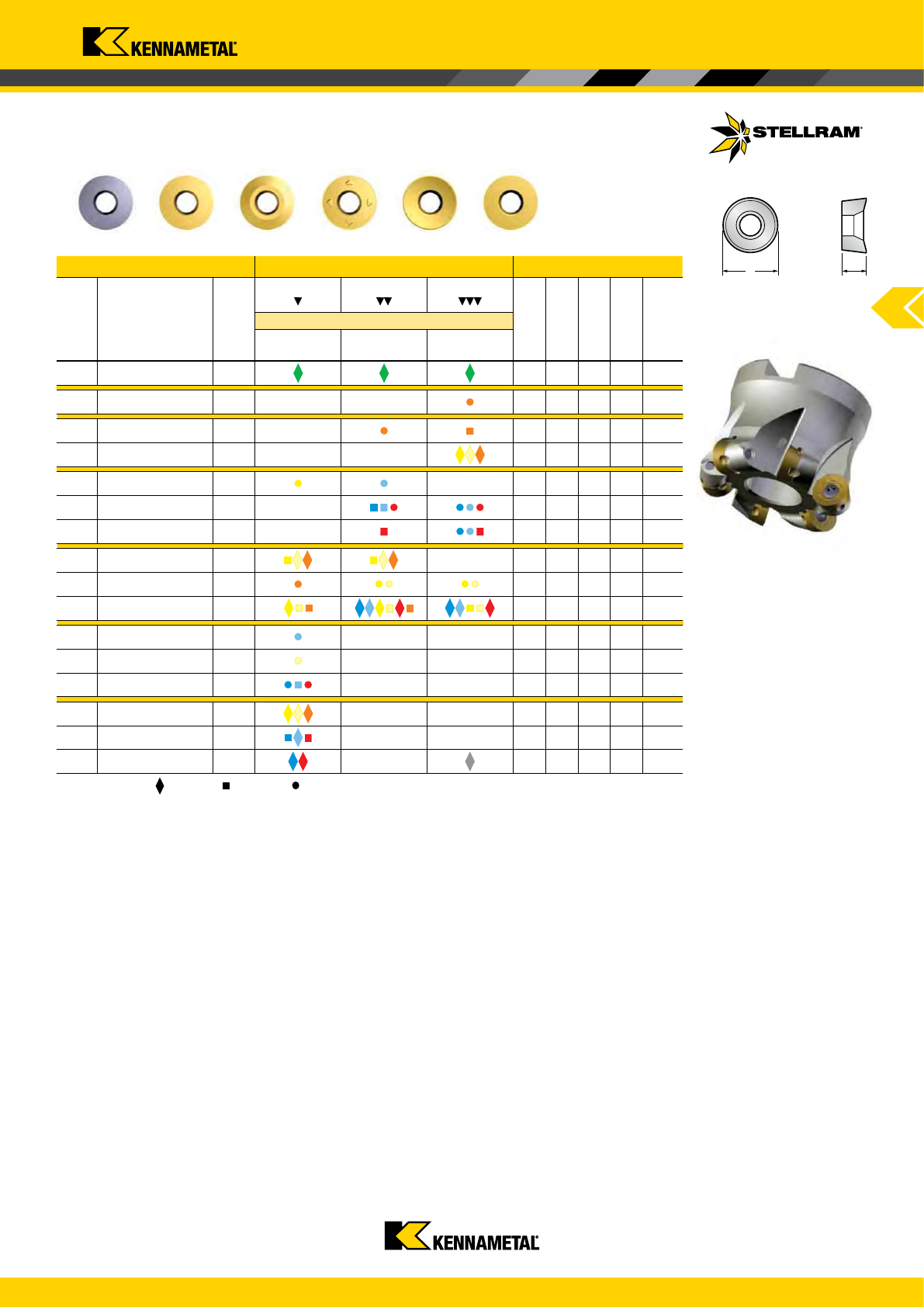

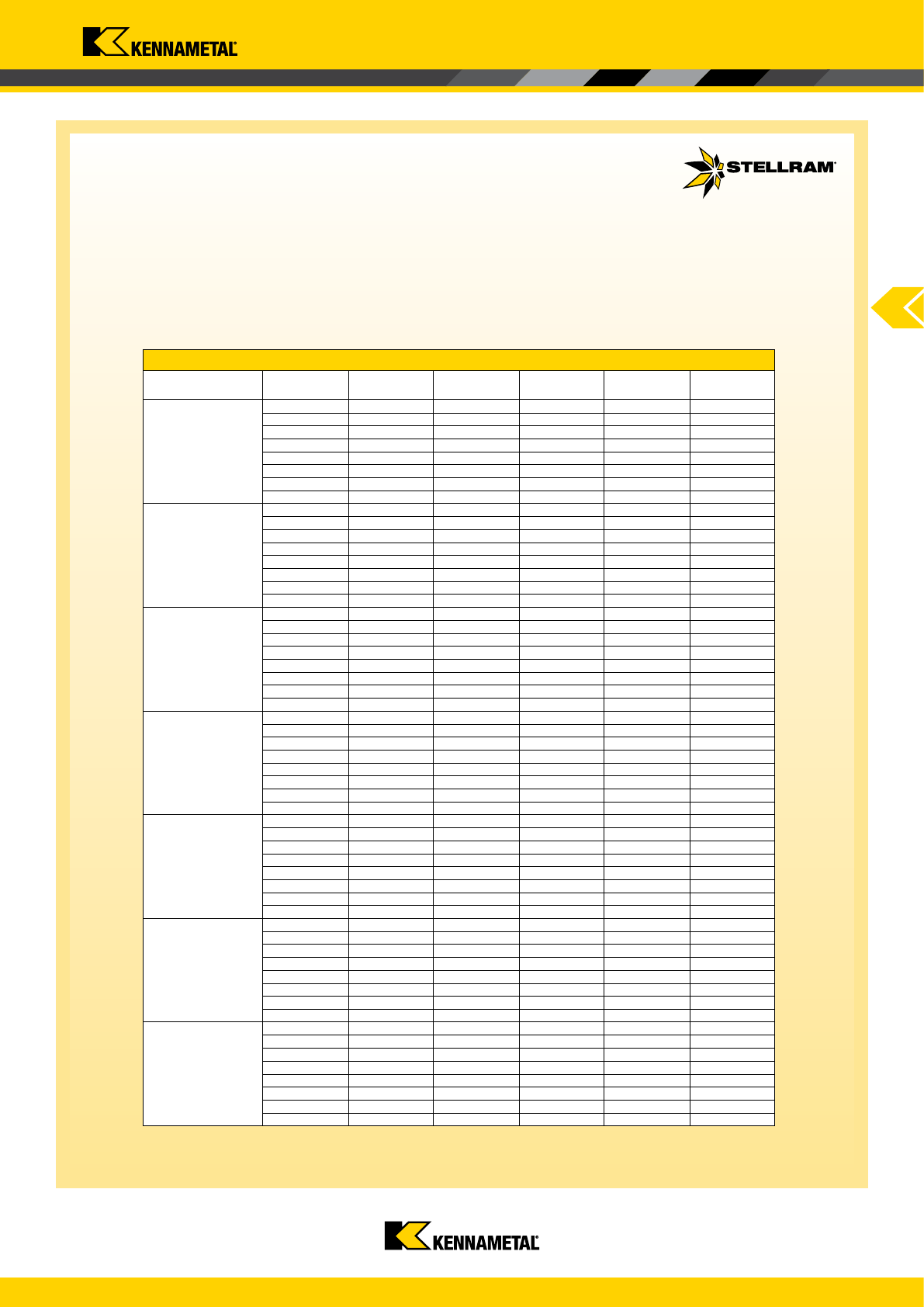

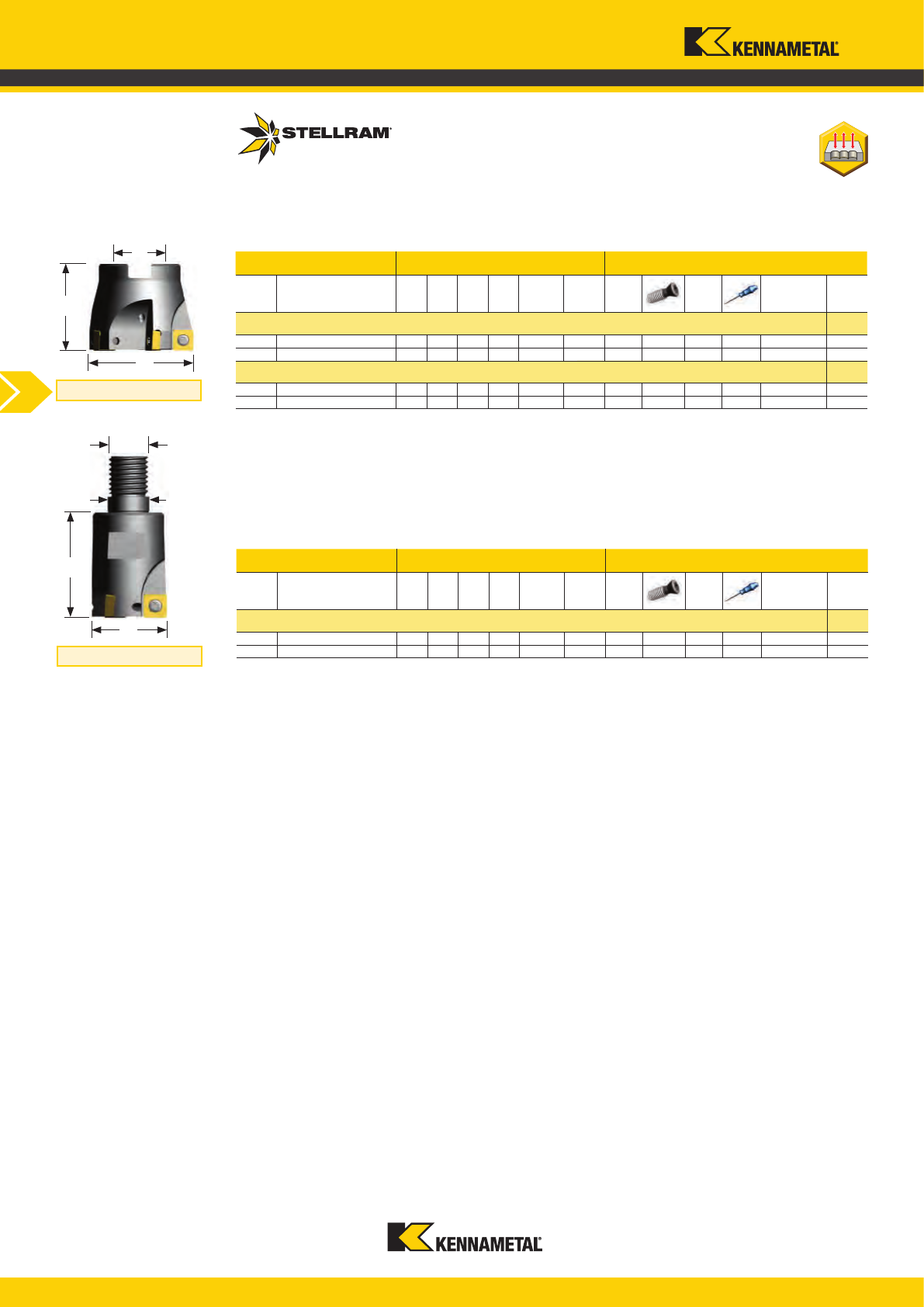

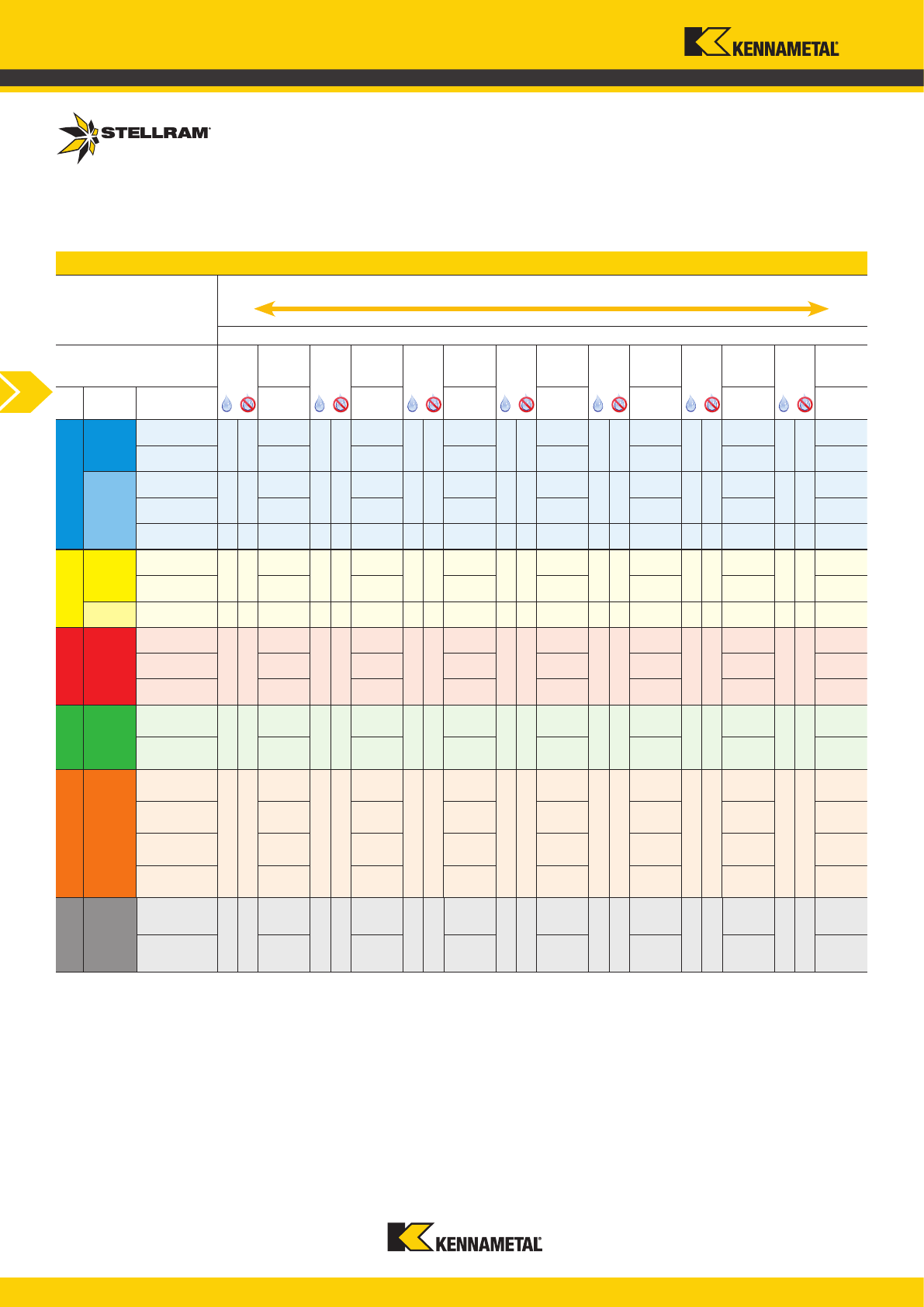

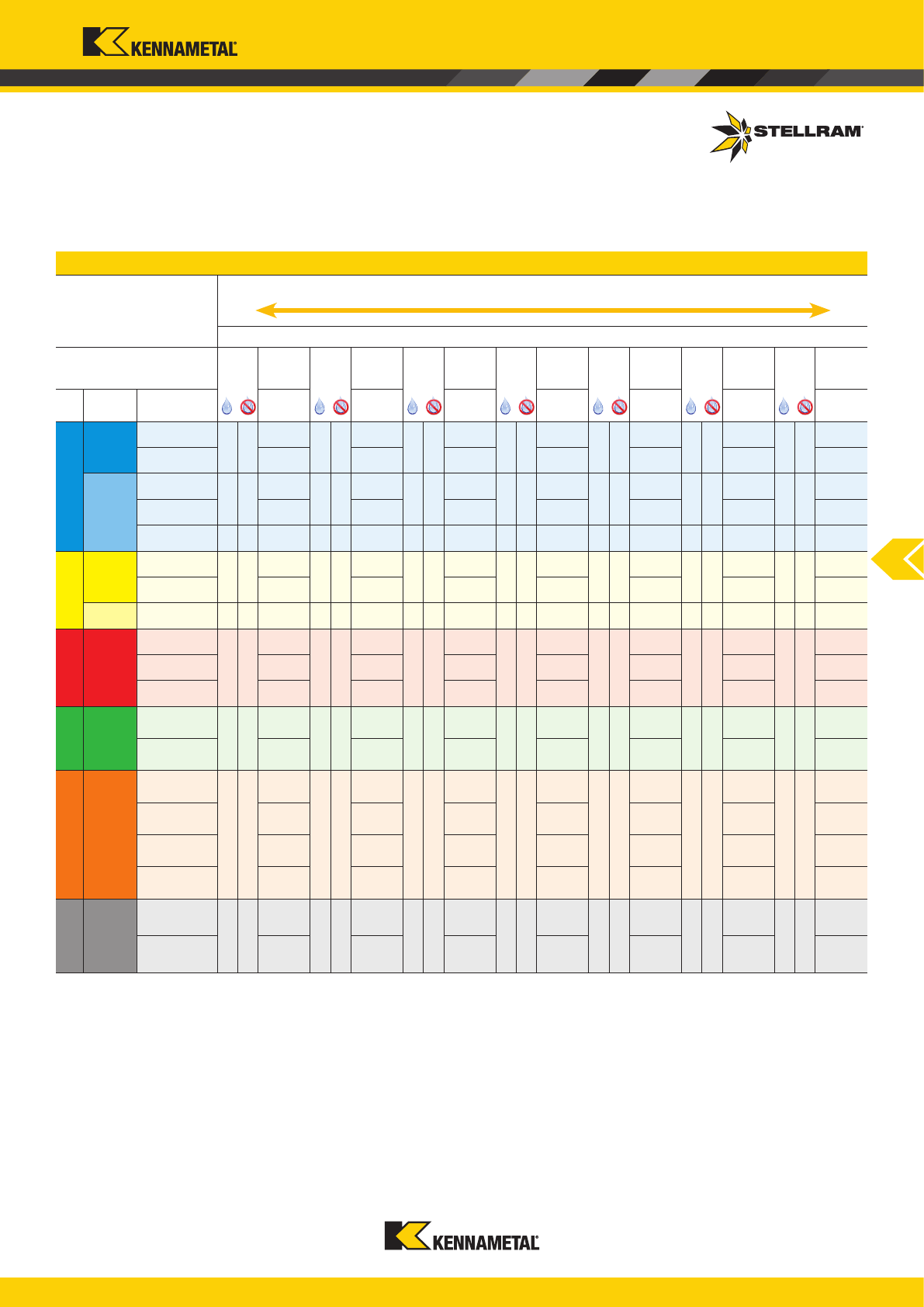

Milling Introduction

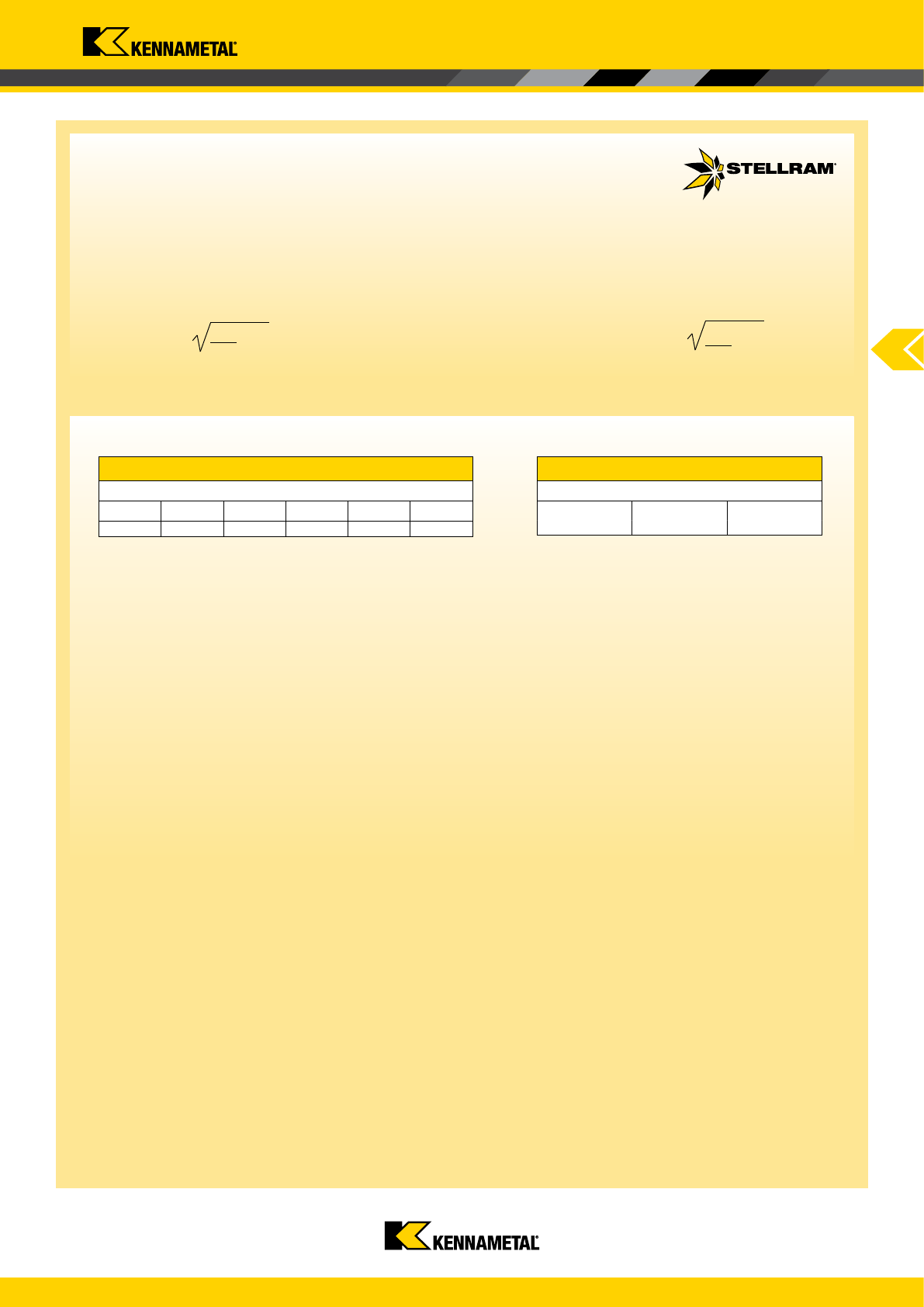

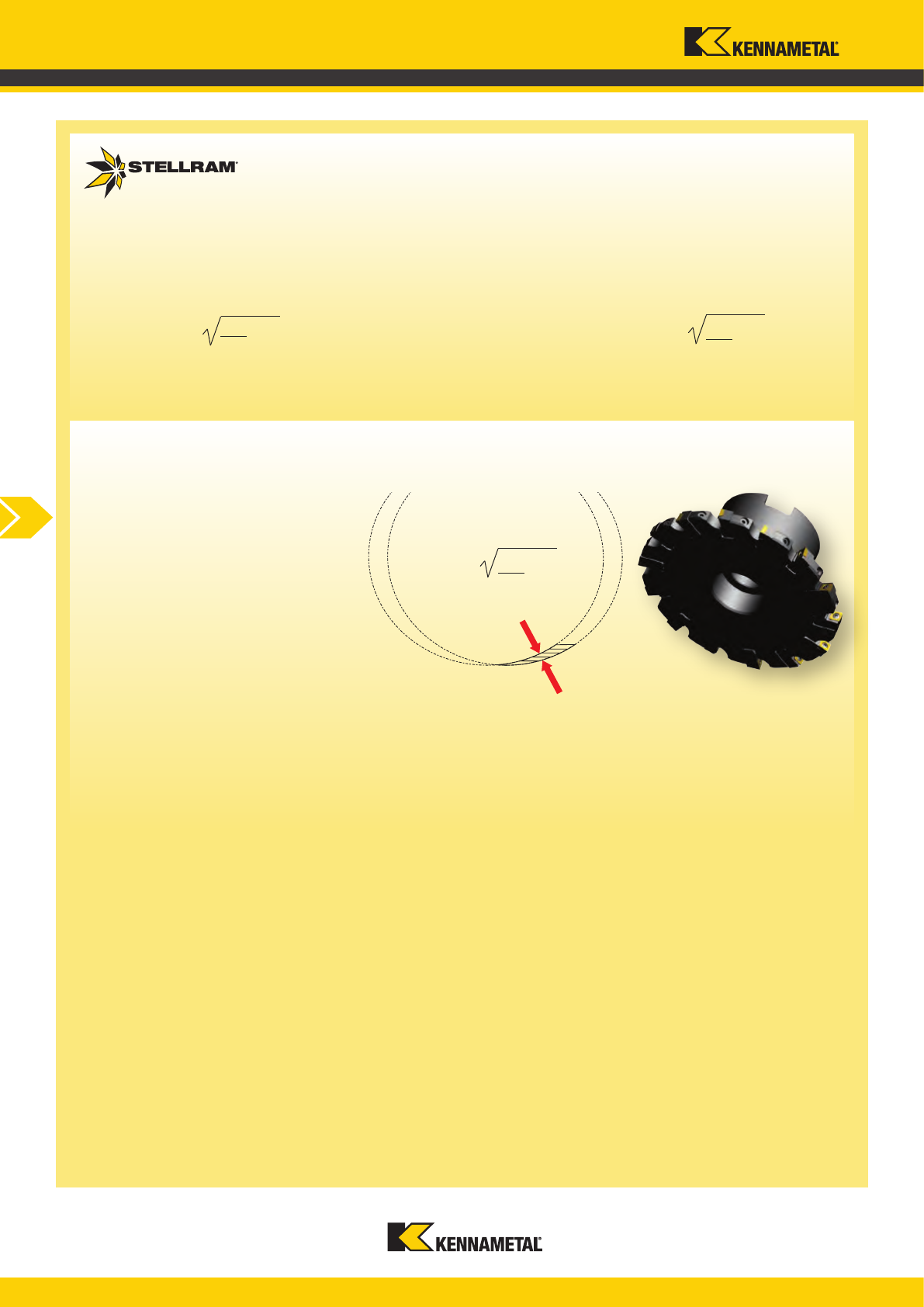

Technical information can be found at the end

of each selected family which contains calculation

formulas, mounting instructions, etc…

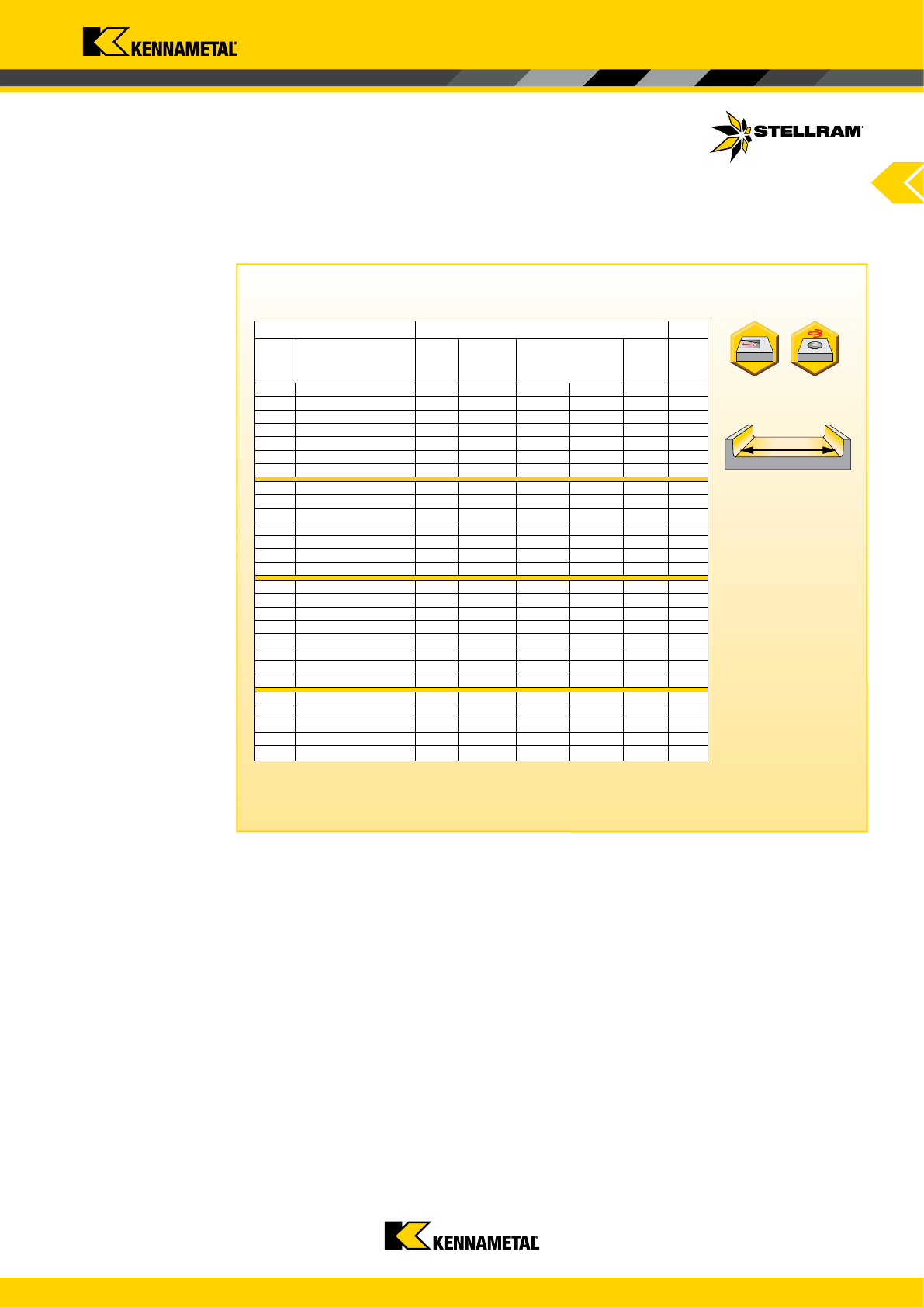

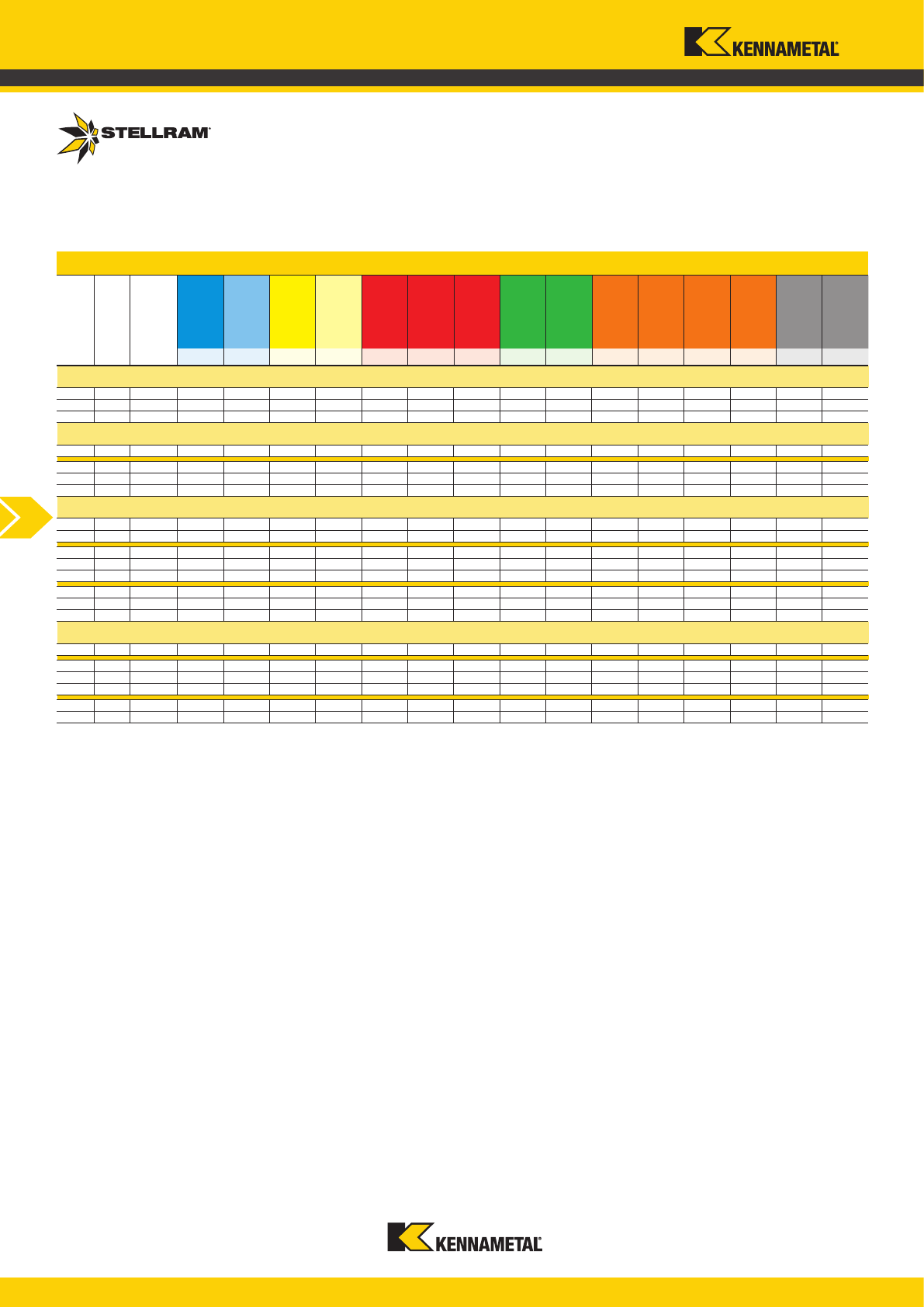

Select the recommended Cutting Speed (vc)

and Coolant recommendations according to

the material to be machined.

Example:

Speed range for XDLW090408SR-D X400

for Facing in Alloyed Steel (Rm 950-

1200 N/mm2 and 280-355 HBN)

70 – 150 m/min

Material specifications can be found in

the Materials Reference Charts

pages D1 - D35.

6 Step Tool Selection (continued)

Tooling Selection Guide

Cutters, Inserts & Cutting Parameters

Recommended Possible

Speed v

c

(m/min)

7792VX Series

Wear Resistance

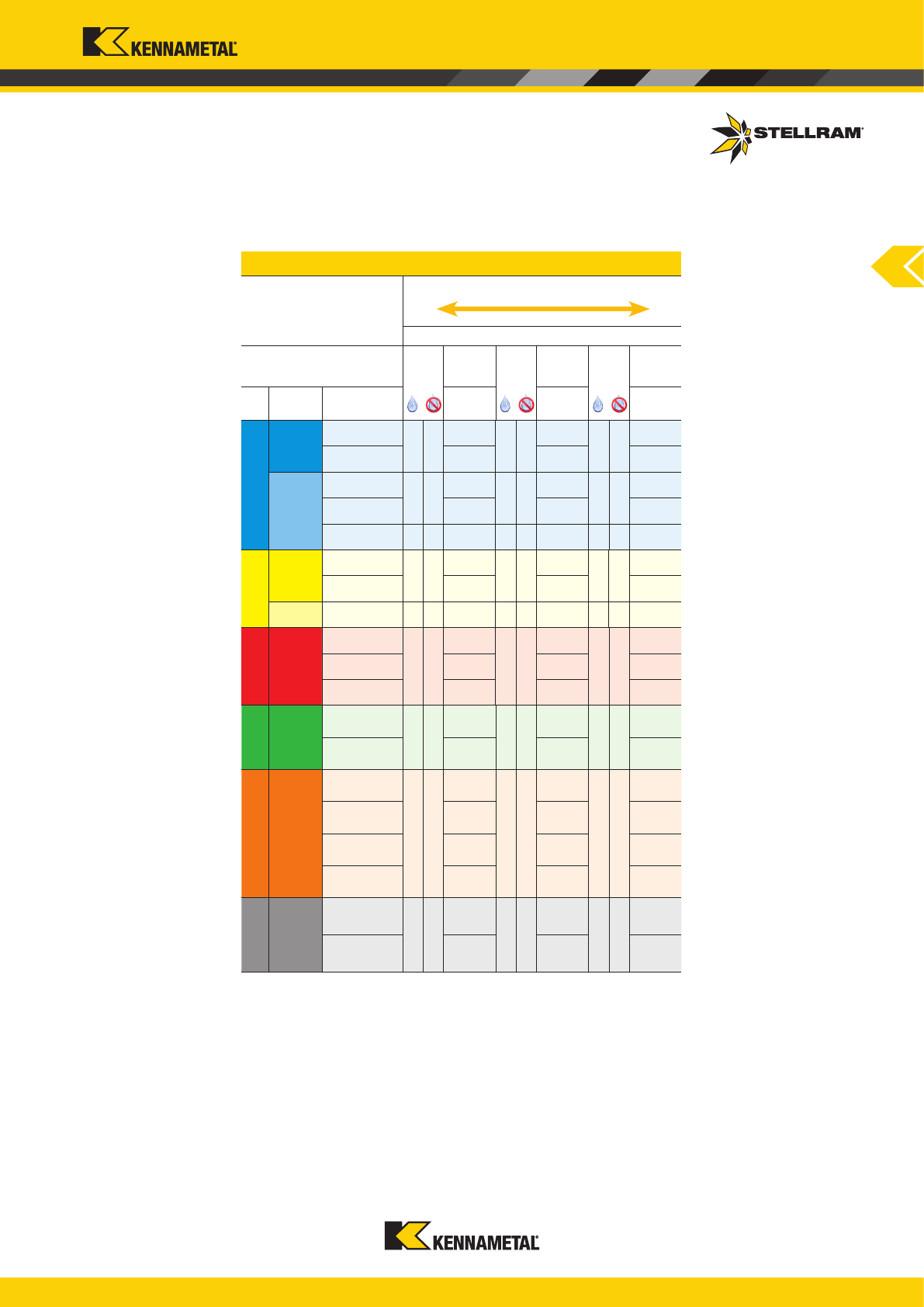

Speed min. - max.

Coolant Recommendation

PVD

X Grade

CVD

X Grade

PVD

Standard

Uncoated

Micrograin

CVD

Standard

CVD

Standard

ISO Materials

Rm and

Hardness

X400 X500 SP6519 GH2 SC6525 SC3025

Unalloyed

Steel

<600 N/mm

2

<180 HBN

<950 N/mm

2

<280 HBN

Alloyed

Steel

700-950 N/mm

2

200-280 HBN

950-1200 N/mm

2

280-355 HBN

1200-1400 N/mm

2

355-415 HBN

Stainless

Steel

Austenitic + Ferritic

300 series

Martensitic

400 series

PH Stainless

Refractory

P.H.

Cast Iron

Grey

GG-Ft

Spheroidal-Ductile

GGG-FGS

Malleable

GTS - MN/MP

Aluminium

& Alloys

Aluminium & Alloys

< 16% Si 116 HBN

Aluminium + Silicon

> 16% Si 92 HBN

High

Temperature

Alloys

Iron Based

Cobalt Based

Nickel Based

Titanium Based

Hard

Materials

Hard Steel

>1400 N/mm

2

>415 HBN

Chilled Cast Iron

>1400 N/mm

2

> 400 HBN

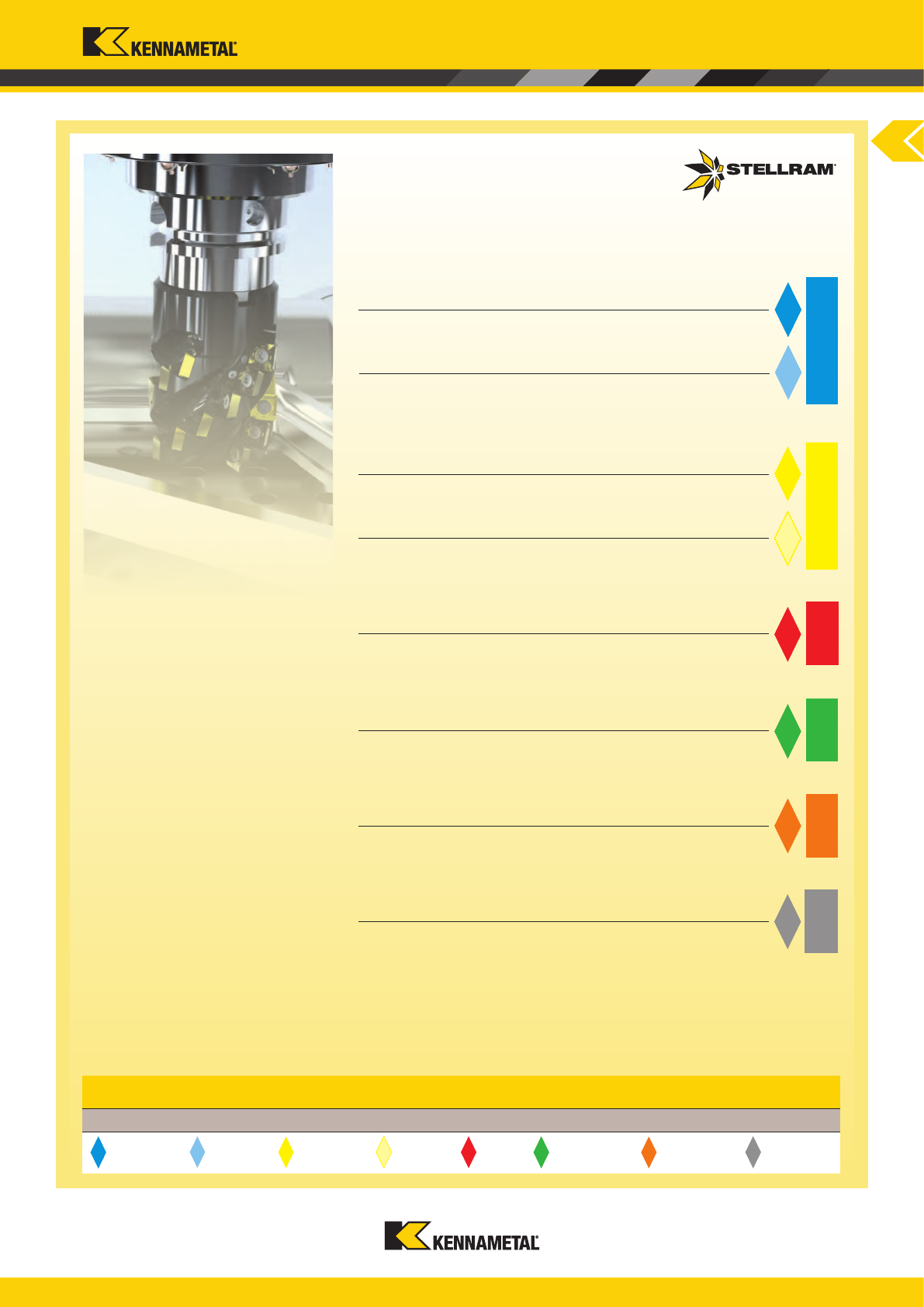

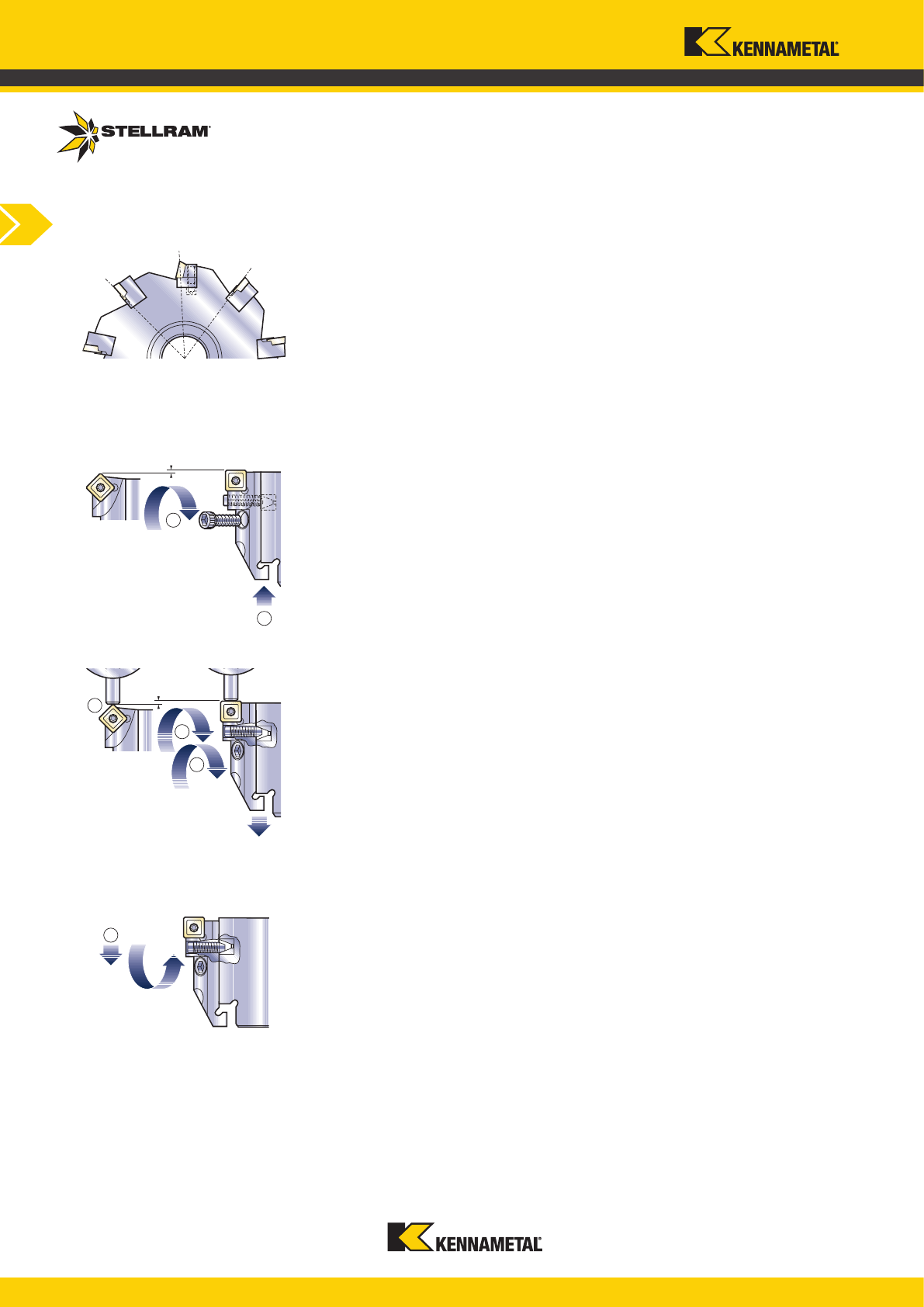

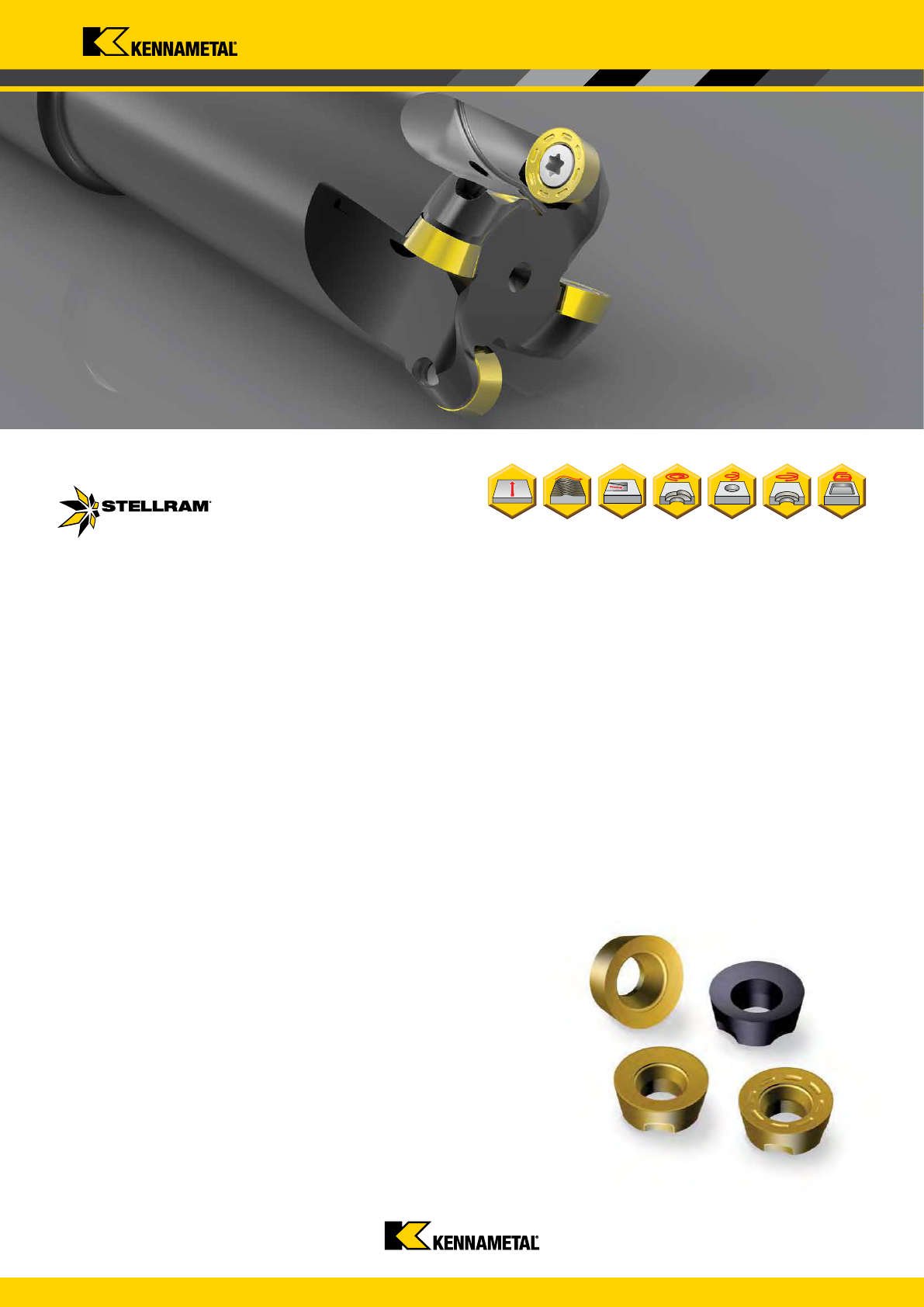

End Mills & Face Mills

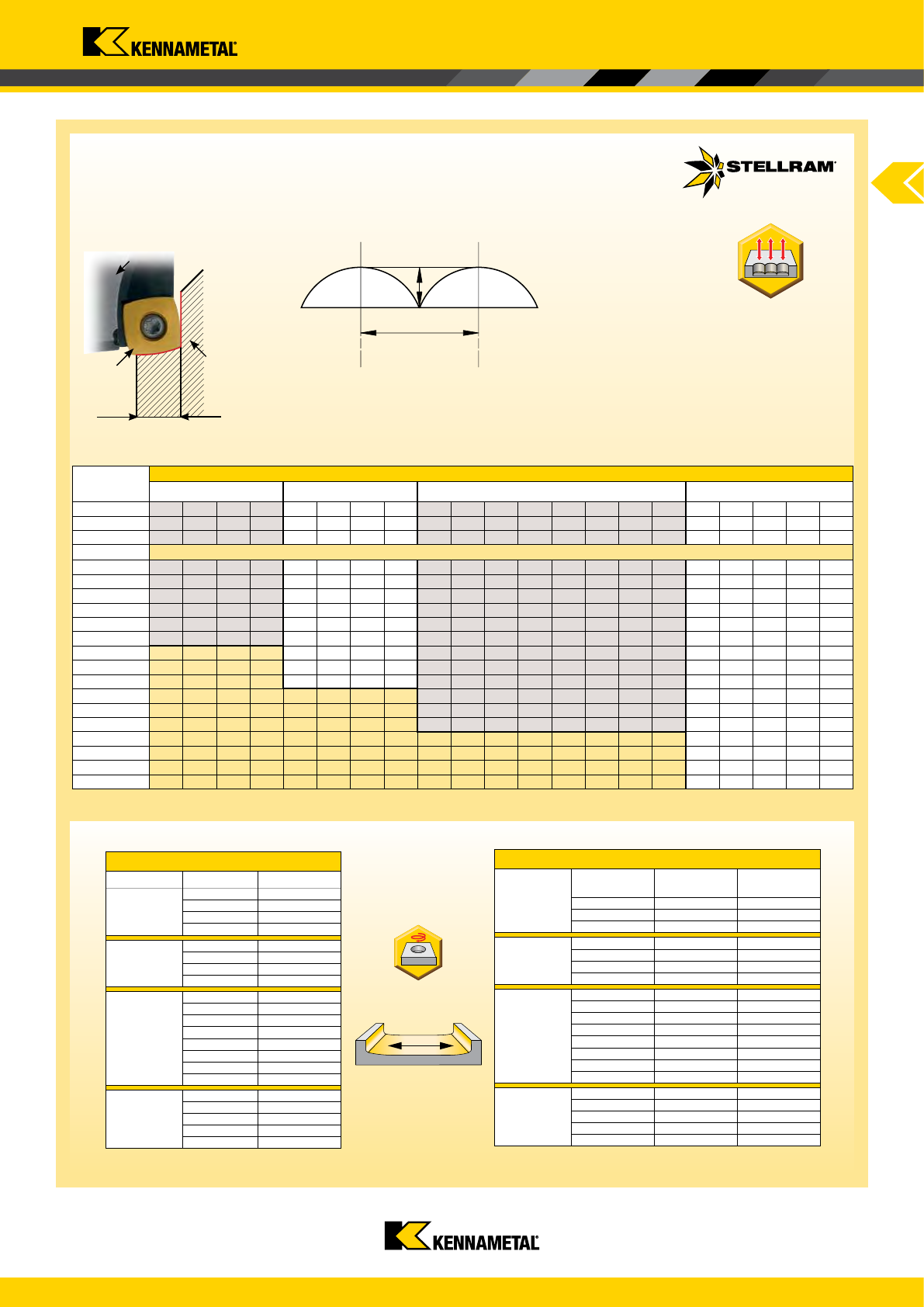

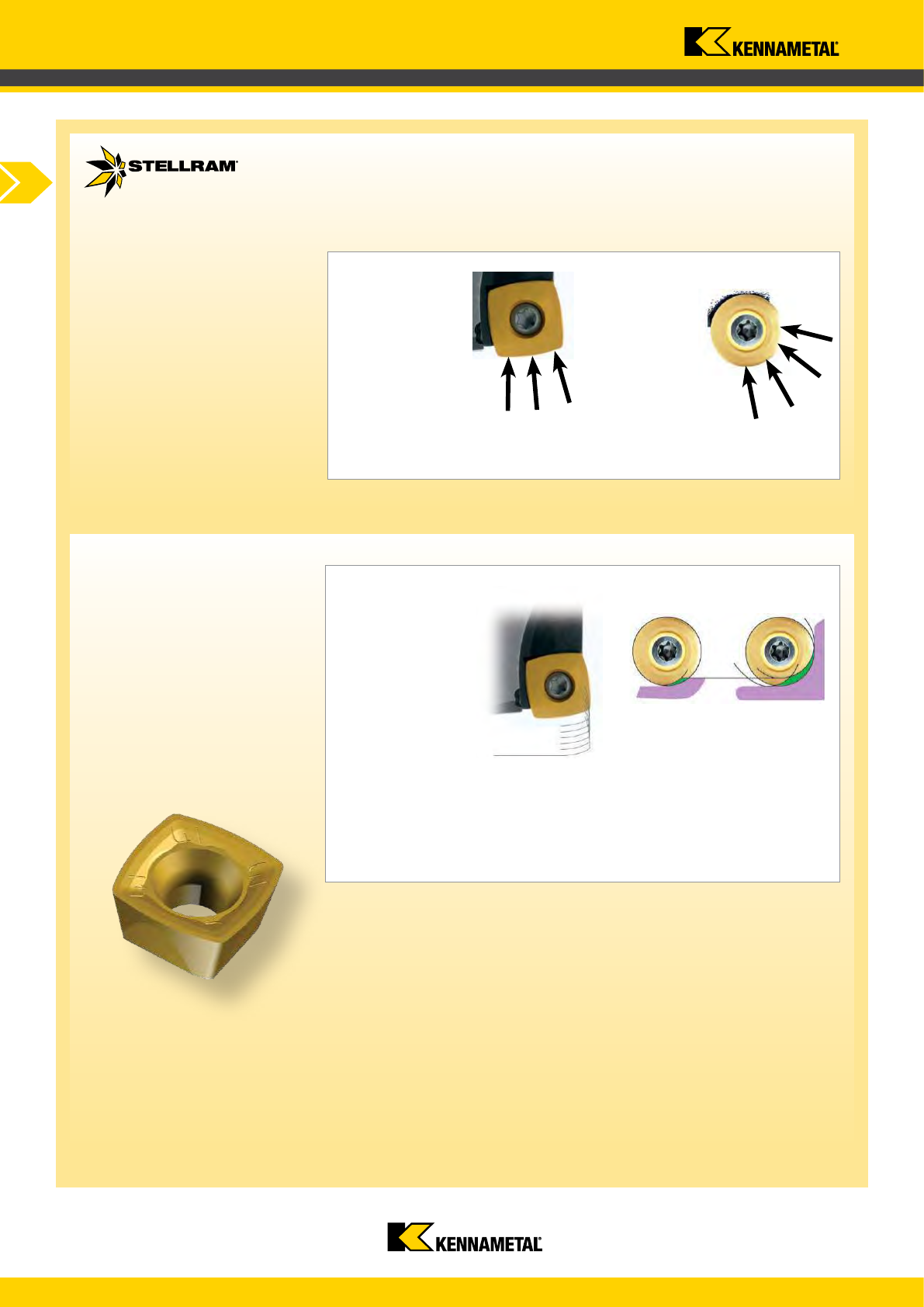

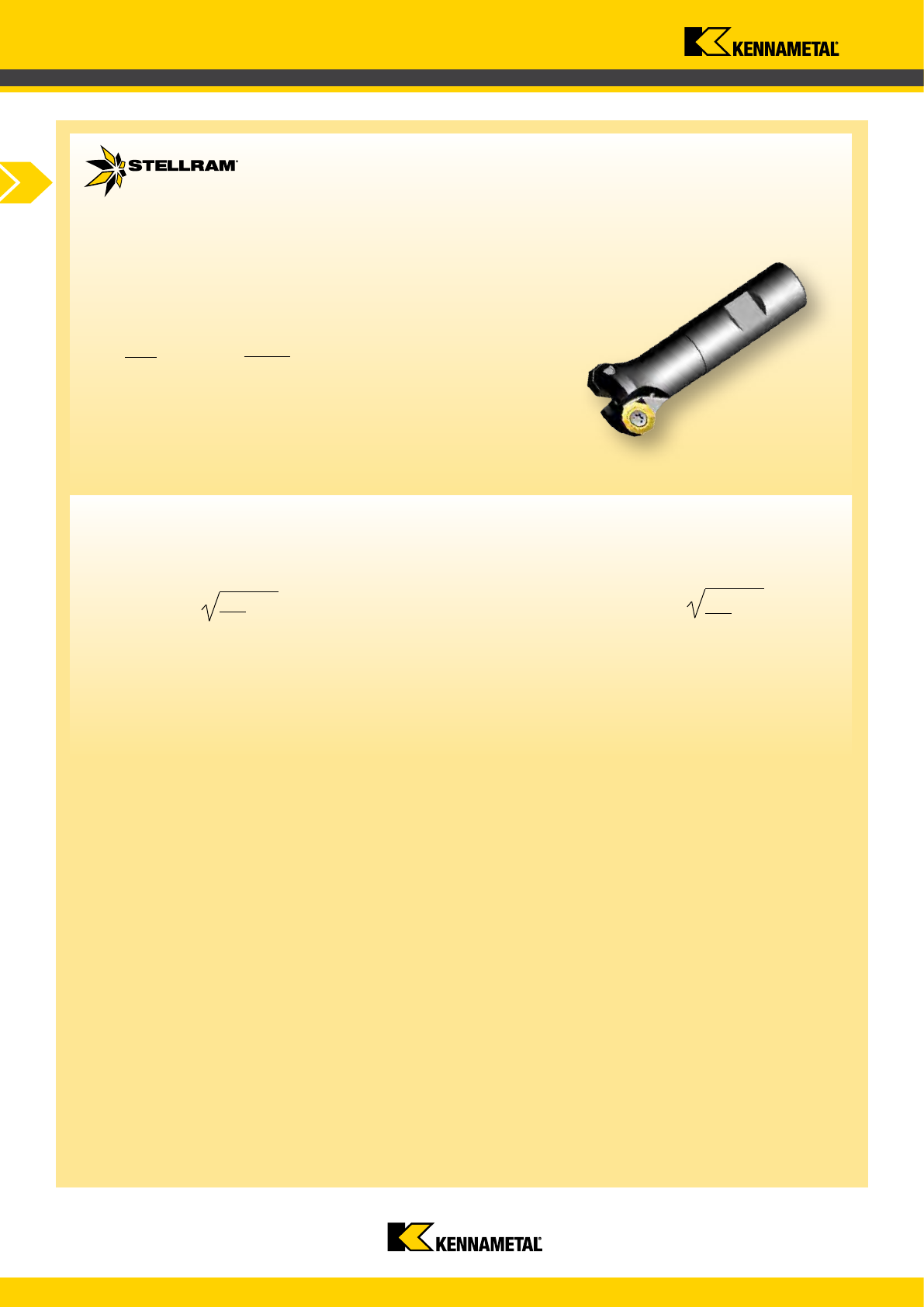

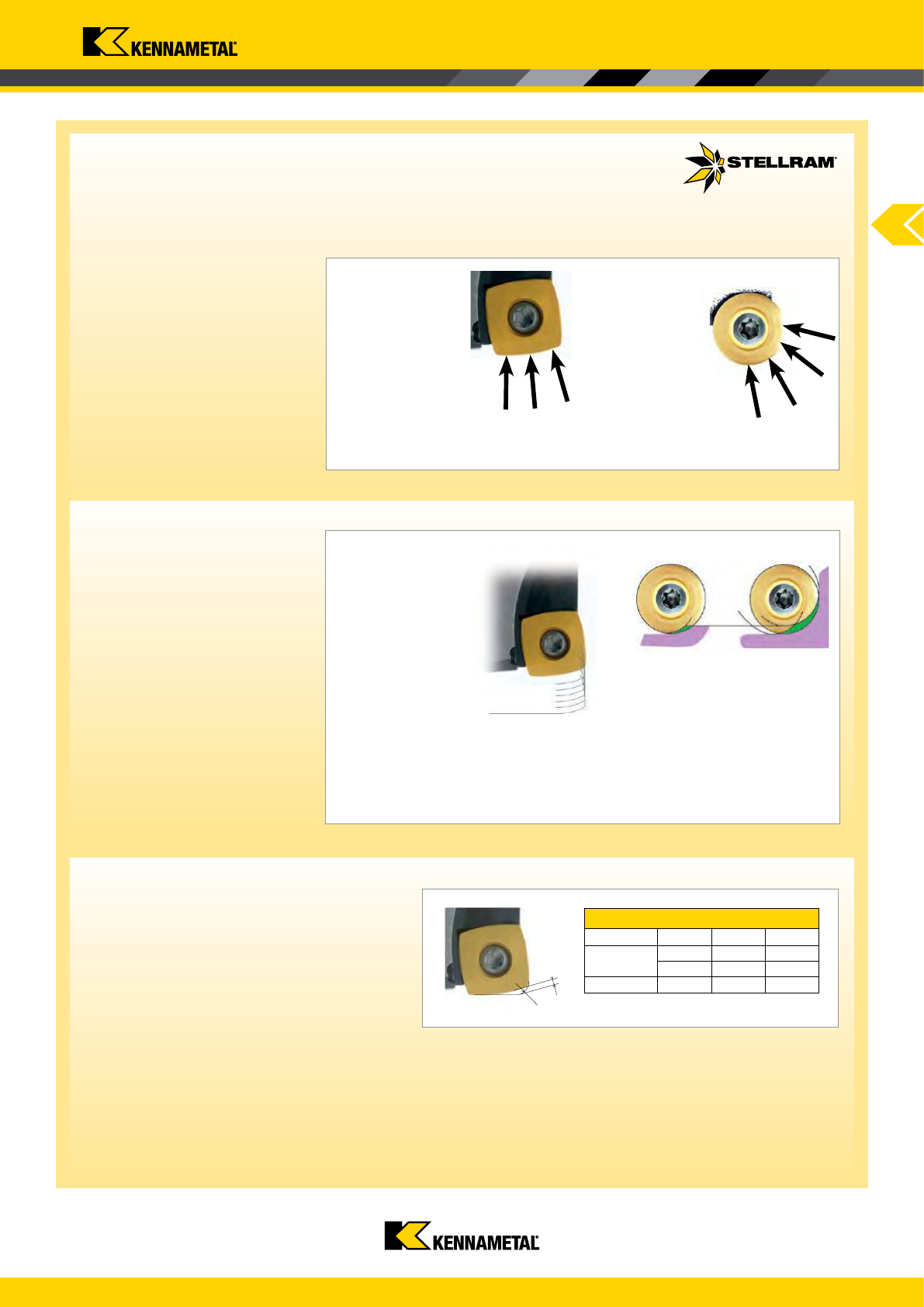

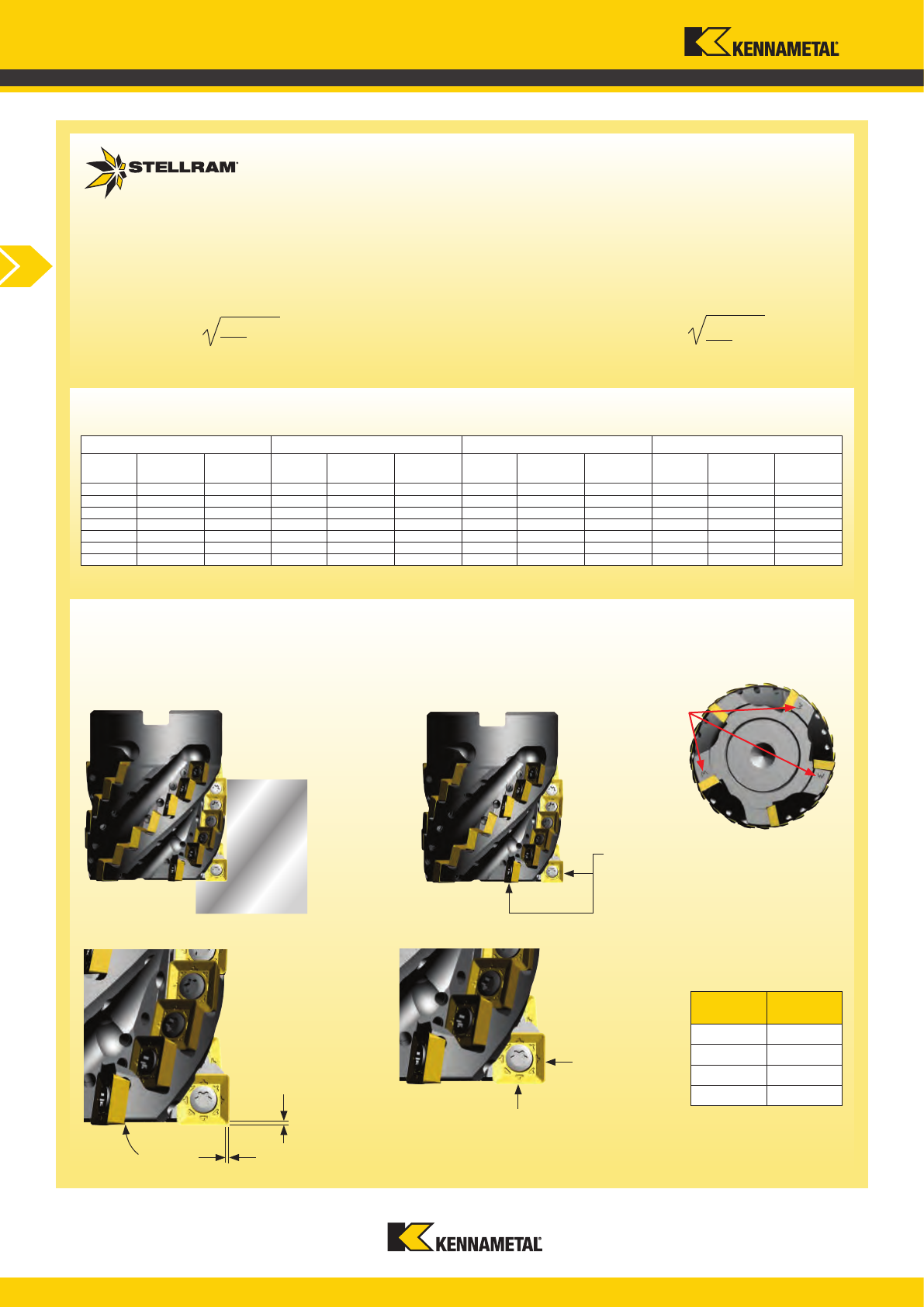

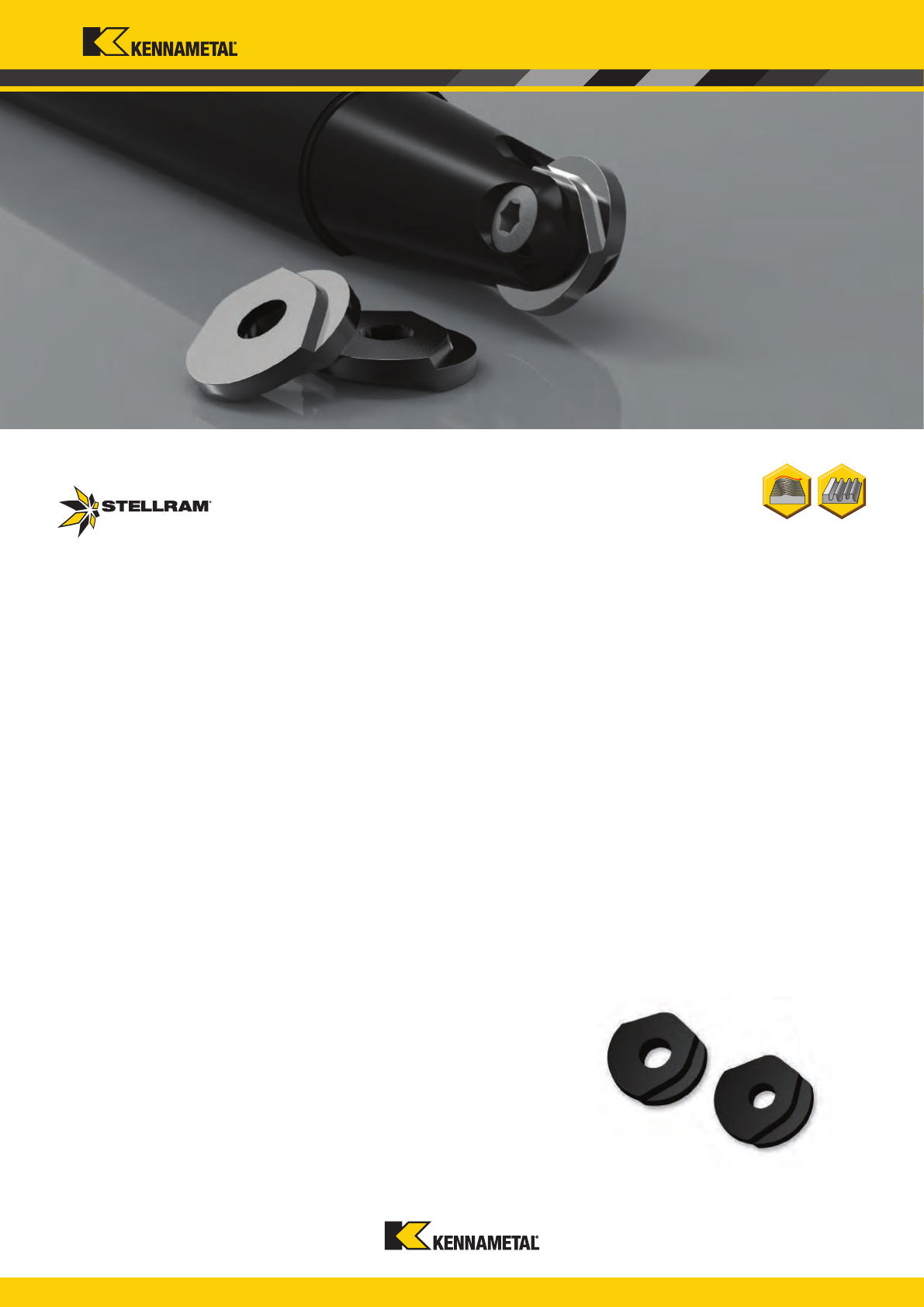

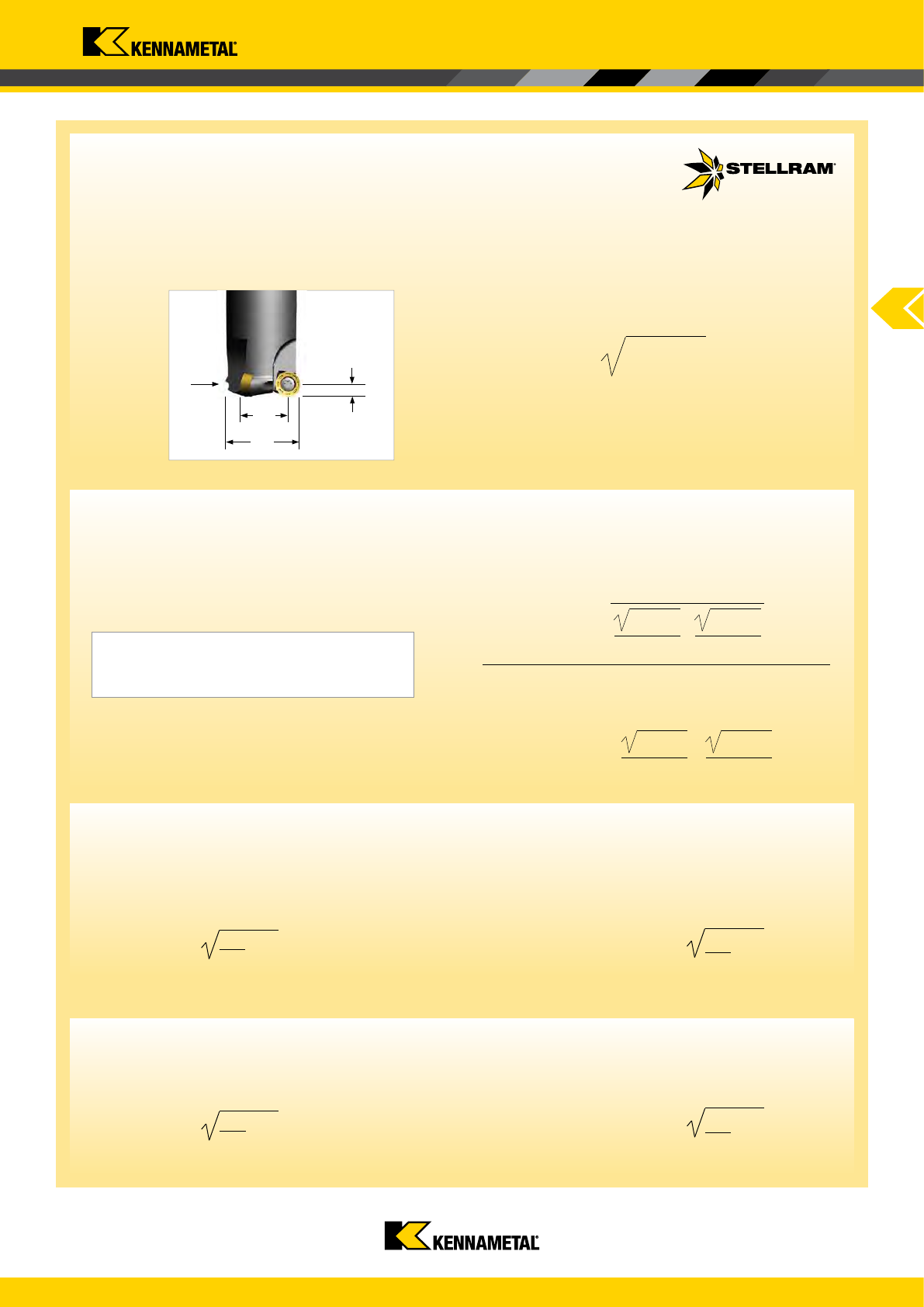

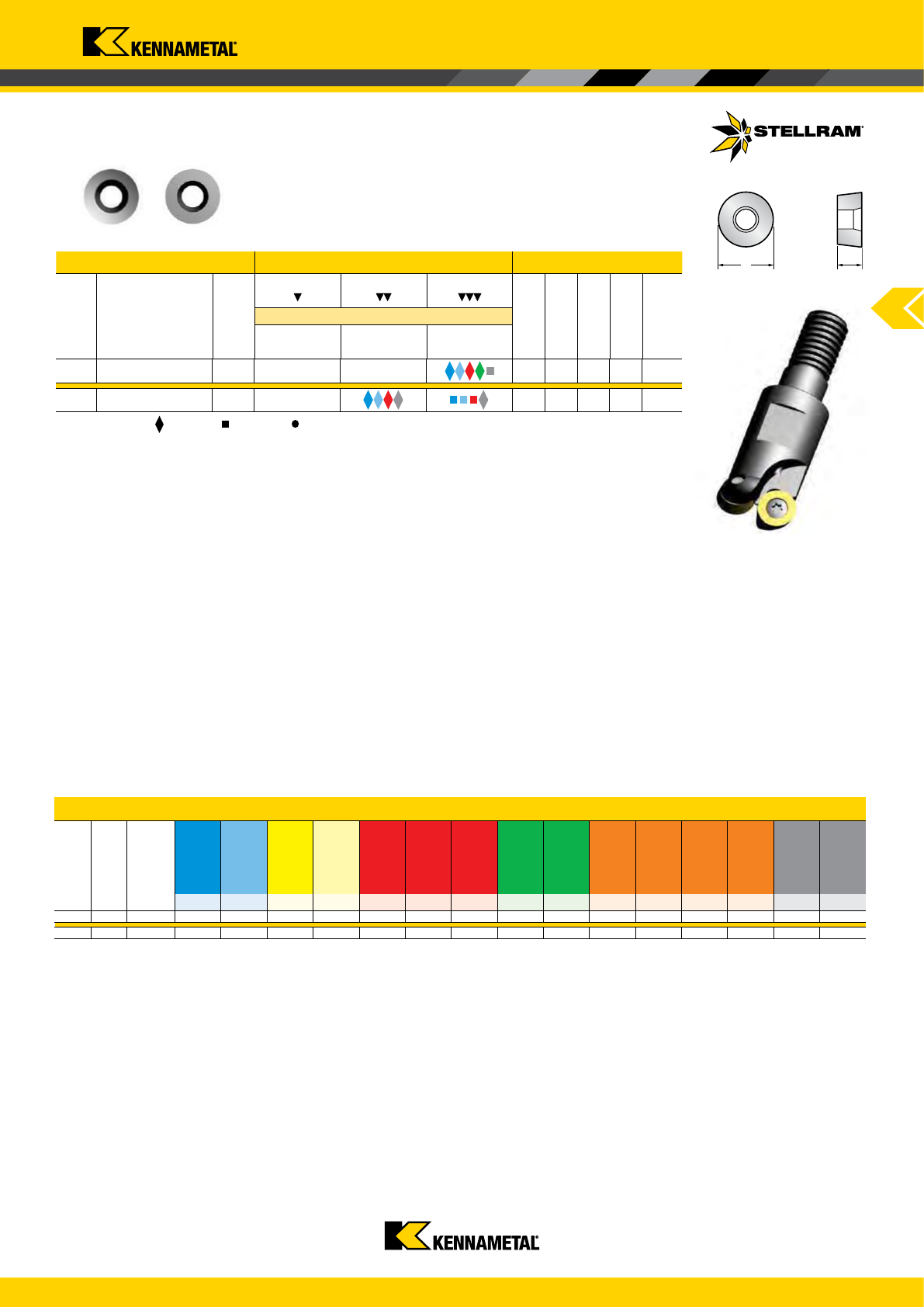

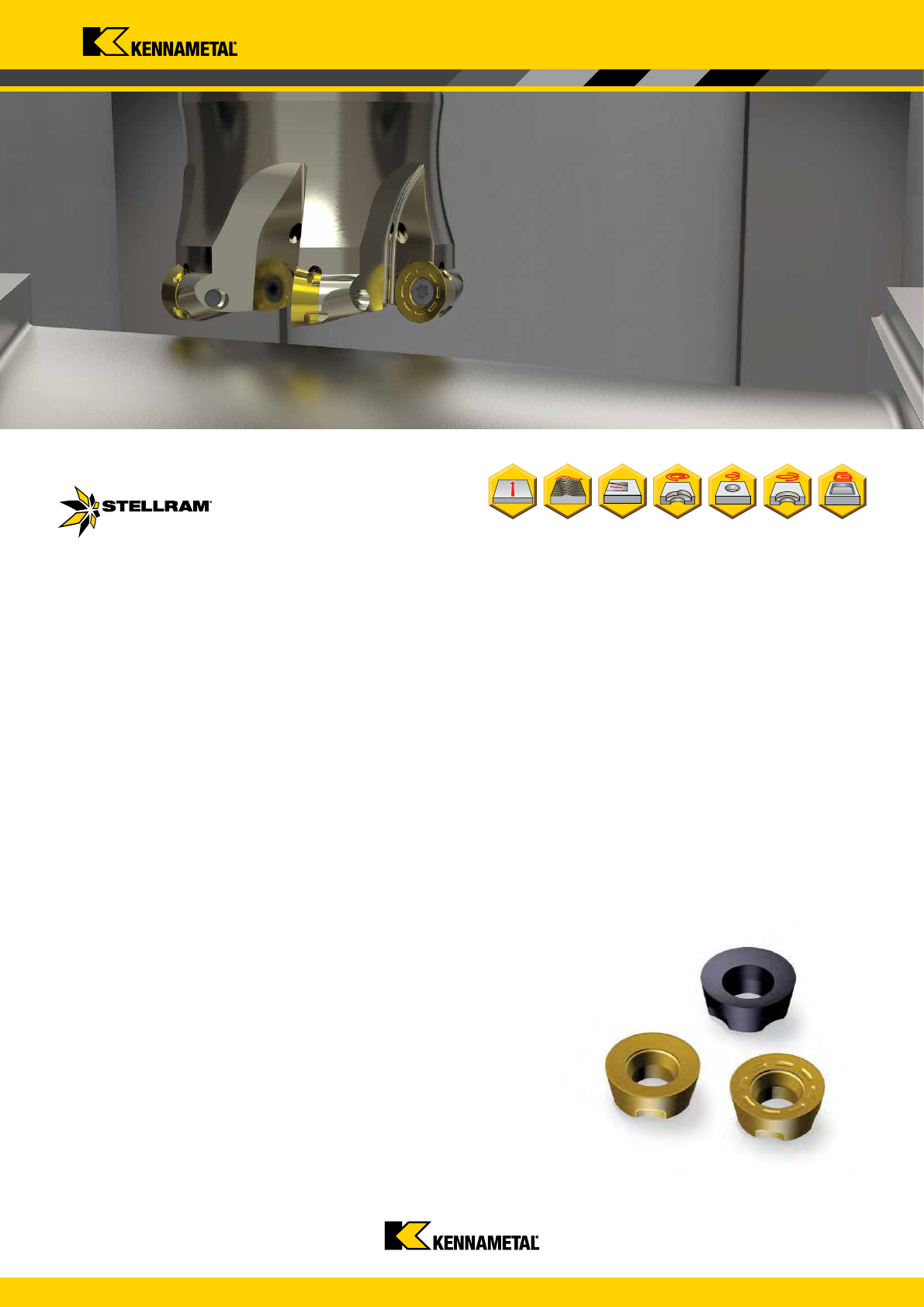

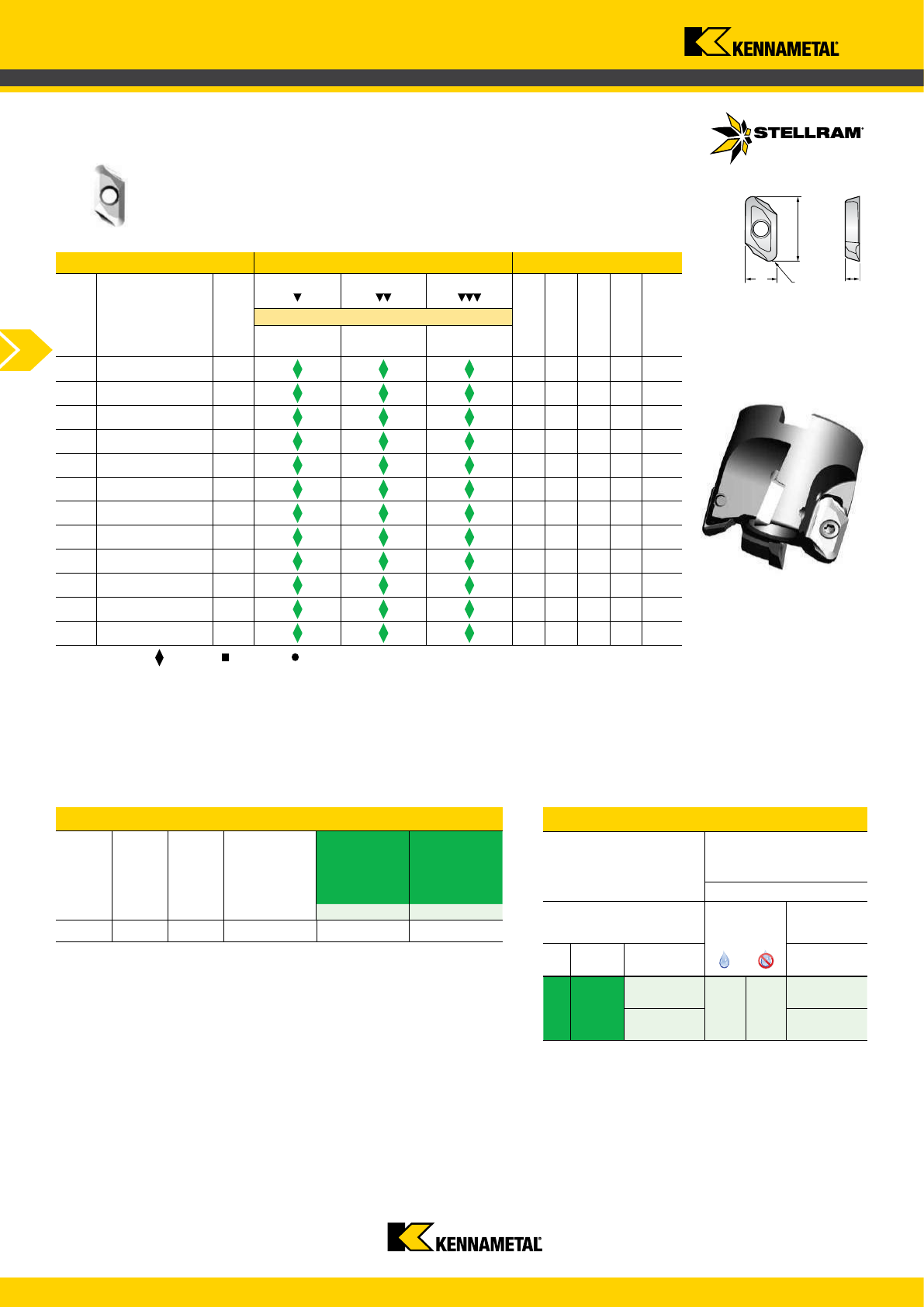

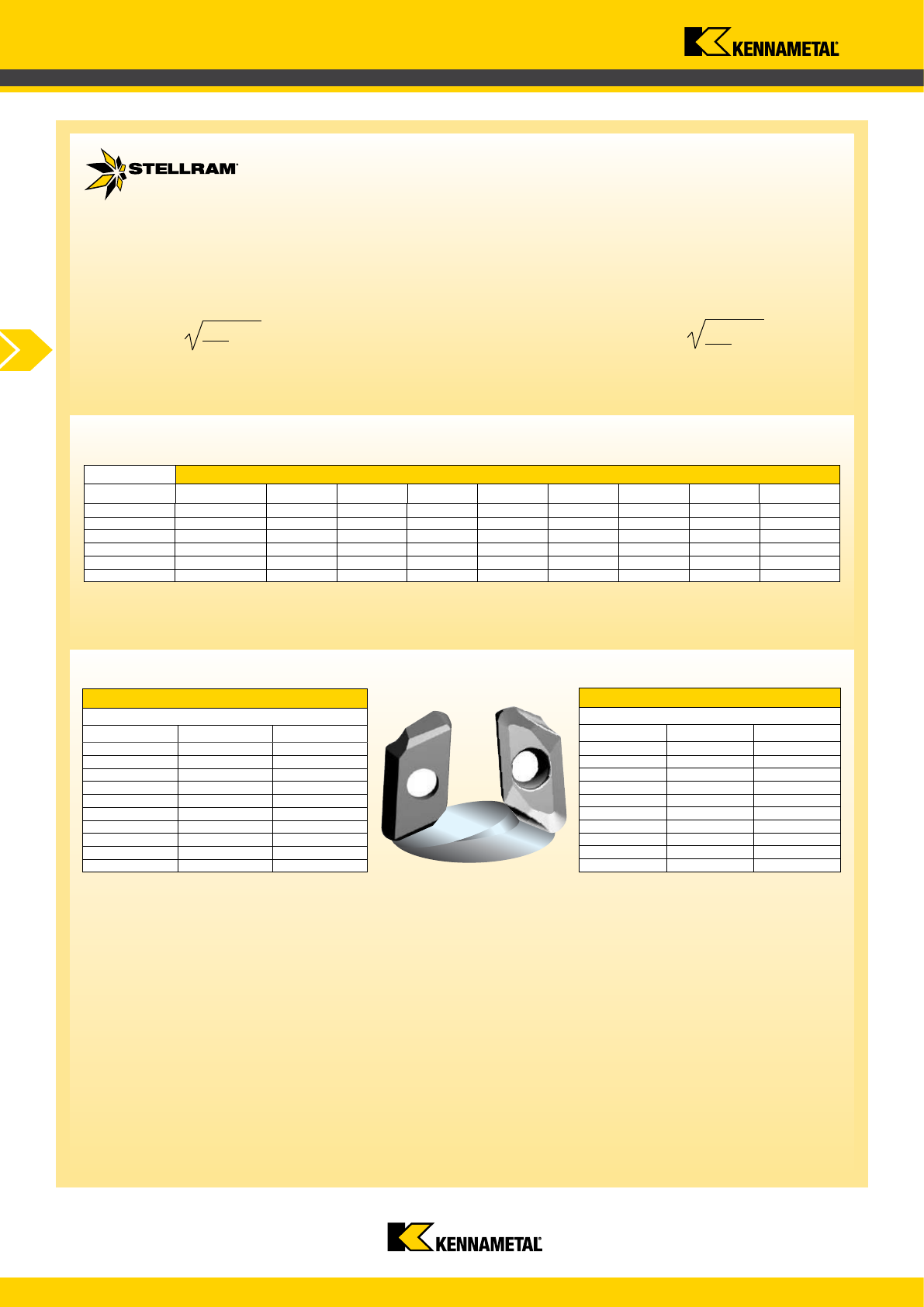

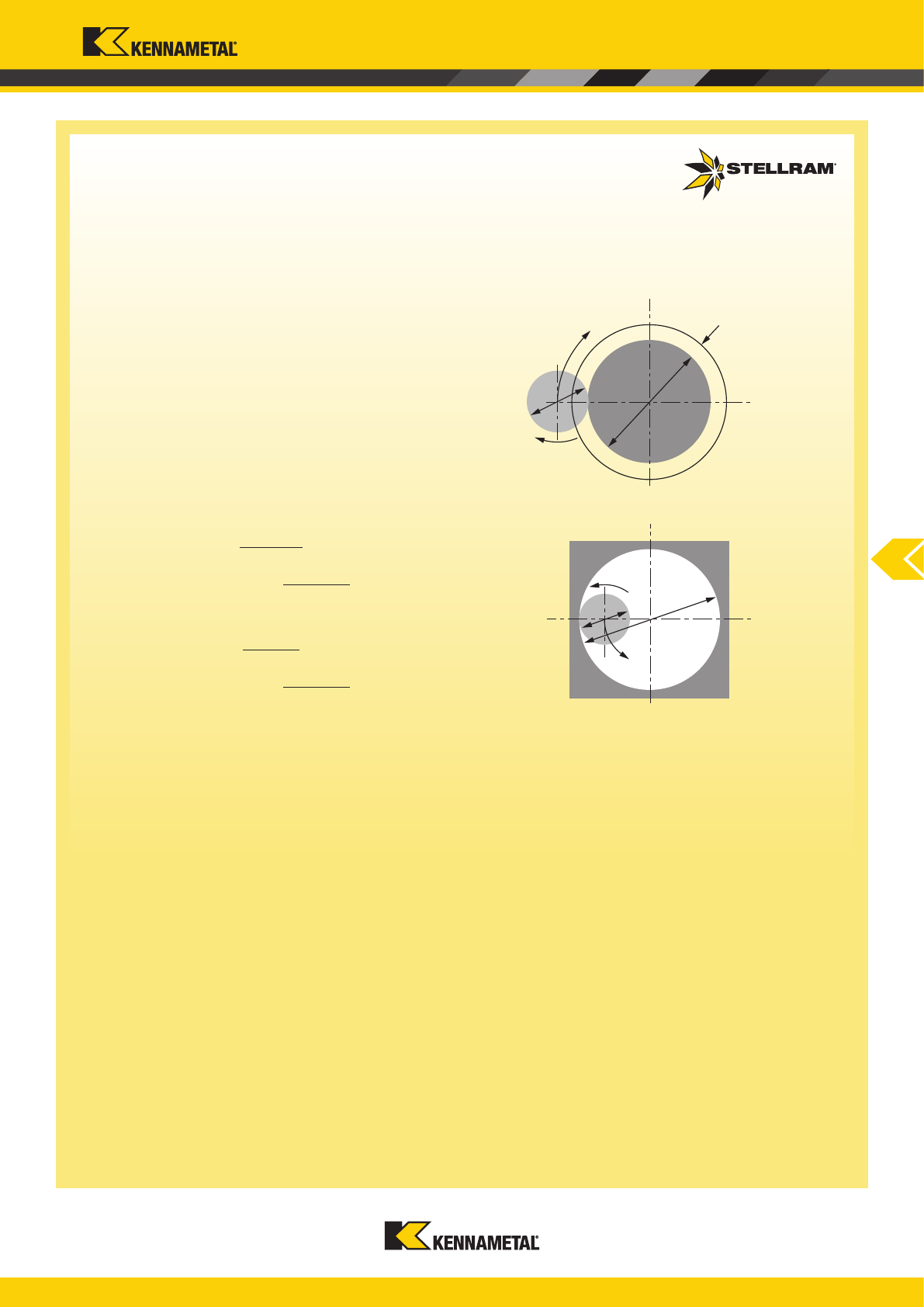

Round insert

•

Greater surface contact.

•

Increased chip section for side

wall machining.

•

Vibration in corners.

•

Undulating side wall cusps.

7792VX

•

Constant cutting

section (chip volume)

irrespective of

position in cavity.

•

Producing a close

to profile side wall.

•

Near-square side walls

possible.

The 7792VX machines with a

constant volume of chip throughout all

aspects of producing cavities and

produces a side wall that is close to

profile.

Round insert tools have increasing chip

volume through the process.

Round Insert Tools

•

Tangential

forces act

around the

radius

•

Leads to vibration

and damage of

the cutting edge

•

Leads to reduced

feed and lower productivity

7792VX

•

Cutting forces

predominantly

axial

•

Relationship

between cutting

edge and work piece

is at its most stable.

•

Results in high feed

rates and consistent

tool life.

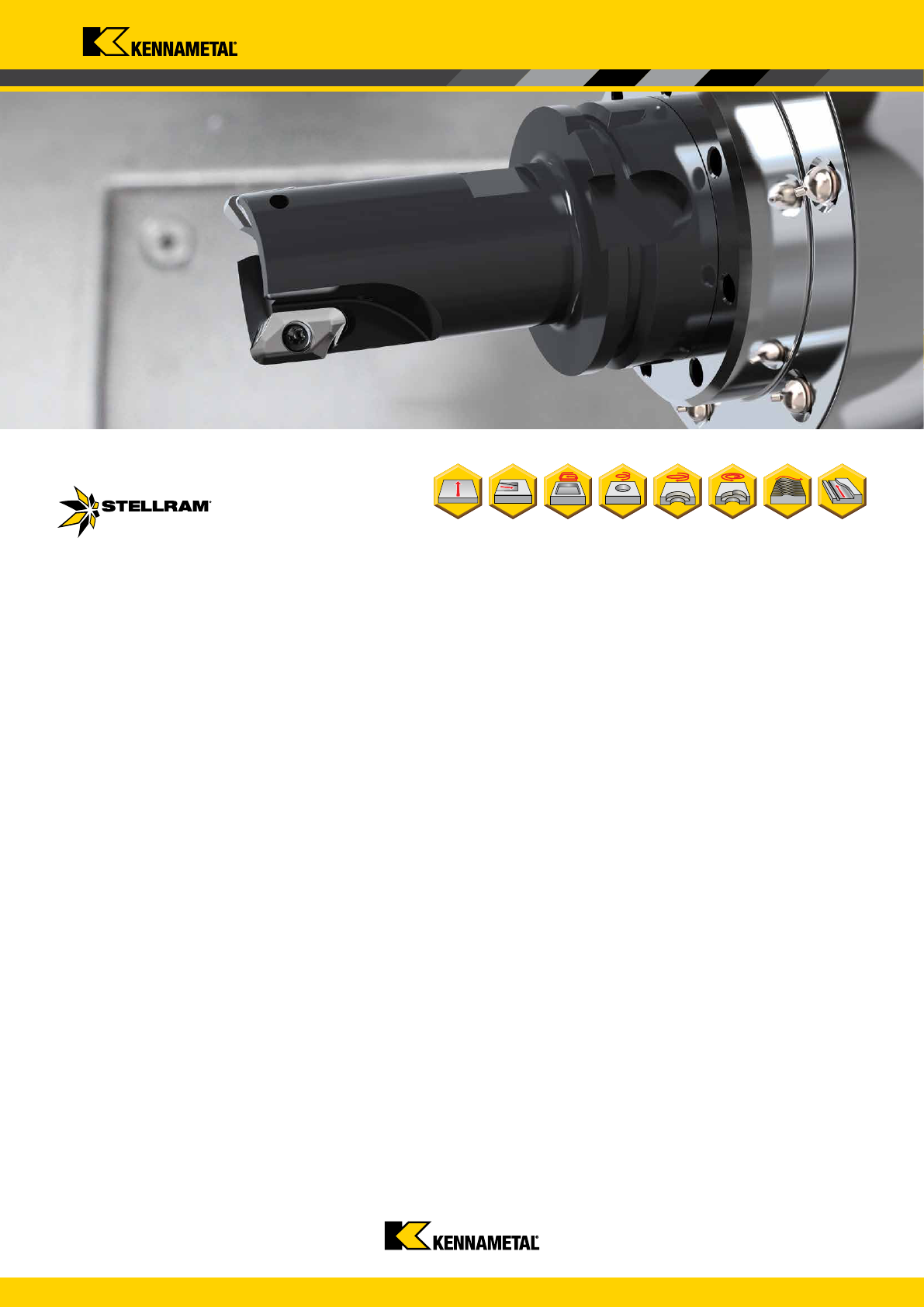

The advantages of face milling and

producing cavities with Stellram’s high

feed face mill are numerous.

The unique design of the insert, approach

angle and the cutter body ensure the

cutting forces are predominantly directed

in the axial direction. The example shown

with a round insert tool shows complex

forces which result in high levels of

vibration and damage to the cutting edge.

Centre clearance Side wall

7792VX

Technical Information

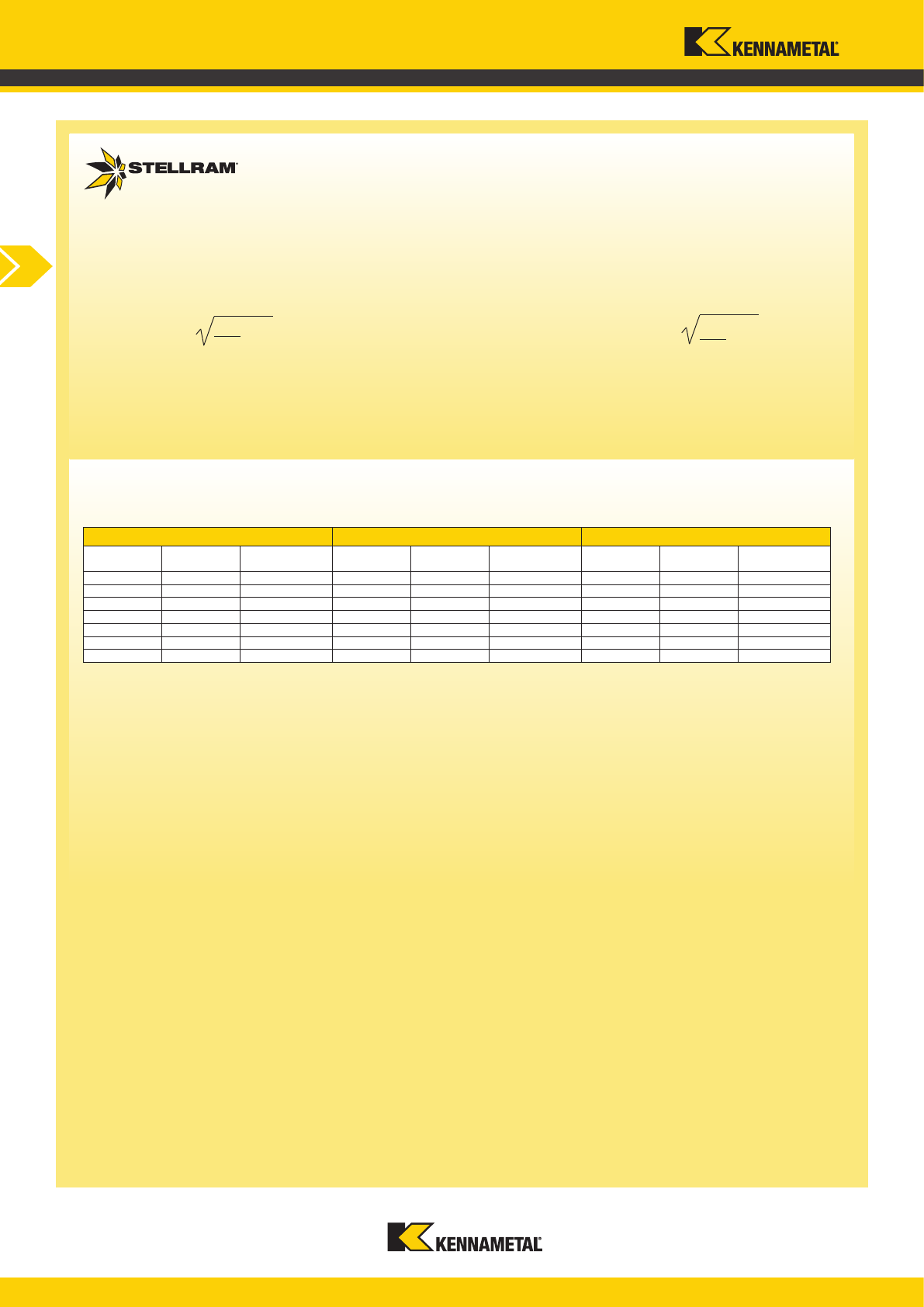

Alloyed Steels

Stainless Steels

Commercial

Name

UNS

Number

UK:

BS,EN

Sweden:

SS

USA:

AISI/SAE

Germany:

Wnr

Germany:

DIN

France:

AFNOR

Italy:

UNI

Spain:

UNF

Japan:

JIS

www.kennametal.com

A5

P

P

M

M

K N

S

H

P

M

K

N

S

H

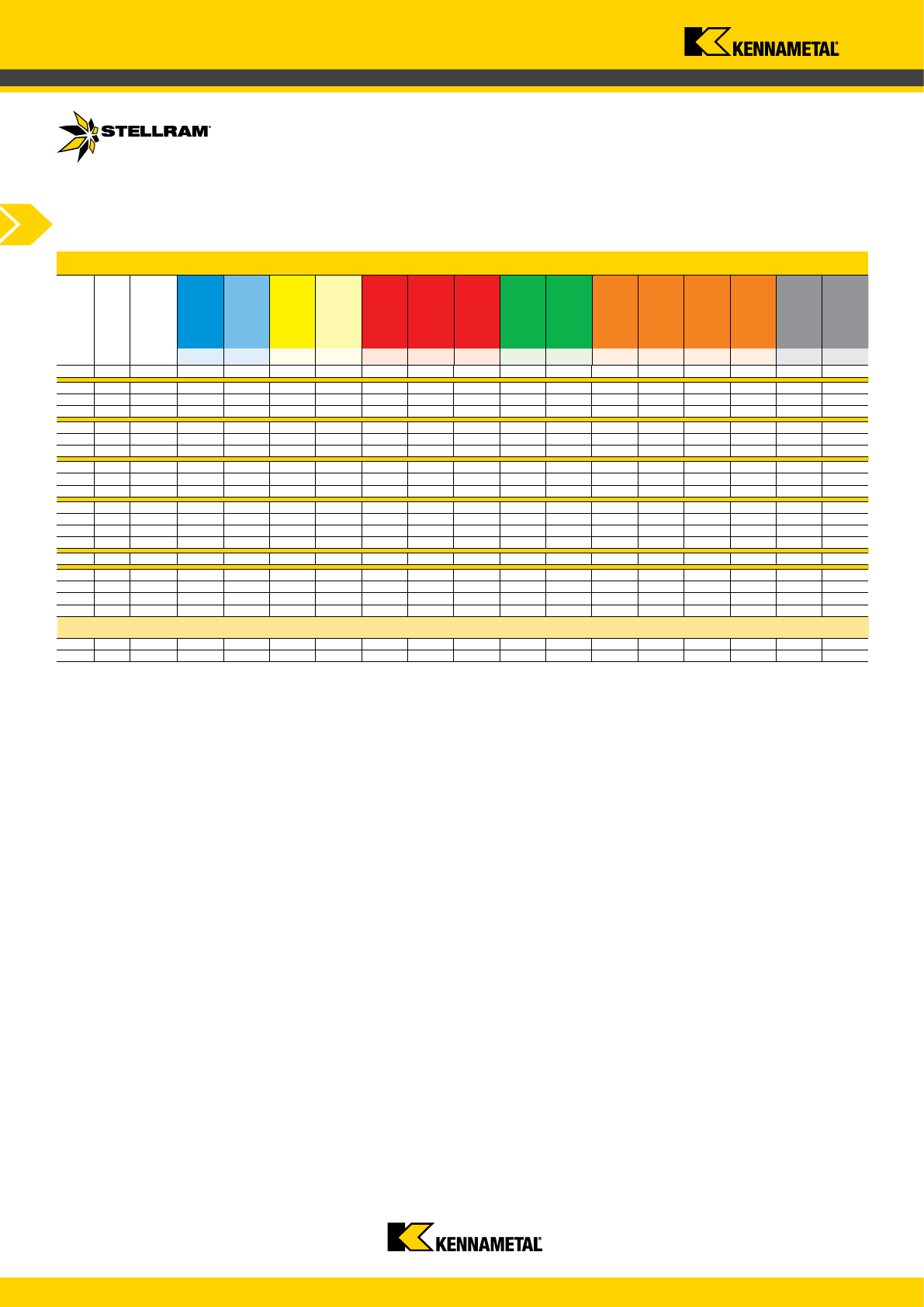

Milling Introduction

Hard Materials (42-45 HRC)

High Temperature Alloys

Cast Irons

PH Stainless

Stainless Steels

Alloyed Steels

Unalloyed Steels

Aluminium & Alloys

Machining Materials Guide

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

www.kennametal.com

A6

•

•

•

•

• •

• •

• • • • • • • •

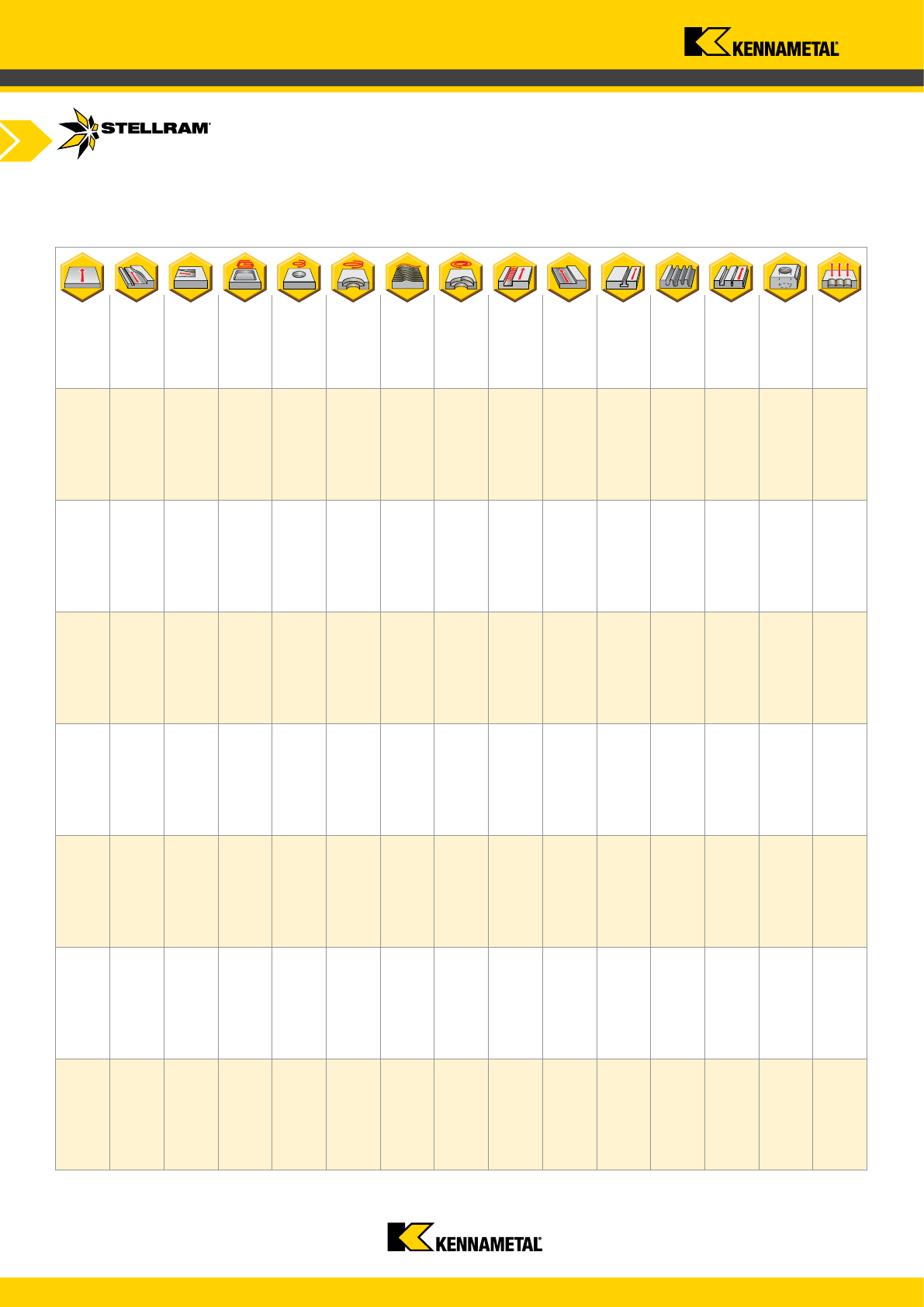

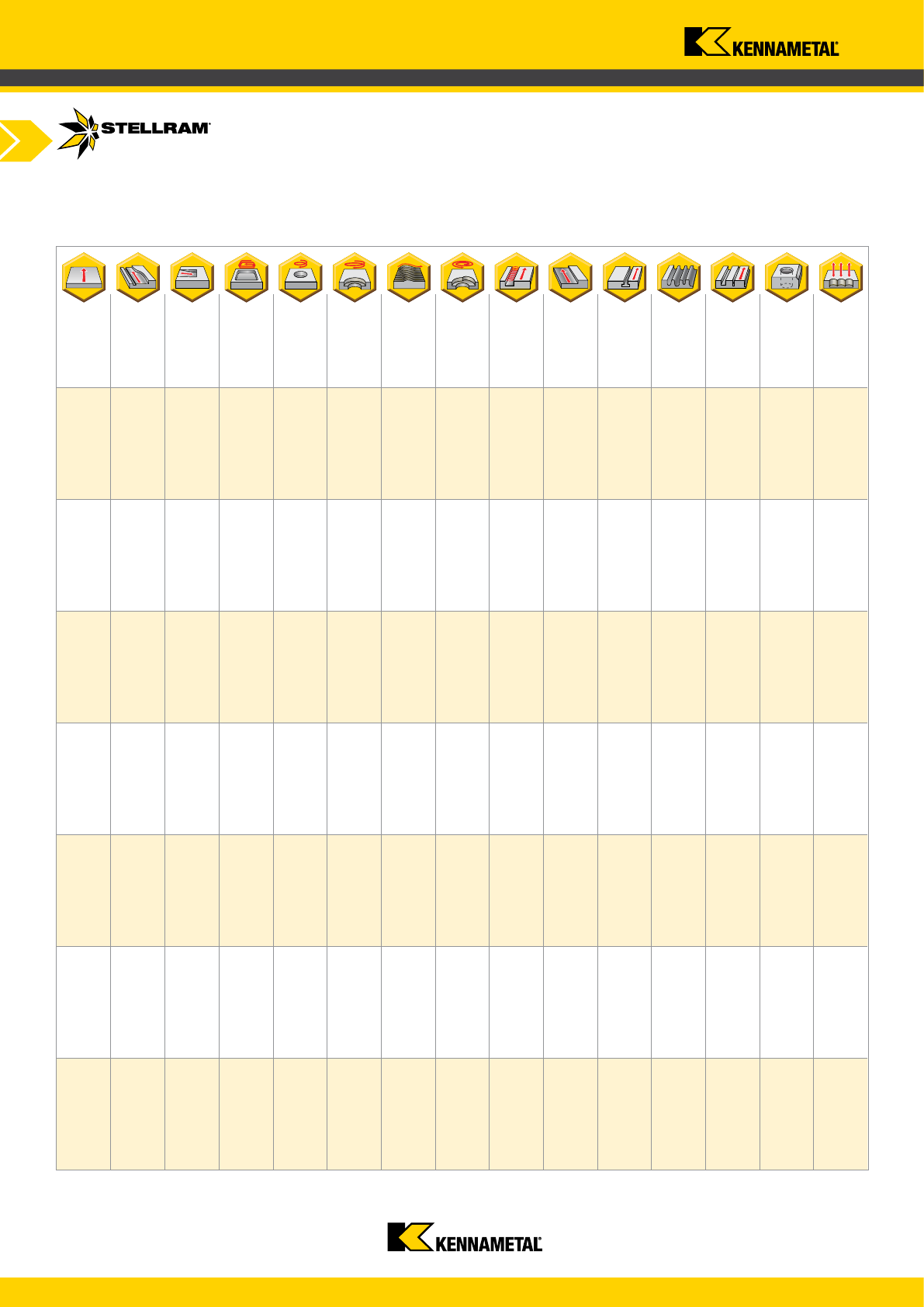

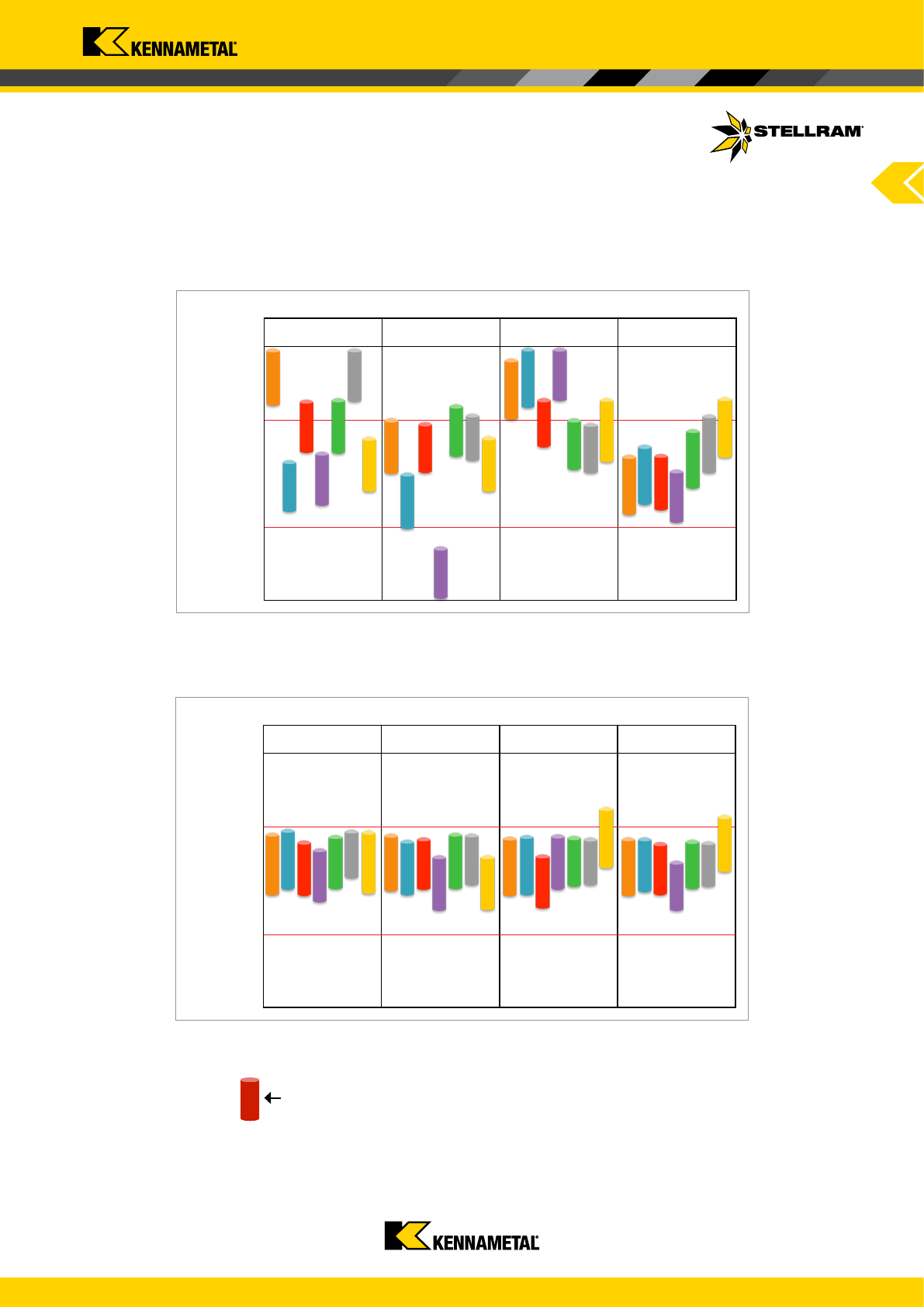

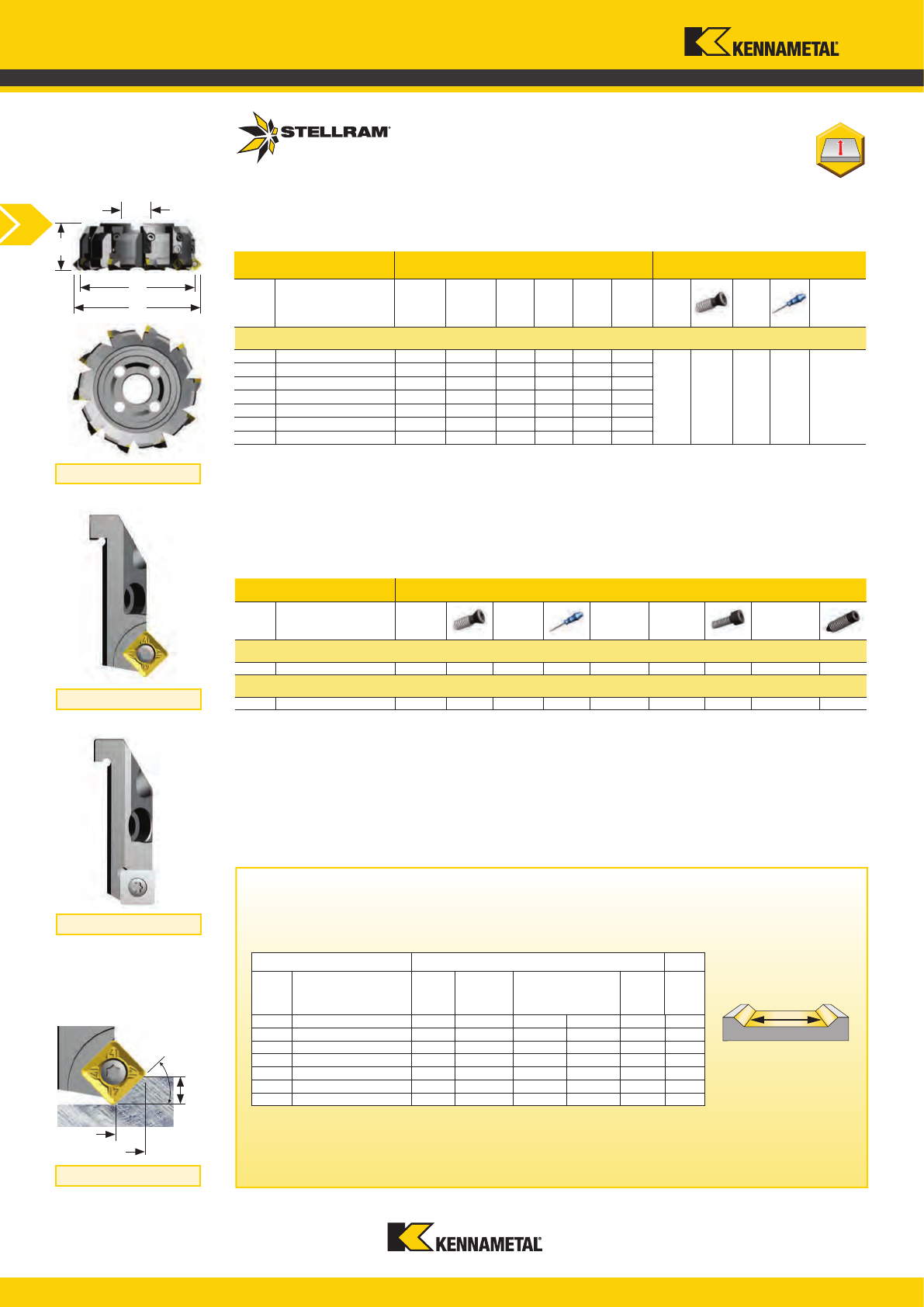

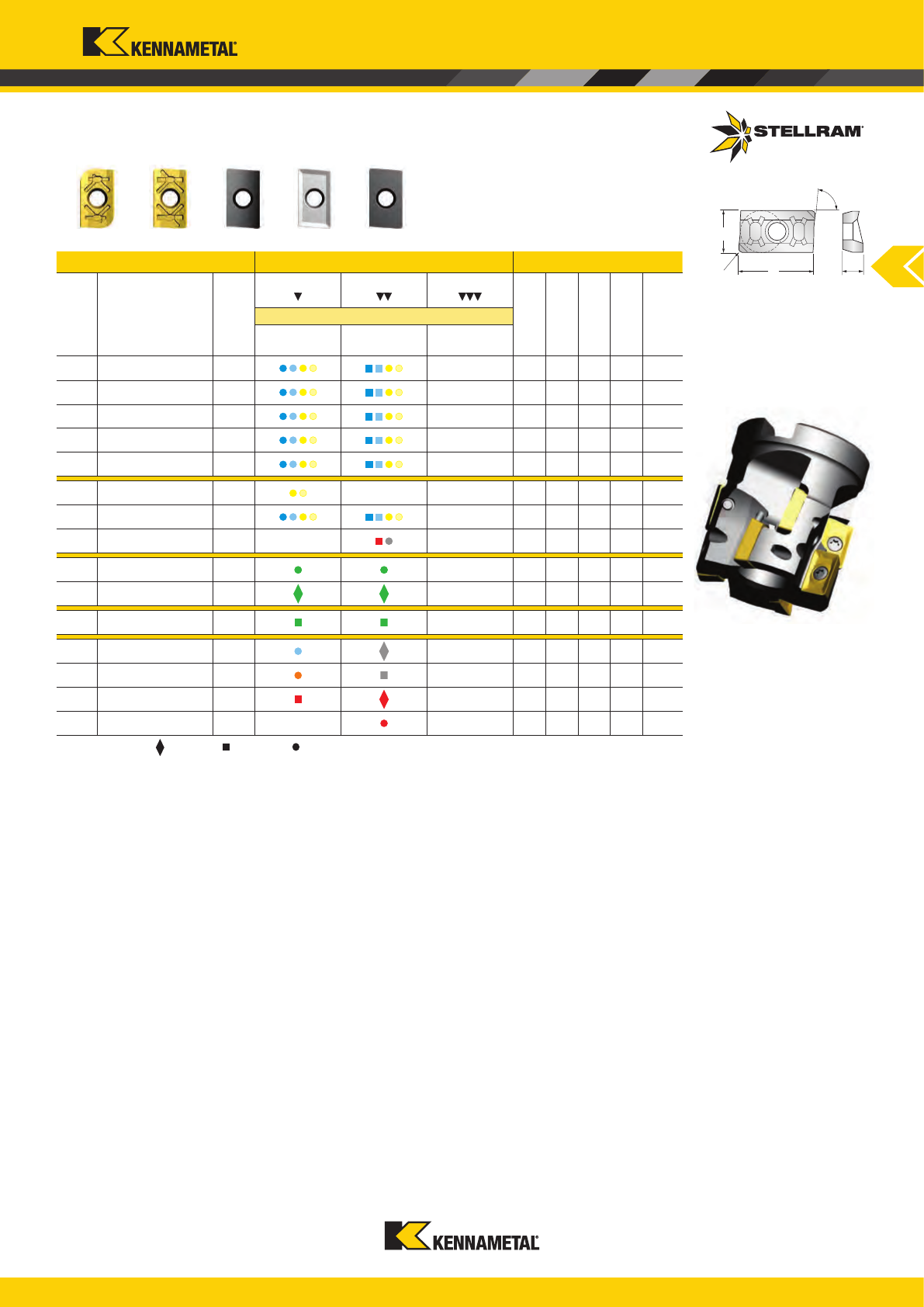

Milling Introduction

Application

Facing

Shoulder /

Proling /

Slotting

Ramping

Pocketing

Helical

Interpolation

Helical

Interpolation

with Bore Hole

Copy / 3D

Spiral /

Circular

Trochoidal

Shoulder /

Proling

T-Slotting

Contour

Milling

Slotting

Shoulder

Chamfering

Plunging

Applications Index

Indexable Tools

www.kennametal.com

A7

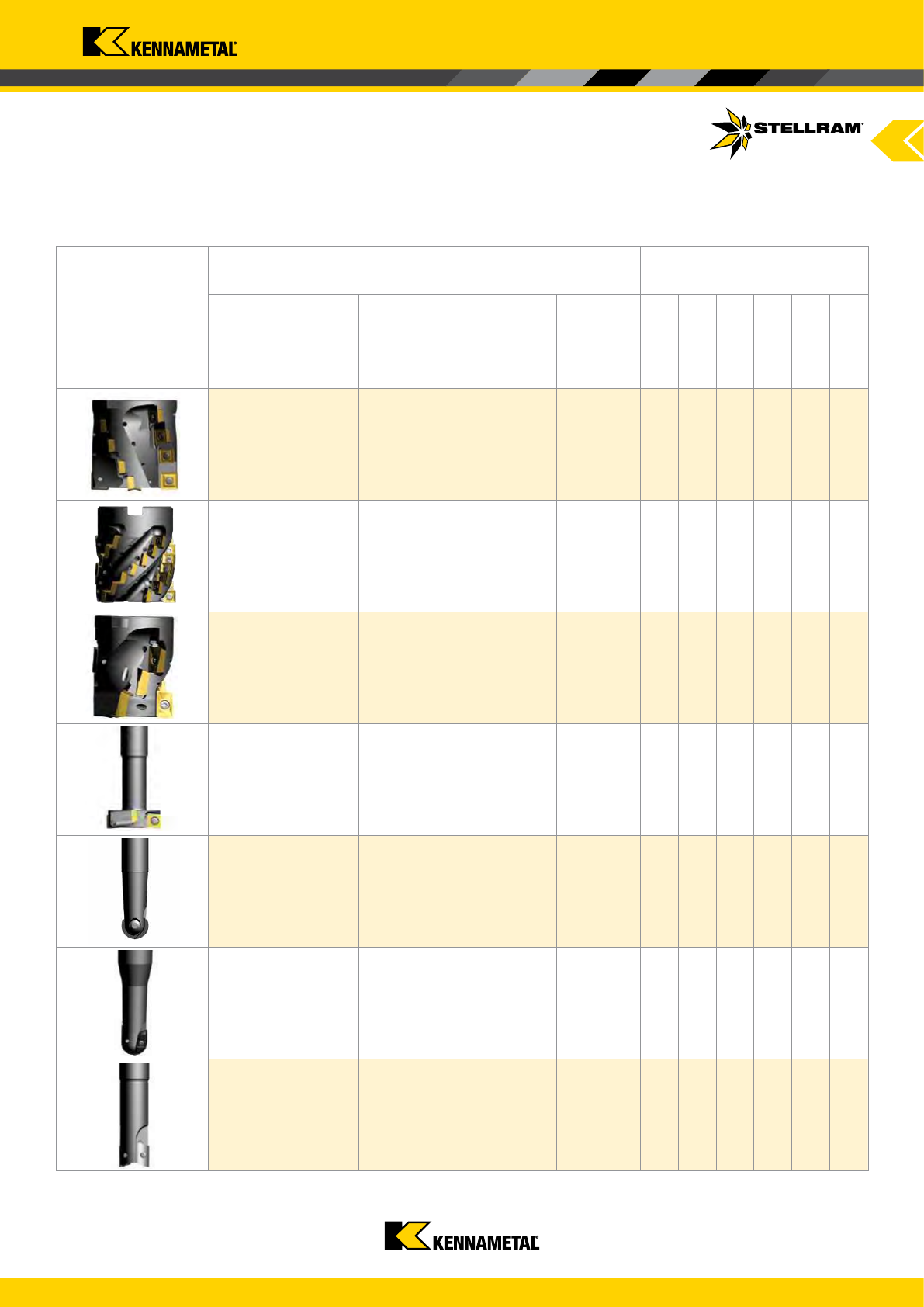

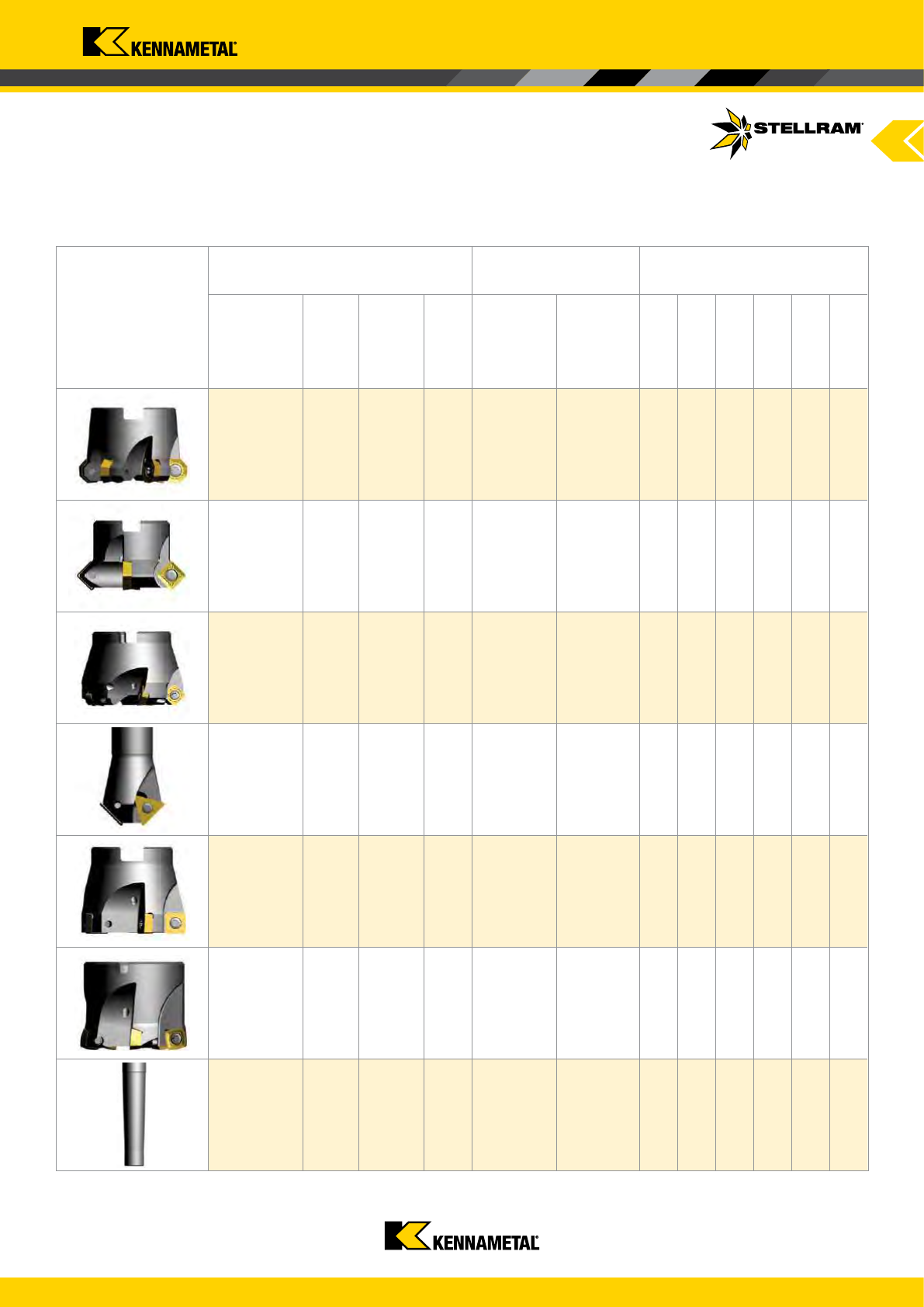

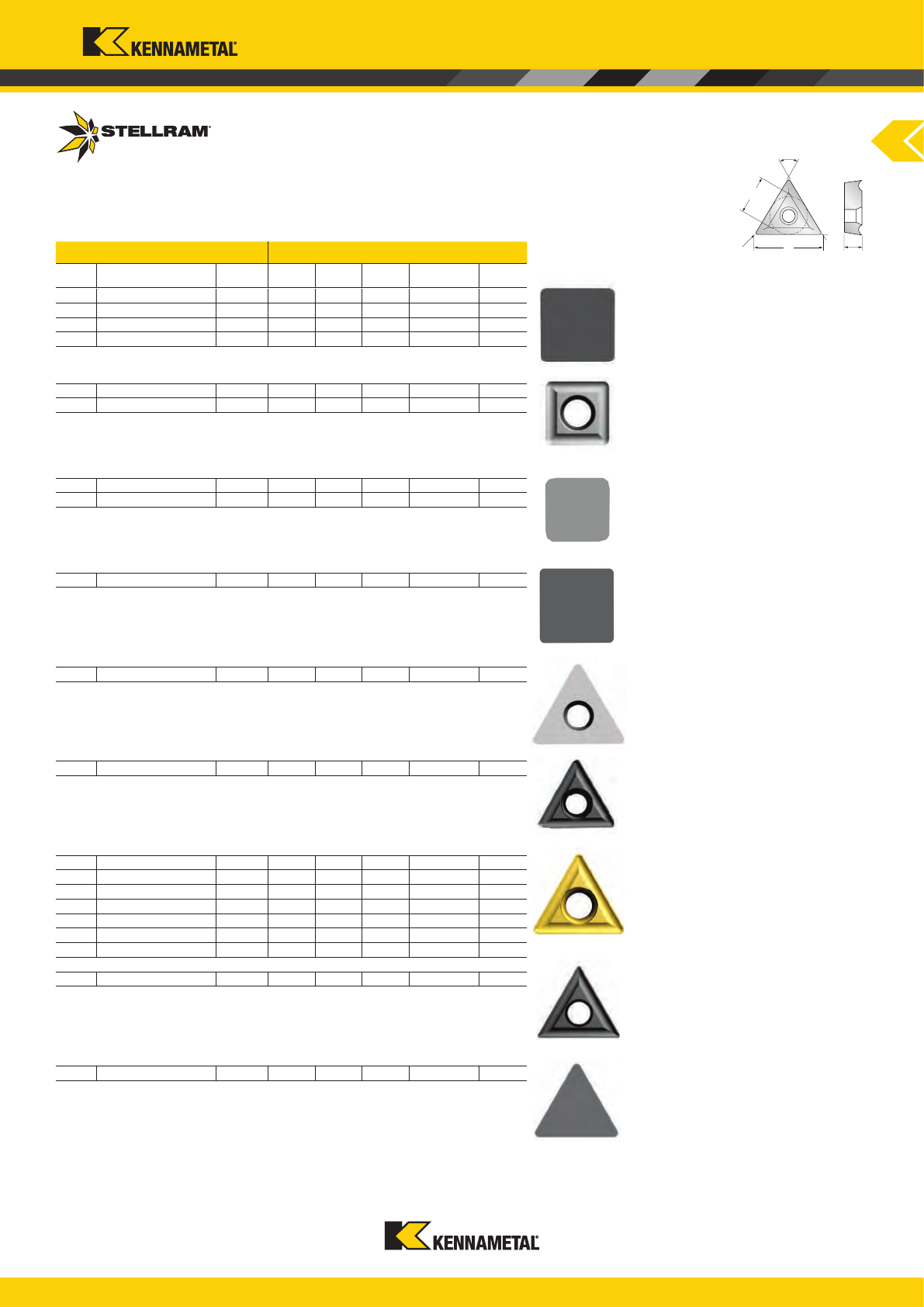

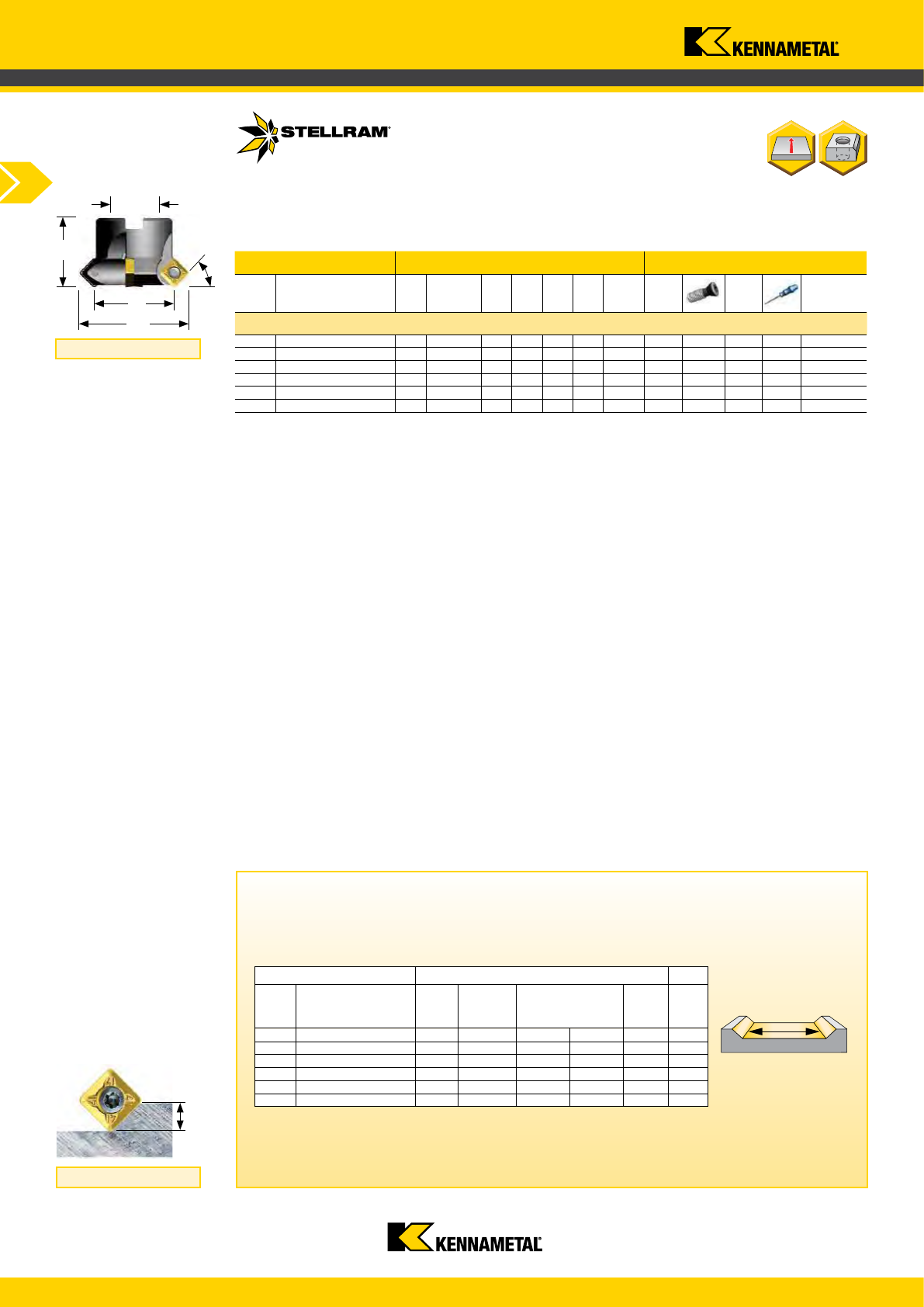

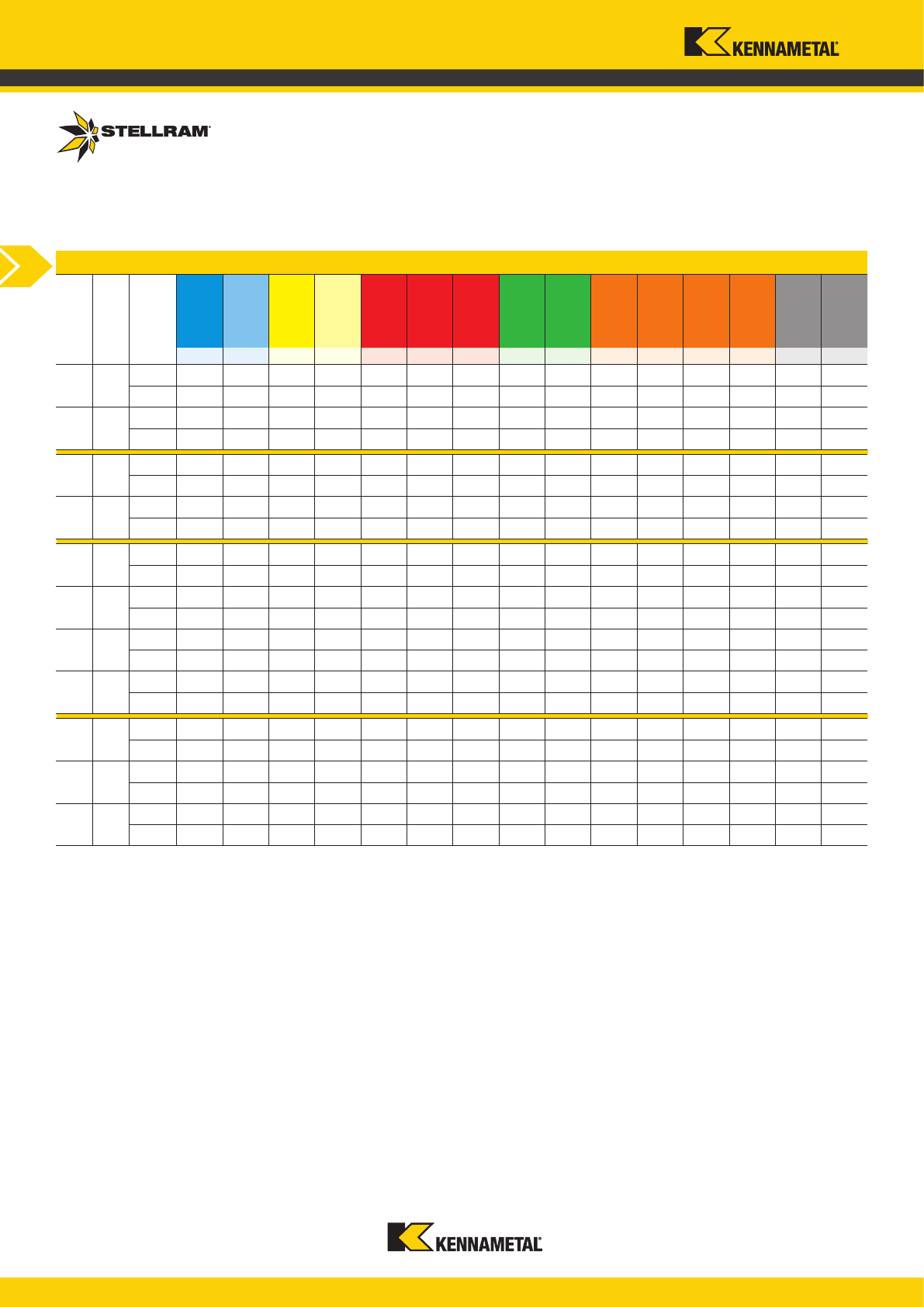

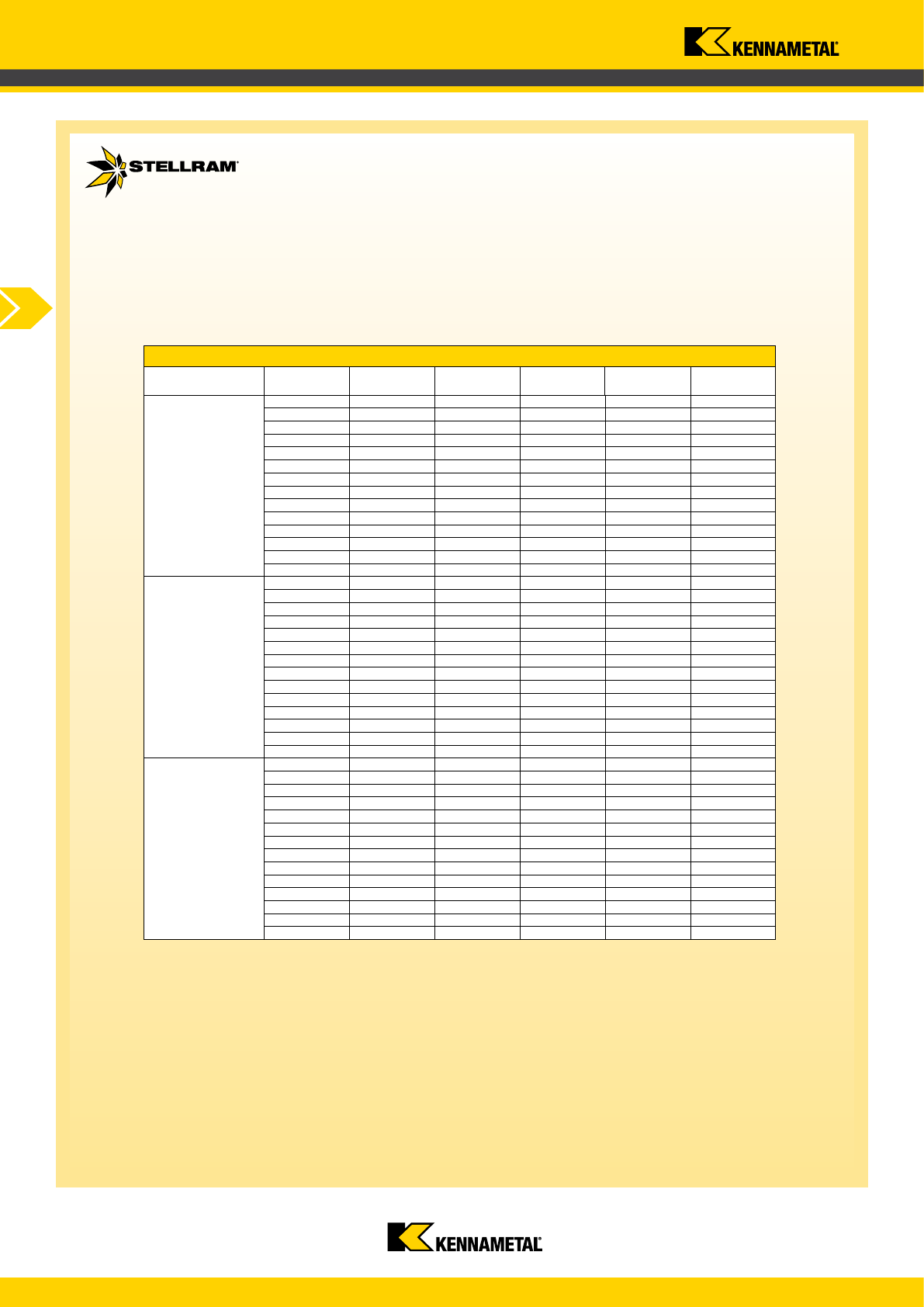

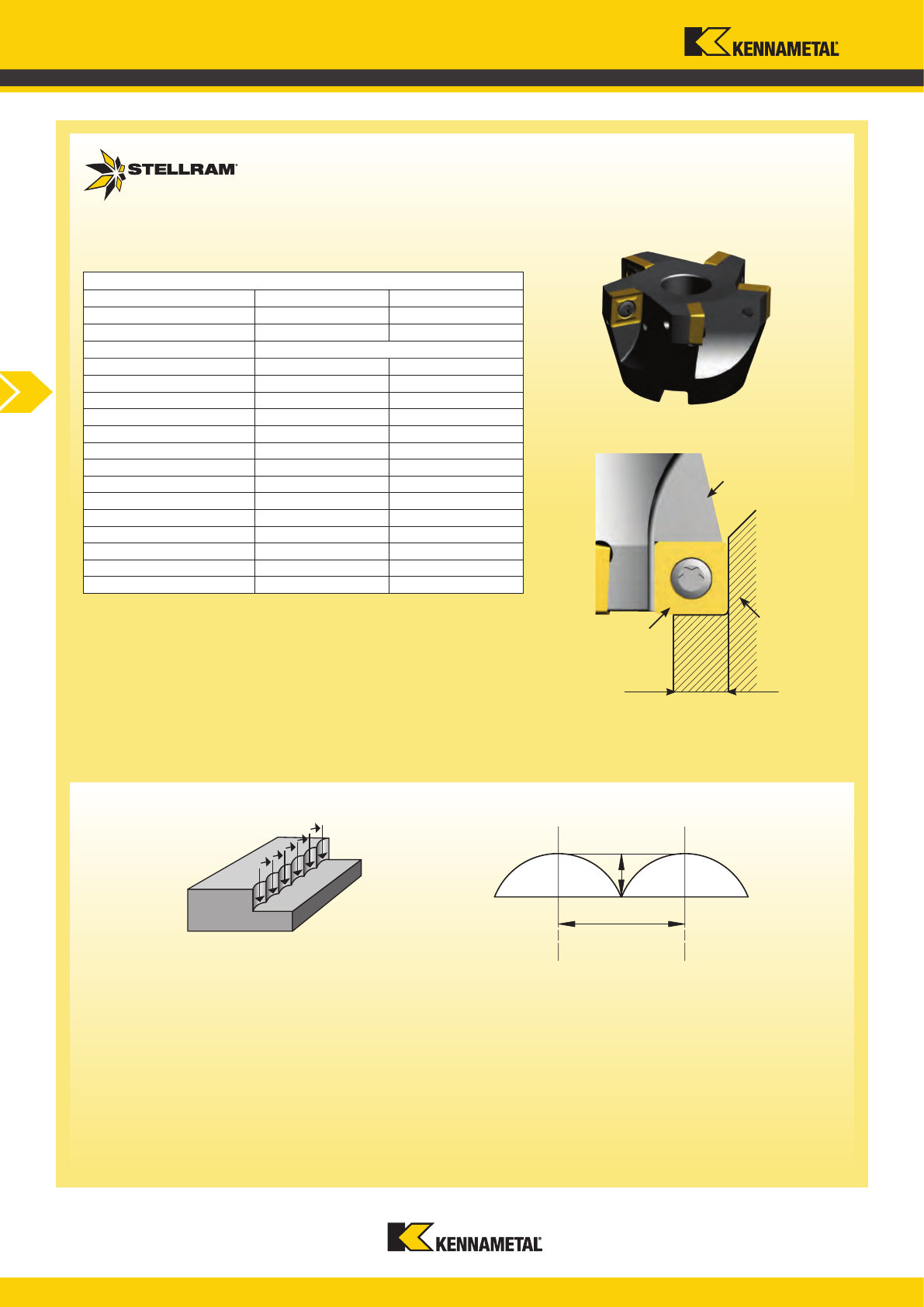

Milling Introduction

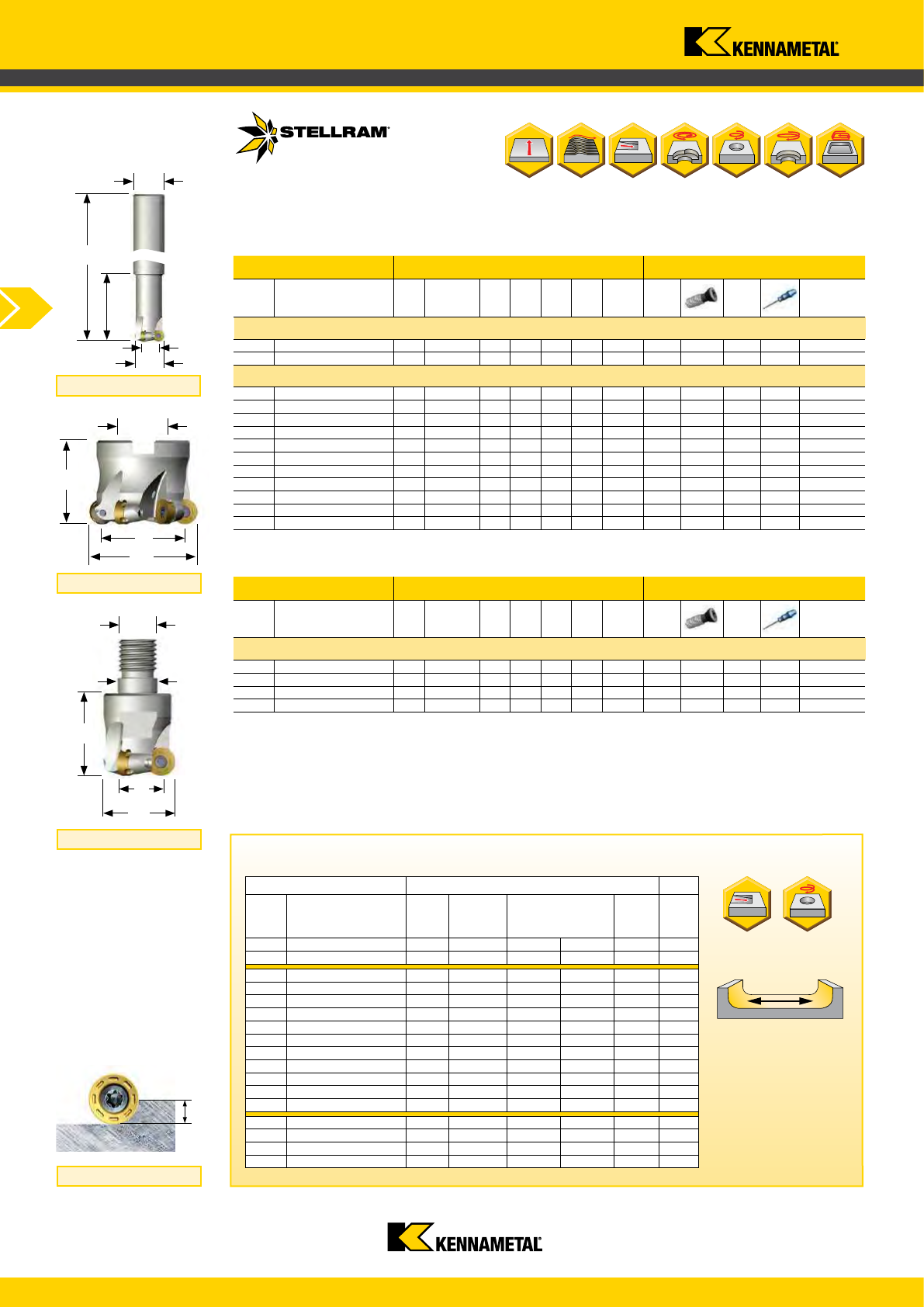

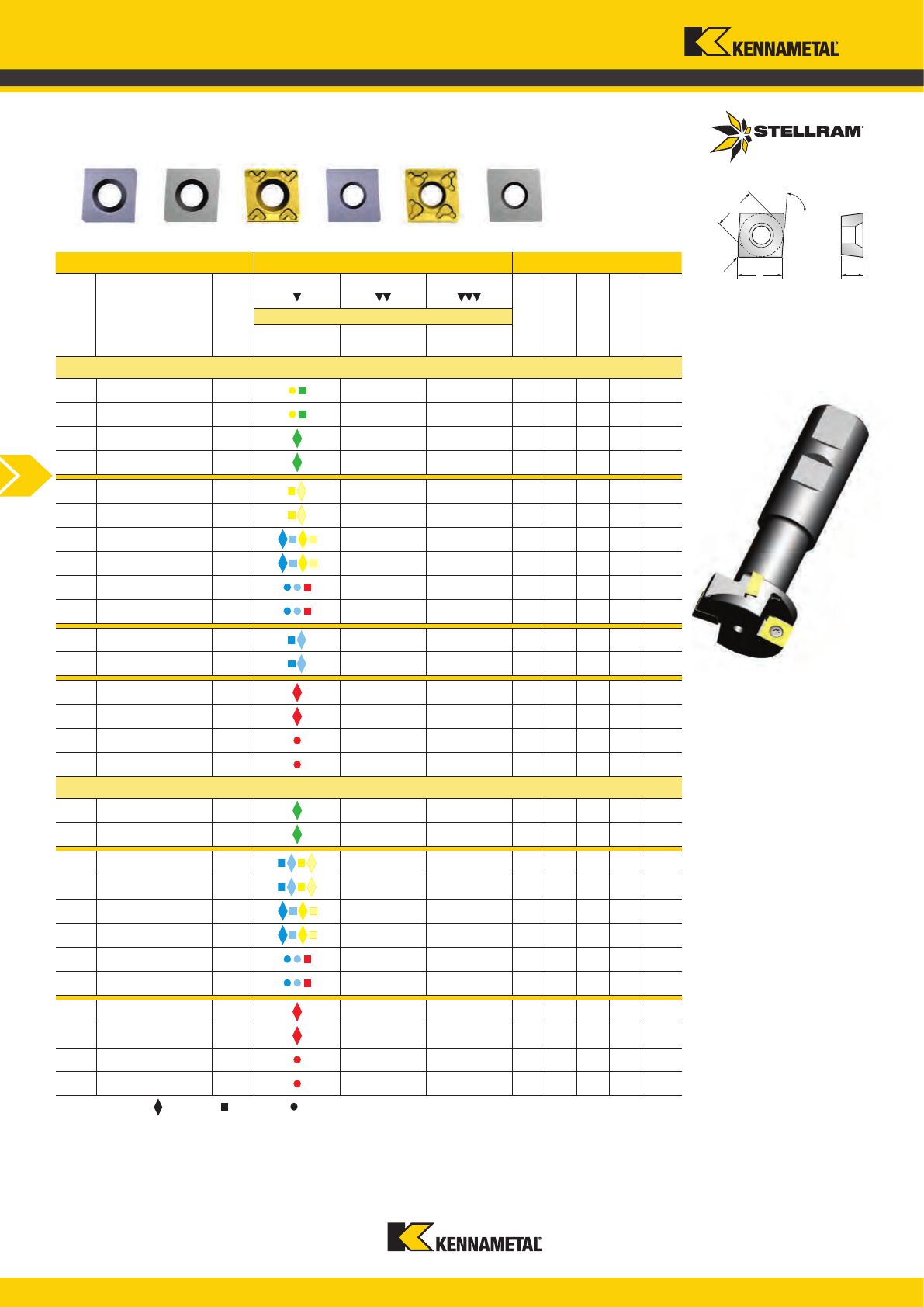

Tool Denition

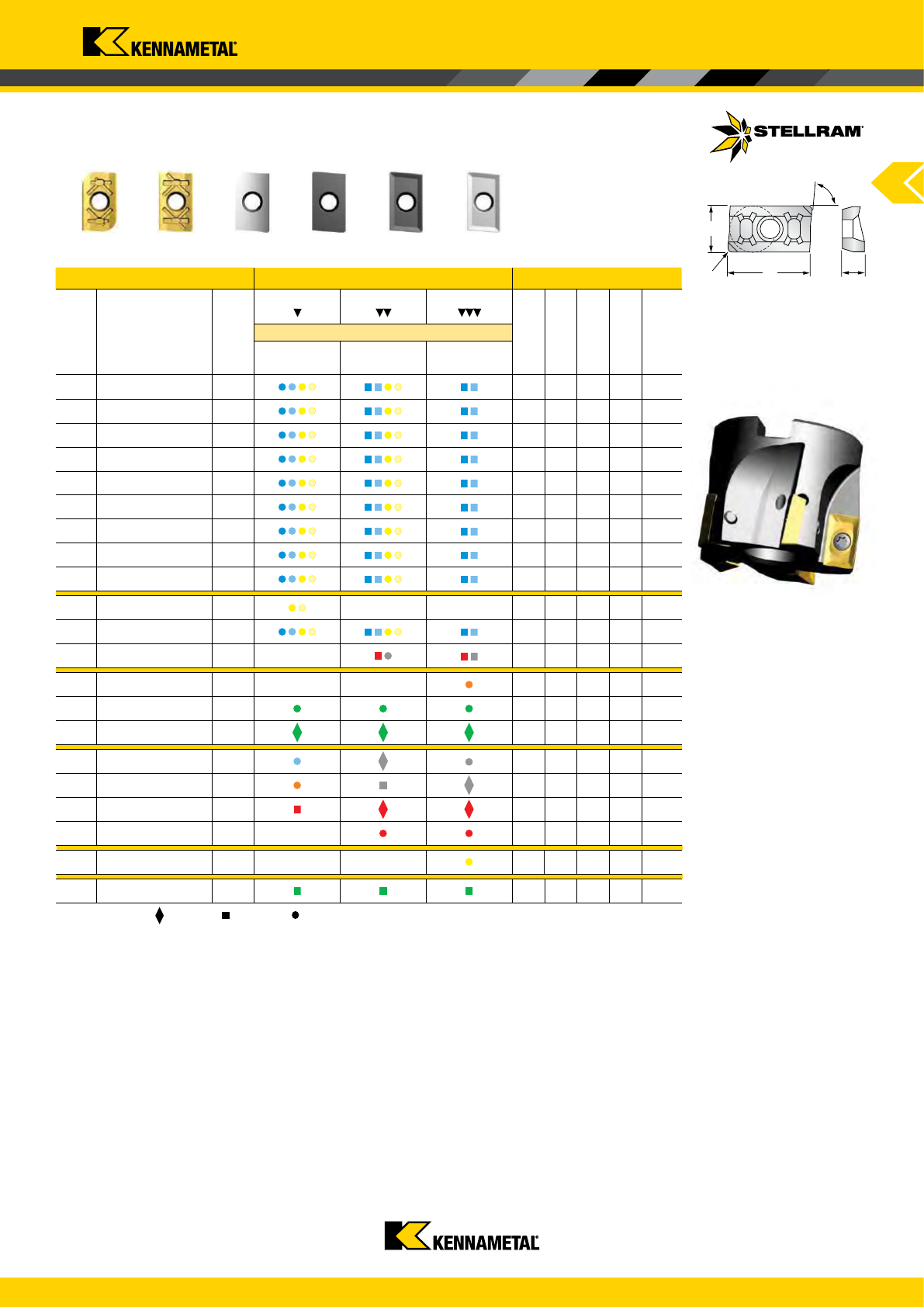

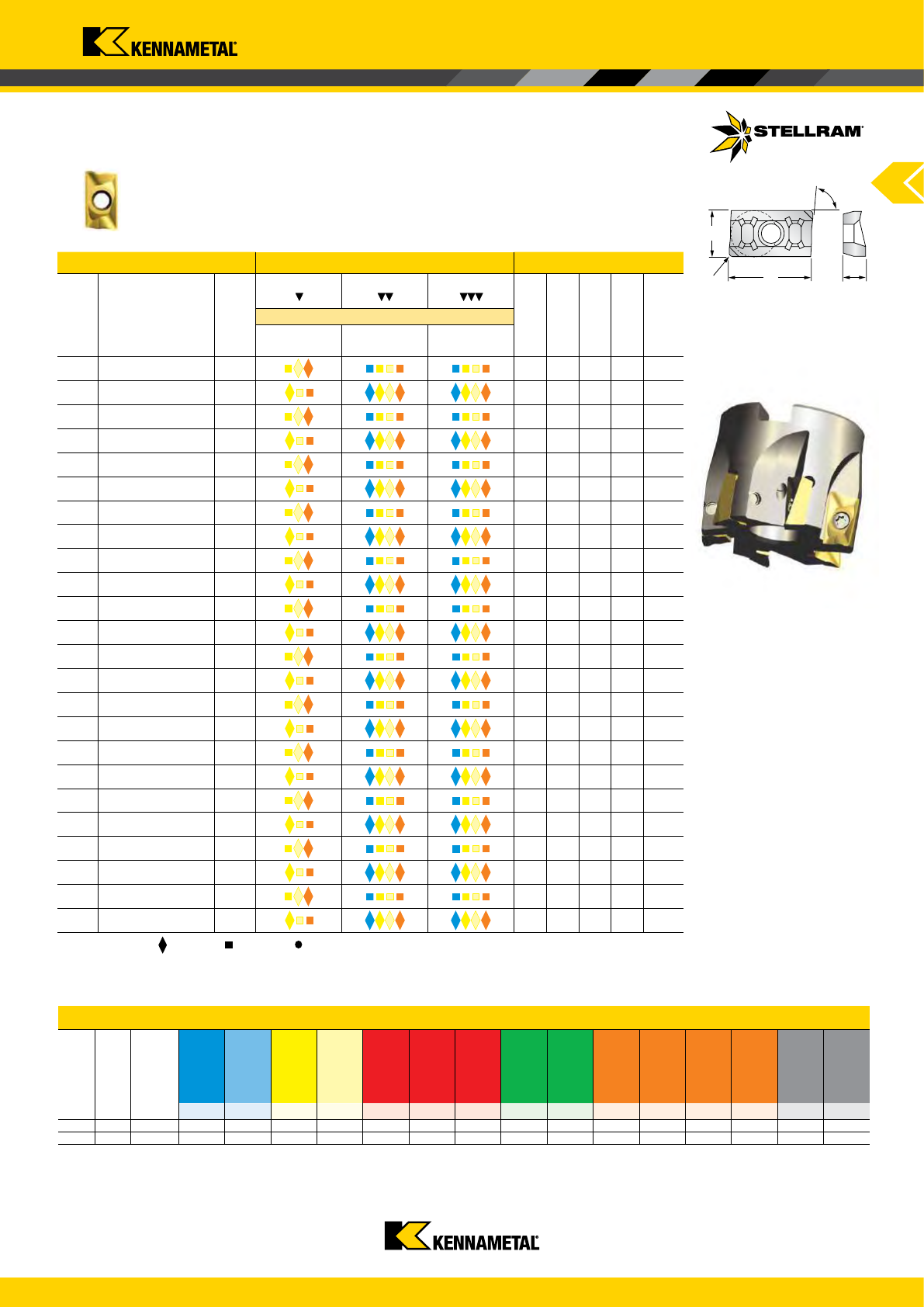

Family Range Dimensions (mm) Body Fixation

Series

Insert Shape

and Size

Angle

Page

a

p

max

Diameter

Range

Modular

Heads

Weldon

Cylindrical

Shell

Mills

Caterpillar

Vee Flange

DIN 69871

Fixation

Taper 50

SC..09T3

SO..12M6

SO..15M6

5210VS

Long Edge

Cutter

(Porcupine)

90°

A165 -

A170

57 32

• •

68 - 77 80 - 100

5230VS

SD..09T3

Cheveron Long

Edge Cutter

(Porcupine)

90°

A171 -

A182

51 80 50

•

SD..1204 57 - 133 63 - 100

5315VA

AD..12T3

Long Edge

Cutter

(Porcupine)

90°

A183 -

A194

23 - 45 25 - 40

• • •

AP..1604 31 - 61 50 - 80

MP..0402 8 - 9 18 - 21

5400VM

MP..0602

T-Slotting

A271 -

A277

11 25

•

MP..0803 14 32

MP..1104 18 40

RG.S

08, 10, 12

16, 20, 25

5500V

Finishing

Ball Nose

A201 -

A206

0,4 - 12,1 8 - 25

• •

XP..1603,

XP..20T3,

XP..2504,

XP..3206,

XP..40T7,

XP..50T7

5505VX Ball Nose

A195 -

A200

16 - 50 16 - 50

• • •

5702VZ ZD..1403

Proling

Pocketing

Shoulder

90°

A247 -

A256

12 20

•

Applications Index

Indexable Tools

www.kennametal.com

A8

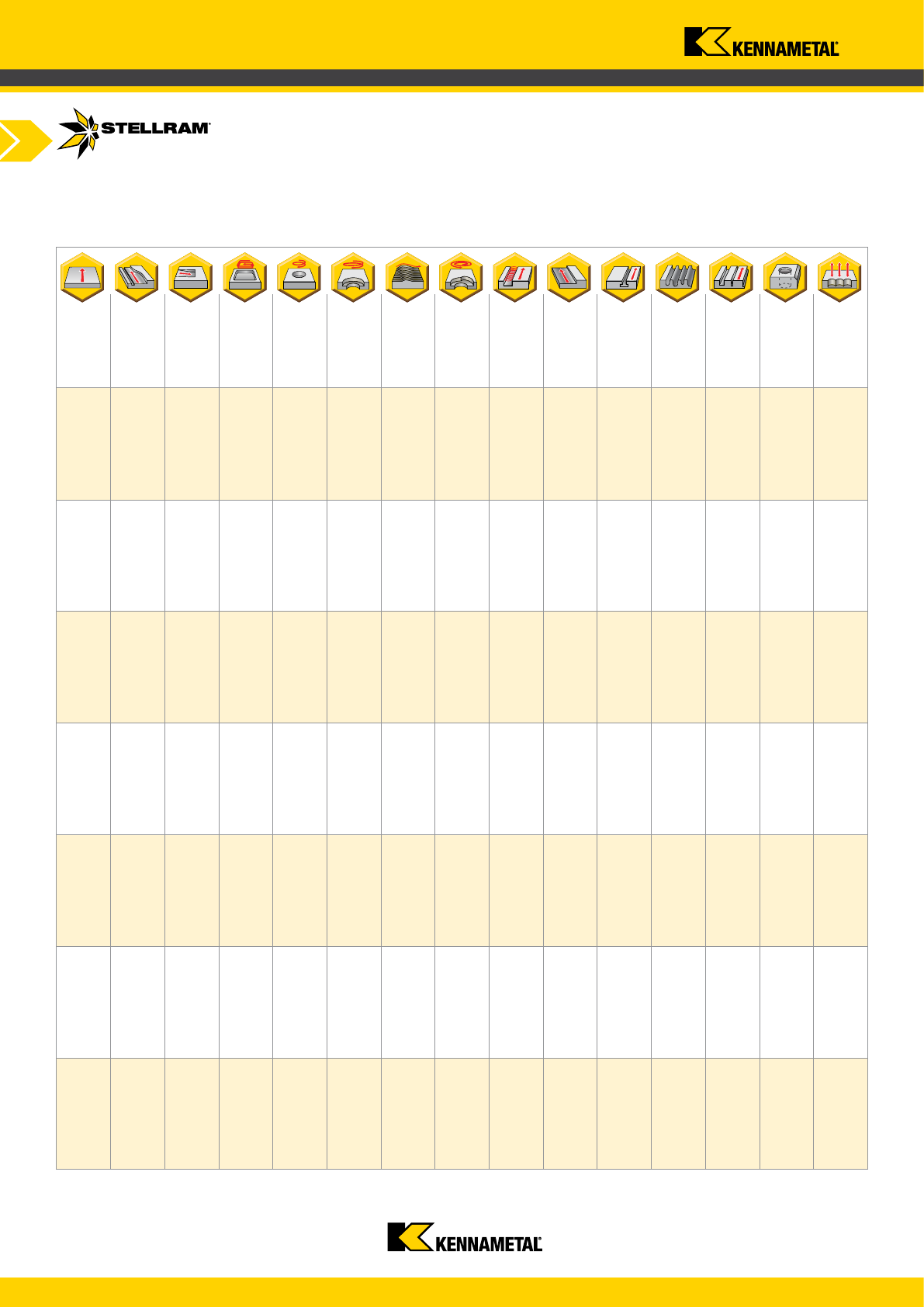

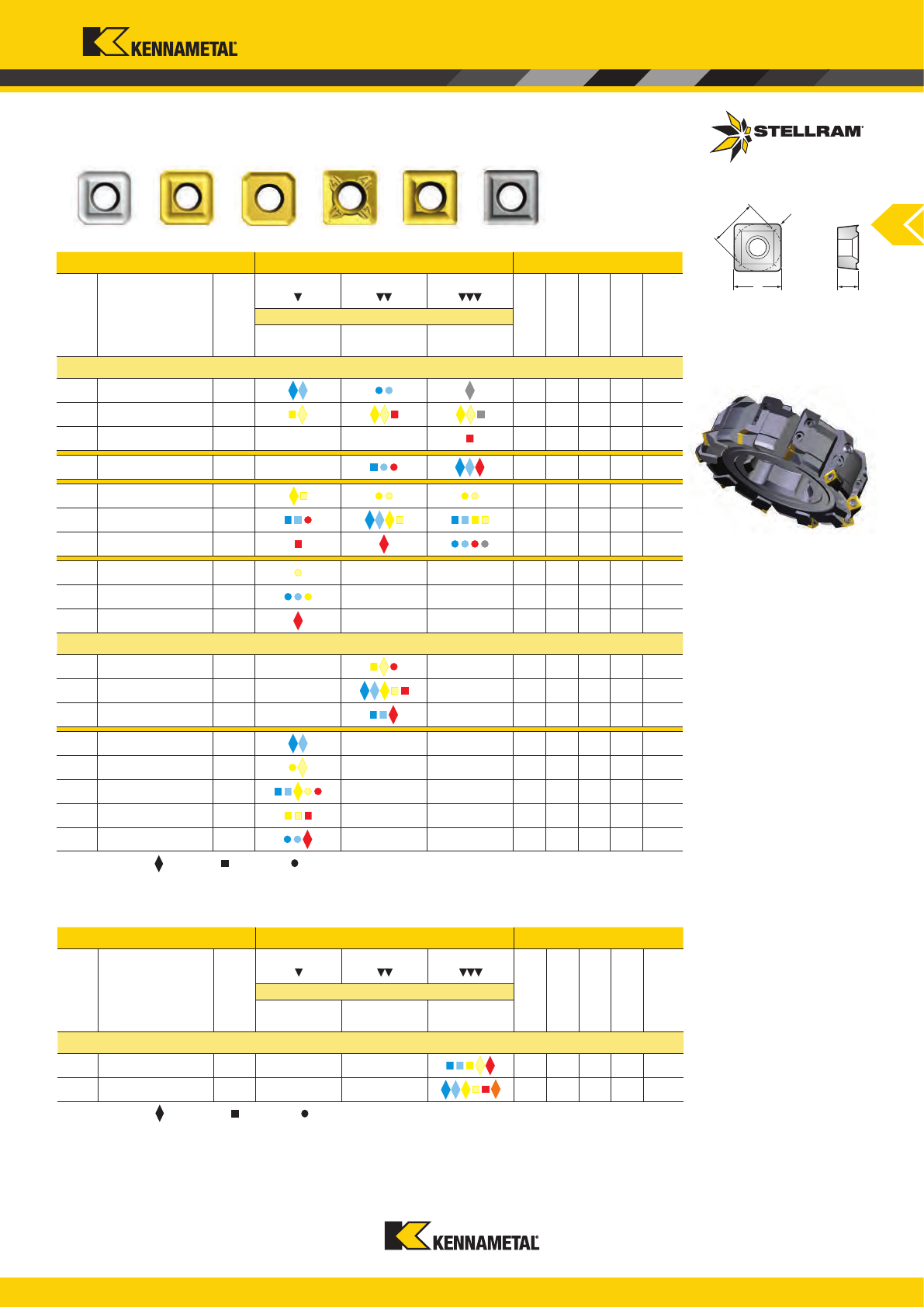

• • • • • • • •

•

• • • • • • • •

• • • • • • •

• • • • • • • •

• • • • • • •

• • • • • • •

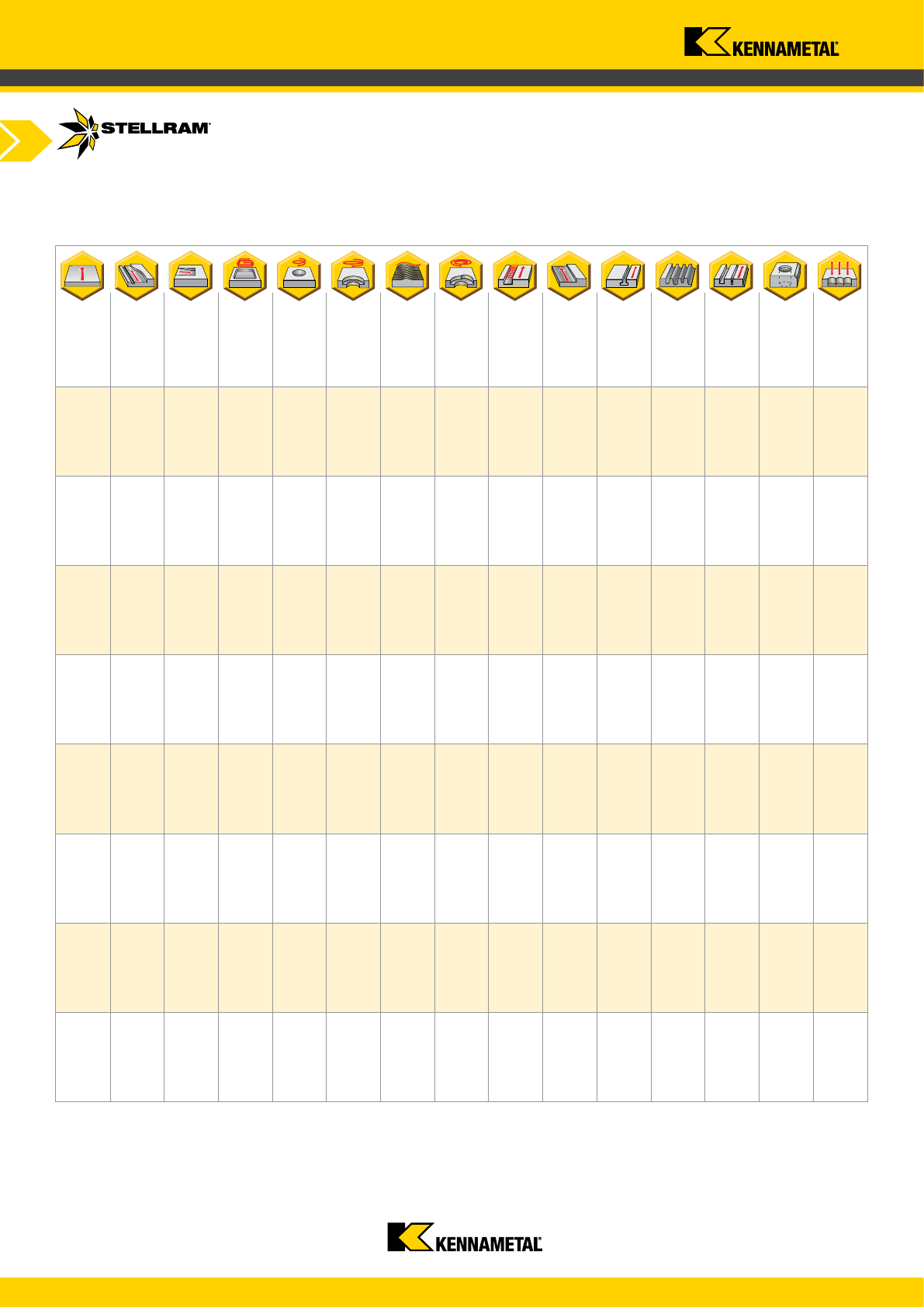

Milling Introduction

Application

Facing

Shoulder /

Proling /

Slotting

Ramping

Pocketing

Helical

Interpolation

Helical

Interpolation

with Bore Hole

Copy / 3D

Spiral /

Circular

Trochoidal

Shoulder /

Proling

T-Slotting

Contour

Milling

Slotting

Shoulder

Chamfering

Plunging

Applications Index

Indexable Tools

www.kennametal.com

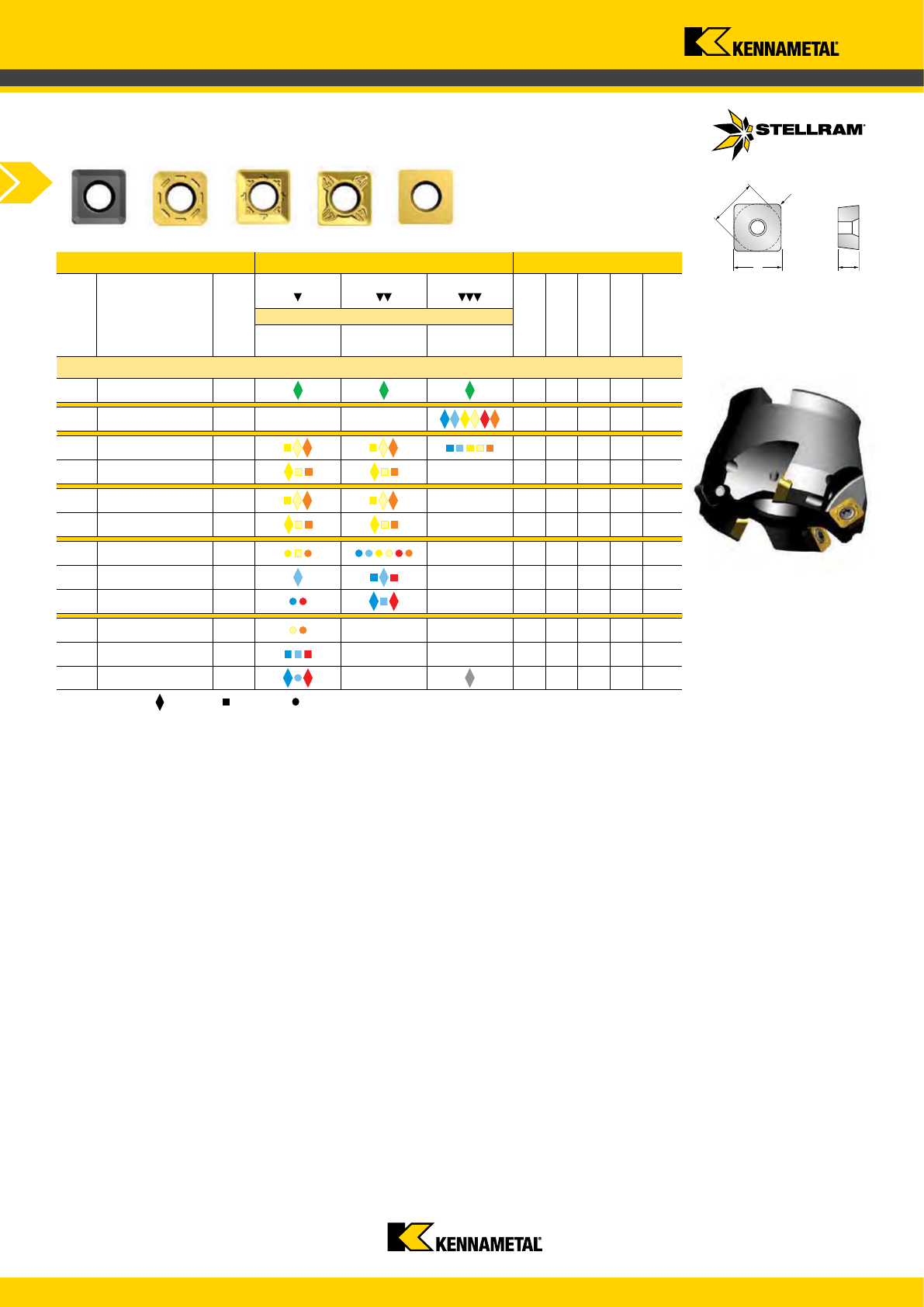

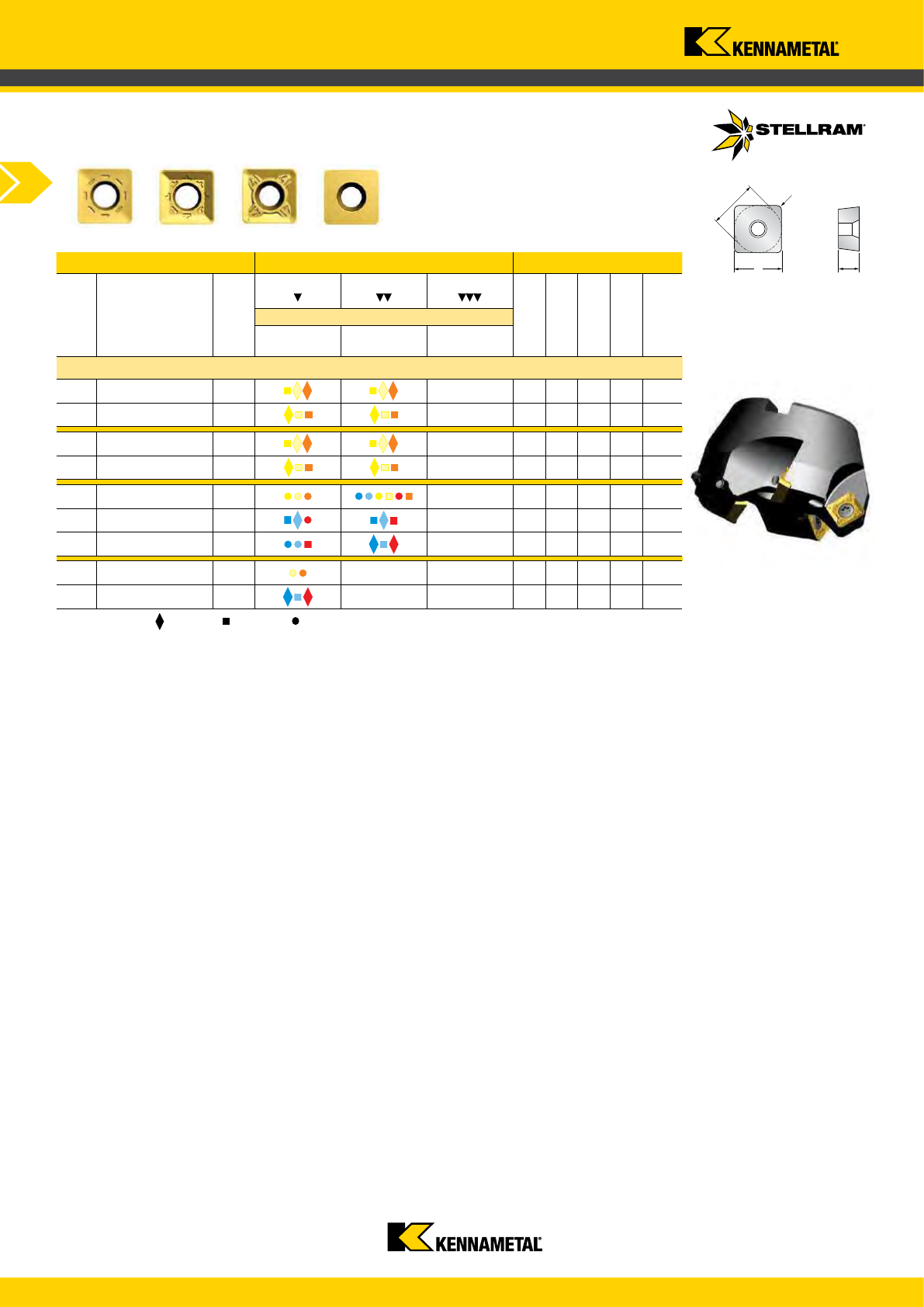

A9

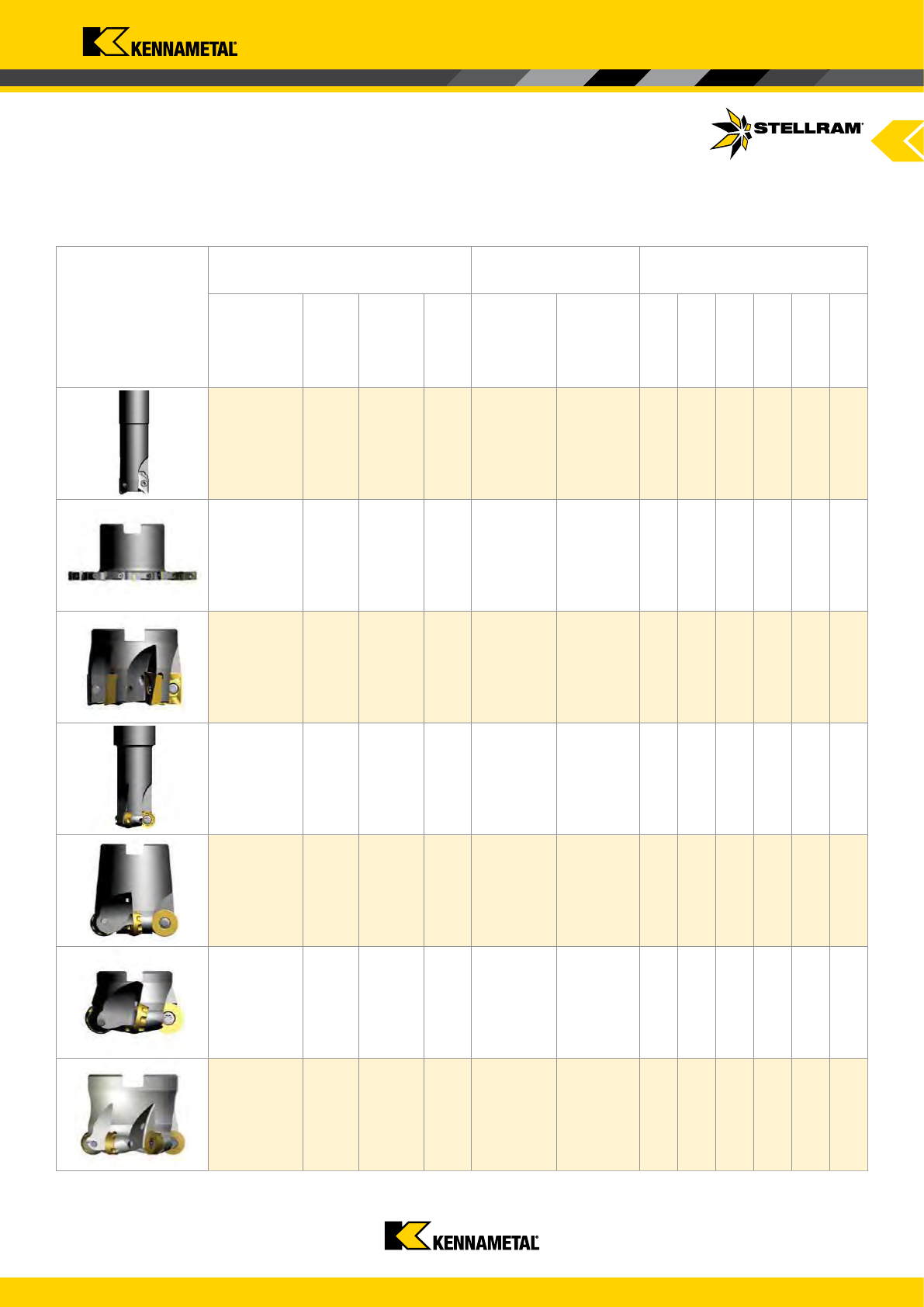

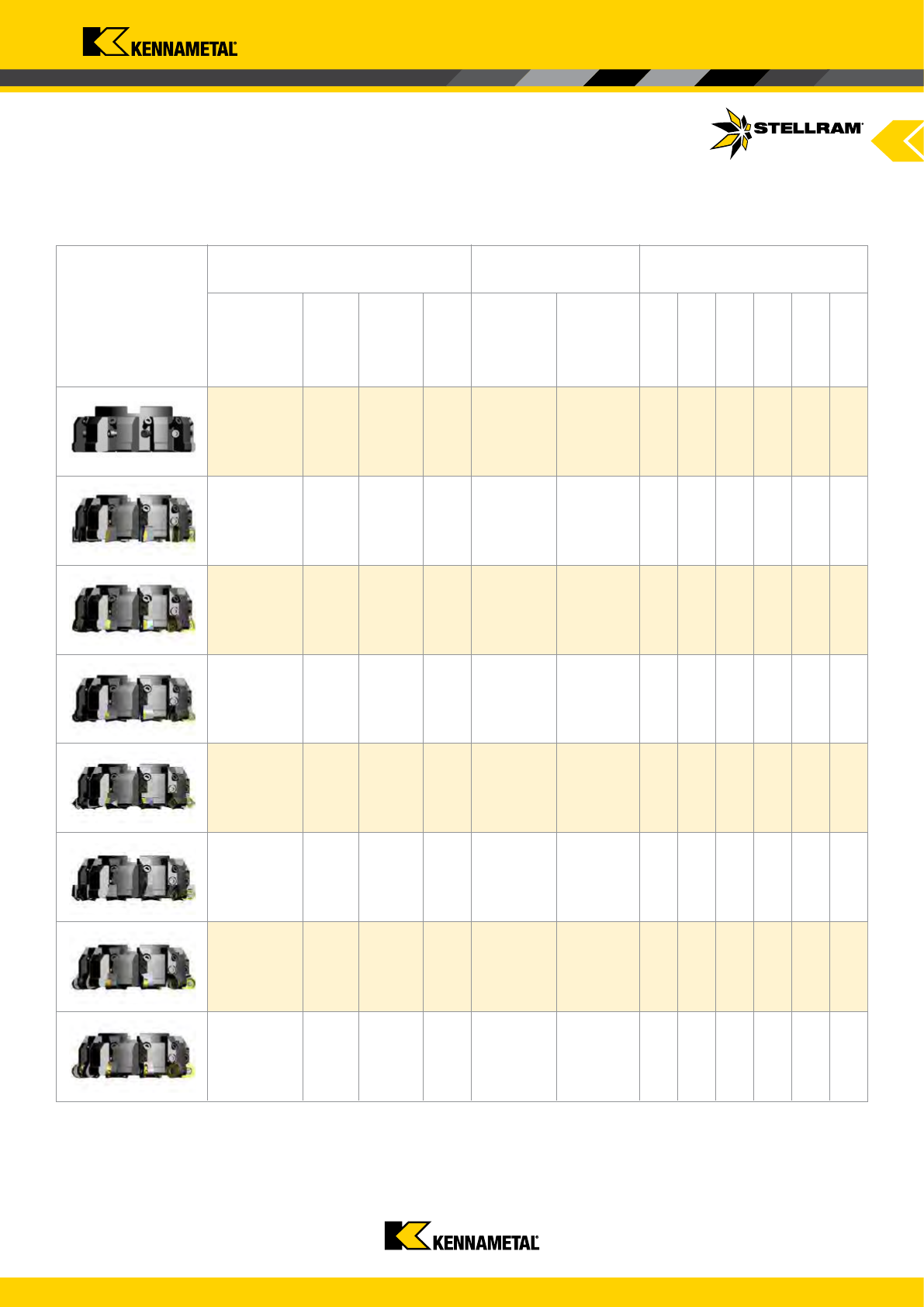

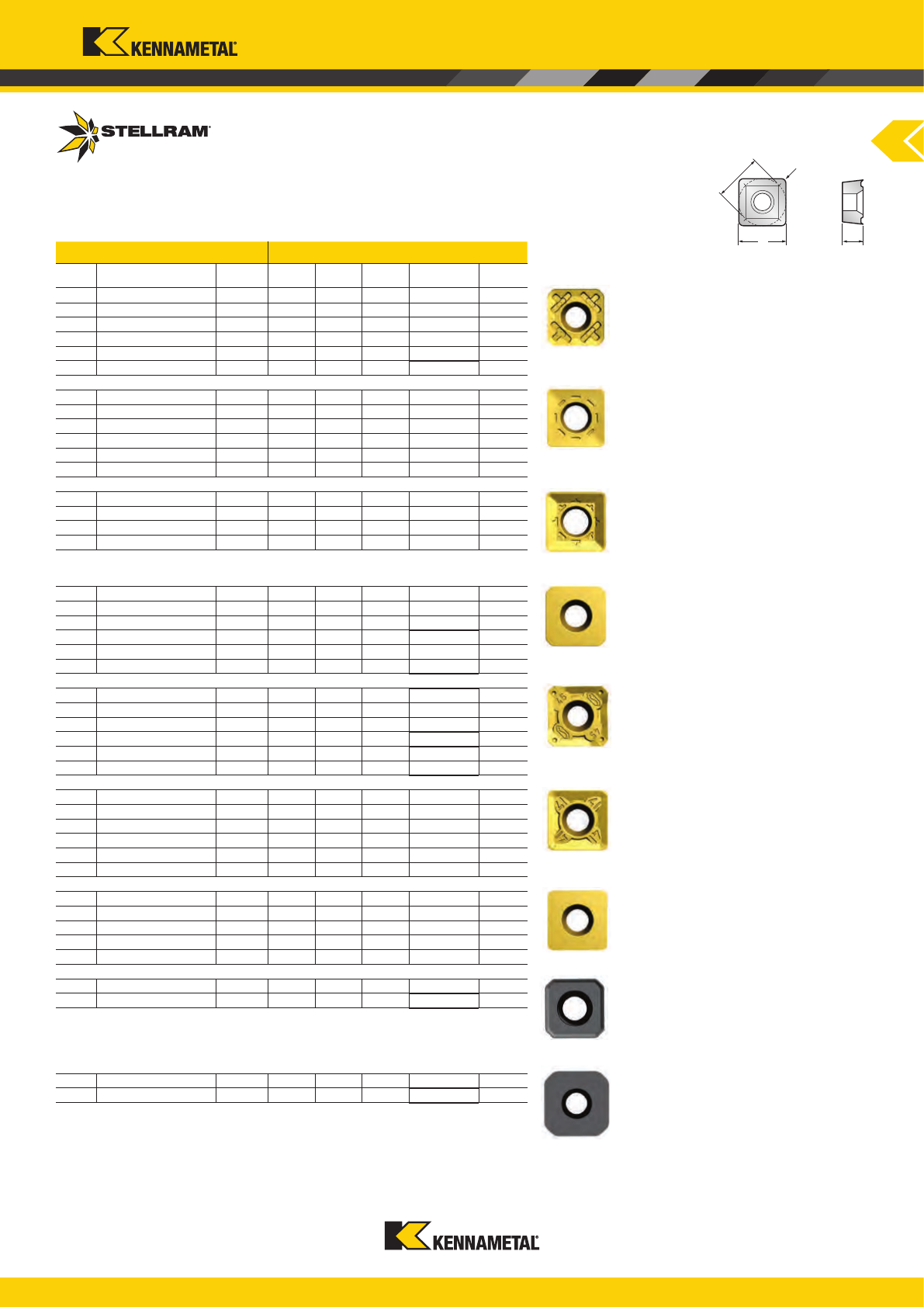

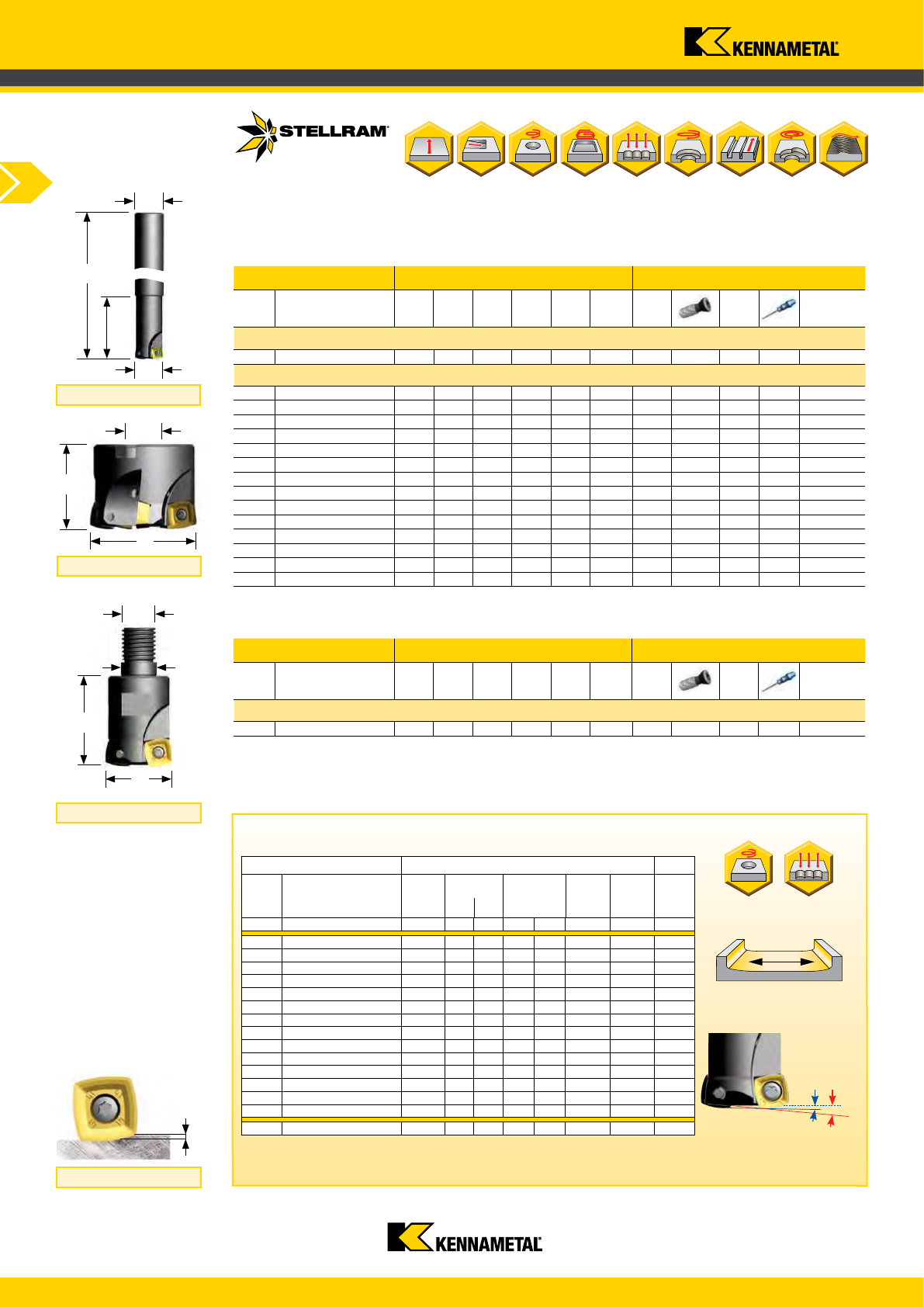

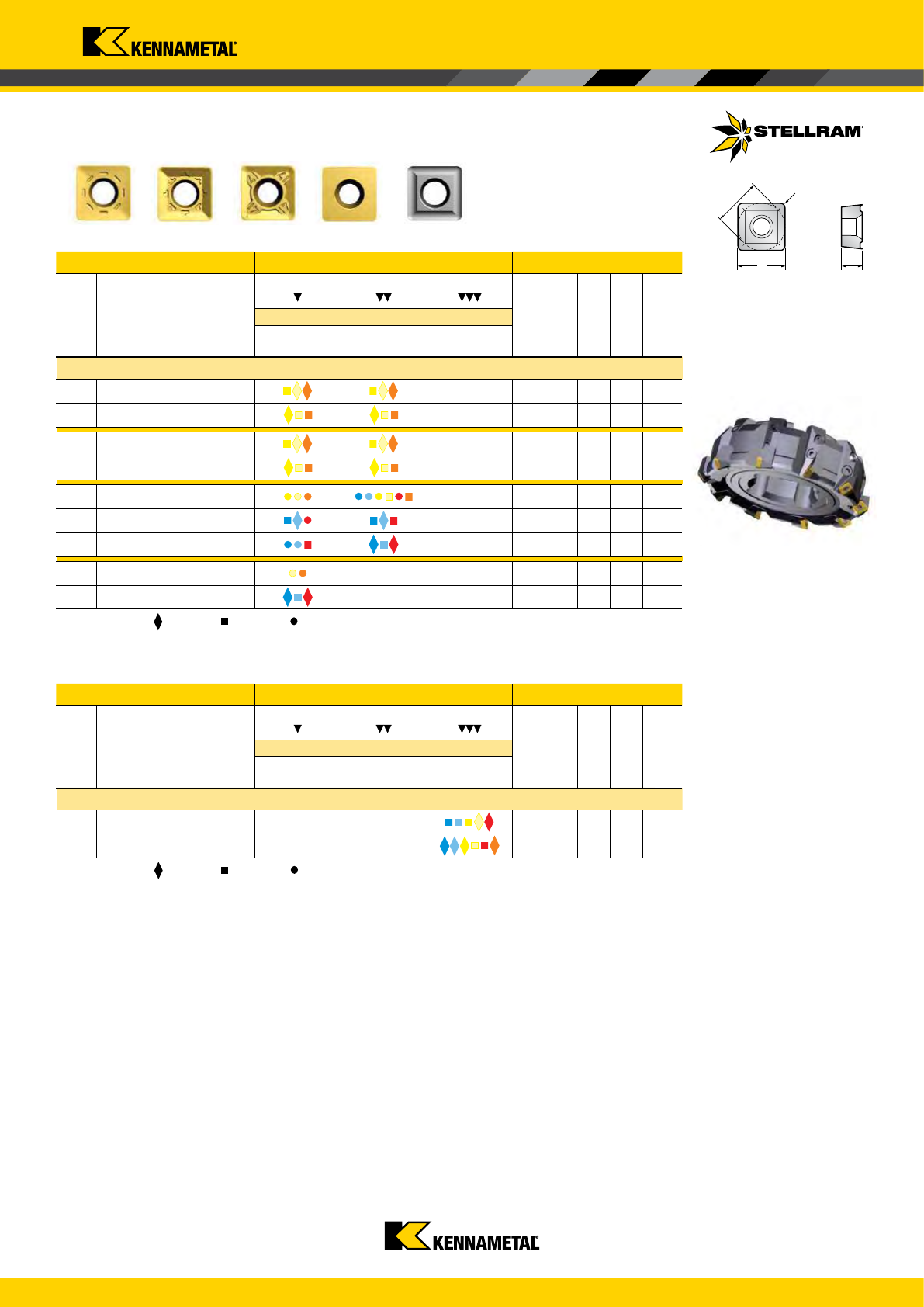

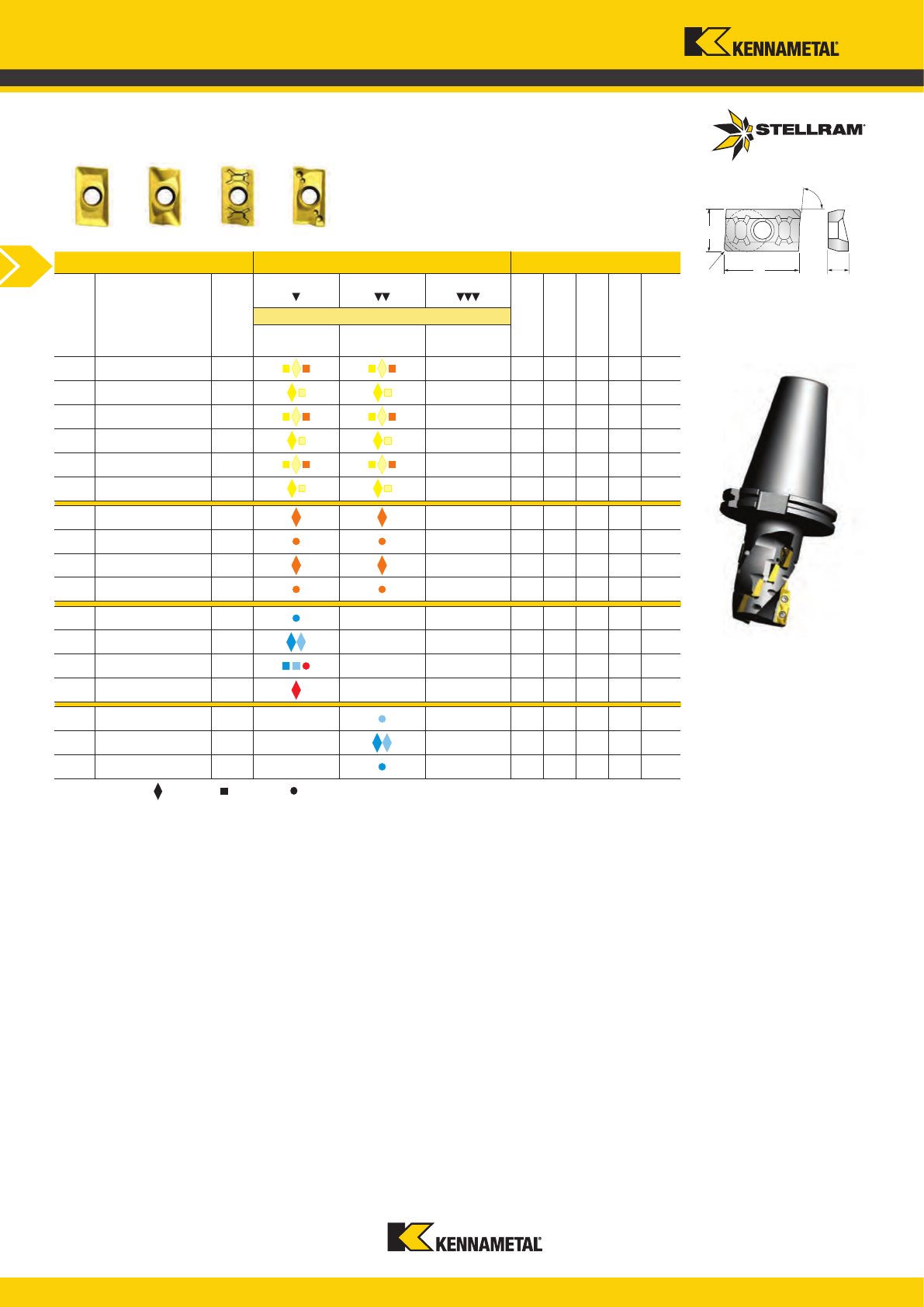

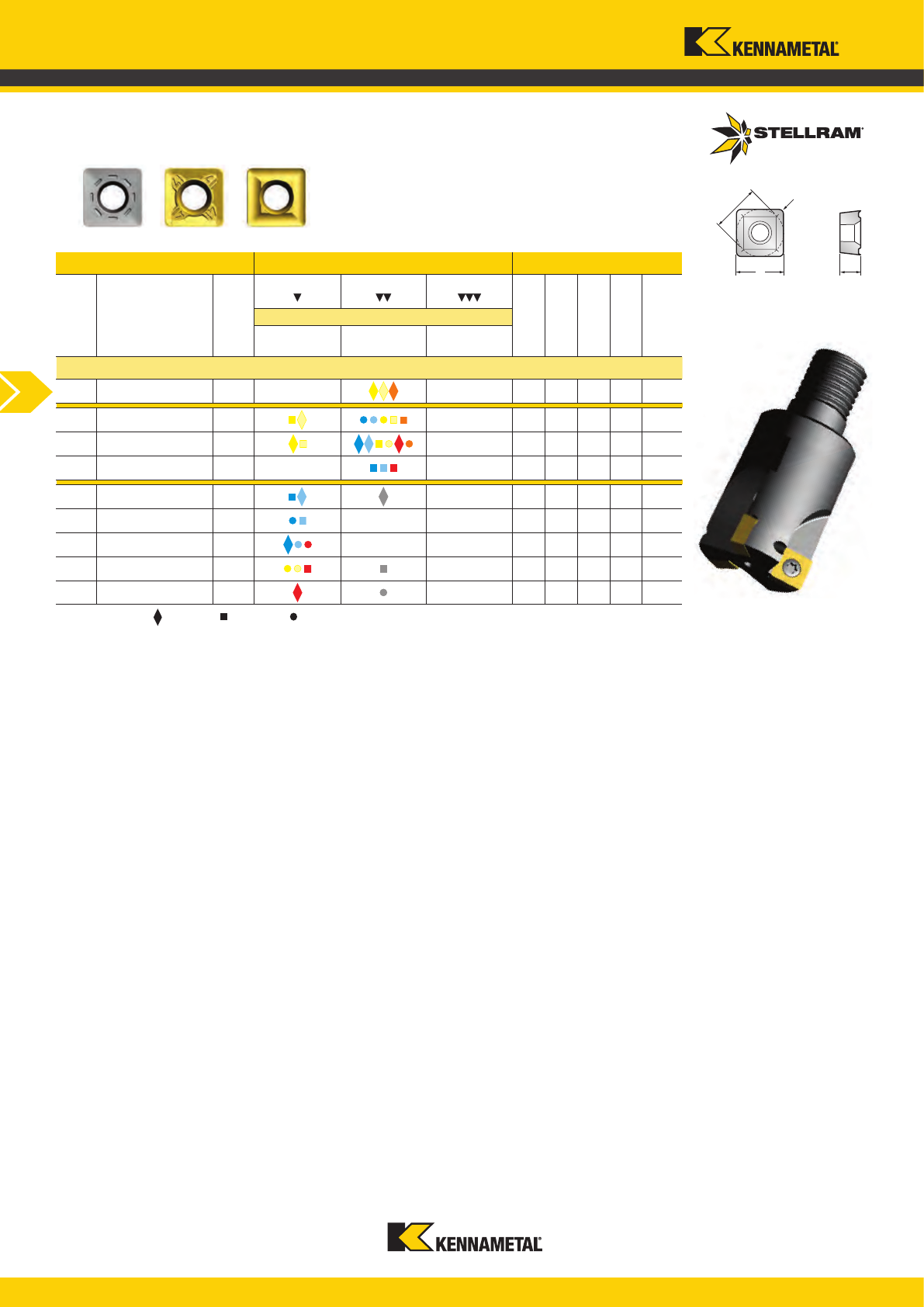

Milling Introduction

Tool Denition

Family Range Dimensions (mm) Body Fixation

Series

Insert Shape

and Size

Angle

Page

a

p

max

Diameter

Range

Modular

Heads

Weldon

Cylindrical

Shell

Mills

Caterpillar

Vee Flange

DIN 69871

Fixation

Taper 50

5720VZ ZD..16M5

Proling

Pocketing

Shoulder

90°

A247 -

A256

16 25 - 80

• • •

MP..0402 6 - 8 63 - 80

7220VM

MP..0602

Slotting

Shoulder

A279 -

A288

8 - 10 100 - 125

•

MP..0803 10 - 14 125 - 160

MP..1104 14 - 20 125 - 160

AD..0903

AD..12T3

AP..1604

8

11

16

10 - 63

20 - 80

25 - 125

7690VA

Facing Shoulder

90°

A45 -

A62

• • • •

7690VAP

RP..0602

RP..0803

RP..10T3

3

4

5

14 - 20

16 - 32

20 - 32

7700VR

Copy

Contour

A207 -

A216

• • •

RD..0702 3, 5 15 - 20

7702VRD

7712VRD

RD..1003

Copy

Contour

A217 -

A230

5 20 - 35

• • •

RD..12T3 6 25 - 80

RD..1604 8 32 - 100

7710VRD20 RD..2006

Copy

Contour

A231 -

A236

10 63 - 160

•

7713VR

RP..10T3

Copy

Contour

A237 -

A246

5 20 - 63

• • •

RP..1204 6 25 - 80

Applications Index

Indexable Tools

www.kennametal.com

A10

• • • • • • • • •

• •

• • • •

•

•

• • • • • • • • •

Milling Introduction

Application

Facing

Shoulder /

Proling /

Slotting

Ramping

Pocketing

Helical

Interpolation

Helical

Interpolation

with Bore Hole

Copy / 3D

Spiral /

Circular

Trochoidal

Shoulder /

Proling

T-Slotting

Contour

Milling

Slotting

Shoulder

Chamfering

Plunging

Applications Index

Indexable Tools

www.kennametal.com

A11

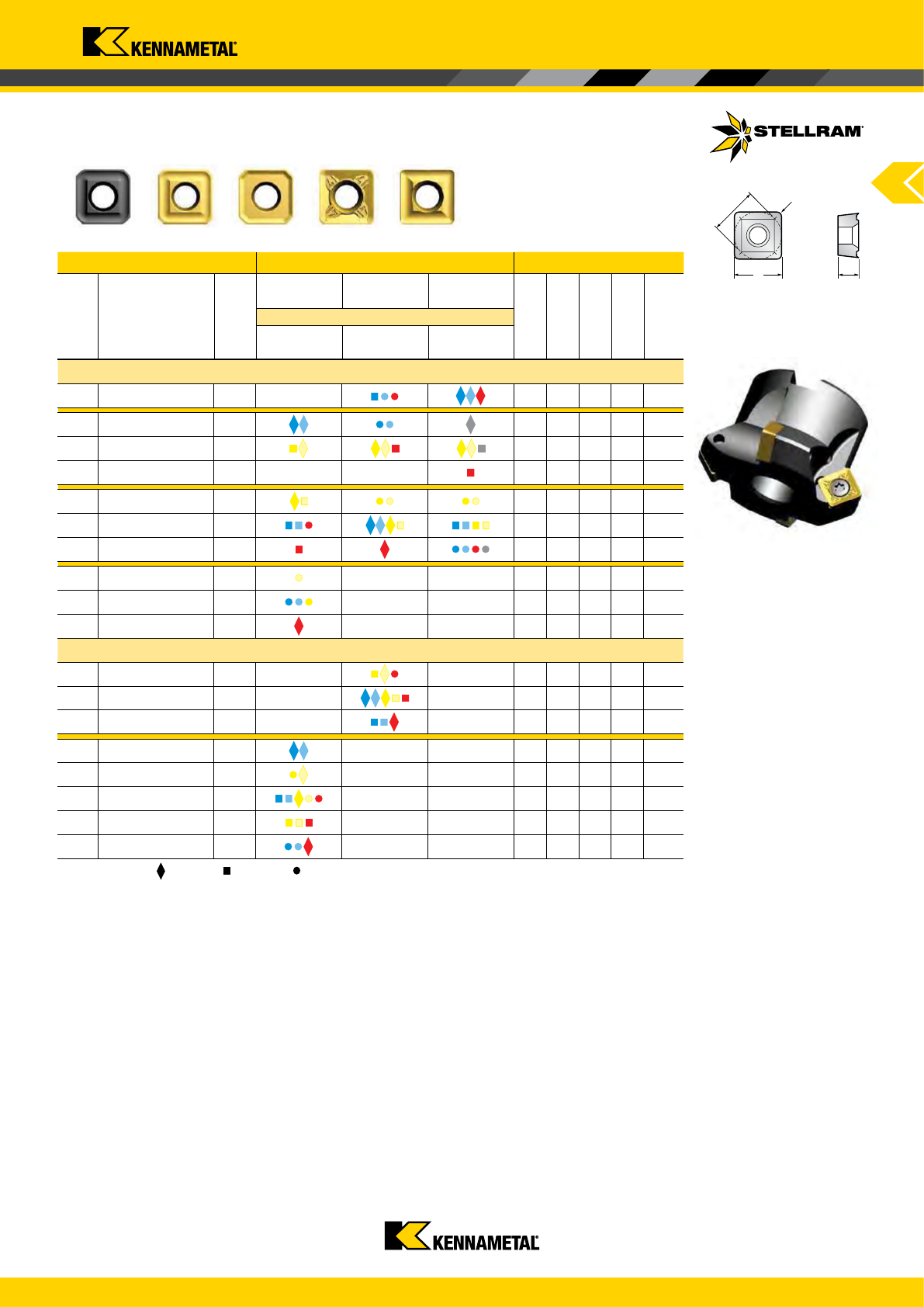

Milling Introduction

Tool Denition

Family Range Dimensions (mm) Body Fixation

Series

Insert Shape

and Size

Angle

Page

a

p

max

Diameter

Range

Modular

Heads

Weldon

Cylindrical

Shell

Mills

Caterpillar

Vee Flange

DIN 69871

Fixation

Taper 50

7745VOD

OD..0404

Facing

42°

A77 -

A86

3,5 25 - 160

• •

OD..0605 4,5 50 - 160

7745VS

SC..09T3

Facing

Chamfering

45°

A87 -

A94

5 16 - 25

• •

SC..12M5 7 40 - 125

7745VSE

SD..09T3

Facing

45°

A95 -

A105

5 16 - 125

• •

SD..1204 7 50 - 125

7745VT

TP..1102

TC..16T3

7,70

6,10 - 11,30

16

20 - 30

Chamfering

45° / 60°

A265 -

A270

•

7760VT TC..16T3 9,50 16 - 25

7791VS

SC..09T3

Plunging

A257 -

A264

a

e

= 8 25 - 50

• •

SC..12M5 a

e

= 11 63 - 80

7792VXP XP..0603 0,90 16 - 32

7792VXD

XD..0904

XD..1205

High Feed

A63 -

A75

1,50

2,50

25 - 50

32 - 160

• • • •

7792VXE XE..1605 3,50 63 - 160

Tungsten

Cylindrical Shank

Extensions

- -

A76

- 16 - 32

•

Applications Index

Indexable Tools

www.kennametal.com

A12

• •

• • • • • • •

• • • • • • • •

•

• •

• • • • •

• • • • •

Milling Introduction

Application

Facing

Shoulder /

Proling /

Slotting

Ramping

Pocketing

Helical

Interpolation

Helical

Interpolation

with Bore Hole

Copy / 3D

Spiral /

Circular

Trochoidal

Shoulder /

Proling

T-Slotting

Contour

Milling

Slotting

Shoulder

Chamfering

Plunging

Applications Index

Indexable Tools

www.kennametal.com

A13

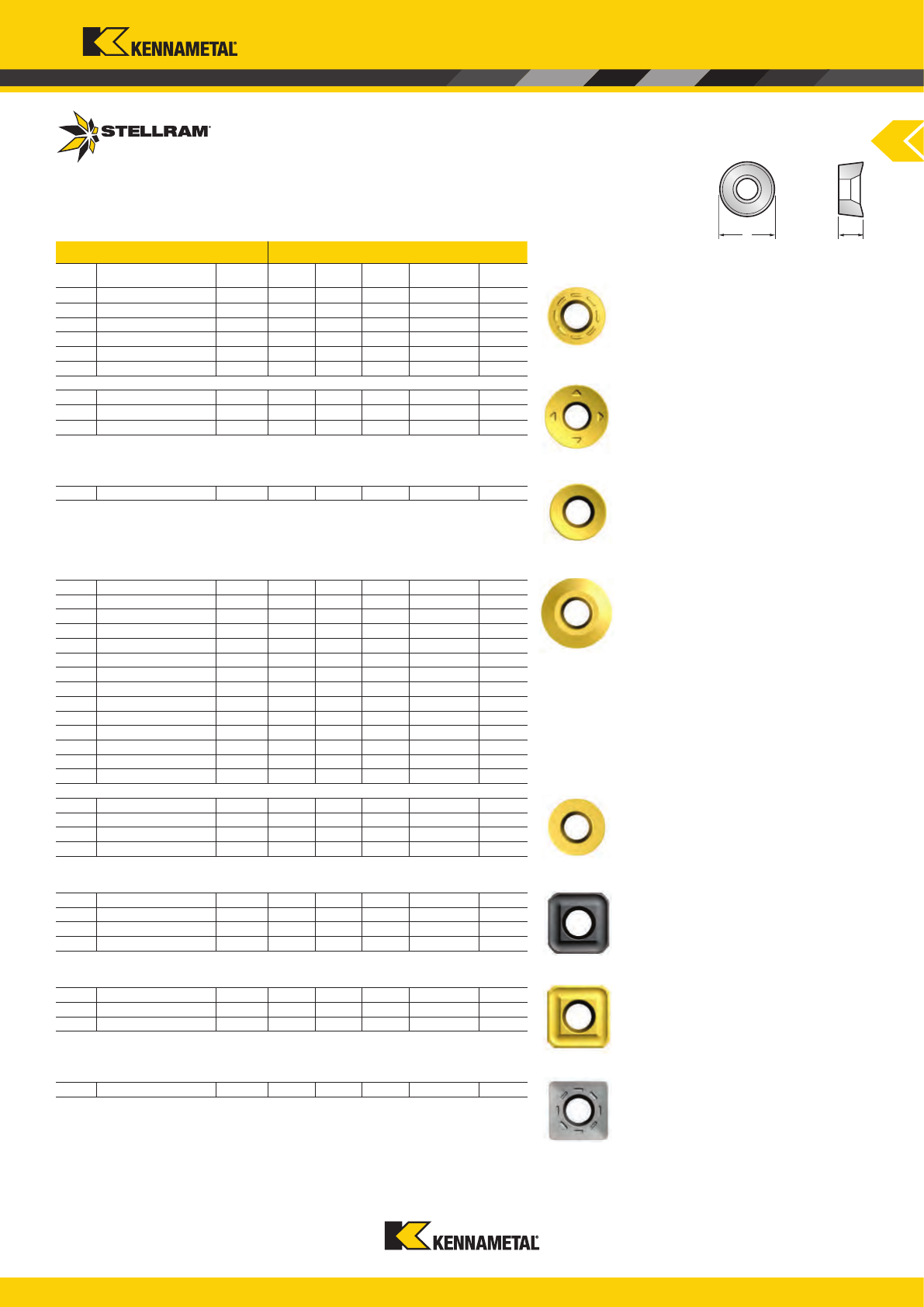

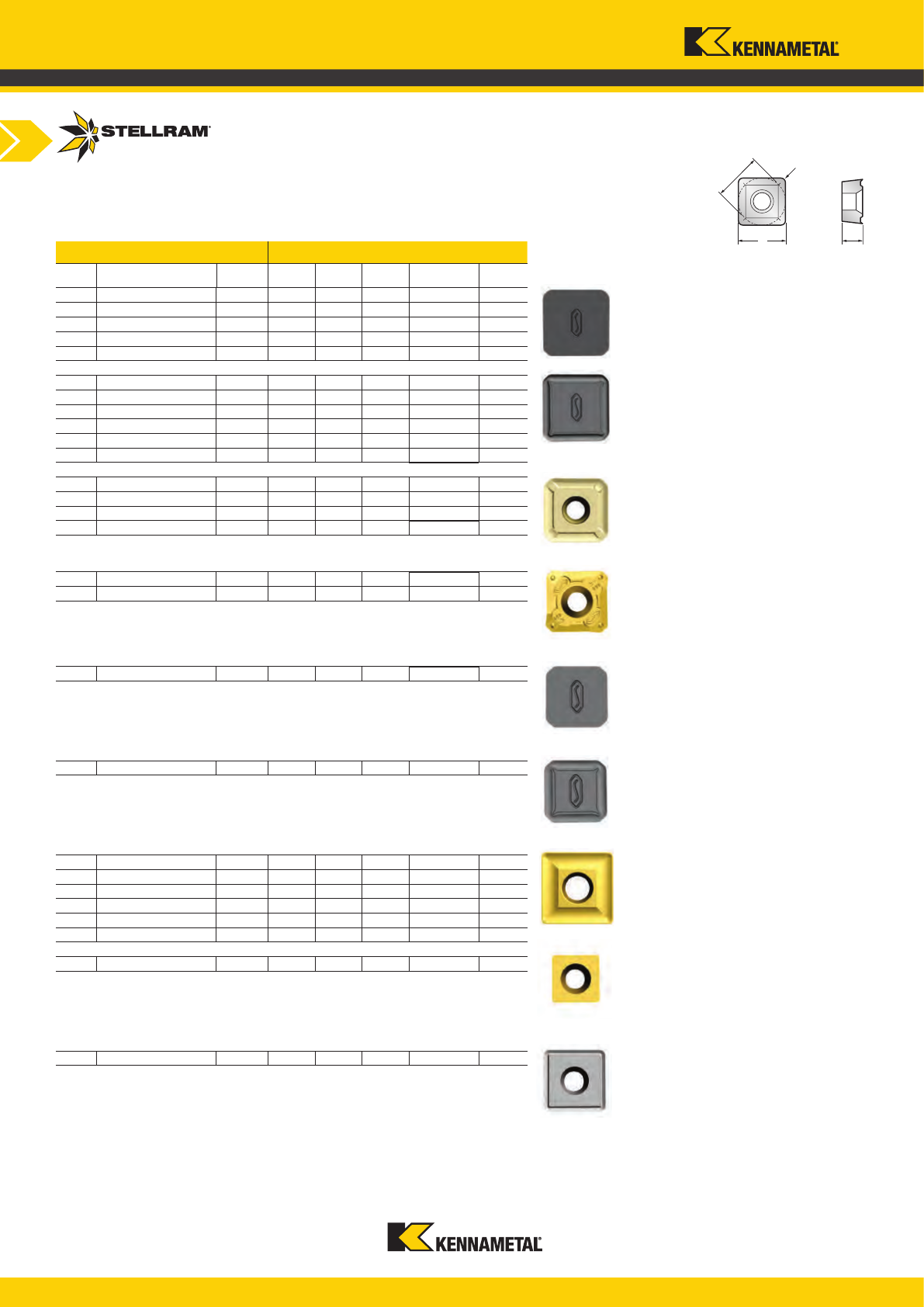

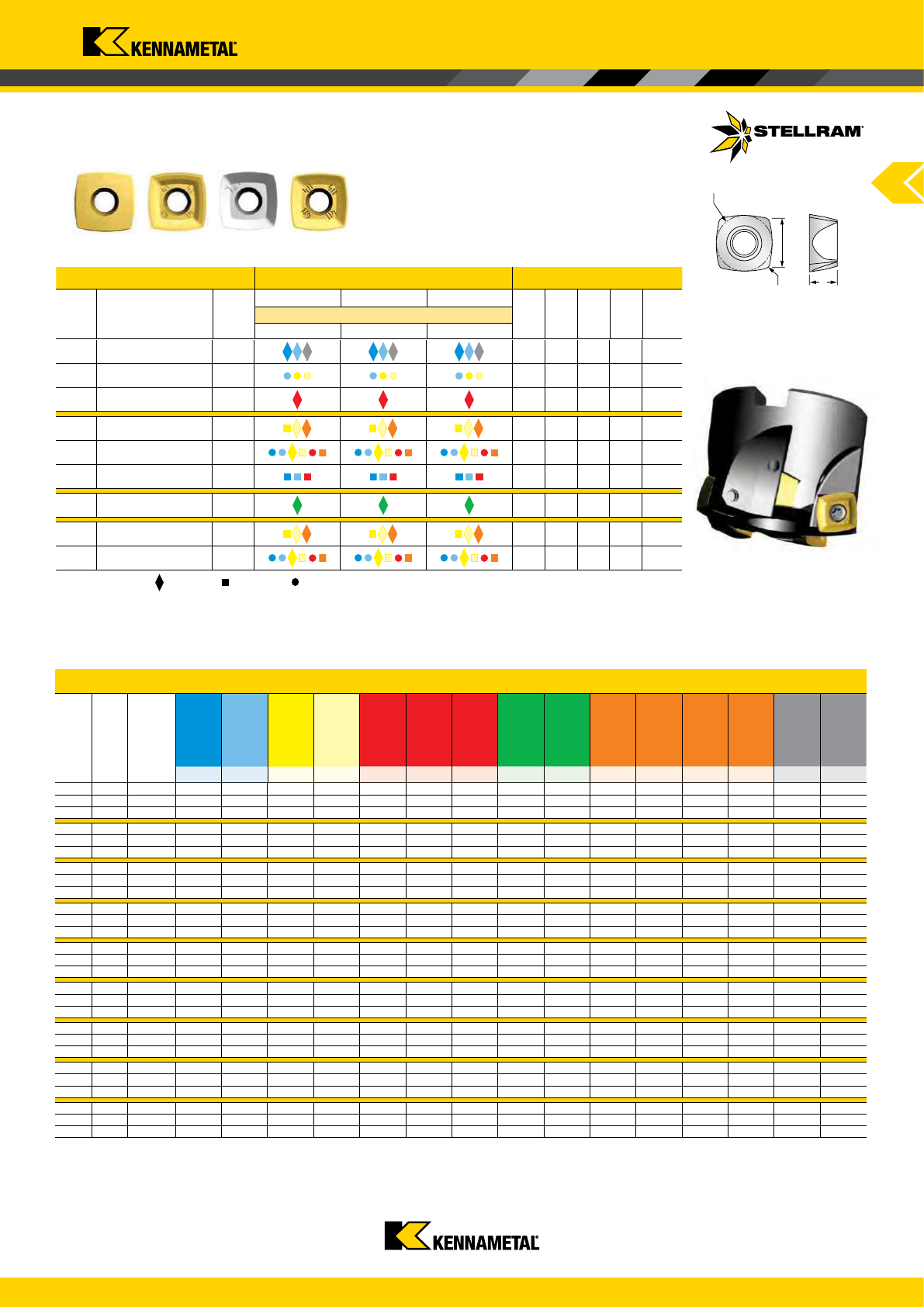

Milling Introduction

Tool Denition

Family Range Dimensions (mm) Body Fixation

Series

Insert Shape

and Size

Angle

Page

a

p

max

Diameter

Range

Modular

Heads

Weldon

Cylindrical

Shell

Mills

Caterpillar

Vee Flange

DIN 69871

Fixation

Taper 50

8000V-8010V Bodies Facing-

A107 -

- 100 - 400

•

A110

80.0VA90-_R-16

Assembly

AP..1604

Facing

90°

A111 -

A116

16 106 - 406

•

80.0VXD92-_R-12

Assembly

80.0VXD92-_R-16

Assembly

High Feed

Facing

XD..1205

A117 -

2,5

106 - 256

•

XE..1605

A124

3,5

80.0VOD45-_R-04

Assembly

80.0VOD45-_R-06

Assembly

Facing

OD..0404

A125 -

A134

3,5

100 - 400

•

OD..0605 4,5

80.0VS45-_R-12

Assembly

SC..12M5 Facing

A135 -

A140

7 100 - 400

•

80.0VSE45-_R-12

Assembly

SD..1204 Facing

A141 -

A148

7 100 - 400

•

80.0VR00-_R-16

Assembly

RP..1606 Facing

A149 -

A154

8 116 - 416

•

80.0VRD00-_R-20

Assembly

RD..2006 Facing

A155 -

A159

10 116 - 416

•

Applications Index

Indexable Tools

www.kennametal.com

A14

Milling Inserts

Grade descriptions are listed by toughness to most wear resistant.

X500

Coating Type: CVD, TiN-TiC-TiN, X-Grade™ Technology

This high performance premium grade with a high level of shock

resistance. This unique grade operates at the low to medium cutting

speeds and is capable of high metal removal rates, while retaining

a secure cutting edge. First choice for Stainless Steel and High

Temperature Alloys as well as other materials where conditions are

unstable.

X400

Coating Type: PVD, TiAlN, X-Grade™ Technology

A patented high performance premium carbide grade with a high level

of toughness and high wear resistant, thin layer PVD coating. For use

in demanding conditions of high metal removal rates or interrupted

cuts. This specically designed grade allows high levels of cutting

pressure and offers increased security of the cutting edge. For use on

Steel and Steel Alloys, Tool Steels and Hardened Steel

(415 - 480 HBN).

SP5419

Coating Type: PVD, TiAlN

The combination of a tough substrate with a new generation of TiAlN

super nano coating, makes this new PVD grade virtually free of

residual stress and extremely hard for unmatched performance.

Used in Steel and Steel Alloys.

Grade Descriptions

Inserts

www.kennametal.com

A15

Milling Inserts

GH2

Uncoated, Micrograin

Micrograin grade designed for use on Cast Irons, Bronzes,

Aluminiums, Kevlar, etc. This grade is tough and able to handle high

pressure, vibration and shock.

X700

Coating Type: PVD, TiAlN, X-Grade™ Technology

This patented high performance premium carbide grade is the

latest in the X-Grade™ Technology programme of coated milling

inserts. It is designed for the toughest of applications in Nickel Based

Alloys, Cobalt Based Alloys, Titanium and Titanium Alloys, as well as

Stainless Steels. It is a combination of a highly durable TiAIN PVD

coating and specially developed carbide substrate that gives an

excellent tool life during long contact times of the cutting edge.

SP6519

Coating Type: PVD, TiAlN

The combination of a tough substrate with a new generation of TiAlN

super nano coating, makes this new PVD coating virtually free of

residual stress and extremely hard for unmatched performance.

Primarily used in Stainless Steel, High Temperature Alloys & Titanium

with stable conditions. Also can be used in Steel, Steel Alloys and Cast

Irons.

Grade Descriptions

Inserts

www.kennametal.com

A16

Milling Inserts

SC6525

Coating Type: CVD, TiN-TiCN-Al

2

O

3

SC6525 has a unique substrate/coating combination, designed

specically for high performance machining of Steel, Steel Alloys

and Cast Irons at elevated surface speeds and feeds.

MP91M

Coating Type: CVD, TiN-MT-TiCN-Al

2

O

3

Primarily used on Steel, Steel Alloys and Cast Iron. Can also be used

in Hardened Steels. With its aluminium oxide coating, this grade is

recommended every time wear characteristics are more important than

toughness.

SP4019

Coating Type - PVD TiAlN Micrograin

A hard grade for light roughing and nishing operations with lower

chip sections. Principle applications are in Stainless Steels, High

Temperature Alloys and Cast Irons. Can also be used in Steel, Steel

Alloys and Hardened Steels.

Grade Descriptions

Inserts

www.kennametal.com

A17

Milling Inserts

SP1019

Coating Type: PVD, TiAlN, Micrograin

Micrograin carbide substrate with a new generation of TiAlN super

nano coating, makes this PVD grade virtually free of residual stress

and extremely hard for unmatched performance. Ideal for ball nose

cutters at higher surface speeds, or for greater wear resistance. Used

in nish machining all Alloys.

SC3025

Coating Type: CVD, TiN - TiCN - Al

2

O

3

A high performance milling grade with multi-layer CVD coating

designed to offer wear and abrasion resistance in Cast Iron materials.

GH1

Uncoated, Micrograin

This micrograin grade is designed for use on Cast Irons, and also

Bronzes, Aluminiums, Kevlar, etc. The grade GH1 works well with or

without coolant with low cutting pressure at high speeds due to sharp

cutting edge.

Grade Descriptions

Inserts

www.kennametal.com

A18

Milling Inserts

SA9608

Uncoated, Cermet (TiCN)

Uncoated Cermet for nishing applications. Excellent thermal

conductivity and wear resistance, providing an excellent surface nish.

For nish face milling of Steel, Steel Alloys, Stainless Steel, Cast Irons

and High Temperature Alloys with wiper insert SPHX12M512EN.

SA9808

Uncoated Cermet (TiCN)

Uncoated Cermet for applications with limited interruptions.

Excellent thermal conductivity and wear resistance, providing an

excellent surface nish. For nish face milling of Steel, Steel Alloys,

Stainless Steels and Cast Irons.

Grade Descriptions

Inserts

www.kennametal.com

A19

-41

-42

-43

-44

Milling Inserts

-44

This geometry is peripheral ground with a ground facet for producing

the best surface quality in most materials while reducing cutting

pressure and power consumption. For nishing applications in Steel,

Steel Alloys, Stainless Steels, High Temperature Alloys and Cast Iron.

-43

This is a general purpose geometry designed to handle tough

conditions and interruped cuts with larger axial depth of cuts. It is

applied to utility ground inserts with ground wiper edges for closer axial

runout tolerance. This geometry is primarily used in Steel, Steel Alloys,

Stainless Steels and Cast Irons.

-42

Is a general purpose geometry. The positive rake and T-land combine

to create a strong cutting edge. The -42 geometry withstands high

cutting forces and interrupted cuts. This geometry can be used for

roughing and semi-nishing in Steel, Steel Alloys, Titanium, High

Temperature Alloys and Stainless Steel with excellent results.

-41

Is a general purpose geometry applied to utility ground inserts. This

economical geometry is available with a number of insert styles for use

in all approach angles. This geometry has positive cutting action and

reinforced cutting edge for roughing applications in Steel, Steel Alloys,

Stainless Steel and Cast Iron.

Cutting Geometries

www.kennametal.com

A20

-45

-46

-48

-412

Milling Inserts

-412

This high positive gometry is slightly more positive than the -41. This

geometry improves tool life on several applications when machining

Stainless Steel and High Temperature Alloys.

-48

The geometry design of this insert provides a smooth cutting action

with excellent chip control. Once positioned in the cutter body the

combined effective cutting geometry produces lower radial forces,

specically in the direction of the feed, leading to a more stable cutting

environment. For machining in Steel, Stainless Steel, Titanium and

High Temperature Alloys.

-46

This positive geometry with high accuracy periphery grinding gives

a positive cutting action. The precise treatment of the cutting edge

ensures effective machining in roughing, semi-nishing and nishing

applications, all materials.

-45

This geometry is designed for machining a wide range of materials

and applications. It is available on utility ground inserts with ground

wiper edges. The –45 geometry provides freer cutting operations and

reduces the “suction effect” associated with higher helical geometries.

This geometry is qualied for Steel, Steel Alloys, Stainless Steels, and

Cast Iron.

Cutting Geometries

www.kennametal.com

A21

-421

-422

-423

-441

Milling Inserts

-441

This geometry is a peripheral ground insert with a sharp cutting edge

for use on Aluminium Alloys, Copper and Brass. The –441 geometry

provides freer cutting operations and reduces the “suction effect”

associated with higher helical geometries.

-423

A strong positive geometry rst with a smaller primary angle and a

small controlled hone to reduce cutting pressures, followed by a higher

secondary angle to allow free cutting of the chip without rubbing on the

insert rake face. Chip ow compresses the chip for easy evacuation.

For roughing and semi-nishing of Nickel Based Alloys, Cobalt Alloys,

Stainless Steels, Titanium Alloys and High Temperature Alloys.

-422

This positive geometry with a 11º chip angle and an “E” edge

preparation for roughing and semi nishing applications. Primarily for

machining of Stainless Steels and High Temperature Alloys. Also can

be used in Steel, Steel Alloys and Cast Irons with very good results.

-421

This high positive geometry with high accuracy periphery grinding.

For use in semi-nishing and nishing applications. Due to the precise

control of the cutting edge, this geometry provides excellent results

when machining High Temperature Alloys.

Cutting Geometries

www.kennametal.com

A22

-442

-721

-701

-D

Milling Inserts

-D

This High Feed geometry fully ground with at top and variable hone

has been designed to machine Steel, Steel Alloys, Tool Steel, Cast

Irons and Hardened Materials up to 534HBN.

-721

This geometry is periphery ground with a pressed, polished top rake

face reducing built up edge. This economical geometry gives excellent

results in machining Aluminium Alloys, Copper and Brass.

-701

This extreme high positive geometry is highly suitable for nishing a

wide range of materials at low feedrates. This geometry provides a

freer cutting action particulary in Aluminium. Titanium and High

Temperature Alloys can also be nished machined when the -701

geometry is combined with grade SP4019 or SP6519. This geometry

is precision ground and gives excellent performance when machining

thin-walled components.

-442

This NEW positive geometry minimizes the pressure from the chip

formation. Utilising an 11º chip angle and and “E” edge preparation for

roughing and semi nishing applications in Stainless Steel and High

Temperature Alloys. This -442 geometry can also be used in machining

Steel, Steel Alloys, and Cast Irons with very good results.

Cutting Geometries

www.kennametal.com

A23

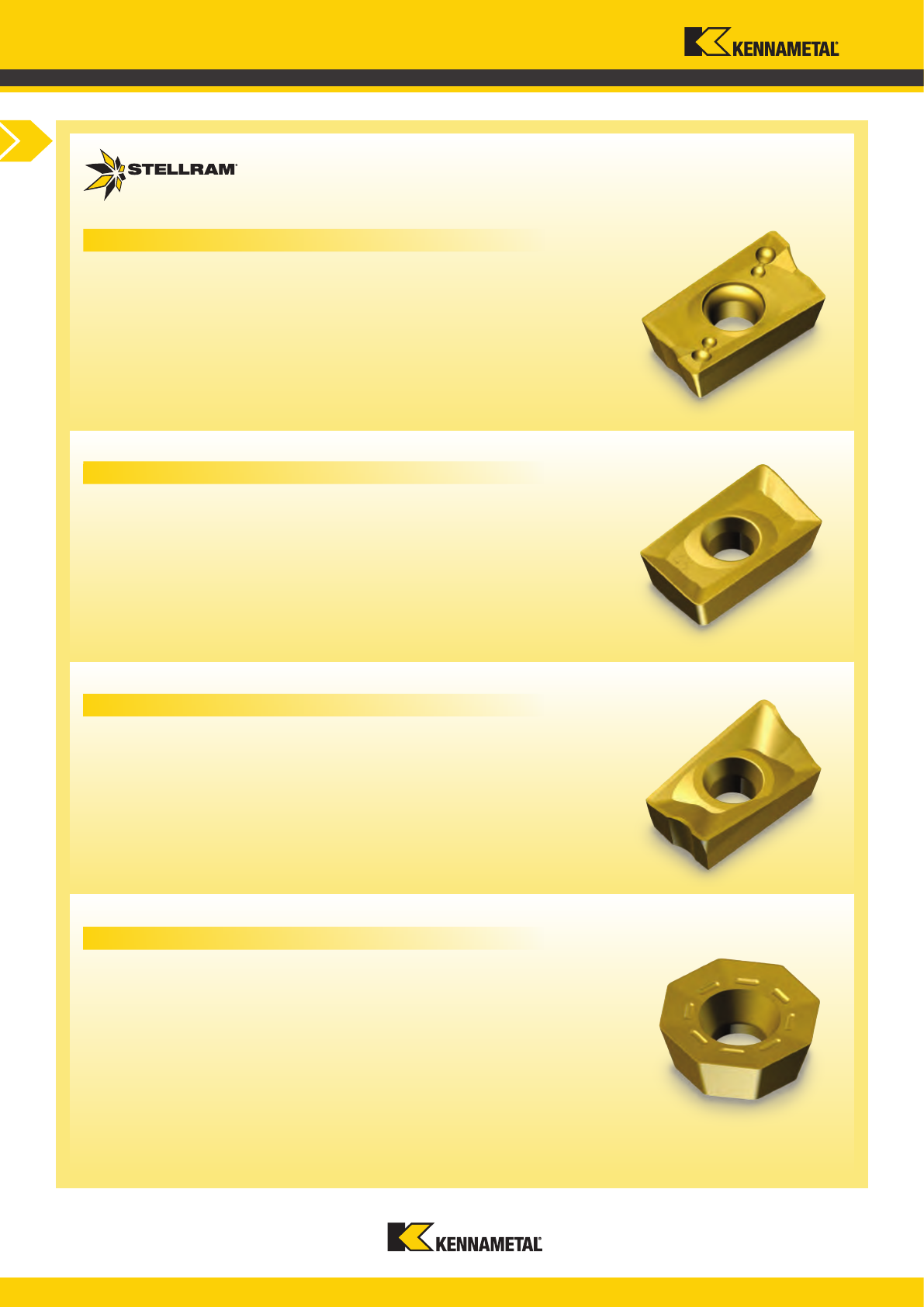

-D41

-D411

-D721

-F

Milling Inserts

-F

This geometry is a roughing ball nose fully ground insert for roughing

and semi-nishing of all Materials except Aluminium. This geometry is

designed with chip grooves for better chip control.

-D721

This highly positive High Feed geometry is designed for machining

Aluminium, Copper and Brass. The periphery ground, polished top

rake face and sharp edge allows a freer cutting action and reduces

built-up edge.

-D411

This positive High Feed geometry with larger corner radius 1,2mm

reduces cutting energy and provides better edge protection

during lower radial engagement applications. Mainly for machining

Titanium, High Temperture Alloys and Stainless Steel. It can also be

used for machining Steel, Steel Alloys and Cast Irons with extremely

good results.

-D41

This positive High Feed geometry primarily used to machine Stainless

Steel, High Temperature Alloys and Titanium. It can also be used for

machining Steel, Steel Alloys and Cast Iron with excellent results. The

-D41 geometry also reduces power consumtion .

Cutting Geometries

www.kennametal.com

A24

-RA

-RG..S

-T

Milling Inserts

-T

This geometry is for general purpose applications when a strong

cutting and excellent chip breaking capibility is required. This

geometry is found on a wide range of Stellram inserts. The design is

nearly as tough as at-top inserts. Mainly to be used when machining

Steel, Steel Alloys, Cast Irons and Hardened Steels.

-RG..S

This geometry is designed for nish machining of 3D proles. It is

extremely accurate and delivers a very long tool life. The RG..S is

excellent when machining a side wall that is close to 90˚. Suitable for

machining of all materials.

-RA

This geometry is a precision insert for milling Cast Iron. The extended

wiper-facet on this insert geometry allows a 50% higher feed rate for

higher productivity. This geometry is available with SC3025, our

leading Cast Iron milling grade.

Cutting Geometries

www.kennametal.com

A25

-TN

-SN

-W

Milling Inserts

-W

This geometry is offered in a number of at-top inserts for numerous

milling applications in a wide range of materials. The at-top inserts are

the best choice when toughness is required for all milling applications.

This geometry offers a stronger cutting edge than a chip-groove insert.

-SN

This geometry is our strongest cutting edge for general purpose

applications and is ideal for unstable cutting conditions, long overhangs

and very high feedrates. For heavy duty applications when machining

Steel, Steel Alloys and Cast Iron. Ideal solution for heavy scale

applications.

-TN

This geometry is a at top design with a strong T-land edge

preparation for preventing chipping in unstable conditions. This

geometry is similar to the -SN geometry, but has a smaller edge

preparation which reduces machine power consumption. For

machining Steel, Steel Alloys and Cast Iron. Should also be used to

machine Stainless Steel and Titanium with heavy scale.

Cutting Geometries

www.kennametal.com

A26

A P F 16W

1 2 3 4 5

A H M O

S T X Z

R

C D

N P

E G

H

N

R

T

W

X

U

Q

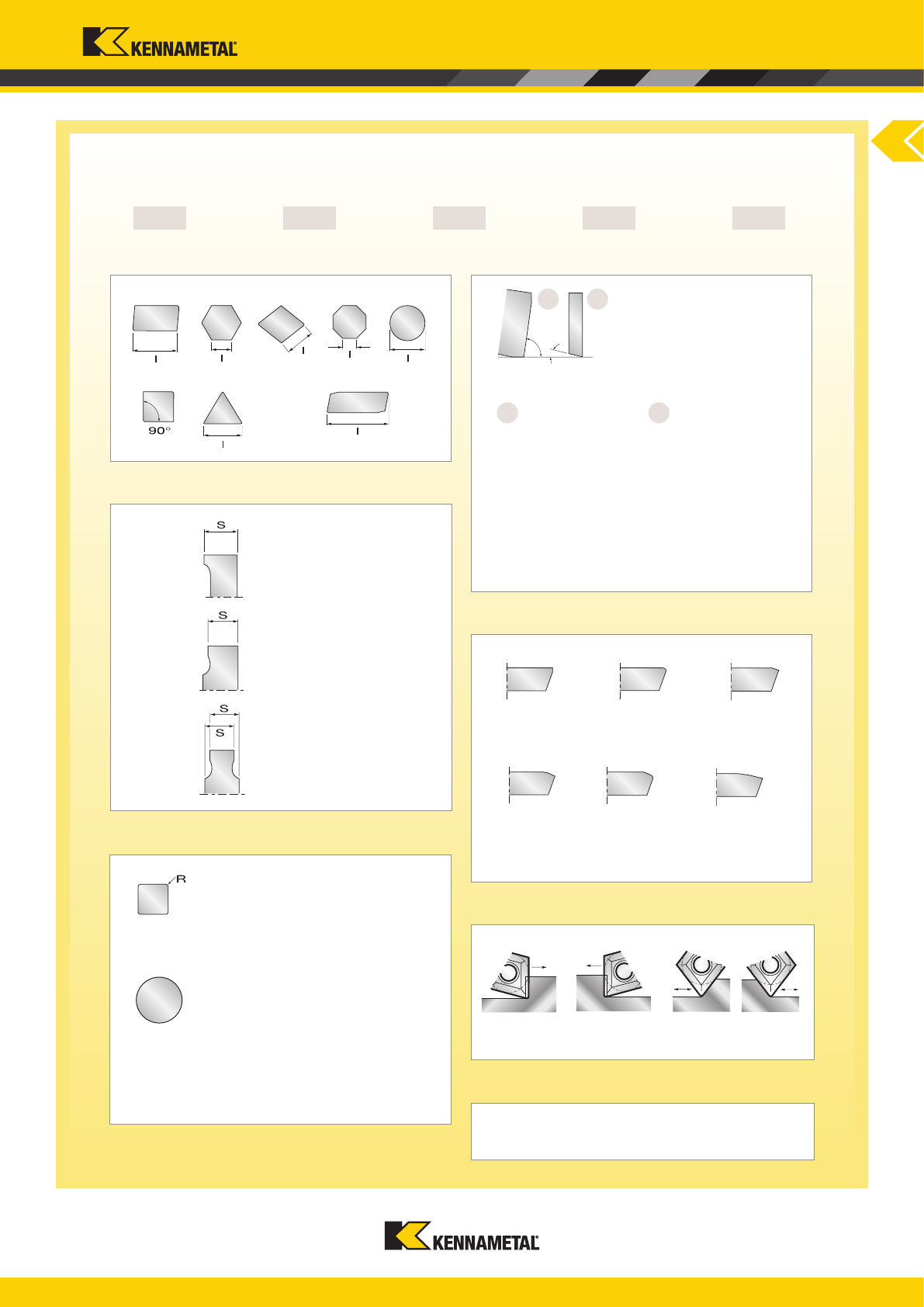

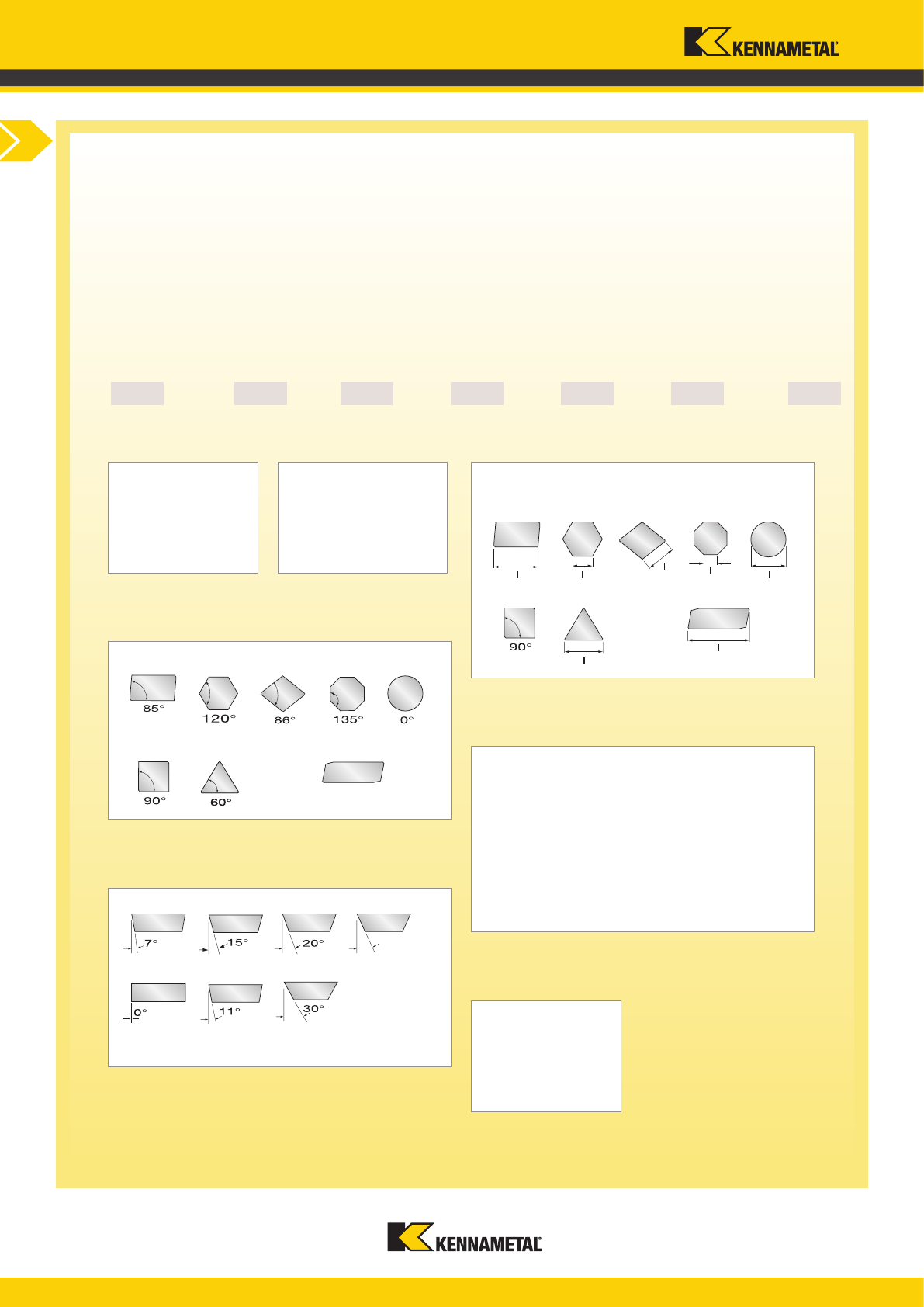

Milling Introduction

4 Type

3 Tolerance

2 Clearance

1 Shape

(1) Indexable inserts with ground wiper edges. (2) Dependent upon the insert size (see ISO 1832 standard)

Class D M S

A

(1)

mm ±0,025 ±0,005 ±0,025

C

(1)

mm ±0,025 ±0,013 ±0,025

E

(1)

mm ±0,025 ±0,025 ±0,025

F

(1)

mm ±0,013 ±0,005 ±0,025

G

mm ±0,025 ±0,025 ±0,130

H

(1)

mm ±0,013 ±0,013 ±0,025

J

(1)

mm from ±0,050 ±0,005 ±0,025

to ±0,150

K

(1)

mm from ±0,050 ±0,013 ±0,025

to ±0,150

L

(1)

mm from ±0,050 ±0,025 ±0,025

to ±0,150

M

mm from ±0,050 from ±0,080 ±0,13

to ±0,150 to ±0,200

N

mm from ±0,050 from ±0,080 ±0,025

to ±0,150 to ±0,200

U

mm from ±0,080 from ±0,130 ±0,13

to ±0,250 to ±0,380

Special feature requiring

additional specifications.

special

Other normal clearances

requiring SPECIAL

specification Symbol

O

.

Insert ISO Designation

Metric

www.kennametal.com

A27

04

6

PD

7

T

8 9 10

R -

A H M O

S T X Z

R

02 = 2,38 mm

03 = 3,18 mm

T3 = 3,97 mm

04 = 4,76 mm

M5 = 5,00 mm

05 = 5,56 mm

06 = 6,35 mm

1 2

21

F E T

K S P

R L N

Milling Introduction

10 Optional

9 Cutting Direction

7 Corner

continued

8 Edge Condition

6 Thickness

7 Corner

5 Size

Manufacturers optional symbol consisting of numbers or letters;

shall be separated from the standardized designation by a dash (-).

OPTIONAL SYMBOL

Neutral Insert

Left Hand InsertRight Hand Insert

OPTIONAL SYMBOL

Double

Chamfered Rounded

Cutting Edges

Chamfered

Rounded

Cutting Edges

Double

Chamfered

Cutting Edges

Chamfered

Cutting Edges

Rounded

Cutting Edges

Sharp Cutting

Edges

OPTIONAL SYMBOL

Z = Any other wiper edge clearance.

Two Letter Symbol:

For wiper edge

normal clearance

A = 3°

B = 5°

C = 7°

D = 15°

E = 20°

F = 25°

G = 30°

N = 0°

P = 11°

For cutting

edge angle

χ

r

A = 45°

D = 60°

E = 75°

F = 85°

P = 90°

Inserts With Wiper Edges.

Rounded Inserts

Symbol = 00

If the Ø is converted from an inch value.

Symbol = M0

If the Ø is converted from a metric value.

Rounded Corner Inserts

Value of corner radius given in 1/10 mm

Note: For sharp corner

Symbol = 00

special

Insert ISO Designation

Metric

www.kennametal.com

A28

d

l

85°

r

s

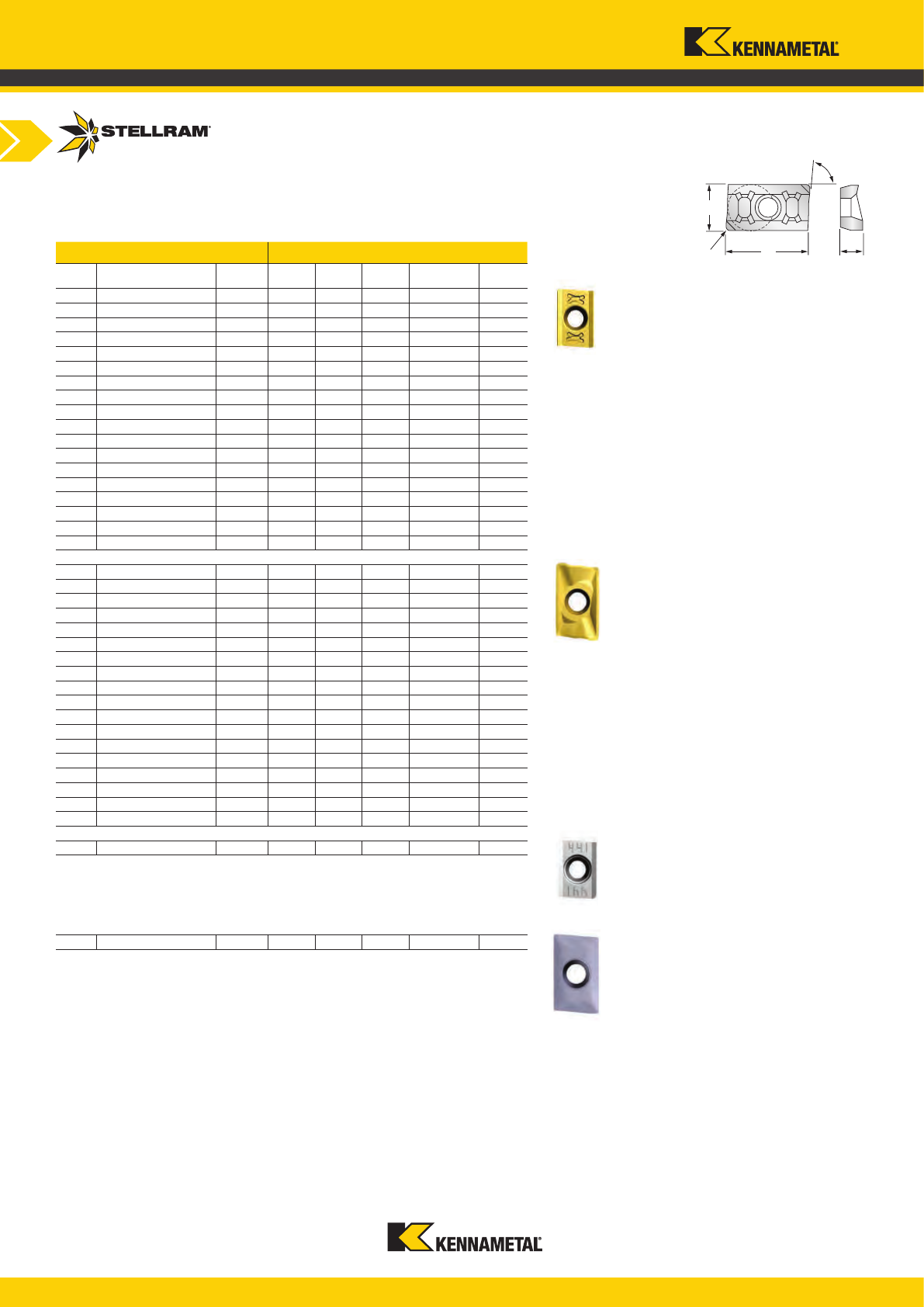

031075 ADET090308SR-42 SP6519 6,35 9,20 3,18 0,80 0,10

031076 ADET090308SR-42 X500 6,35 9,20 3,18 0,80 0,10

031094 ADET090310SR-42 SP6519 6,35 9,20 3,18 1,00 0,10

024913 ADET090310SR-42 X500 6,35 9,20 3,18 1,00 0,10

031096 ADET090312SR-42 SP6519 6,35 9,20 3,18 1,20 0,10

031095 ADET090312SR-42 X500 6,35 9,20 3,18 1,20 0,10

030980 ADET090316SR-42 SP6519 6,35 9,20 3,18 1,60 0,10

030942 ADET090316SR-42 X500 6,35 9,20 3,18 1,60 0,10

031098 ADET090320SR-42 SP6519 6,35 9,20 3,18 2,00 0,10

031097 ADET090320SR-42 X500 6,35 9,20 3,18 2,00 0,10

031100 ADET090324SR-42 SP6519 6,35 9,20 3,18 2,40 0,10

031099 ADET090324SR-42 X500 6,35 9,20 3,18 2,40 0,10

031102 ADET090330SR-42 SP6519 6,35 9,20 3,18 3,00 0,10

031101 ADET090330SR-42 X500 6,35 9,20 3,18 3,00 0,10

031104 ADET090332SR-42 SP6519 6,35 9,20 3,18 3,20 0,10

031103 ADET090332SR-42 X500 6,35 9,20 3,18 3,20 0,10

031093 ADET0903PDSR-42 SP6519 6,35 9,20 3,18

0,10

031092 ADET0903PDSR-42 X500 6,35 9,20 3,18 0,10

030857 ADET12T308ER-48 SP6519 7,87 12,70 3,76 0,80 0,04

030856 ADET12T308ER-48 X500 7,87 12,70 3,76 0,80 0,04

030800 ADET12T312ER-48 SP6519 7,87 12,70 3,76 1,20 0,04

030808 ADET12T312ER-48 X500 7,87 12,70 3,76 1,20 0,04

030771 ADET12T316ER-48 SP6519 7,87 12,70 3,76 1,60 0,04

030809 ADET12T316ER-48 X500 7,87 12,70 3,76 1,60 0,04

030909 ADET12T320ER-48 SP6519 7,87 12,70 3,76 2,00 0,04

030908 ADET12T320ER-48 X500 7,87 12,70 3,76 2,00 0,04

030859 ADET12T324ER-48 SP6519 7,87 12,70 3,76 2,40 0,04

030858 ADET12T324ER-48 X500 7,87 12,70 3,76 2,40 0,04

030911 ADET12T330ER-48 SP6519 7,87 12,70 3,76 3,00 0,04

030910 ADET12T330ER-48 X500 7,87 12,70 3,76 3,00 0,04

030772 ADET12T332ER-48 SP6519 7,87 12,70 3,76 3,20 0,04

030810 ADET12T332ER-48 X500 7,87 12,70 3,76 3,20 0,04

030913 ADET12T340ER-48 SP6519 7,87 12,70 3,76 4,00 0,04

030912 ADET12T340ER-48 X500 7,87 12,70 3,76

4,00 0,04

030770 ADET12T3PDER-48 SP6519 7,87 12,70 3,76 0,04

030807 ADET12T3PDER-48 X500 7,87 12,70 3,76 0,04

024916 ADET0903PDFR-441 GH1 6,35 9,20 3,18 0,03

029098 ADGT12T3PDFR-721 GH1 7,87 12,70 3,76 0,05

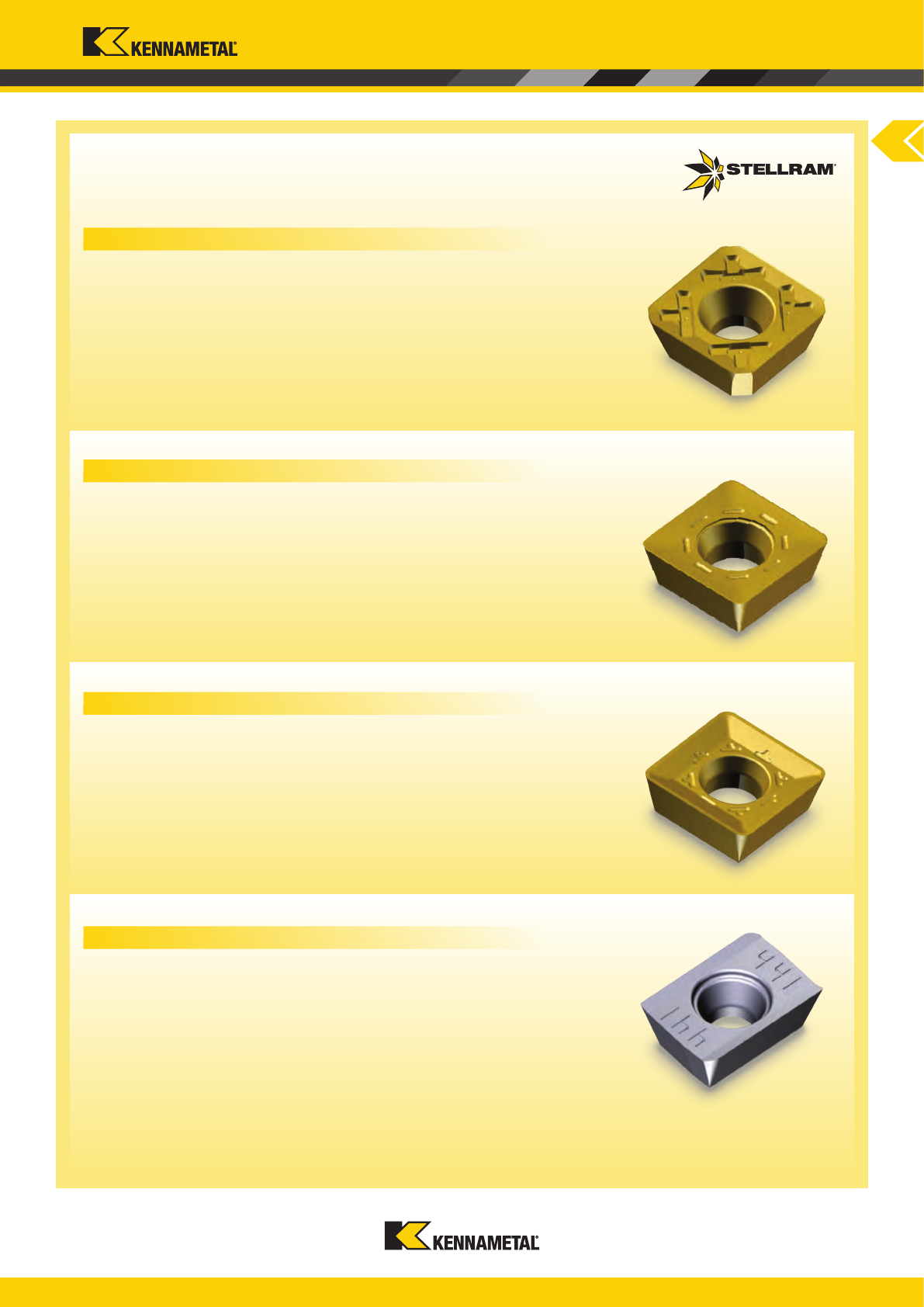

Milling Introduction

ADGT_-721

Ground circumference

χ

90° one face

pressed chip-breaker

ADET_-48

Ground circumference

χ

90° one face

pressed chip-breaker

ADET_-441

Ground circumference

χ

90° one face

pressed chip-breaker

ADET_-42

Ground circumference

χ

90° one face

pressed chip-breaker

Facet

Facet

Facet

Facet

Facet

Facet

Product Dimensions (mm)

EDP Item Description Grade d (IC) l s r h

m

min

Alphabetical Index

AD Milling Style Inserts

www.kennametal.com

A29

d

l

85°

r

s

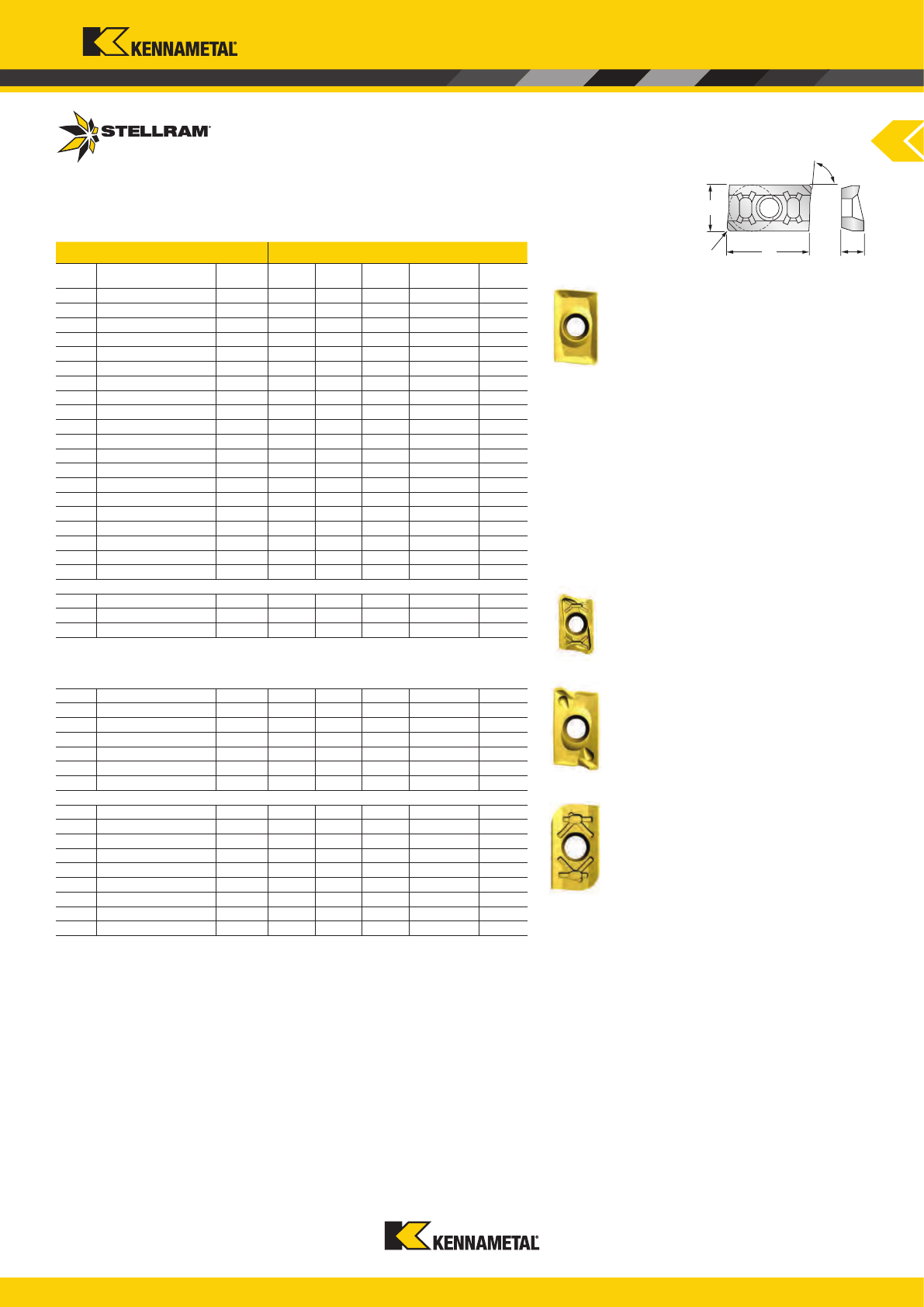

031526 ADHT12T308ER-46 SP6519 7,87 12,70 3,76 0,80 0,05

029329 ADHT12T308ER-46 X500 7,87 12,70 3,76 0,80 0,05

030406 ADHT12T308ER-46 X700 7,87 12,70 3,76 0,80 0,05

031527 ADHT12T316ER-46 SP6519 7,87 12,70 3,76 1,60 0,05

029331 ADHT12T316ER-46 X500 7,87 12,70 3,76 1,60 0,05

030407 ADHT12T316ER-46 X700 7,87 12,70 3,76 1,60 0,05

031530 ADHT12T320ER-46 SP6519 7,87 12,70 3,76 2,00 0,05

029337 ADHT12T320ER-46 X500 7,87 12,70 3,76 2,00 0,05

030408 ADHT12T320ER-46 X700 7,87 12,70 3,76 2,00 0,05

031528 ADHT12T324ER-46 SP6519 7,87 12,70 3,76 2,40 0,05

029333 ADHT12T324ER-46 X500 7,87 12,70 3,76 2,40 0,05

031531 ADHT12T330ER-46 SP6519 7,87 12,70 3,76 3,00 0,05

029339 ADHT12T330ER-46 X500 7,87 12,70 3,76 3,00 0,05

031515 ADHT12T332ER-46 SP6519 7,87 12,70 3,76 3,20 0,05

029036 ADHT12T332ER-46 X500 7,87 12,70 3,76 3,20 0,05

030409 ADHT12T332ER-46 X700 7,87 12,70 3,76 3,20 0,05

031529 ADHT12T340ER-46 SP6519 7,87 12,70 3,76

4,00 0,05

029335 ADHT12T340ER-46 X500 7,87 12,70 3,76 4,00 0,05

031525 ADHT12T3PDER-46 SP6519 7,87 12,70 3,76 0,05

029327 ADHT12T3PDER-46 X500 7,87 12,70 3,76 0,05

017286 ADKT0903PDER-43 MP91M 6,35 9,20 3,18 0,05

031463 ADKT0903PDER-43 SP6519 6,35 9,20 3,18 0,05

015150 ADKT0903PDER-43 X500 6,35 9,20 3,18 0,05

027915 ADKT12T3PDER-45 MP91M 7,87 12,70 3,76 0,05

027916 ADKT12T3PDER-45 SC3025 7,87 12,70 3,76 0,05

031514 ADKT12T3PDER-45 SP6519 7,87 12,70 3,76 0,05

027913 ADKT12T3PDER-45 X500 7,87 12,70 3,76 0,05

023082 ADKT1505PDER-45 MP91M 9,65 16,05 5,56 0,06

031464 ADKT1505PDER-45 SP6519 9,65 16,05 5,56 0,06

023083 ADKT1505PDER-45 X500 9,65 16,05 5,56 0,06

033179 APET160402TR-42 SP6519 9,52 16,66 4,76 0,20 0,10

033180 APET160408TR-42 SP6519 9,52 16,66 4,76 0,80 0,10

033181 APET160410TR-42 SP6519 9,52 16,66 4,76 1,00 0,10

033182 APET160415TR-42 SP6519 9,52 16,66 4,76 1,50 0,10

033183 APET160420TR-42 SP6519 9,52 16,66 4,76 2,00 0,10

033184 APET160425TR-42 SP6519 9,52 16,66 4,76 2,50 0,10

033185 APET160430TR-42 SP6519 9,52 16,66 4,76 3,00 0,10

033186 APET160440TR-42 SP6519 9,52 16,66 4,76 4,00 0,10

033187 APET160460TR-42 SP6519 9,52 16,66 4,76 6,00 0,10

Milling Introduction

APET_-42

Ground circumference

χ

90° one

face pressed chip-breaker

ADKT_-45

Ground wiper edges

χ

90° one face

pressed chip-breaker

ADKT_-43

Ground wiper edges

χ

90° one face

pressed chip-breaker

ADHT_-46

Ground circumference

χ

90° one

face pressed chip-breaker

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Product Dimensions (mm)

EDP Item Description Grade d (IC) l s r h

m

min

Alphabetical Index

AD - AP Milling Style Inserts

www.kennametal.com

A30

d

l

85°

r

s

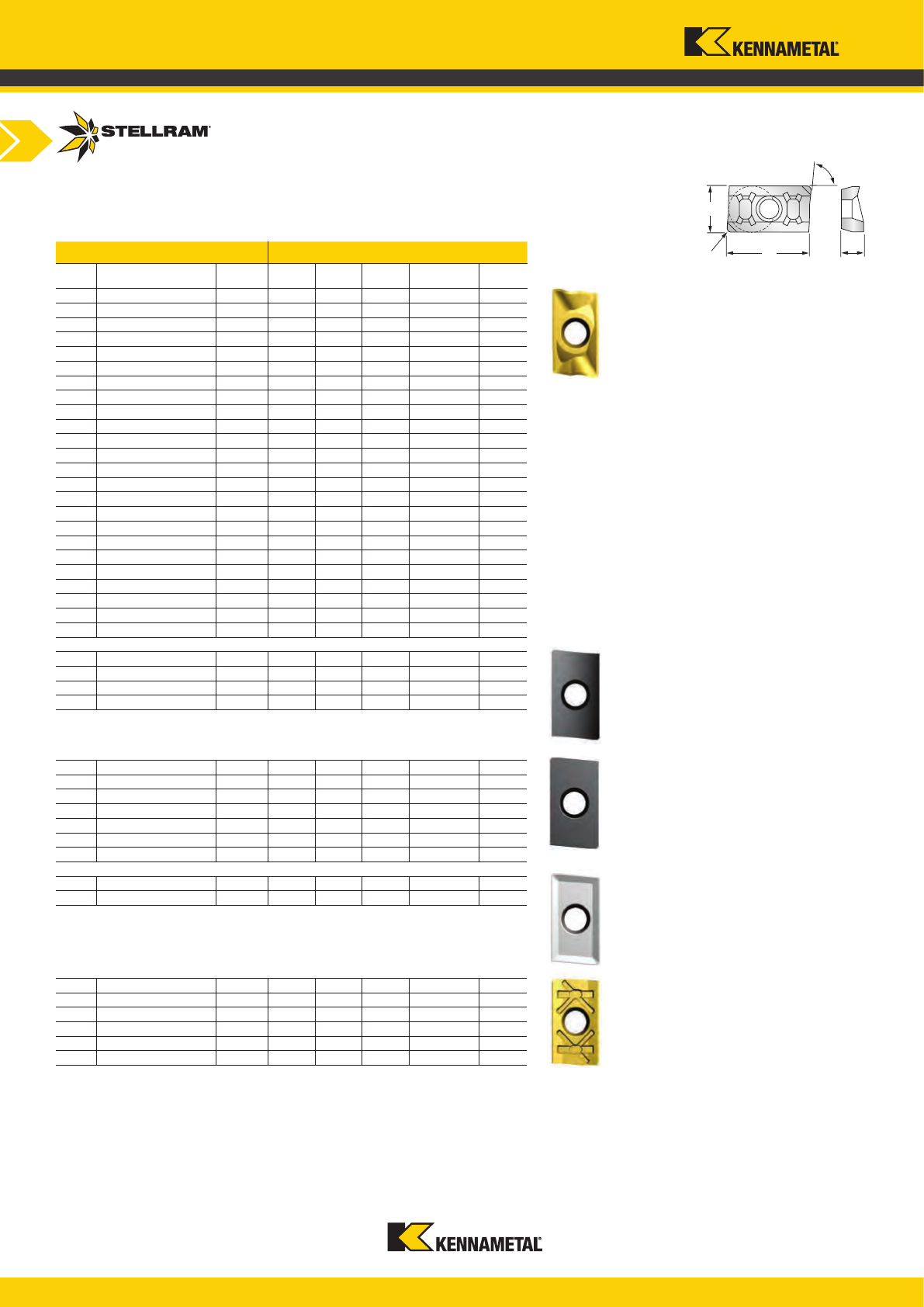

030861 APET160408ER-48 SP6519 9,52 16,66 4,76 0,80 0,04

030860 APET160408ER-48 X500 9,52 16,66 4,76 0,80 0,04

030799 APET160412ER-48 SP6519 9,52 16,66 4,76 1,20 0,04

030812 APET160412ER-48 X500 9,52 16,66 4,76 1,20 0,04

030774 APET160416ER-48 SP6519 9,52 16,66 4,76 1,60 0,04

030813 APET160416ER-48 X500 9,52 16,66 4,76 1,60 0,04

030915 APET160420ER-48 SP6519 9,52 16,66 4,76 2,00 0,04

030914 APET160420ER-48 X500 9,52 16,66 4,76 2,00 0,04

030917 APET160424ER-48 SP6519 9,52 16,66 4,76 2,40 0,04

030916 APET160424ER-48 X500 9,52 16,66 4,76 2,40 0,04

030919 APET160430ER-48 SP6519 9,52 16,66 4,76 3,00 0,04

030918 APET160430ER-48 X500 9,52 16,66 4,76 3,00 0,04

030775 APET160432ER-48 SP6519 9,52 16,66 4,76 3,20 0,04

030814 APET160432ER-48 X500 9,52 16,66 4,76 3,20 0,04

030906 APET160440ER-48 SP6519 9,52 16,66 4,76 4,00 0,04

030907 APET160440ER-48 X500 9,52 16,66 4,76 4,00 0,04

030921 APET160450ER-48 SP6519 9,52 16,66 4,76

5,00 0,04

030920 APET160450ER-48 X500 9,52 16,66 4,76 5,00 0,04

030923 APET160460ER-48 SP6519 9,52 16,66 4,76 6,00 0,04

030922 APET160460ER-48 X500 9,52 16,66 4,76 6,00 0,04

030925 APET160464ER-48 SP6519 9,52 16,66 4,76 6,40 0,04

030924 APET160464ER-48 X500 9,52 16,66 4,76 6,40 0,04

030773 APET1604PDER-48 SP6519 9,52 16,66 4,76 0,04

030811 APET1604PDER-48 X500 9,52 16,66 4,76 0,04

033188 APEX1604PDER-701 SP6519 9,52 16,66 4,76 0,02

017624 APEX1604PDFL-701 GH1 9,52 16,66 4,76 0,02

014066 APEX1604PDFR-701 GH1 9,52 16,66 4,76 0,02

033189 APEX1604PDFR-701 SP4019 9,52 16,66 4,76 0,02

017291 APFW1604PDER MP91M 9,52 16,66 4,76 0,04

017630 APFW1604PDTL GH1 9,52 16,66 4,76 0,10

034692 APFW1604PDTL SP4019 9,52 16,66 4,76 0,10

017628 APFW1604PDTR GH1 9,52 16,66 4,76 0,10

027883 APFW1604PDTR SC3025 9,52 16,66 4,76 0,10

033191 APFW1604PDTR SP4019 9,52 16,66 4,76 0,10

033190 APFW1604PDTR X400 9,52 16,66 4,76 0,10

033192

APHT1604PDER SP4019 9,52 16,66 4,76 0,04

015154 APHT1604PDFR GH1 9,52 16,66 4,76 0,02

017292 APHT1604PDTL-42 MP91M 9,52 16,66 4,76 0,10

031513 APHT1604PDTL-42 SP6519 9,52 16,66 4,76 0,10

017635 APHT1604PDTL-42 X500 9,52 16,66 4,76 0,10

017293 APHT1604PDTR-42 MP91M 9,52 16,66 4,76 0,10

031466 APHT1604PDTR-42 SP6519 9,52 16,66 4,76 0,10

015155 APHT1604PDTR-42 X500 9,52 16,66 4,76 0,10

Milling Introduction

APEX_-701

Completely ground

χ

90° concave

cutting face

APHT_

Ground circumference

χ

90° one

face pressed chip-breaker

APHT_-42

Ground circumference

χ

90° one

face pressed chip-breaker

APFW_

Ground circumference

χ

90°

without chip-breaker

APET_-48

Ground circumference

χ

90° one

face pressed chip-breaker

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Product Dimensions (mm)

EDP Item Description Grade d (IC) l s r h

m

min

Alphabetical Index

AP Milling Style Inserts

www.kennametal.com

A31

d

l

85°

r

s

031495 APHT160408ER-46 SP6519 9,52 16,66 4,76 0,80 0,10

027869 APHT160408ER-46 X500 9,52 16,66 4,76 0,80 0,10

031496 APHT160416ER-46 SP6519 9,52 16,66 4,76 1,60 0,10

027870 APHT160416ER-46 X500 9,52 16,66 4,76 1,60 0,10

031497 APHT160424ER-46 SP6519 9,52 16,66 4,76 2,40 0,10

027871 APHT160424ER-46 X500 9,52 16,66 4,76 2,40 0,10

031397 APHT160432ER-46 SP6519 9,52 16,66 4,76 3,20 0,10

027872 APHT160432ER-46 X500 9,52 16,66 4,76 3,20 0,10

031542 APHT160440ER-46 SP6519 9,52 16,66 4,76 4,00 0,10

027873 APHT160440ER-46 X500 9,52 16,66 4,76 4,00 0,10

031498 APHT160450ER-46 SP6519 9,52 16,66 4,76 5,00 0,10

027874 APHT160450ER-46 X500 9,52 16,66 4,76 5,00 0,10

031541 APHT160464ER-46 SP6519 9,52 16,66 4,76 6,40 0,10

027875 APHT160464ER-46 X500 9,52 16,66 4,76 6,40 0,10

017861 APKT1003PDFR-3M GH1 6,68 10,50 3,18 0,05

017294 APKT1604PDER-43 MP91M 9,52 16,66 4,76 0,08

027887 APKT1604PDER-43 SC3025 9,52 16,66 4,76 0,08

031468

APKT1604PDER-43 SP6519 9,52 16,66 4,76 0,08

015156 APKT1604PDER-43 X500 9,52 16,66 4,76 0,08

023112 APKT1003PDER-45 MP91M 6,68 10,50 3,18 0,05

031467 APKT1003PDER-45 SP6519 6,68 10,50 3,18 0,05

023113 APKT1003PDER-45 X500 6,68 10,50 3,18 0,05

023114 APKT1604PDER-45 MP91M 9,52 16,66 4,76 0,06

031469 APKT1604PDER-45 SP6519 9,52 16,66 4,76 0,06

023115 APKT1604PDER-45 X500 9,52 16,66 4,76 0,06

024926 MPEX0602PPFL-701 GH1 6,35 6,35 2,38 0,02

024927 MPEX0602PPFR-701 GH1 6,35 6,35 2,38 0,02

024928 MPEX0803PPFL-701 GH1 7,94 7,94 3,18 0,02

017642 MPEX0803PPFR-701 GH1 7,94 7,94 3,18 0,02

034527 MPEX0803PPFL-701 SP4019 7,94 7,94 3,18 0,02

034528 MPEX0803PPFR-701 SP4019 7,94 7,94 3,18 0,02

017644 MPEX1104PPFL-701 GH1 11,11 11,11 4,76 0,02

017643 MPEX1104PPFR-701 GH1 11,11 11,11 4,76 0,02

034523 MPFW0402PPTL SP4019 4,76 4,76 2,38 0,07

034524 MPFW0402PPTR SP4019 4,76 4,76 2,38 0,07

031508 MPFW0402PPTL SP6519 4,76 4,76 2,38 0,07

031507 MPFW0402PPTR

SP6519 4,76 4,76 2,38 0,07

034525 MPFW0602PPTL SP4019 6,35 6,35 2,38 0,07

034526 MPFW0602PPTR SP4019 6,35 6,35 2,38 0,07

031571 MPFW0602PPTL SP6519 6,35 6,35 2,38 0,07

031570 MPFW0602PPTR SP6519 6,35 6,35 2,38 0,07

Milling Introduction

MPFW_

Ground circumference

χ

90°

without chip-breaker

MPEX_-701

Completely ground

χ

90° concave

cutting face

APKT_-43

Ground wiper edges

χ

90° one face

pressed chip-breaker

APKT_-45

Ground wiper edges

χ

90° one face

pressed chip-breaker

APKT_-3M

Ground wiper edges

χ

90° one face

pressed chip-breaker

APHT_-46

Ground circumference

χ

90° one

face pressed chip-breaker

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Product Dimensions (mm)

EDP Item Description Grade d (IC) l s r h

m

min

Alphabetical Index

AP - MP Milling Style Inserts

www.kennametal.com

A32

d

l

r

86°

s

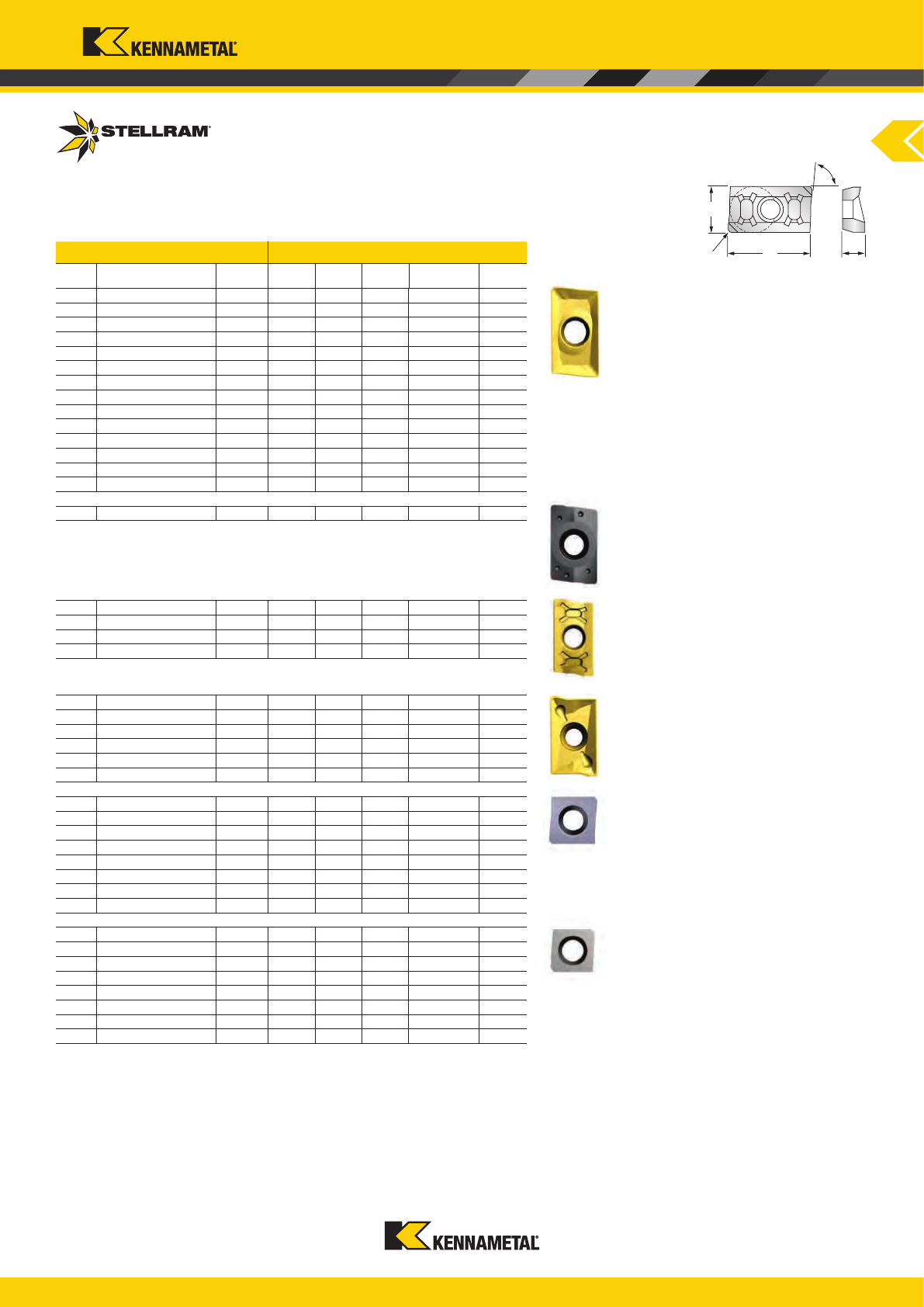

017658 MPFW0803PPTL GH1 7,94 7,94 3,18 0,10

017655 MPFW0803PPTR GH1 7,94 7,94 3,18 0,10

034529 MPFW0803PPTL SP4019 7,94 7,94 3,18 0,10

034530 MPFW0803PPTR SP4019 7,94 7,94 3,18 0,10

034532 MPFW0803PPTL X400 7,94 7,94 3,18 0,10

034531 MPFW0803PPTR X400 7,94 7,94 3,18 0,10

017439 MPFW1104PPTL GH1 11,11 11,11 4,76 0,15

017440 MPFW1104PPTR GH1 11,11 11,11 4,76 0,15

034533 MPFW1104PPTL SP4019 11,11 11,11 4,76 0,15

034534 MPFW1104PPTR SP4019 11,11 11,11 4,76 0,15

017296 MPHT0803PPTL-42 MP91M 7,94 7,94 3,18 0,10

017297 MPHT0803PPTR-42 MP91M 7,94 7,94 3,18 0,10

031510 MPHT0803PPTL-42 SP6519 7,94 7,94 3,18 0,10

031509 MPHT0803PPTR-42 SP6519 7,94 7,94 3,18 0,10

015138 MPHT0803PPTL-42 X500 7,94 7,94 3,18 0,10

015140 MPHT0803PPTR-42 X500 7,94 7,94 3,18 0,10

017298 MPHT1104PPTL-42 MP91M 11,11 11,11 4,76 0,10

017299 MPHT1104PPTR-42 MP91M 11,11 11,11 4,76 0,10

031512 MPHT1104PPTL-42 SP6519 11,11 11,11 4,76 0,10

031511

MPHT1104PPTR-42 SP6519 11,11 11,11 4,76 0,10

015141 MPHT1104PPTL-42 X500 11,11 11,11 4,76 0,10

015142 MPHT1104PPTR-42 X500 11,11 11,11 4,76 0,10

017667 MPHW0402PPTL X500 4,76 4,76 2,38 0,07

017666 MPHW0402PPTR X500 4,76 4,76 2,38 0,07

017669 MPHW0602PPTL X500 6,35 6,35 2,38 0,07

017668 MPHW0602PPTR X500 6,35 6,35 2,38 0,07

015180 MPMT060204EN-43 X500 6,35 6,35 2,38 0,40 0,04

022199 ODET0404APEN-44 MP91M 12,70 4,00 4,76 0,04

031470 ODET0404APEN-44 SP6519 12,70 4,00 4,76 0,04

022198 ODET0404APEN-44 X500 12,70 4,00 4,76 0,04

026591 ODET0605APEN-44 MP91M 16,00 6,00 5,55 0,04

034513 ODET0605APEN-44 SP4019 16,00 6,00 5,55 0,04

031501 ODET0605APEN-44 SP6519 16,00 6,00 5,55 0,04

026592 ODET0605APEN-44 X500 16,00 6,00 5,55 0,04

024911 ODET0404APFN-441 GH1 12,70 4,00 4,76 0,02

026588 ODET0605APFN-441 GH1 16,00 6,00 5,55 0,02

027884 ODEW0404APTR-RA SC3025 12,70 4,00 4,76 0,19

027885 ODEW0605APTR-RA SC3025 16,00 6,00 5,55 0,19

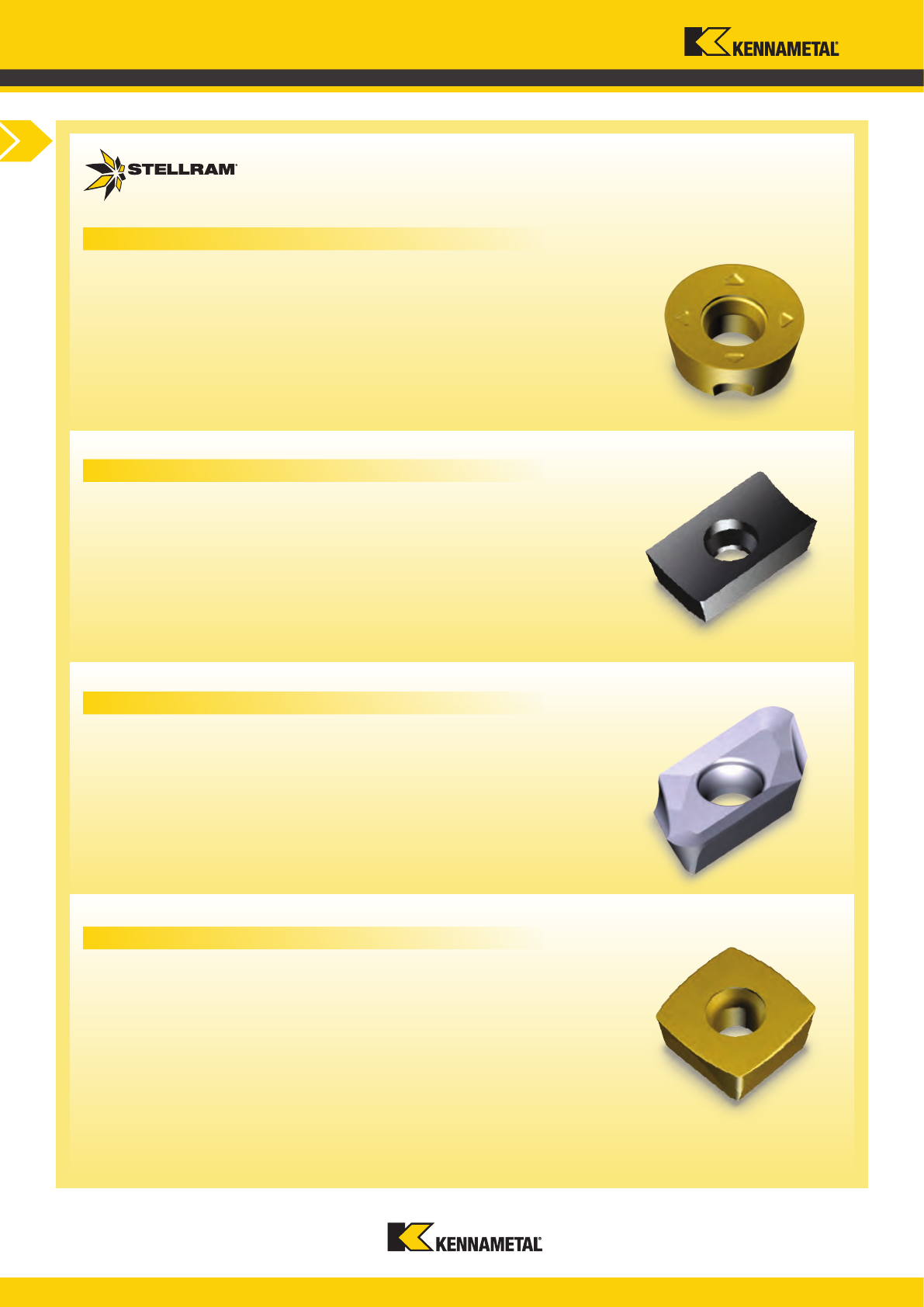

Milling Introduction

ODEW_-RA

Ground circumference

χ

42° without

chip-breaker

ODET_-441

Ground circumference

χ

42° one

face pressed chip-breaker

ODET_-44

Ground circumference

χ

42° one

face pressed chip-breaker

MPMT_

As pressed circumference

χ

90° one

face pressed chip-breaker

MPFW_

Ground circumference

χ

90°

without chip-breaker

MPHW_

Ground circumference

χ

90°

without chip-breaker

MPHT_-42

Ground circumference

χ

90° one

face pressed chip-breaker

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Facet

Product Dimensions (mm)

EDP Item Description Grade d (IC) l s r h

m

min

Alphabetical Index

MP - OD Milling Style Inserts

www.kennametal.com

A33

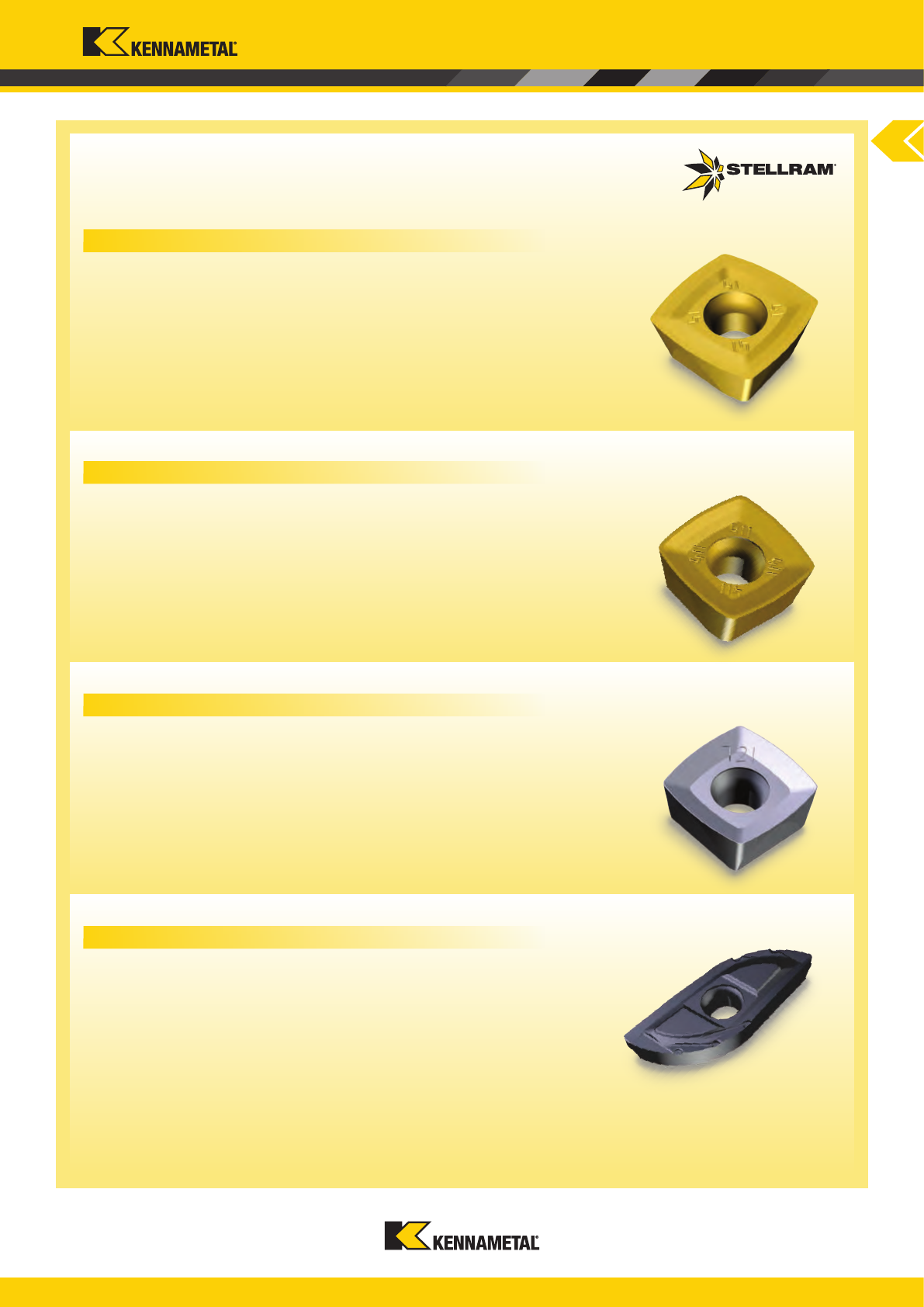

l

r

135°

d

s

017303 ODMT040408EN-41 MP91M 12,70 4,00 4,76 0,80 0,04

031471 ODMT040408EN-41 SP6519 12,70 4,00 4,76 0,80 0,04

015143 ODMT040408EN-41 X500 12,70 4,00 4,76 0,80 0,04

030330 ODMT040408EN-41 X700 12,70 4,00 4,76 0,80 0,04

017775 ODMT0404APEN-41 MP91M 12,70 4,00 4,76 0,04

031472 ODMT0404APEN-41 SP6519 12,70 4,00 4,76 0,04

022061 ODMT0404APEN-41 X500 12,70 4,00 4,76 0,04

026589 ODMT0605APEN-41 MP91M 16,00 6,00 5,55 0,04

034514 ODMT0605APEN-41 SP4019 16,00 6,00 5,55 0,04

031502 ODMT0605APEN-41 SP6519 16,00 6,00 5,55 0,04

026590 ODMT0605APEN-41 X500 16,00 6,00 5,55 0,04

031540 ODMT040408EN-412 SP6519 12,70 4,00 4,76 0,80 0,06

030768 ODMT040408EN-412 X500 12,70 4,00 4,76 0,80 0,06

030769 ODMT040408EN-412 X700 12,70 4,00 4,76 0,80 0,06

017304 ODMW040408SN MP91M 12,70 4,00 4,76 0,80 0,27

029096 ODMW040408SN SC3025 12,70 4,00 4,76 0,80 0,27

031462 ODMW040408SN SP6519 12,70 4,00 4,76 0,80 0,27

017672 ODMW040408SN X500 12,70 4,00

4,76 0,80 0,27

025836 ODMW060512SN MP91M 16,00 6,00 5,55 1,20 0,27

029097 ODMW060512SN SC3025 16,00 6,00 5,55 1,20 0,27

031483 ODMW060512SN SP6519 16,00 6,00 5,55 1,20 0,27

025838 ODMW060512SN X500 16,00 6,00 5,55 1,20 0,27

026595 ODMW060512TN MP91M 16,00 6,00 5,55 1,20 0,17

034515 ODMW060512TN SP4019 16,00 6,00 5,55 1,20 0,17

031503 ODMW060512TN SP6519 16,00 6,00 5,55 1,20 0,17

026596 ODMW060512TN X500 16,00 6,00 5,55 1,20 0,17

034556 RDET0702M0E-701 SP4019 7,00 - 2,38 3,50 0,03

034558 RDET1003M0E-701 SP4019 10,00 - 3,18 5,00 0,05

034560 RDET12T3M0E-701-X6 SP4019 12,00 - 3,97 6,00 0,05

034563 RDET1604M0E-701-X8 SP4019 16,00 - 4,76 8,00 0,05

031533 RDHT2006M0E-42-X8 SP6519 20,00 - 6,35 10,00 0,08

029310 RDHT2006M0E-42-X8 X500 20,00 - 6,35 10,00 0,08

034557 RDHW0702M0T SP4019 7,00 - 2,38 3,50 0,075

034559 RDHW1003M0T SP4019 10,00 - 3,18 5,00 0,15

034561 RDHW12T3M0T-20-X6 SP4019

12,00 - 3,97 6,00 0,20

031519 RDHW12T3M0T-20-X6 SP5419 12,00 - 3,97 6,00 0,20

034562 RDHW12T3M0T-X6 SP4019 12,00 - 3,97 6,00 0,15

034564 RDHW1604M0T-30-X8 SP4019 16,00 - 4,76 8,00 0,30