www.kennametal.com

VII

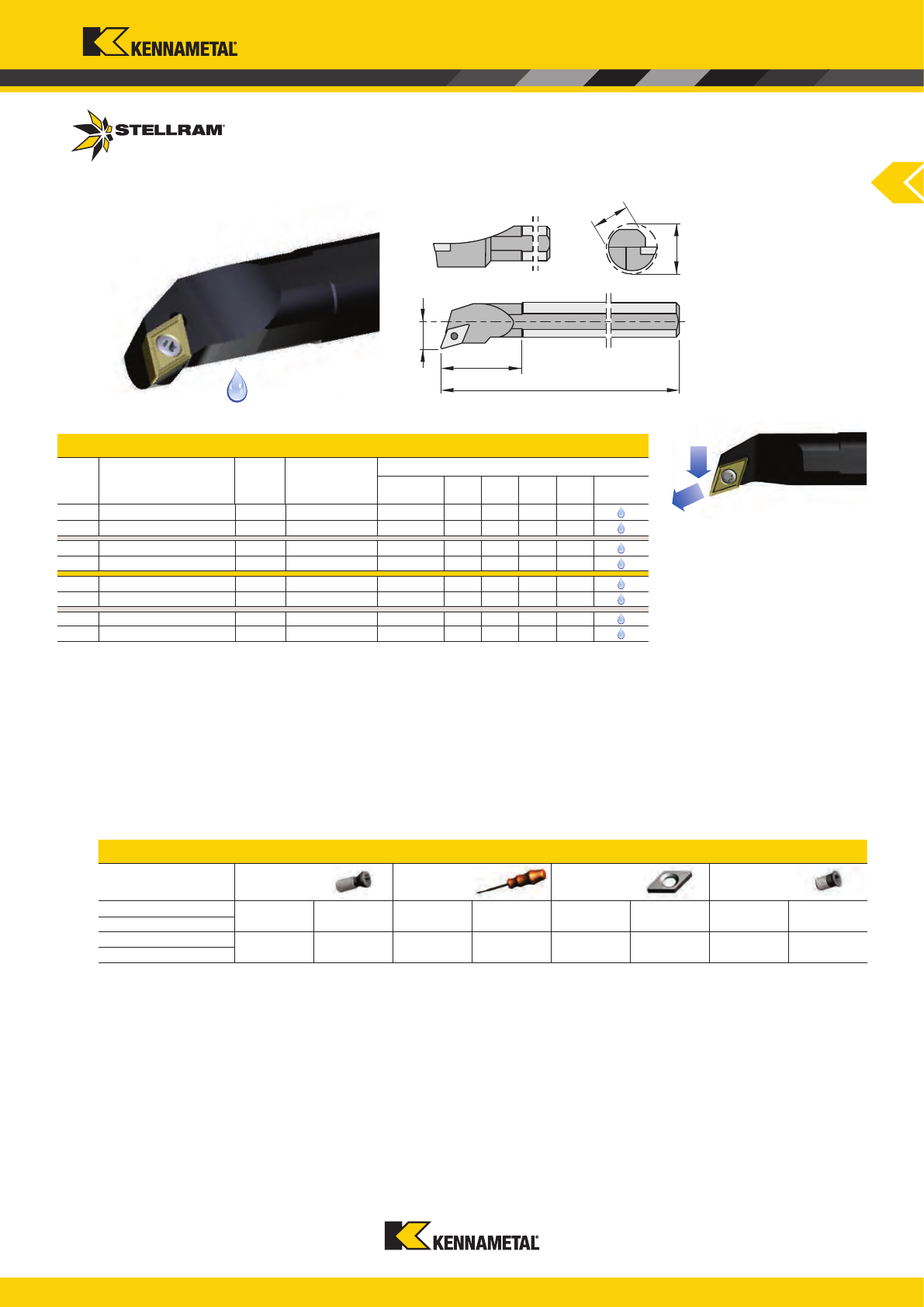

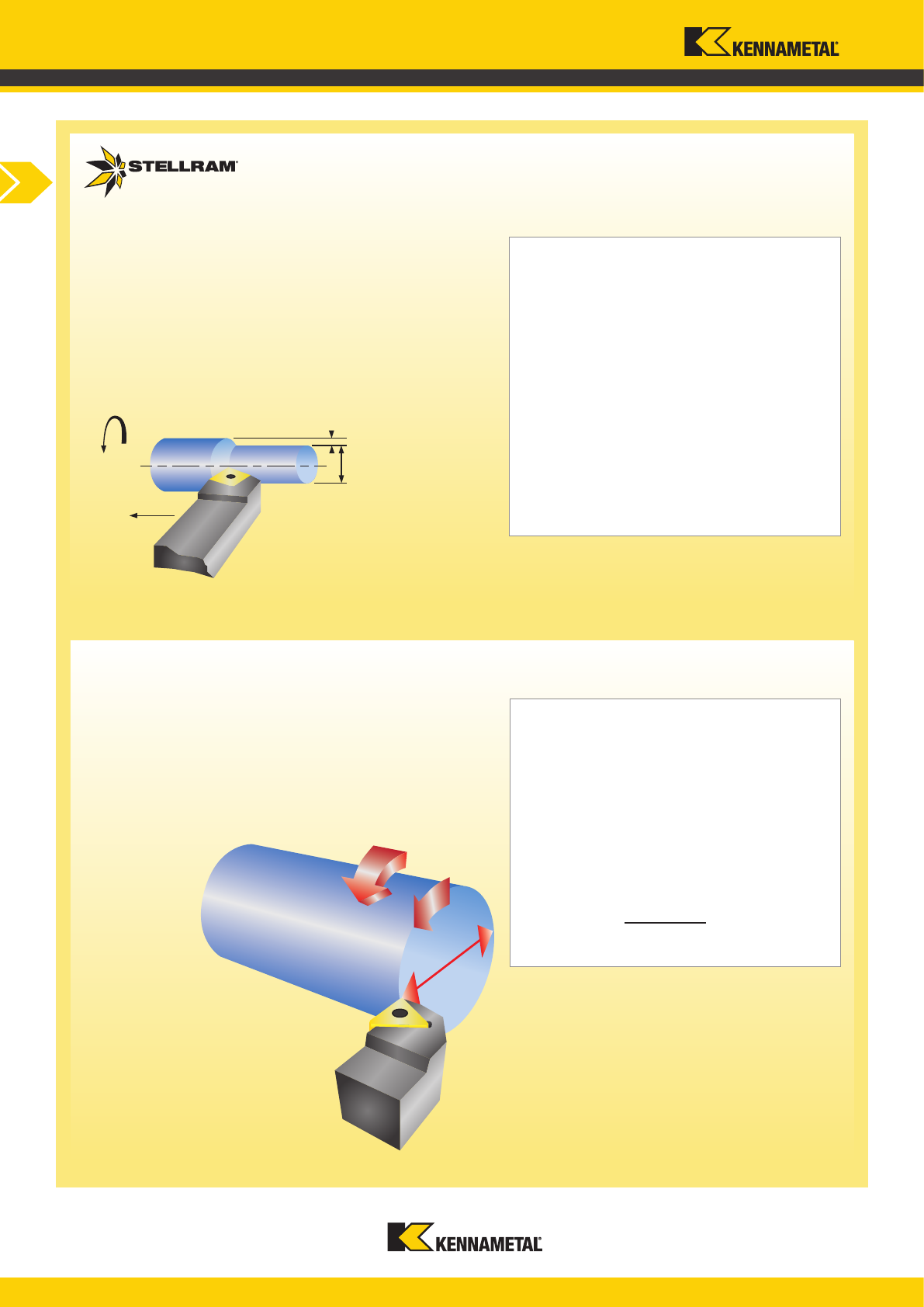

Turning

TURNING

www.kennametal.com

C1

Introduction

Turning

IINTRODUCTION ................................................................................................................................................ C1 - C3

FIRST CHOICE GUIDE ............................................................................................................................ C4 - C11

GEOMETRY USER GUIDE .............................................................................................................................. C12

DEFINITIONS OF GEOMETRIES .......................................................................................................... C13 - C23

GRADES SELECTION ..................................................................................................................................... C24

GRADE DESCRIPTIONS ....................................................................................................................... C25 - C29

GRADE GEOMETRY ............................................................................................................................. C30 - C31

CUTTING SPEED .................................................................................................................................. C32 - C33

ISO GRADE CLASSIFICATION ....................................................................................................................... C34

TURNING INSERTS

INSERT DESIGNATIONS ...................................................................................................................... C36 - C37

TOOLHOLDER DESIGNATIONS ........................................................................................................... C38 - C41

INSERT STYLES

C STYLE ........................................................................................................................................... C42 - C65

D STYLE ........................................................................................................................................... C66 - C87

E STYLE ......................................................................................................................................... C88 - C103

R STYLE ....................................................................................................................................... C104 - C111

S STYLE ....................................................................................................................................... C112 - C128

T STYLE ....................................................................................................................................... C129 - C141

V STYLE ....................................................................................................................................... C142 - C161

W STYLE ...................................................................................................................................... C162 - C172

SPARES ............................................................................................................................................. C173 - C189

TECHNICAL INFORMATION ............................................................................................................. C191 - C203

THREADING

THREADING INSERTS & TOOLHOLDERS ...................................................................................... C205 - C246

THREADING TECHNICAL ................................................................................................................. C247 - C263

GROOVING

................................................................................................................................................. C265 - C276

MINI CUT ............................................................................................................................................ C277 - C280

PART-OFF

.................................................................................................................................................. C281 - C285

Turning

Contents

www.kennametal.com

C2

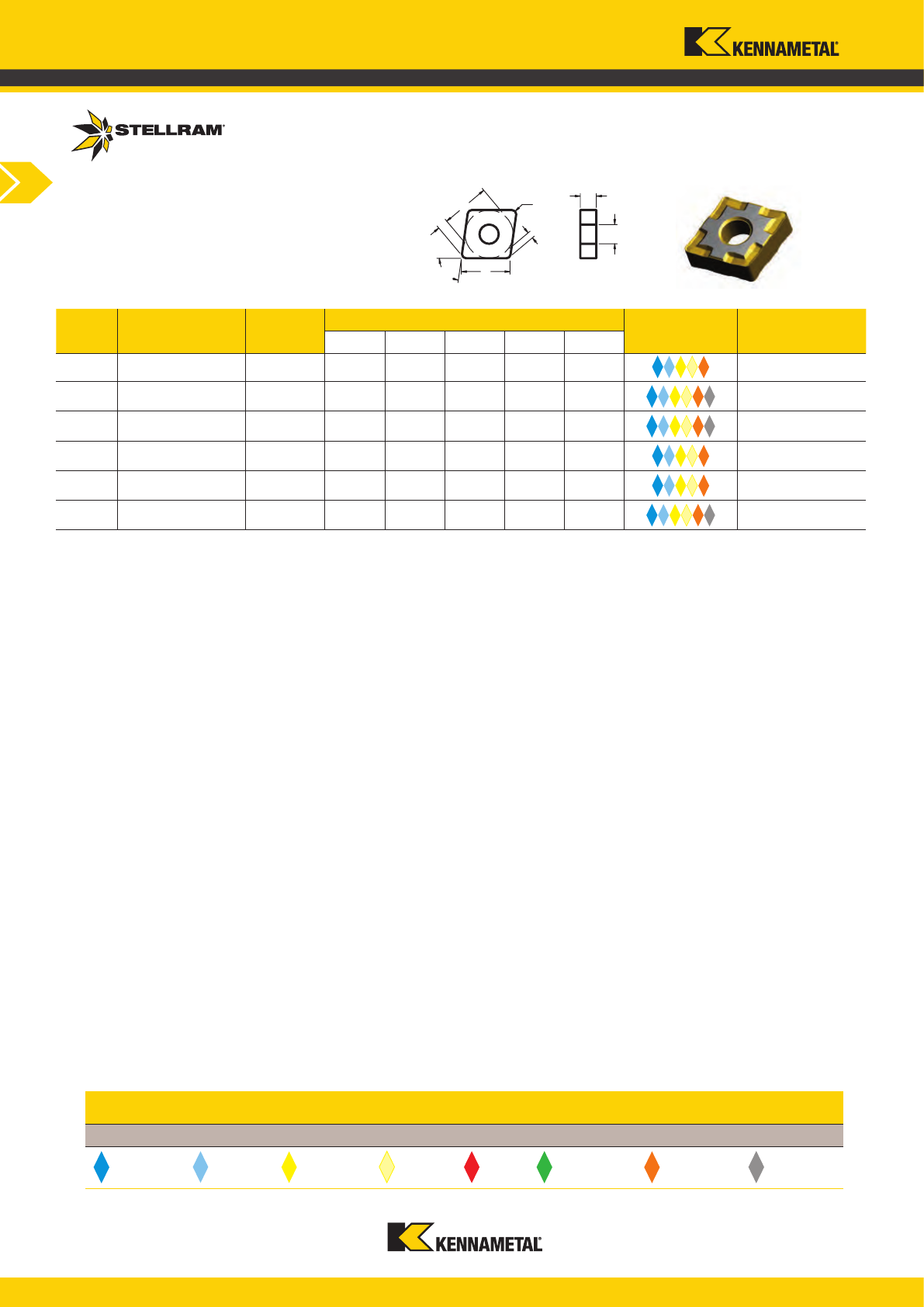

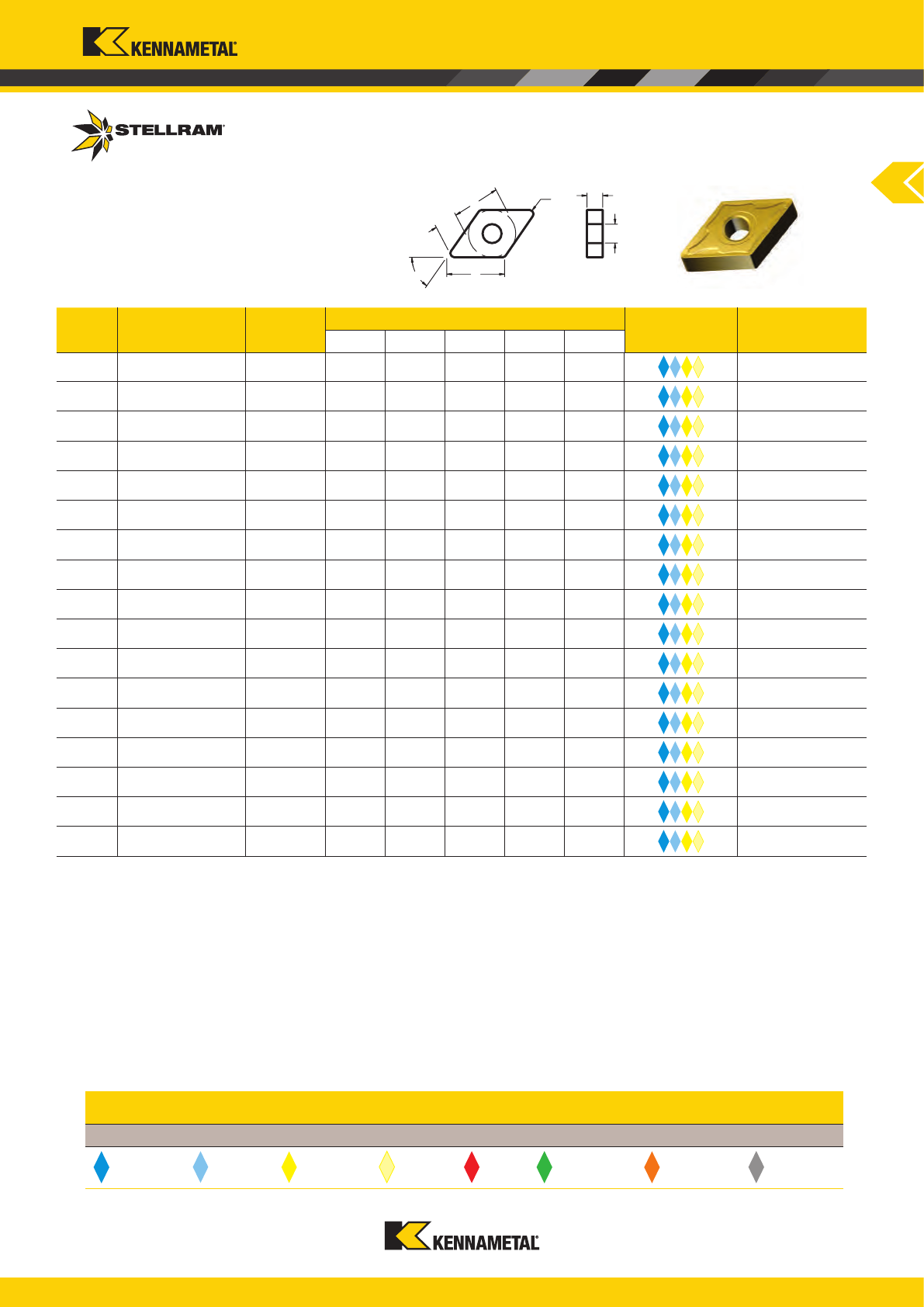

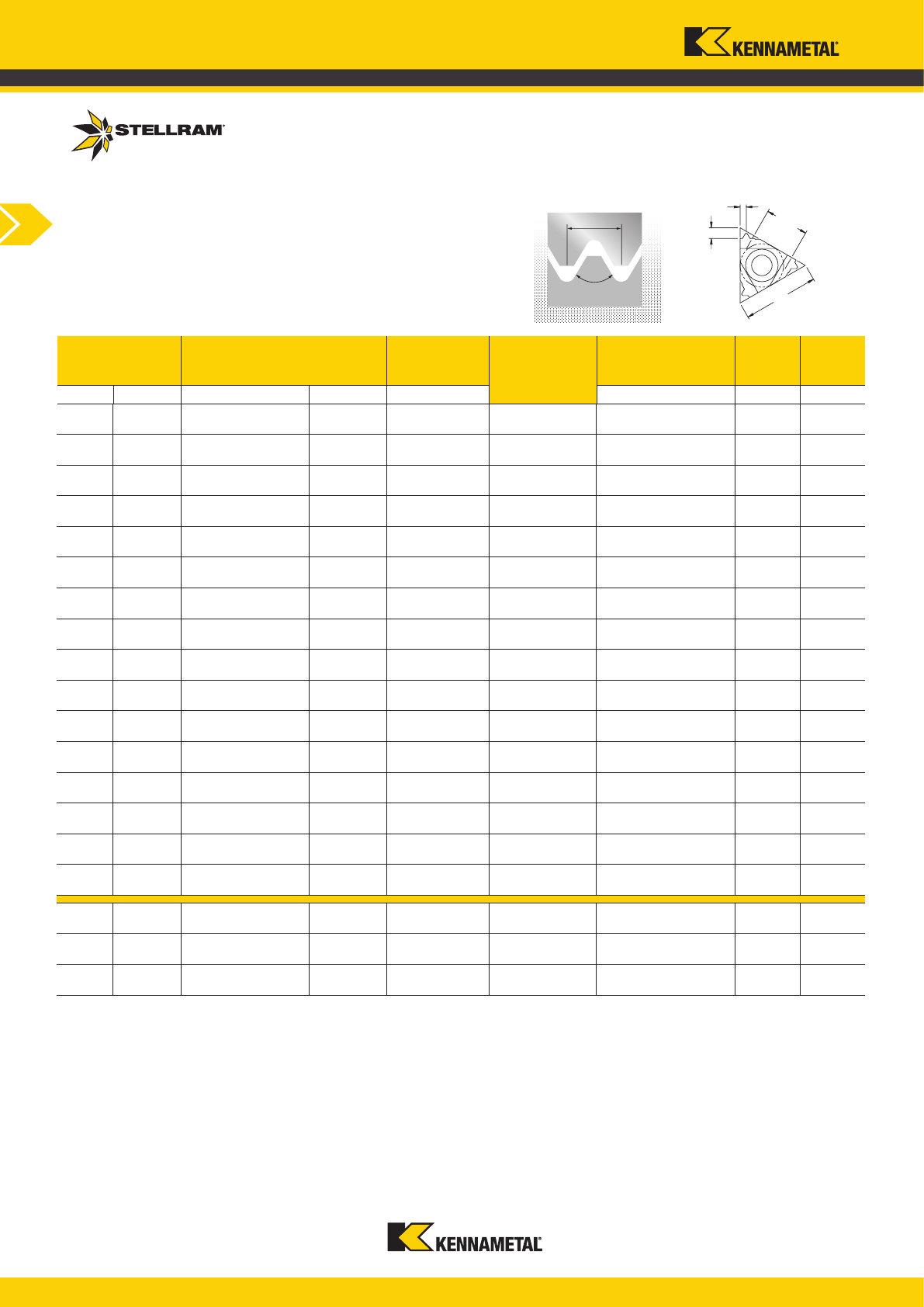

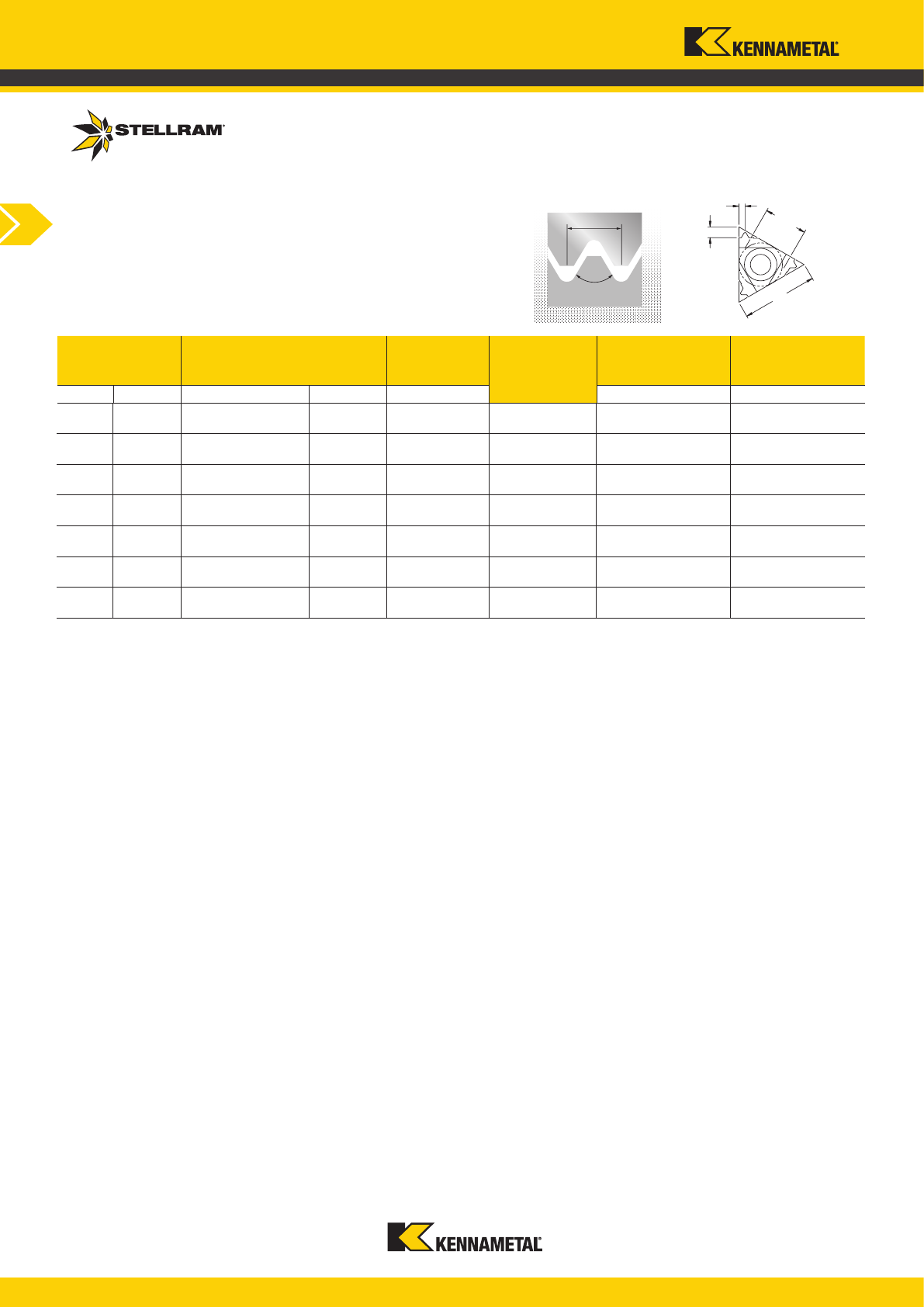

0,0

1B

SP0819

Vc (m/min)

140 - 450

NL250

Vc (m/min)

40 - 165

NL250

Vc (m/min)

60 - 245

f

n

(mm/rev)

0,1 - 0,3

a

p

(mm)

0,5 - 2,0

f

n

(mm/rev)

0,15 - 0,45

a

p

(mm)

0,75 - 3,0

2N

NL250

Vc (m/min)

105 - 410

NL920

Vc (m/min)

30 - 90

NL300

Vc (m/min)

60 -230

4T

f

n

(mm/rev)

0,25 - 0,5

a

p

(mm)

1,2 - 5,5

NL300

Vc (m/min)

100 - 380

NL920

Vc (m/min)

30 - 90

NL400

Vc (m/min)

50 - 215

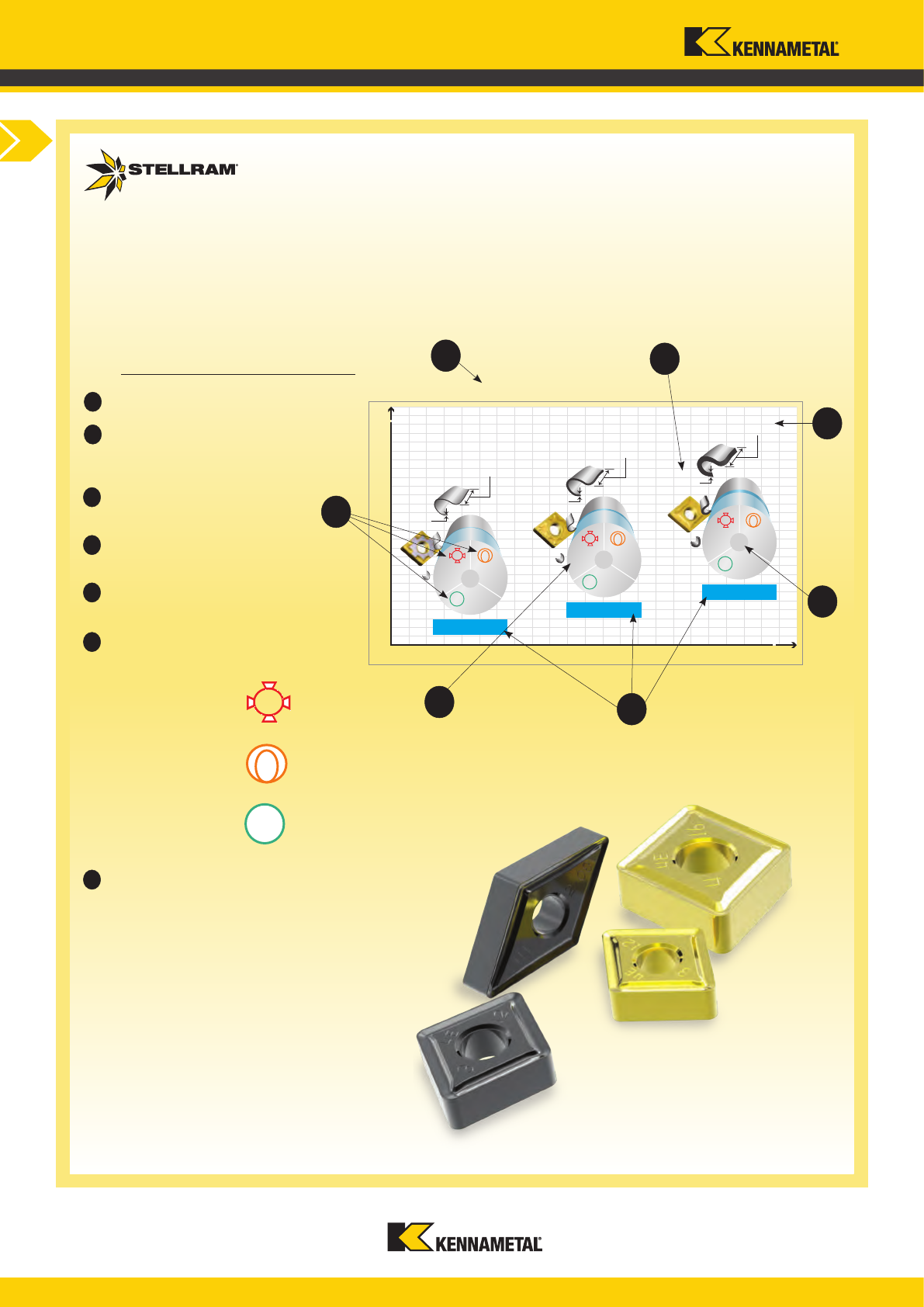

3

4

5

6

2

7

1

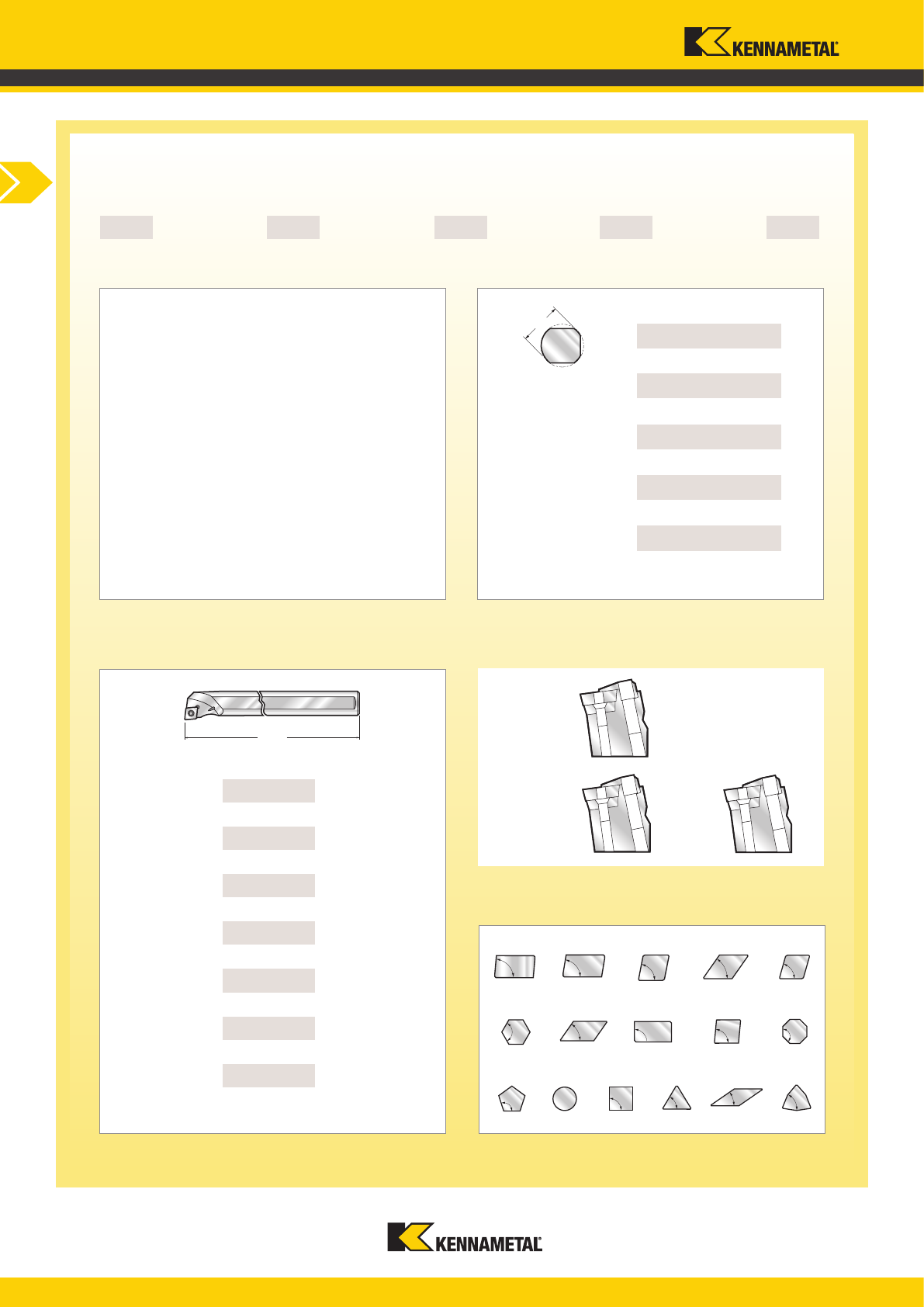

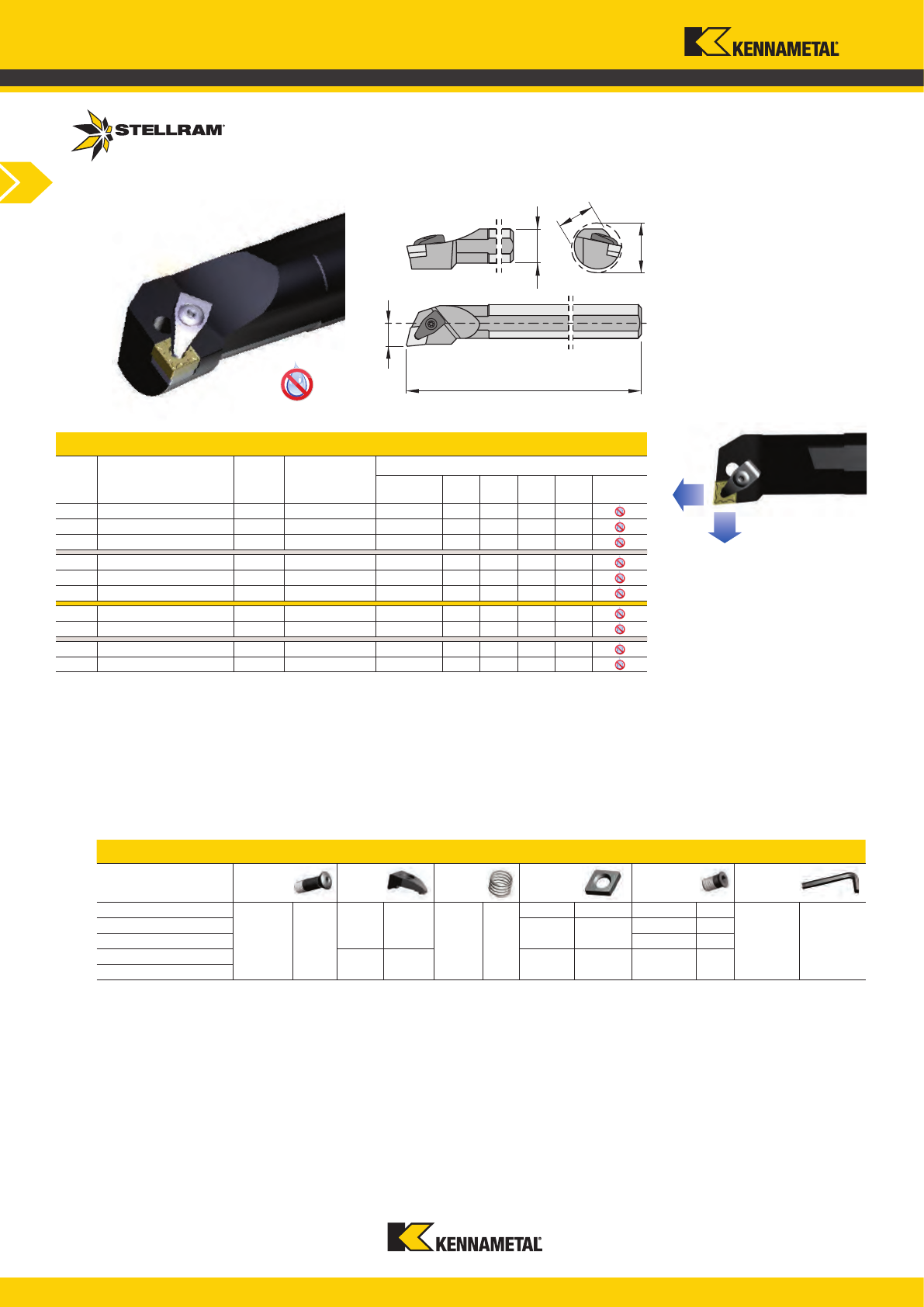

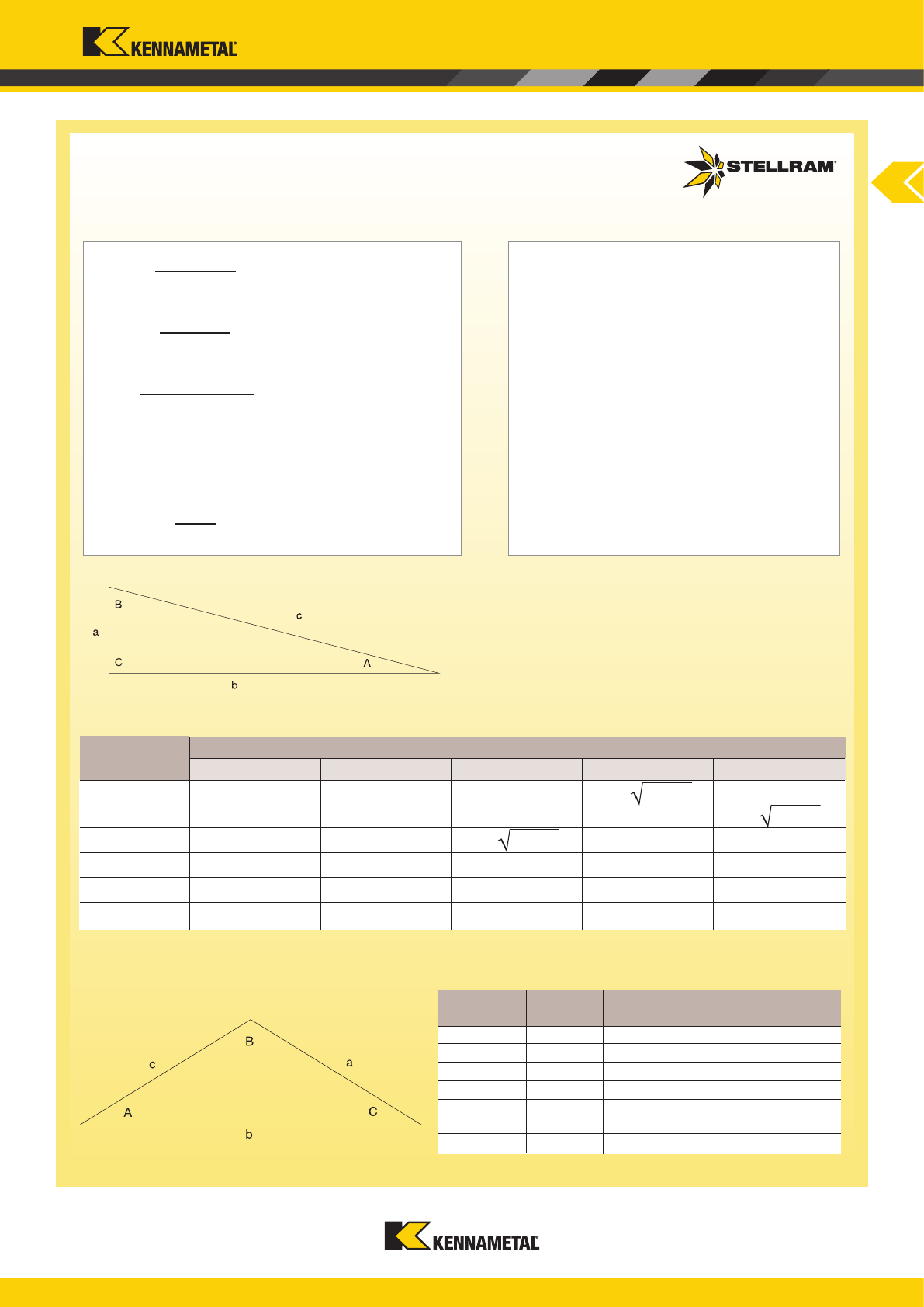

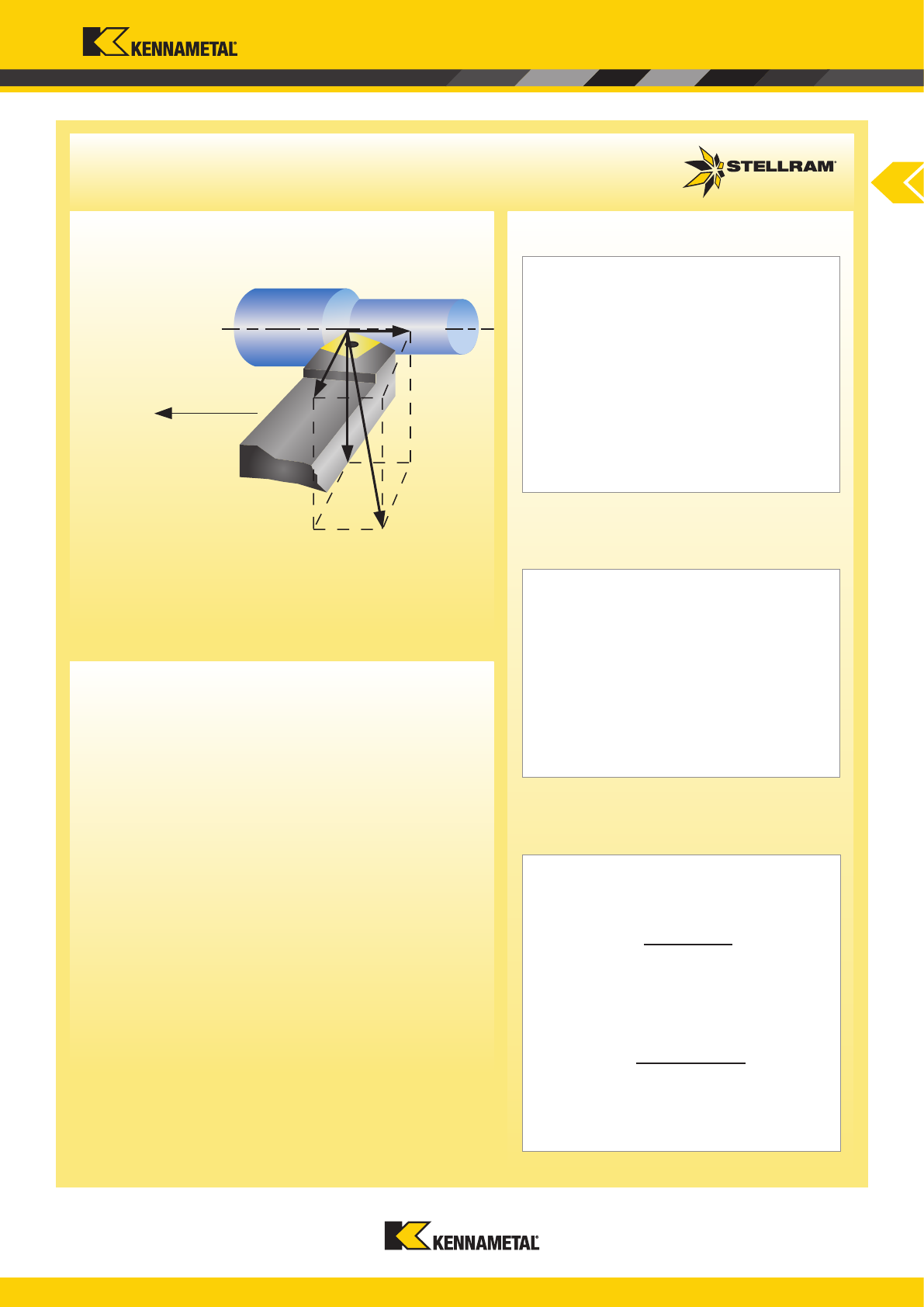

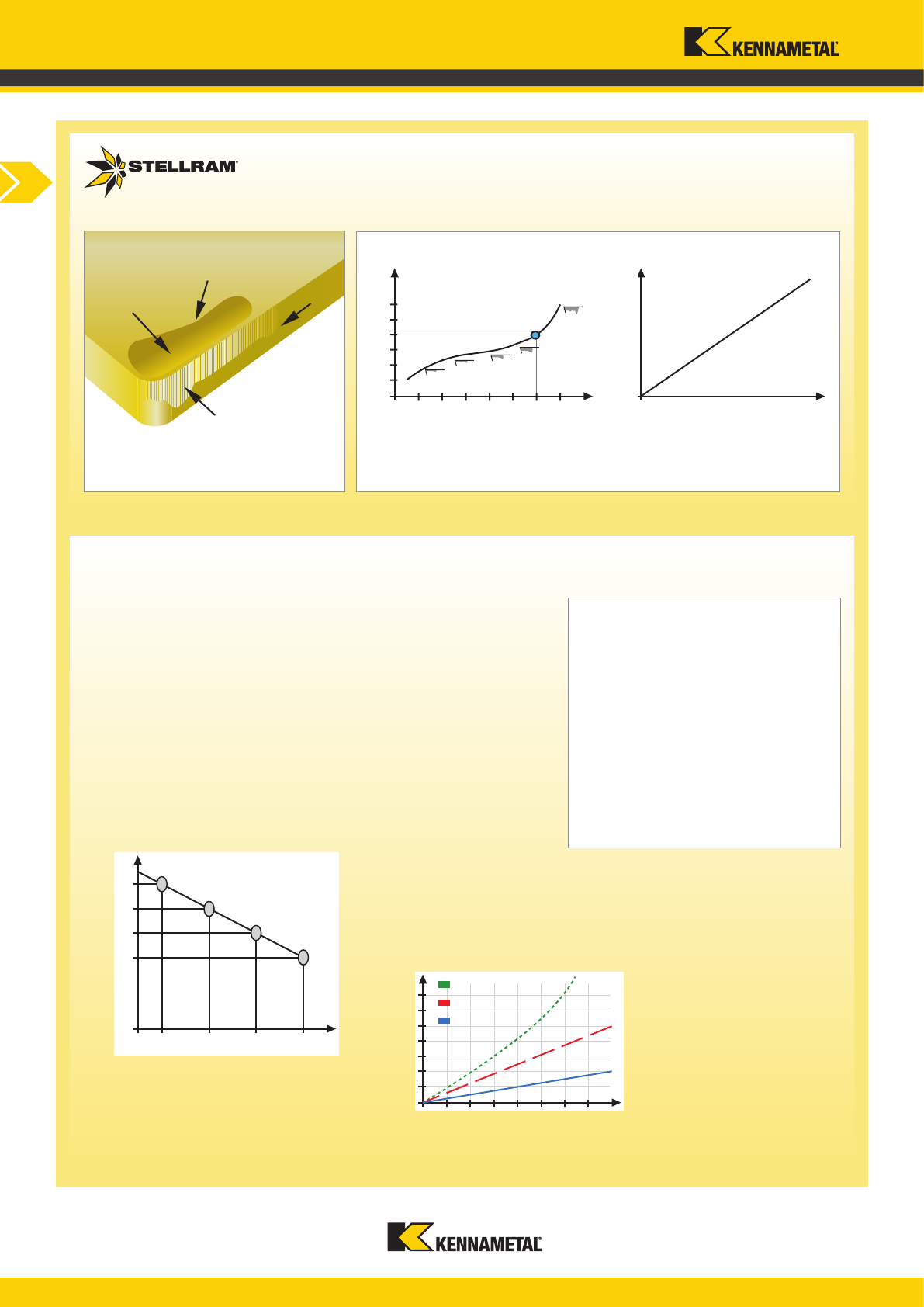

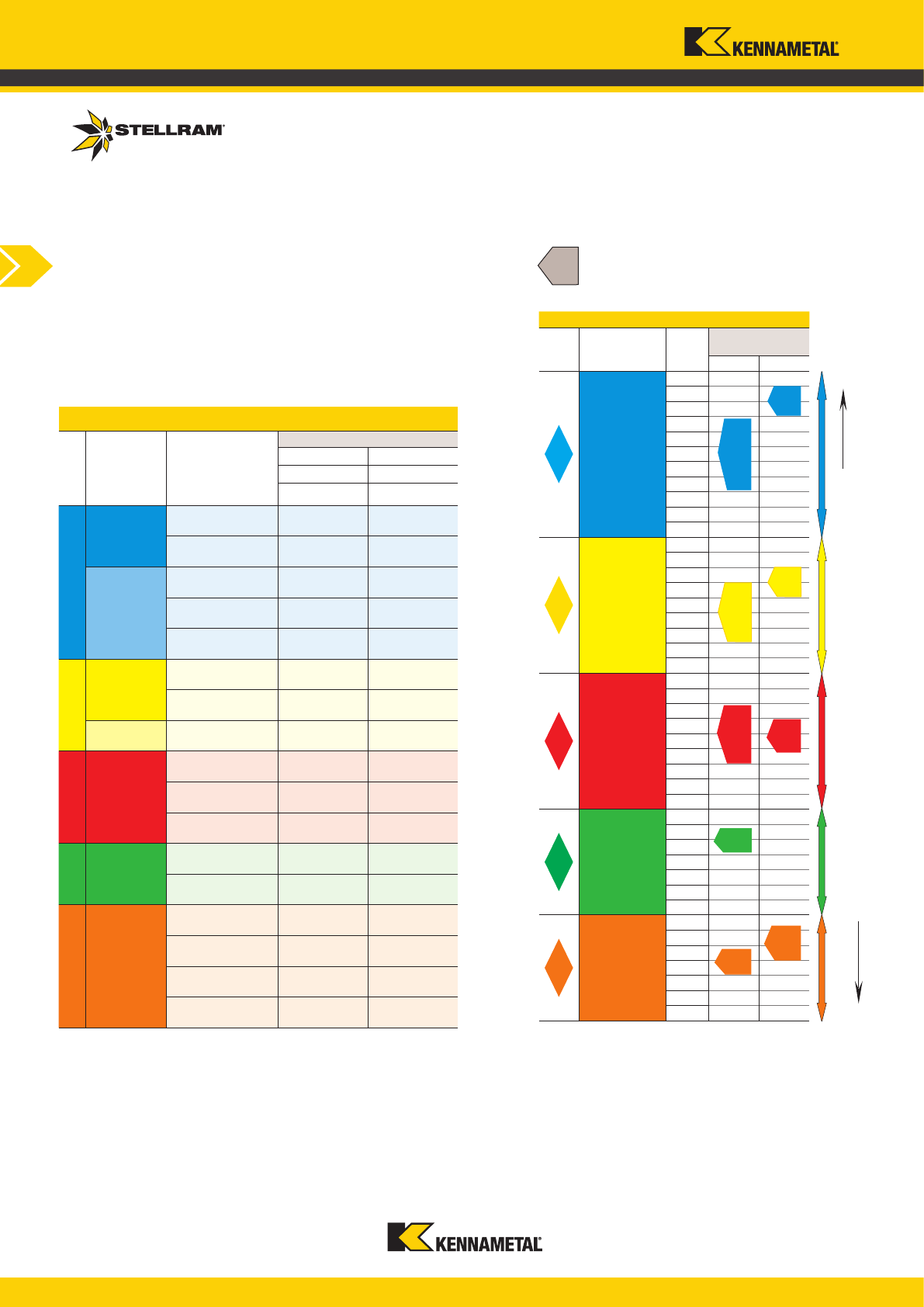

Introduction

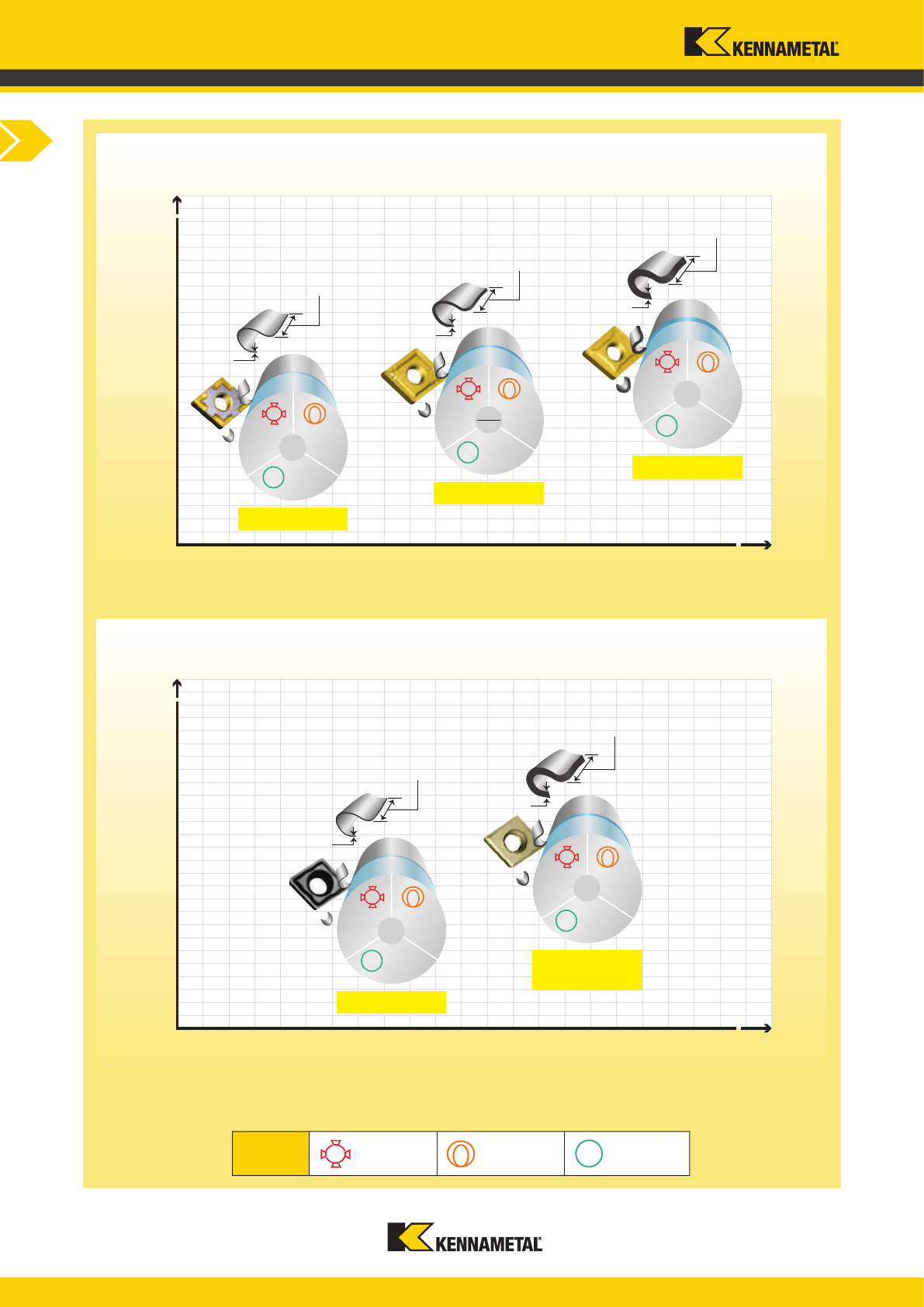

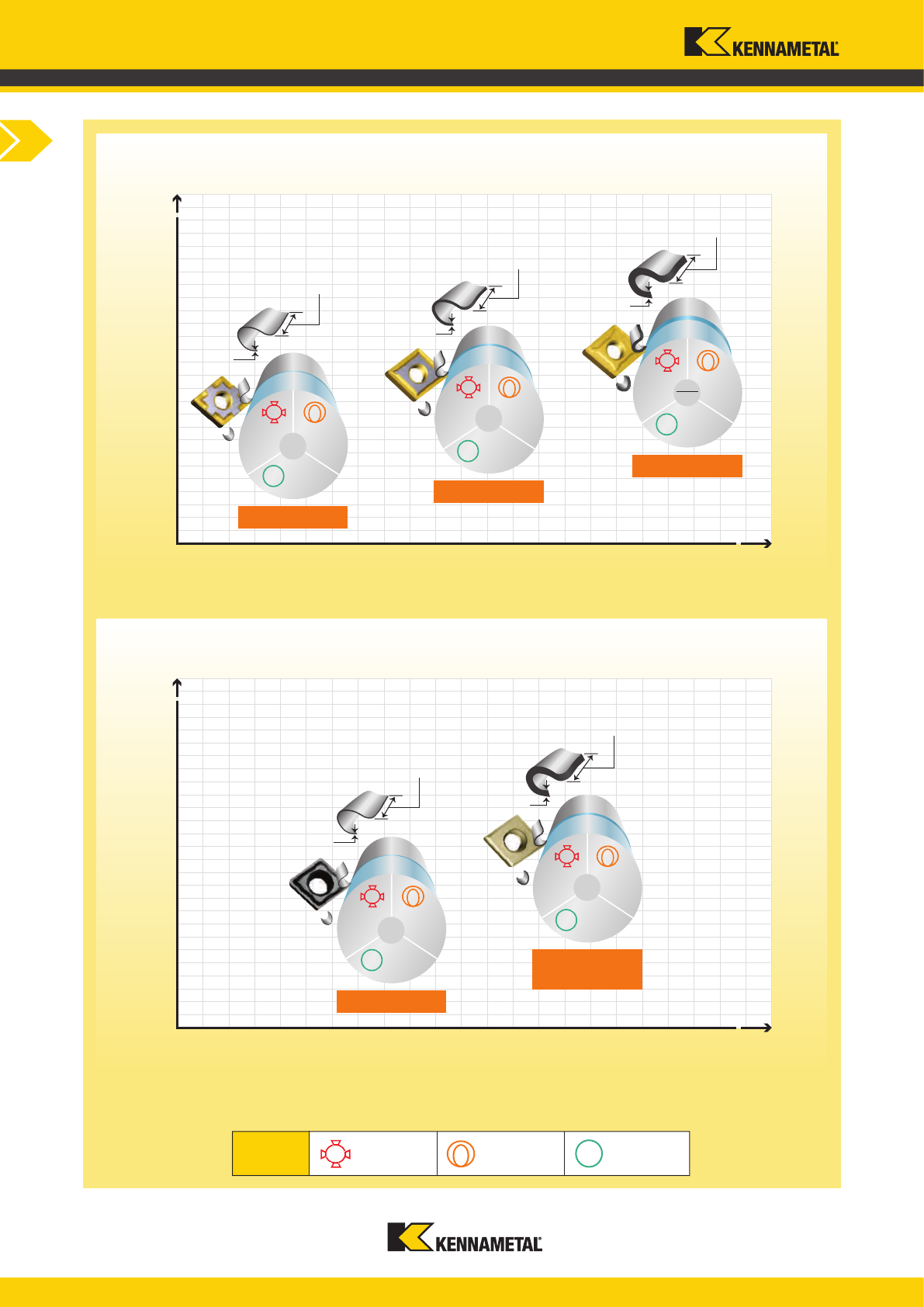

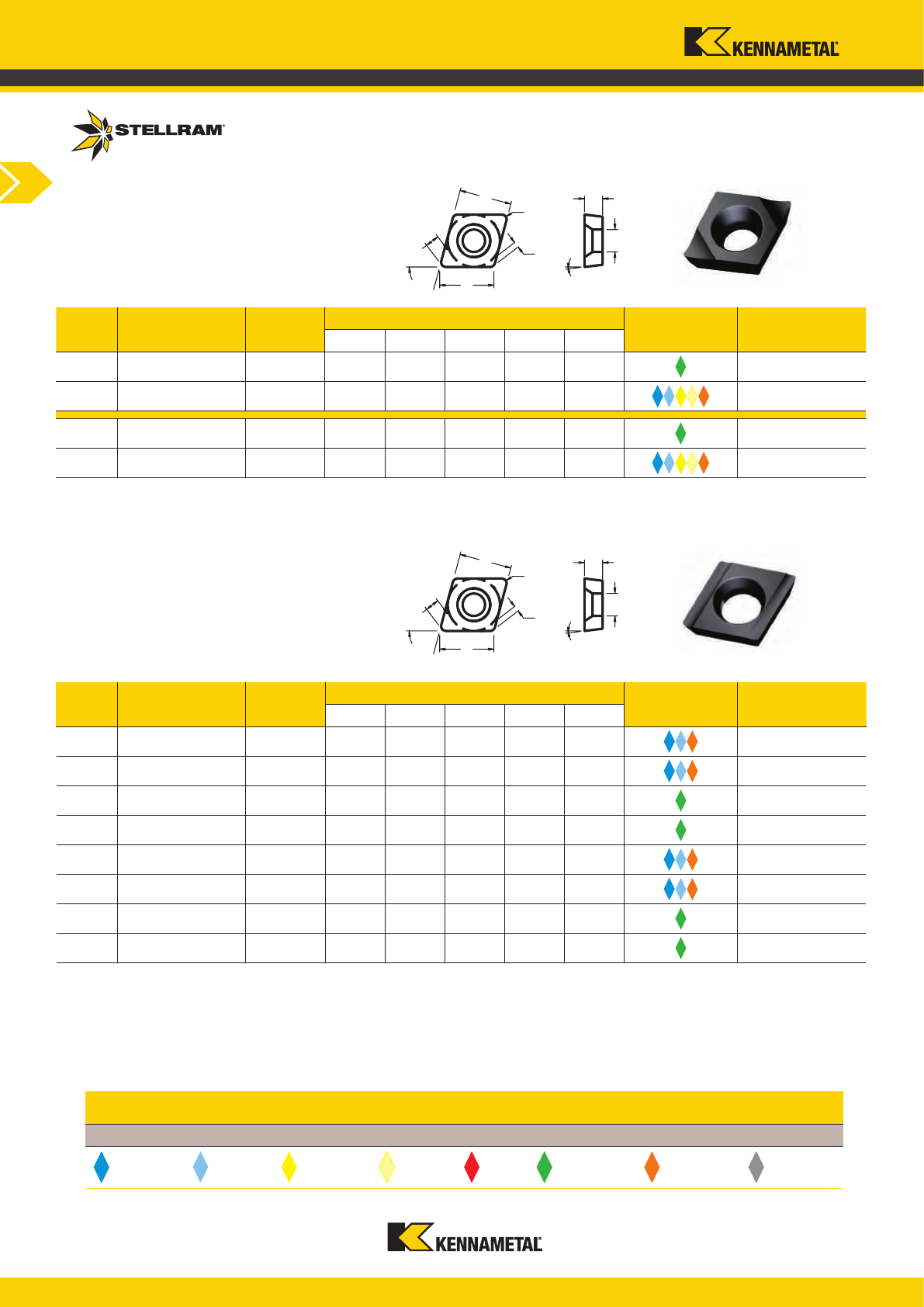

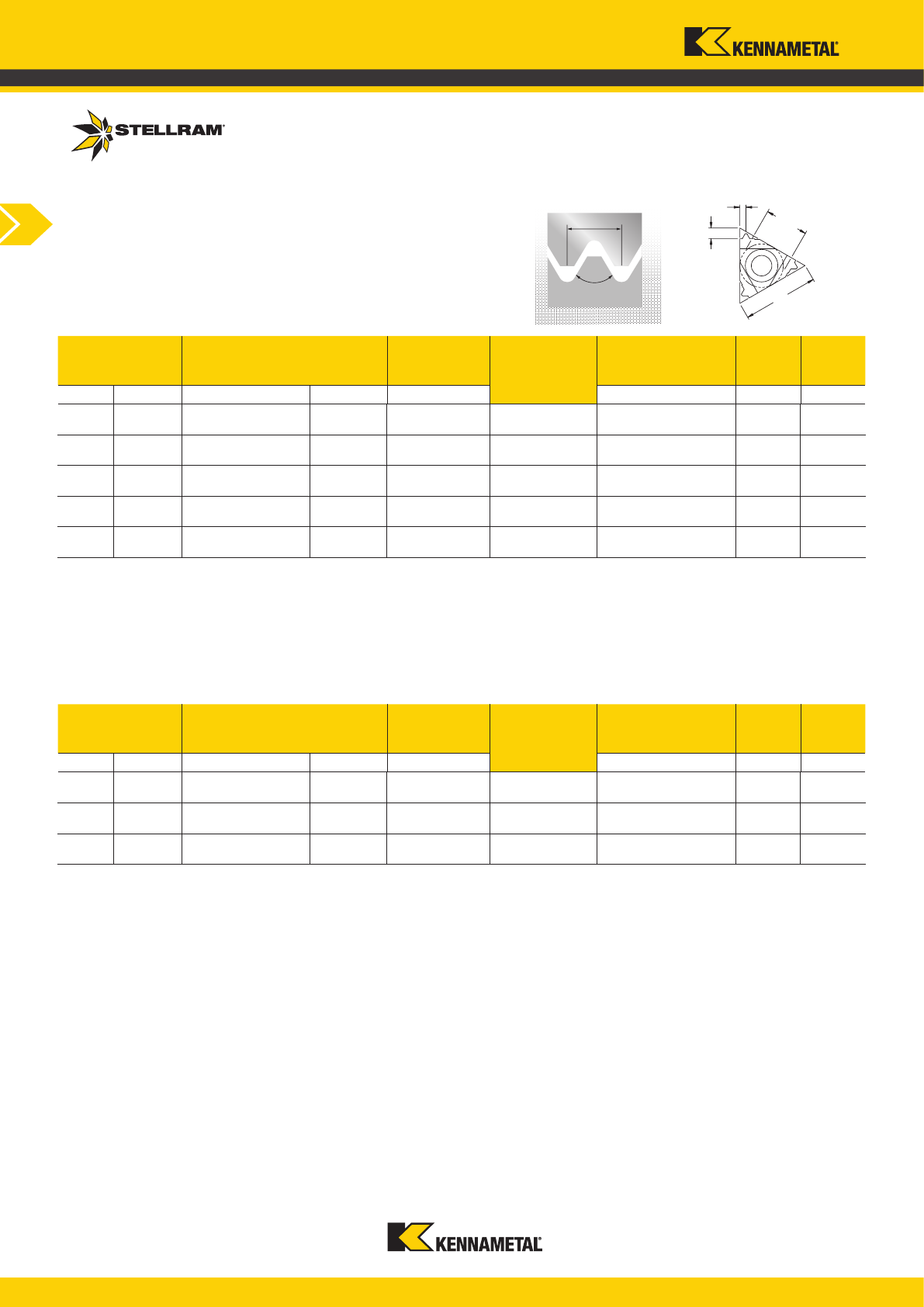

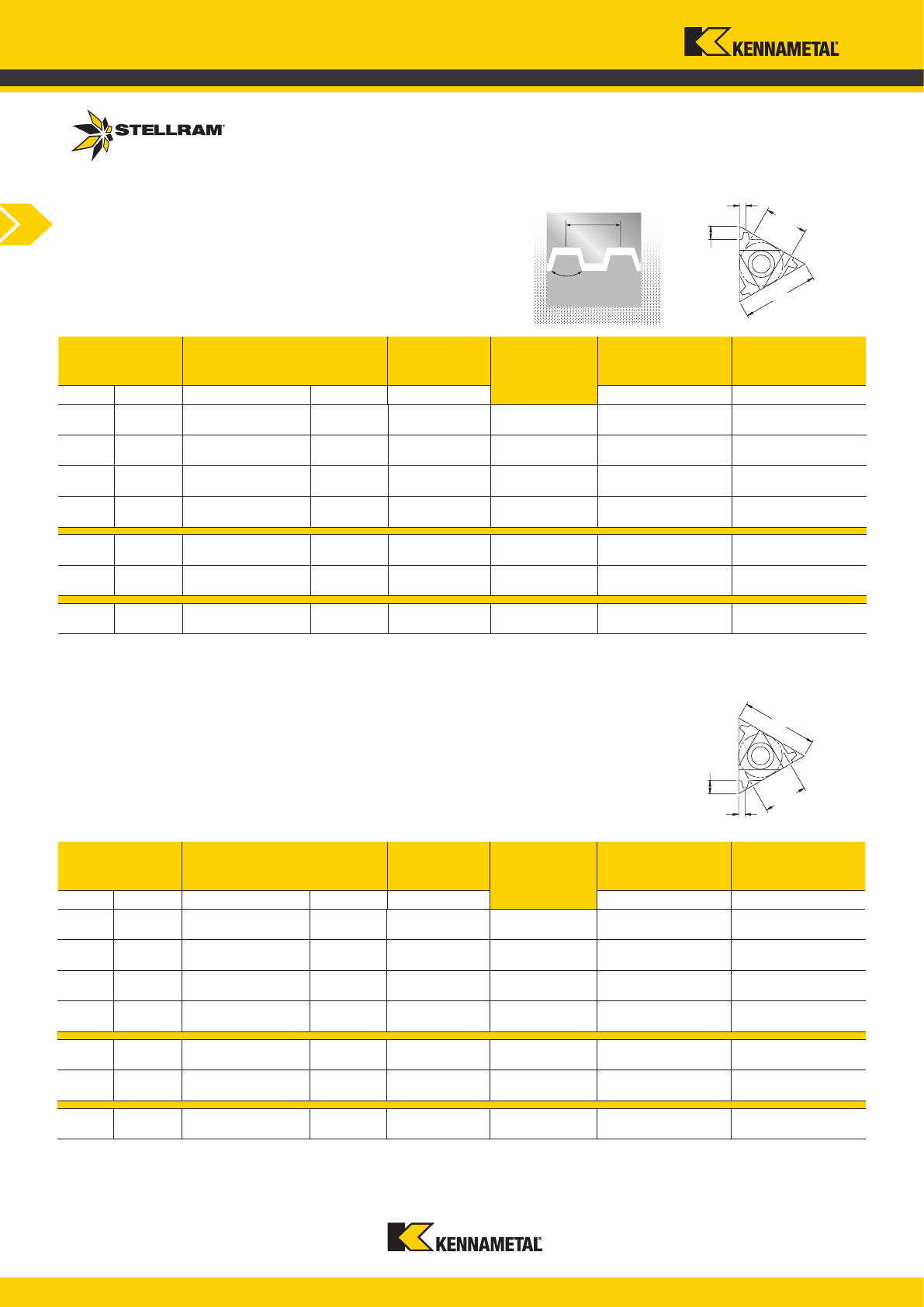

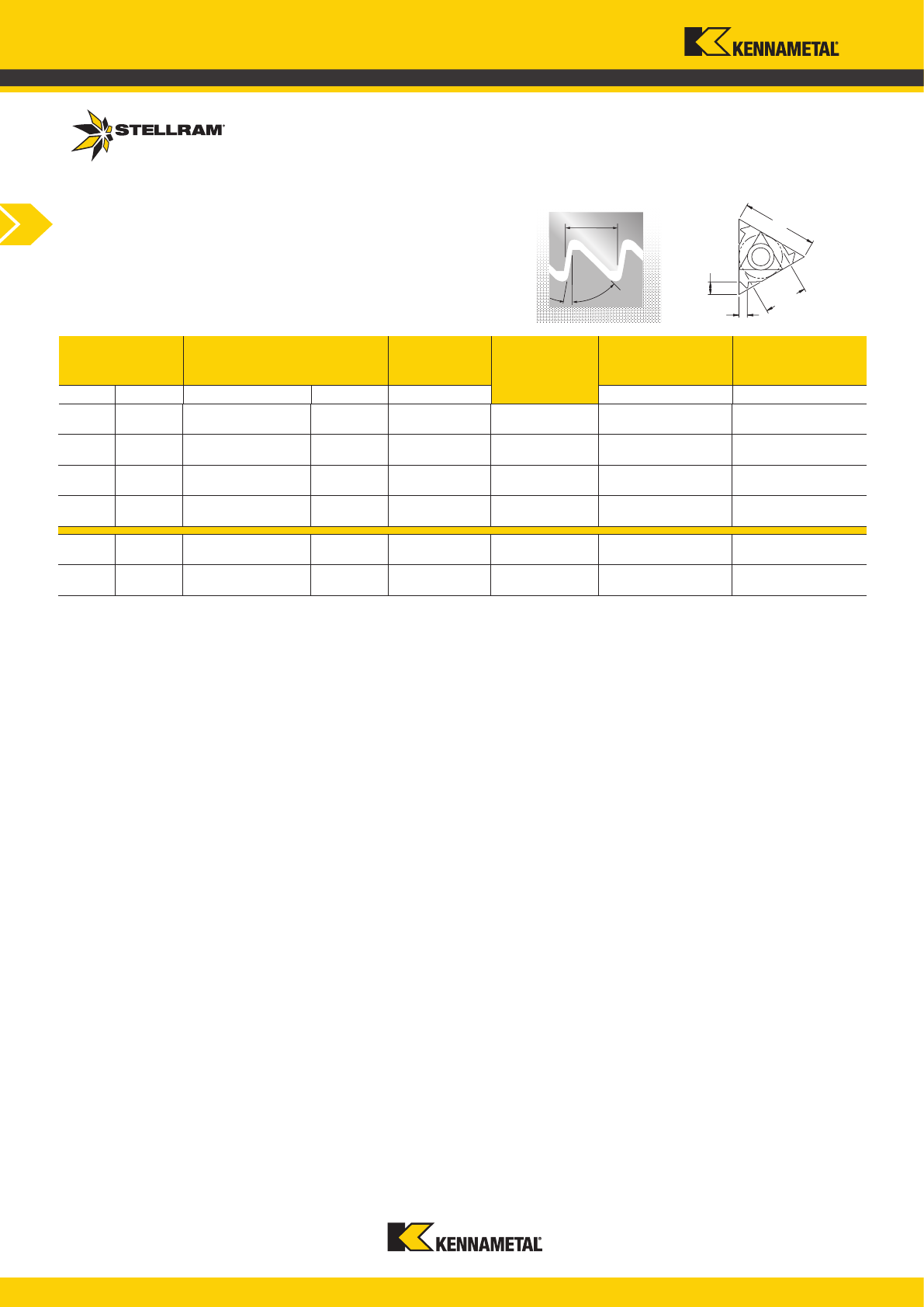

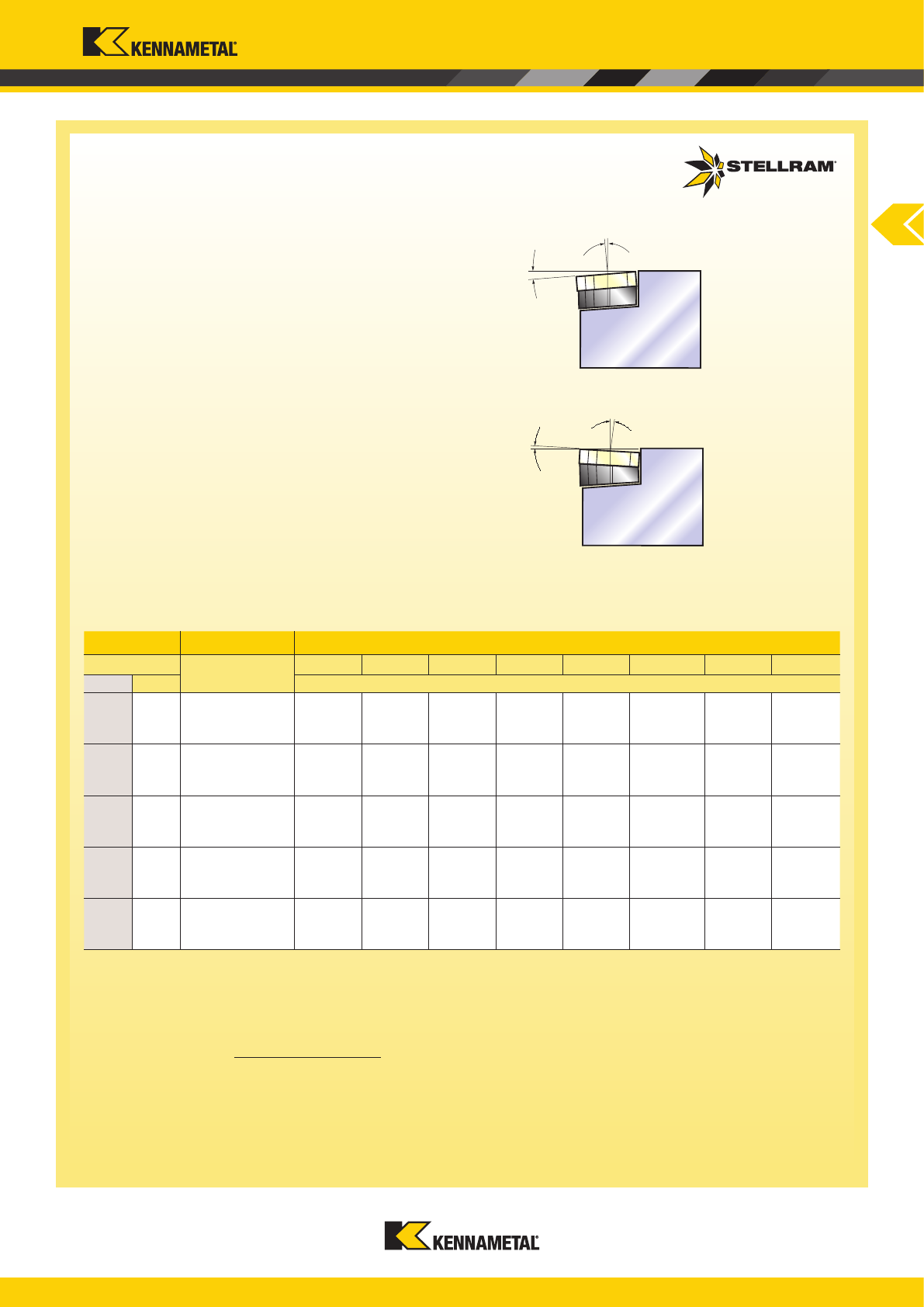

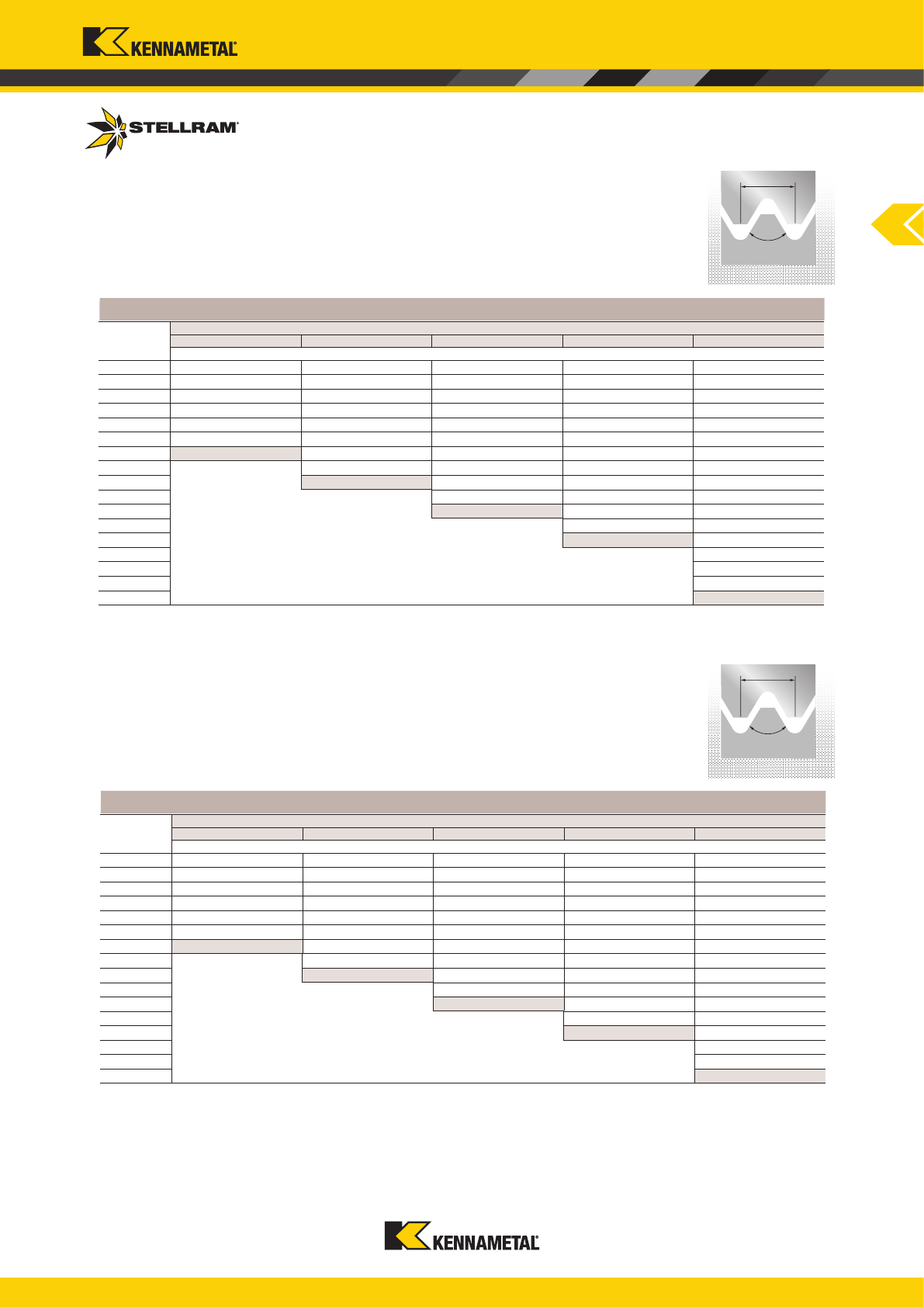

Negative Inserts – Unalloyed Steel

ROUGHING

MEDIUM

FINISHING

Select your material.

Select your machining

operation from finishing to

roughing.

Recommended geometry for

the operation.

Maximum and minimum depth

of cut for this geometry.

Maximum and minimum feed

for this geometry.

Choose the machining

condition as below:

Interrupted cut

Varying depth

of cut

Good condition

Recommended grade and

cutting speeds for this

condition.

1st Choice

The following Material Guide pages enable you to select the

appropriate geometry and grade along with a suggested start

point for speeds and feeds. Simply select the material to be

machined and type of machining operation.

7

6

5

4

3

1

2

D.O.C. a

p

(mm)

Feed fn (mm/rev)

Turning

Tool Selection

www.kennametal.com

C3

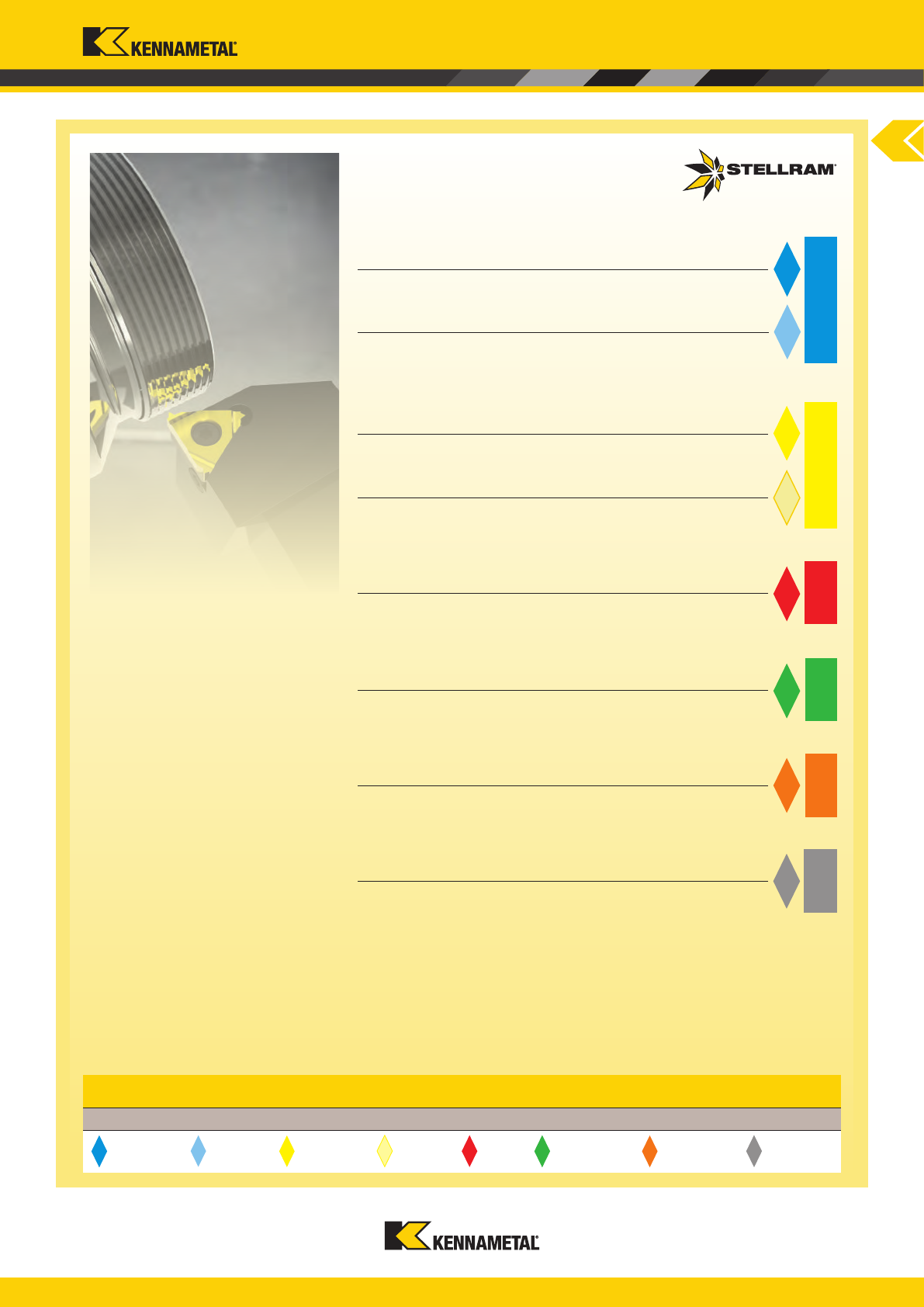

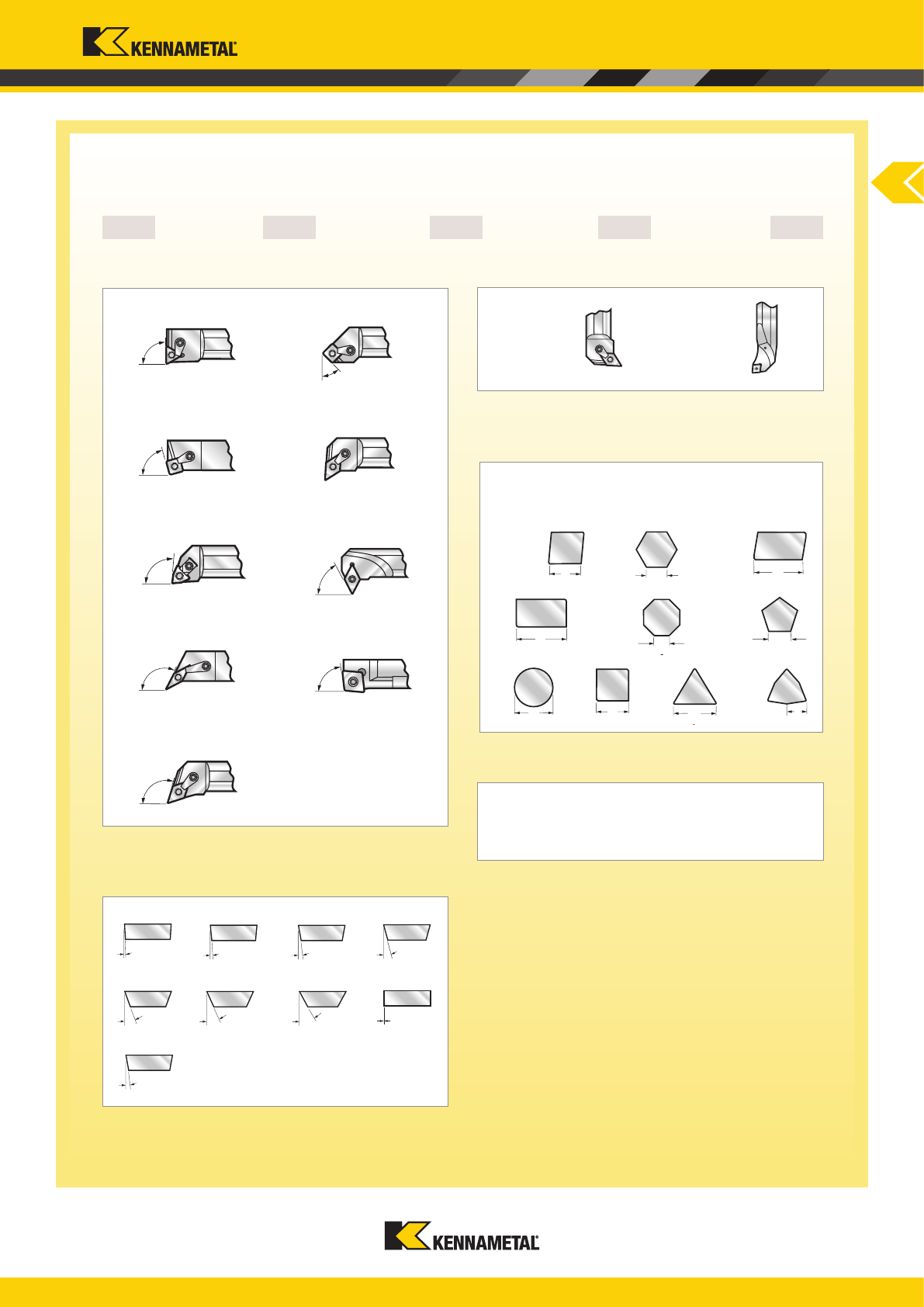

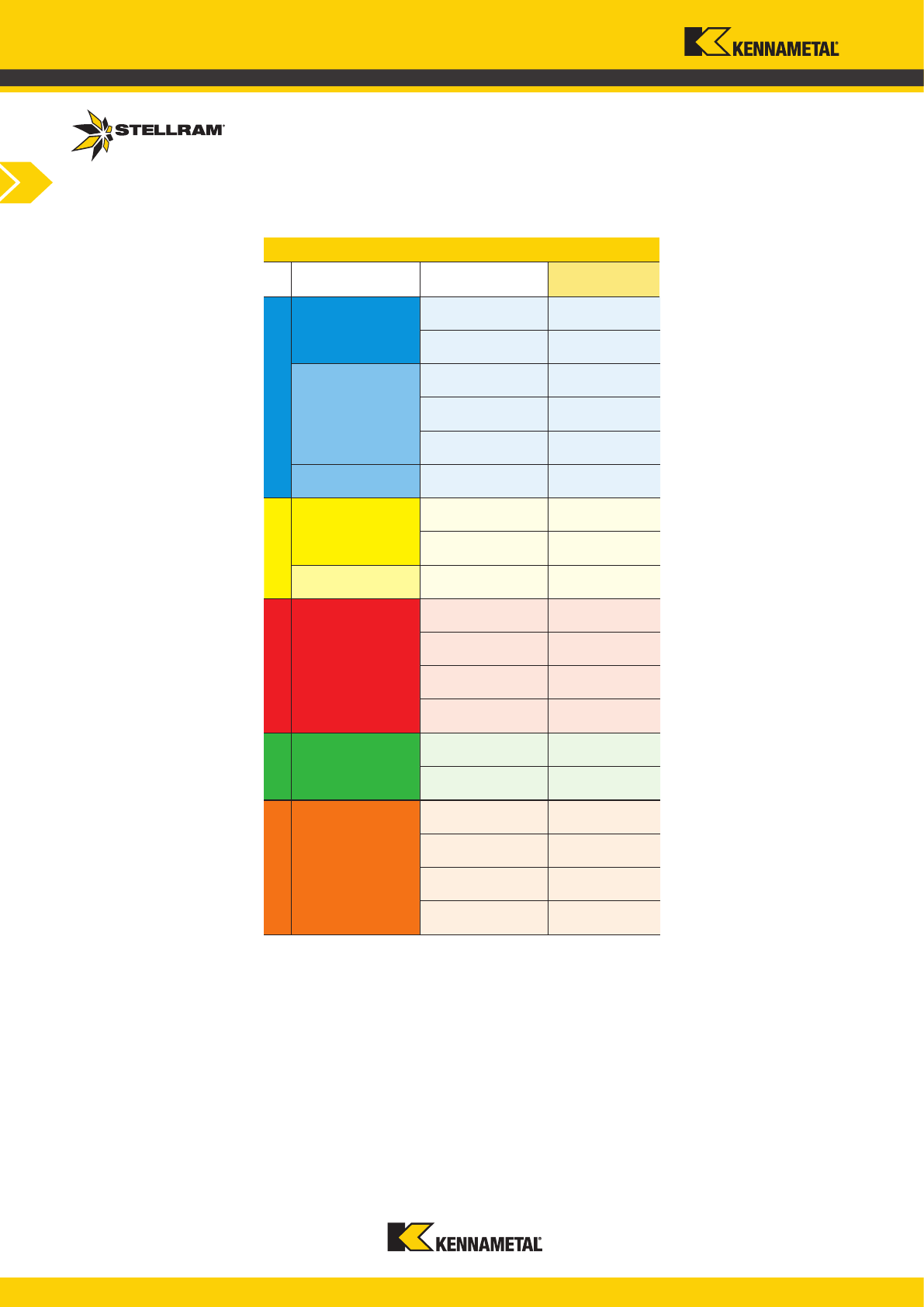

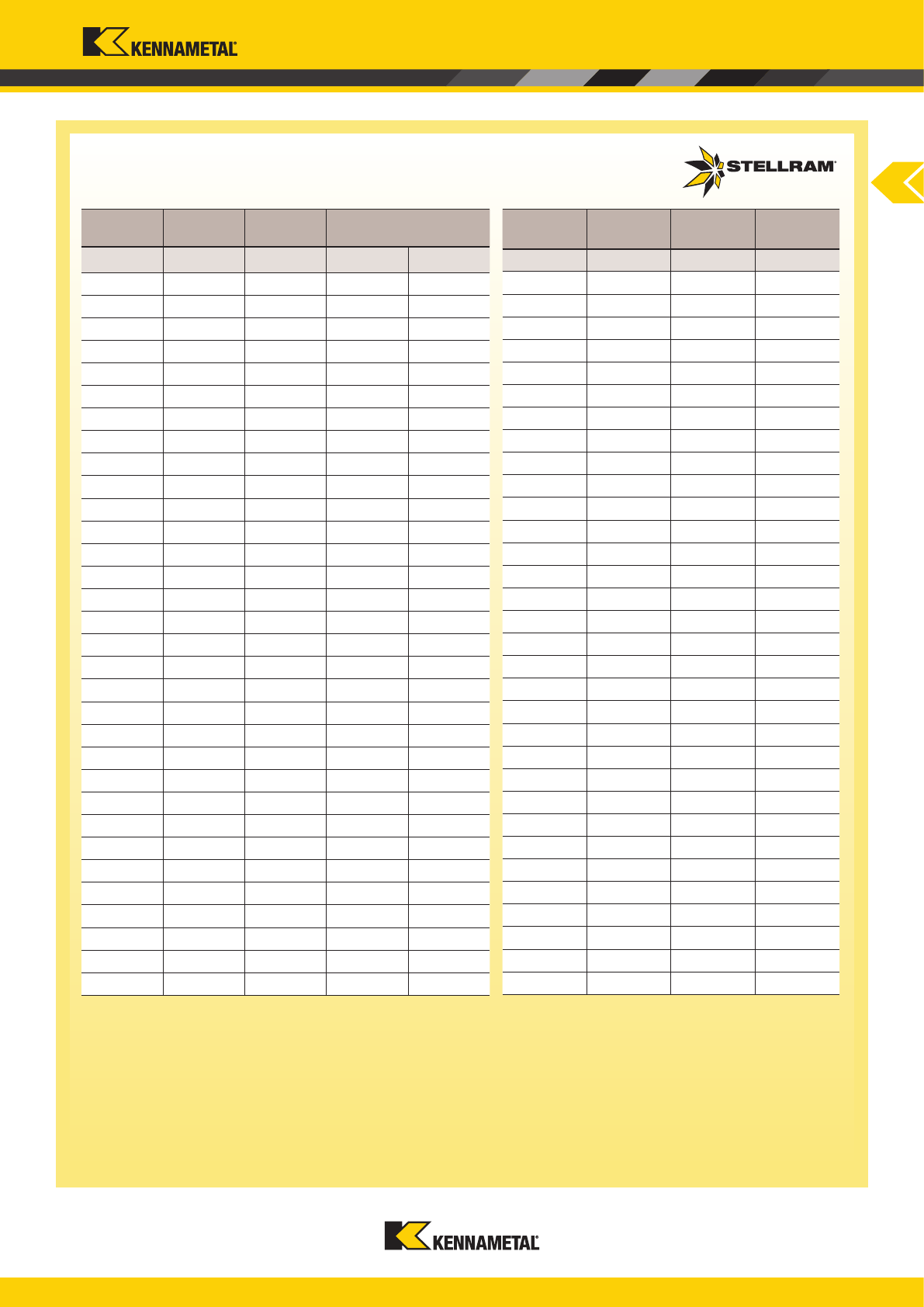

P

M

K

N

S

H

P

P

M

M

K N

S

H

Introduction

Hard Materials (52-56 HRC)

High Temperature Alloys

Cast Irons

PH Stainless

Stainless Steels

Alloyed Steels

Unalloyed Steels

Aluminum & Alloys

Turning

Machining Materials Guide

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

www.kennametal.com

C4

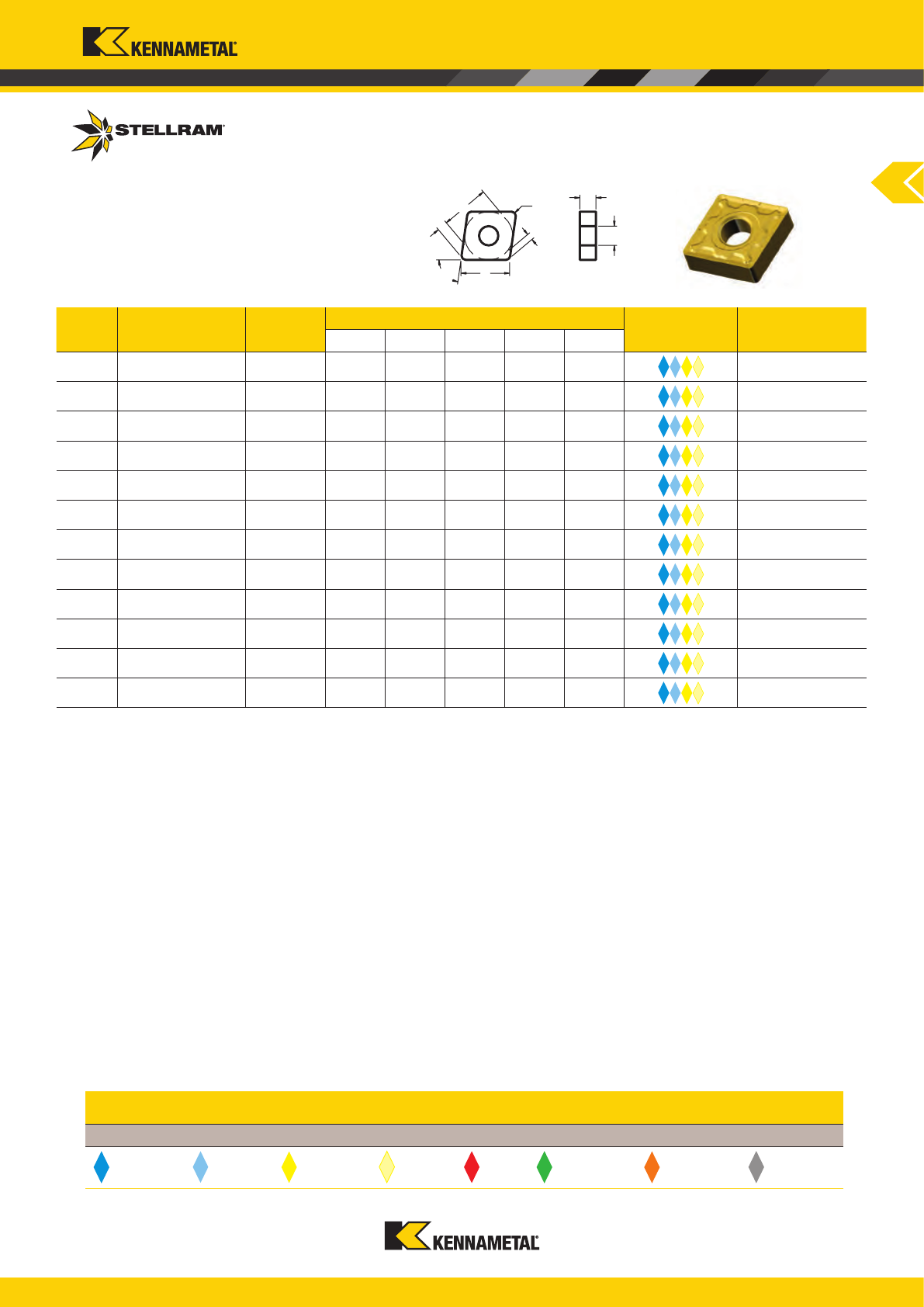

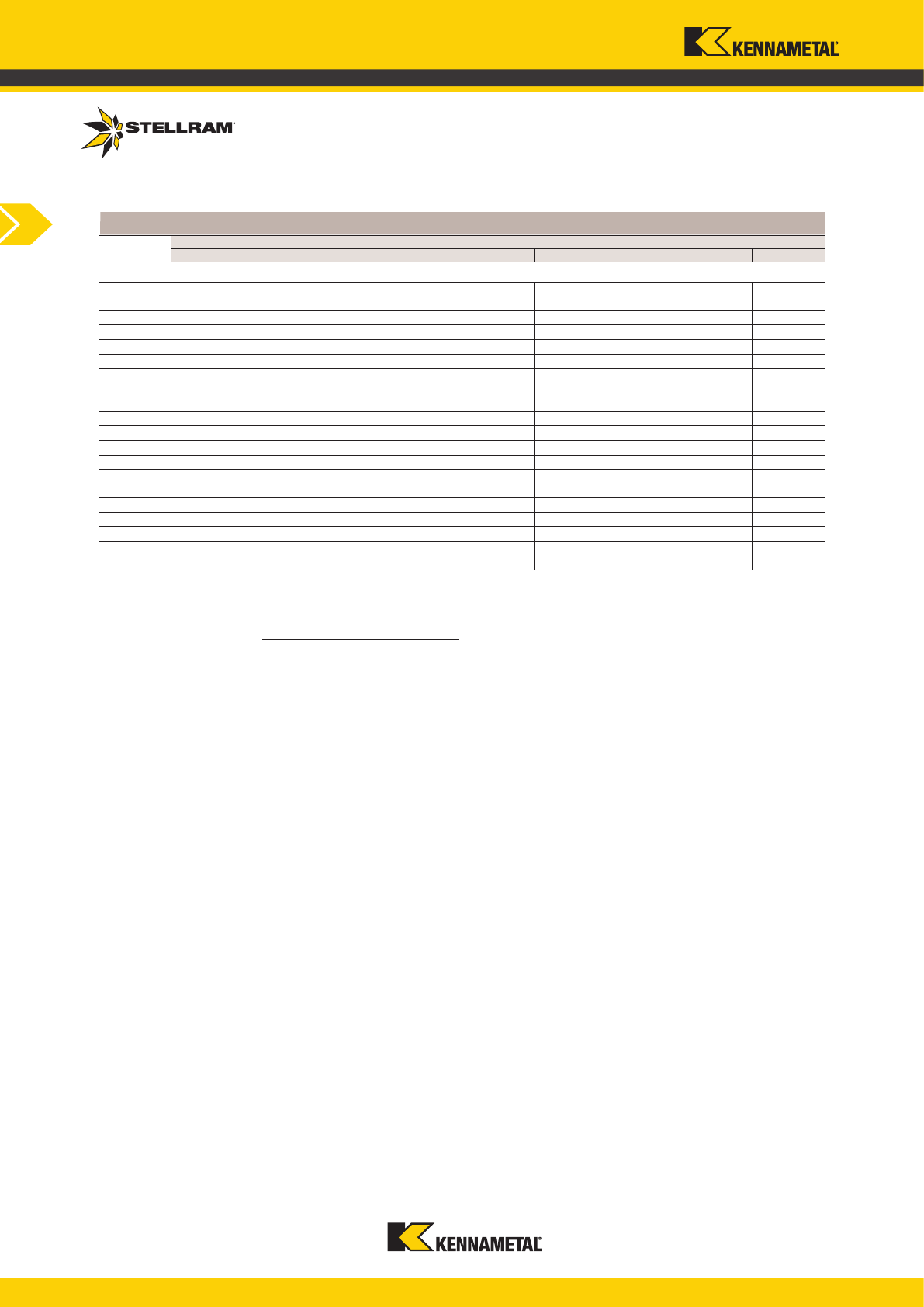

0,0

1B

SP0819

Vc (m/min)

140 - 450

NL250

Vc (m/min)

40 - 165

NL250

Vc (m/min)

60 - 245

f

n

(mm/rev)

0,1 - 0,3

a

p

(mm)

0,5 - 2,0

f

n

(mm/rev)

0,15 - 0,45

a

p

(mm)

0,75 - 3,0

2N

NL250

Vc (m/min)

105 - 410

NL920

Vc (m/min)

30 - 90

NL300

Vc (m/min)

60 -230

4T

f

n

(mm/rev)

0,25 - 0,5

a

p

(mm)

1,2 - 5,5

NL300

Vc (m/min)

100 - 380

NL920

Vc (m/min)

30 - 90

NL400

Vc (m/min)

50 - 215

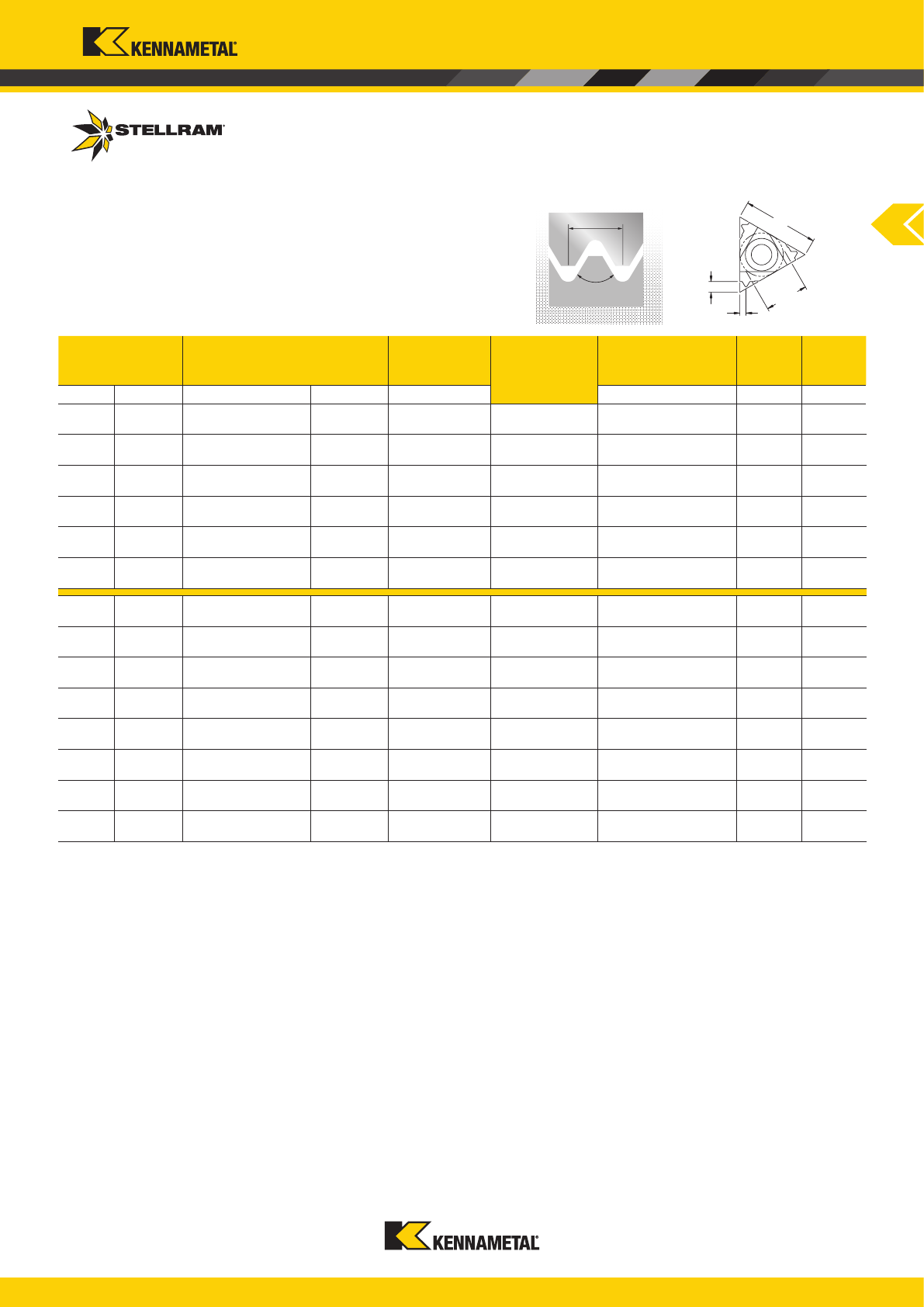

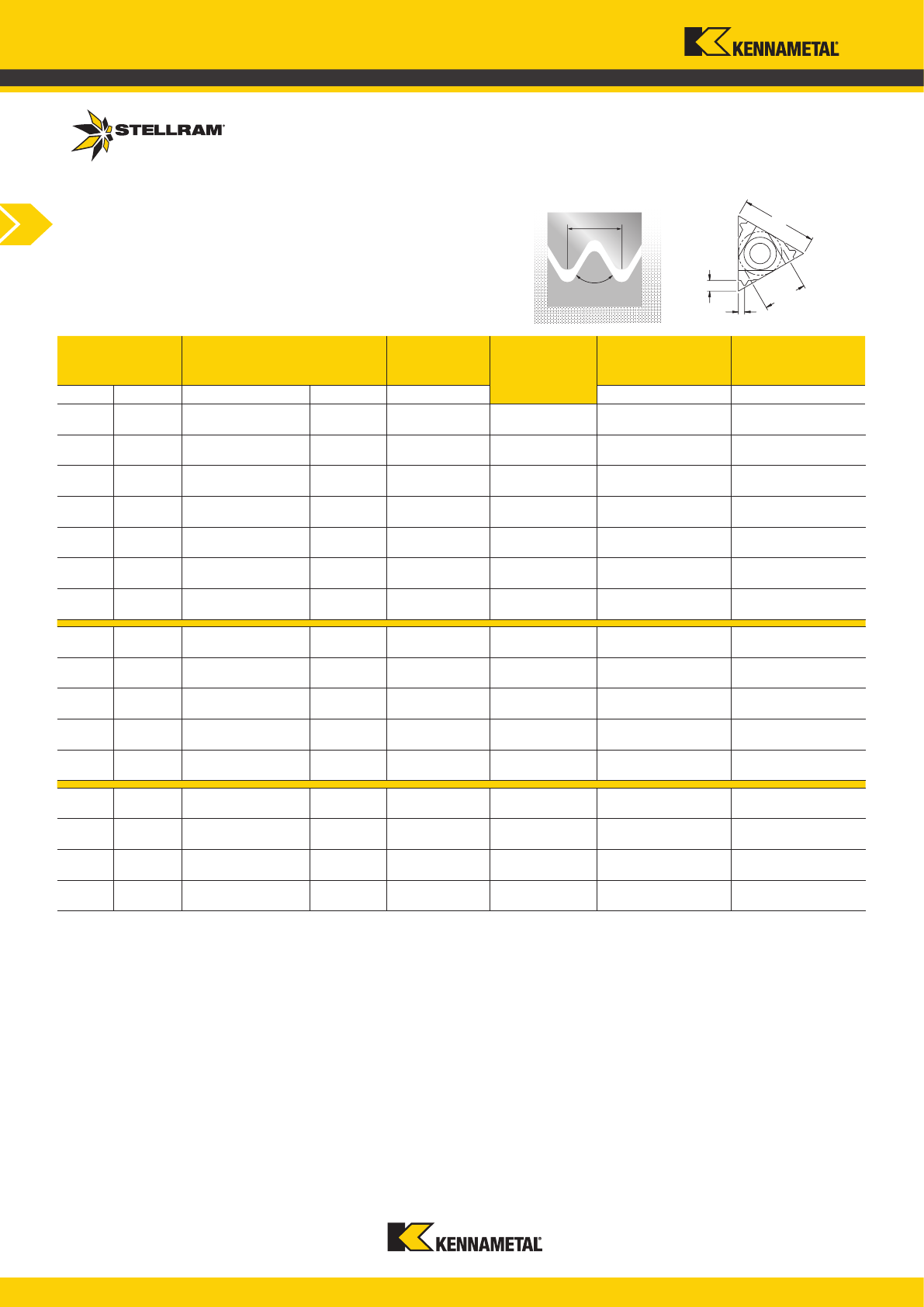

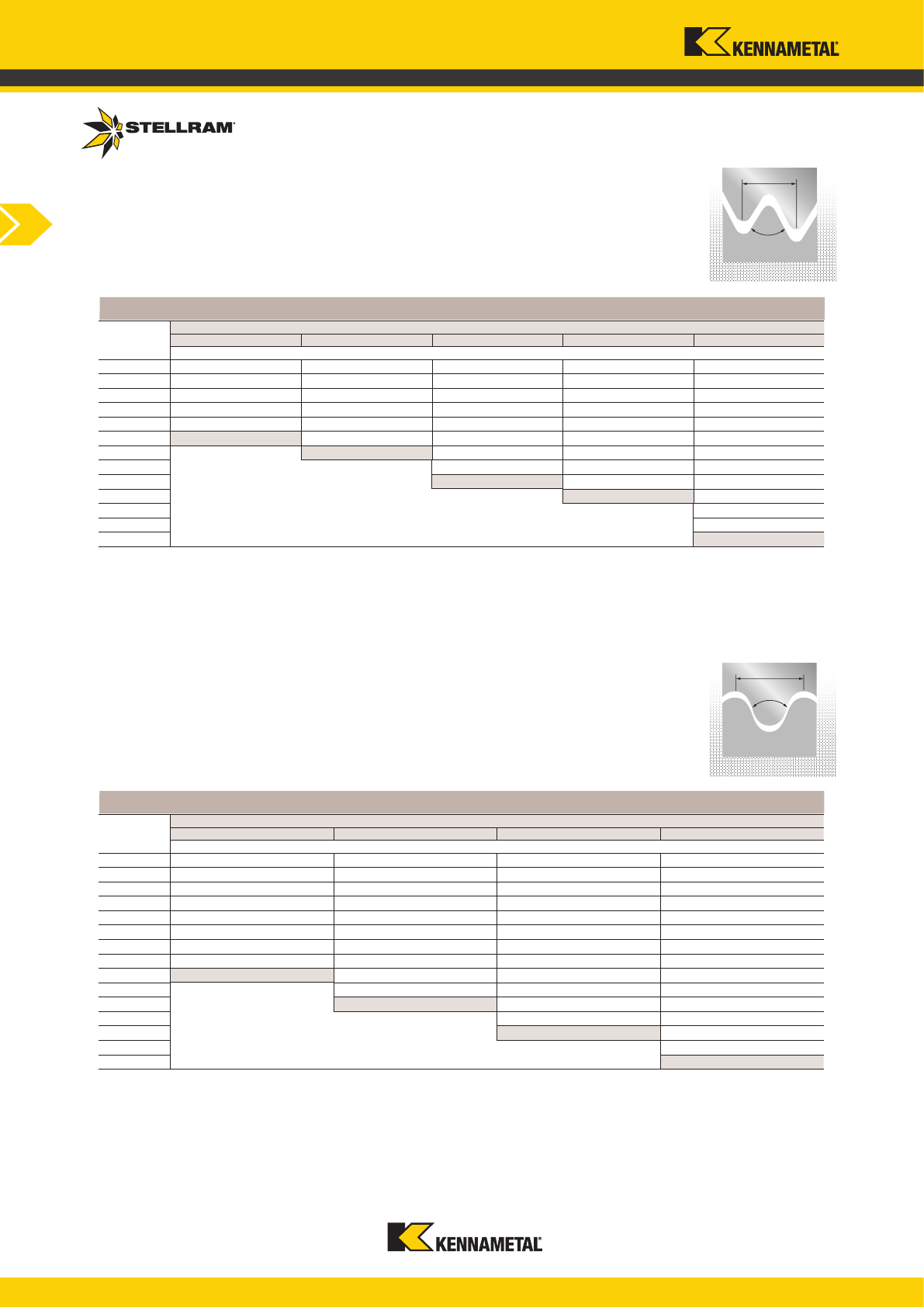

*

0.0

62

SP4019

Vc (m/min)

135 - 440

SP4019

Vc (m/min)

55 - 175

SP4019

Vc (m/min)

80 - 265

f

n

(mm/rev)

0,025 - 0,25

a

p

(mm)

0,25 - 3,0

73

SP4019

Vc (m/min)

135 - 440

NL920

Vc (m/min)

30 - 90

NL300

Vc (m/min)

60 - 230

f

n

(mm/rev)

0,07 - 0,5

a

p

(mm)

0,4 - 5,0

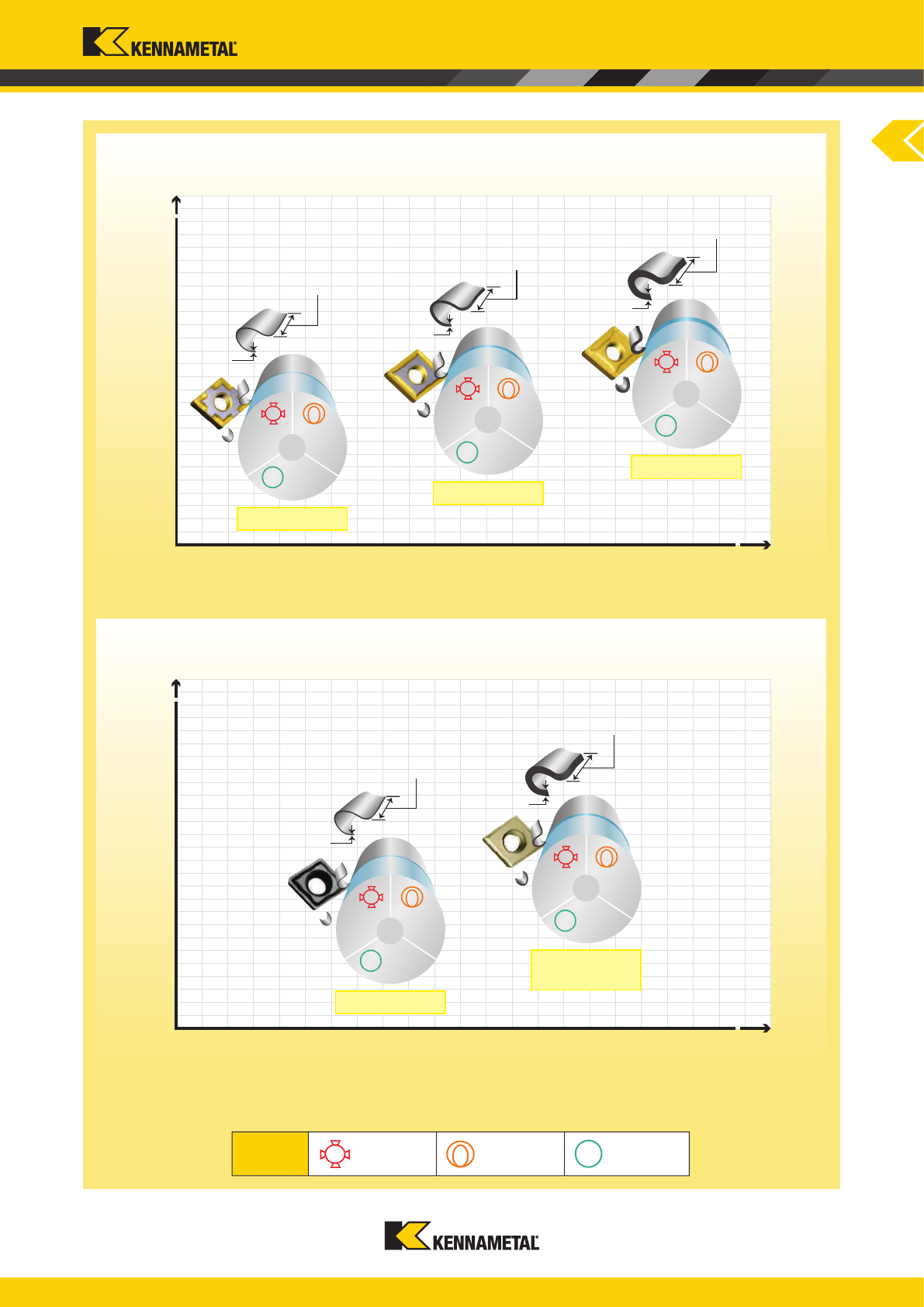

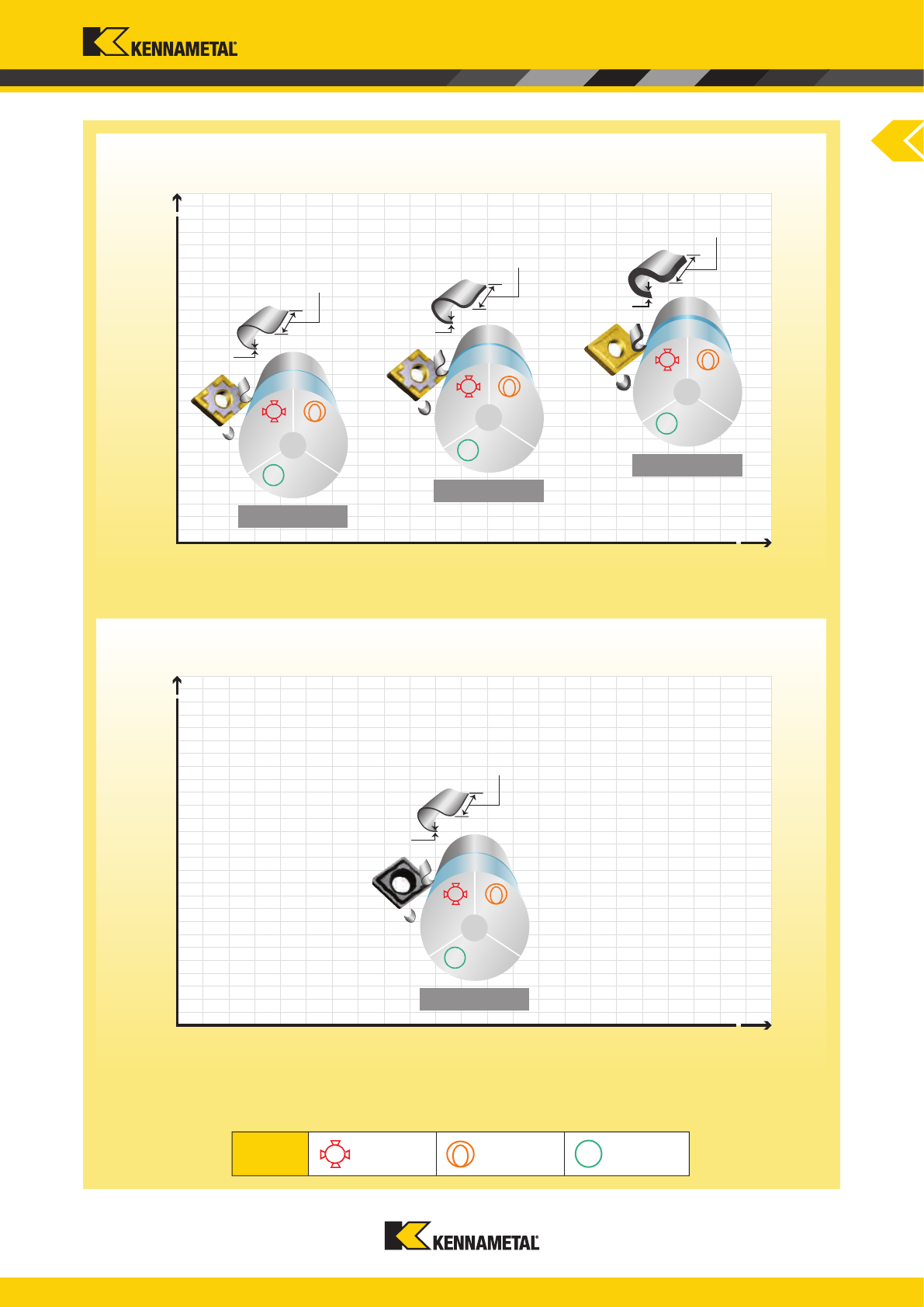

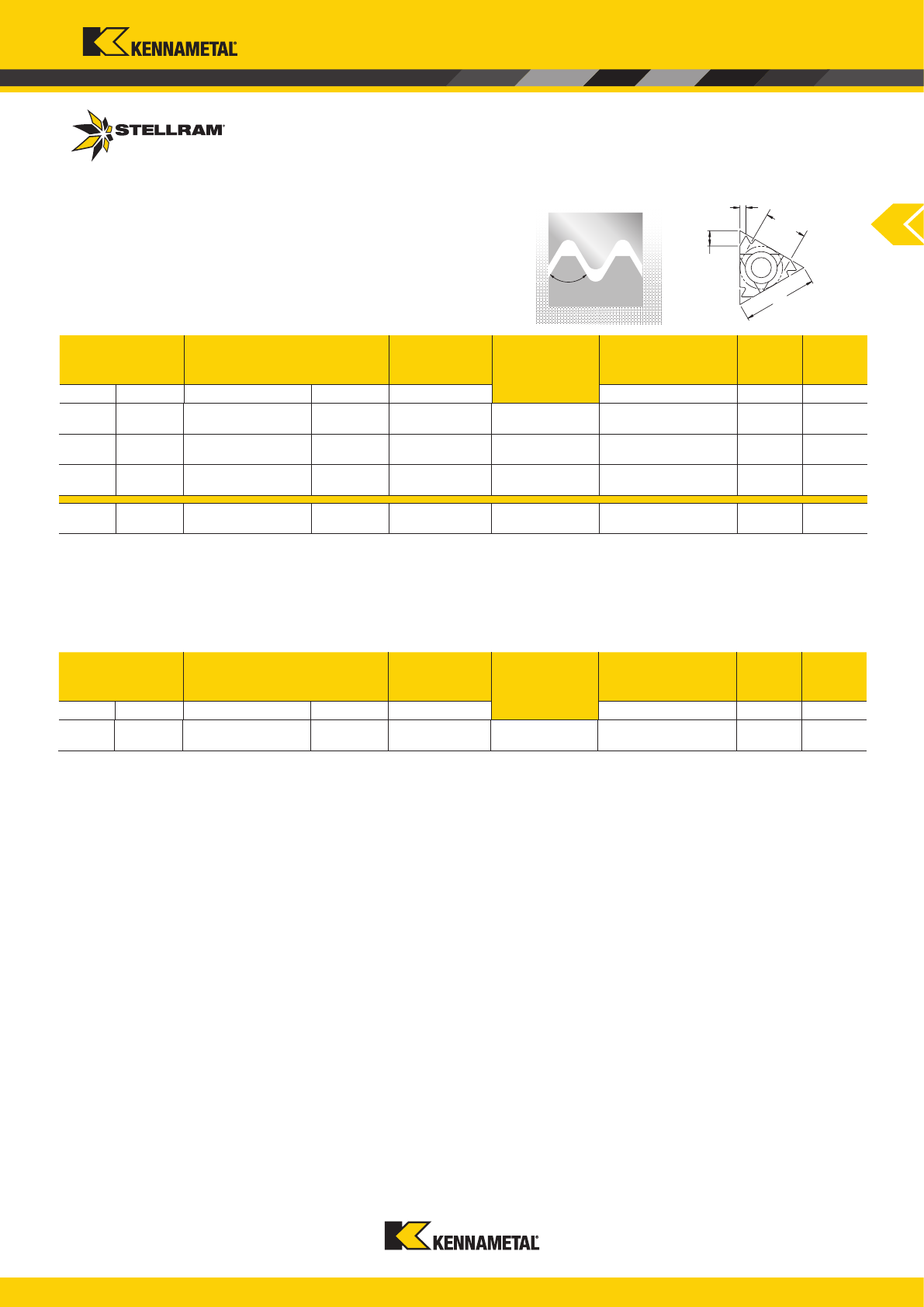

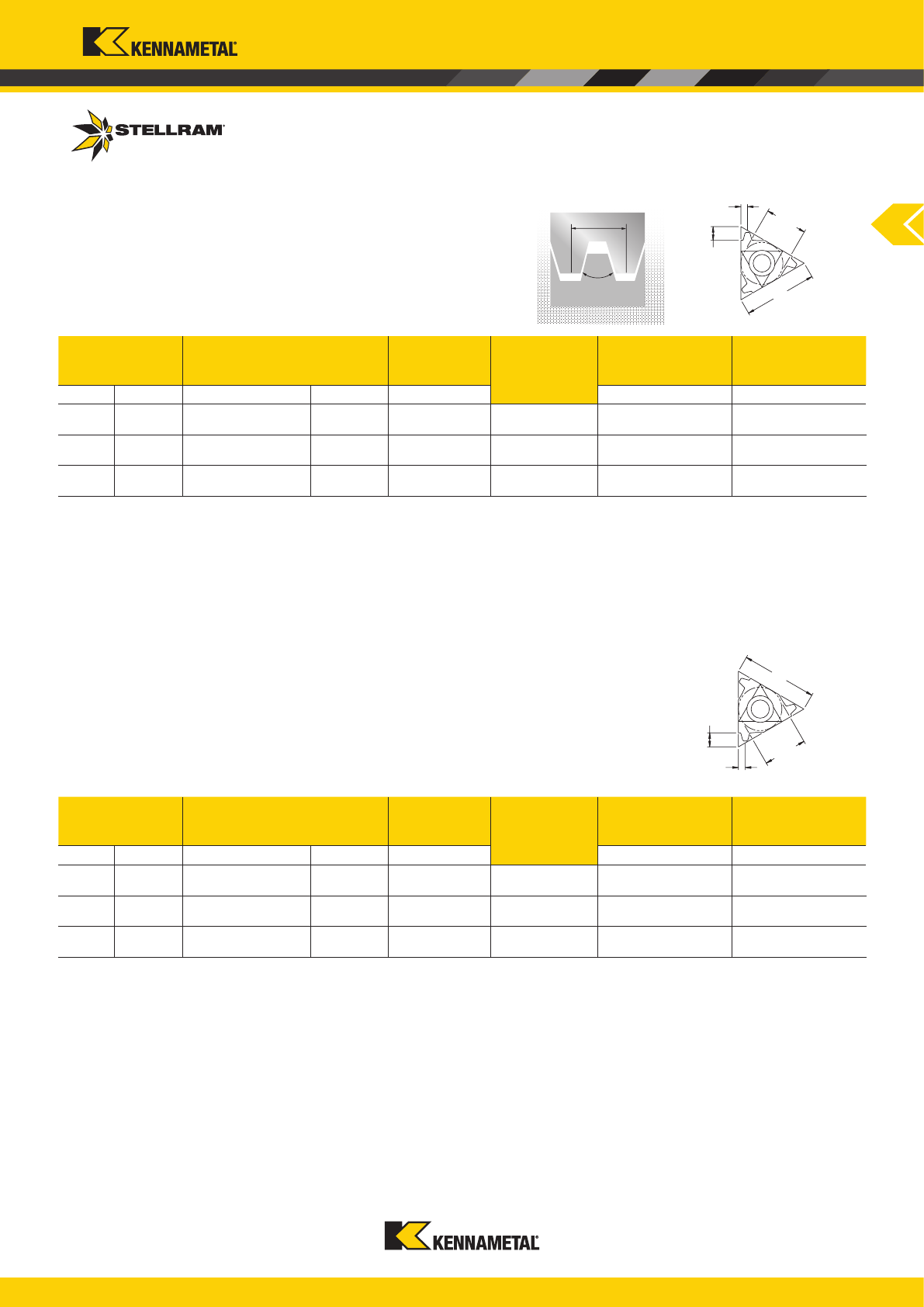

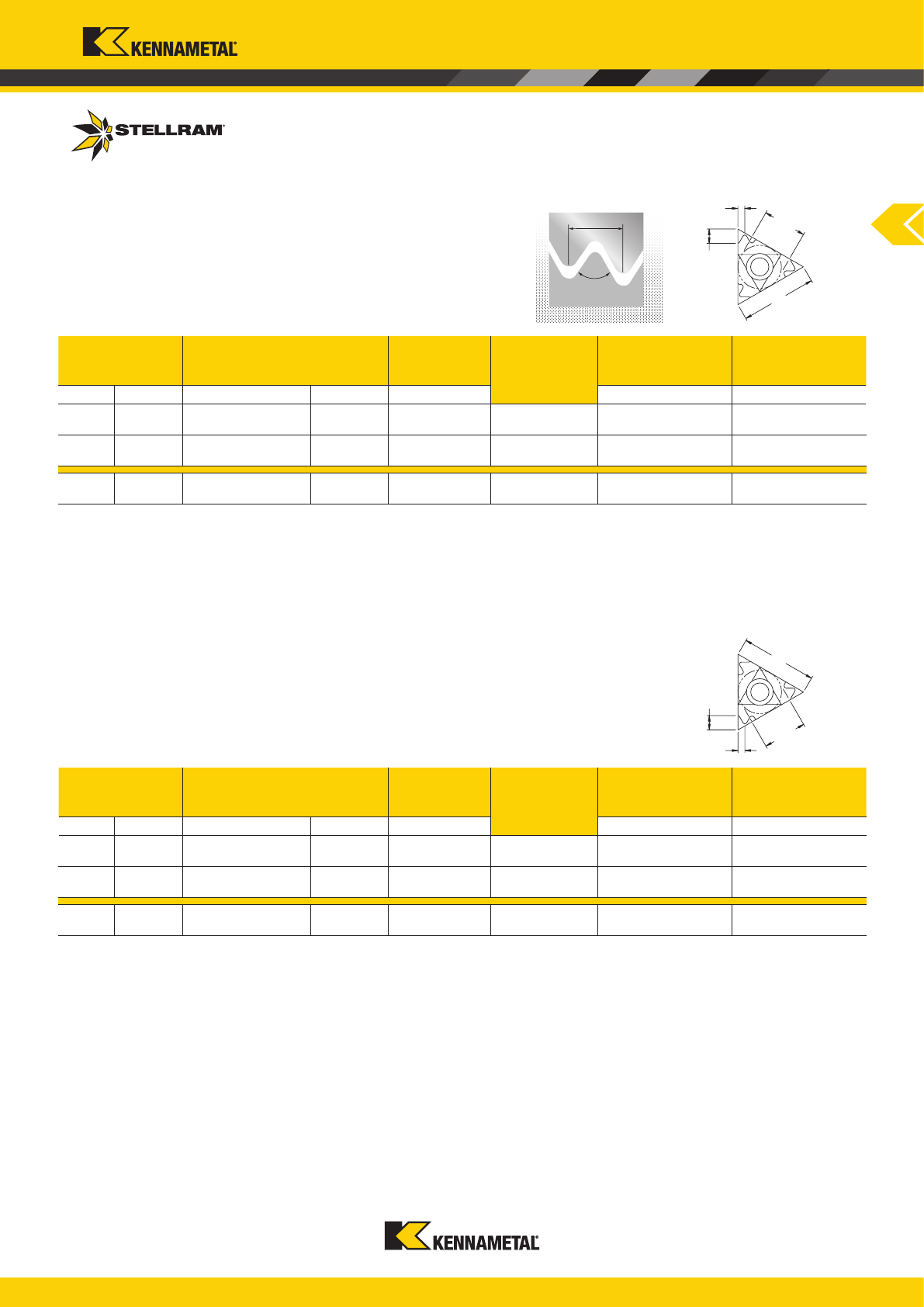

Introduction

MEDIUM-

ROUGHING

FINISHING

ROUGHING

MEDIUM

FINISHING

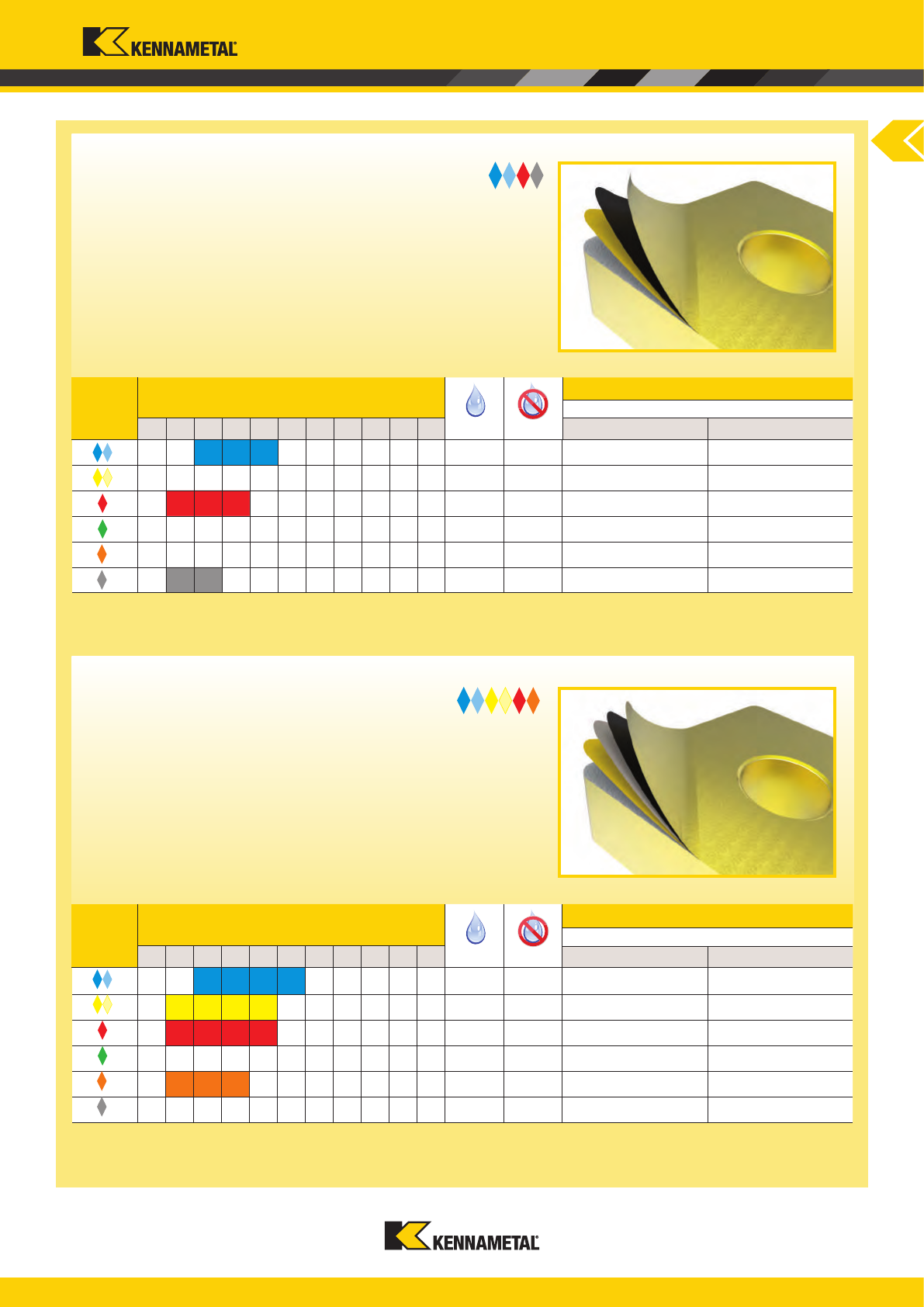

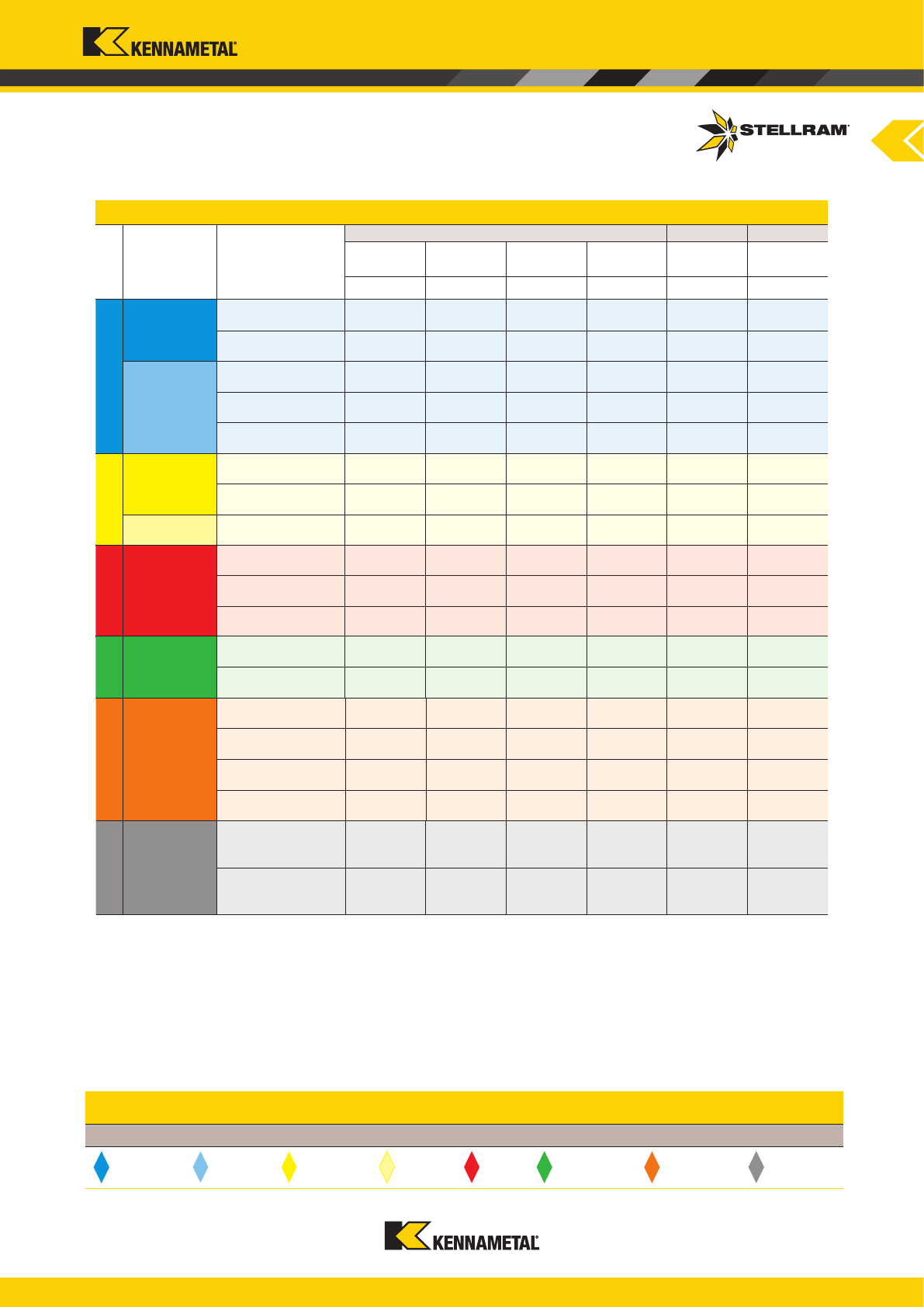

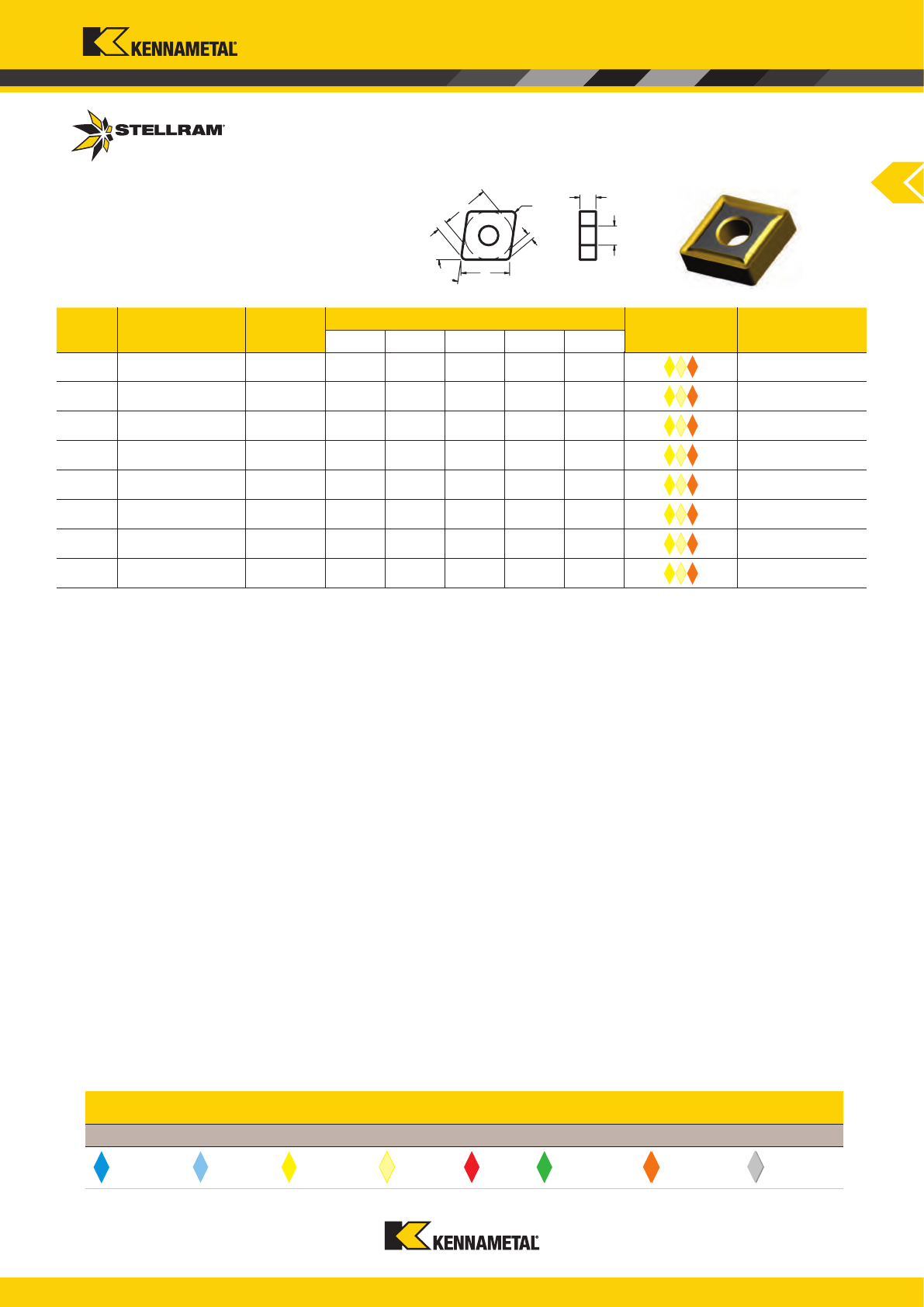

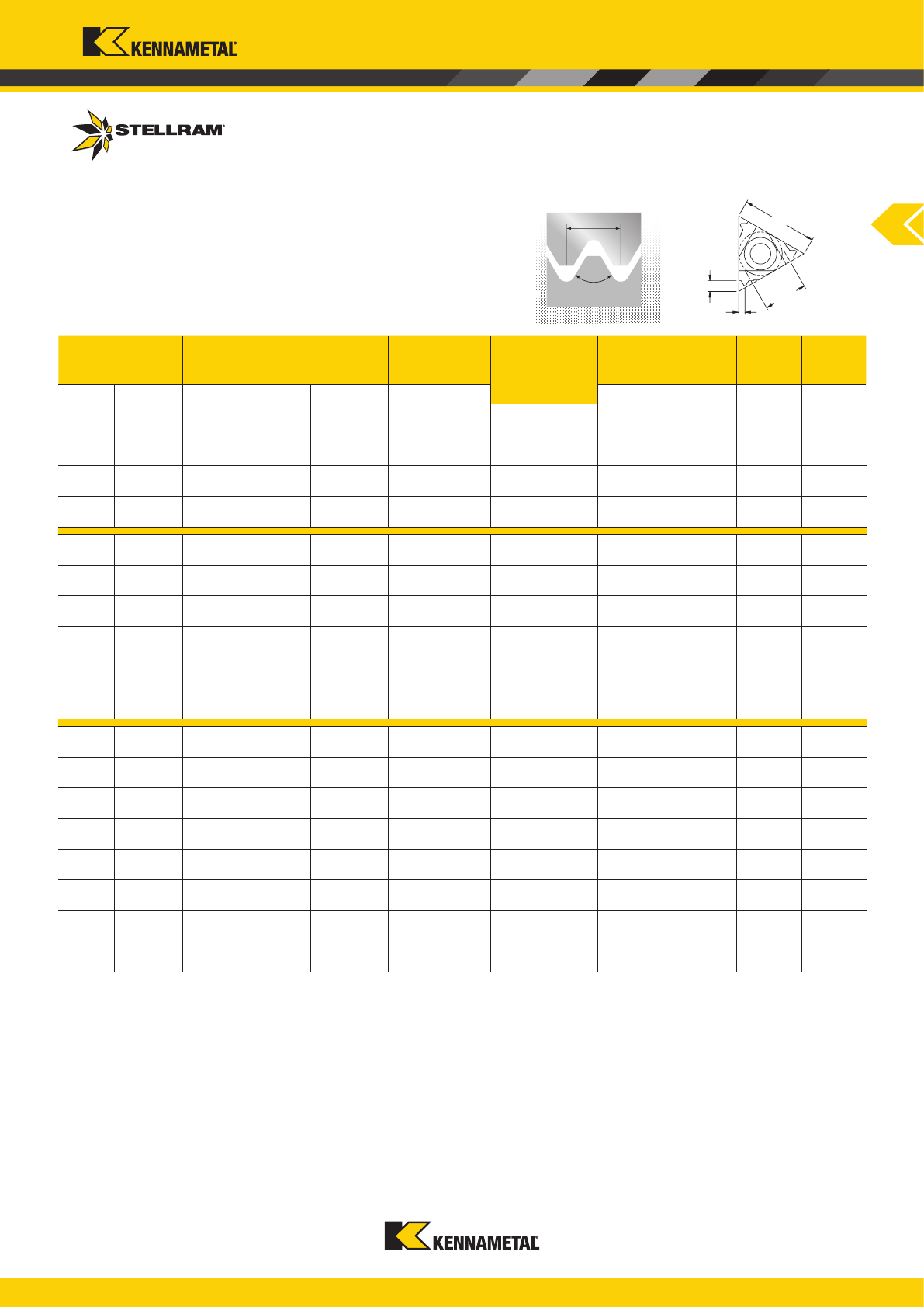

Metric

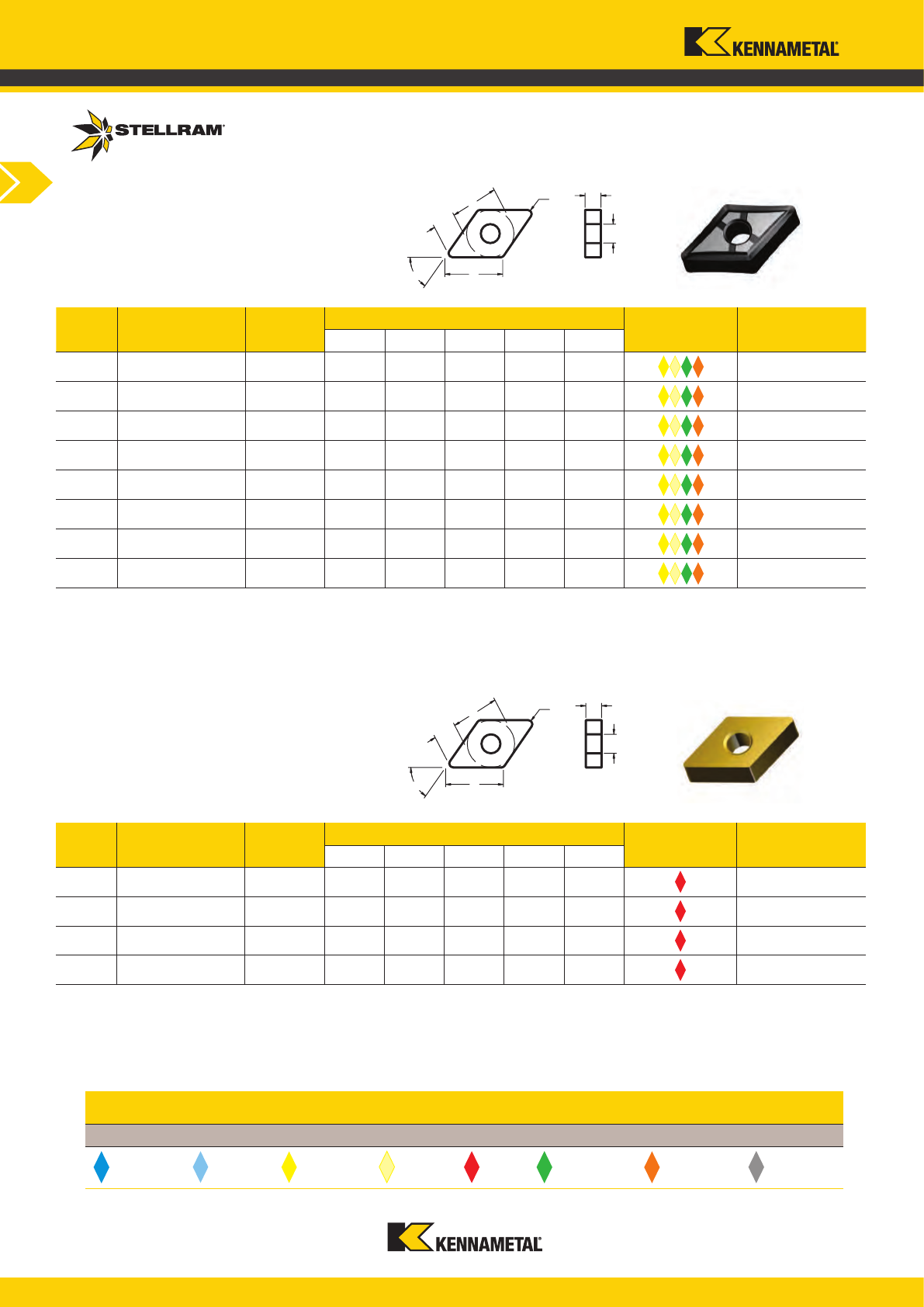

Positive Inserts – Unalloyed Steel

*Note: For Heavy Roughing applications see 5R geometry, page C17.

Metric

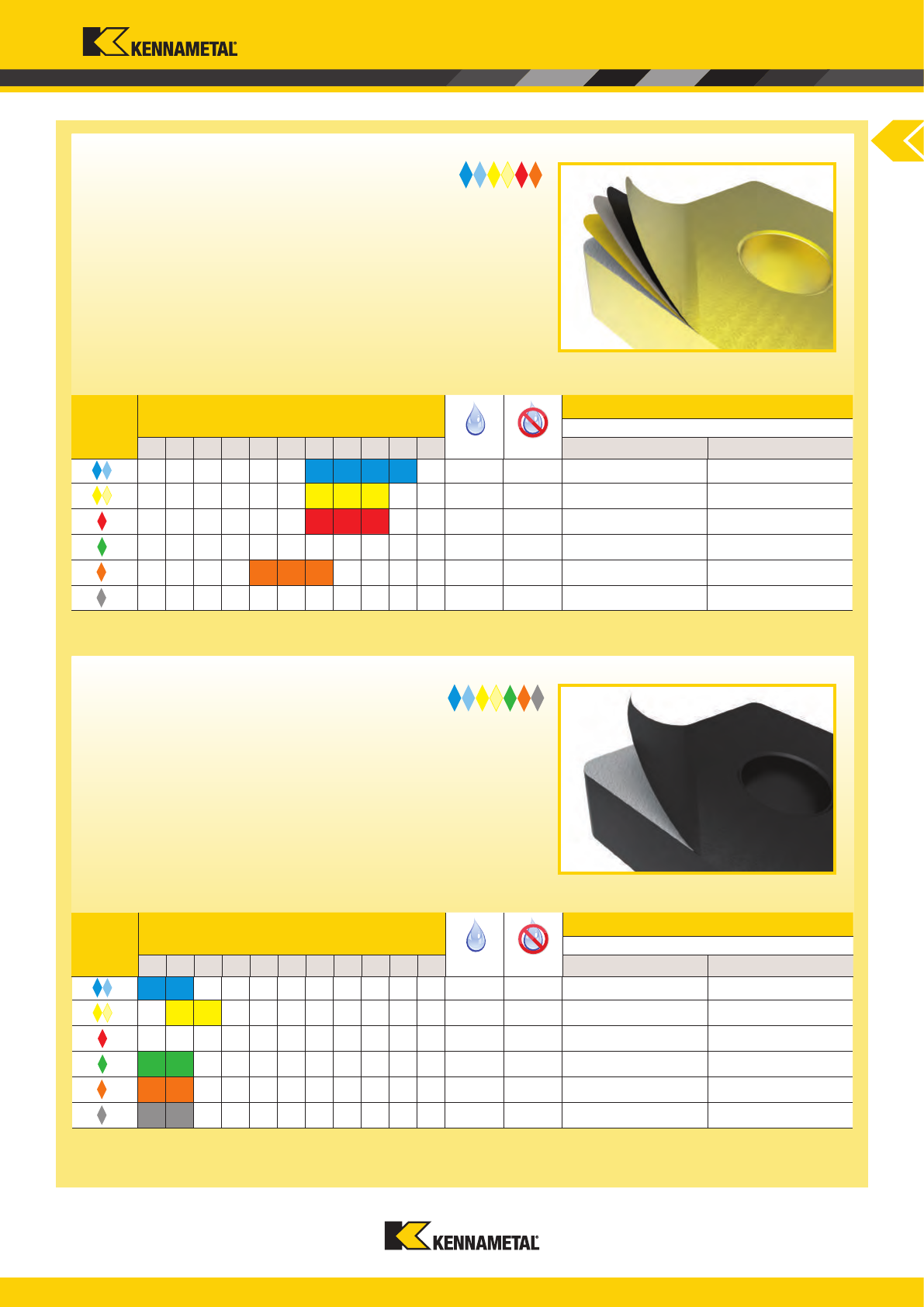

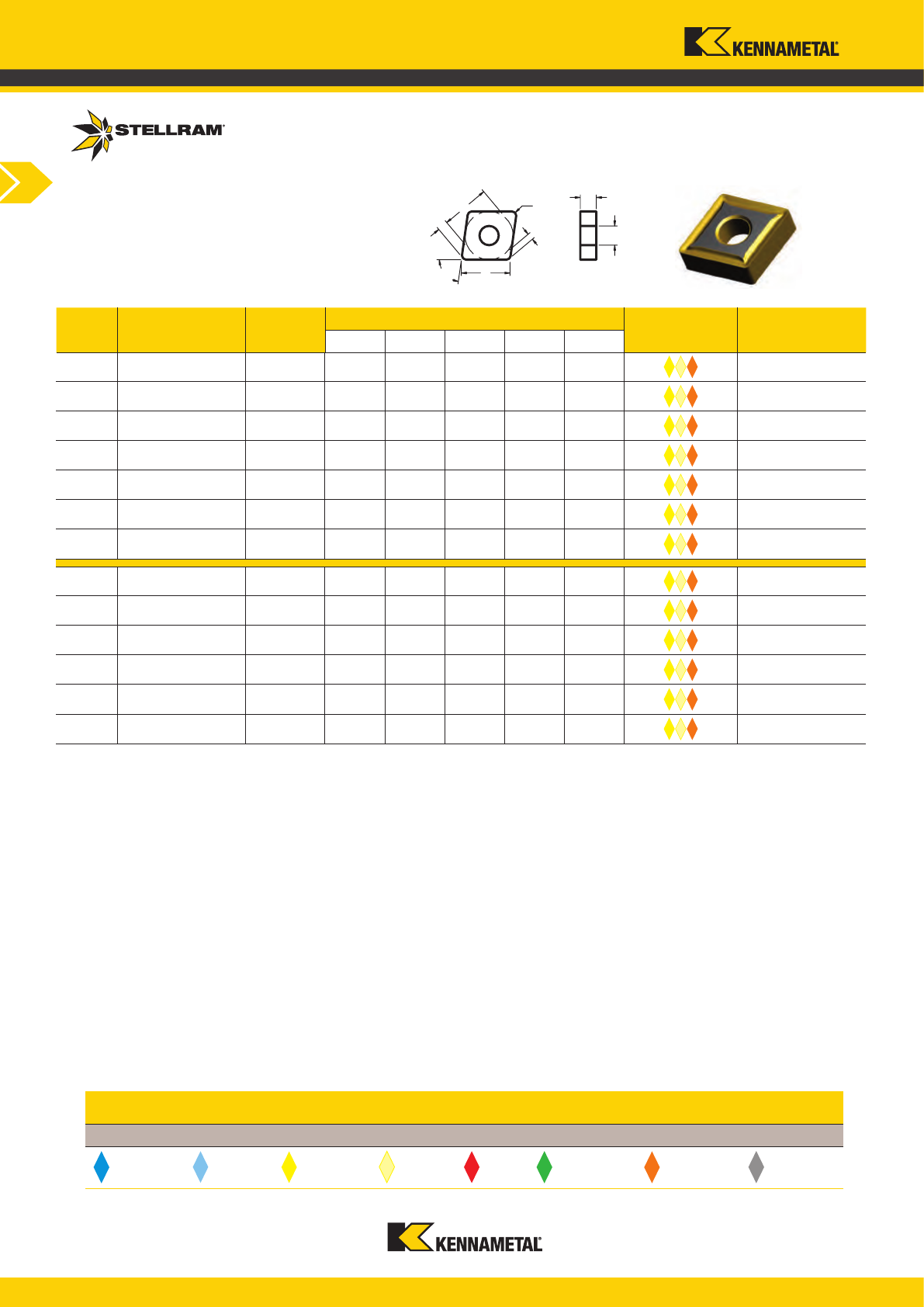

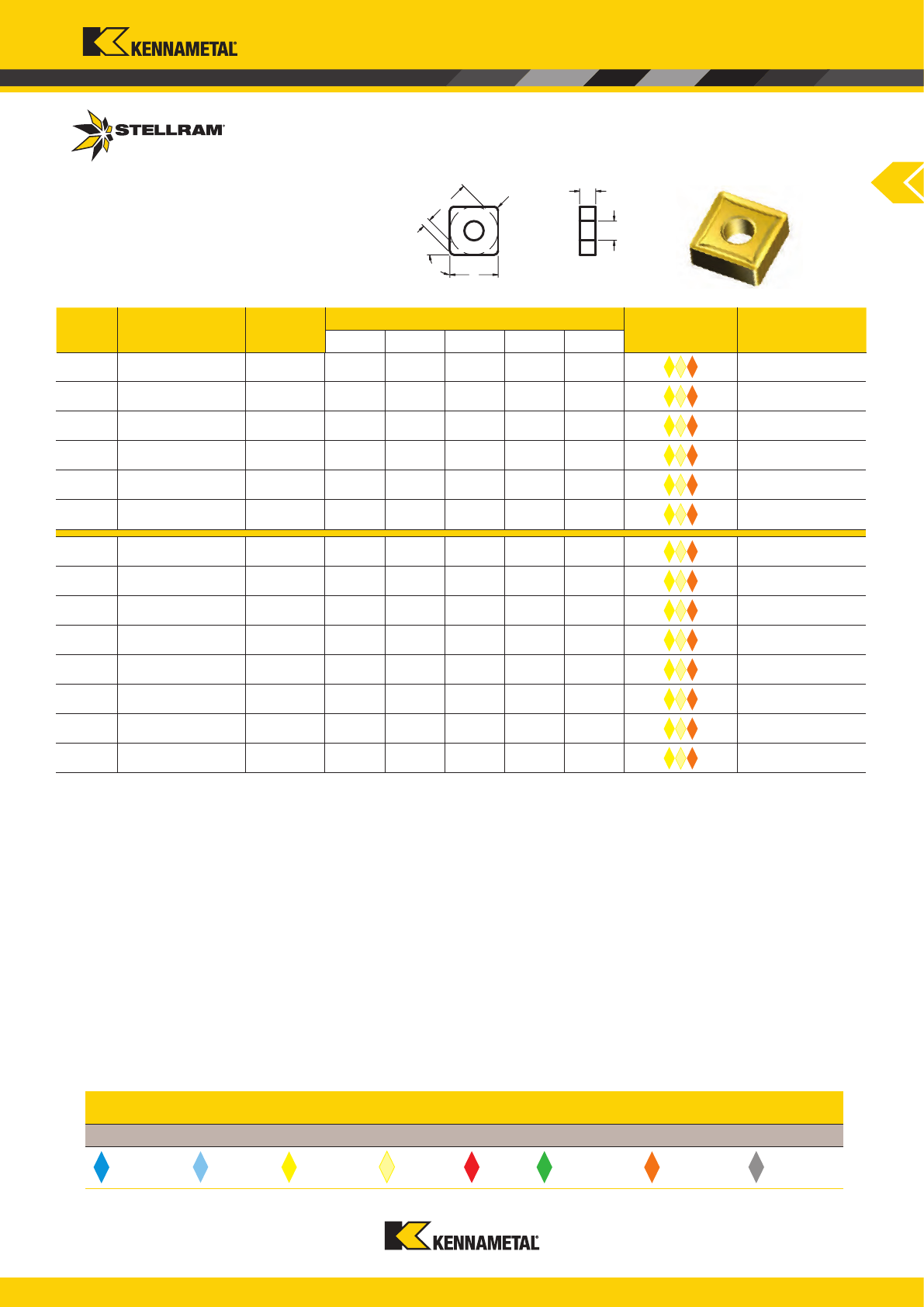

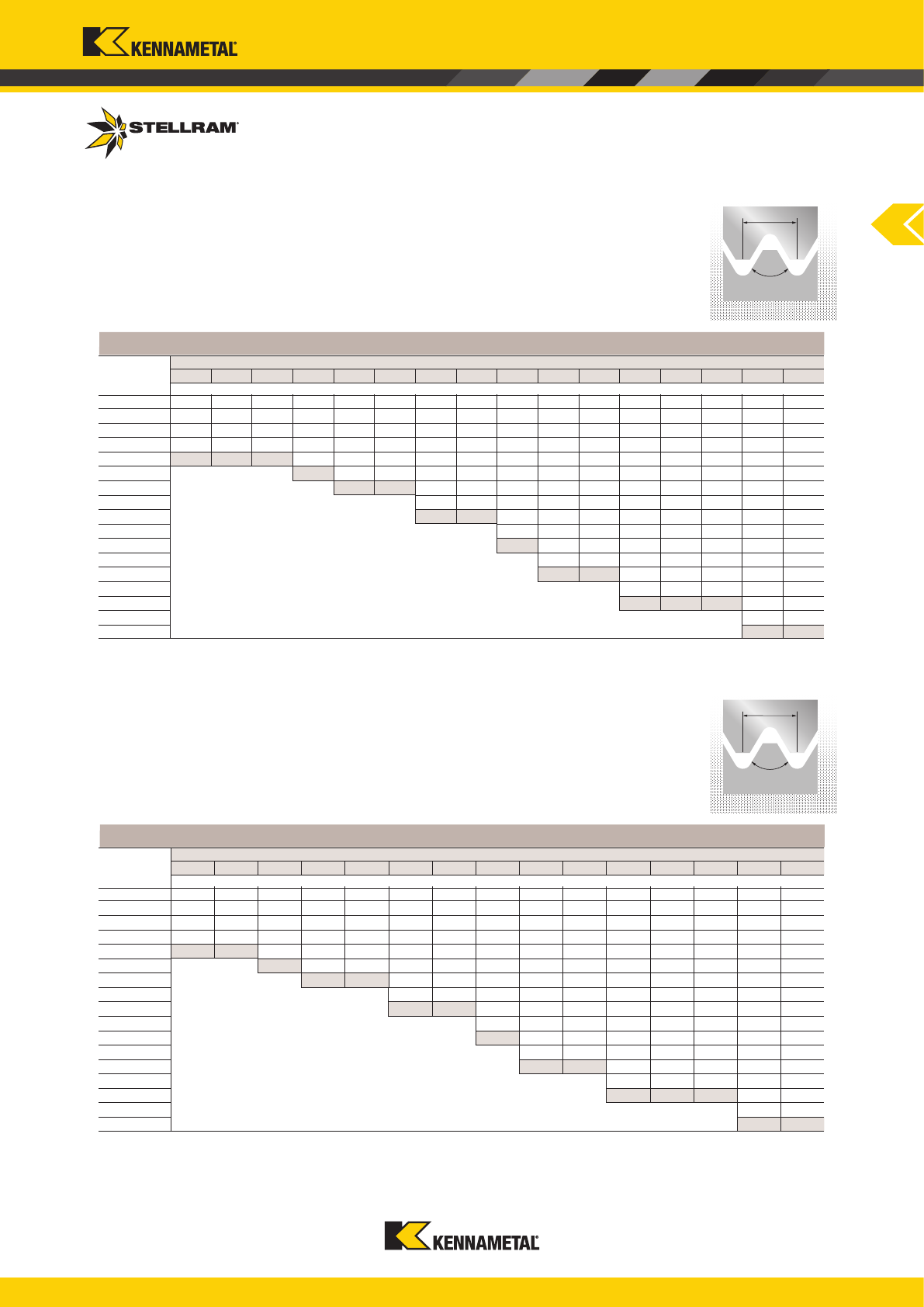

Negative Inserts – Unalloyed Steel

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

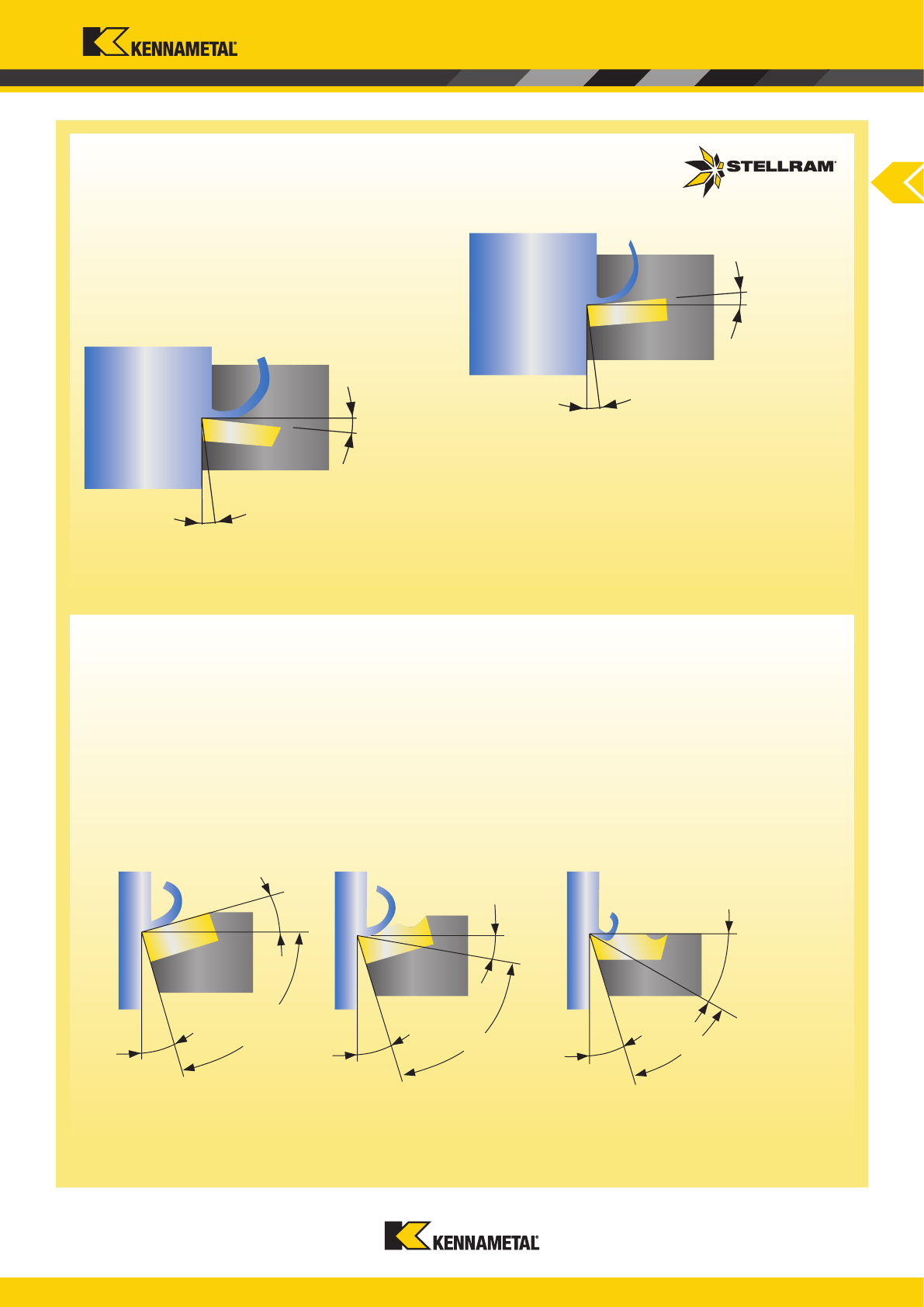

Negative/Positive

First Choice — Unalloyed Steel

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C5

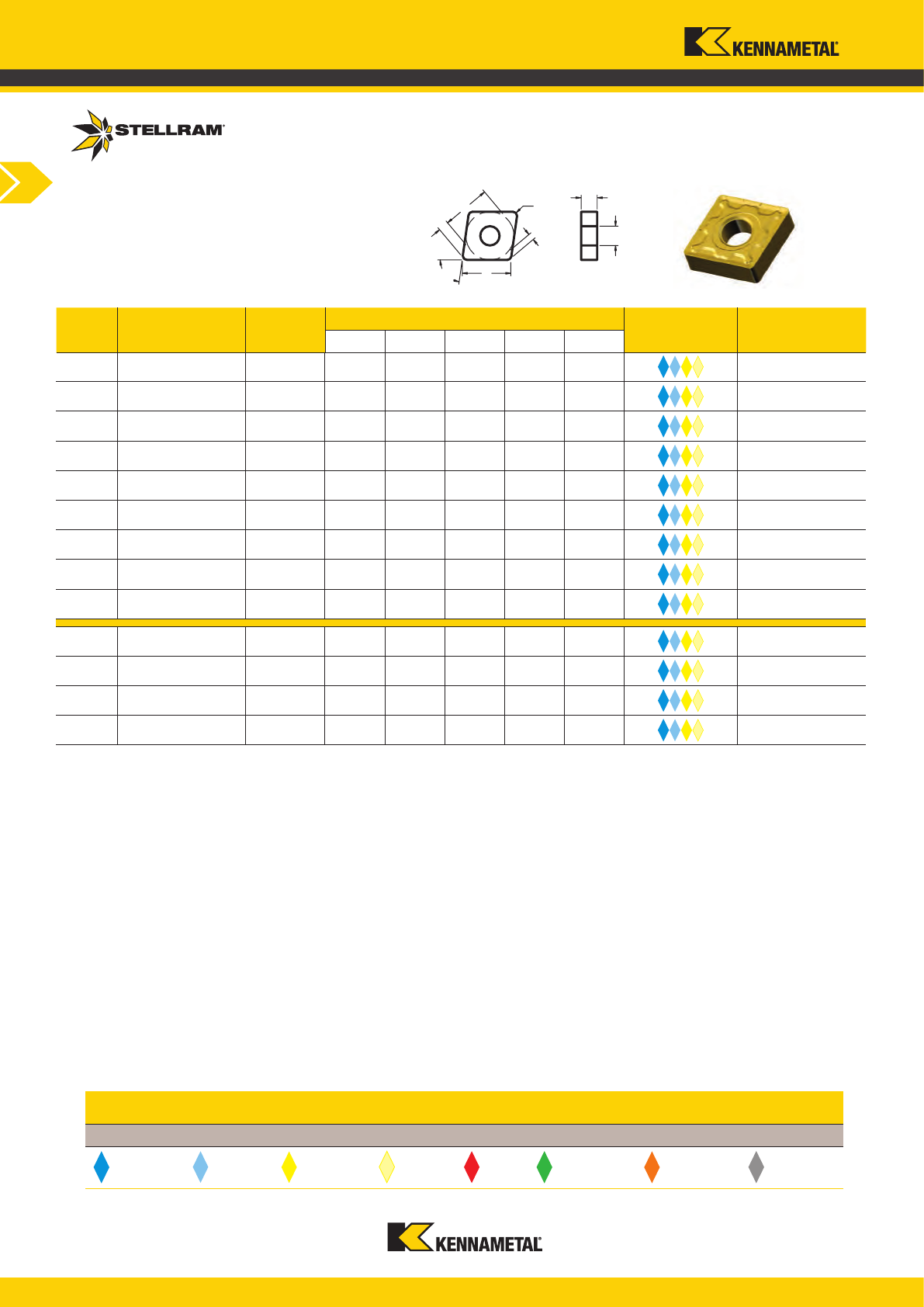

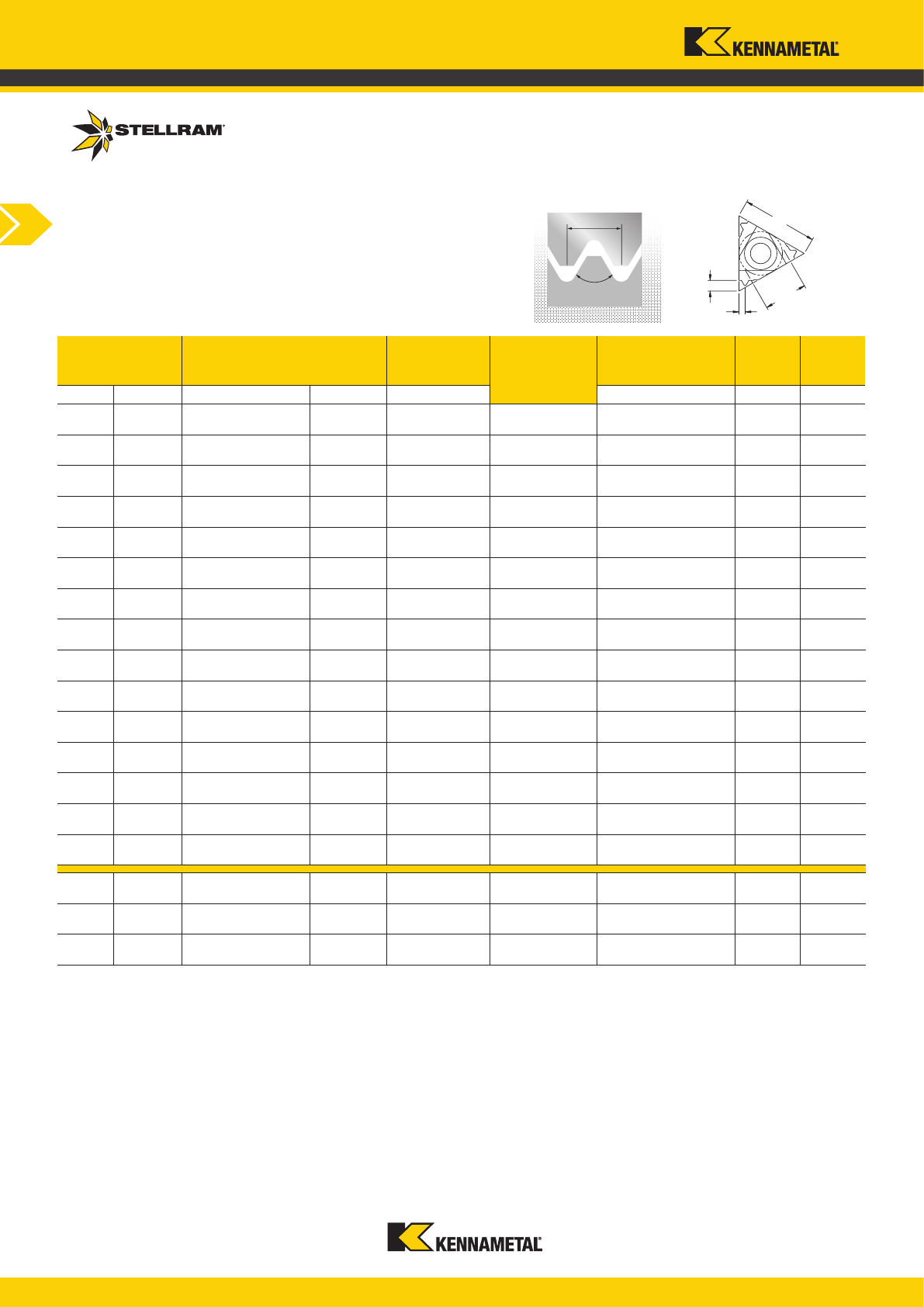

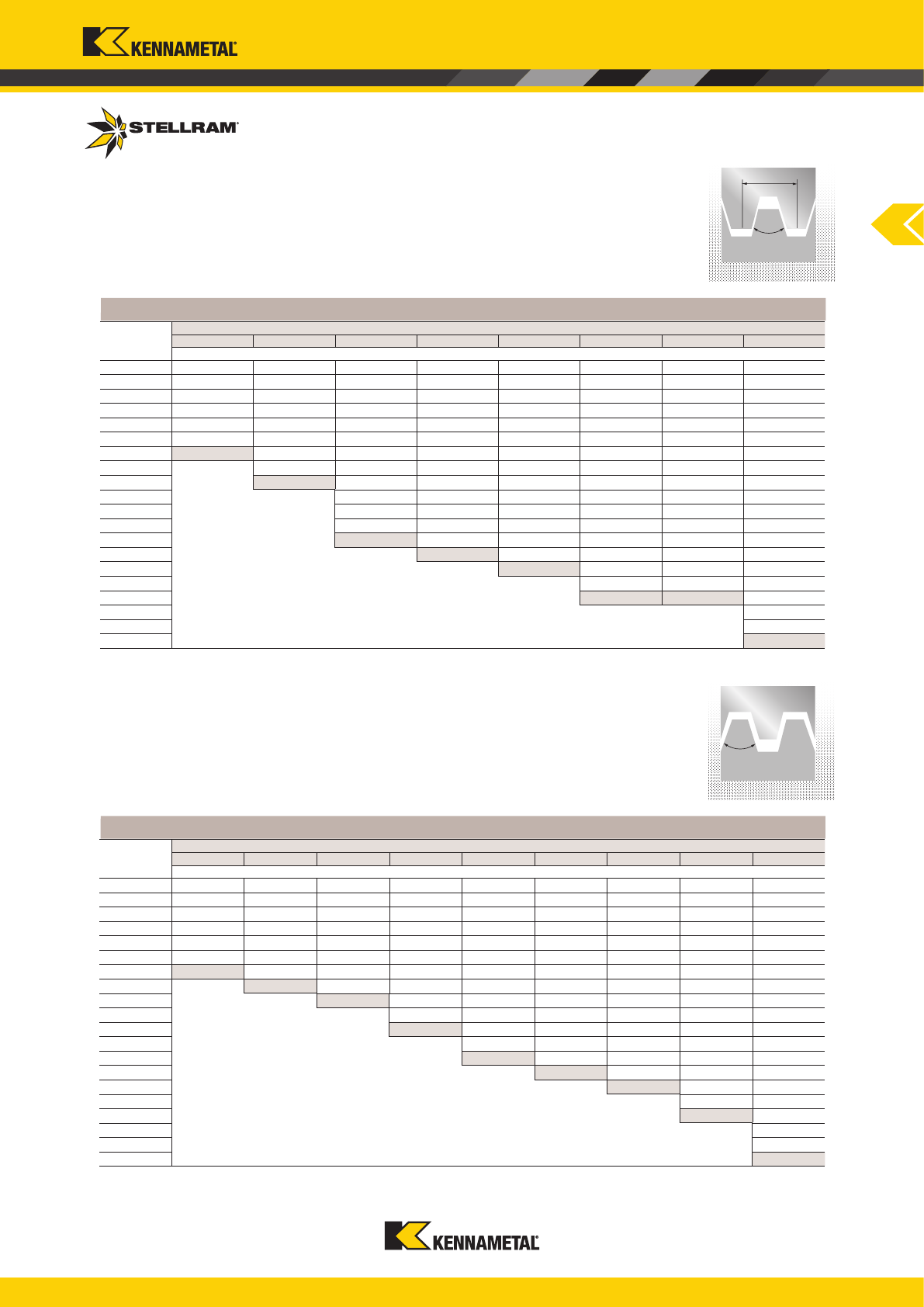

*

0,0

1B

SP0819

Vc (m/min)

80 - 270

NL250

Vc (m/min)

25 - 95

NL250

Vc (m/min)

35 - 145

f

n

(mm/rev)

0,1 - 0,3

a

p

(mm)

0,5 - 2,0

2N

NL250

Vc (m/min)

60 - 240

NL920

Vc (m/min)

20 - 55

NL300

Vc (m/min)

35 -140

f

n

(mm/rev)

0,15 - 0,45

a

p

(mm)

0,75 - 3,0

4T

NL300

Vc (m/min)

60 - 230

NL920

Vc (m/min)

20 - 55

NL400

Vc (m/min)

30 - 130

f

n

(mm/rev)

0,25 - 0,5

a

p

(mm)

1,2 - 5,5

0,0

62

SP4019

Vc (m/min)

80 - 265

SP4019

Vc (m/min)

30 - 110

SP4019

Vc (m/min)

50 - 160

f

n

(mm/rev)

0,025 - 0,25

a

p

(mm)

0,25 - 3,0

73

SP4019

Vc (m/min)

80 - 265

NL920

Vc (m/min)

20 - 55

NL300

Vc (m/min)

35 - 140

f

n

(mm/rev)

0,07 - 0,5

a

p

(mm)

0,4 - 5,0

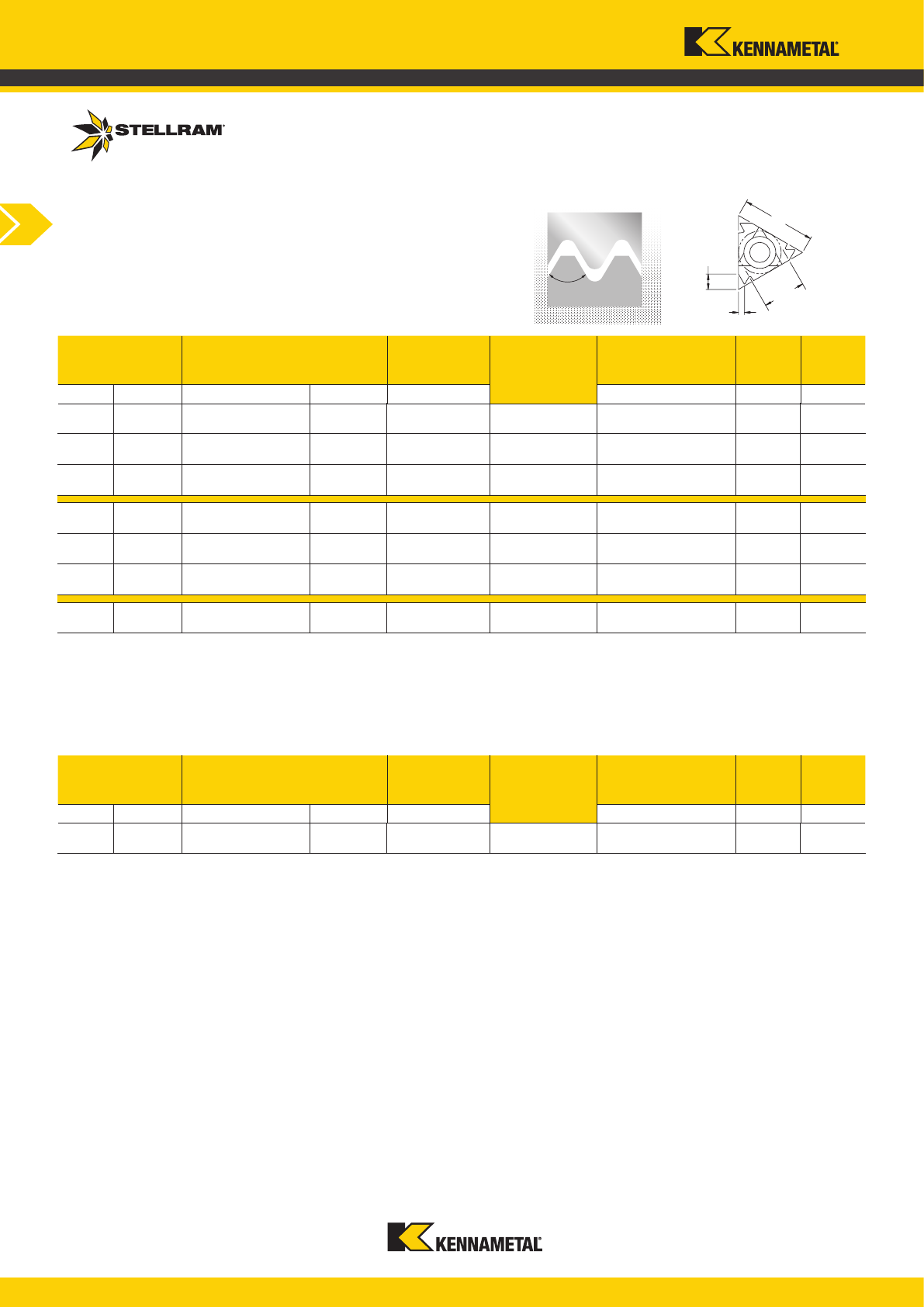

Introduction

MEDIUM-

ROUGHING

FINISHING

ROUGHING

MEDIUM

FINISHING

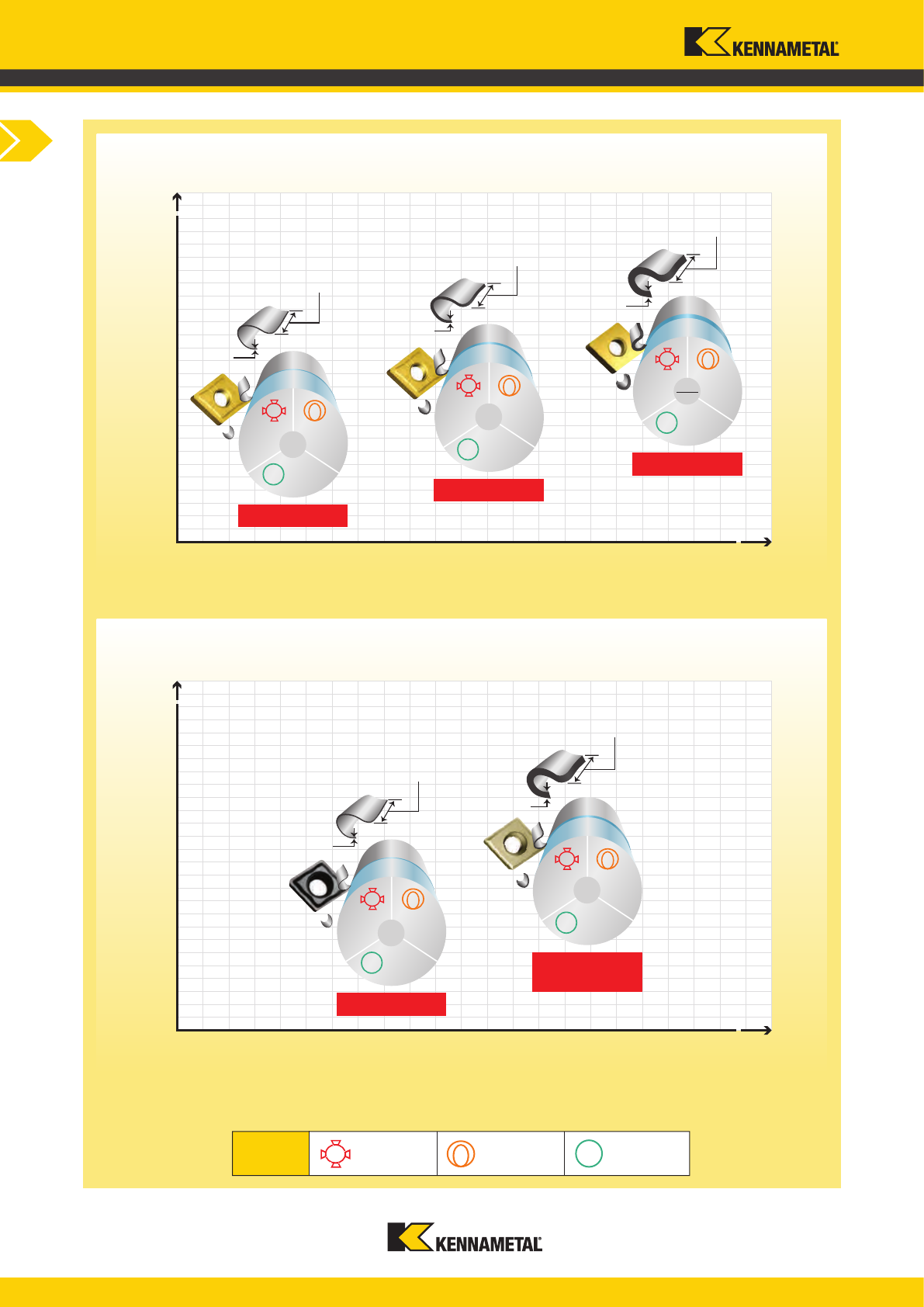

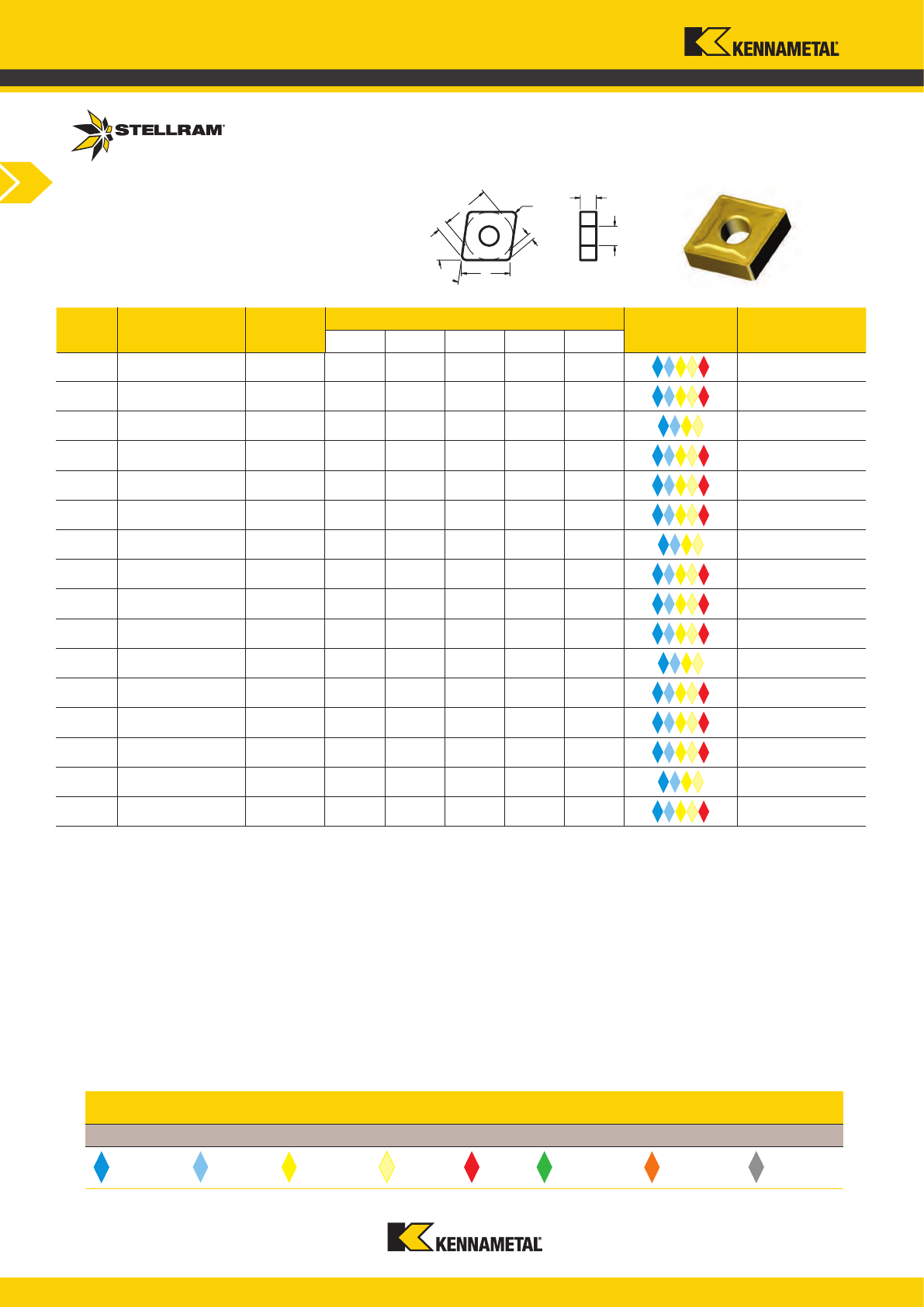

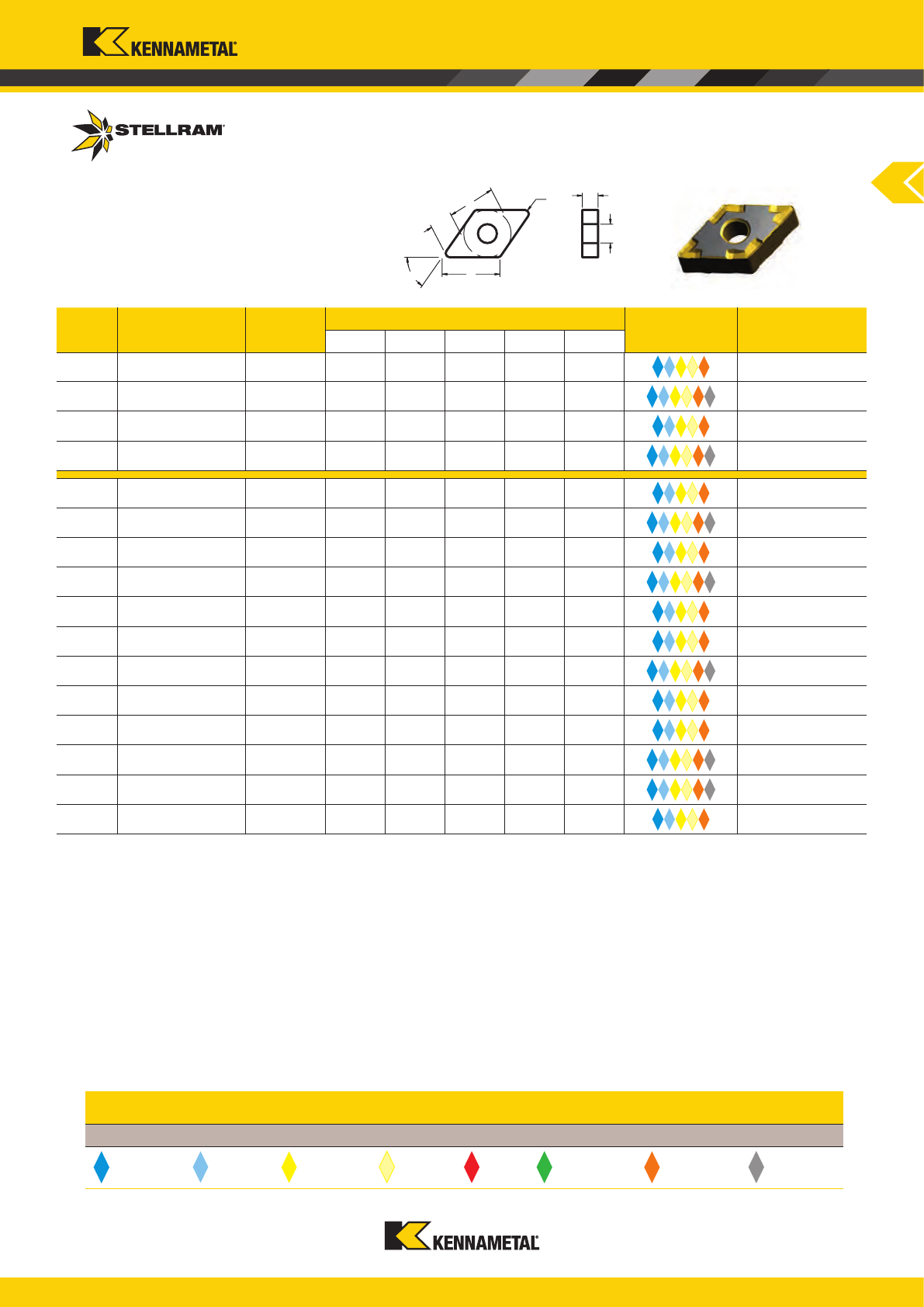

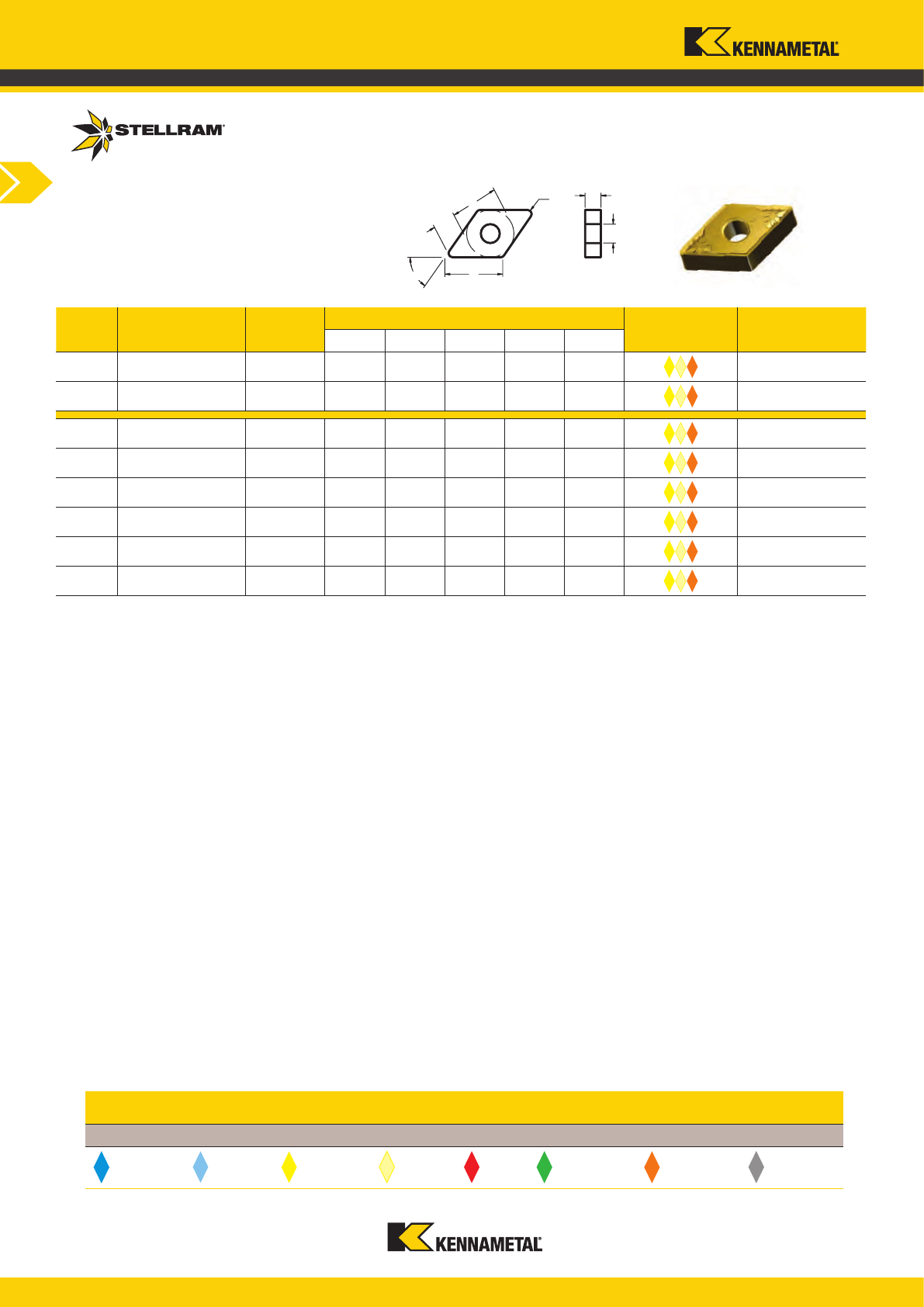

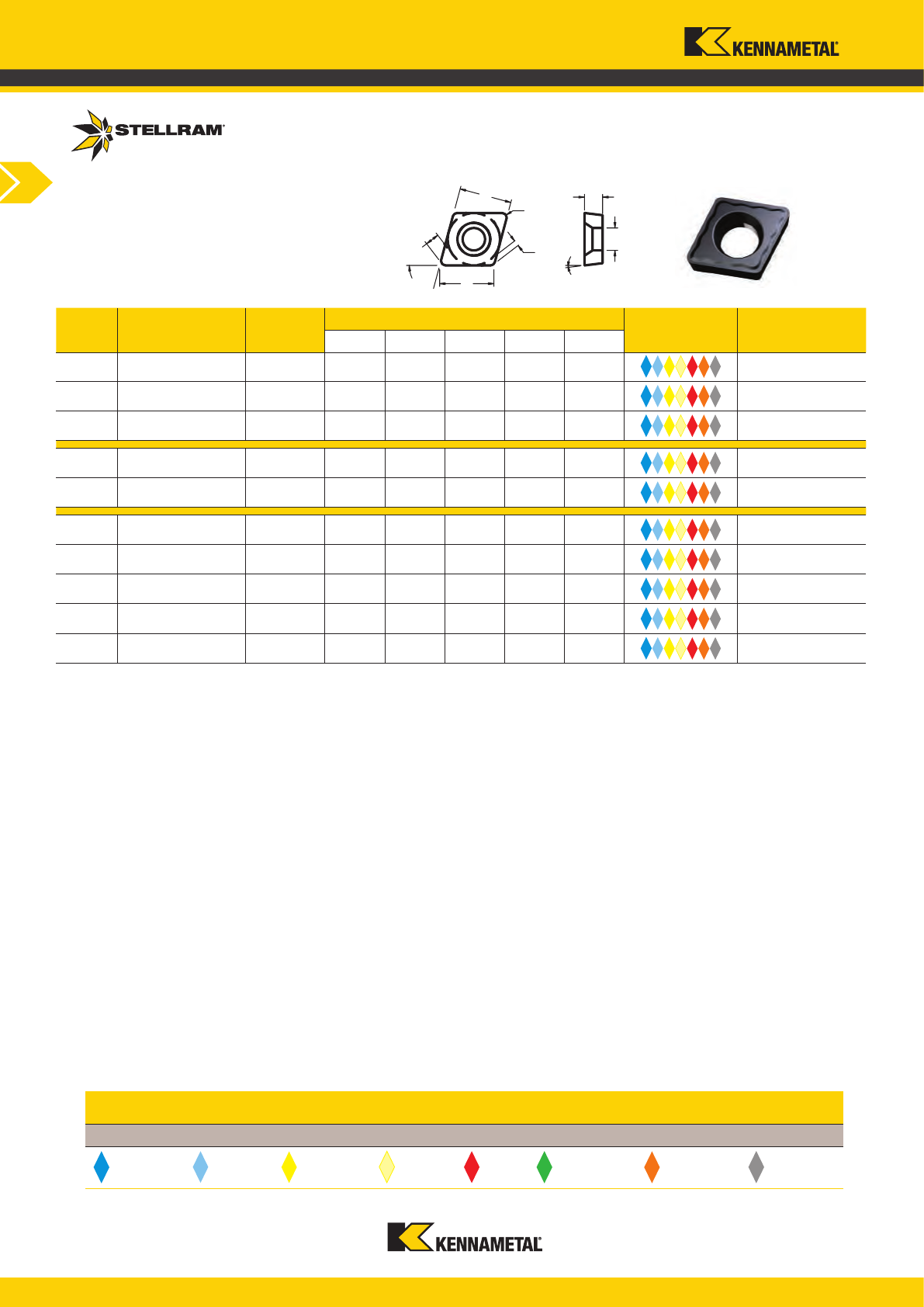

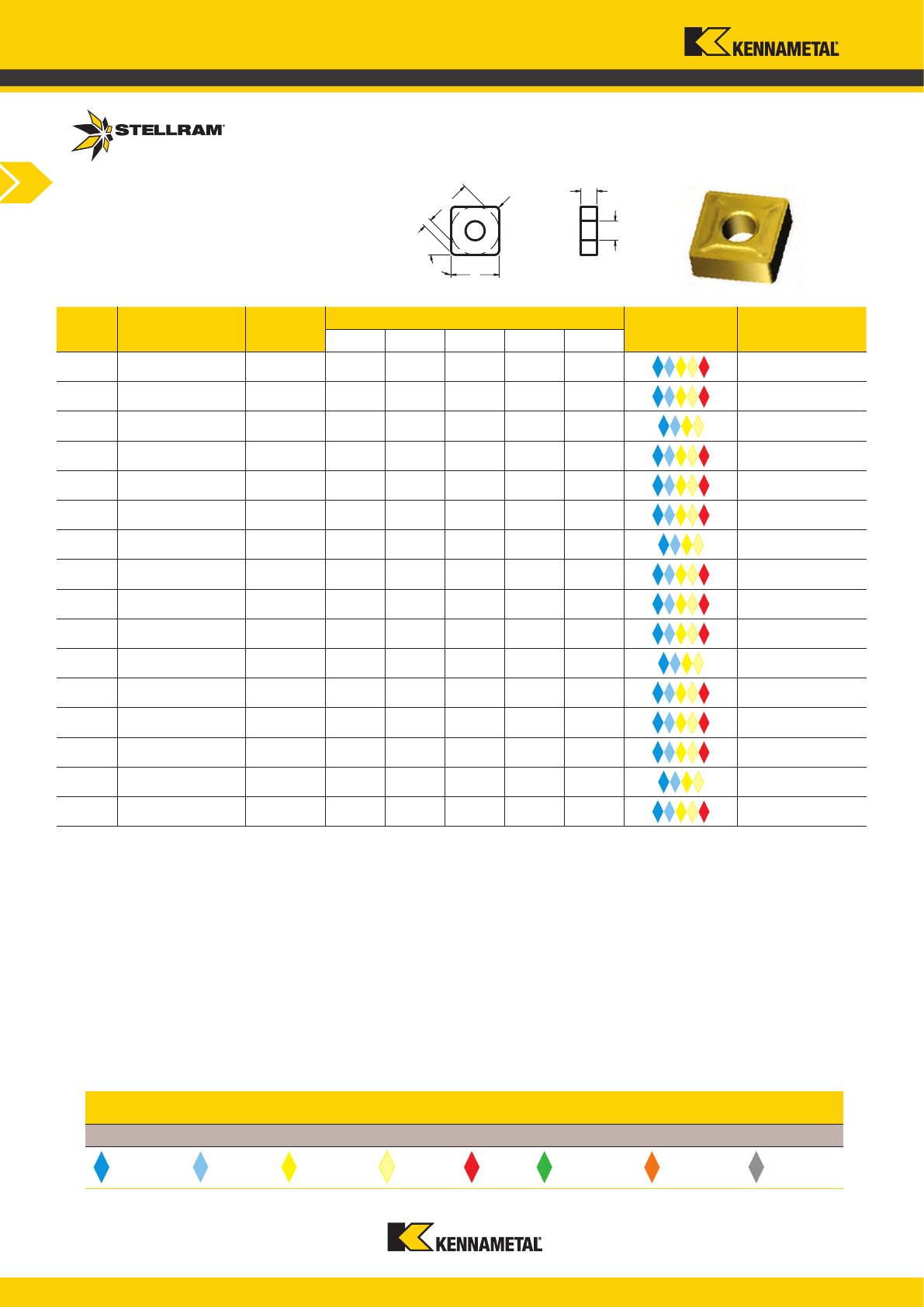

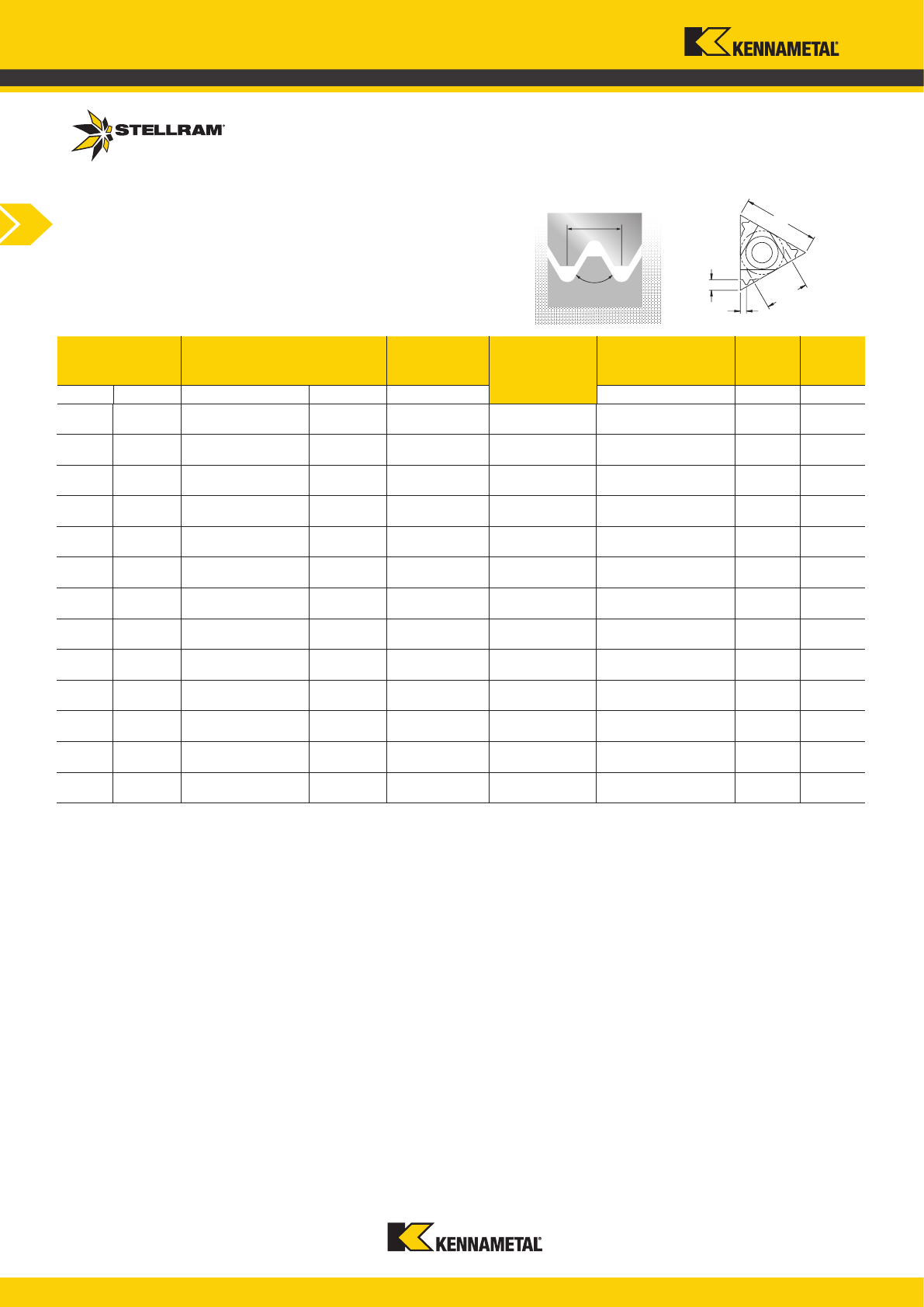

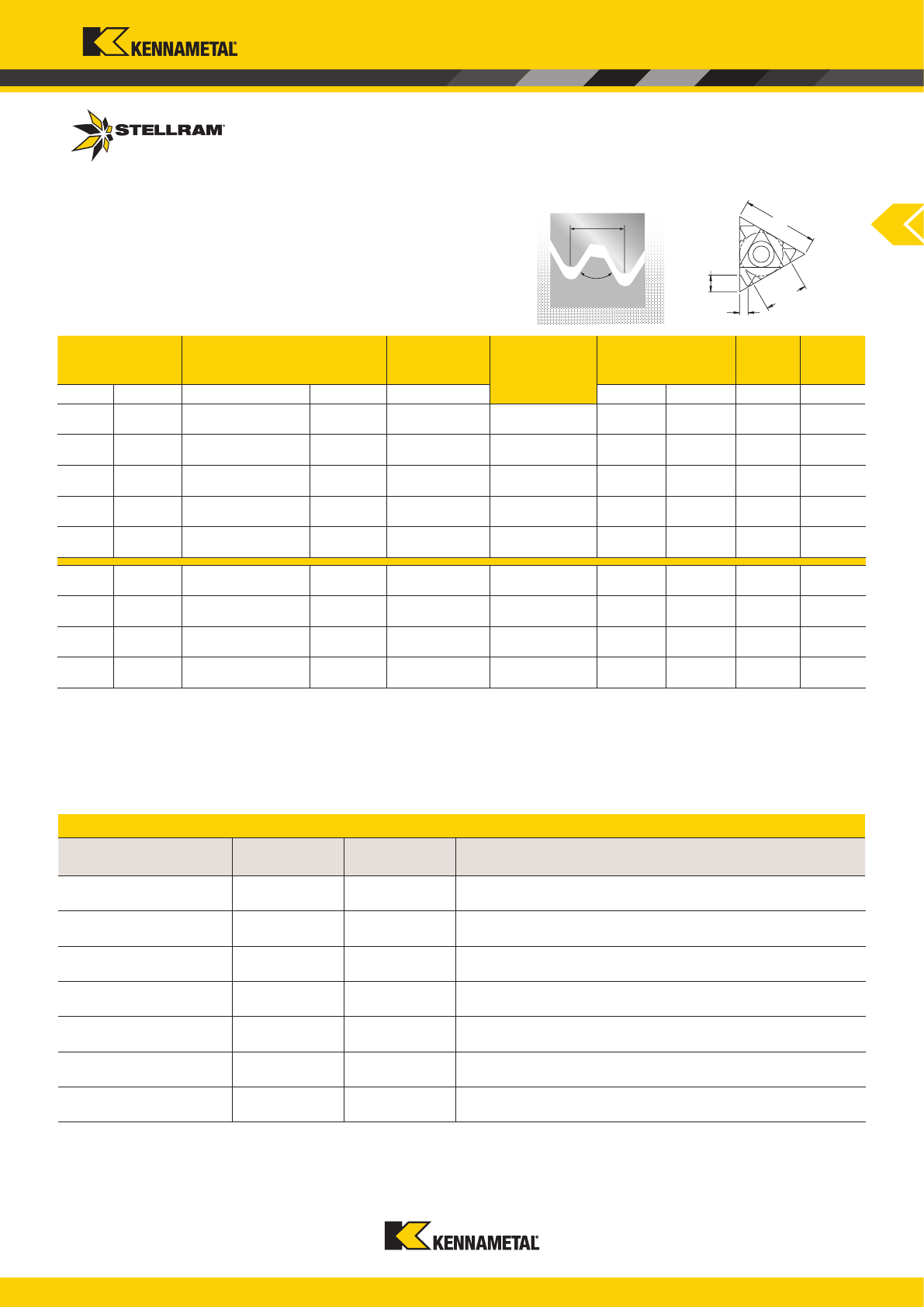

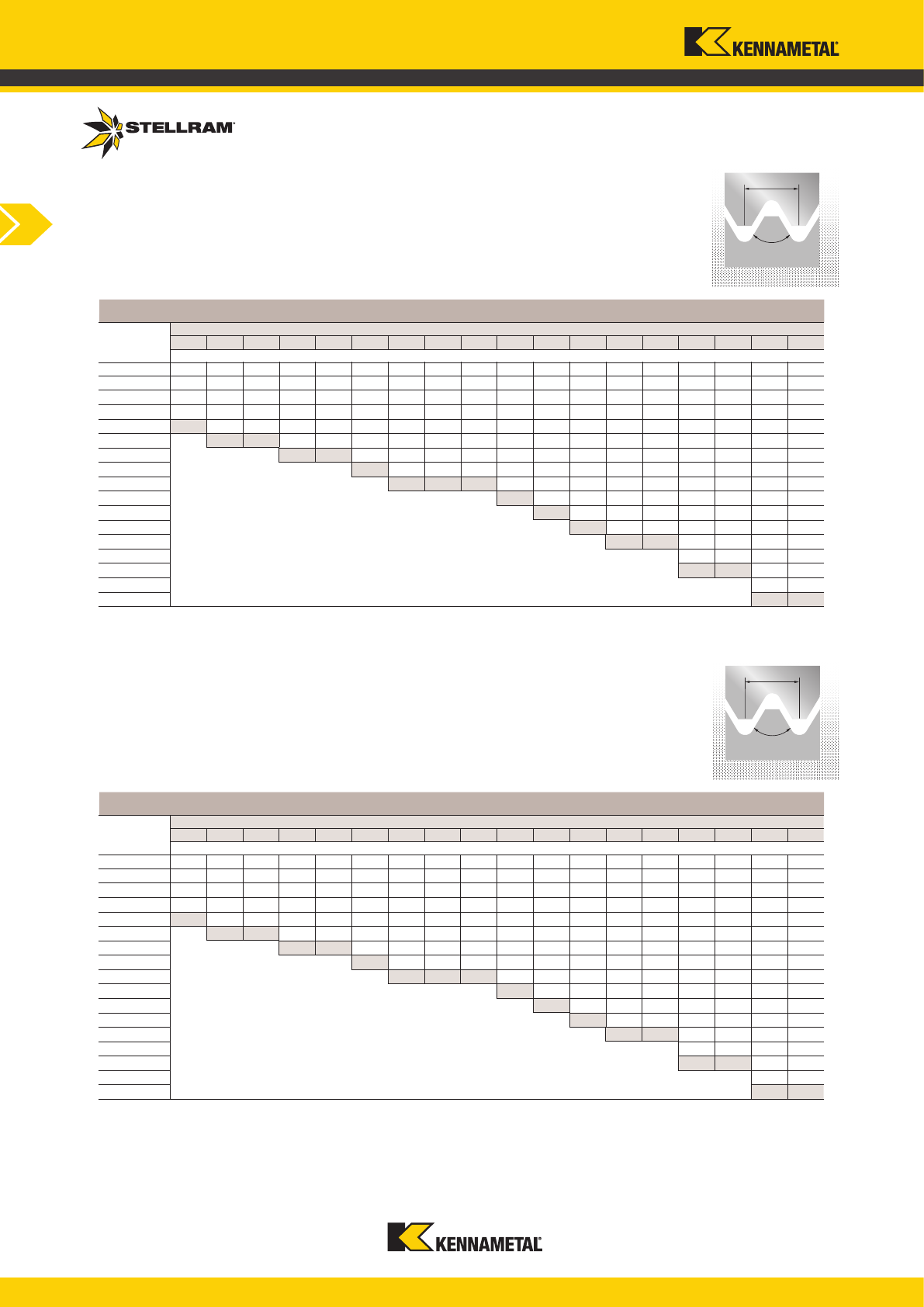

Metric

Positive Inserts – Alloyed Steel

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

*Note: For Heavy Roughing applications see 5R geometry, page C17.

Metric

Negative Inserts – Alloyed Steel

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Negative/Positive

First Choice — Alloyed Steel

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C6

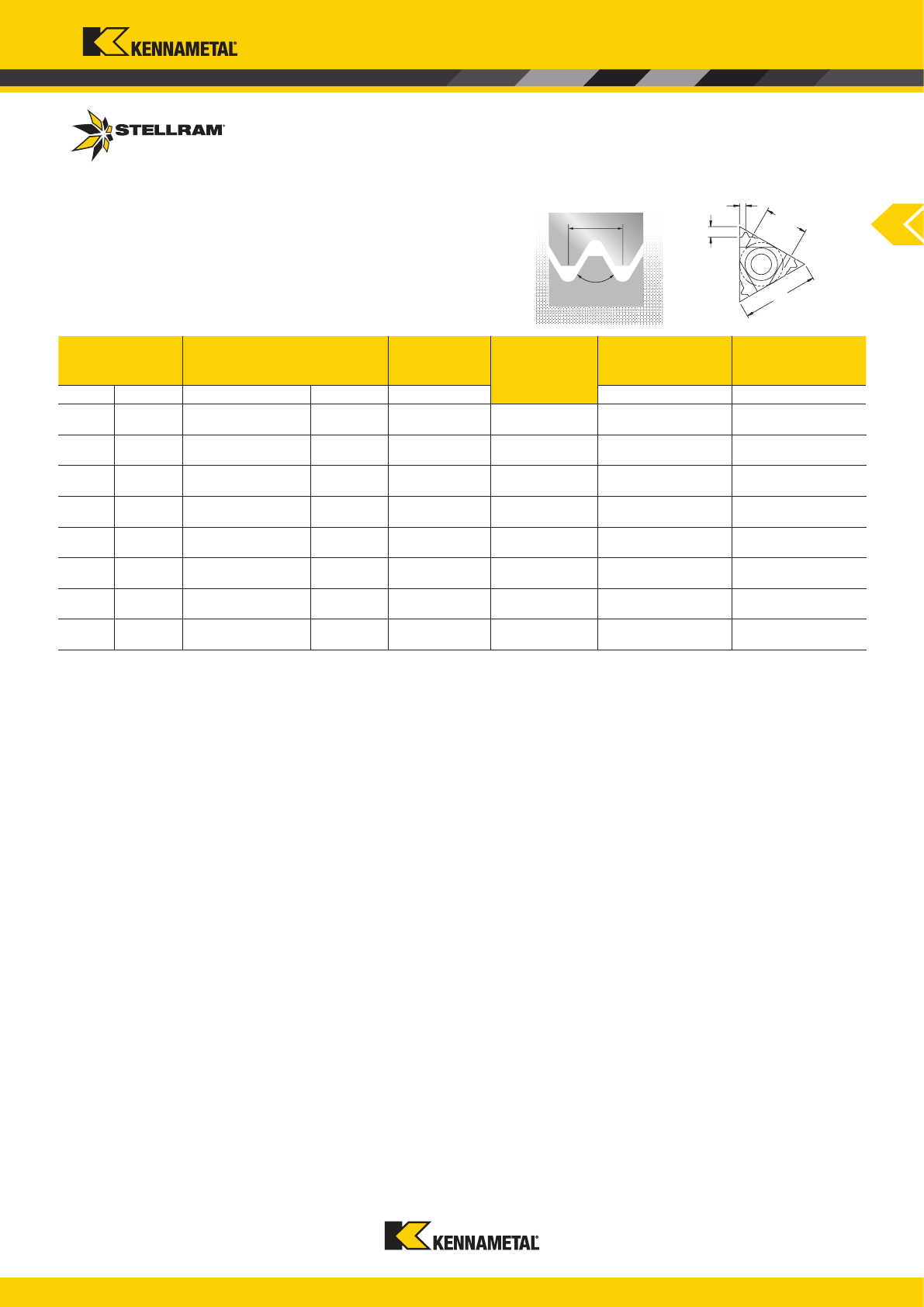

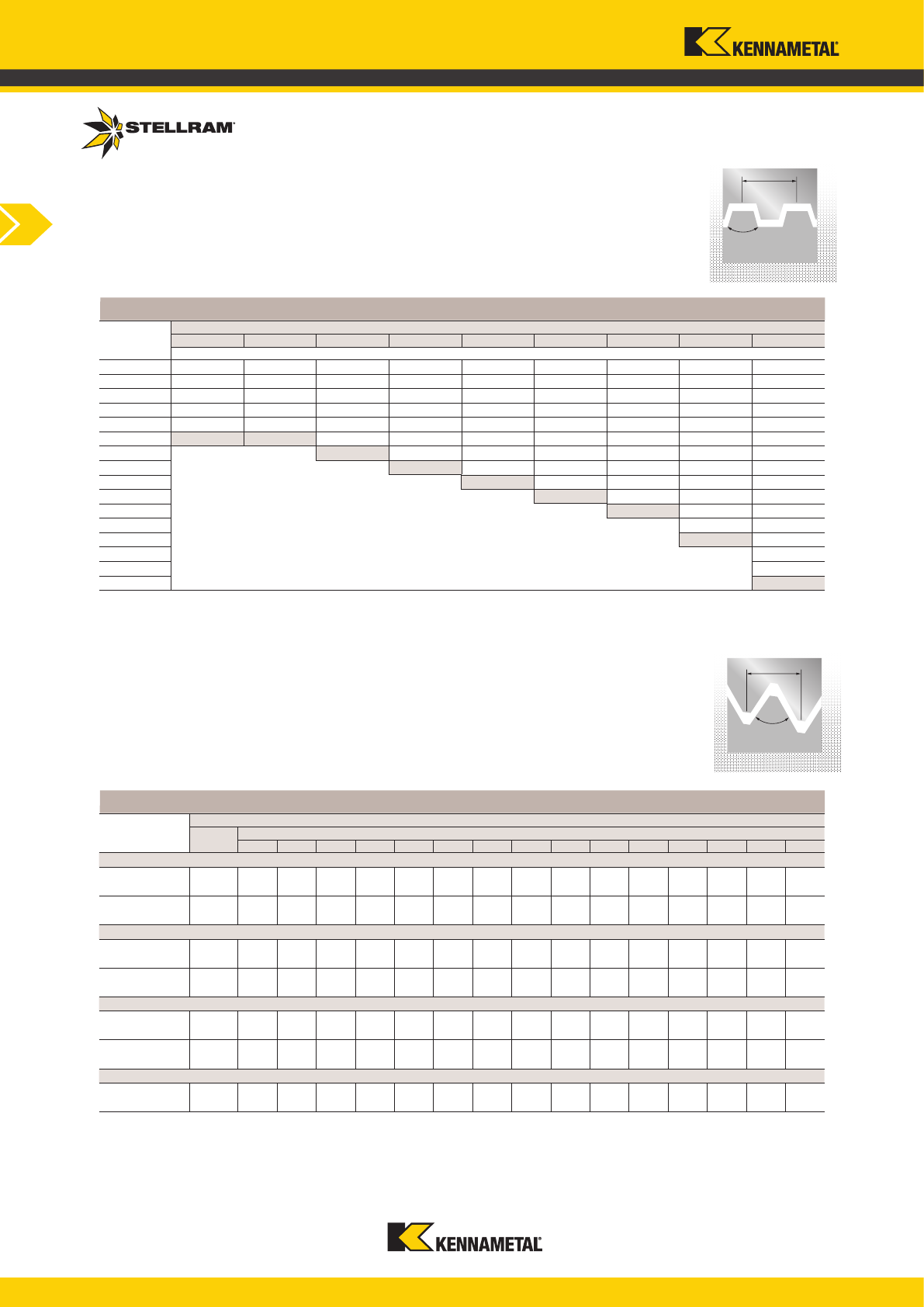

*

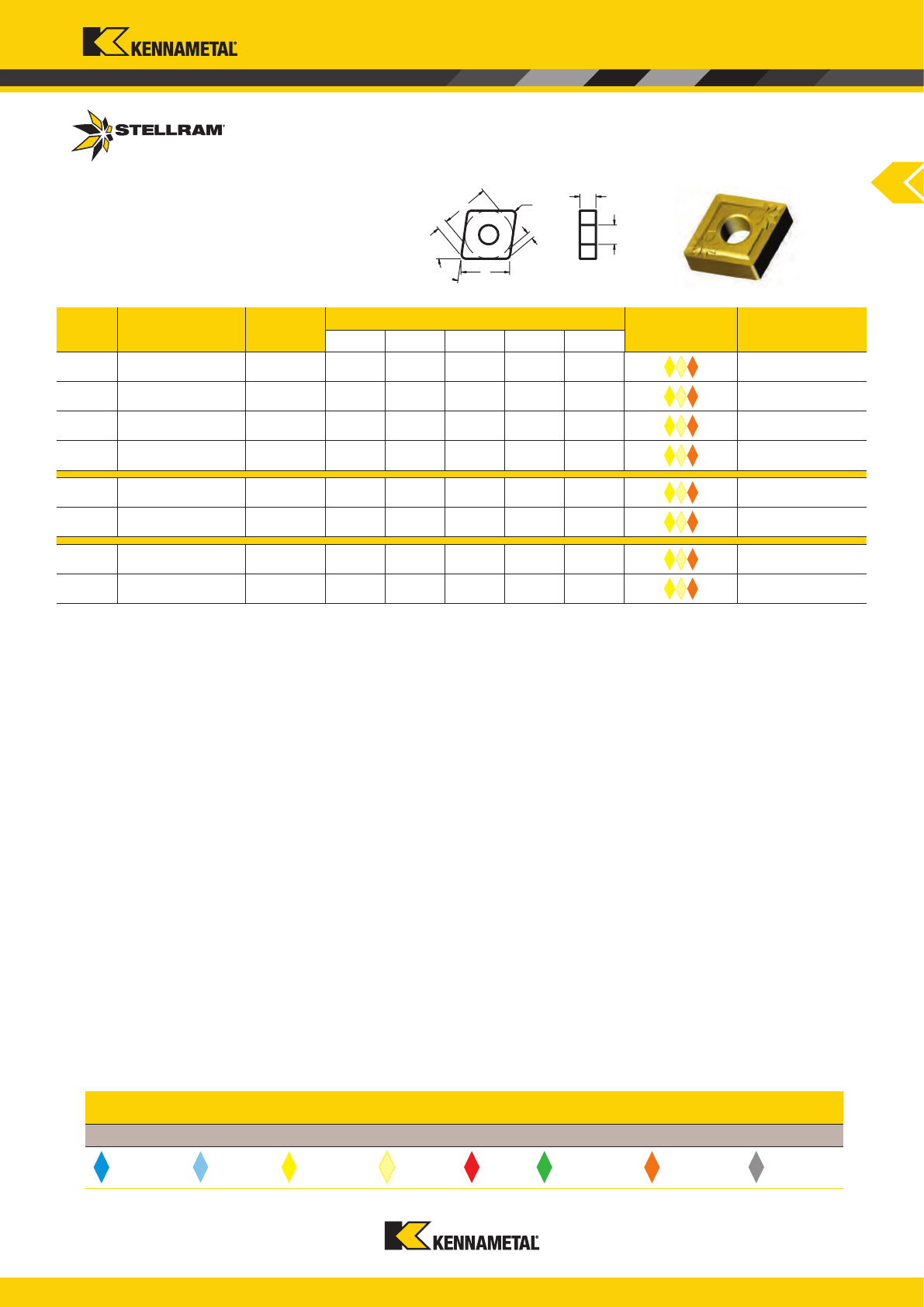

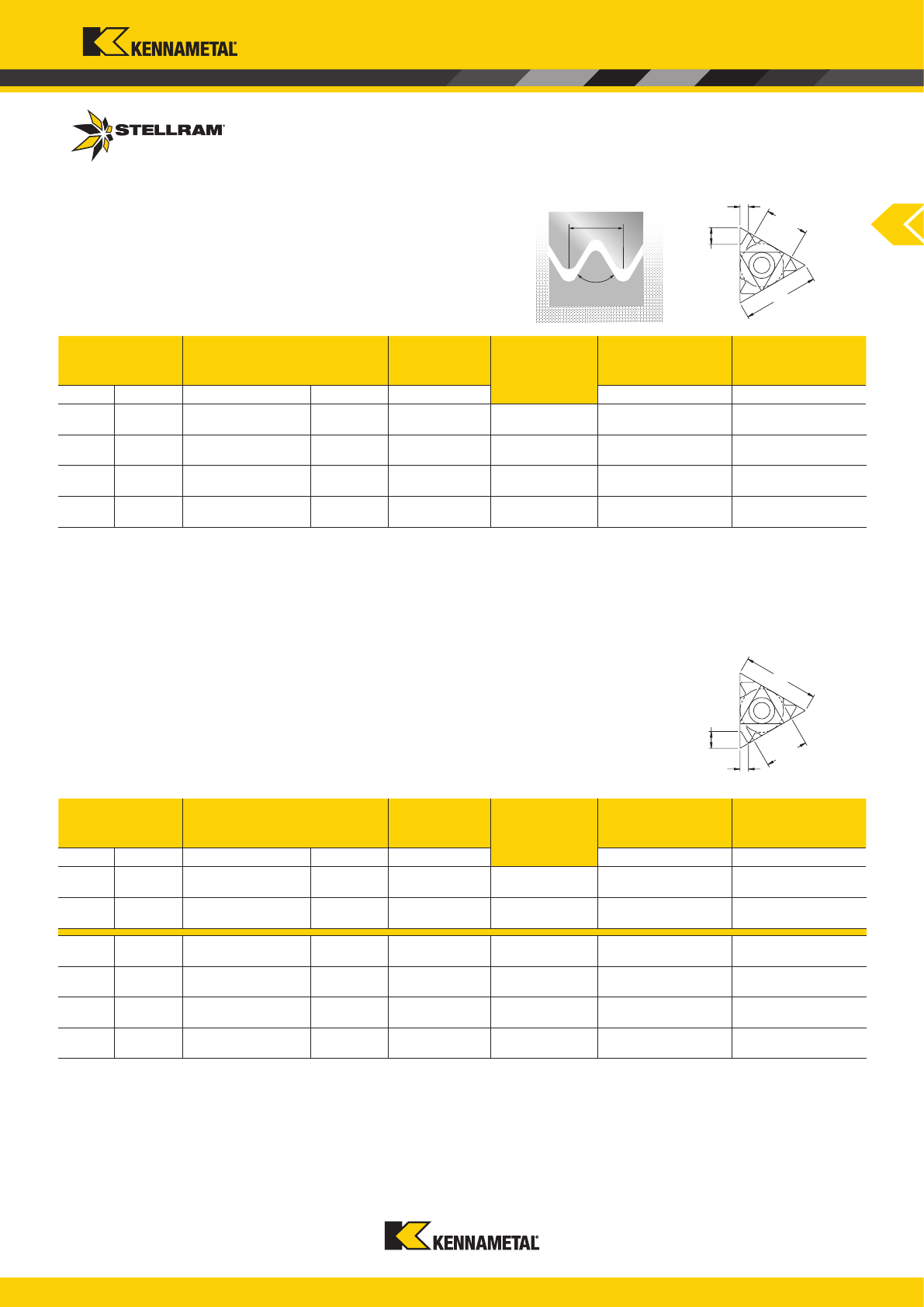

0,0

1B

SP0819

Vc (m/min)

150 -305

SP0819

Vc (m/min)

90 - 185

f

n

(mm/rev)

0,15 - 0,4

a

p

(mm)

0,25 - 2,5

f

n

(mm/rev)

0,12 - 0,40

a

p

(mm)

1,25 - 3,0

SP4019

Vc (m/min)

135 - 300

NL920

Vc (m/min)

30 - 60

SP4019

Vc (m/min)

80 - 180

3J

3J

2N

2N

3J

4T

NL250

Vc (m/min)

105 - 275

NL920

Vc (m/min)

30 - 60

NL400

Vc (m/min)

55 - 150

f

n

(mm/rev)

0,35 -0,55

a

p

(mm)

2,5 -5,0

0,0

62

SP4019

Vc (m/min)

135 - 300

SP4019

Vc (m/min)

55 - 120

SP4019

Vc (m/min)

80 - 180

f

n

(mm/rev)

0,025 - 0,25

a

p

(mm)

0,75 - 3,0

73

SP4019

Vc (m/min)

135 - 300

NL920

Vc (m/min)

30 - 60

SP4019

Vc (m/min)

80 - 180

f

n

(mm/rev)

0,07 - 0,5

a

p

(mm)

0,4 - 5,0

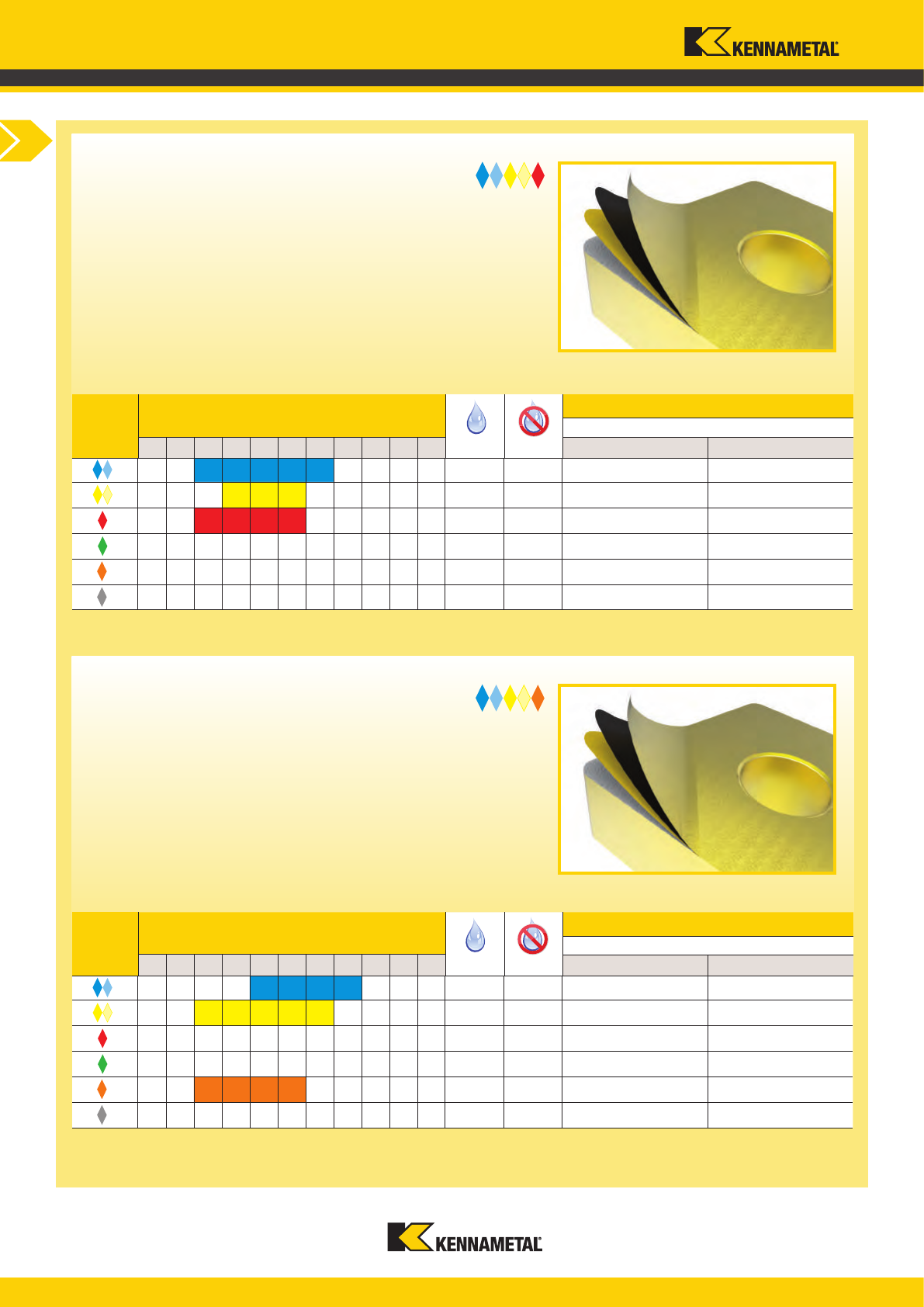

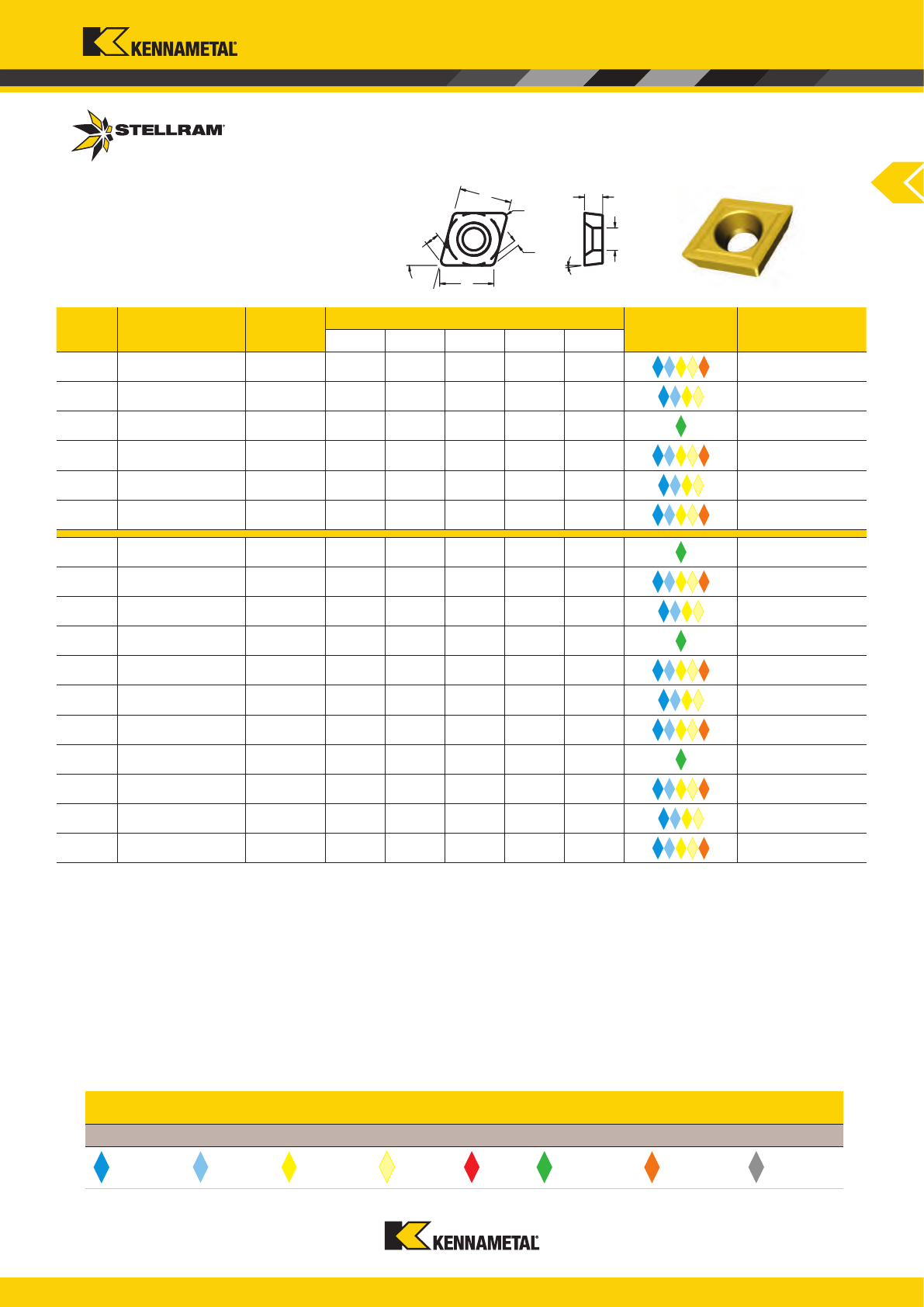

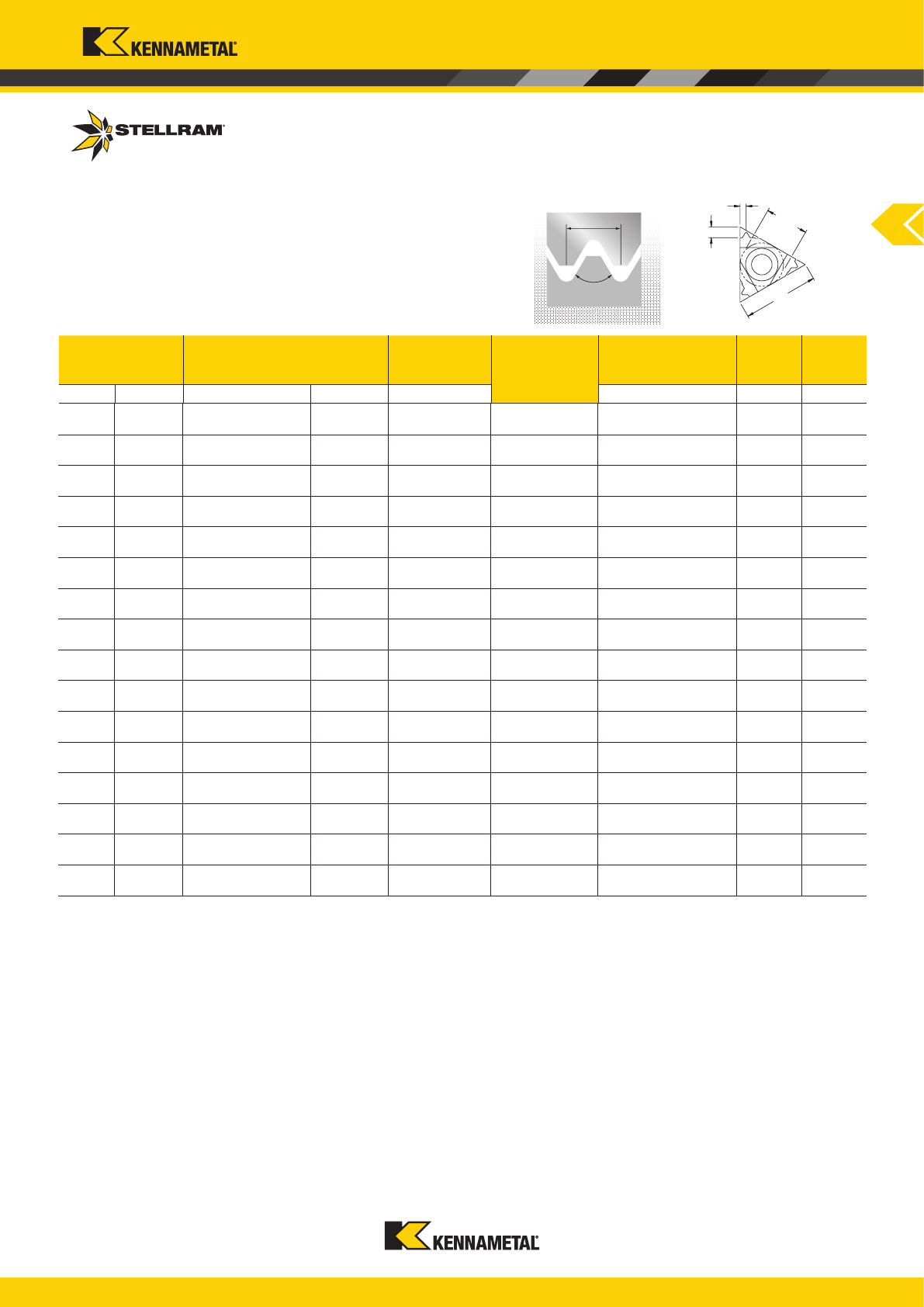

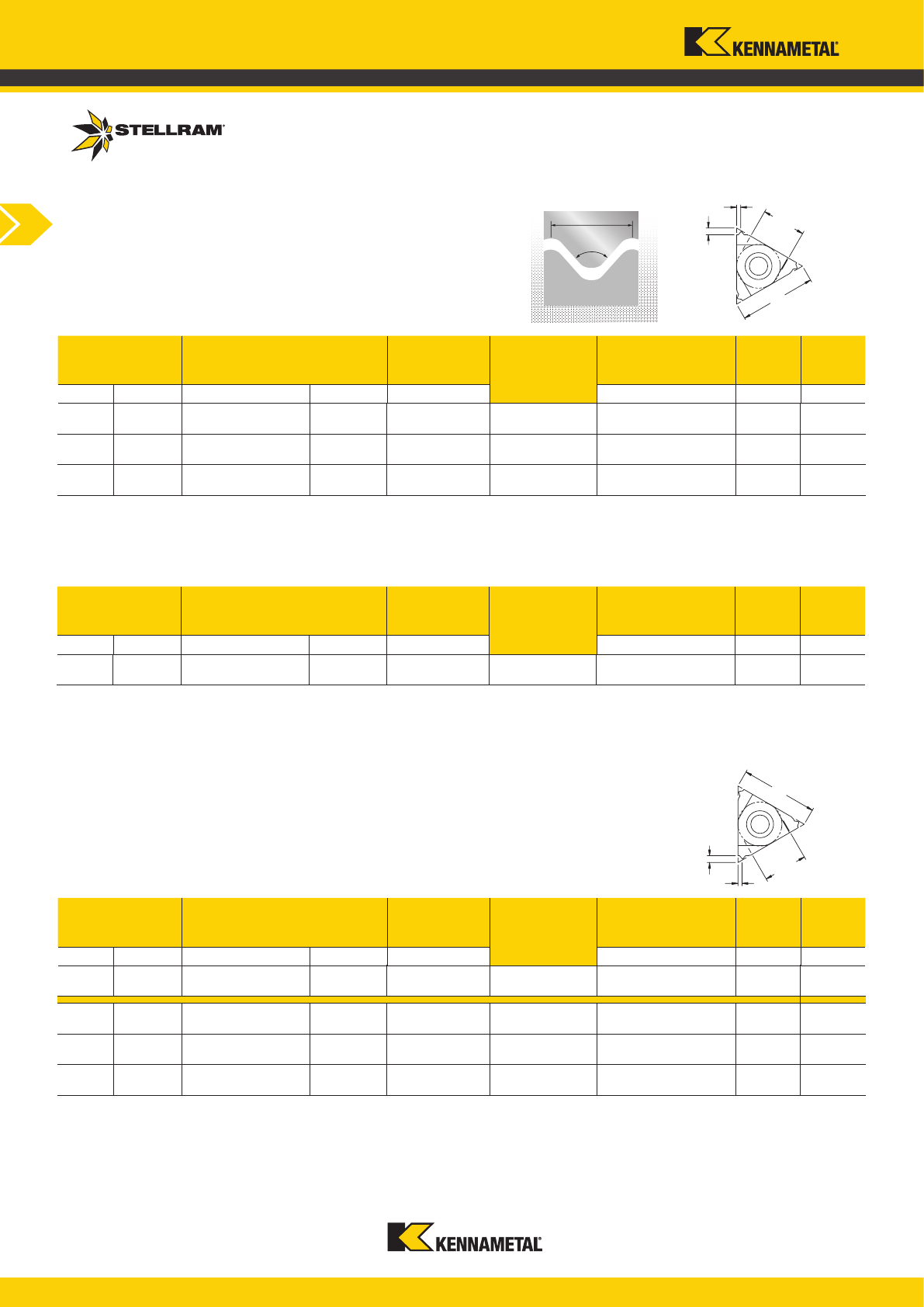

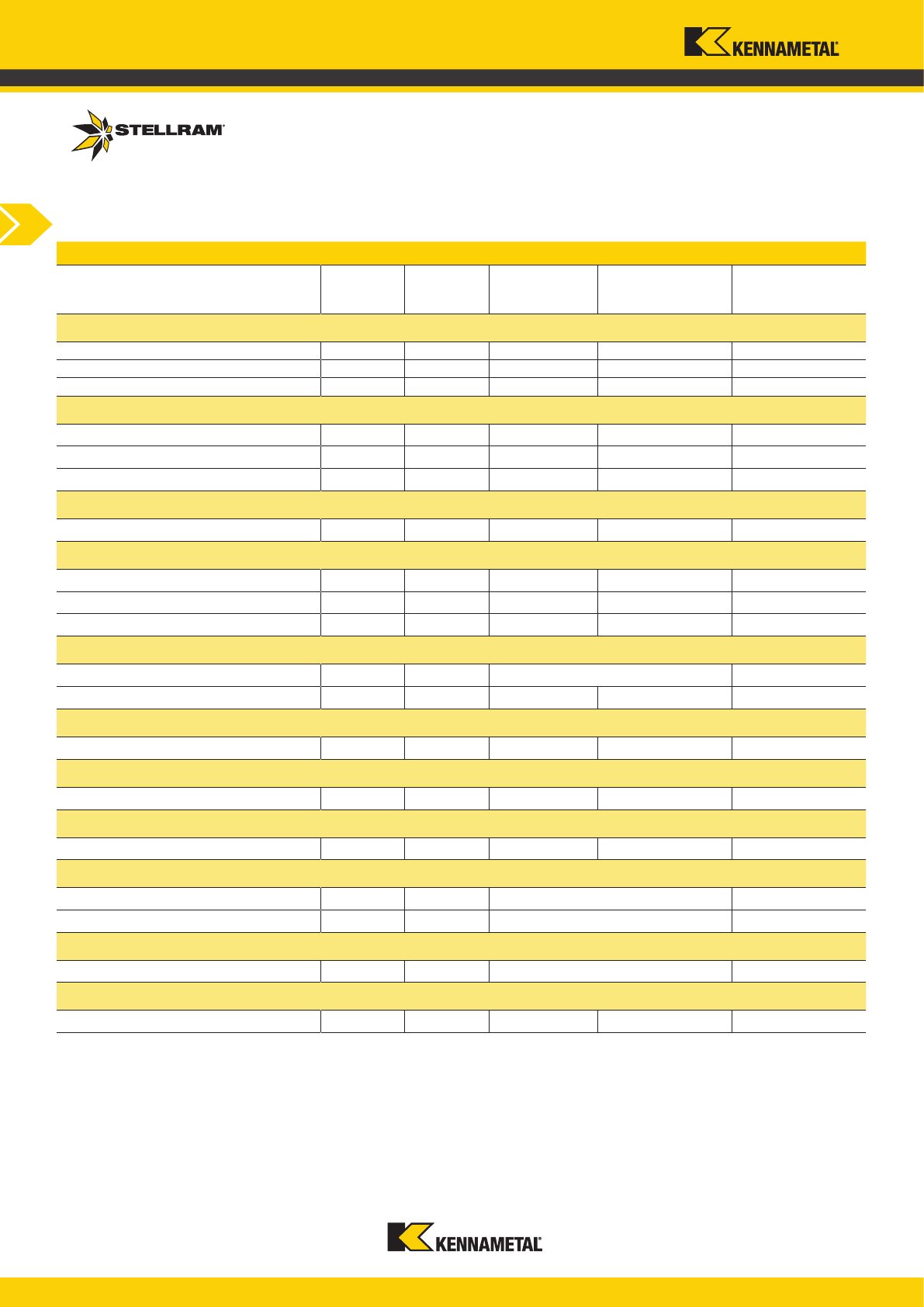

Introduction

MEDIUM-

ROUGHING

FINISHING

ROUGHING

MEDIUM

FINISHING

*Note: For Heavy Roughing applications see 5R geometry, page C17.

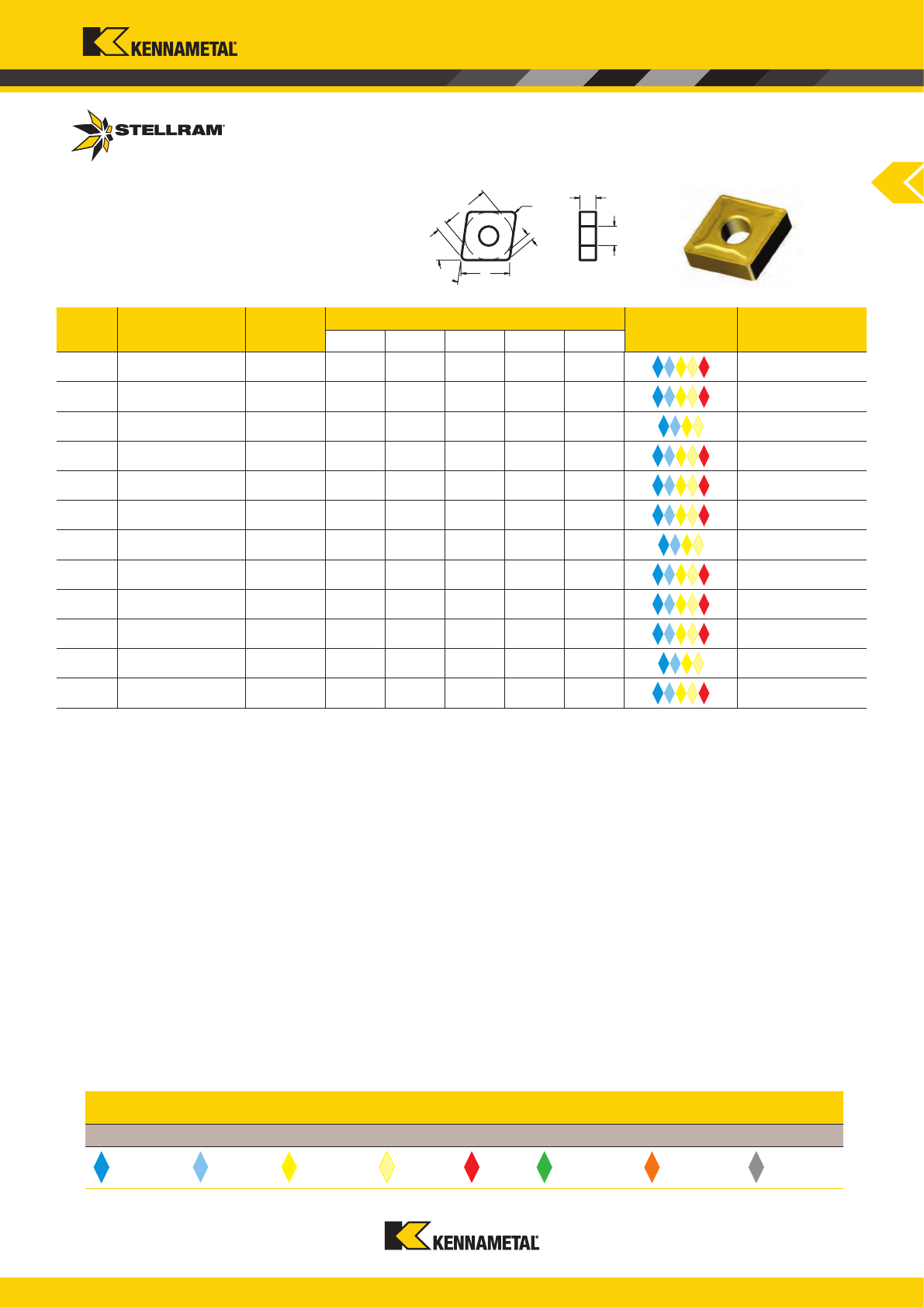

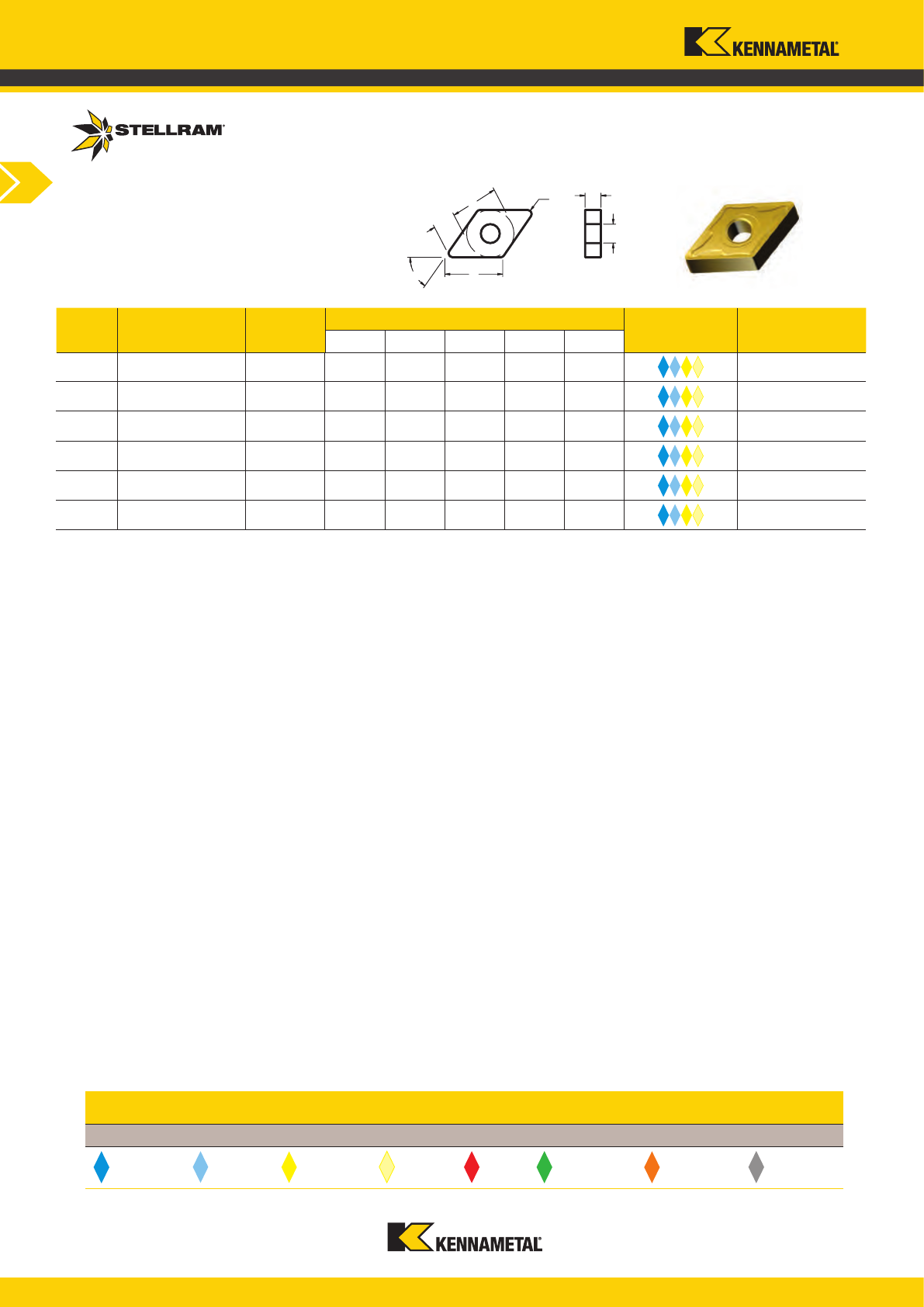

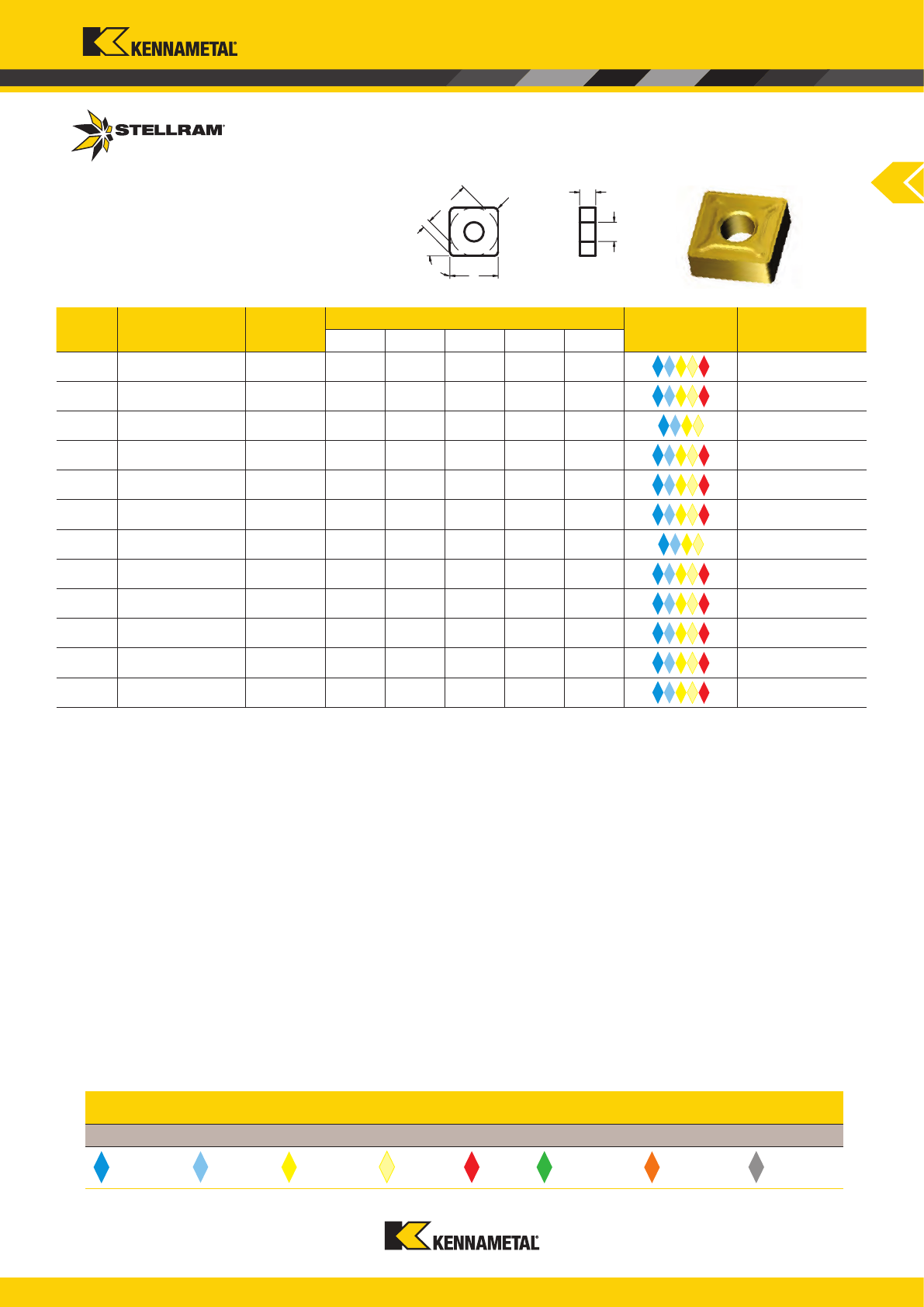

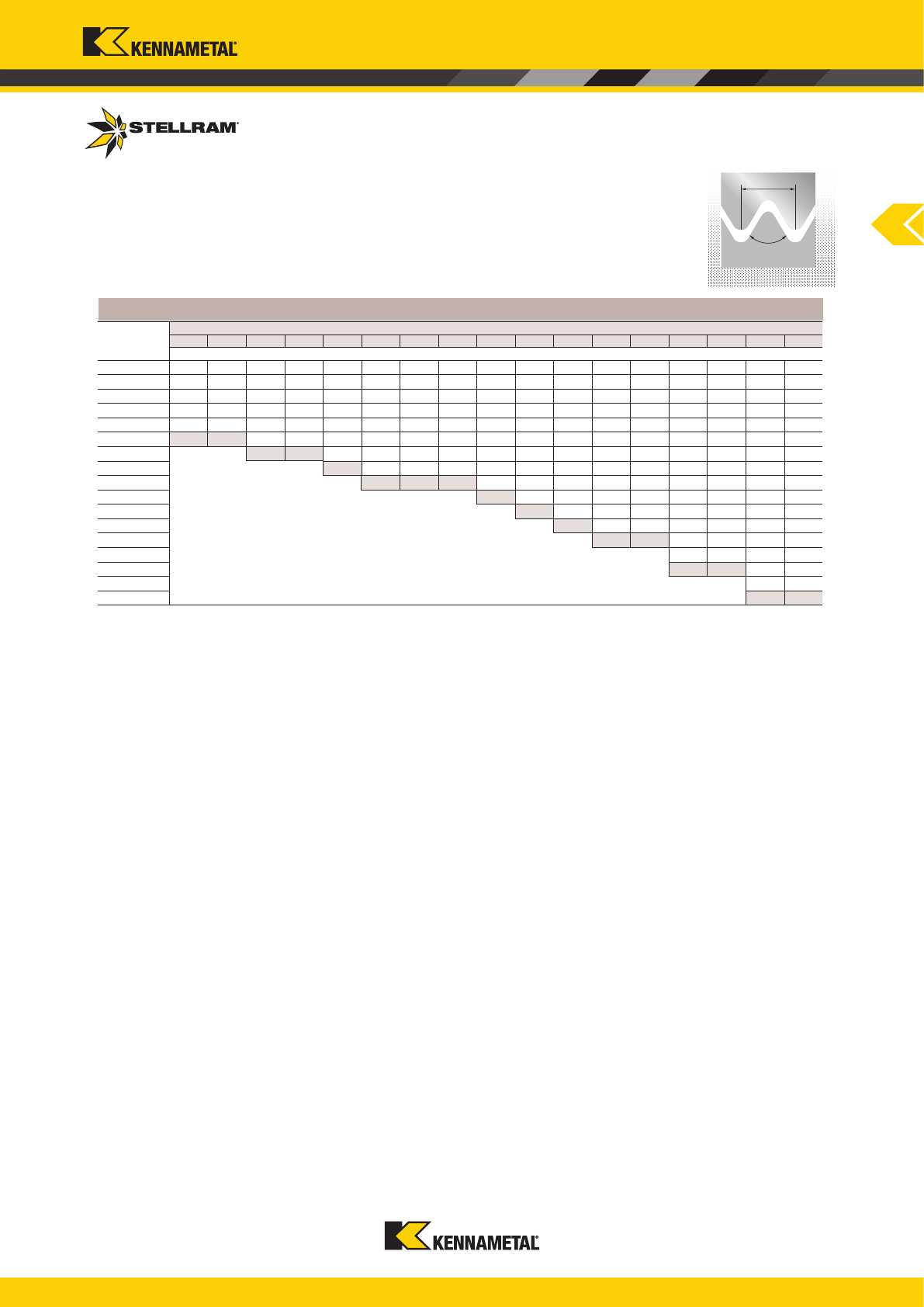

Metric

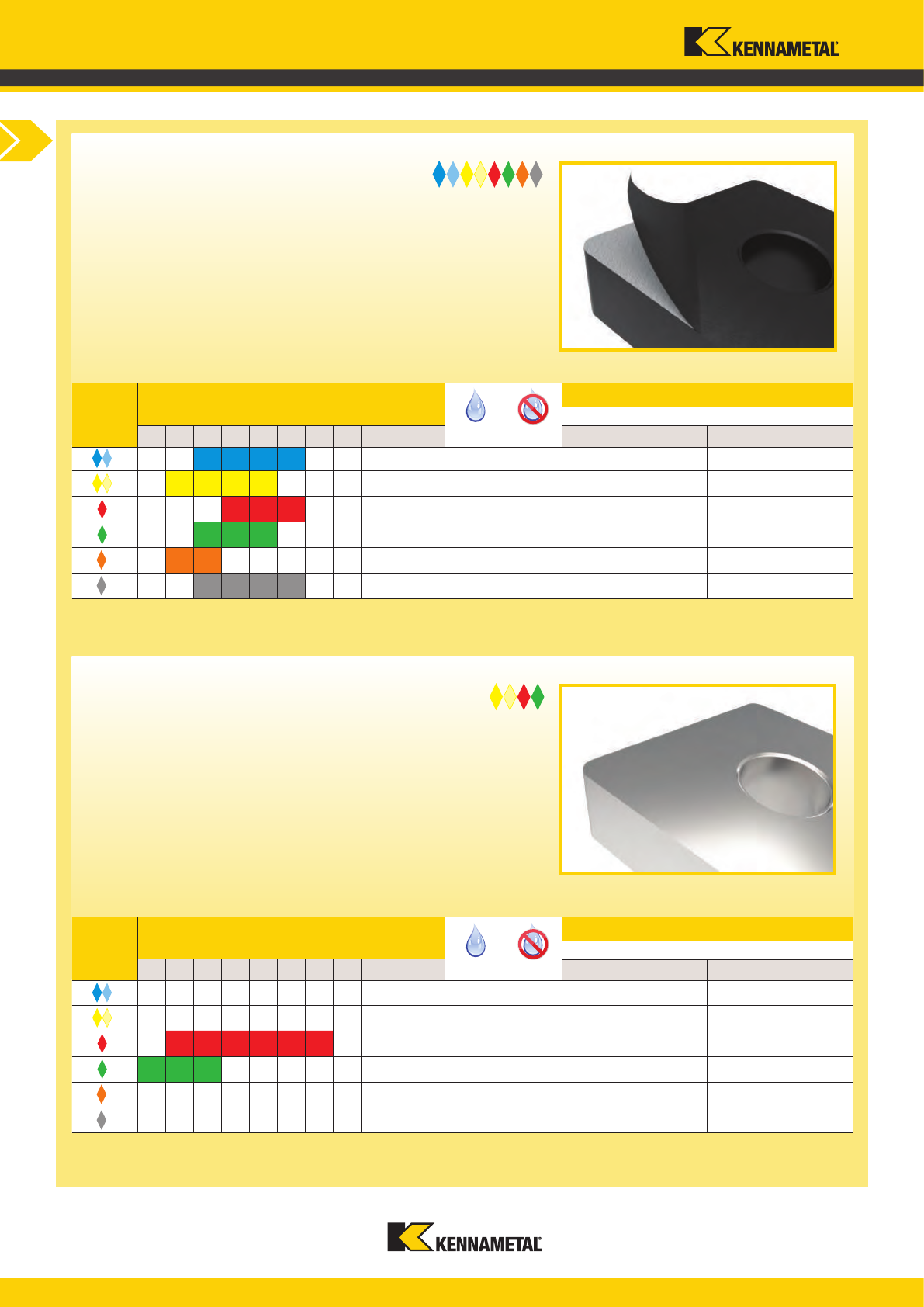

Positive Inserts – Stainless Steel

Metric

Negative Inserts – Stainless Steel

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Negative/Positive

First Choice — Stainless Steel 300-400

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C7

*

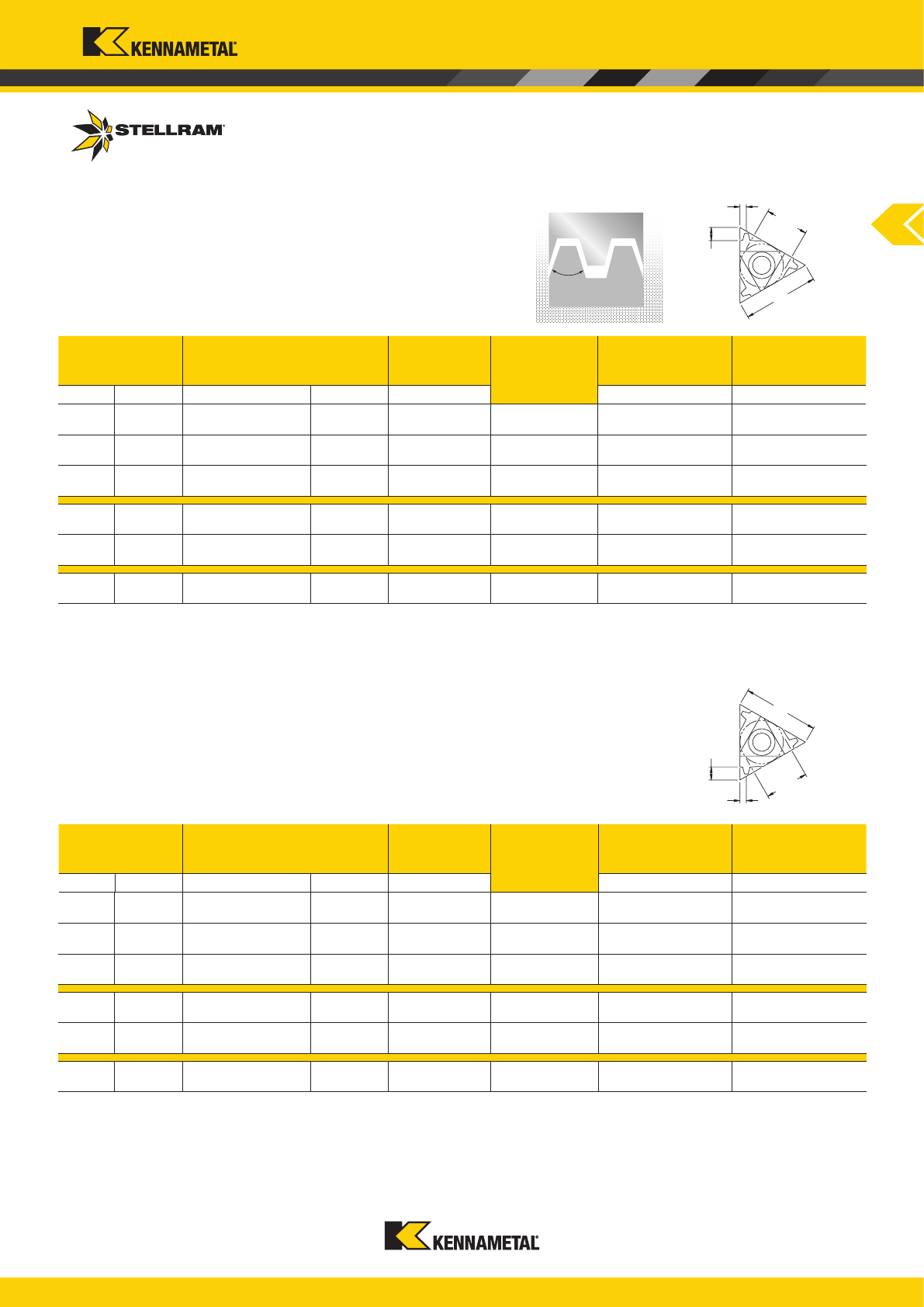

0,0

1B

SP0819

Vc (m/min)

75 -165

SP0819

Vc (m/min)

45 - 100

f

n

(mm/rev)

0,15 - 0,4

a

p

(mm)

0,25 - 2,5

4E

SP0819

Vc (m/min)

75 - 165

NL400

Vc (m/min)

20 - 50

SP0819

Vc (m/min)

45 - 100

f

n

(mm/rev)

0,20 - 0,45

a

p

(mm)

0,75 - 3,5

4T

NL250

Vc (m/min)

60 - 146

NL920

Vc (m/min)

20 - 35

NL400

Vc (m/min)

30 - 80

f

n

(mm/rev)

0,35 -0,55

a

p

(mm)

2,5 -5,0

0,0

62

SP4019

Vc (m/min)

75- 160

SP4019

Vc (m/min)

30 - 65

SP4019

Vc (m/min)

45 - 100

f

n

(mm/rev)

0,025 - 0,25

a

p

(mm)

0,75 - 3,0

73

SP4019

Vc (m/min)

75 - 160

NL920

Vc (m/min)

20 - 35

SP4019

Vc (m/min)

45 - 100

f

n

(mm/rev)

0,07 - 0,5

a

p

(mm)

0,4 - 5,0

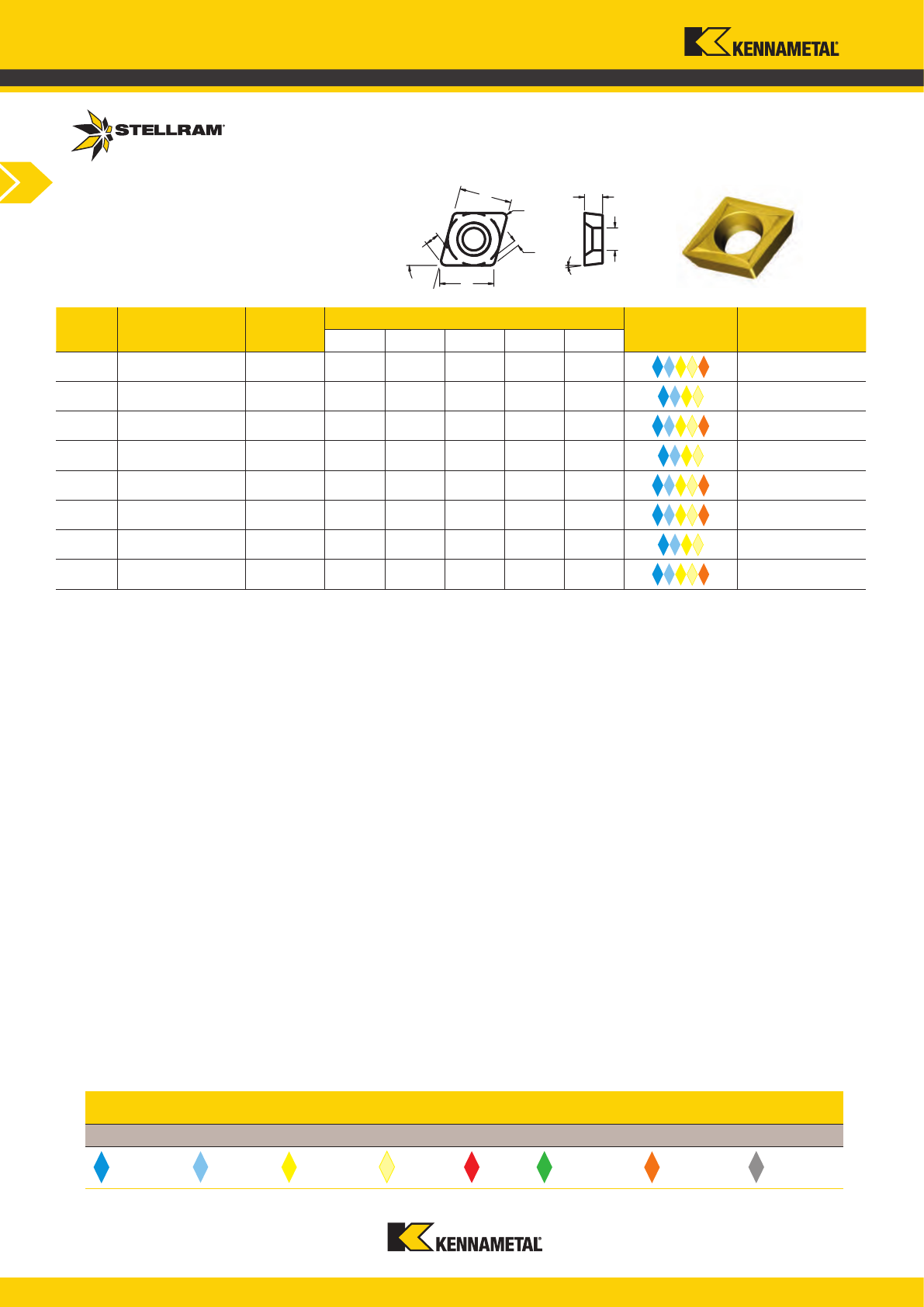

Introduction

MEDIUM-

ROUGHING

FINISHING

ROUGHING

MEDIUM

FINISHING

*Note: For Heavy Roughing applications see 5R geometry, page C17.

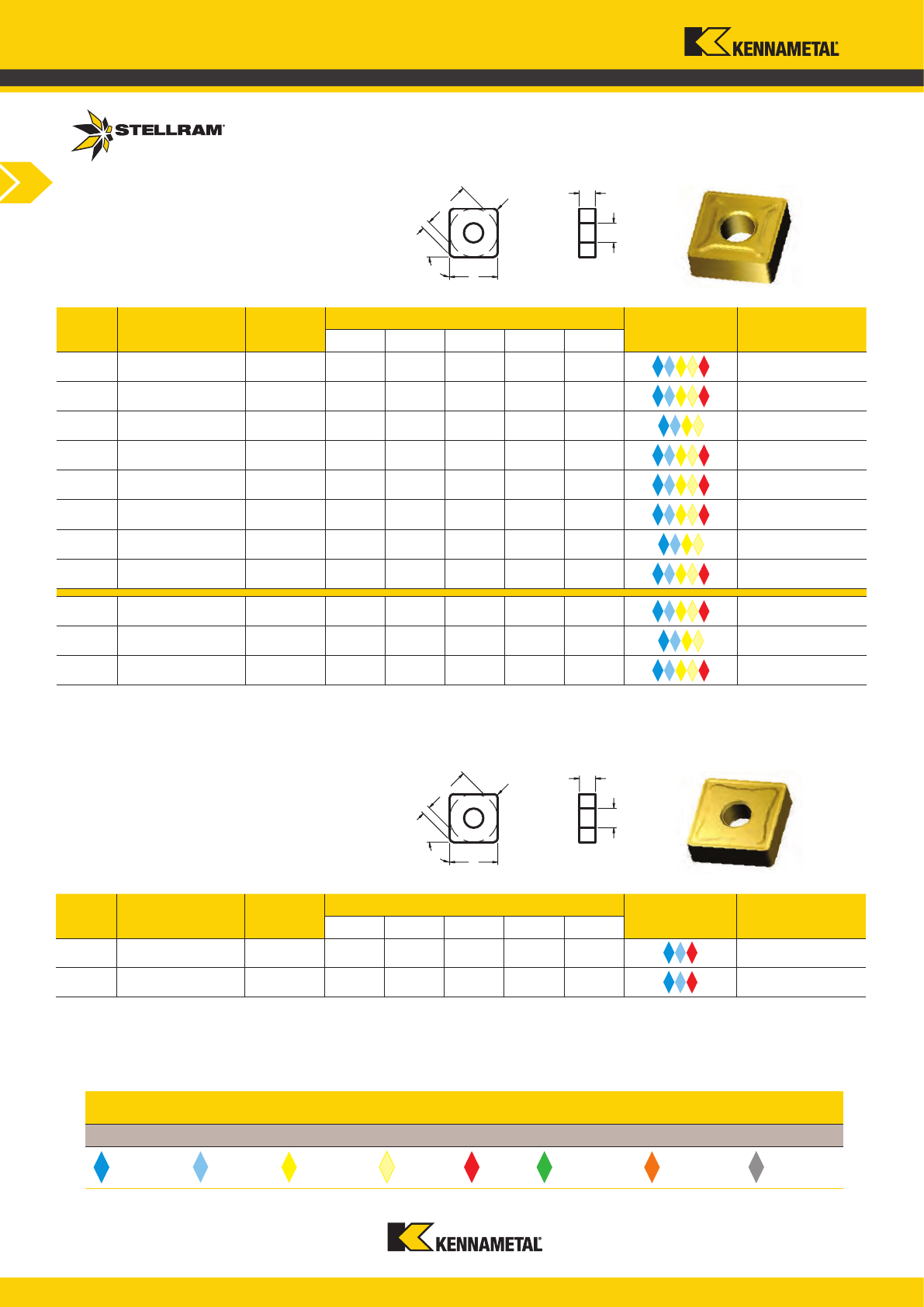

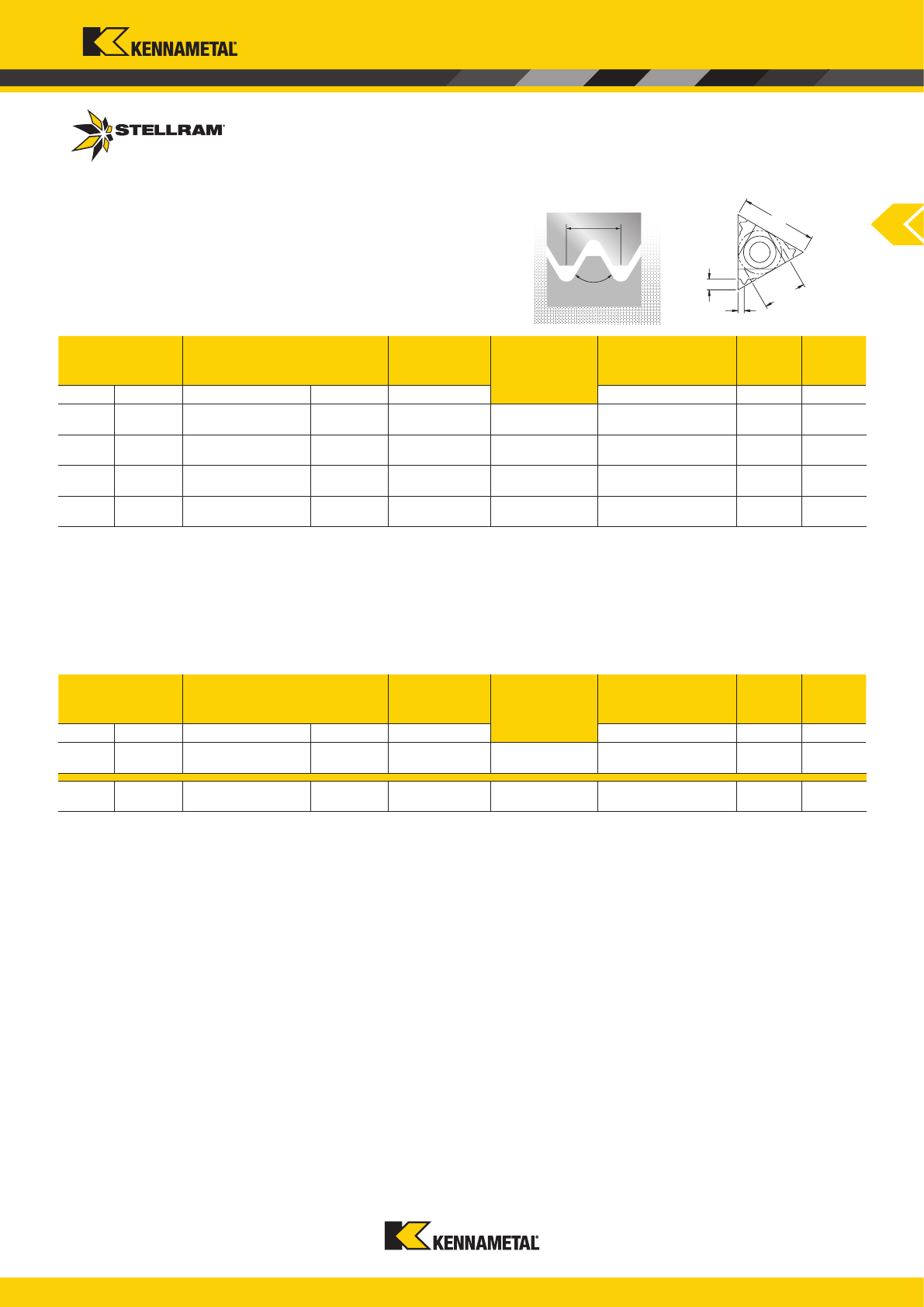

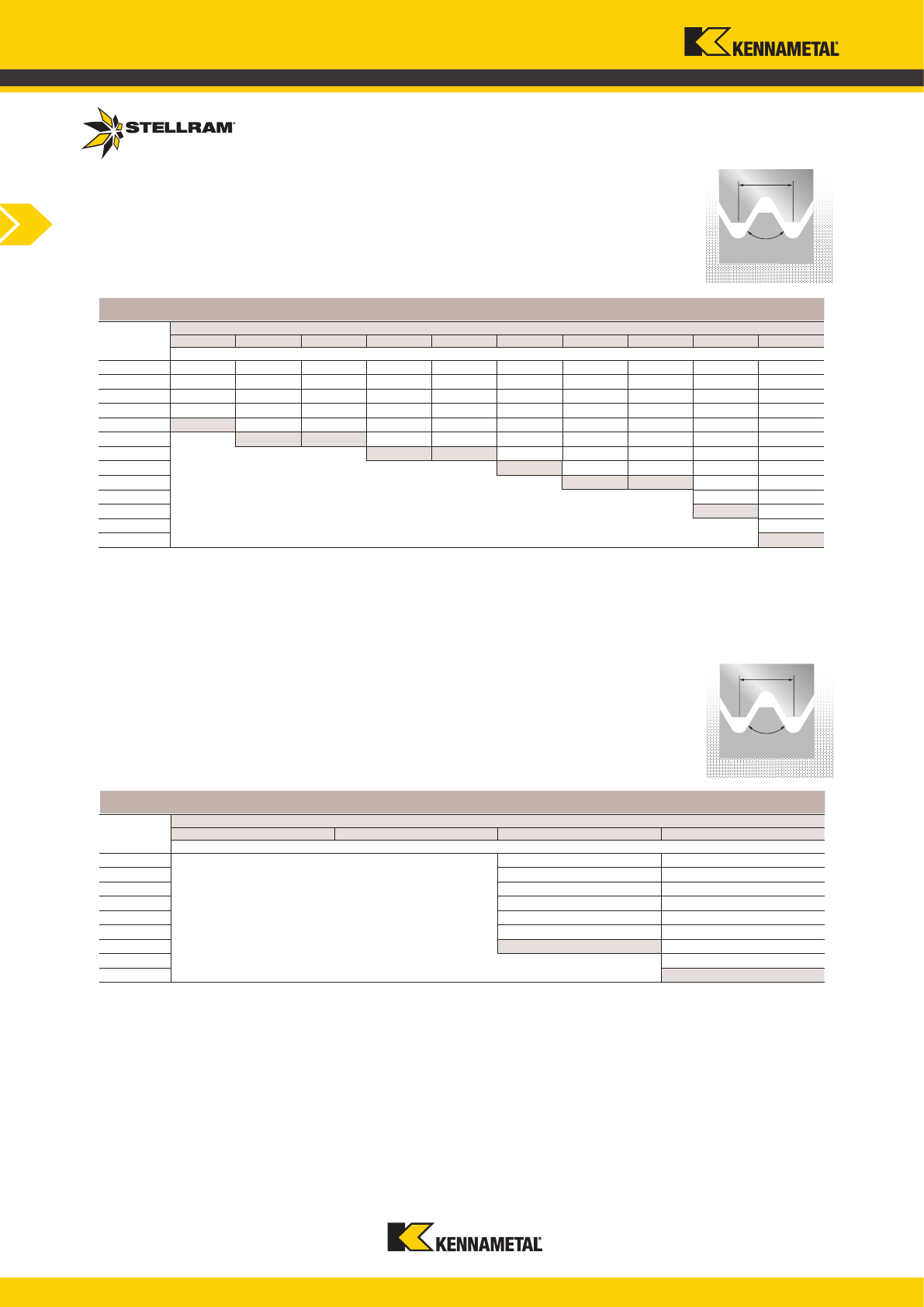

Metric

Positive Inserts – Stainless Steel PH

Metric

Negative Inserts – Stainless Steel PH

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Negative/Positive

First Choice — Stainless Steel PH

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C8

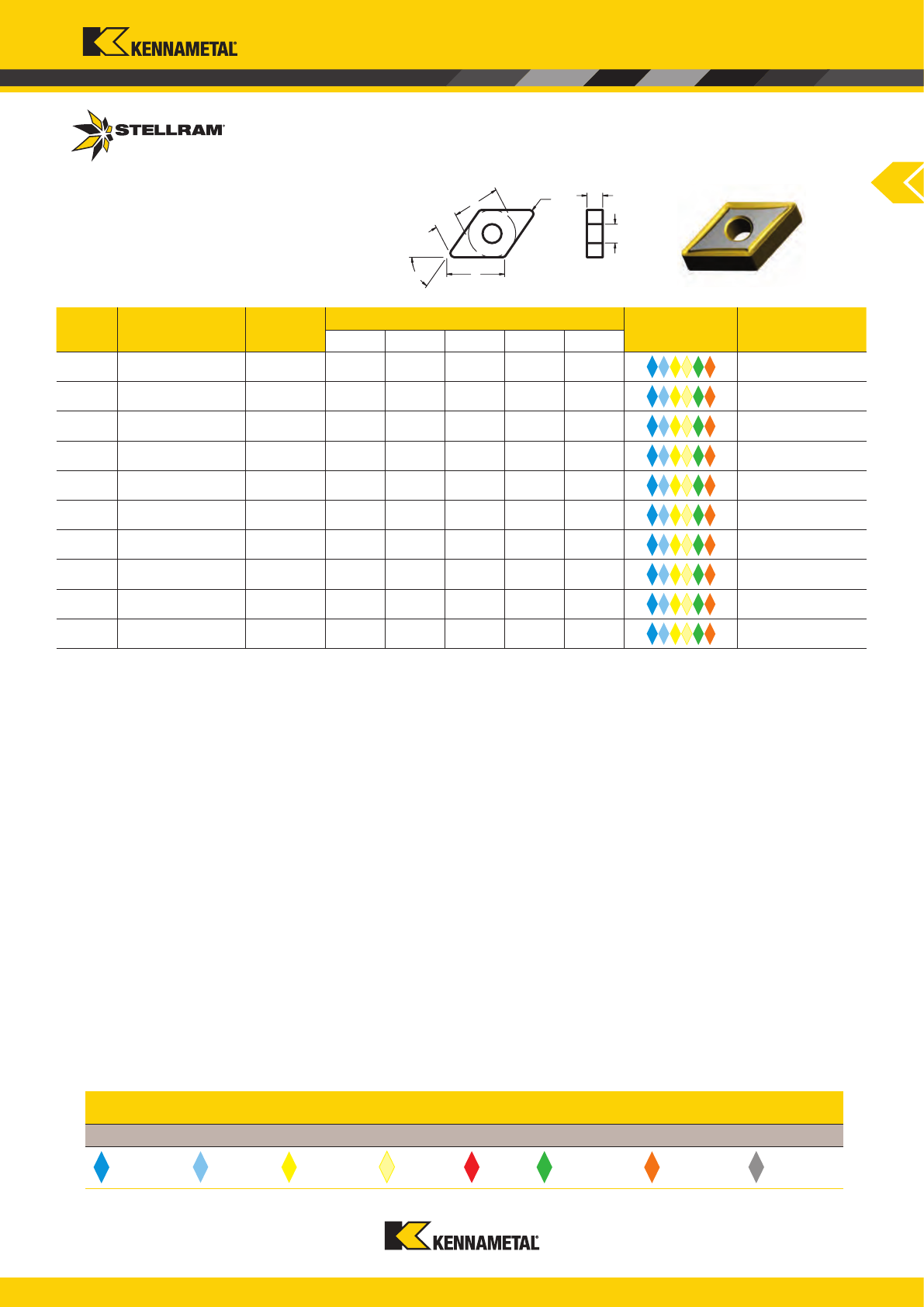

0,0

4U

NL200

Vc (m/min)

95 - 410

NL200

Vc (m/min)

40 - 165

NL200

Vc (m/min)

60 - 245

f

n

(mm/rev)

0,1 - 0,55

a

p

(mm)

0,5 - 4,0

4U

NL200

Vc (m/min)

95 - 410

NL200

Vc (m/min)

40 - 165

NL200

Vc (m/min)

60 - 245

f

n

(mm/rev)

0,1 - 0,55

a

p

(mm)

0,5 - 4,0

NL200

Vc (m/min)

95 - 410

NL250

Vc (m/min)

40 - 150

NL250

Vc (m/min)

60 - 225

f

n

(mm/rev)

0,2 - 0,6

a

p

(mm)

0,5 - 9,0

PLATE

4U

Flat

4U

Flat

0,0

62

SP4019

Vc (m/min)

120 - 440

SP4019

Vc (m/min)

70 - 265

f

n

(mm/rev)

0,025 - 0,25

a

p

(mm)

0,25 - 3,0

73

NL300

Vc (m/min)

90 - 335

NL300

Vc (m/min)

55 - 200

f

n

(mm/rev)

0,07 - 0,5

a

p

(mm)

0,4 - 5,0

NL920

Vc (m/min)

25 - 80

Introduction

MEDIUM-

ROUGHING

FINISHING

ROUGHING

MEDIUM

FINISHING

Metric

Positive Inserts – Cast Iron

Metric

Negative Inserts – Cast Iron

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Negative/Positive

First Choice — Cast Iron

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C9

0,0

3F

SP0819

Vc (m/min)

275 - 975

SP0819

Vc (m/min)

165 - 585

f

n

(mm/rev)

0,2 - 0,35

a

p

(mm)

1,0 - 3,0

0.0

-X

GH1

Vc (m/min)

180 - 825

GH1

Vc (m/min)

110 - 495

f

n

(mm/rev)

0,05 - 0,2

a

p

(mm)

0,8 - 2,0

64

GH1

Vc (m/min)

180 -825

GH1

Vc (m/min)

70 - 330

GH1

Vc (m/min)

110 - 495

f

n

(mm/rev)

0,35 - 0,6

a

p

(mm)

2,0 - 6,0

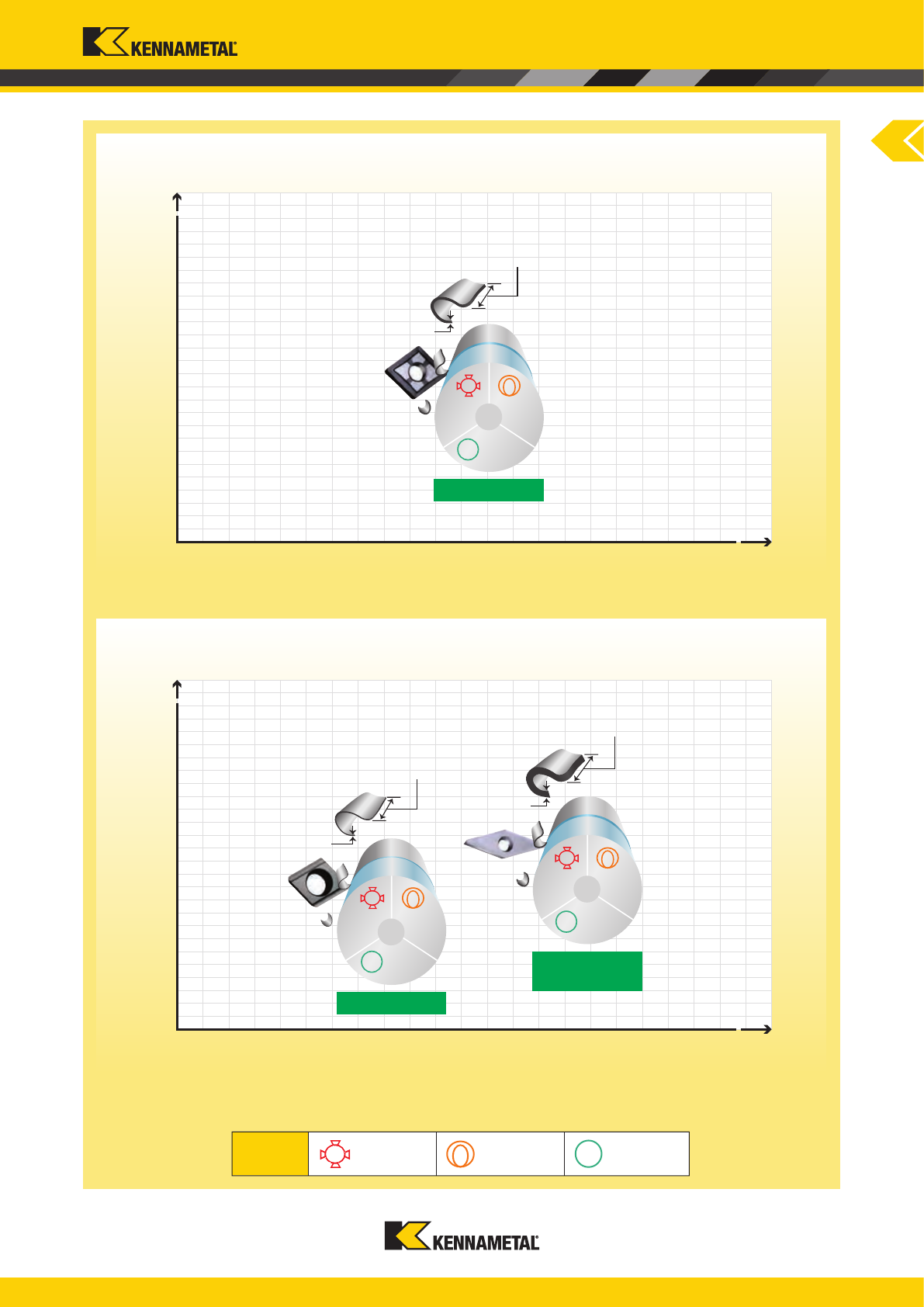

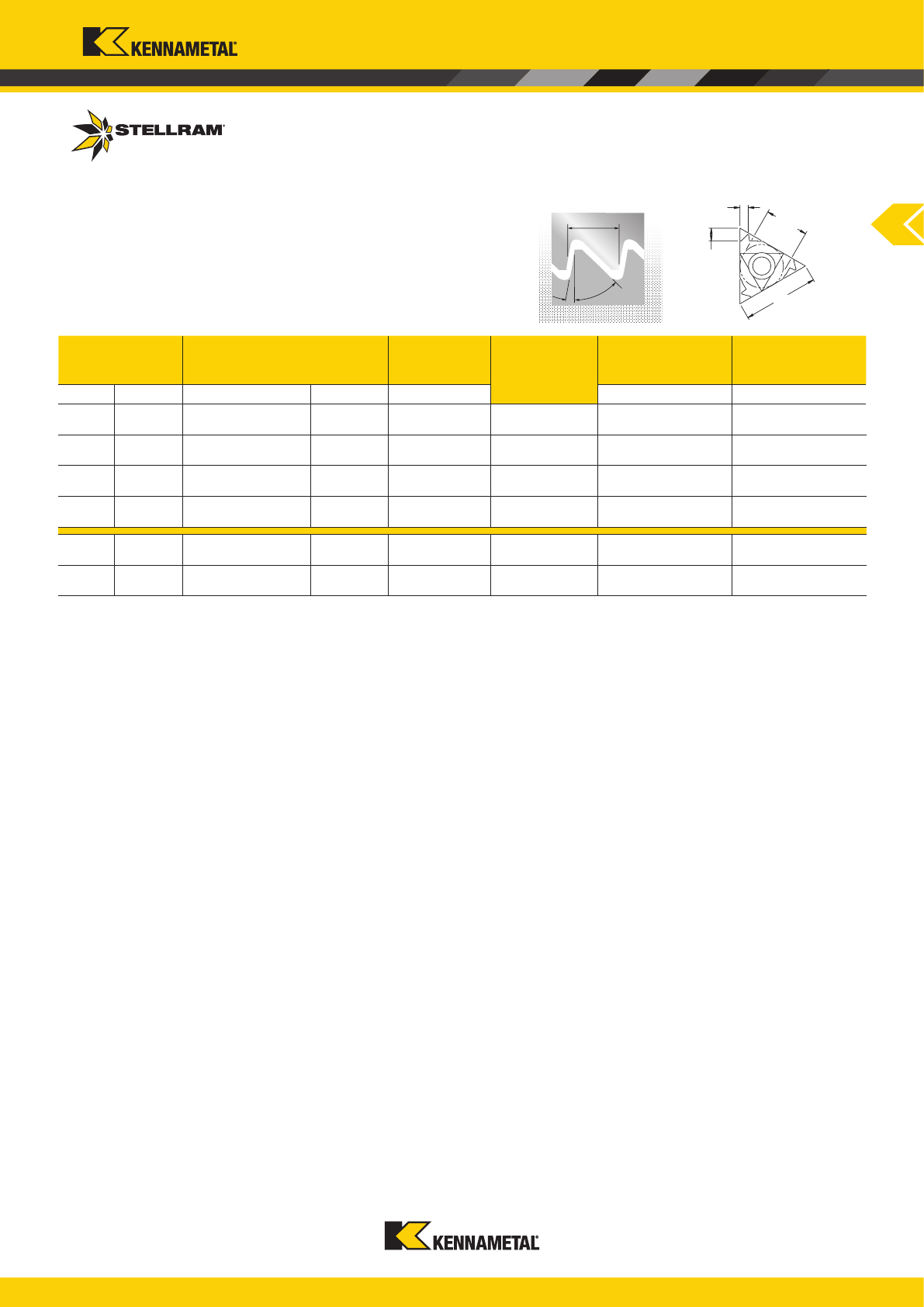

Introduction

MEDIUM-

ROUGHING

FINISHING

MEDIUM

Metric

Positive Inserts – Aluminum & Alloys

Metric

Negative Inserts – Aluminum & Alloys

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Negative/Positive

First Choice — Aluminum & Alloys

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C10

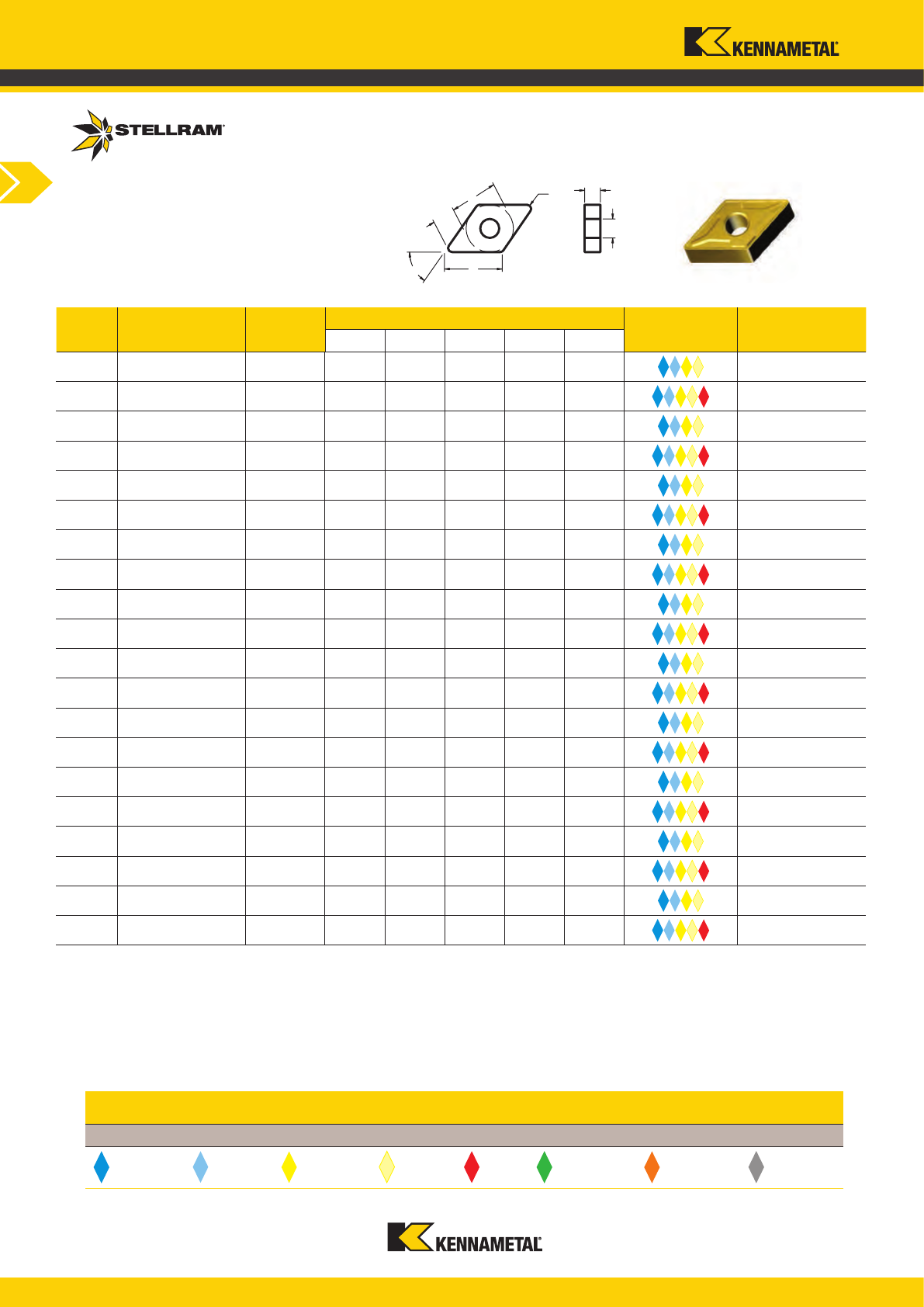

*

0,0

1B

SP0819

Vc (m/min)

30 - 90

SP0819

Vc (m/min)

20 - 55

f

n

(mm/rev)

0,1 - 0,35

a

p

(mm)

0,5 - 2,5

4E

SP0819

Vc (m/min)

30 - 90

NL400

Vc (m/min)

10 - 30

SP0819

Vc (m/min)

20 - 55

f

n

(mm/rev)

0,20 - 0,45

a

p

(mm)

0,75 - 3,5

SA6609

Vc (m/min)

180 - 360

NL920

Vc (m/min)

10 - 20

NL400

Vc (m/min)

15 -40

f

n

(mm/rev)

0,3 - 0,5

a

p

(mm)

2,5 - 5,0

4T

Plate

Flat

4T 4T

0,0

62

SP4019

Vc (m/min)

25 - 90

SP4019

Vc (m/min)

10 - 40

SP4019

Vc (m/min)

15 - 55

f

n

(mm/rev)

0,025 - 0,25

a

p

(mm)

0,25 - 3,0

73

SP4019

Vc (m/min)

25 - 40

NL920

Vc (m/min)

10 - 30

f

n

(mm/rev)

0,07 - 0,4

a

p

(mm)

0,4 - 3,0

Introduction

MEDIUM-

ROUGHING

FINISHING

ROUGHING

MEDIUM

FINISHING

*Note: For Heavy Roughing applications see 5R geometry, page C17.

Metric

Positive Inserts – High Temperature Alloys

Metric

Negative Inserts – High Temperature Alloys

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Negative/Positive

First Choice — High Temperature Alloys

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C11

0,0

1B

SP0819

Vc (m/min)

65 - 140

SP0819

Vc (m/min)

40 - 85

f

n

(mm/rev)

0,1 - 0,25

a

p

(mm)

0,5 - 1,0

1B

SP0819

Vc (m/min)

65 -140

SP0819

Vc (m/min)

40 -85

f

n

(mm/rev)

0,1 - 0,25

a

p

(mm)

0,5 - 1,0

4U

NL200

Vc (m/min)

50 -120

f

n

(mm/rev)

0,1 - 0,25

a

p

(mm)

0,5 - 2,0

NL200

Vc (m/min)

20 -50

NL200

Vc (m/min)

30 -70

0,0

62

SP4019

Vc (m/min)

60 - 130

SP4019

Vc (m/min)

40 - 80

f

n

(mm/rev)

0,025 - 0,15

a

p

(mm)

0,25 - 1,0

Introduction

FINISHING

ROUGHING

MEDIUM

FINISHING

Metric

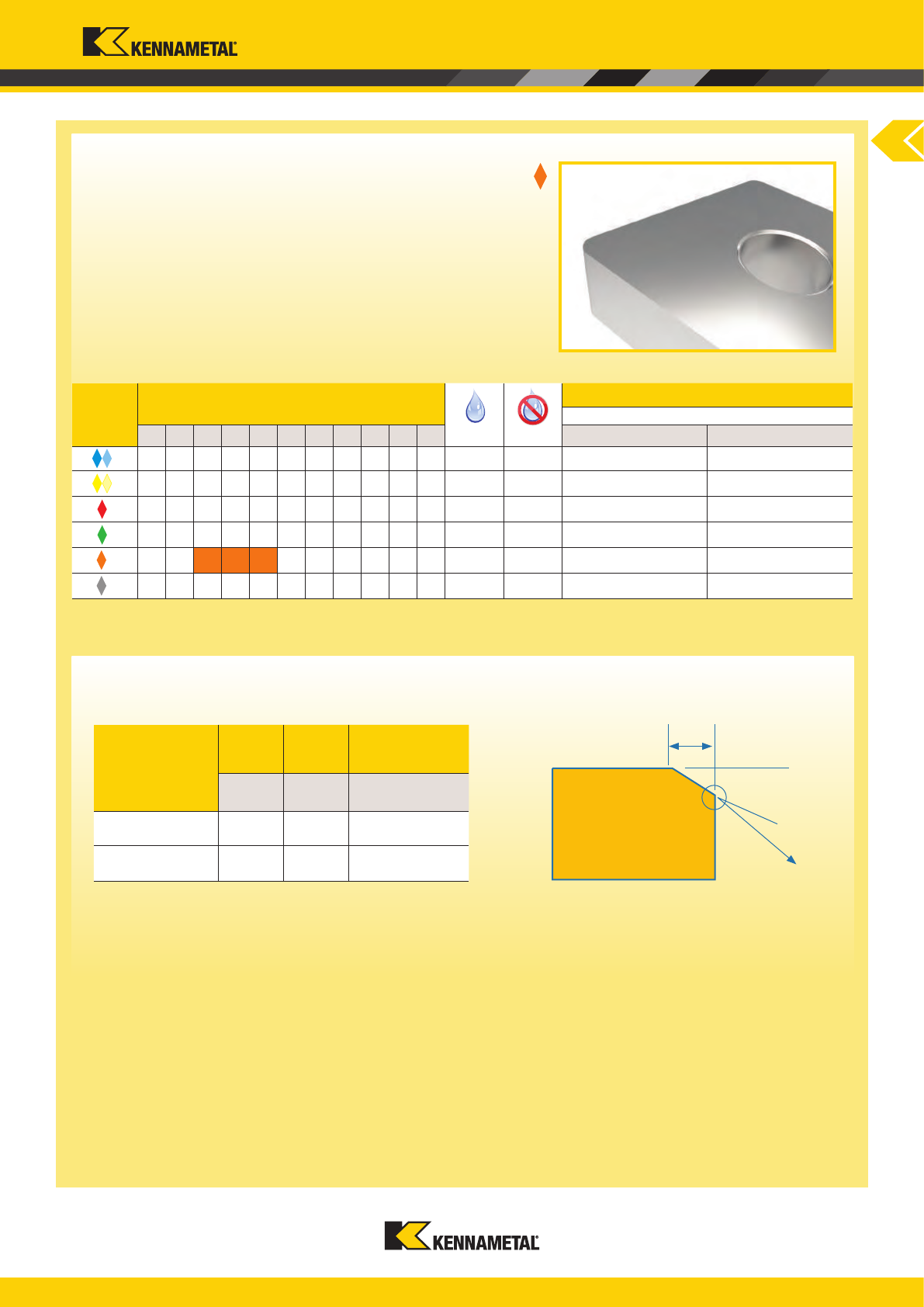

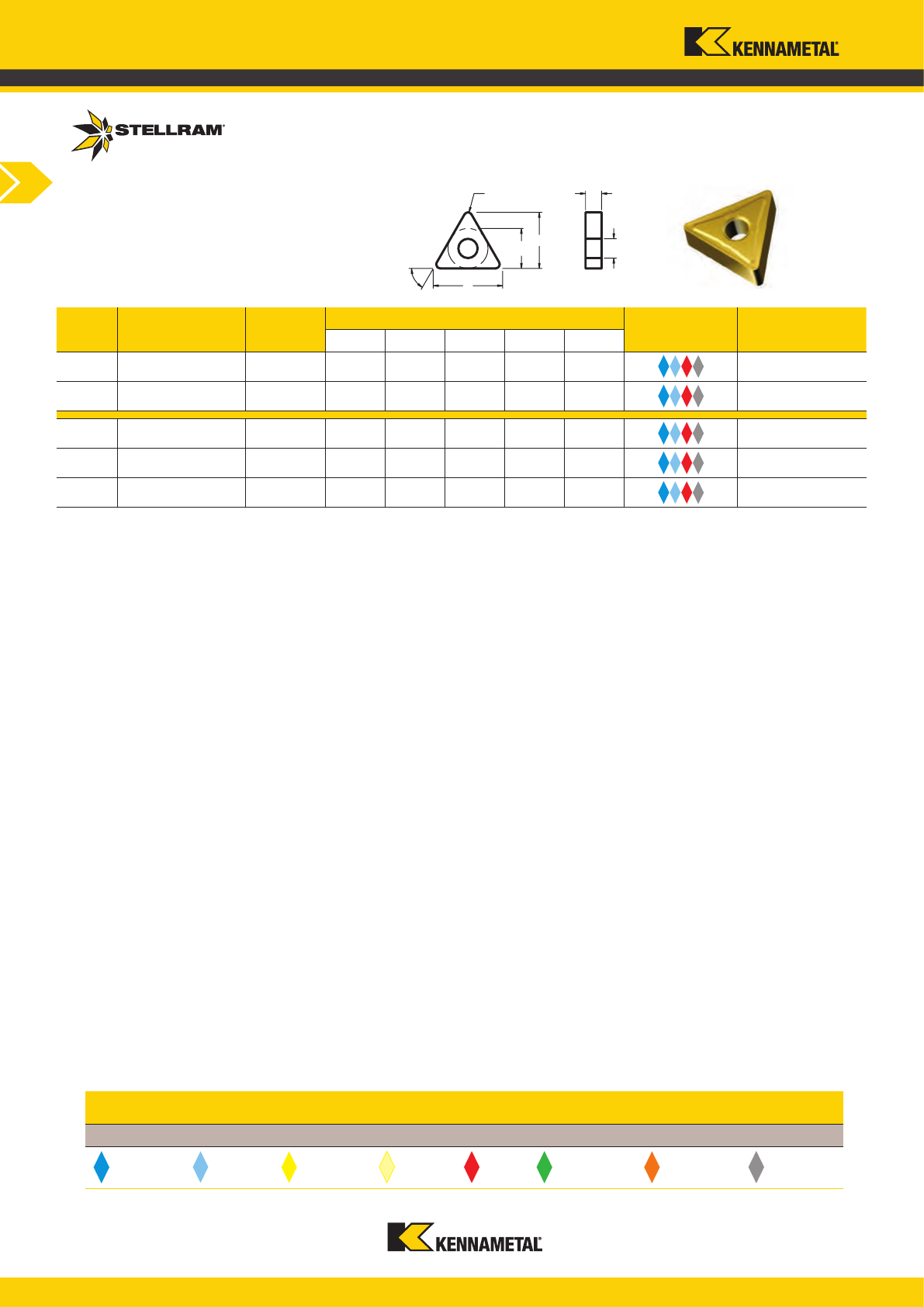

Positive Inserts – Hard Materials

Metric

Negative Inserts – Hard Materials

Please note the above recommended cutting speeds, geometries and grades are for guidance only.

For more detailed information, see pages C12 - C23 (geometry technical information & grade technical information).

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

D.O.C. a

p

(mm)

Feed f

n

(mm/rev)

Negative/Positive

First Choice — Hard Materials

Good

condition

Interrupted

cut

Varying depth

of cut

Key

www.kennametal.com

C12

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

0,50

a

p

(depth of cut

)

0.060

0.100

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.157

inchmm

inch

mm

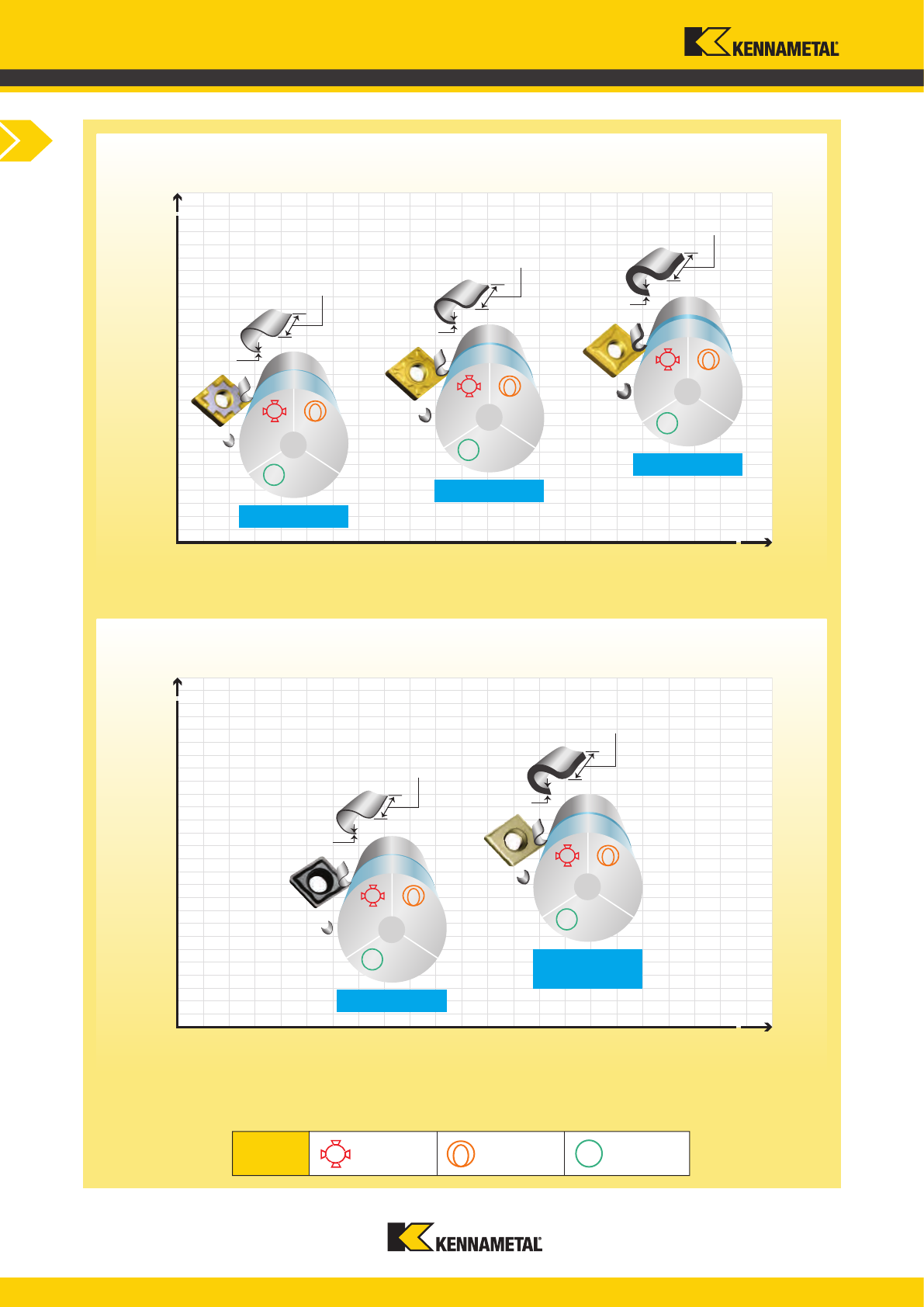

2N

4 4 4

NL250

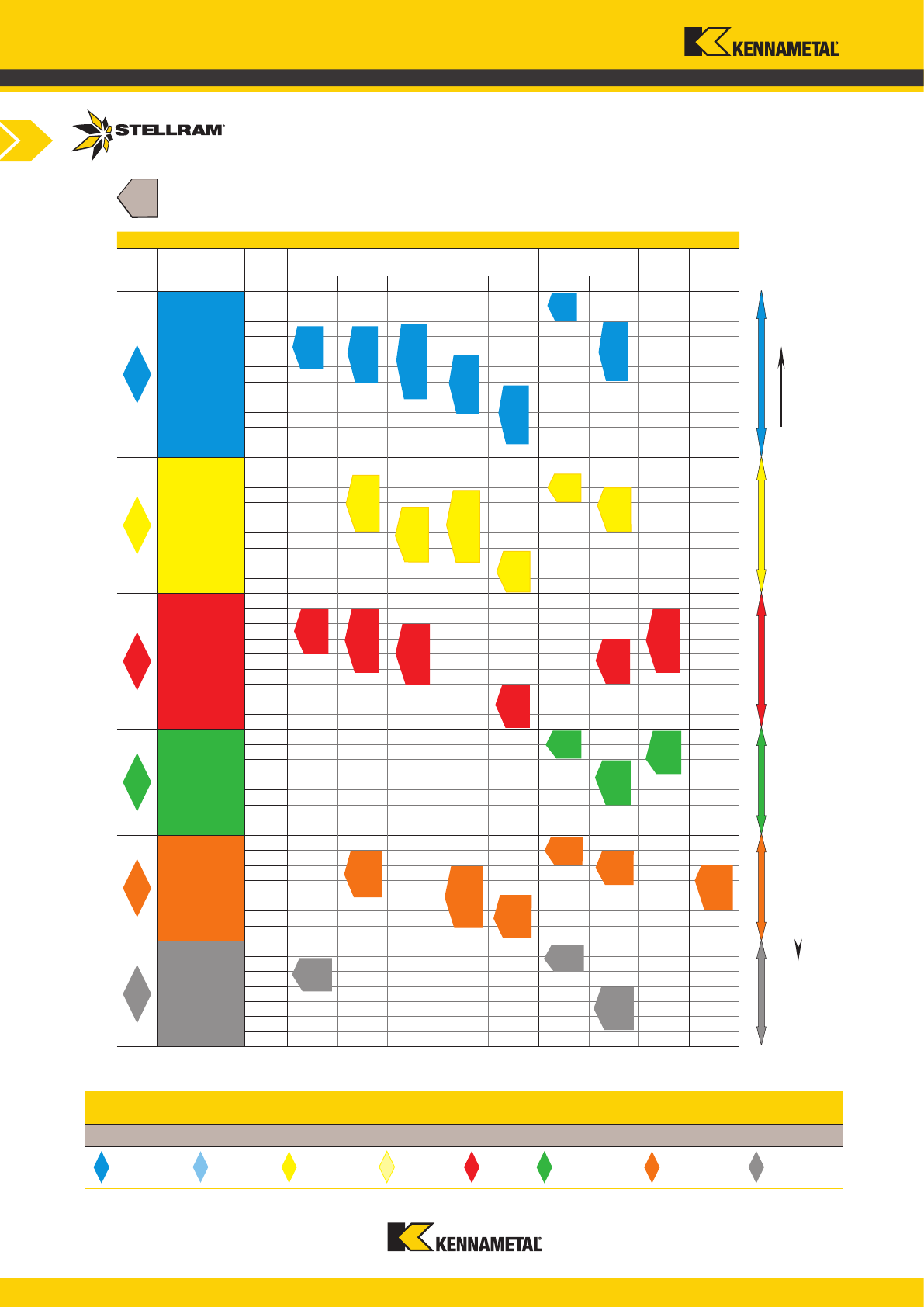

P M K N S H

NL300

P M K N S H

NL920

P M K N S H

2

1

3

4

5

4

5

2

3

1

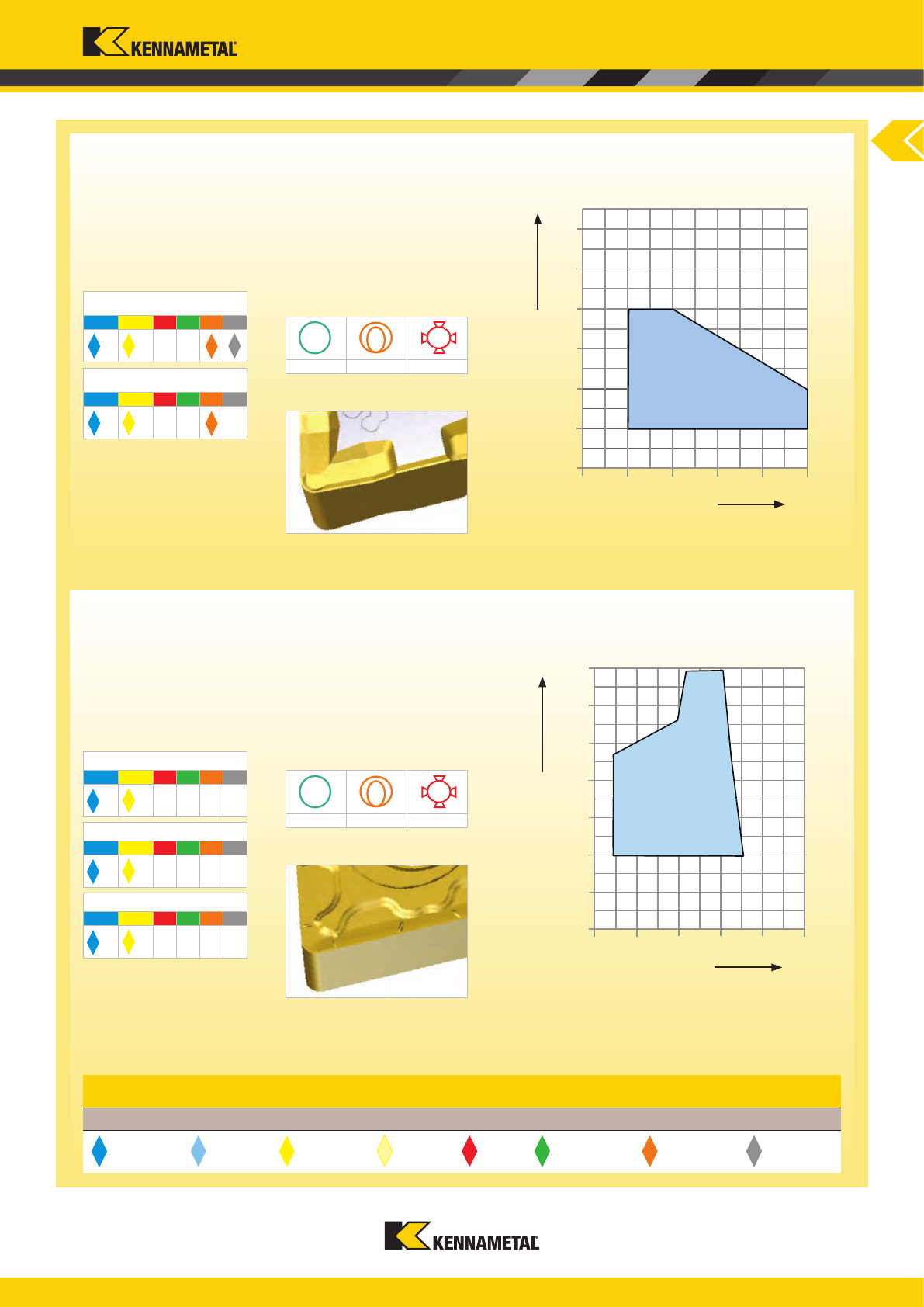

Introduction

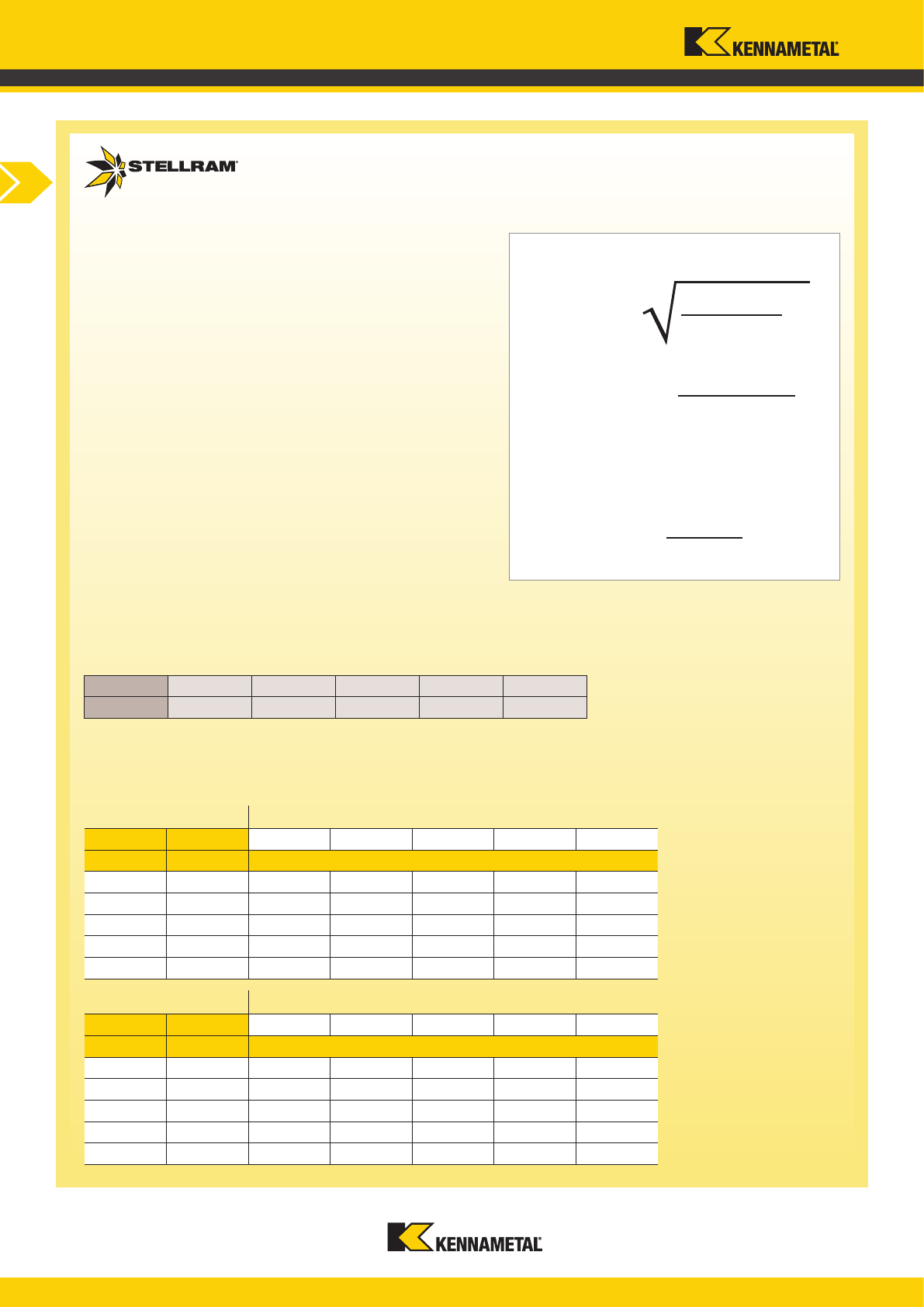

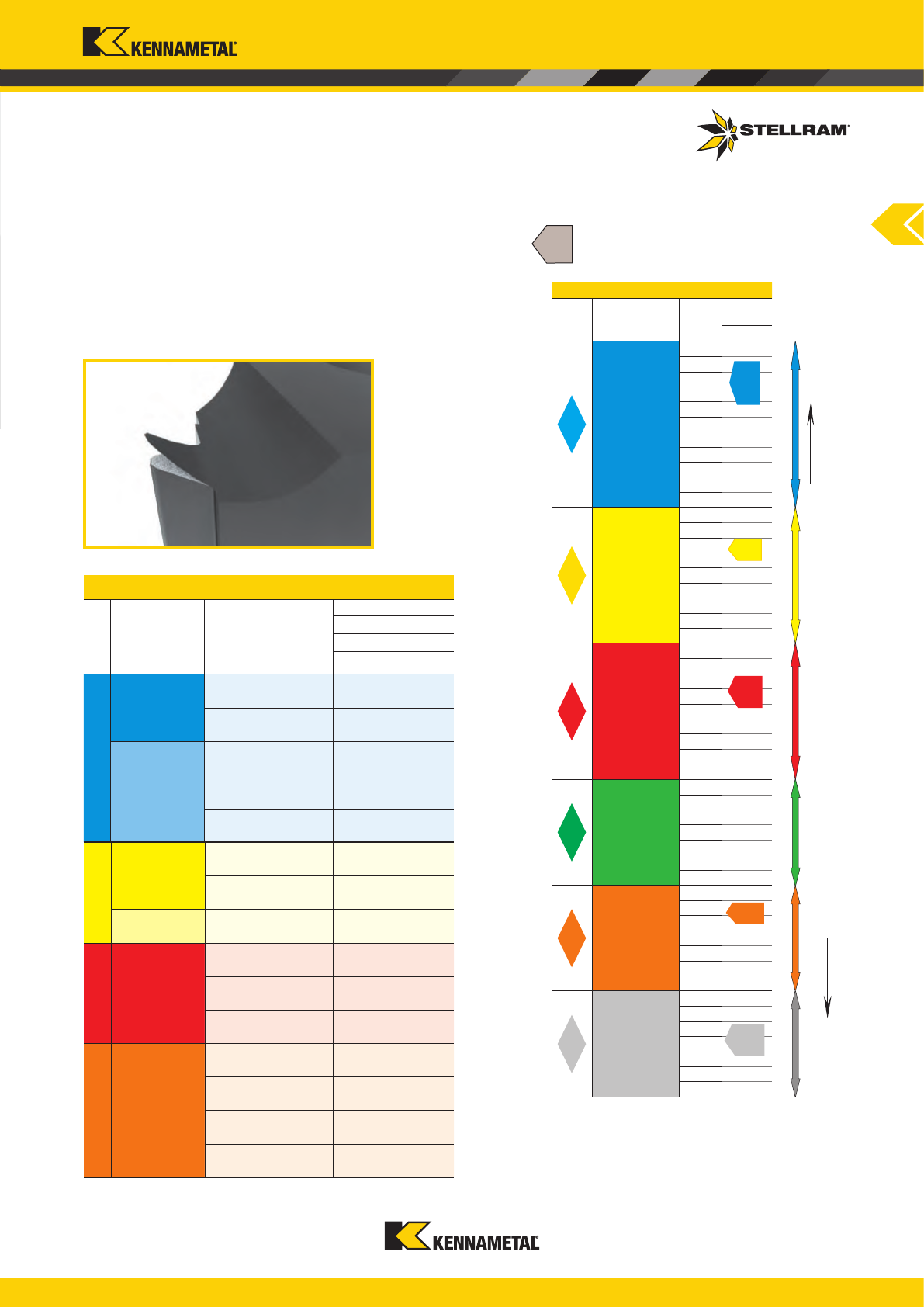

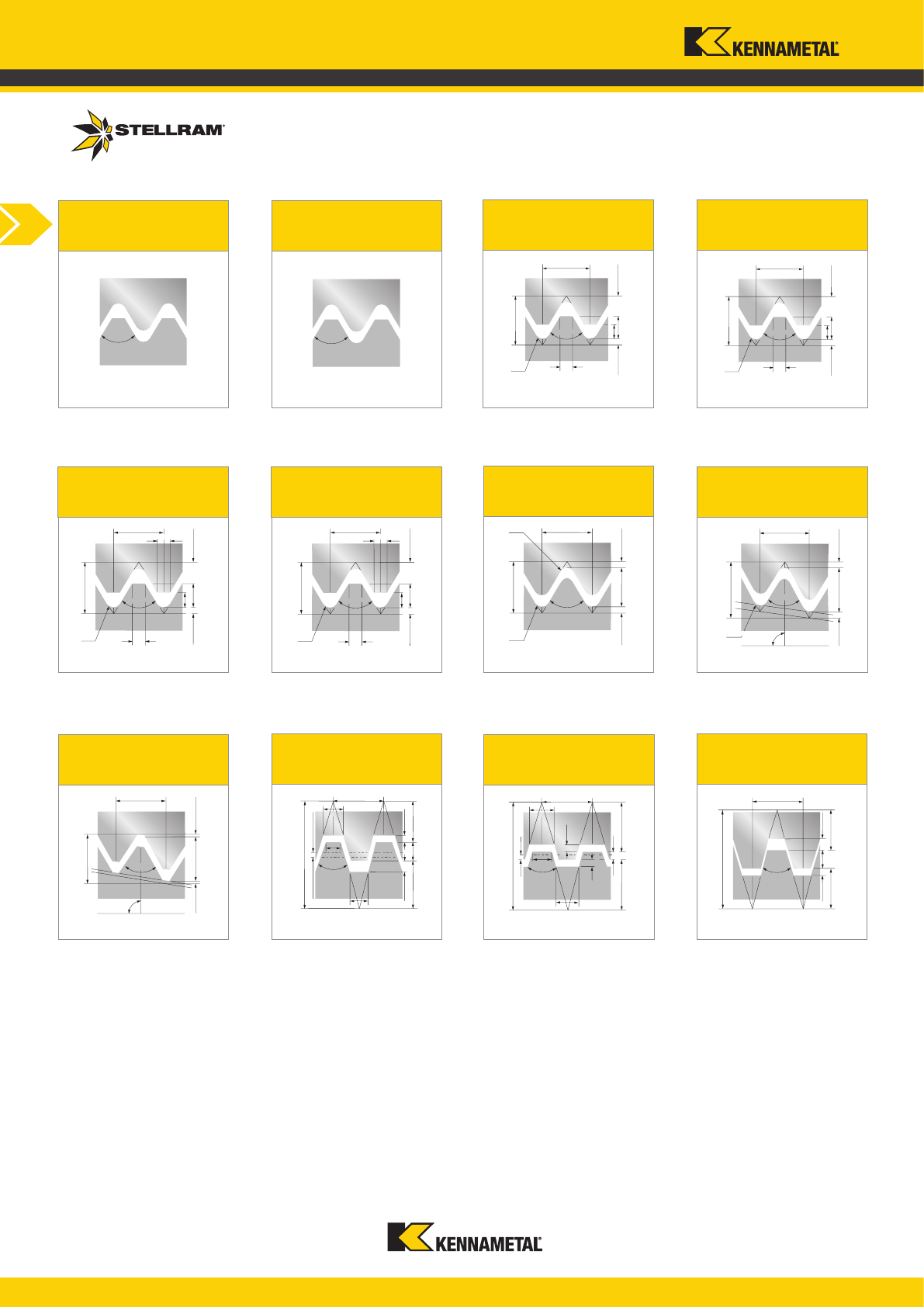

Geometry User Guide

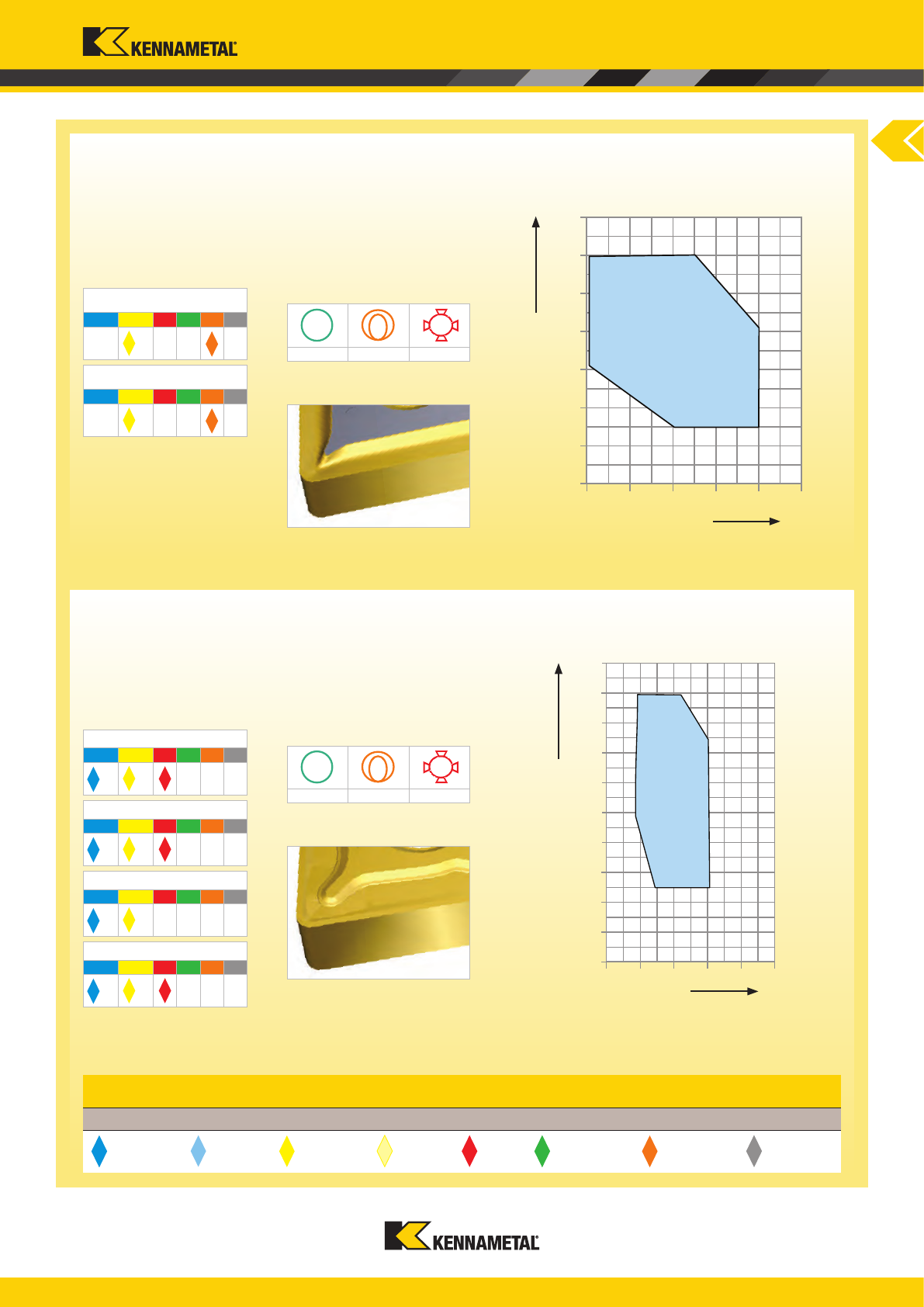

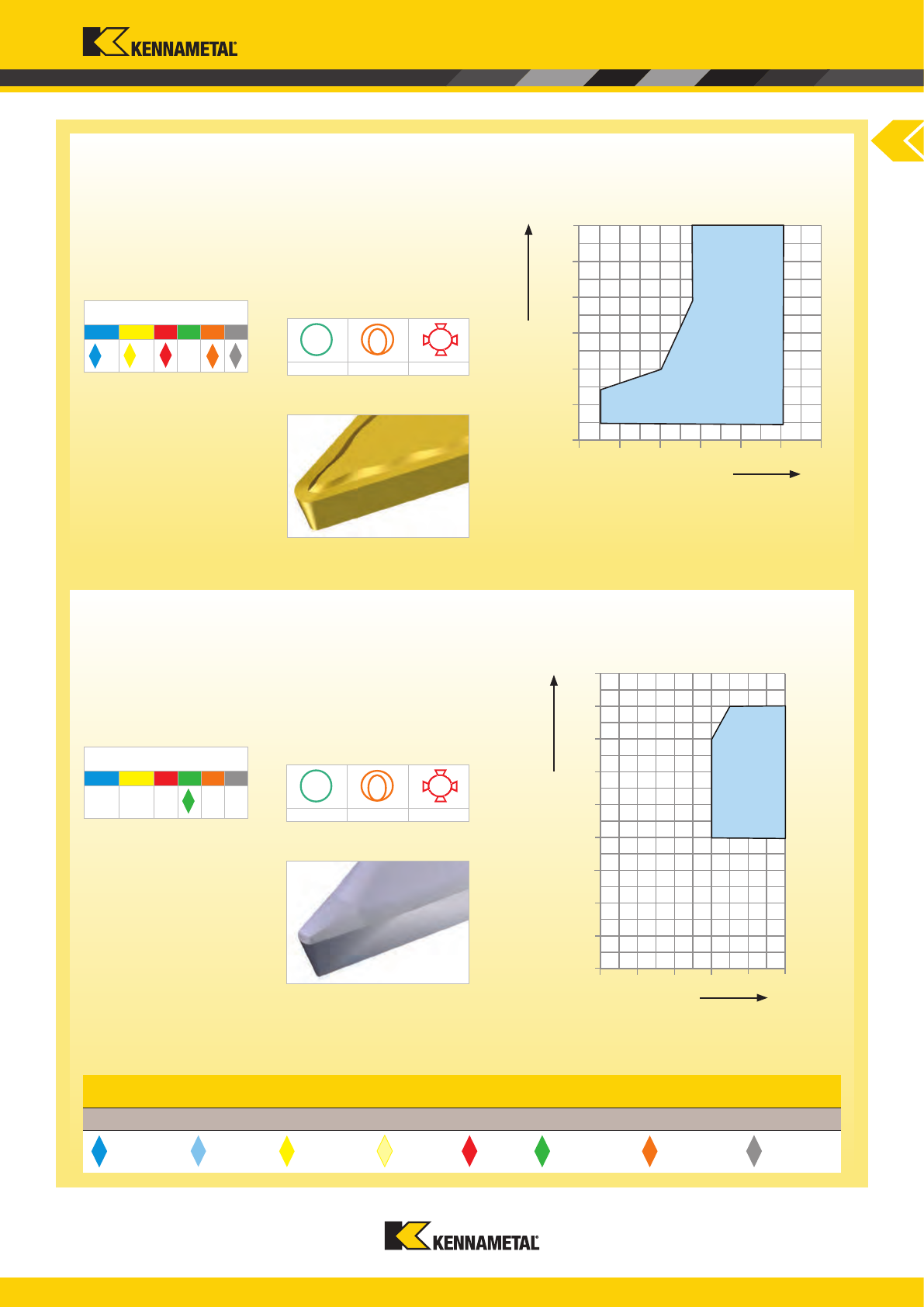

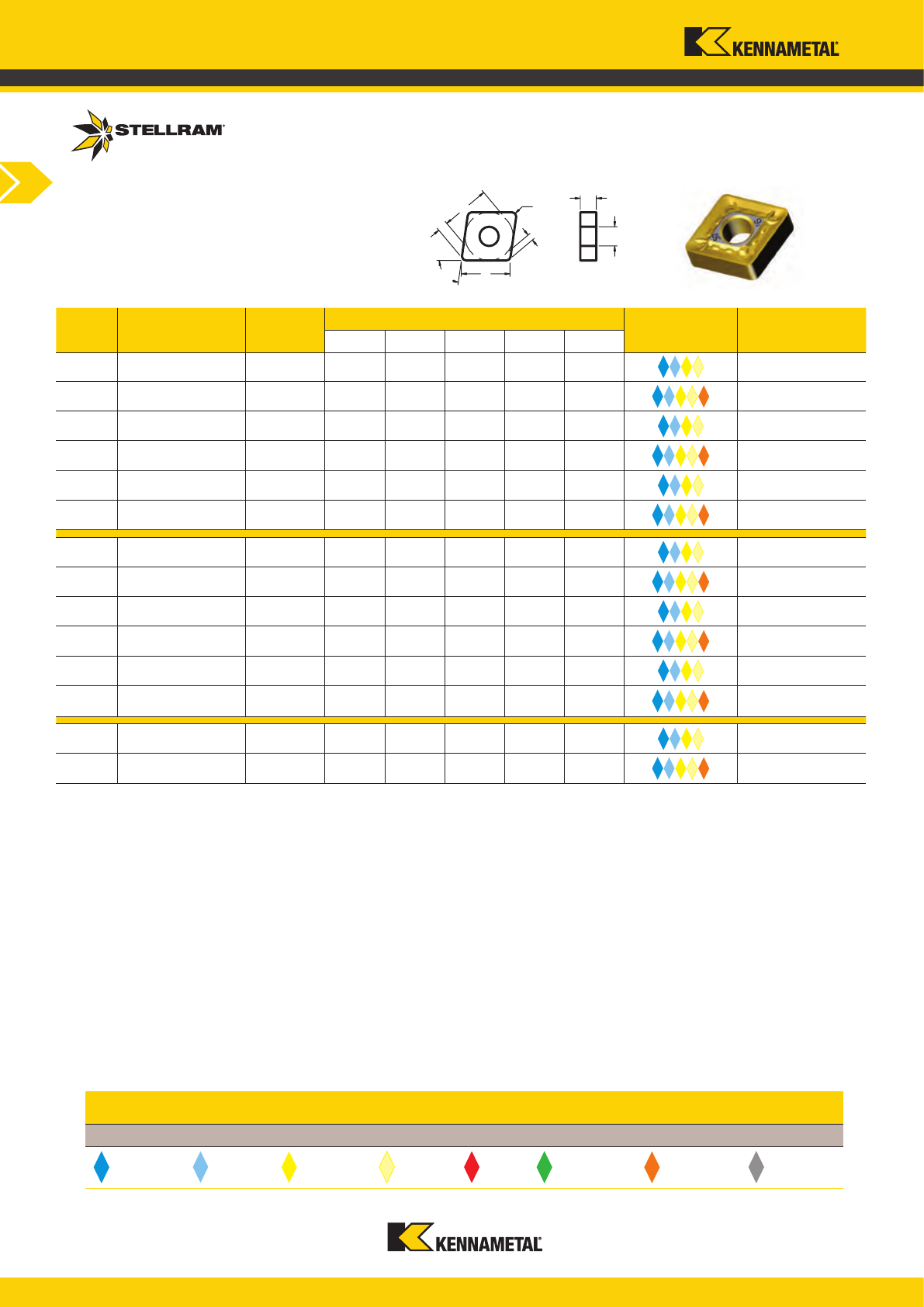

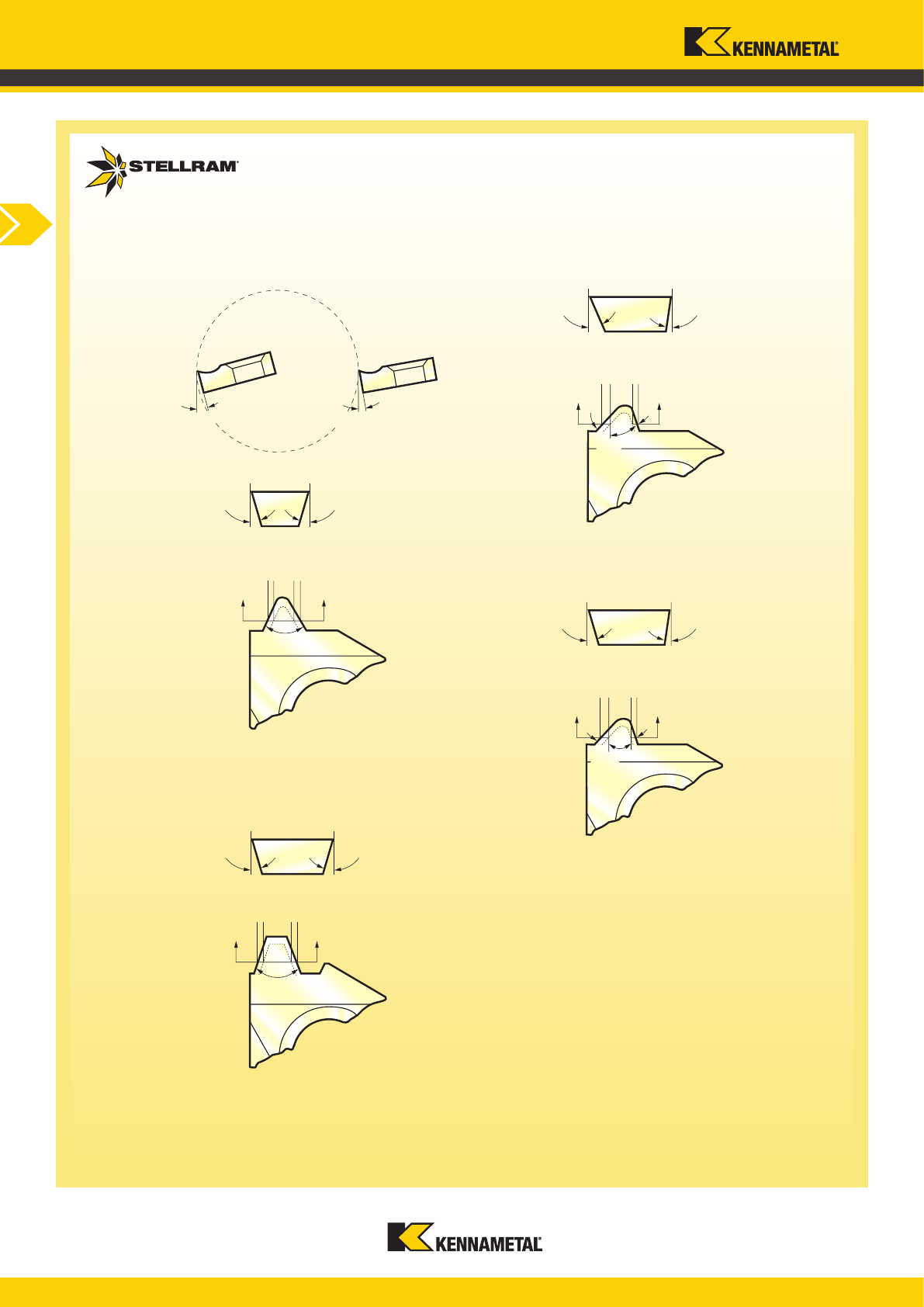

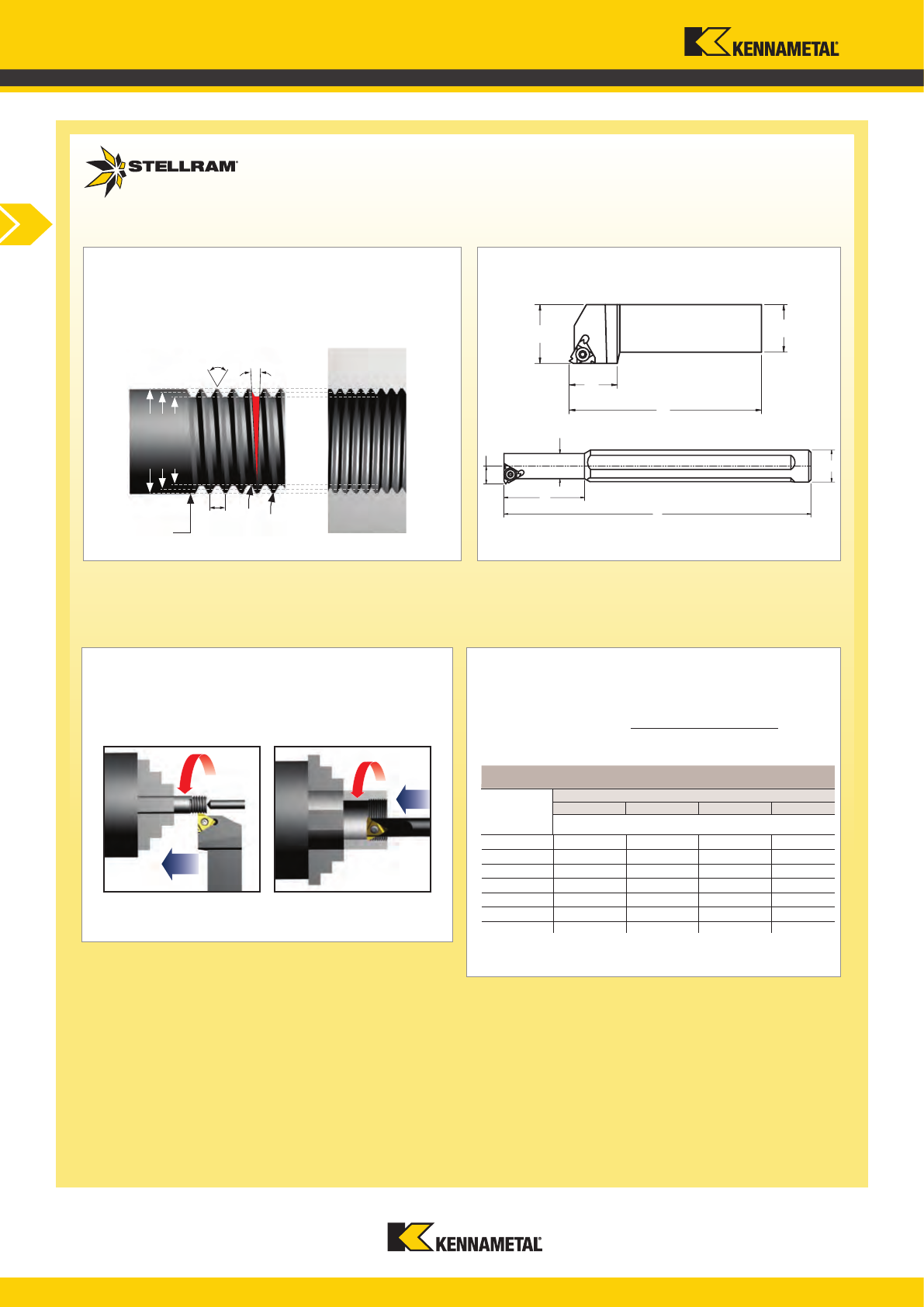

2N Geometry Technical Information

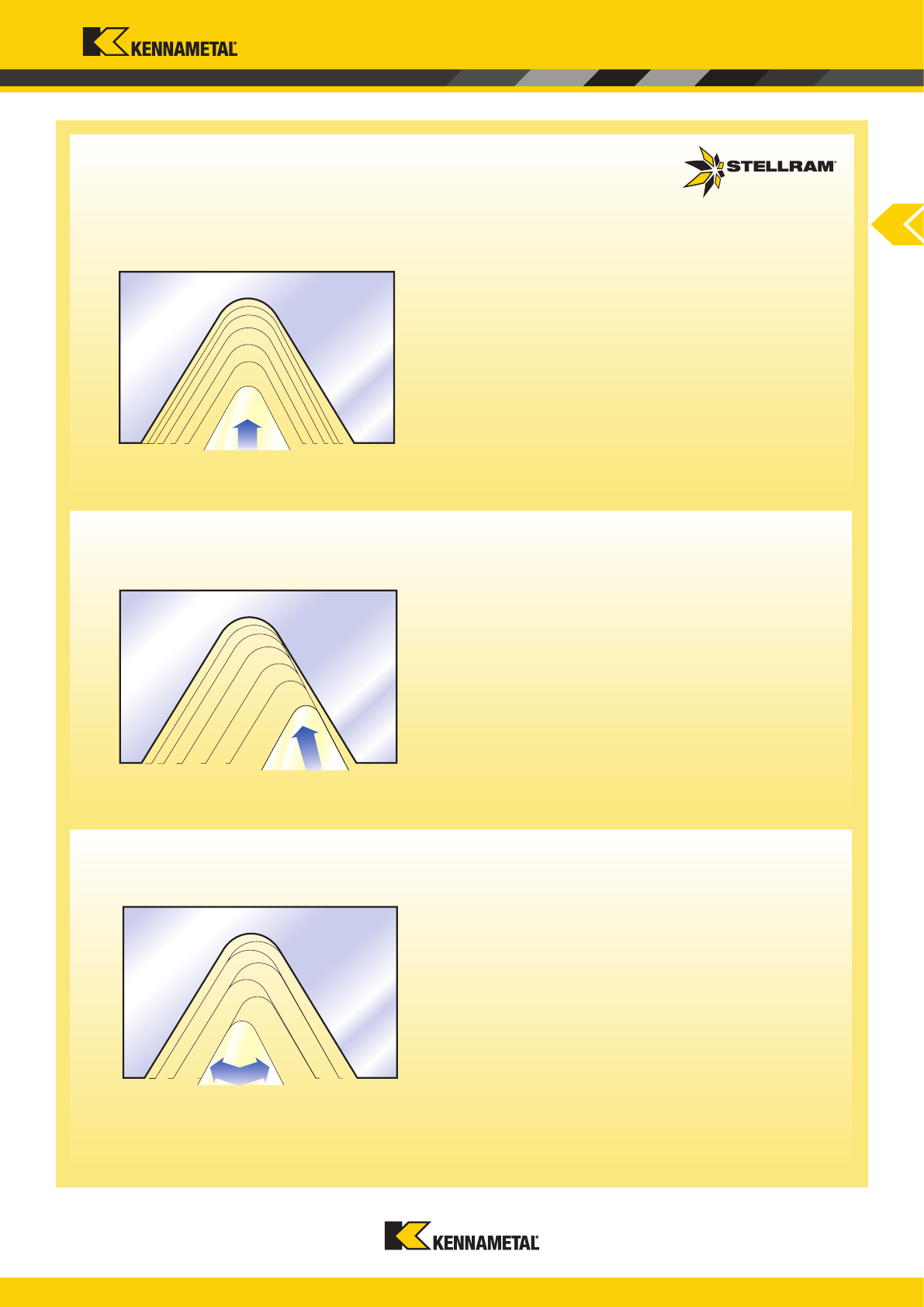

Light to Medium Roughing:

The 2N Geometry’s positive rake angle, provides a positive cutting action

with reduced cutting pressure, making it an excellent first choice for a

wide range of applications and materials.

Available in Grades: NL250, NL300 & NL920

Alloyed Steel: 900 - 1200 N/mm

2

HBN 260 - 340

Profile

Cutting Condition

Materials Application

1st Choice

Diamond will indicate the

recommended insert for each

material. Stellram’s Material

Guide enables you to find the

right insert for your machining

requirements.

Application information

Material Guide information –

diamond indicates the

recommended materials

related to the geometry.

Detailed outline of geometry

profile.

Identifies depth of cut (D.O.C)

and feed rate range applicable

to the geometry.

Cutting condition applicable

to geometry.

f

n

(feed/rev)

a

p

(depth of cut)

2N Inserts

CNMG120408E-2N

www.kennametal.com

C13

P

P

M

M

K N

S

H

CNMG120408E-1B

CNMG432A-1B

Alloyed Steel: 4140 (41CrMo4)

0,10 0,400,30 0,500,20

f

n

(feed /rev)

0.004 0.016

0.012 0.020

0.008

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,60

0.023

1,000.040

2,000.080

3,000.118

1B

inchmm

inch

mm

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

0,50

a

p

(depth of cut

)

0.060

0.100

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.157

inchmm

inch

mm

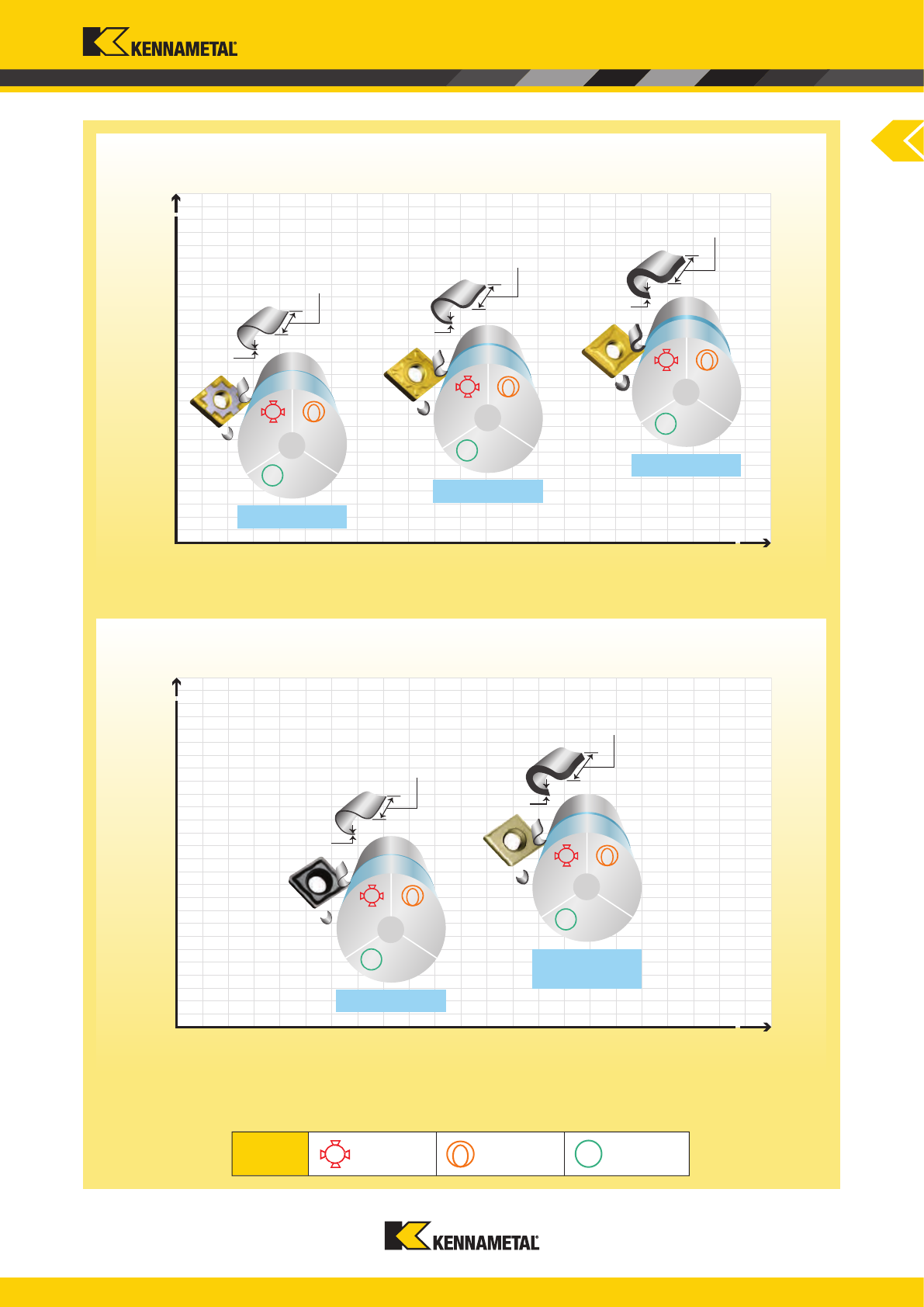

2N

P

P

M

M

K N

S

H

4 4 8

SP0819

P M K N S H

NL400

P M K N S H

4 4 4

NL250

P M K N S H

NL300

P M K N S H

NL920

P M K N S H

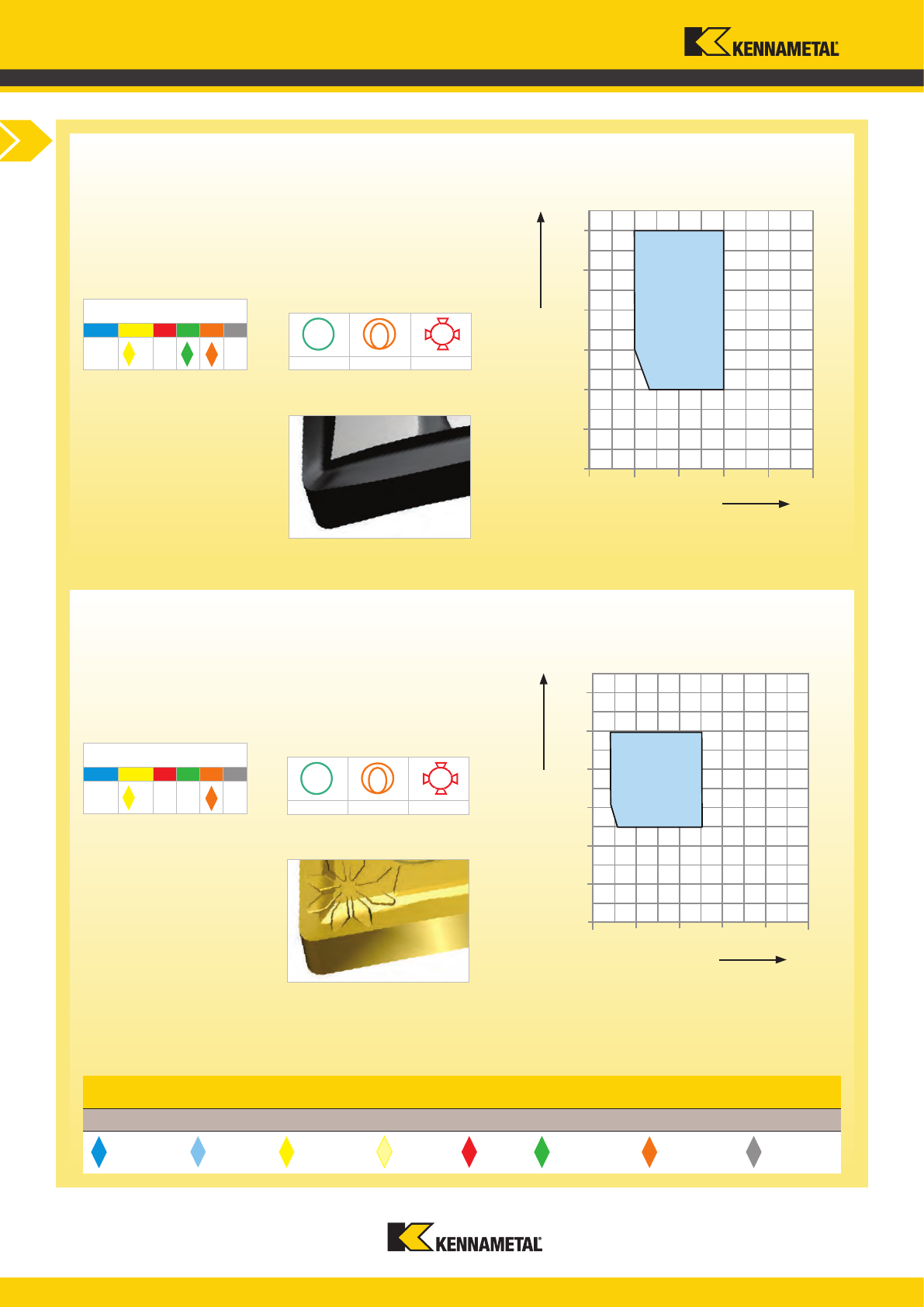

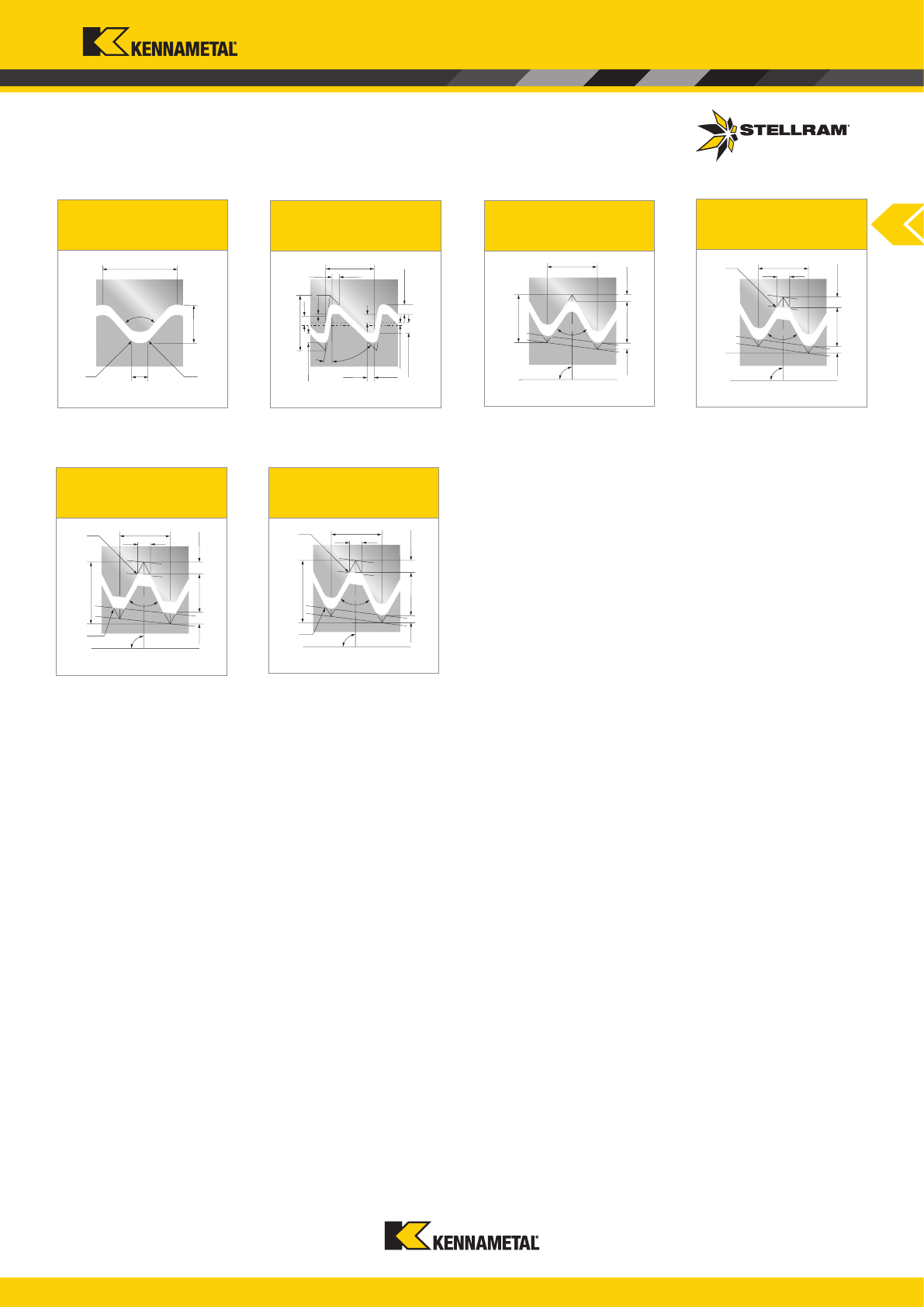

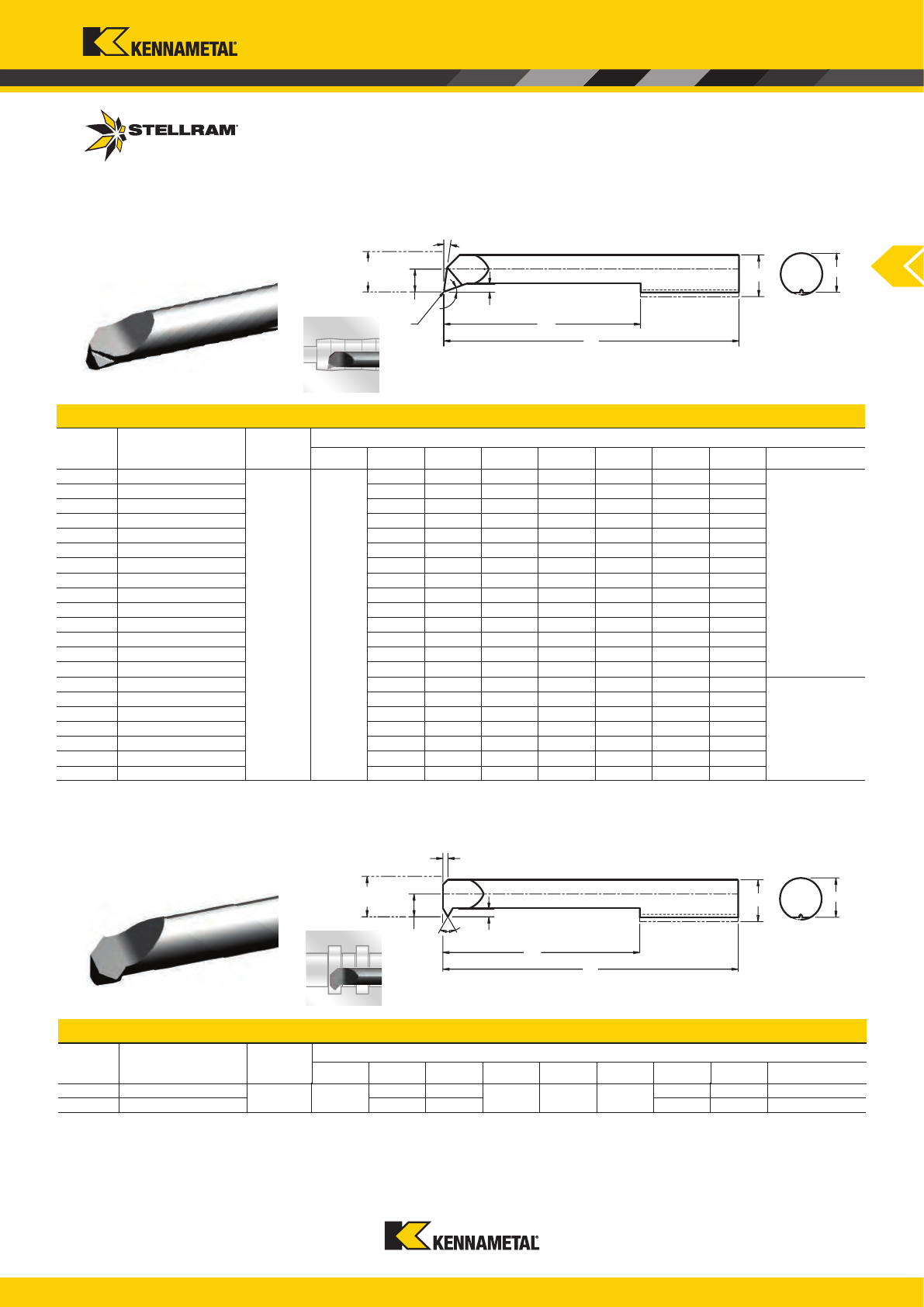

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

a

p

(depth of cut)

f

n

(feed/rev)

CNMG120408E-2N

Alloyed Steel: 900 - 1200 N/mm

2

HBN 260 - 340

2N Geometry Technical Information

Light to Medium Roughing:

The 2N Geometry’s positive rake angle, provides a positive cutting action

with reduced cutting pressure, making it an excellent first choice for a

wide range of applications and materials.

Available in Grades: NL250, NL300 & NL920

CNMG120408E-1B

Alloyed Steel: 4140 (41CrMo4)

1B Geometry Technical Information

Finishing:

The 1B Geometry is ideal for the finish machining of Steels, Stainless

Steels, and High Temperature Alloys. The precisely controlled cutting

edge and nose profile removes material cleanly and efficiently, leaving

a superior surface finish. Available in Grades: SP0819 & NL250

2N Inserts

Negative Insert Geometries

1B Inserts

Profile

Cutting Condition

Materials Application

Profile

Cutting Condition

Materials Application

www.kennametal.com

C14

P

P

M

M

K N

S

H

CNGG120408E-3F

CNGG432-3F

Stainless Steel: ATI 316!

0,10 0,40 0,30 0,50 0,20

f

n

(feed /rev)

0.004 0.0160.012 0.0200.008

1,50

2,5

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

3F

CNMG120408E-3J

CNMG432A-3J

Stainless Steel: ATI 316!

0,10 0,40 0,30 0,50 0,20

f (feed/rev)

0.004 0.016

0.012 0.0200.008

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

3J

inch mm

inch

mm

P

P

M

M

K N

S

H

4 4 8

SP0819

P M K N S H

4 4

SP4019

P M K N S H

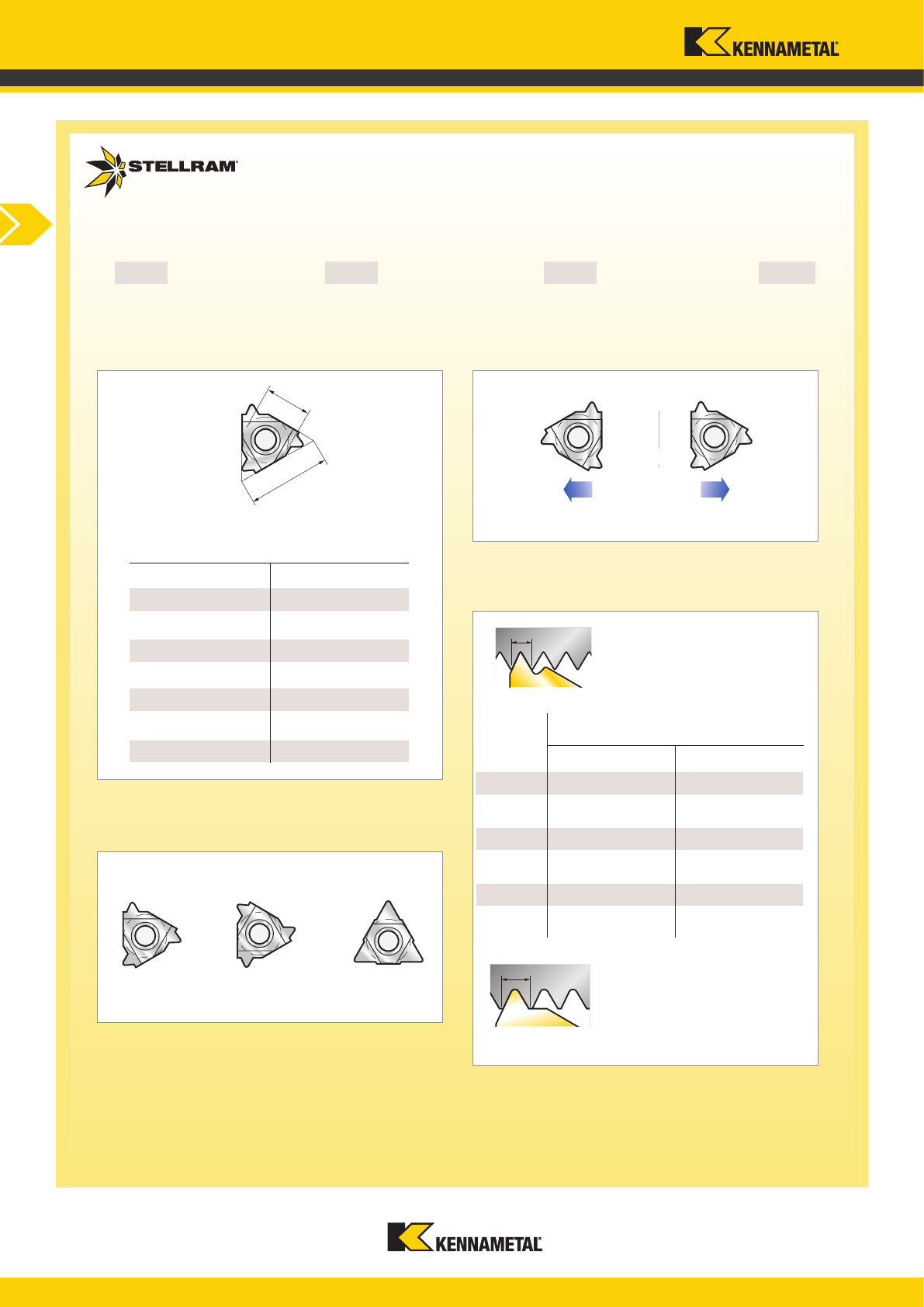

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

a

p

(depth of cut)

f

n

(feed/rev)

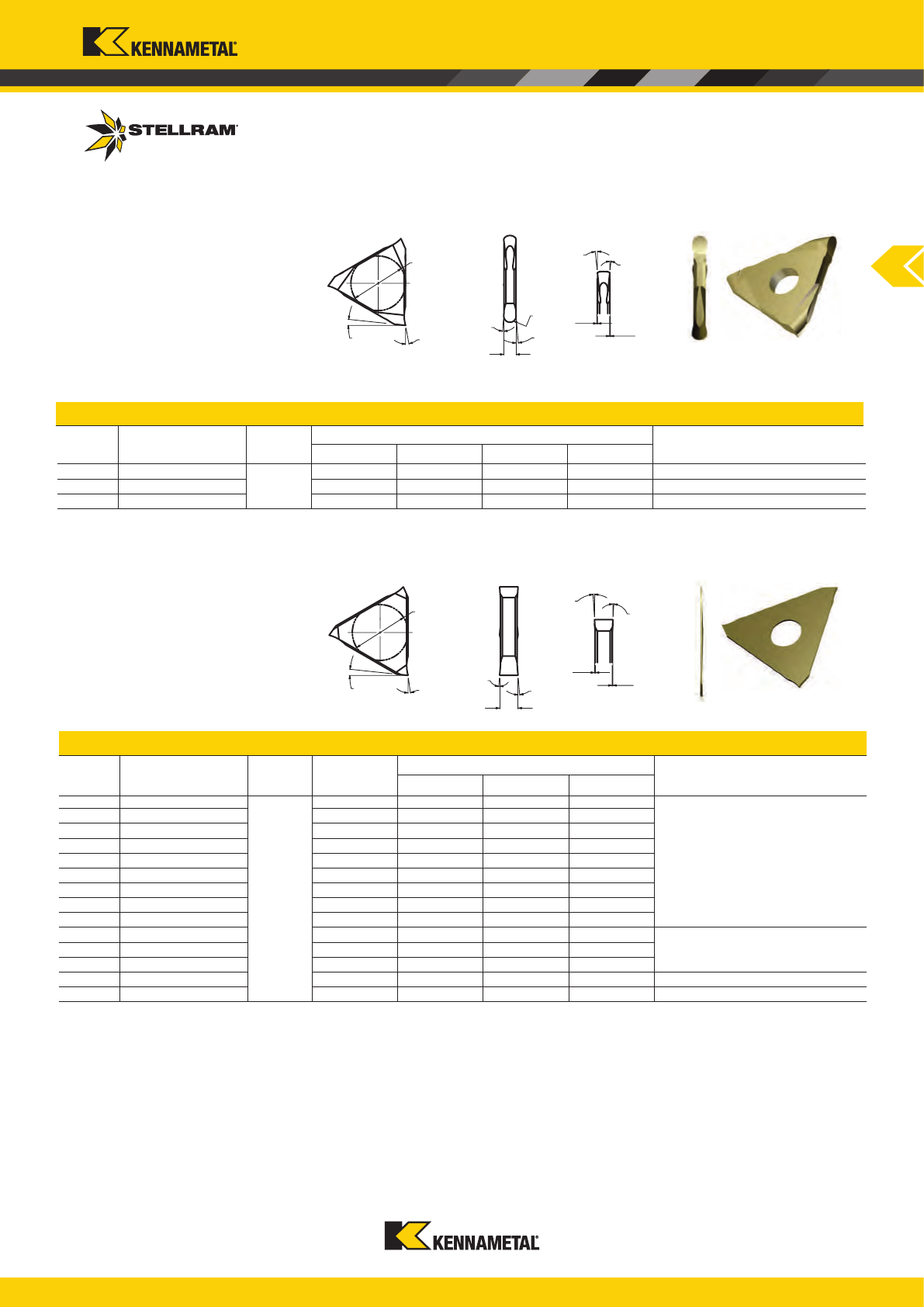

CNMG120408E-3J

Stainless Steel: ATI 316™

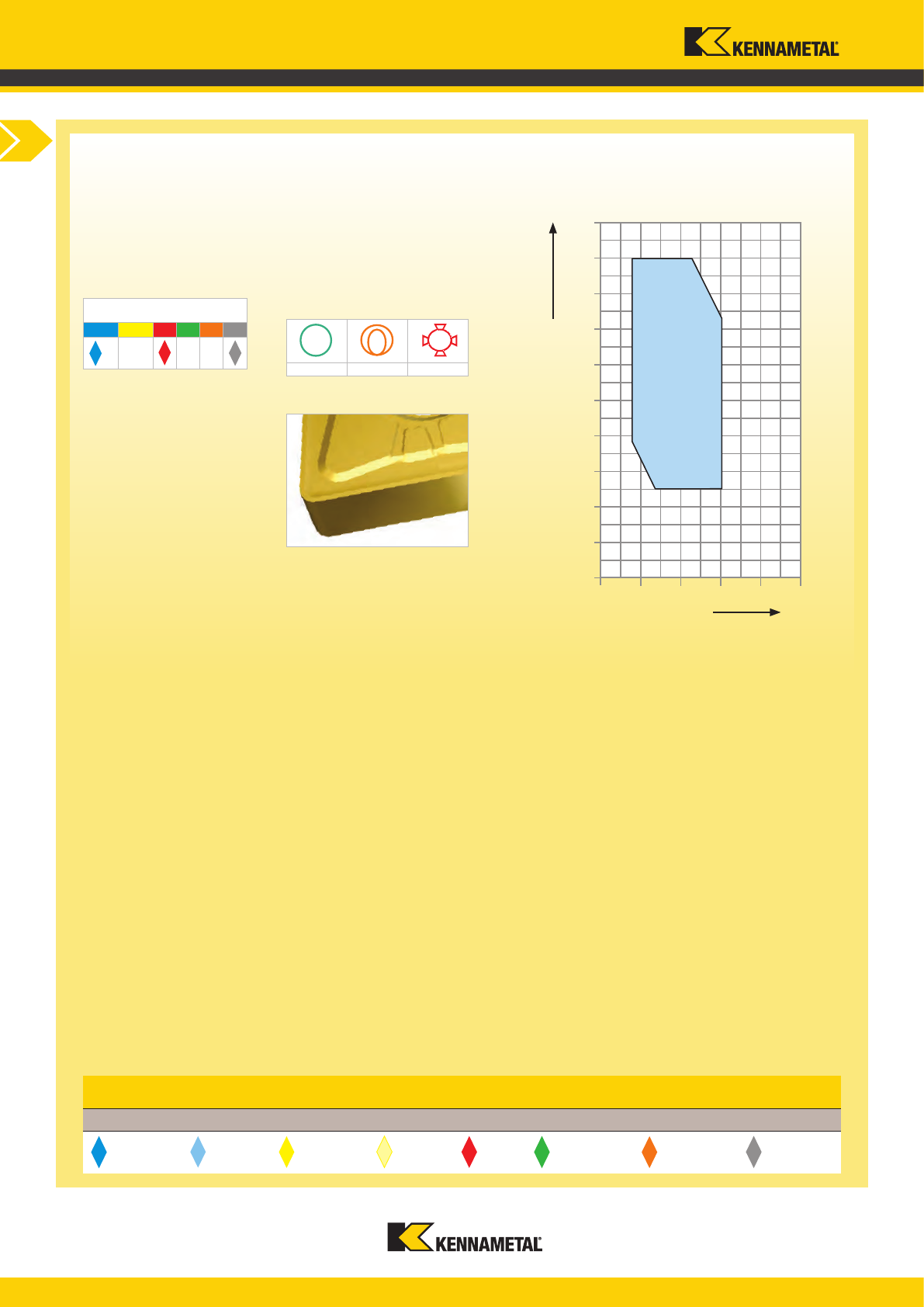

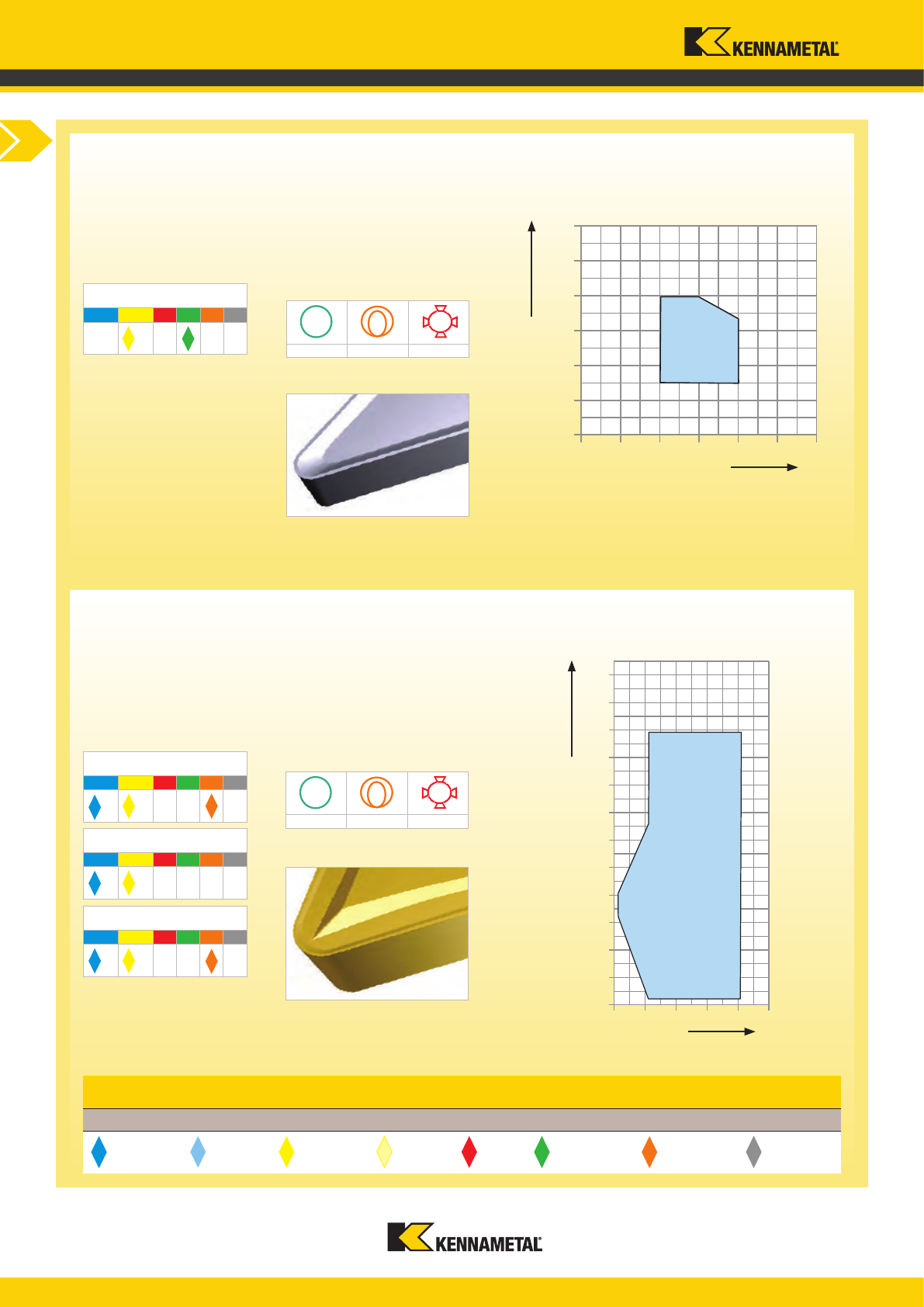

3J Geometry Technical Information

Medium to Light Roughing:

The 3J Geometry has a smooth cutting action which reduces cutting

forces, improves surface finishes and increases the tool life, making it

ideal for the machining of Stainless Steels. Available in Grade: SP4019

CNGG120408E-3F

Stainless Steel: ATI 316™

3F Geometry Technical Information

Finishing to Light Roughing:

The 3F Geometry has a precision ground periphery to ensure a

precise cutting edge profile, with accurate indexability. The micro edge

conditioning reduces the cutting pressure, built-up edge and improves

the surface finish in difficult to machine materials. Available in Grade:

SP0819

3J Inserts

Negative Insert Geometries

3F Inserts

Profile

Materials Application

Cutting Condition

Profile

Materials Application

Cutting Condition

Light

www.kennametal.com

C15

P

P

M

M

K N

S

H

CNMG120408E-4E

CNMG432A-4E

Titanium Alloy: ATI 6-4!

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4E

4,00 0.157

inch mm

inch

mm

800 - 1200 N/mm

2

HBN

230 - 340

CNMG120408E-4T

CNMG432A-4T

Alloyed Steel:

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004

0.0160.012 0.020

0.008

1,50

2,50

4,50

3,50

0,50

5,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0.216

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

4T

:

inch mm

inch

mm

P

P

M

M

K N

S

H

4 4

SP0819

P M K N S H

NL400

P M K N S H

4 4 4

NL250

P M K N S H

NL300

P M K N S H

NL400

P M K N S H

NL920

P M K N S H

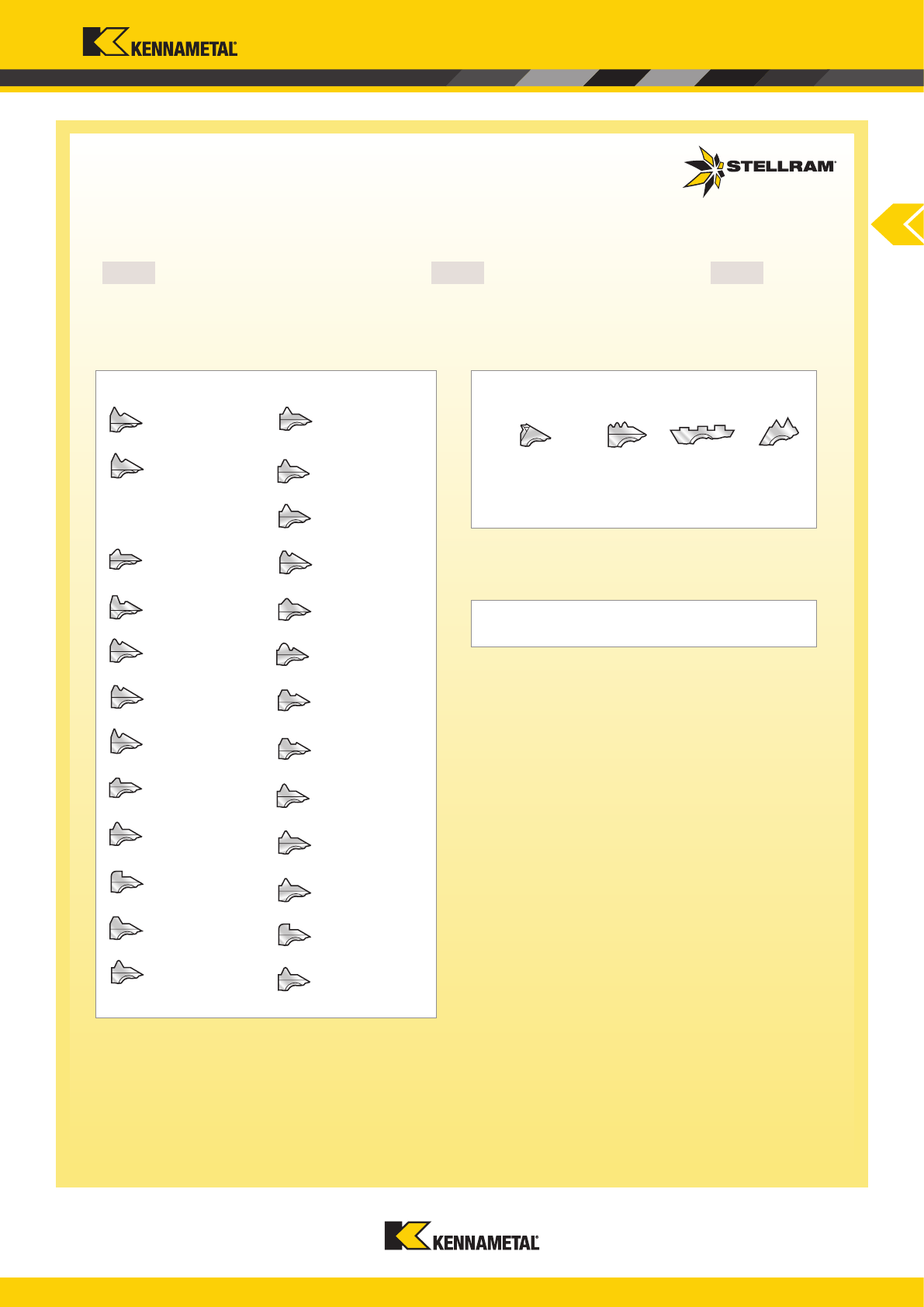

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

a

p

(depth of cut)

f

n

(feed/rev)

CNMG120408E-4T

Alloyed Steel: 800 - 1200 N/mm

2

HBN 230 - 340

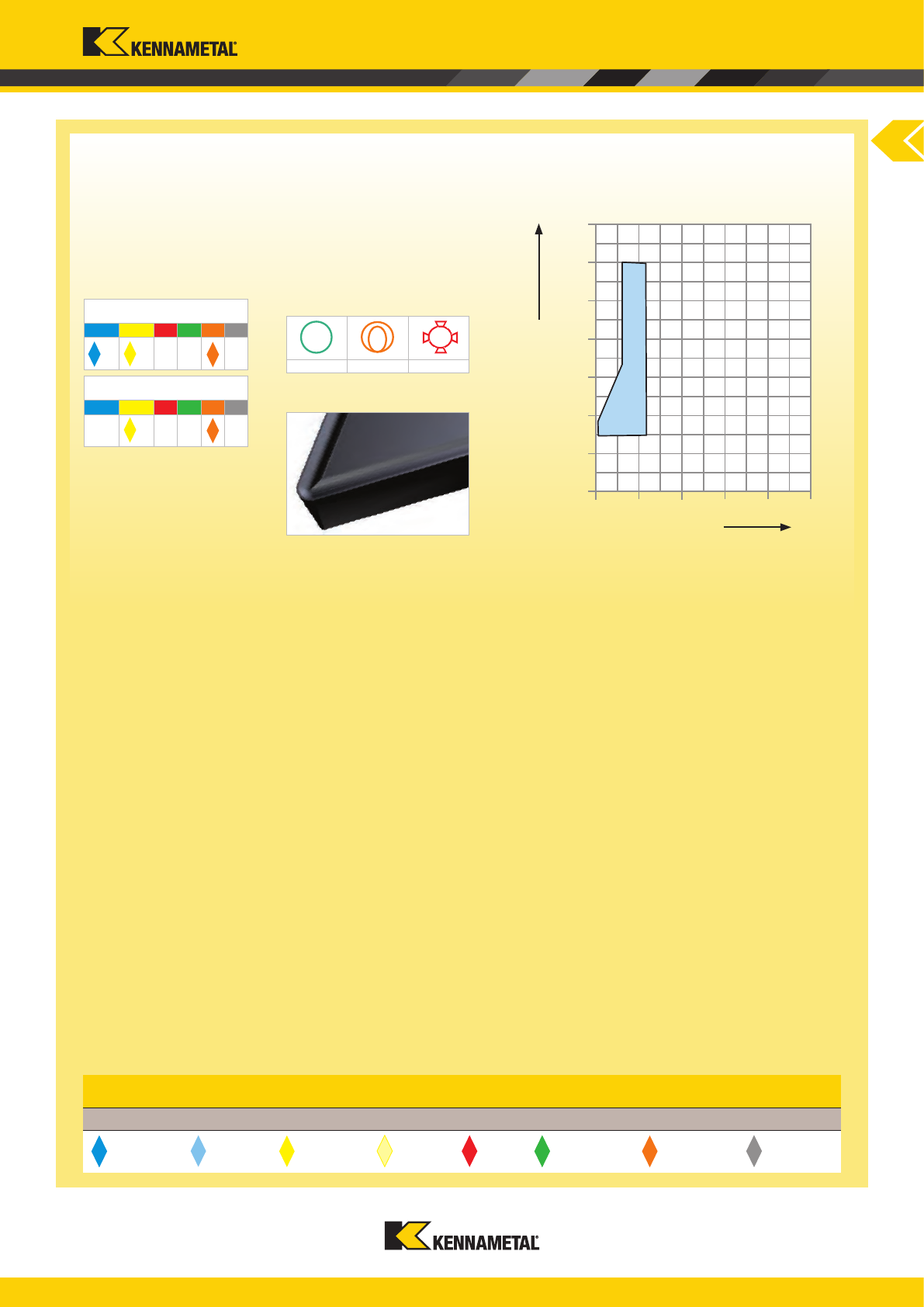

4T Geometry Technical Information

General Purpose Roughing:

The 4T Geometry is the first choice for general purpose machining of all

Steels, Stainless Steels and Cast Irons.

Available in Grades: NL250, NL300, NL400 & NL920

CNMG120408E-4E

Titanium Alloy: ATI 6-4™

4E Geometry Technical Information

Semi-Finishing to Light Roughing:

The 4E Geometry was designed specifically for the machining of

High Nickel, High Cobalt, and Titanium based alloys. It’s reinforced

chip-breaker and precision edge condition enhances the performance

of this geometry. Available in Grades: SP0819 & NL400

4T Inserts

Negative Insert Geometries

4E Inserts

Profile

Materials Application

Cutting Condition

Profile

Materials Application

Cutting Condition

Light

www.kennametal.com

C16

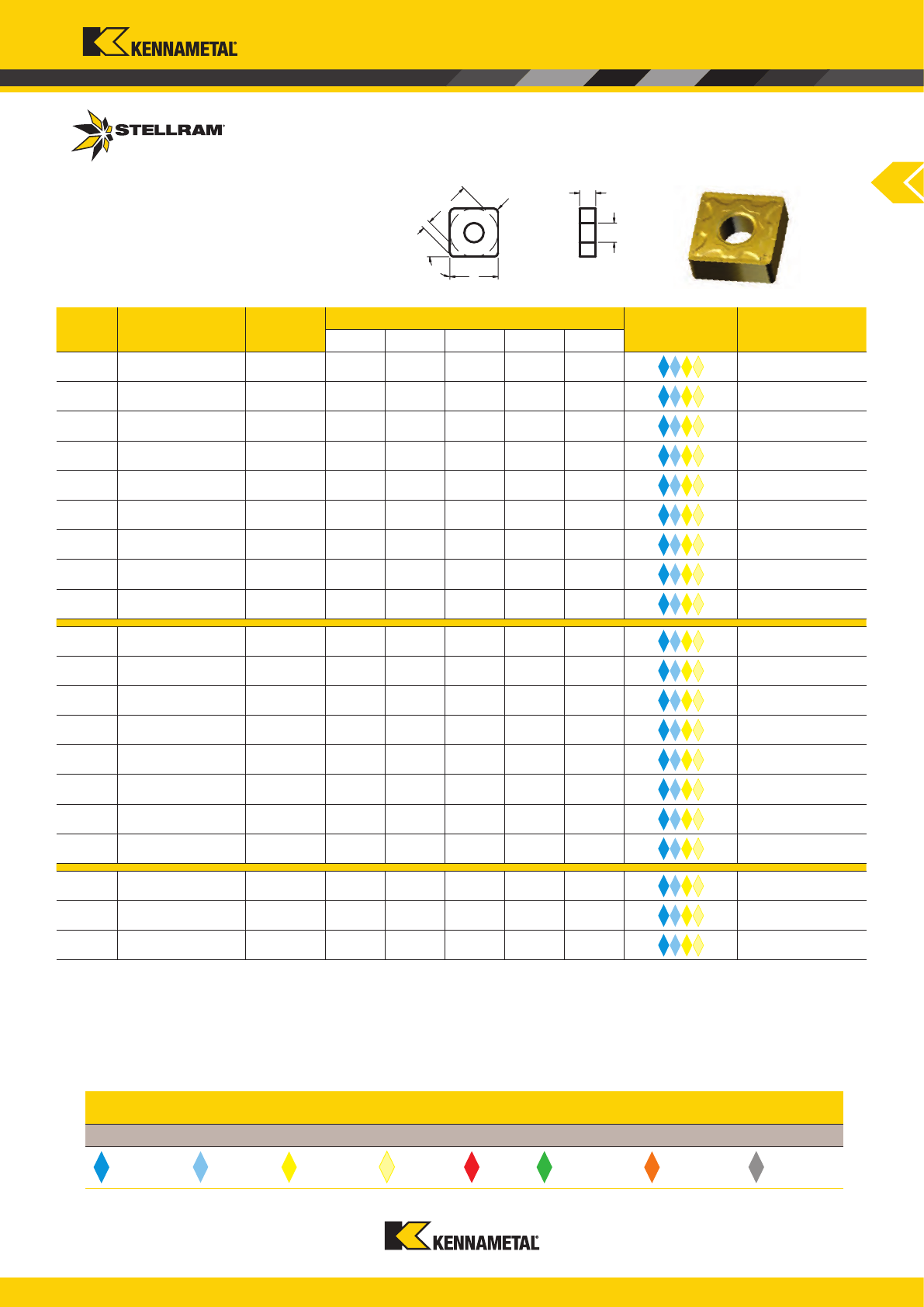

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

CNMG120408E-4U

CNMG432A-4U

Ductile Iron: HBN 170

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

4,50

3,50

0,50

5,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0.216

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

4U

inchmm

inch

mm

4 4

NL200

P M K N S H

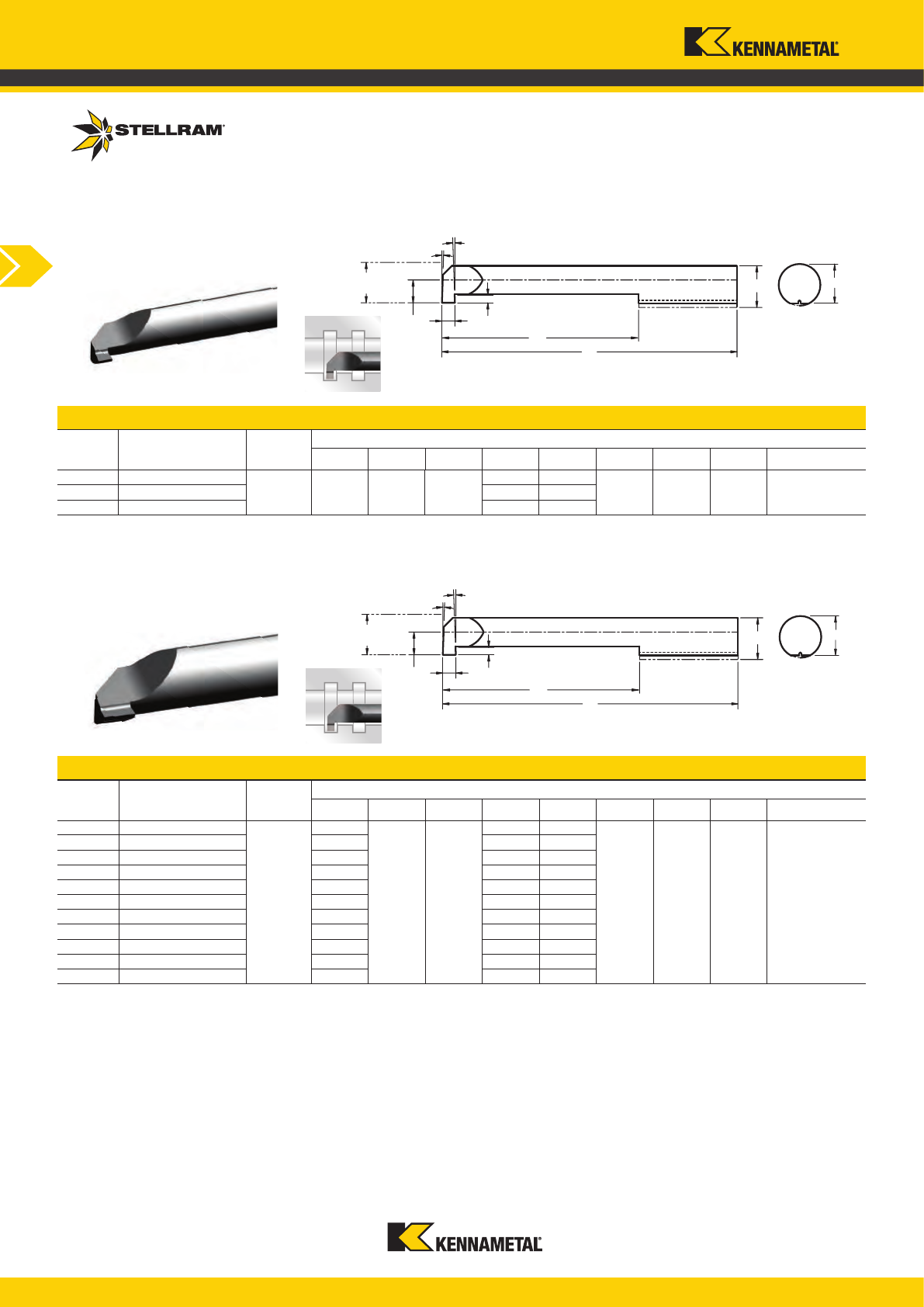

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

CNMG120408E-4U

Ductile Iron: HBN 170

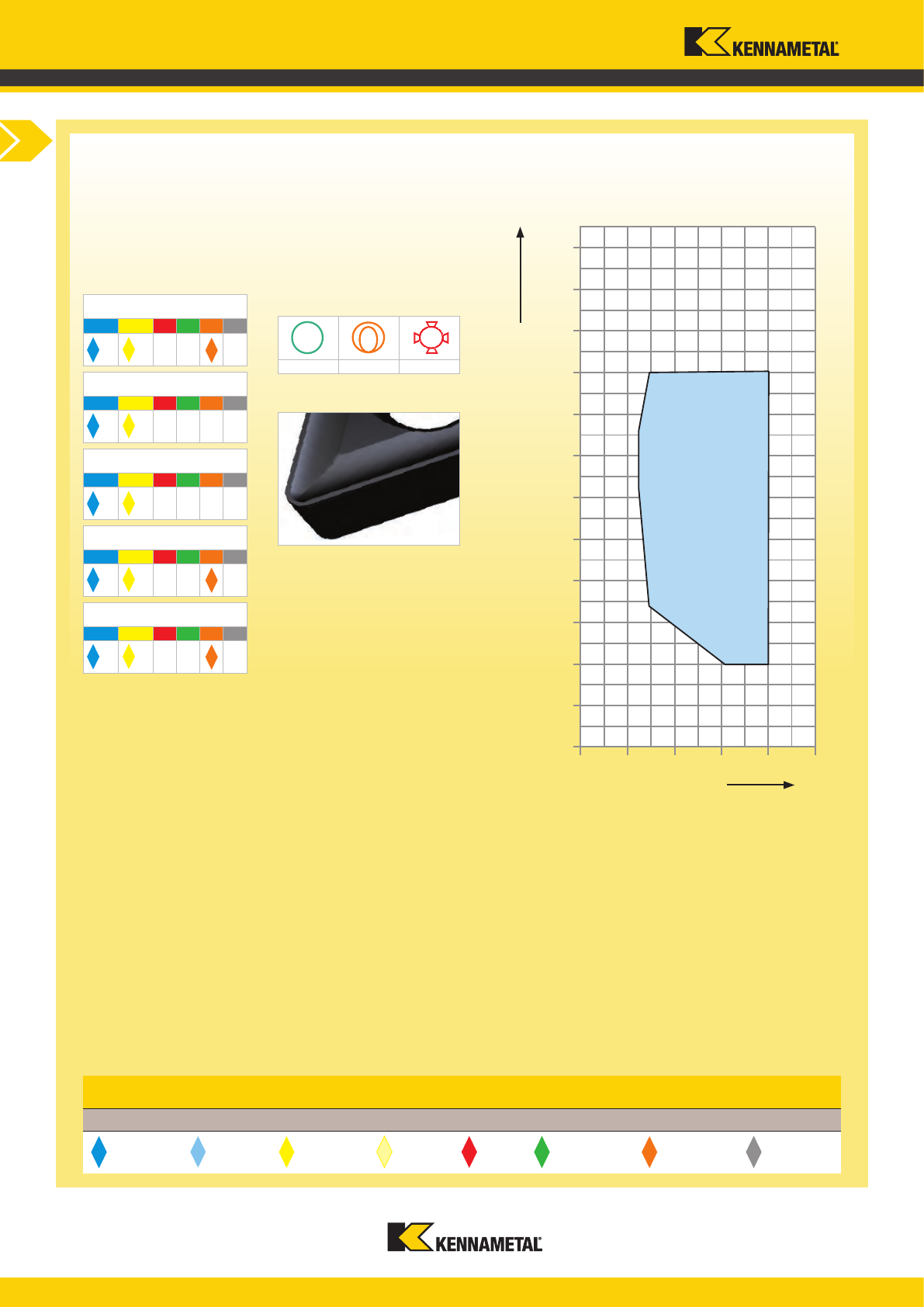

4U Geometry Technical Information

Medium to Roughing:

The 4U Geometry was designed specifically for roughing applications

in Grey, Ductile and Malleable Irons. The geometry design produces

low cutting pressure with excellent chip control, enhancing the tool life.

Available in Grade: NL200

Negative Insert Geometries

4U Inserts

Profile

Cutting Condition

Materials Application

Light

www.kennametal.com

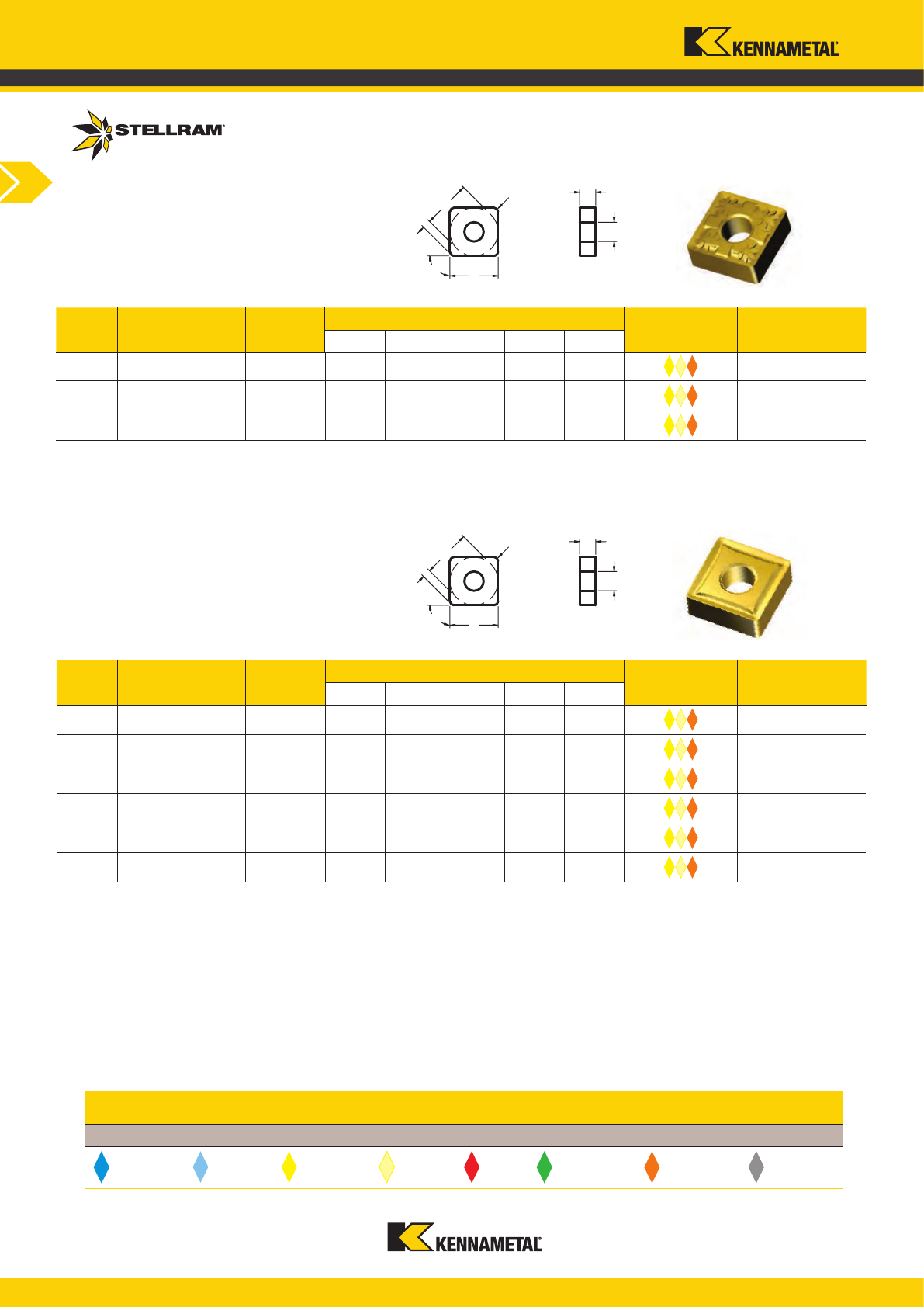

C17

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

Stainless Steel: ATI 316!

CNMM190616E-5R

CNMM644A-5R

0,10

0,40 0,30

0,50

0,20

f

n

(feed/rev)

0.004

0.016

0.012

0.020

0.008

1,50

2,50

4,50

3,50

0,50

5,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0.216

6,00 0.235

6,50 0.255

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

0,70 0,80 0,90 1,00

7,00

7,50

8,00

8,50

9,00

9,50

10,00

5R

0.255

0.295

0.315

0.335

0.354

0.374

0.394

0.027 0.031 0.035 0.040

inchmm

inch

mm

4 4 4

NL300

P M K N S H

NL400

P M K N S H

NL920

P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

CNMM190616E-5R

Stainless Steel: ATI 316™

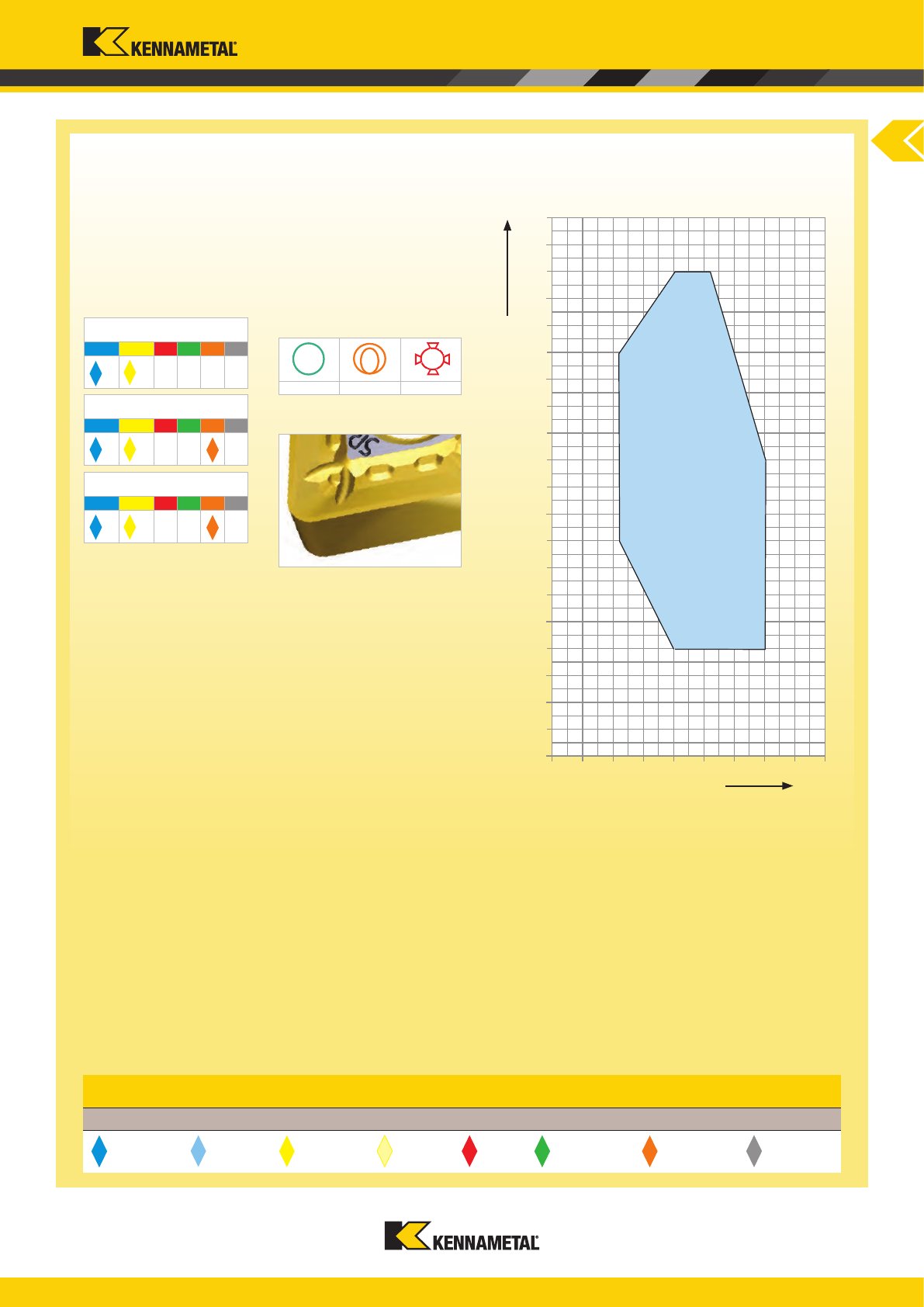

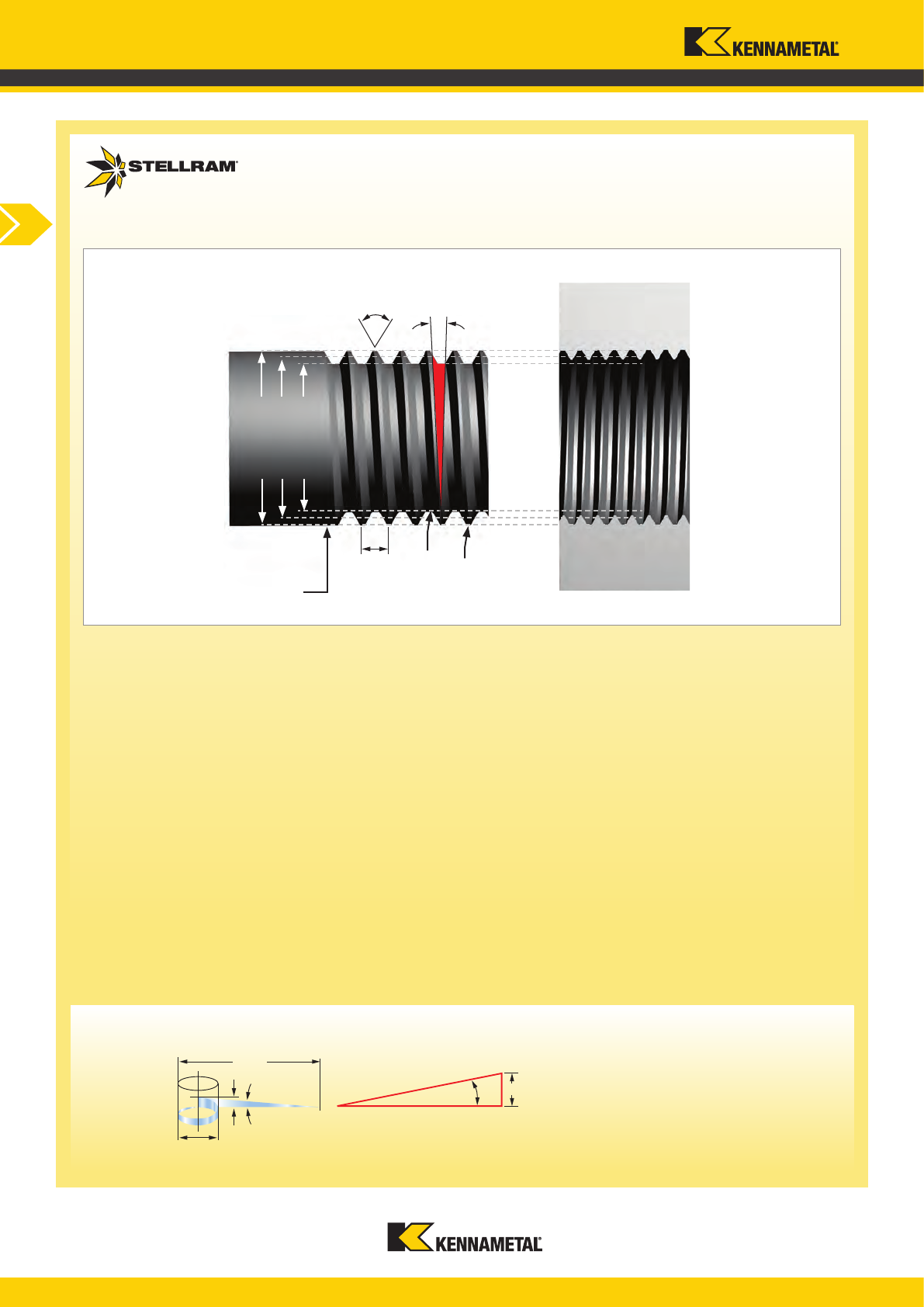

5R Geometry Technical Information

Single Sided Heavy Roughing:

The 5R Geometry was designed specifically for the heavy, rough

machining of Steels, Stainless Steels, High Nickel, High Cobalt and

Titanium based alloys. It is the first choice when stability, high feed

rates and strong edge conditions are required.

Available in Grades: NL300, NL400 & NL920

Negative Insert Geometries

5R Inserts

Profile

Cutting Condition

Materials Application

www.kennametal.com

C18

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

EPEX040204F-15

EPEX1.51-15

Aluminium: <16% Si HBN 116

0,05

0,20

0,15 0,25

0,10

f

n

(feed/rev)

0.002 0.0080.006 0.0100.004

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,30

0.015

1,00 0.040

2,00 0.080

3,00 0.118

-15

inchmm

inch

mm

750 - 950 N/mm

2

HBN

220 - 270

WPMT050304E-61

Unalloyed Steel:

0,05 0,20 0,15 0,25 0,10

f

n

(feed/rev)

0.002 0.0080.006 0.0100.004

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,30

0.015

1,00 0.040

2,00 0.080

3,00 0.118

-61

inchmm

inch

mm

4

8

4

SP4019

P M K N S H

GH1

P M K N S H

4 4

8

SP4019

P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

a

p

(depth of cut)

f

n

(feed/rev)

WPMT050304E-61

Unalloyed Steel: 750 - 950 N/mm

2

HBN 220 - 270

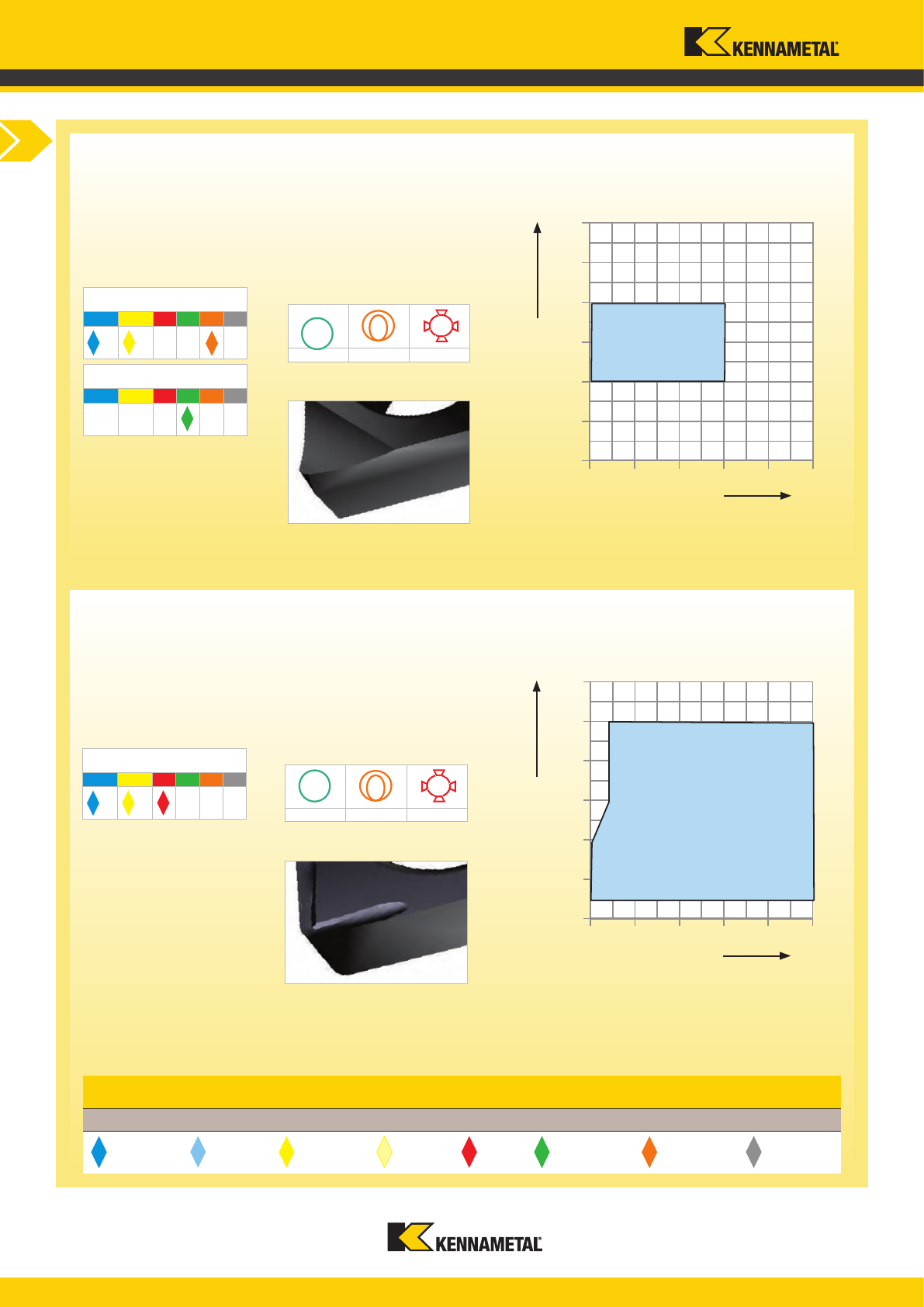

-61 Geometry Technical Information

Finishing:

The -61 Geometry has 6 cutting edges and is one of the most

economical inserts for small part machining. The chip-breaker provides

good chip control and surface finish.

Available in Grade: SP4019

EPEX040204F-15

Aluminium: <16% Si HBN 116

-15 Geometry Technical Information

Medium to Finishing:

The -15 Geometry is ideally suited to applications which require light

depths of cut and feeds, and where vibration could be an issue. This

geometry is ground and has a sharp edge condition.

Available in Grades: SP4019 & GH1

-61 Inserts

Positive Insert Geometries

-15 Inserts

Profile

Cutting Condition

Materials Application

Profile

Cutting Condition

Materials Application

www.kennametal.com

C19

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

Unalloyed Steel:

750 - 950 N/mm

2

HBN

220 - 270

EPGT060204E-62

EPGT21.51A-62

0,05 0,20 0,15 0,25 0,10

f

n

(feed/rev)

0.002 0.0080.006 0.0100.004

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,00

0.000

1,00 0.040

2,00 0.080

3,00 0.118

-62

0,30

0.015

inchmm

inch

mm

DCGT11T308F-64

DCGT32.52A-64

Aluminium: <16% Si HBN 116

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

4,50

3,50

0,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

-64

inchmm

inch

mm

4 4

8

SP0819

P M K N S H

4 4

8

GH1

P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

a

p

(depth of cut)

f

n

(feed/rev)

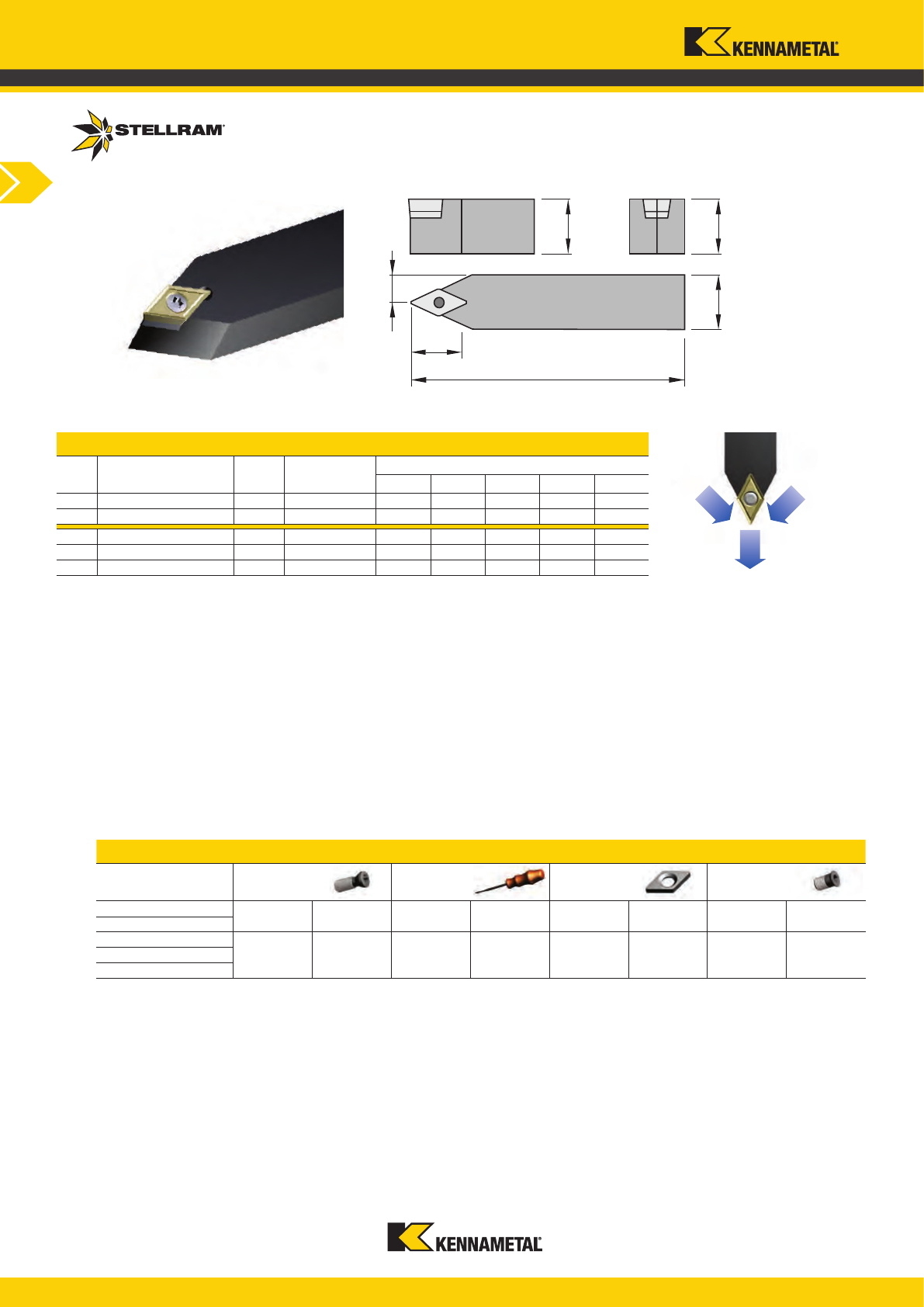

DCGT11T308F-64

Aluminium: <16% Si HBN 116

-64 Geometry Technical Information

Medium to Roughing:

The -64 Geometry is a very positive geometry, with polished top rake and

ground periphery. Specifically designed for the machining of Aluminum,

Plastics and Soft Alloys.

Available in Grade: GH1

EPGT060204E-62

Unalloyed Steel: 750 - 950 N/mm

2

HBN 220 - 270

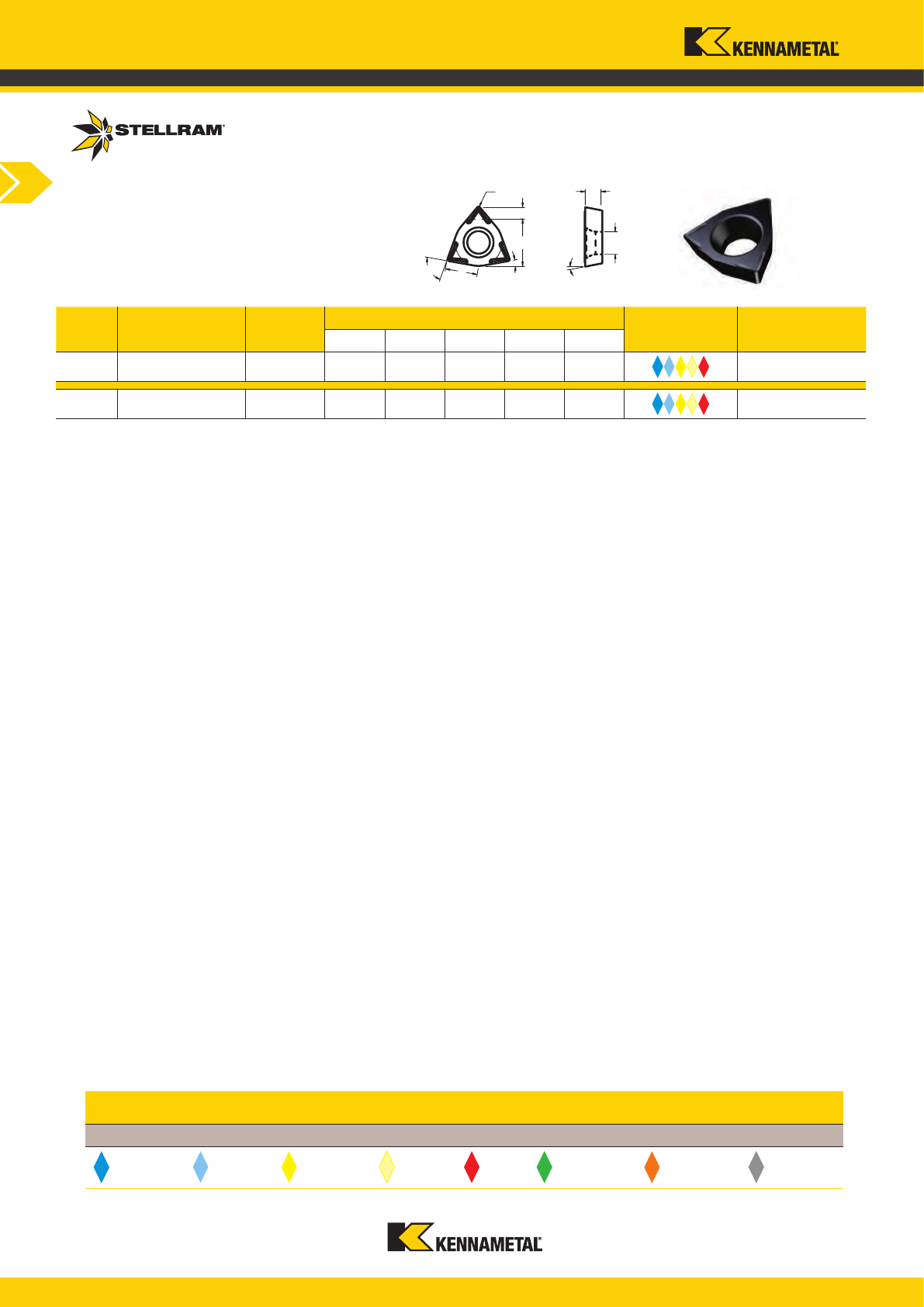

-62 Geometry Technical Information

Finishing:

The -62 Geometry is one of the most versatile geometries for the

machining of Steels, Stainless Steels, High Nickel, High Cobalt and

Titanium based alloys. This positive geometry was designed for a wide

variety of finishing applications.

Available in Grade: SP4019

-64 Inserts

Positive Insert Geometries

-62 Inserts

Profile

Cutting Condition

Materials Application

Profile

Cutting Condition

Materials Application

www.kennametal.com

C20

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

450 - 700 N/mm

2

HBN

120 - 180

Stainless Steel:

VCGT130304E-66

VCGT2.51A-66

0,05 0,20 0,15

0,25

0,10

f

n

(feed/rev)

0.002 0.0080.006 0.0100.004

1,50

2,50

0,50

a

p

(depth of cut)

0.060

0.100

0.020

0,00

0.000

1,00 0.040

2,00 0.080

3,00 0.118

-66

0,30

0.015

inchmm

inch

mm

CCMT120408E-73

CCMT432A-73

Alloyed Steel:

900 - 1200 N/mm

2

HBN

260 - 340

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

4,50

3,50

0,50

5,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0.216

6,00 0.235

6,50 0.255

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

-73

inchmm

inch

mm

4 4

8

GH1

P M K N S H

4 4 4

SP4019

P M K N S H

NL300

P M K N S H

NL920

P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

VCGT130304E-66

a

p

(depth of cut)

f

n

(feed/rev)

CCMT120408E-73

Alloyed Steel: 900 - 1200 N/mm

2

HBN 260 - 340

-73 Geometry Technical Information

Medium to Roughing:

The -73 Geometry is an as pressed geometry, covering a wide range

of applications and materials, making it the ideal first choice for most

medium to roughing, machining applications.

Available in Grades: SP4019, NL300 & NL920

Stainless Steel: 450 - 700 N/mm

2

HBN 120 - 180

-66 Geometry Technical Information

Medium to Finishing:

The -66 Geometry has a precision ground periphery and pressed in chip-

breaker, with a sharp edge condition, ideally suited for fine chip control

when machining medical and small precision components.

Available in Grade: GH1

-73 Inserts

Positive Insert Geometries

-66 Inserts

Profile

Cutting Condition

Materials Application

Profile

Cutting Condition

Materials Application

www.kennametal.com

C21

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

VCMT160408E-M

VCMT332A-M

Unalloyed Steel:

750 - 950 N/mm

2

HBN

220 - 270

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

3,50

0,50

a

p

(depth of cut)

0.060

0.100

0.138

0.020

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

-M

inchmm

inch

mm

4 4

8

SP4019

P M K N S H

GH1

P M K N S H

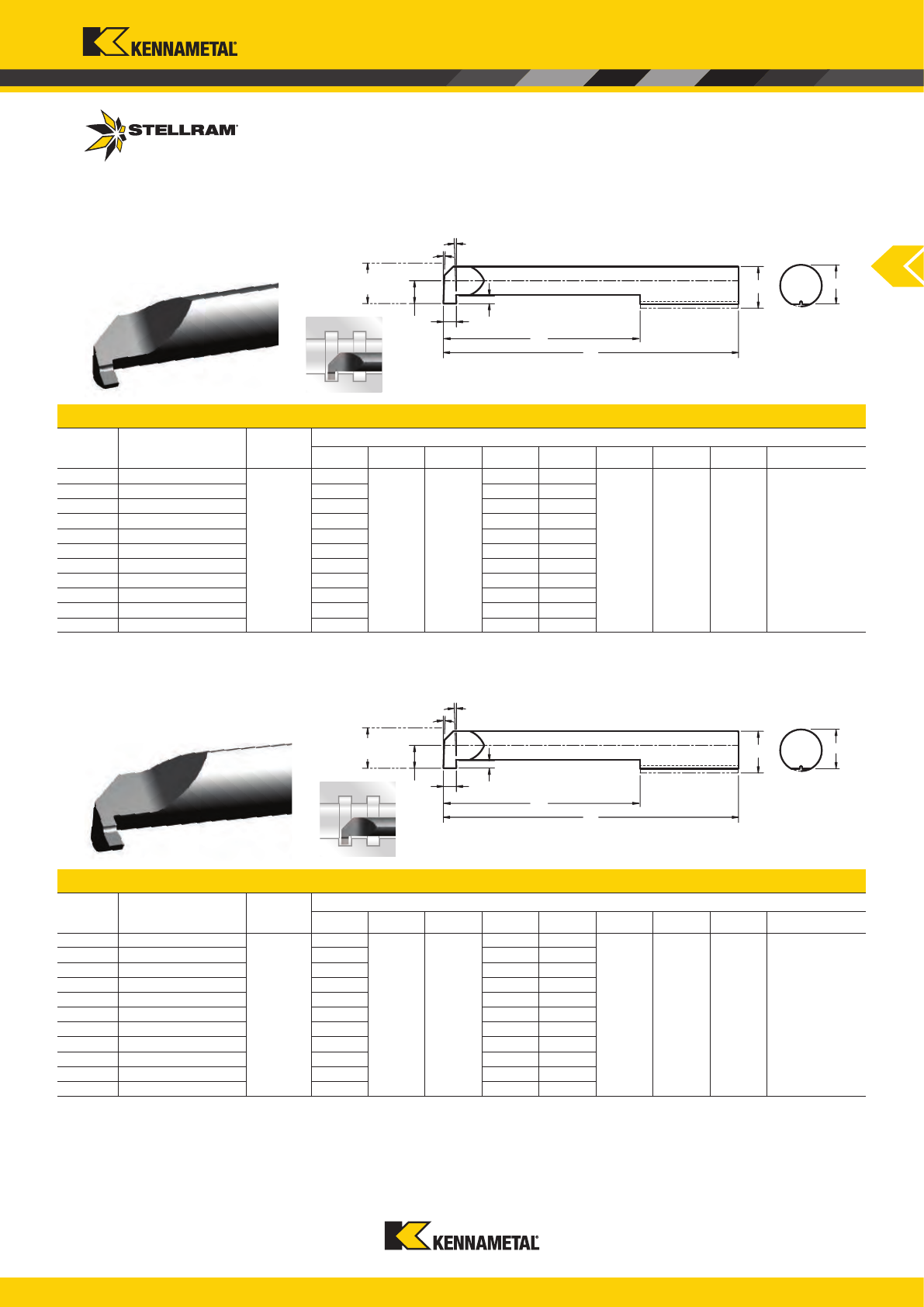

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

VCMT160408E-M

Unalloyed Steel: 750 - 950 N/mm

2

HBN 220 - 270

-M Geometry Technical Information

Medium to Finishing:

The -M Geometry has a small, well defined chip-breaker for a soft cutting

action, resulting in very little stress being produced, when machining

small diameter components.

Available in Grades: SP4019 & GH1

Positive Insert Geometries

-M Inserts

Profile

Cutting Condition

Materials Application

www.kennametal.com

C22

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

TCMT16T308E

TCMT32.53A

Unalloyed Steel:

750 - 950 N/mm

2

HBN

220 - 270

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

4,50

3,50

0,50

5,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0.216

6,00 0.235

6,50 0.255

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

-T

inchmm

inch

mm

4 4 4

SP4019

P M K N S H

NL250

P M K N S H

NL300

P M K N S H

NL400

P M K N S H

NL920

P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

TCMT16T308E

Unalloyed Steel: 750 - 950 N/mm

2

HBN 220 - 270

-T Geometry Technical Information

Medium to Roughing:

The -T Geometry is a utility geometry giving a stable cutting action

in a wide vareity of demanding applications.

Available in Grades: SP4019, NL250, NL300, NL400 & NL920

Positive Insert Geometries

-T Inserts

Profile

Cutting Condition

Materials Application

www.kennametal.com

C23

P

P

M

M

K N

S

H

P

P

M

M

K N

S

H

ECMX12T308EL

ECMX422AL

Aluminium: <16% Si HBN 116

0,10 0,40 0,30 0,50 0,20

f

n

(feed/rev)

0.004 0.0160.012 0.0200.008

1,50

2,50

4,50

3,50

0,50

5,50

a

p

(depth of cut)

0.060

0.100

0.180

0.138

0.020

0.216

6,00 0.235

6,50 0.255

0,60

0.023

1,00 0.040

2,00 0.080

3,00 0.118

4,00 0.160

-X

inchmm

inch

mm

4 4 8

SP4019

P M K N S H

GH1

P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

a

p

(depth of cut)

f

n

(feed/rev)

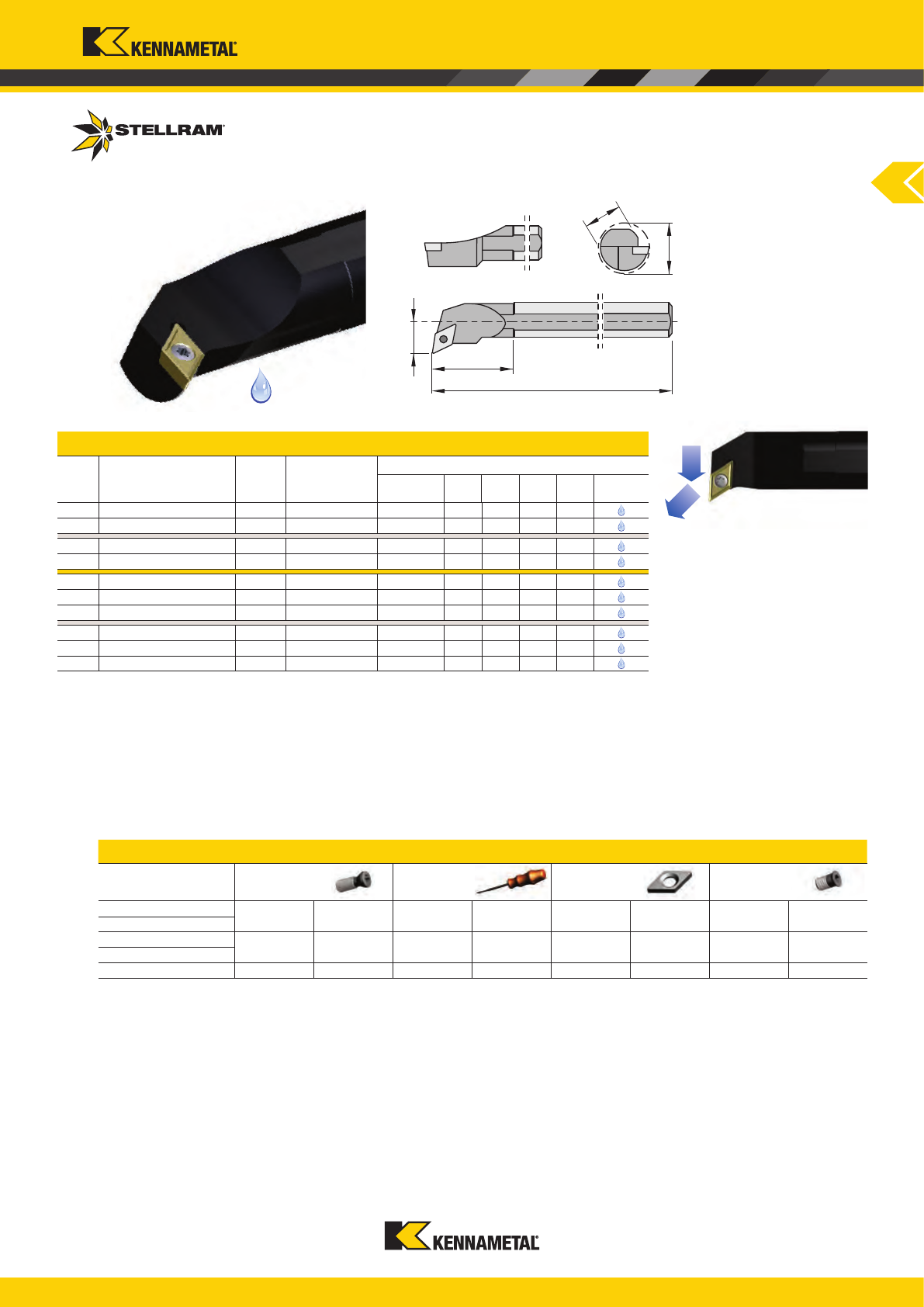

ECMX12T308EL

Aluminium: <16% Si HBN 116

-X Geometry Technical Information

Medium to Roughing:

The -X Geometry has a precision ground parallel chip groove,

available with a fully ground periphery or as pressed, both with a

sharp edge condition. Ideal for the machining of components which

have vibration sensitive applications.

Available in Grades: SP4019 & GH1

Positive Insert Geometries

-X Inserts

Profile

Cutting Condition

Materials Application

www.kennametal.com

C24

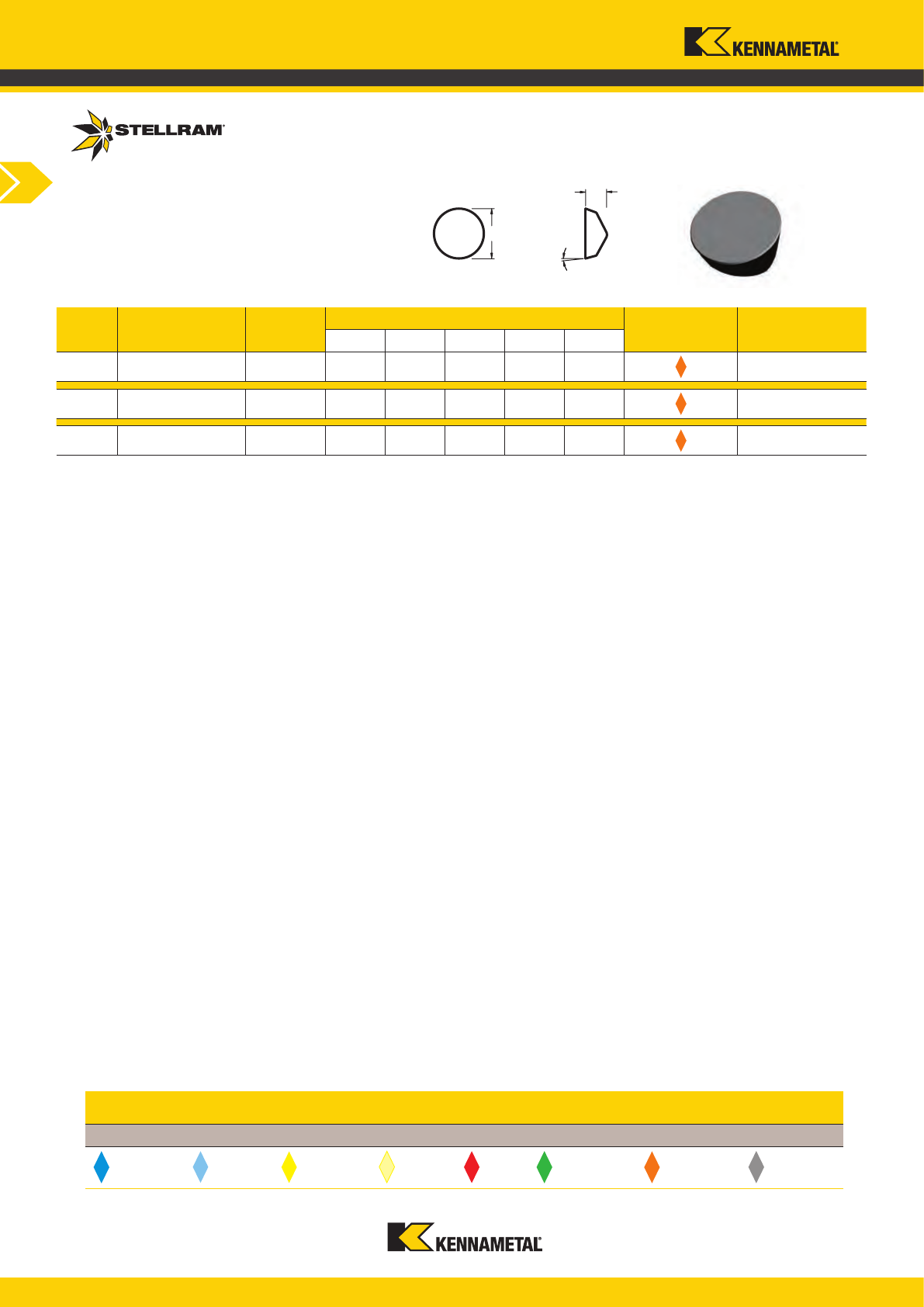

GH1

NL200 NL250 NL300 NL400 NL920

SP0819 SP4019

SA6609

Introduction

Grade Selection

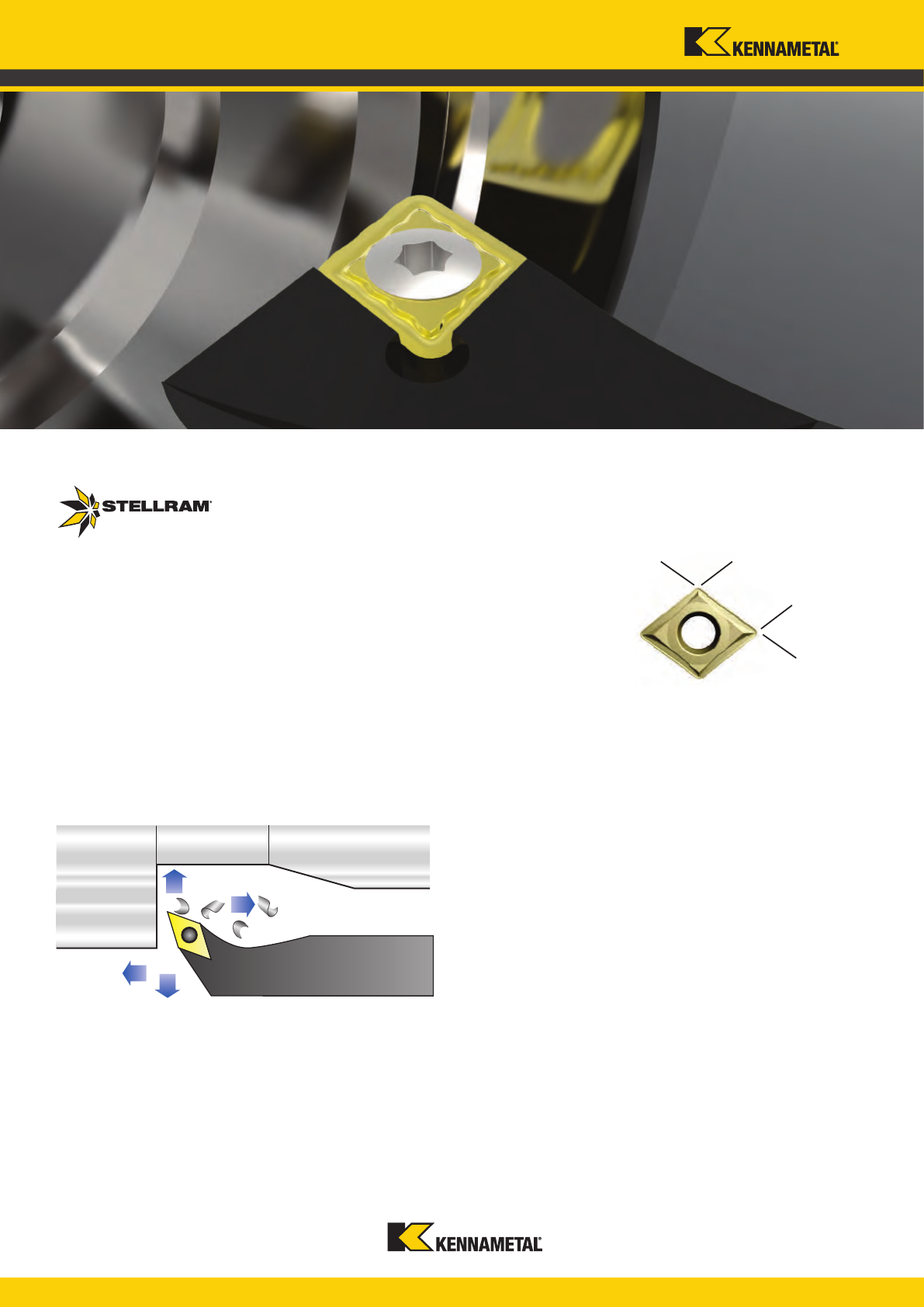

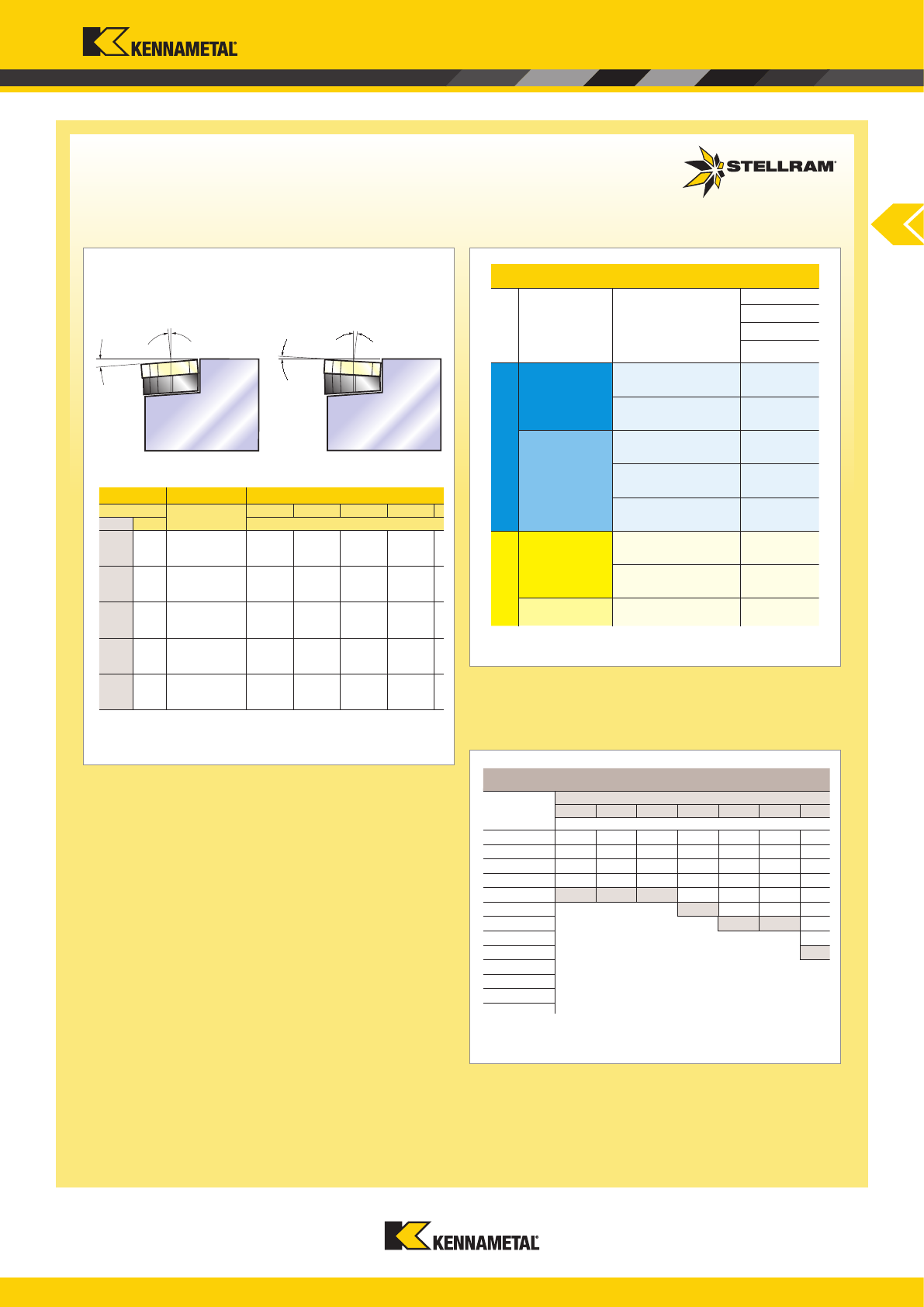

Stellram’s range of carbide and ceramic grades

offer solutions to suit all material groups.

Cutting Material

Groups

Uncoated Grade

Stellram’s uncoated GH1 grade is a micro-gain carbide offering excellent wear

resistance at high cutting speeds, in various materials and applications.

NL = CVD Coated Grades

The NL range of CVD coated grades with enhanced surface layering have been

specically developed and engineered to machine at elevated cutting conditions,

in a broad range of materials.

WEAR RESISTANCE

TOUGHNESS

SP = PVD Coated Grades

These PVD coated grades can be applied to varying applications and materials,

but primarily designed to machine stainless steels, and high temperature alloys.

SA = Ceramic Grade

SA6609 is an advanced silicon-carbide whisker reinforced ceramic grade,

which makes it very resistant to edge facture and notch wear, especially when

machining high nickel, and high cobalt based alloys.

WEAR RESISTANCE

TOUGHNESS

WEAR RESISTANCE

TOUGHNESS

WEAR RESISTANCE

TOUGHNESS

www.kennametal.com

C25

P

60 405

M

60 275

K

95 375

N

S

20 80

H

NL250

01 05 10 15 20 25 30 35 40 45 50

P

60 415

M

K

95 410

N

S

H

45 125

NL200

01 05 10 15 20 25 30 35 40 45 50

Introduction

Vc max

Vc min

m/min

m/min

Vc max

Vc min

Application Range

Cutting speed

Application Range

Cutting speed

Recommended Acceptable

Recommended Acceptable

NL250

Coating Type: CVD

Wear resistant grade for semi-nishing and nishing applications.

Suitable for stable conditions with limited interrupted machining.

Available in the following geometries:

Finishing: 1B

Light-Medium Roughing: 2N

Roughing: 4T

Flat Top: Roughing

NL200

Coating Type: CVD

First choice to machine Cast Iron, this grade has a very good

resistance to wear and deformation, suitable for medium and

nishing applications on gray and malleable cast irons.

Available in the following geometries:

Medium – Roughing: 4U

MAX DRY

MAX DRY

Grade Descriptions

NL200 & NL250

www.kennametal.com

C26

P

50 360

M

50 245

K

N

S

15 70

H

NL400

01 05 10 15 20 25 30 35 40 45 50

P

60 380

M

60 255

K

90 335

N

S

H

NL300

01 05 10 15 20 25 30 35 40 45 50

Introduction

Vc max

Vc max

Vc min

Vc min

m/min

m/min

Application Range

Cutting speed

Application Range

Cutting speed

Recommended Acceptable

NL400

Coating Type: CVD

A very tough grade for medium and rough machining, primarily

on Stainless Steel and Exotic Alloys. Good resistance to thermal

diffusion, and accepts light interruption.

Available in the following geometries:

Light Roughing – Semi-Finishing: 4E

Roughing: 4T

Single Sided Heavy Roughing: 5R

Recommended Acceptable

NL300

Coating Type: CVD

A tough but wear resistant grade for medium and rough

machining with light scale but, no interruption. General purpose

for Steels and Cast Iron materials.

Available in the following geometries:

Medium roughing: -73

Light-Medium Roughing: 2N

Roughing: 4T

Single Sided Heavy Roughing: 5R

Medium – Roughing:-T

MAX DRY

MAX DRY

Grade Descriptions

NL300 & NL400

www.kennametal.com

C27

P

80 450

M

75 315

K

N

275 975

S

25 90

H

65 140

SP0819

01 05 10 15 20 25 30 35 40 45 50

P

45 225

M

40 155

K

70 225

N

S

15 45

H

NL920

01 05 10 15 20 25 30 35 40 45 50

Introduction

Vc max

Vc max

Vc min

Vc min

m/min

m/min

Application Range

Cutting speed

Application Range

Cutting speed

NL920

Coating Type: CVD

A ne grain but tough grade, with a high degree of edge security

on Steels and Stainless Steels. Performs well on rough and heavy

machining applications, including interrupted applications.

Available in the following geometries:

Light-Medium: 2N

Roughing: 4T

Sing Sided Heavy Roughing: 5R

Medium –Roughing: -73

Medium –Roughing: -T

Recommended Acceptable

SP0819

Coating Type: PVD

A very wear resistant micro grain substrate with a new

generation of TiAlN coating. First choice to machine difcult

to machine materials, including PH Stainless Steel. Requires

higher cutting speeds in nishing and medium operations, with

stable conditions and clean material.

Available in the following geometries:

Finishing: 1B

Finishing-Light Roughing: 3F

Semi Finishing – Light Roughing: 4E

Recommended Acceptable

MAX DRY

MAX DRY

Grade Descriptions

NL920 & SP0819

www.kennametal.com

C28

P

M

K

70 225

N

185 825

S

H

GH1

01 05 10 15 20 25 30 35 40 45 50

P

80 440

M

75 300

K

120 440

N

365 975

S

25 90

H

60 130

SP4019

01 05 10 15 20 25 30 35 40 45 50

Introduction

Vc max

Vc max

Vc min

Vc min

m/min

m/min

Application Range

Cutting speed

Application Range

Cutting speed

Recommended Acceptable

GH1

Coating Type: Uncoated

A very wear resistant uncoated micrograin for Cast Irons,

Hardened Steel to 58 HRC and non ferrous alloys. Produces

a low cutting pressure at high speed due to sharp cutting edge

denition.

Available in the following positive geometries:

Medium – Roughing: X

Medium – Finishing: -64

Medium – Finishing: -66

Medium – Finishing: M

Recommended Acceptable

SP4019

Coating Type: PVD

A tough micro-grain substrate with new generation TiAlN

coating, renders this PVD grade extremely hard for unmatched

performance in all materials.

Available in the following geometries:

Finishing: -62 (positive) Medium – Roughing: -X

Finishing – Light Roughing: 3J Finishing: -61

Medium -Roughing: -73 (positive) Medium- Roughing: -T

Medium – Finishing: -15

MAX DRY

MAX DRY

Grade Descriptions

SP4019 & GH1

www.kennametal.com

C29

E010 0.05 20° 0

E030 0.15 20° 0

P

M

K

N

S

180 450

H

SA6609

01 05 10 15 20 25 30 35 40 45 50

W

β

W β

Introduction

mmmm

mm

Vc maxVc min

m/min

Hone

Edge Condition

Hone

Application Range

Cutting speed

Recommended Acceptable

SA6609

Coating Type: Uncoated

A whisker ceramic grade for roughing and medium machining

applications, on High Temperature Alloys. Excellent wear

resistance with elevated cutting surface speeds.

Available in two edge preparation:

Finishing to medium: E010

Medium to roughing: E030

MAX DRY

Grade Descriptions

SA6609

www.kennametal.com

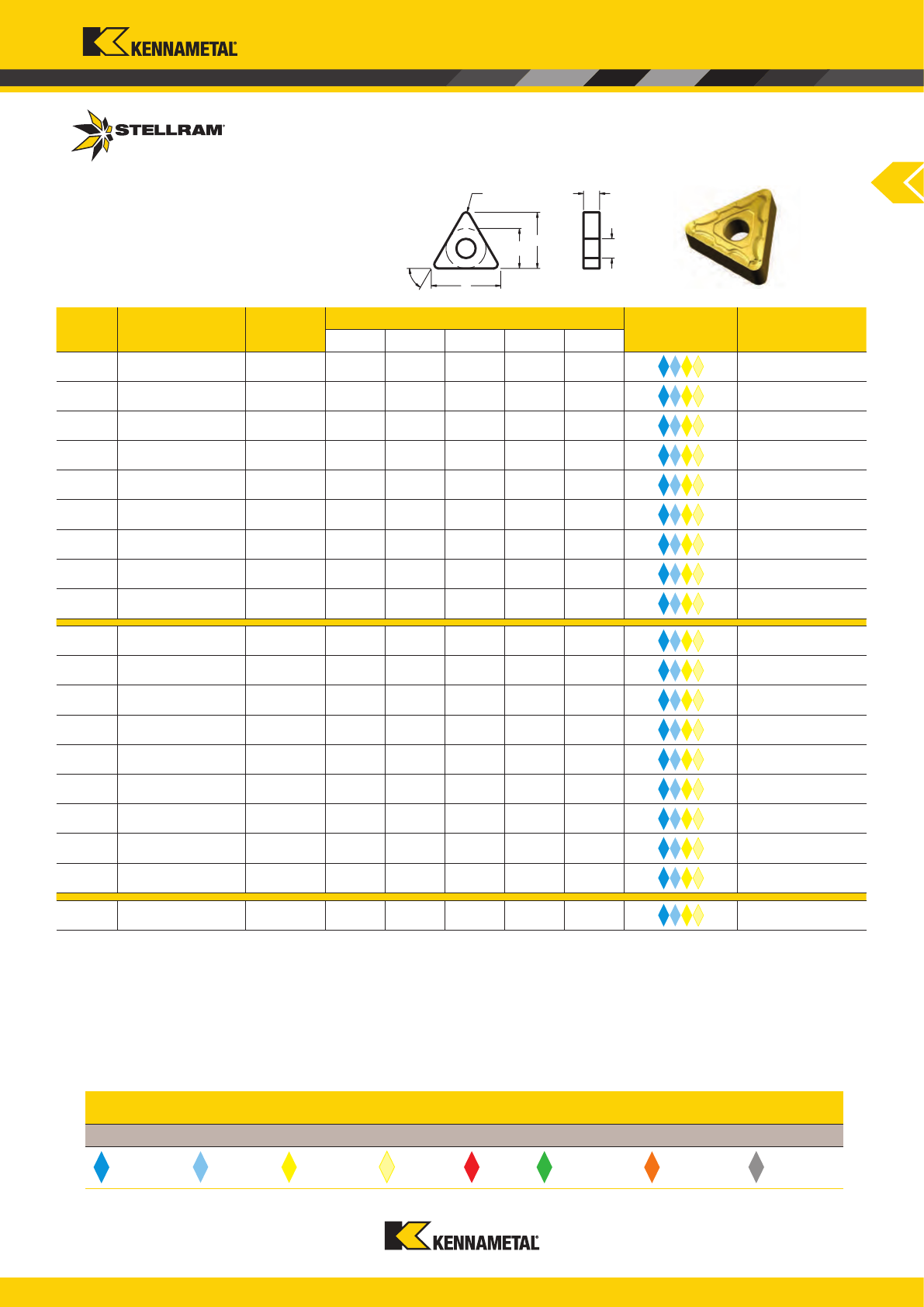

C30

P

P

M

M

K N

S

H

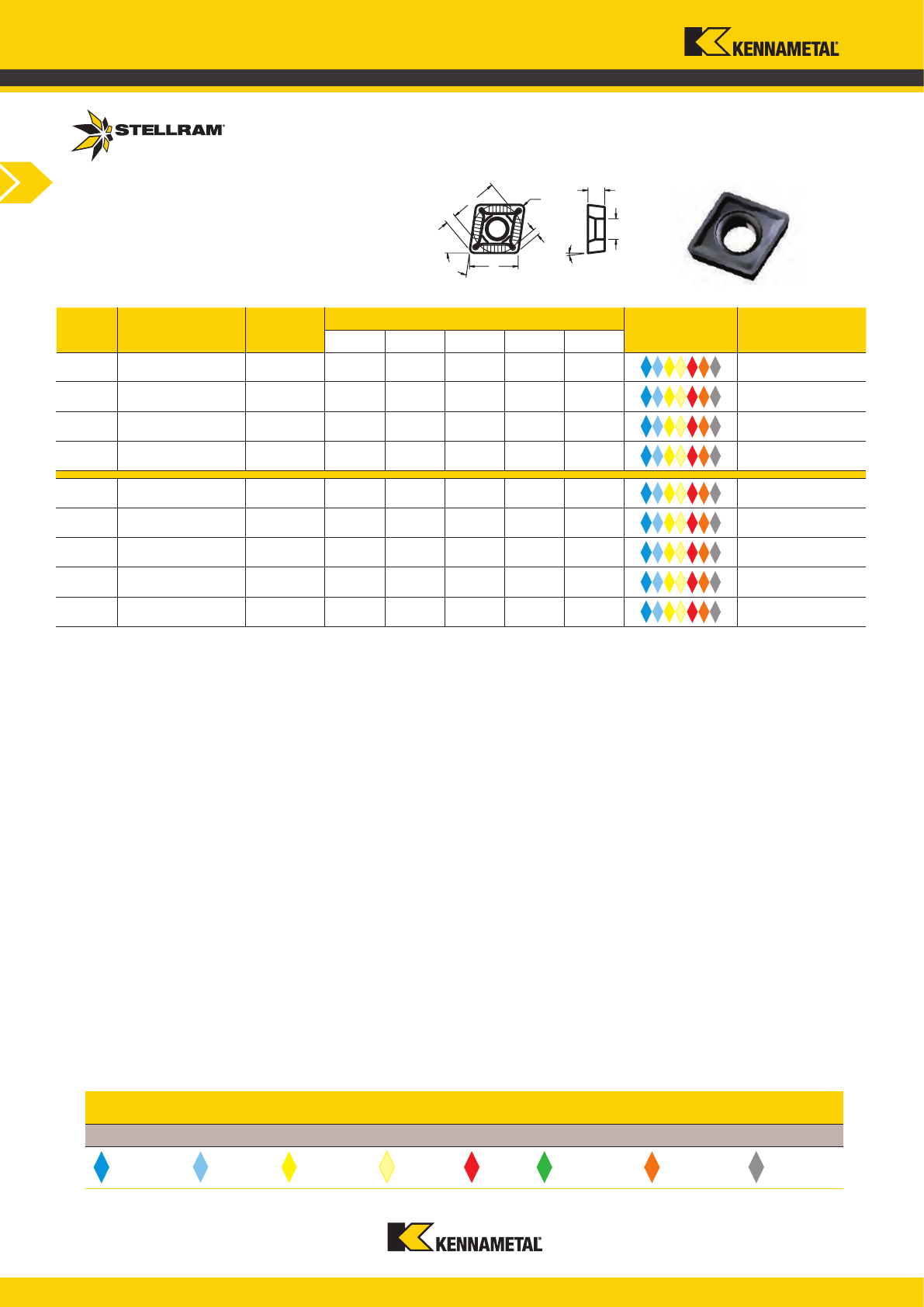

1B

2N

3F

3J

4E

4T

4U

5R

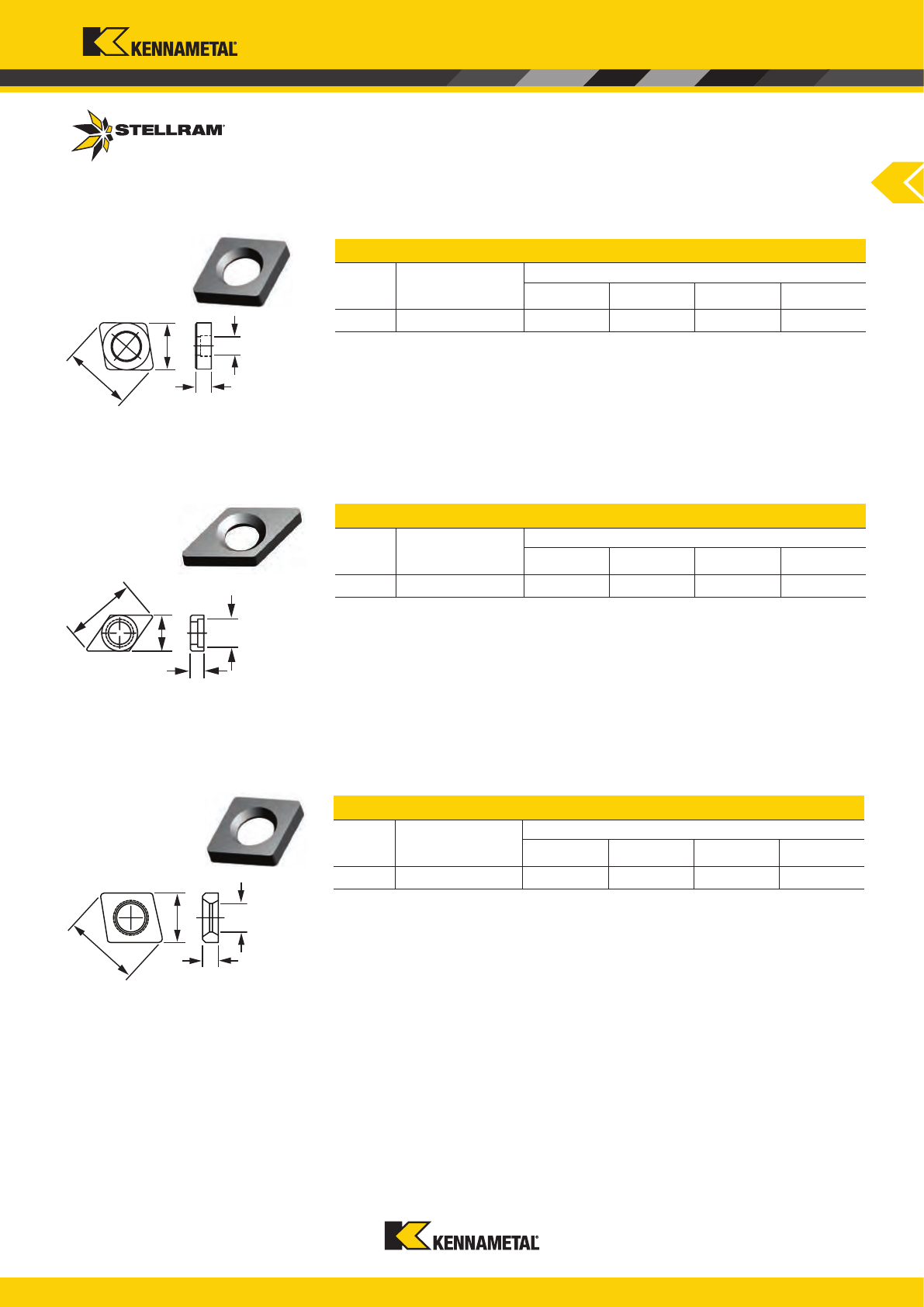

SP0819 SP4019 NL200 NL250

P M K N S H P M K N S H P M K N S H P M K N S H

1B

2N

3F

3J

4E

4T

4U

5R

NL300 NL400 NL920

P M K N S H P M K N S H P M K N S H

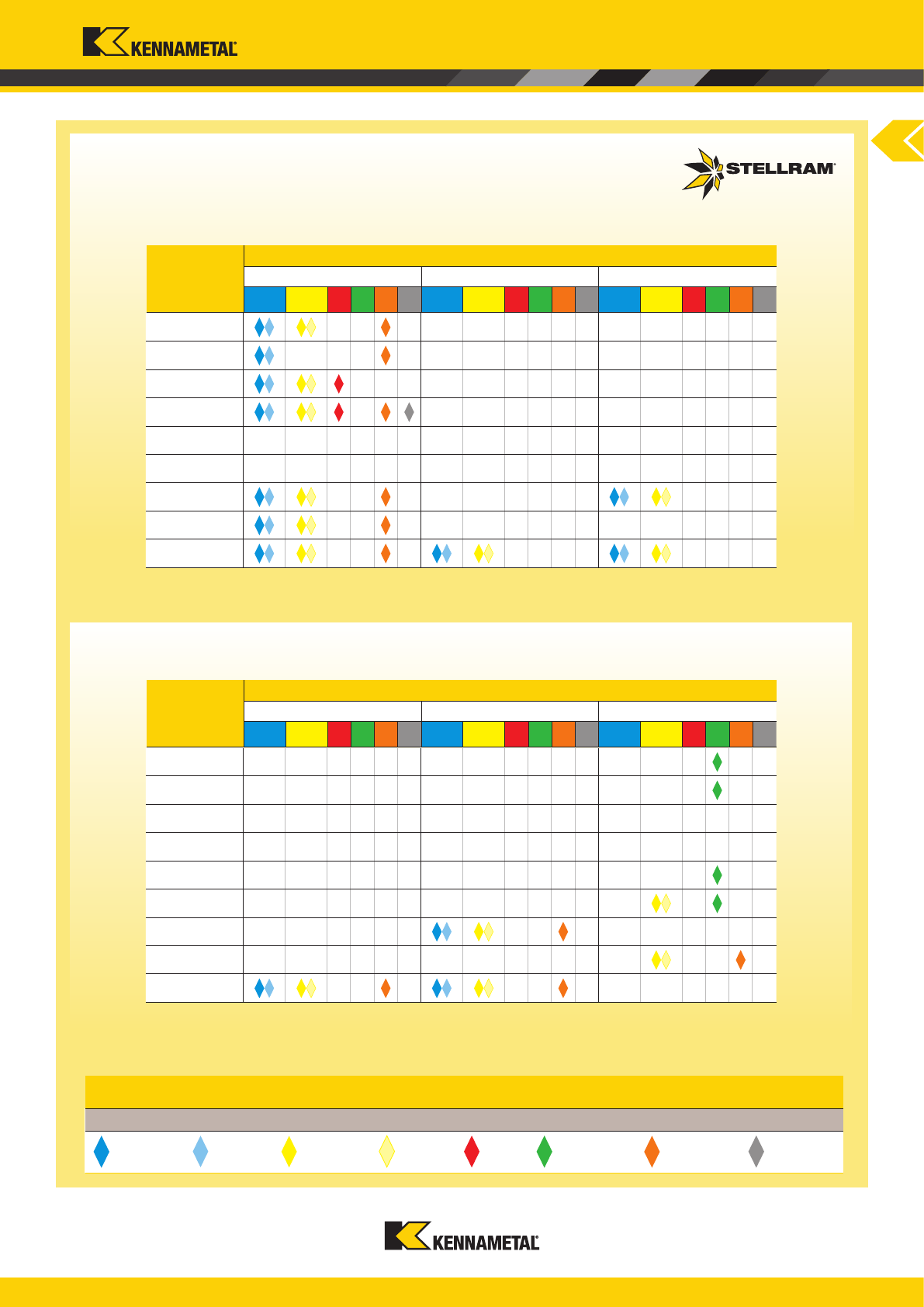

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

Flat-Top

Flat-Top

Grade

Grade

Geometry

Geometry

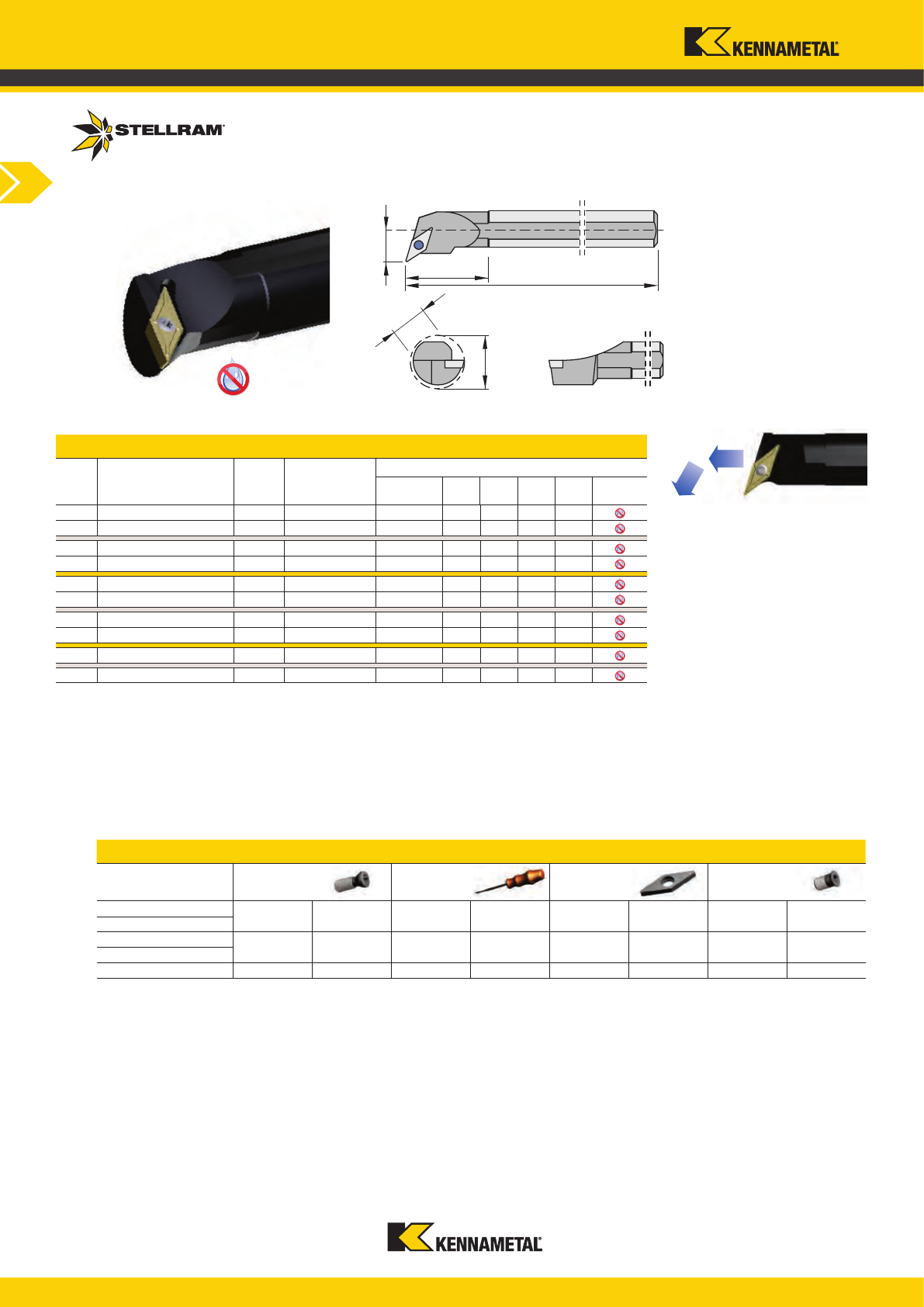

Negative Turning: Geometry, Grade and Material Selection

Negative Turning: Geometry, Grade and Material Selection

Grade Geometry

Negative Turning

P

P

M

M

K N

S

H

www.kennametal.com

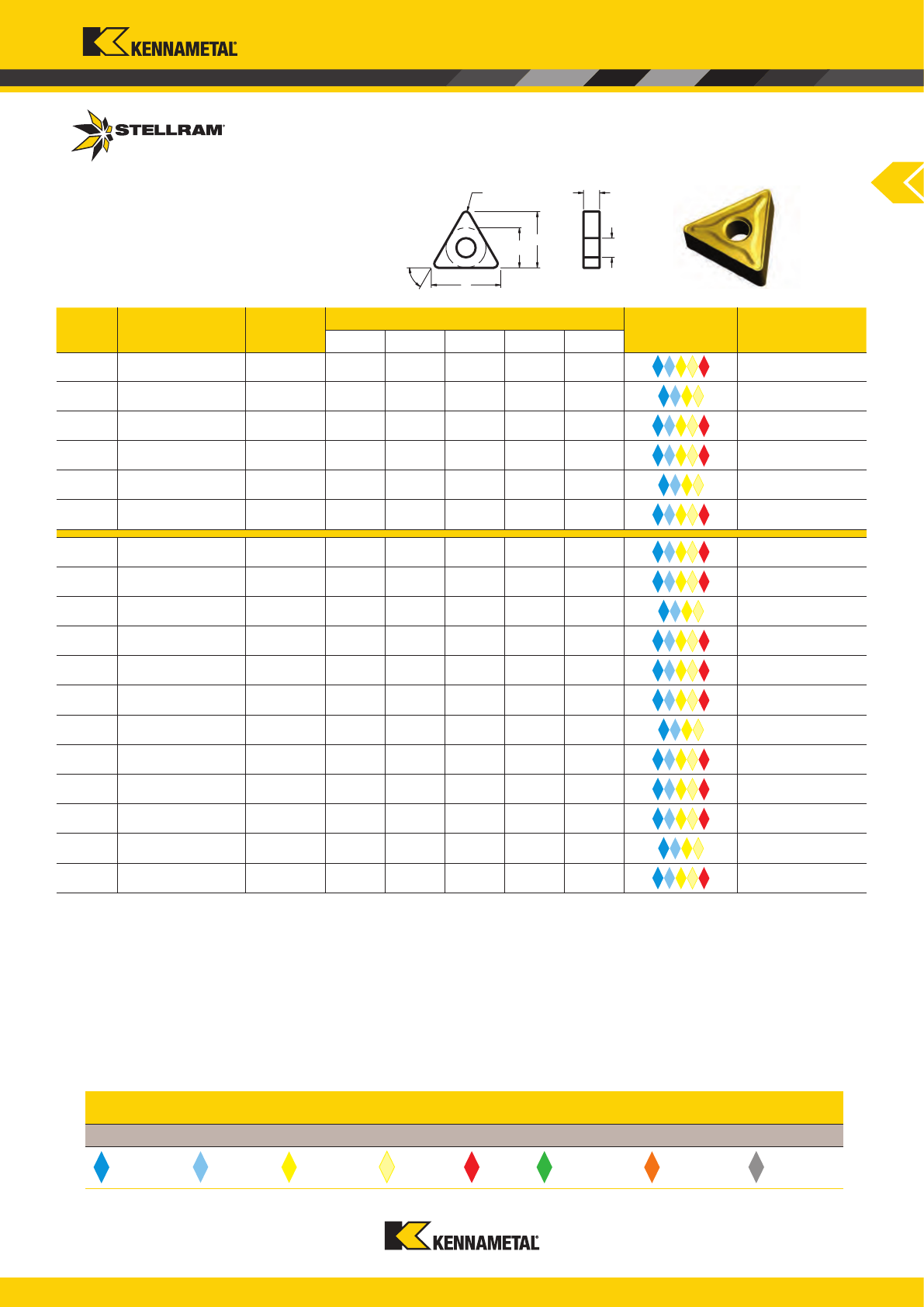

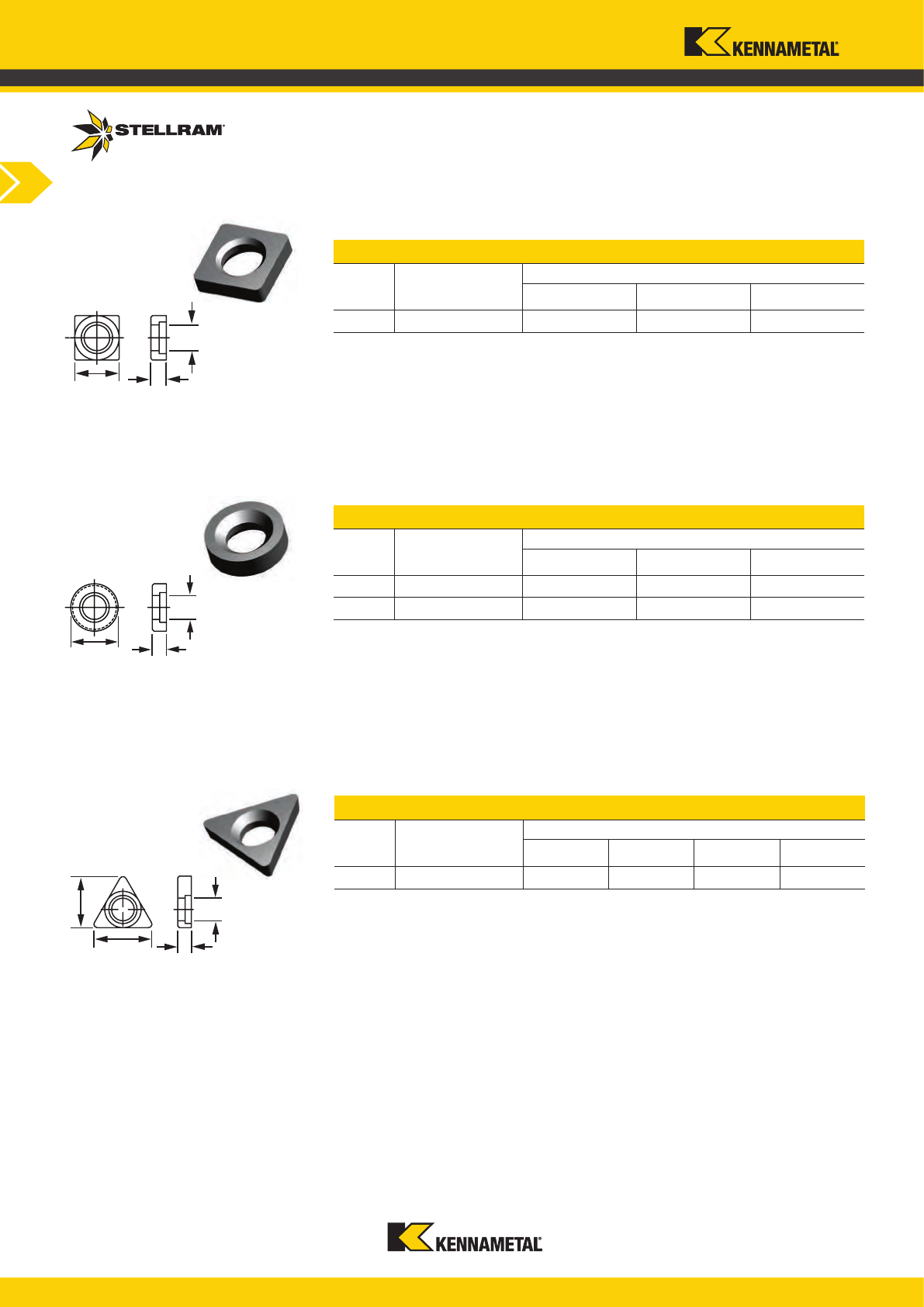

C31

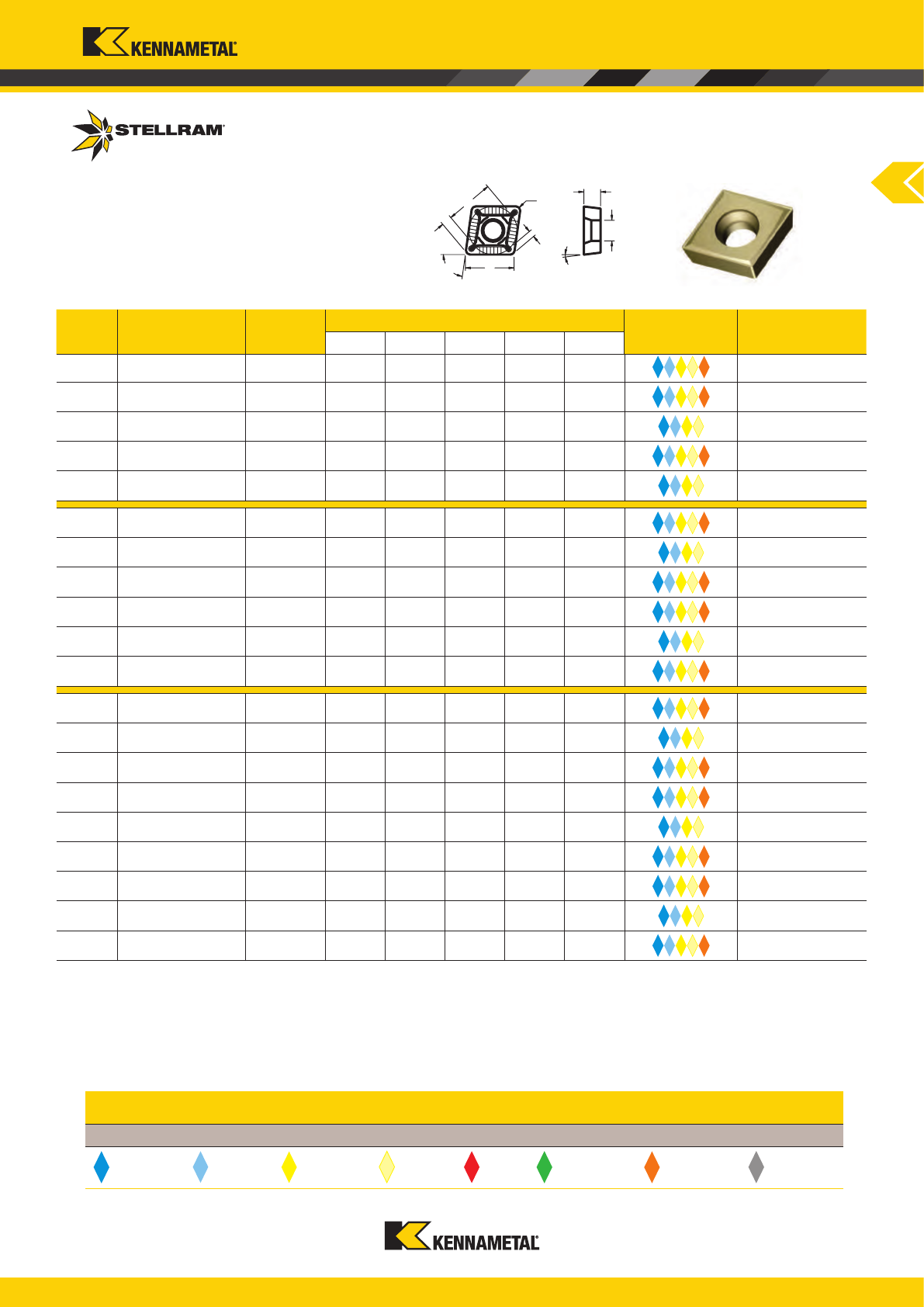

15

X

61

62

64

66

73

M

T

SP4019 NL250 NL300

P M K N S H P M K N S H P M K N S H

15

X

61

62

64

66

73

M

T

NL400 NL920 GH1

P M K N S H P M K N S H P M K N S H

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

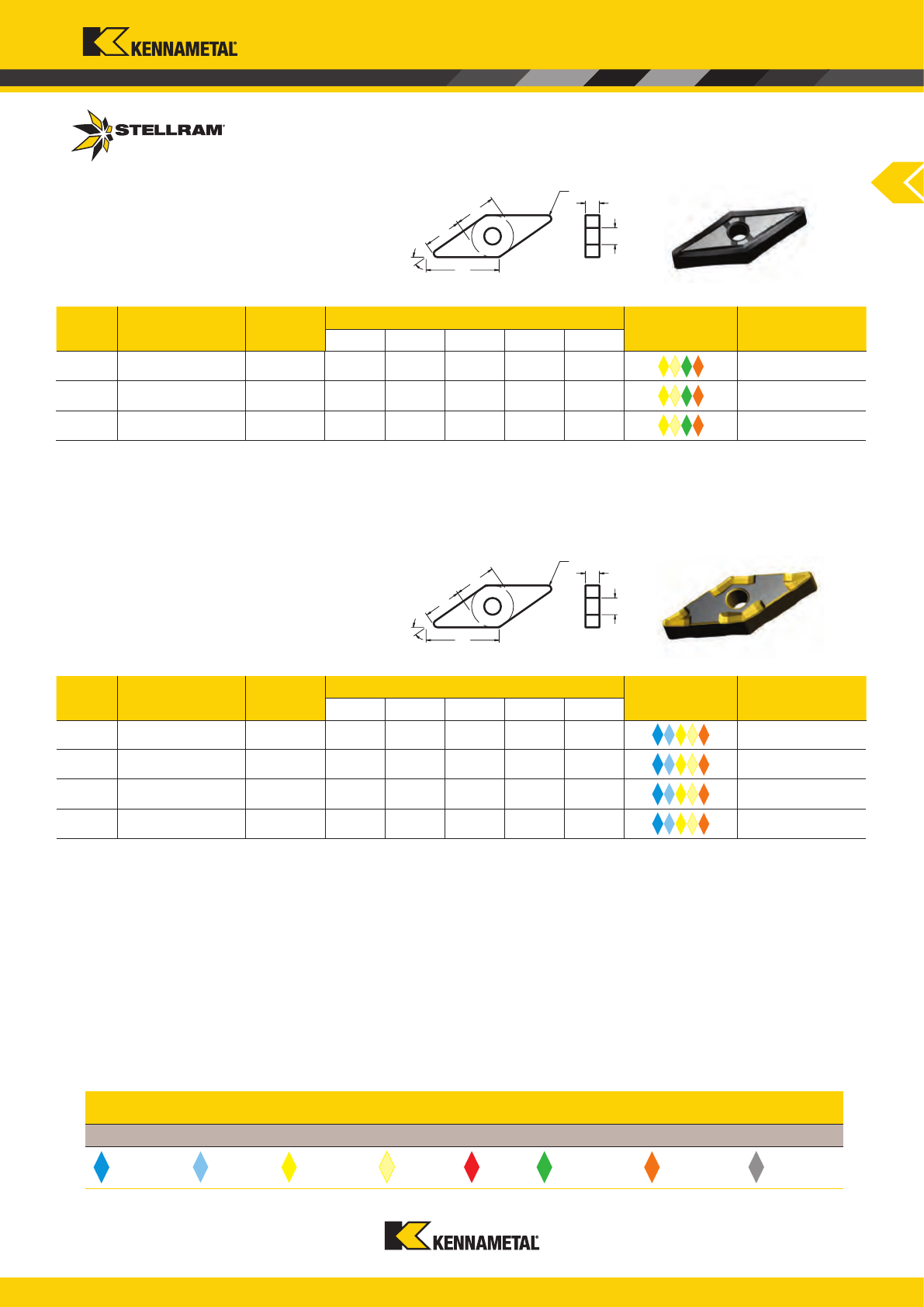

Positive Turning: Geometry, Grade and Material Selection

Positive Turning: Geometry, Grade and Material Selection

Grade

Geometry

Grade

Geometry

Grade Geometry

Positive Turning

www.kennametal.com

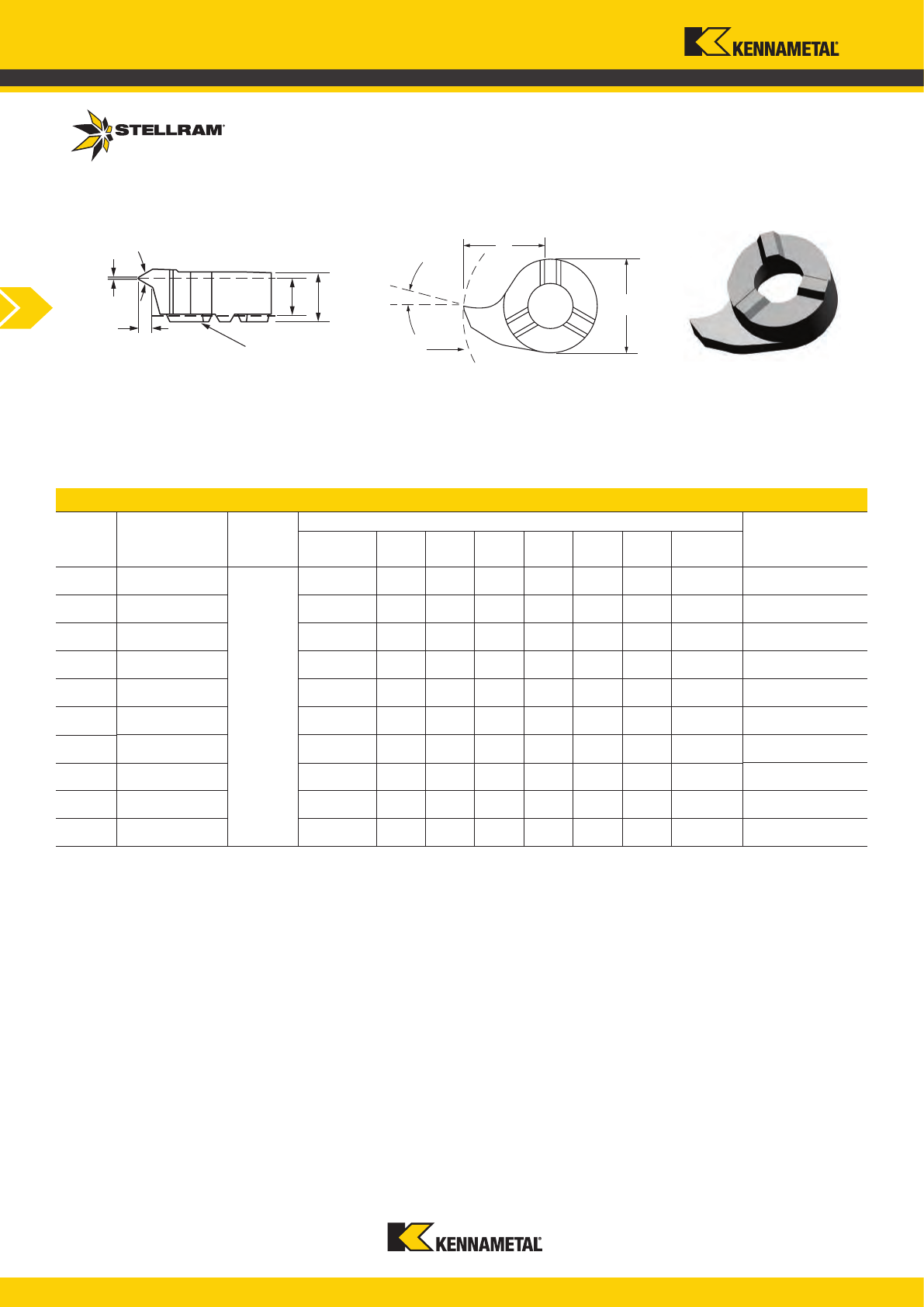

C32

P

P

M

M

K N

S

H

N

M

110 - 274 110 - 255 91 - 244 79 - 152

105 - 263 105 - 245 88 - 234 76 - 146

59 - 146 60 - 135 49 - 130 42 - 81

P

167 - 415 162 - 406 158 - 381 135 - 361 117 - 226

108 - 269 105 - 263 102 - 244 88 - 234 76 - 146

99 - 247 97 - 241 94 - 229 80 - 215 70 - 134

90 - 224 88 - 220 85 - 201 73 - 195 63 - 122

62 - 153 60 - 150 58 - 134 50 - 133 43 - 83

NL200 NL250 NL300 NL400 NL920

K

165 - 411 161 - 373 157- 335 116 - 224

143 -355 139 - 322 135 - 290 100 - 193

96 - 239 94 - 217 91 - 195 68 - 130

S

23 - 59 20 - 52 17 - 33

19 - 48 16 - 42 14 - 26

20 - 51 17 - 46 15 - 28

32 - 80 27 - 72 23 - 45

H

45 - 125

50 - 120

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

Hard

Materials

Hard Steel

>1400 N/mm

2

>415 HBN

Chilled Cast Iron

>1400 N/mm

2

>400 HBN

High

Temperature

Alloys

Iron Based

Cobalt Based

Nickel Based

Titanium Based

Aluminium

& Alloys

Aluminium & Alloys

< 16% 116 HB

Aluminium + Silicon

> 16% 92 HB

Cast Iron

Grey

GG-Ft

Spheroidal-Ductile

GGG-FGS

Malleable

GTS - MN/MP

Stainless

Steel

Austenitic + Ferritic

300 series

Martensitic

400 series

PH Stainless

Refractory

P.H.

min. - max.

min. - max. min. - max.

min. - max.

min. - max.

ISO

Materials Rm and Hardness

CVD Coated

Unalloyed

Steel

<600 N/mm

2

<180 HBN

<950 N/mm

2

<280 HBN

Alloyed

Steel

700-950 N/mm

2

200-280 HBN

950-1200 N/mm

2

280-355 HBN

1200-1400 N/mm

2

355-415 HBN

Cutting Speed

(Vc) m/min

Cutting Speed (v

c

) m/min

www.kennametal.com

C33

P

P

M

M

K N

S

H

K

206 - 438 134 - 268 226 - 482 116 - 224

178 - 378 116 - 232 195 - 416 100 - 193

120 - 255 78 - 156 132 - 280 60 - 130

P

212 - 451 208 - 442 135 - 271 230 - 485

138 - 293 135 -287 88 - 176 150 -315

126 - 268 123 - 263 80 - 161 135 - 290

115 - 244 112 - 239 73 - 146 125 - 265

78 - 167 77 - 163 50 - 100 85 - 180

M

143 - 305 140 - 299 107 - 229 154 -329 80 - 150

149 - 317 135 - 287 102 - 220 160 - 342 80 - 160

76 - 163 75 - 159 57 - 122 82 - 175 40 - 80

N

396 - 976 365 - 975 366 - 915

335 - 823

274 - 671 244 - 610 183 - 549

S

31 - 65 30 - 64 20 - 39 33 - 70 15 - 35 180 - 450

25 - 53 24 - 52 16 - 32 27 - 57 15 - 25 180 - 400

27 - 57 26 - 56 17 - 34 29 - 61 15 - 30 180 - 360

42 - 89 41- 88 27 - 54 45 - 96 25 - 45

H

70 - 140 62 - 131

65 - 135 60 - 127

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

Hard

Materials

Hard Steel

>1400 N/mm

2

>415 HBN

Chilled Cast Iron

>1400 N/mm

2

>400 HBN

High

Temperature

Alloys

Iron Based

Cobalt Based

Nickel Based

Titanium Based

Aluminium

& Alloys

Aluminium & Alloys

< 16% 116 HB

Aluminium + Silicon

> 16% 92 HB

Cast Iron

Grey

GG-Ft

Spheroidal-Ductile

GGG-FGS

Malleable

GTS - MN/MP

Stainless

Steel

Austenitic + Ferritic

300 series

Martensitic

400 series

PH Stainless

Refractory

P.H.

Unalloyed

Steel

<600 N/mm

2

<180 HBN

<950 N/mm

2

<280 HBN

Alloyed

Steel

700-950 N/mm

2

200-280 HBN

950-1200 N/mm

2

280-355 HBN

1200-1400 N/mm

2

355-415 HBN

ISO

Materials Rm and Hardness

PVD Uncoated Ceramic

SP0819 SP4019

SP4030

(Grooving)

SP4066

(Threading)

GH1

Micrograin

SA6609

Cutting Speed

(Vc) m/min

Cutting Speed (v

c

) m/min

www.kennametal.com

C34

P

P

M

M

K N

S

H

P

P01

P05

P10

P15

P20

P25

P30

P35

P40

P45

P50

M

M01

M05

M10

M15

M20

M25

M30

M35

M40

K

K01

K05

K10

K15

K20

K25

K30

K35

K40

N

N01

N05

N10

N15

N20

N25

N30

S

S01

S05

S10

S15

S20

S25

S30

H

H01

H05

H10

H15

H20

H25

H30

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Introduction

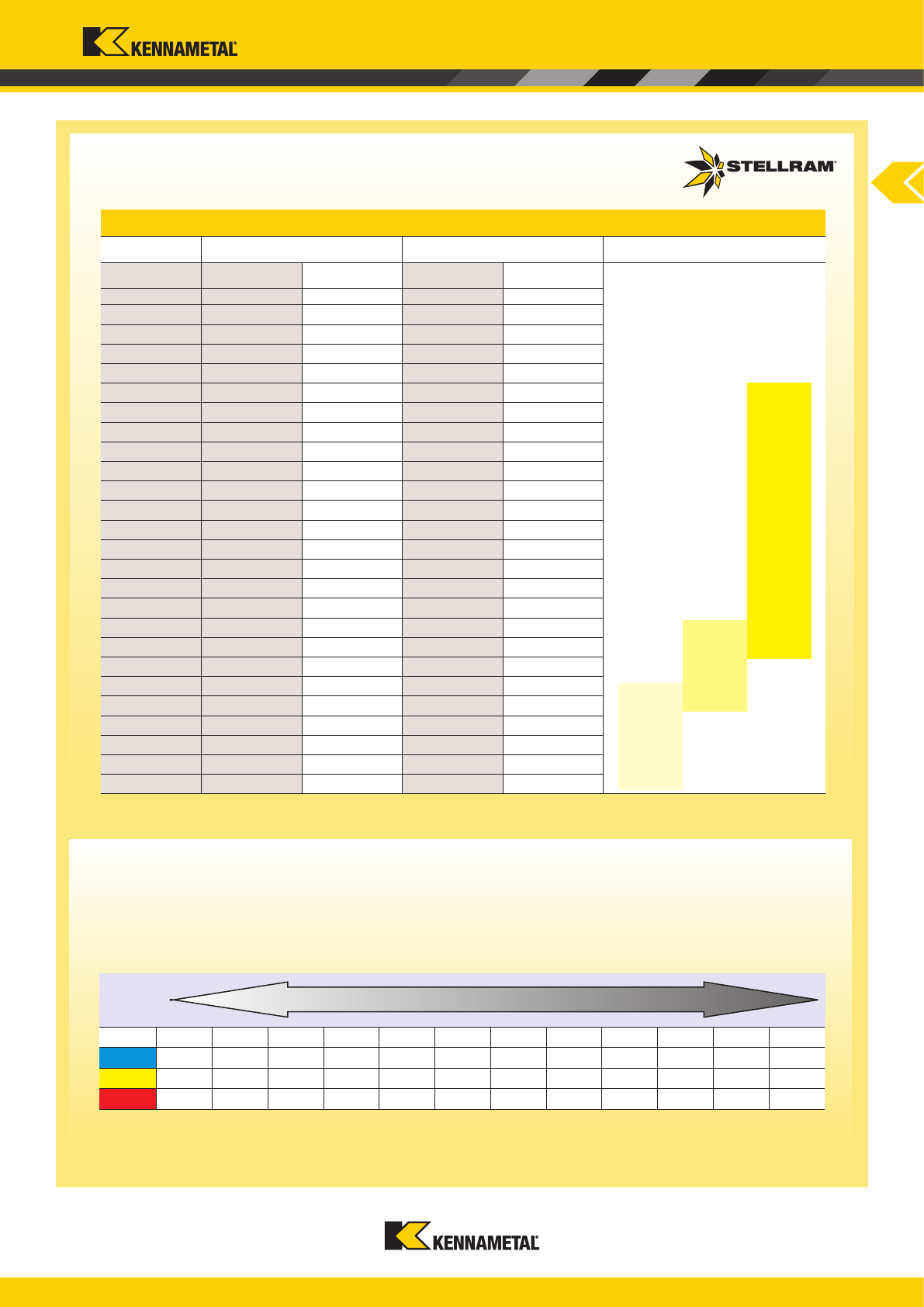

ISO Grade Classication

Groups Materials Code

CVD Grades PVD Grades

Uncoated

Grade

Whisker

Ceramic

Unalloyed

andAlloyed

Steels

Stainless Steels

Cast Irons

Aluminum &

Alloys

High

Temperature

Alloys

Hard Materials

NL200 NL250 NL300 NL400 NL920 SP0819 SP4019 GH1 SA6609

Optimum Grade Performance

Increasing - wear resistance - Increasing cutting speed

Increasing - shock resistance - Increasing - feed

ISO Turning Grade

Classification Chart

www.kennametal.com

C35

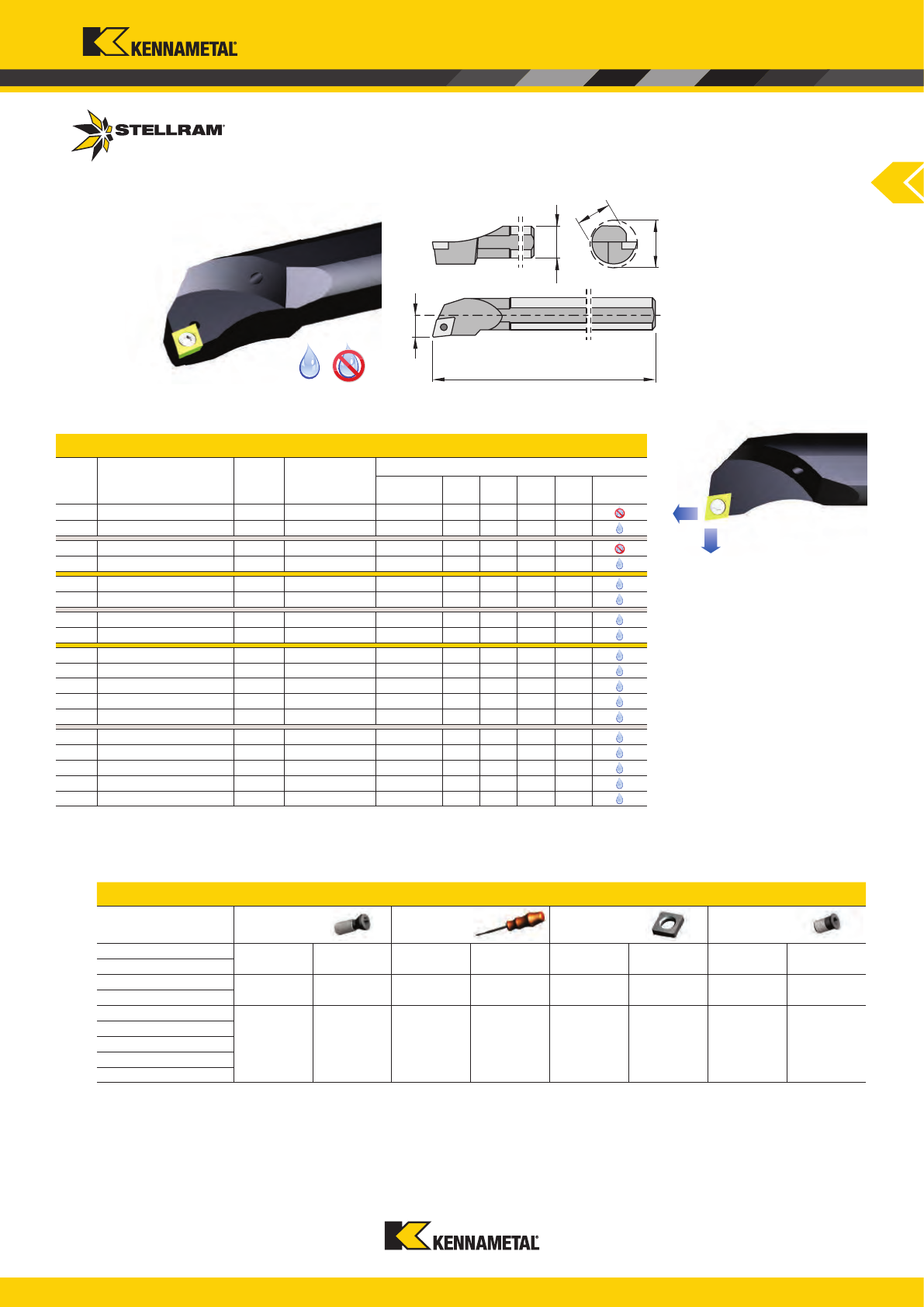

Turning Inserts

www.kennametal.com

C36

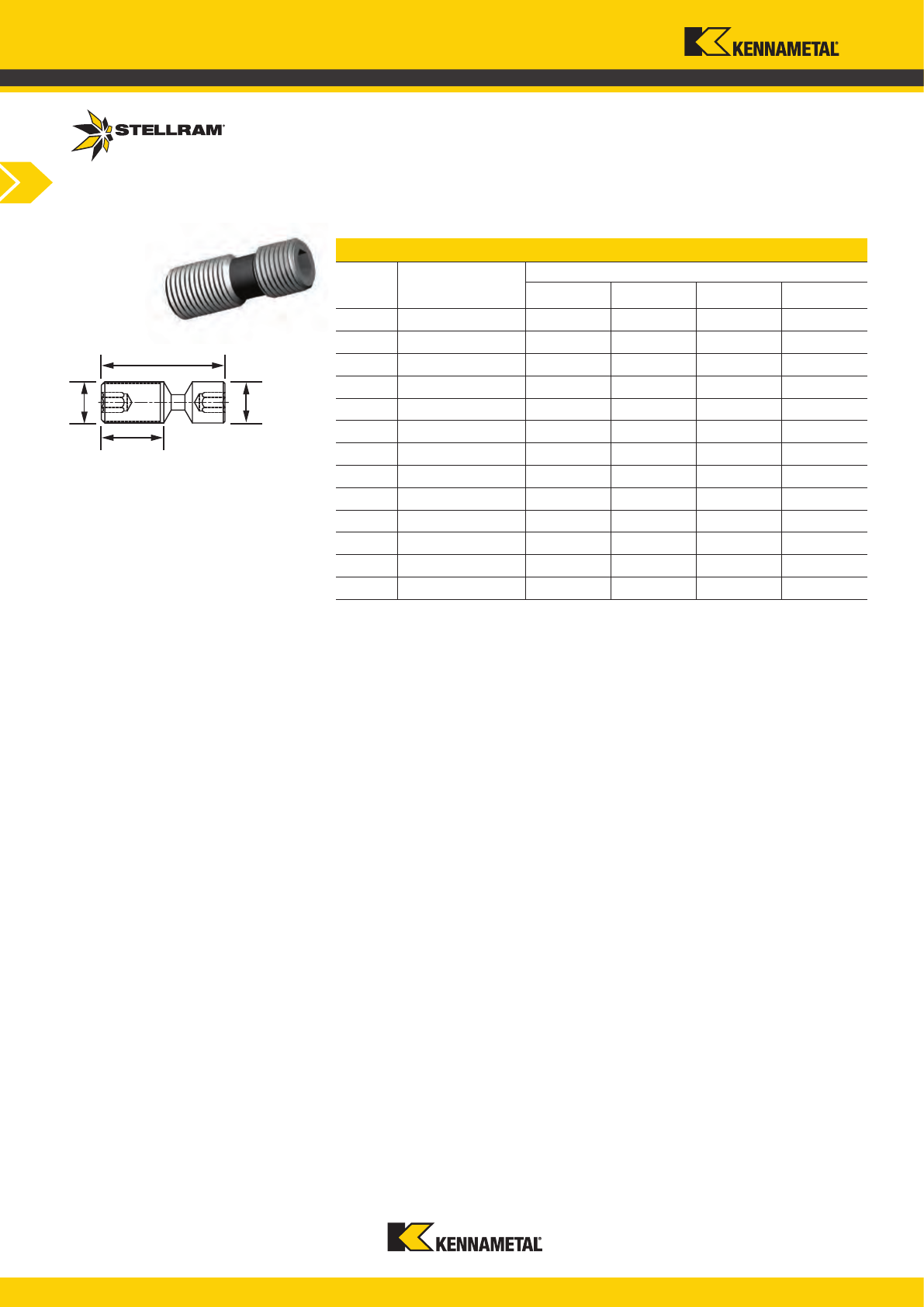

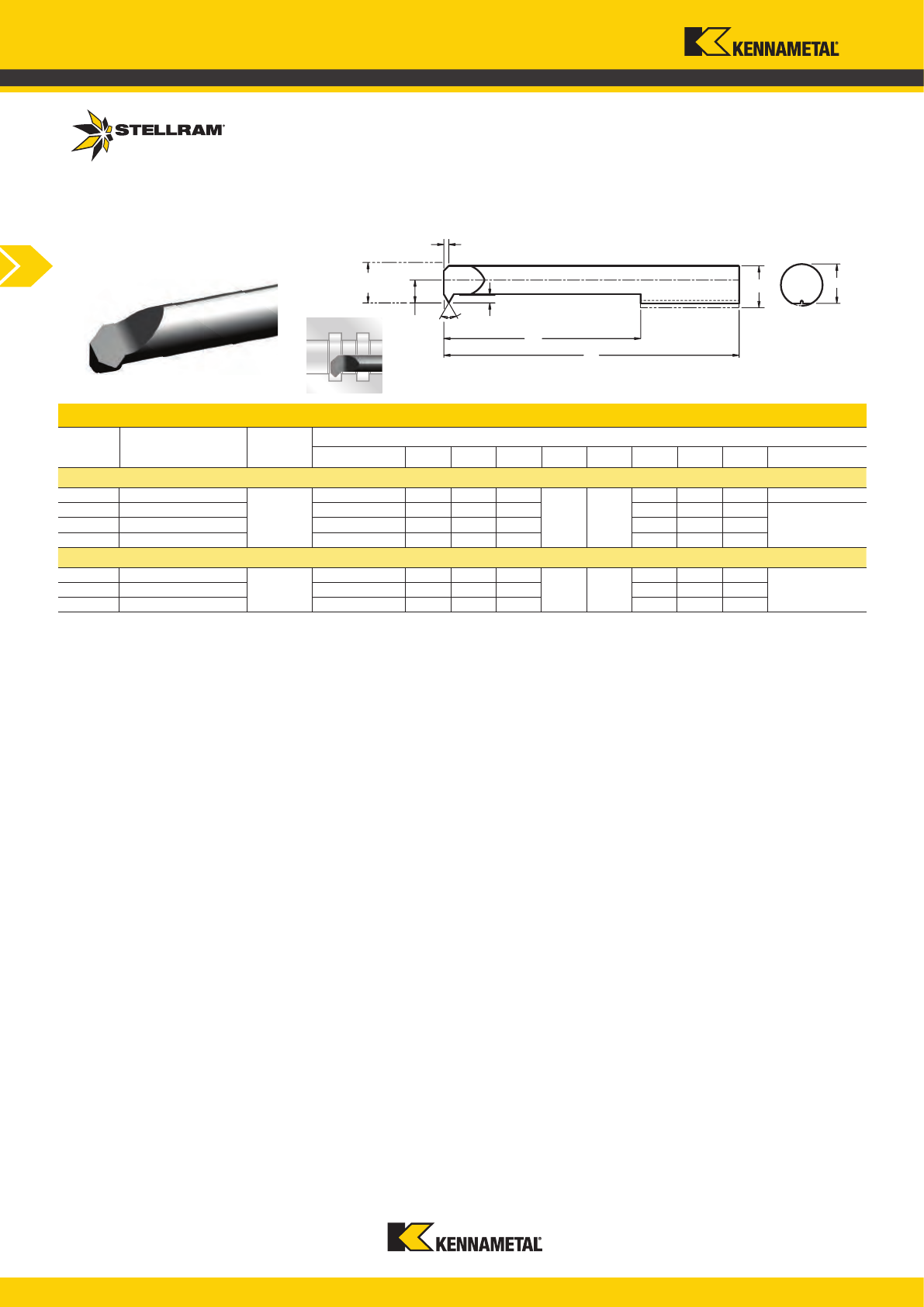

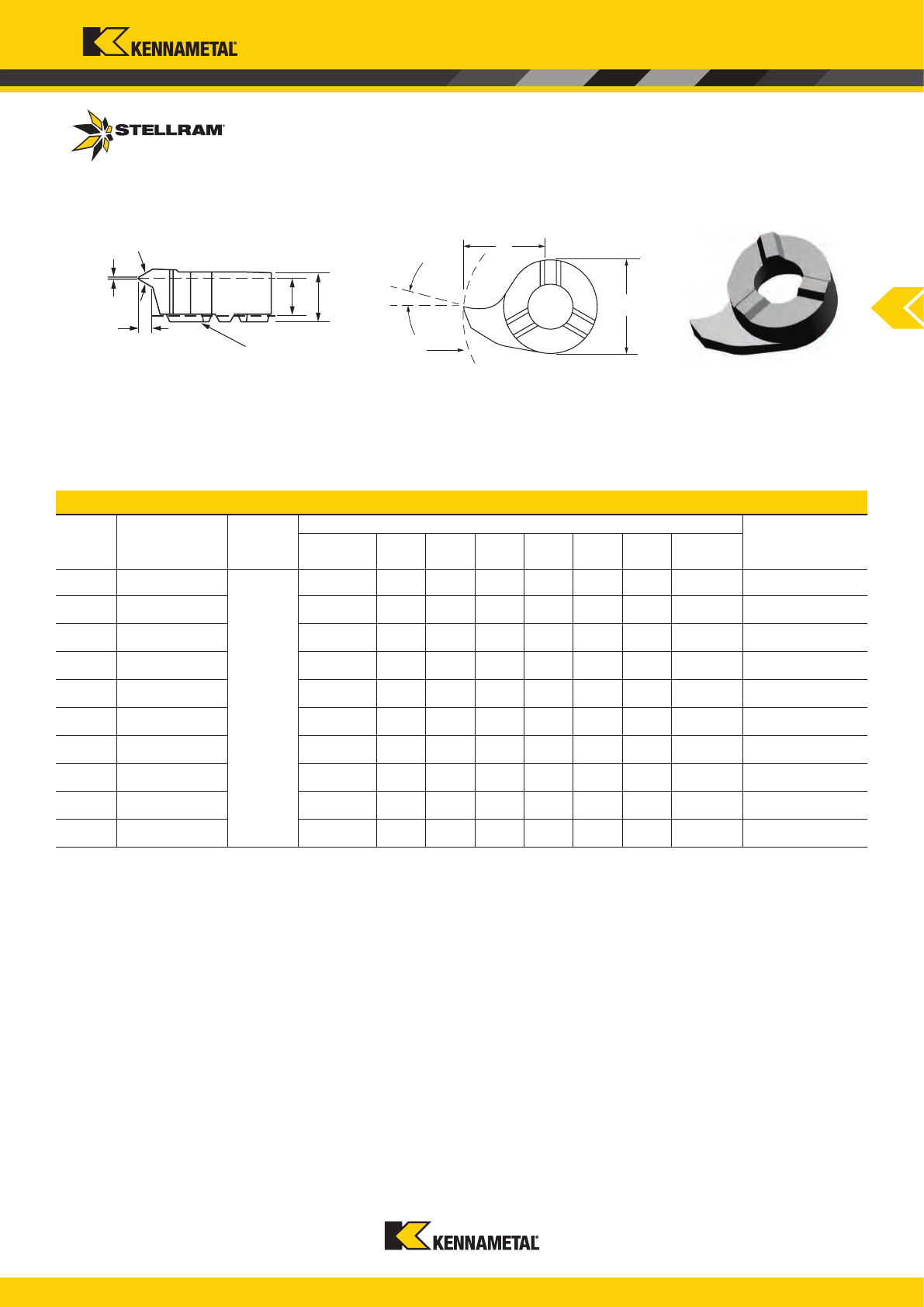

IC d m

J, K, L, M, N U M, N U

4,76 ±0,05 ±0,08 ±0,08 ±0,13

5,56 ±0,05 ±0,08 ±0,08 ±0,13

6 ±0,05 ±0,08 ±0,08 ±0,13

6,35 ±0,05 ±0,08 ±0,08 ±0,13

7,94 ±0,05 ±0,08 ±0,08 ±0,13

8 ±0,05 ±0,08 ±0,08 ±0,13

9,525 ±0,05 ±0,08 ±0,08 ±0,13

10 ±0,05 ±0,08 ±0,08 ±0,13

12 ±0,08 ±0,13 ±0,13 ±0,2

12,7 ±0,08 ±0,13 ±0,13 ±0,2

15,875 ±0,1 ±0,18 ±0,15 ±0,27

16 ±0,1 ±0,18 ±0,15 ±0,27

19,05 ±0,1 ±0,18 ±0,15 ±0,27

20 ±0,1 ±0,18 ±0,15 ±0,27

25 ±0,13 ±0,25 ±0,18 ±0,38

25,4 ±0,13 ±0,25 ±0,18 ±0,38

31,75 ±0,15 ±0,25 ±0,2 ±0,38

32 ±0,15 ±0,25 ±0,2 ±0,38

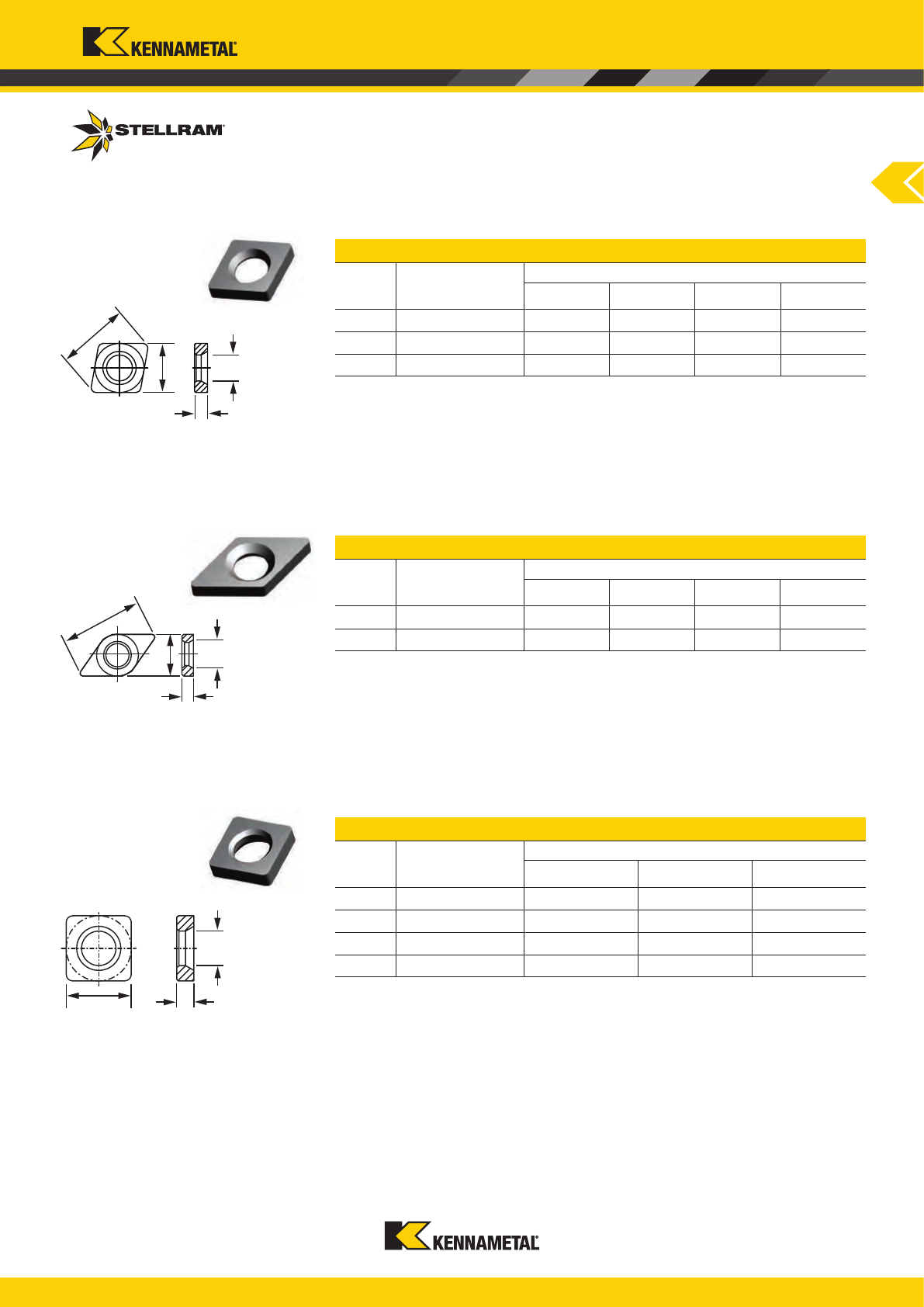

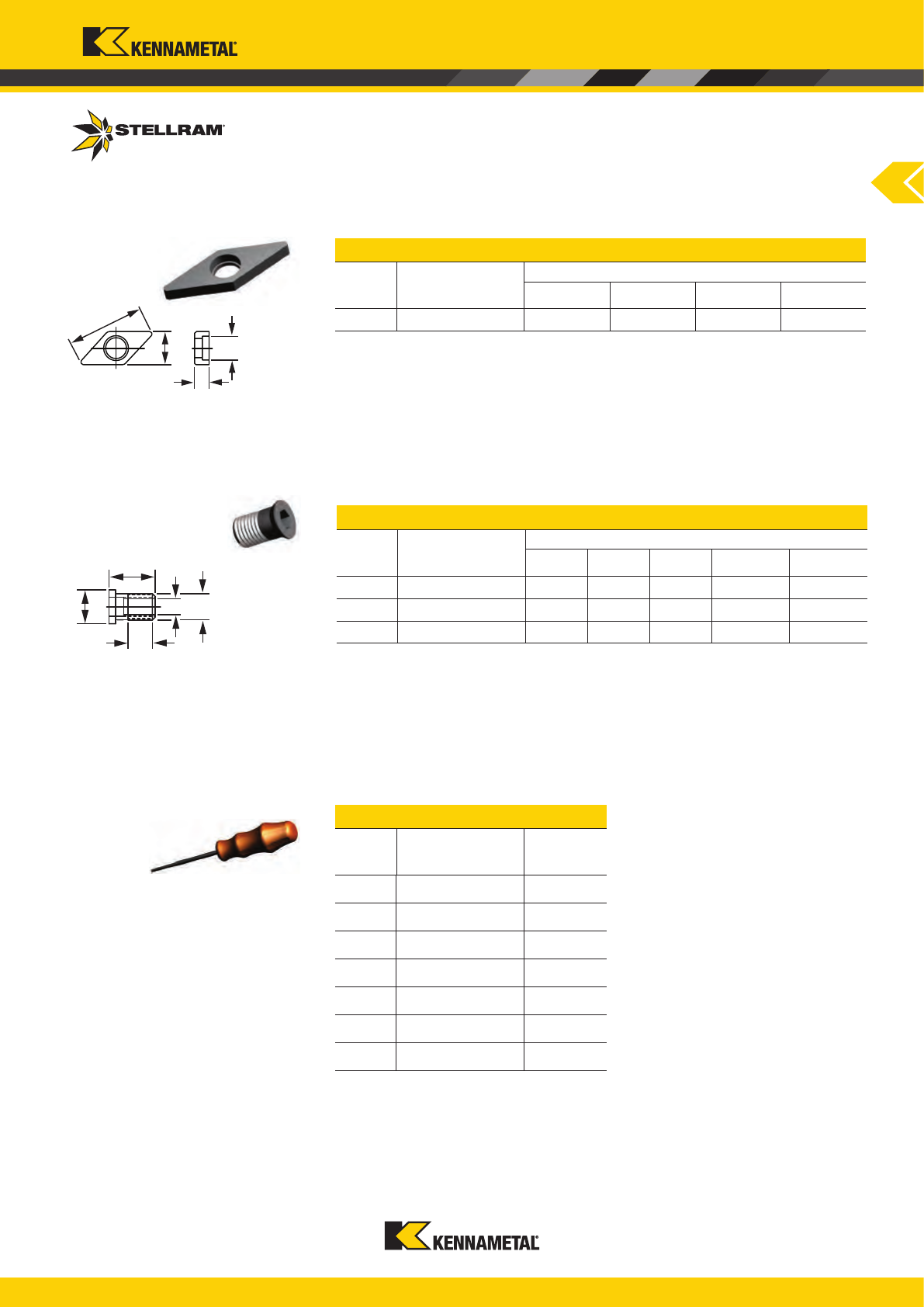

S N M G

1 2 3 4

A

3°

B

5°

C

7°

D

15°

E

20°

F

25°

G

30°

N

0°

P

11°

d

m

d

m

d

m

d

m

s

C

80°

D

55°

E

75°

A

85°

H

120°

K

55°

L

90°

M

86°

O

135°

P

108°

R

360°

S

90°

T

60°

V

35°

W

80°

82°

B

A

70° - 90°

C F G

70° - 90°

B

70° - 90°

H

70° - 90°

J M N

40° - 60°

Q

R

40° - 60°

T

40° - 60°

U

40° - 60°

W

X

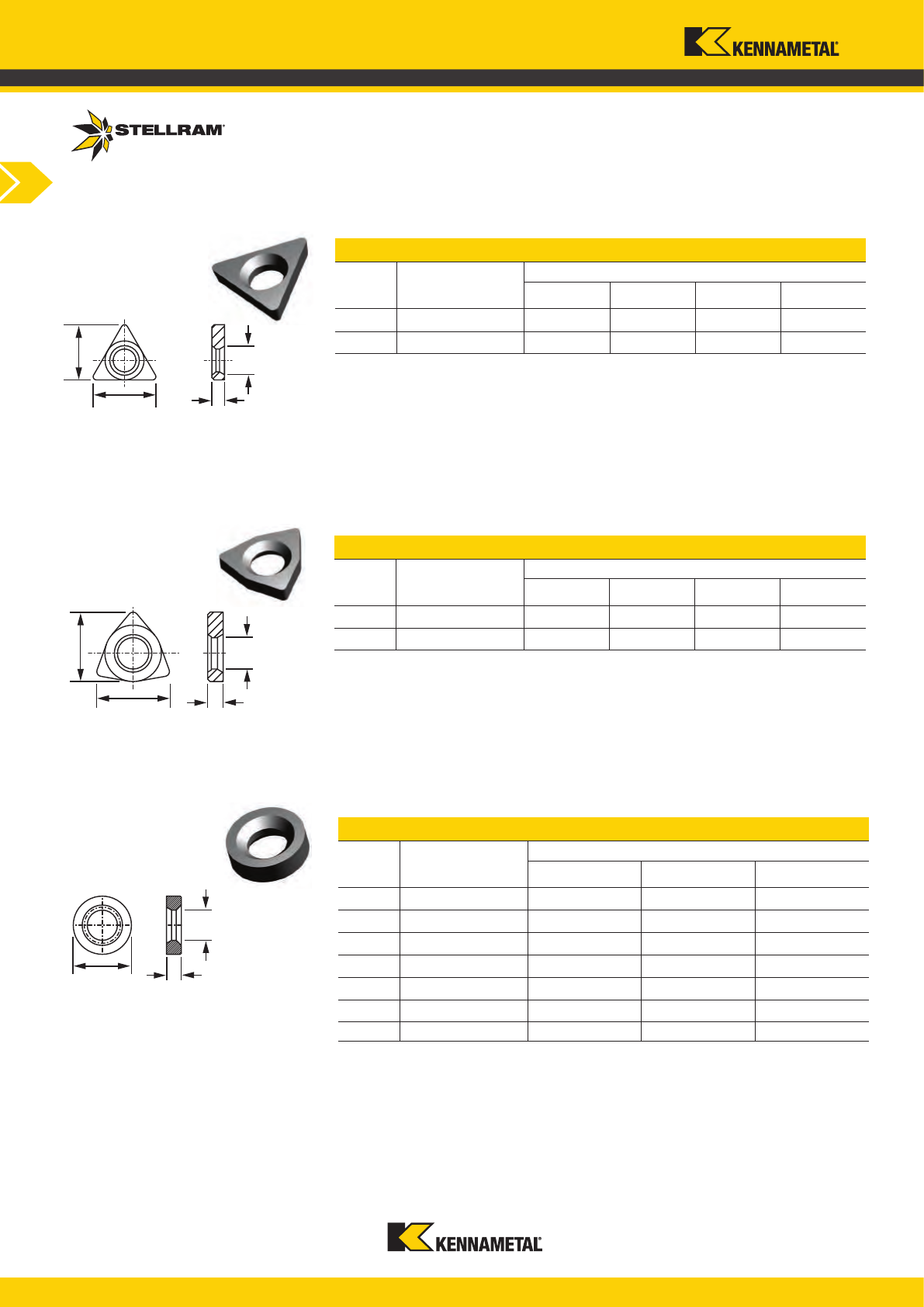

d m s

A ±0,025 ±0,005 ±0,025

C ±0,025 ±0,013 ±0,025

E ±0,025 ±0,025 ±0,025

F ±0,013 ±0,005 ±0,025

G ±0,025 ±0,025 ±0,13

H ±0,013 ±0,013 ±0,025

J * ±0,005 ±0,025

K * ±0,013 ±0,025

L * ±0,025 ±0,025

M * * ±0,127

U * * ±0,127

N * * ±0,025

5,56 ±0,05 ±0,11

6,35 ±0,05 ±0,11

7,94 ±0,05 ±0,11

9,525 ±0,05 ±0,11

12,7 ±0,08 ±0,15

15,875 ±0,10 ±0,18

19,05 ±0,10 ±0,18

Turning Inserts

IC d

m

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

Valid for shape D only (M

& N Tolerance)

Valid for shapes:

C, E, H, M, O, P, S, T, R, W

Class

Special feature

requiring

additional

specification

4 Type

*

See tables below.

3 Tolerance

Other normal clearances

requiring SPECIAL specification

Symbol

O

.

2 Clearance

1 Shape

ISO Insert Designation

www.kennametal.com

C37

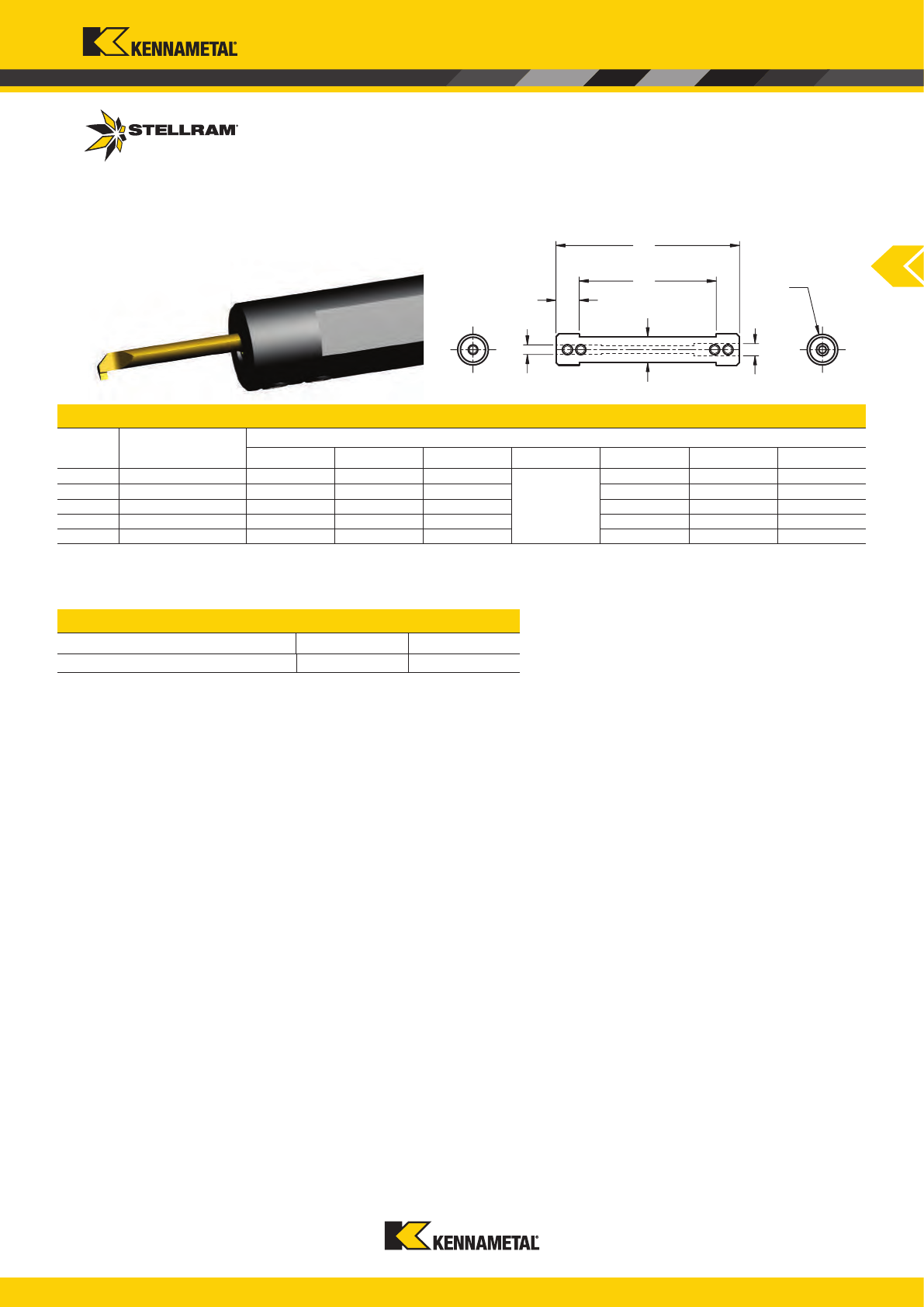

0804

6 7

L

I

O

I

P

I

C, D,

E, M,

V

I

H

I

A, B,

K

I

R

I

S

I

T

I

W

I

E

8

A = 45°

D = 60°

E = 75°

F = 85°

G = 87°

P = 90°

Z =

A = 3°

B = 5°

C = 7°

D = 15°

E = 20°

F = 25°

G = 30°

N = 0°

P = 11°

Z =

01

= 1,588

T1

= 1,984

02

= 2,381

03

= 3,175

T3

= 3,969

04

= 4,763

05

= 5,556

06

= 6,350

07

= 7,938

09

= 9,525

11

= 11,113

12

= 12,700

14

= 14,288

15

= 15,875

s

A, B,

C, N,

O, W.

H, M,

R, T.

F, G,

J, U.

s

s

s

00 =

01 = 0,1

02 = 0,2

04 = 0,4

08 = 0,8

12

= 1,2

16

= 1,6

20

= 2,0

24

= 2,4

28 = 2,8

32

= 3,2

40

= 4,0

48 = 4,8

56 = 5,6

64 = 6,4

X =

F

E

T

S

κ

r

r

ε

12

5

Turning Inserts

7 Corner continued

Major cutting

edge

Minor cutting edge

Wiper edge

Chamfered

corner

Symbol

Sharp

Honed

(Rounded)

Chamfered

(Negative Land)

Chamfered +

Honed

8 Edge Condition

=

SHARP CORNER

ANY OTHER

Examples:

Inserts with rounded corners. The corner radius

is indicated in 0.1mm. Integers to be preceded by

a 0 (zero). If the corner is not rounded, use the

symbol of designation 00 (zero zero).

Integers to be preceded by a 0 (zero) or the letter T.

Disregard any decimals.

Examples:

6 Thickness

Inserts with wiper edges

Cutting edge Angle (κ

r

) Wiper edge normal

1st letter: Clearance 2nd letter: (

a

n

)

ANY OTHER

ANY OTHER

7 Corner

Integers to be preceded by a 0 (zero).

Disregard any decimals. e.g. 9.525 = 09

5 Size

ISO Insert Designation

www.kennametal.com

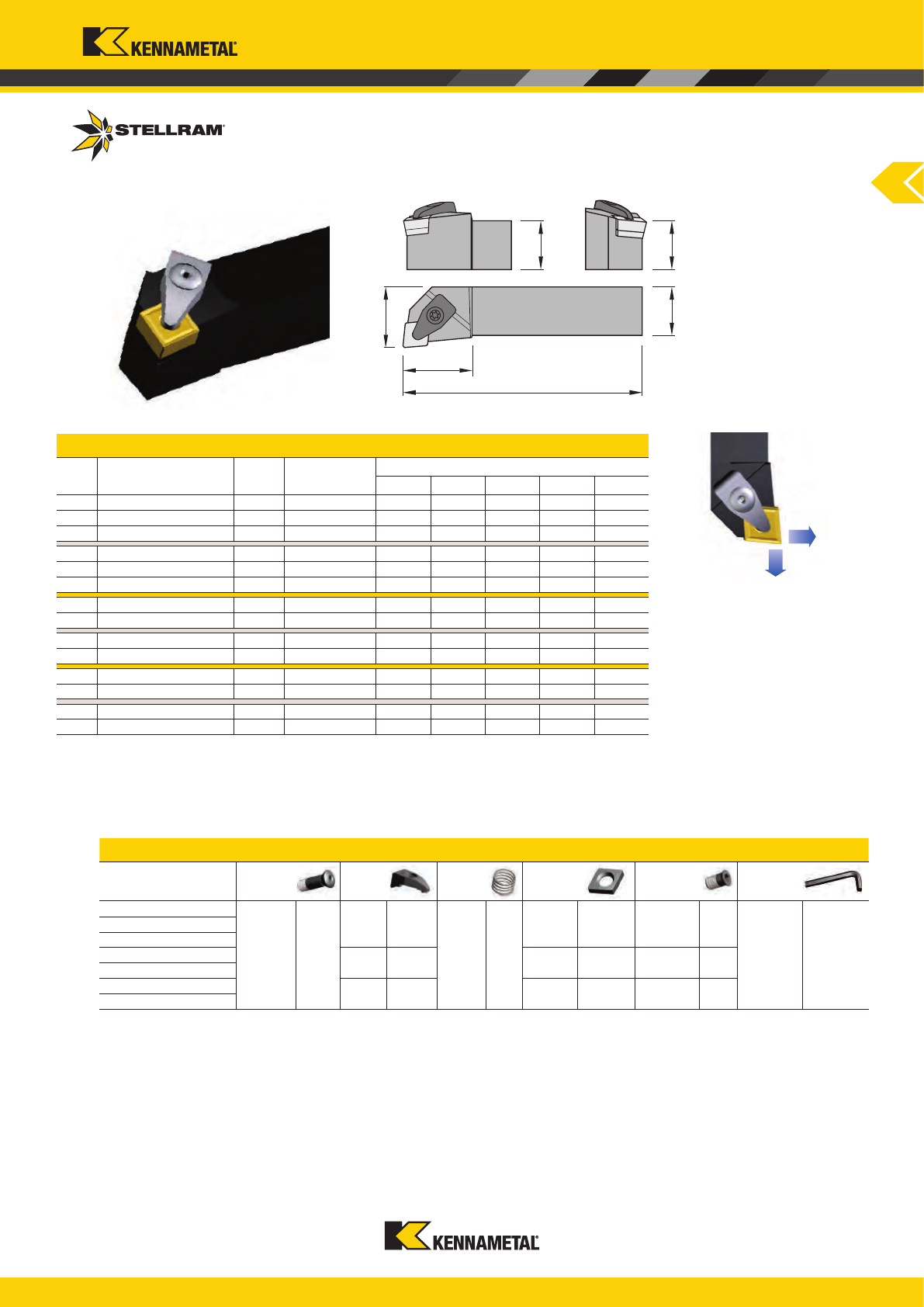

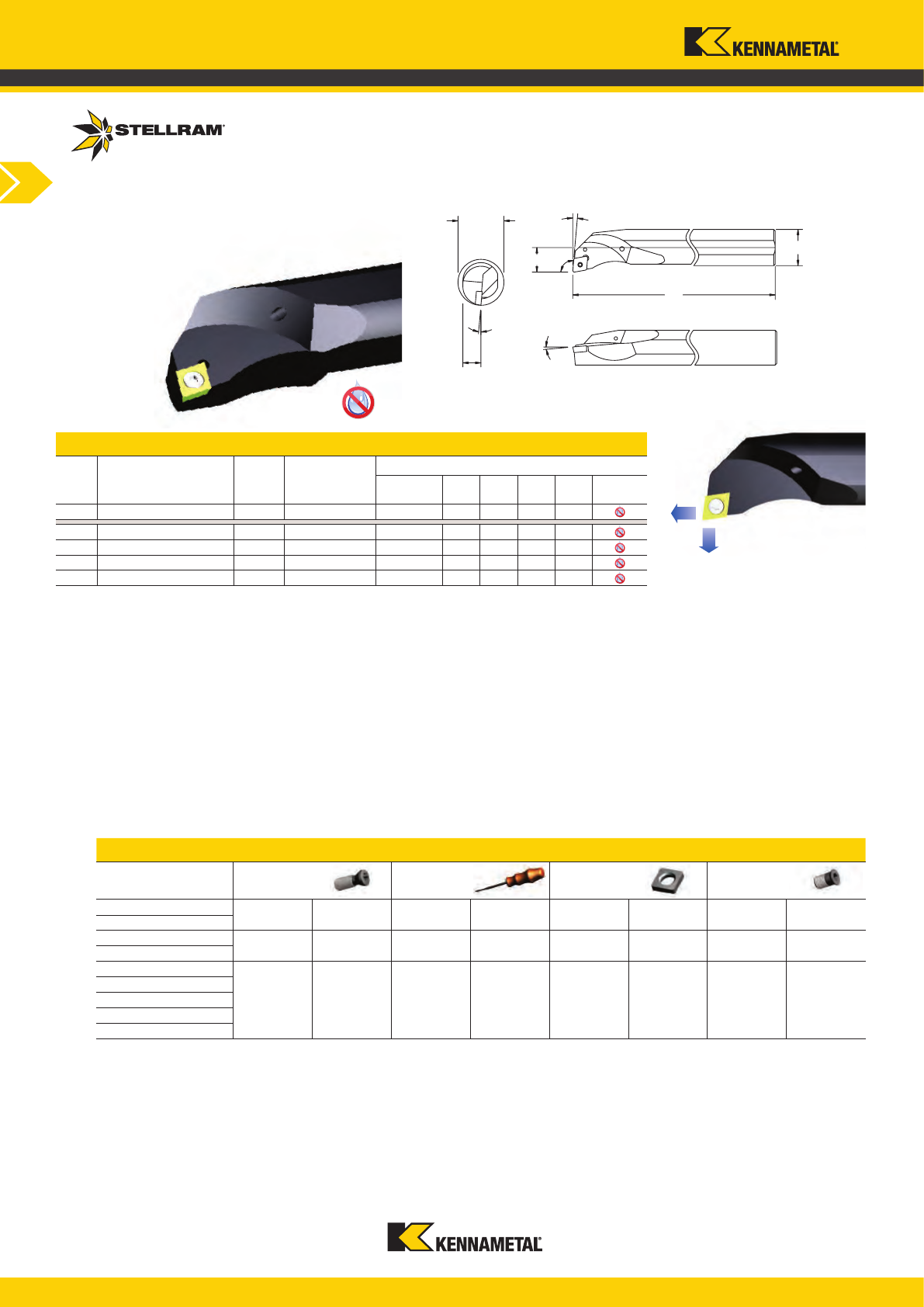

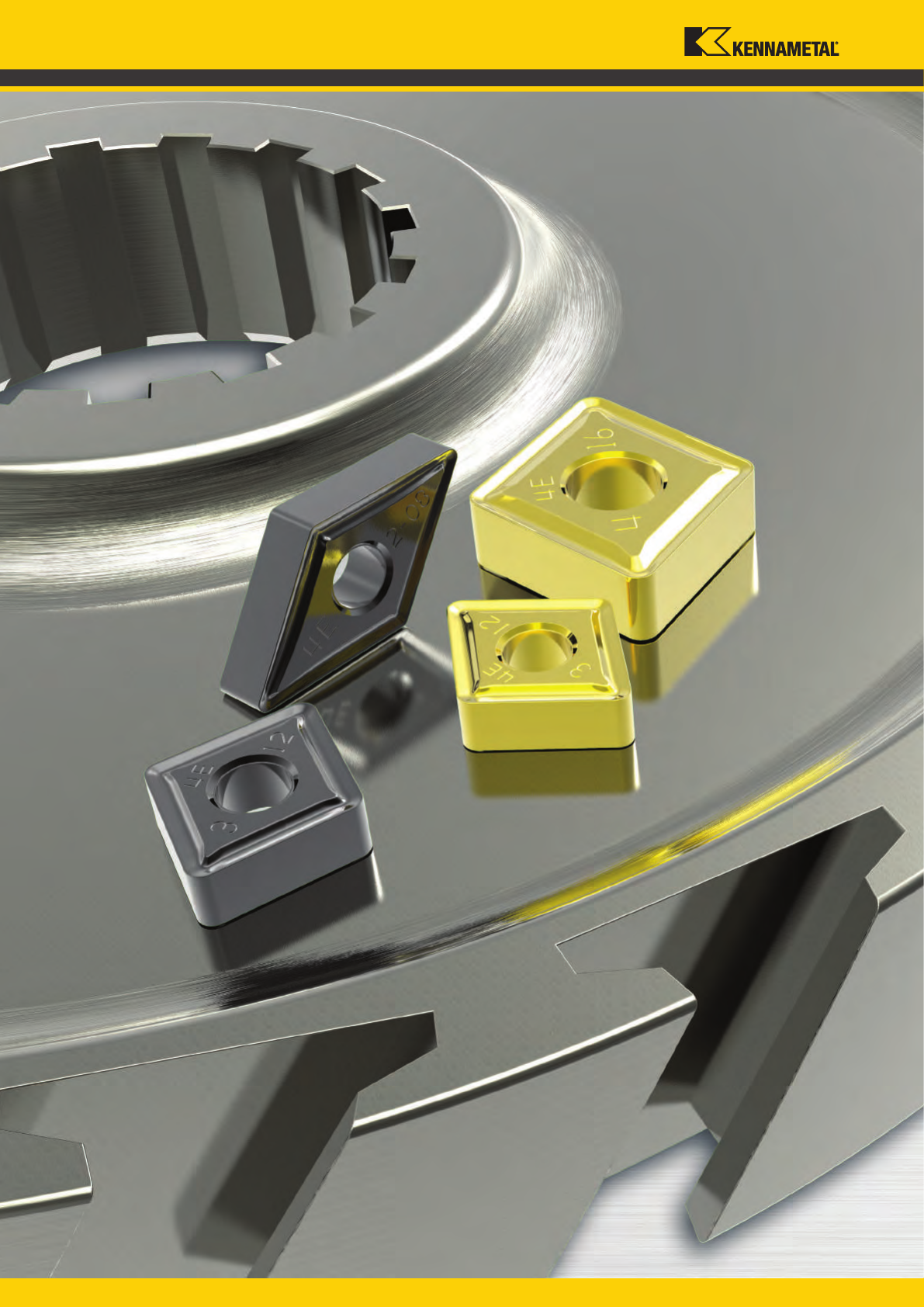

C38

P

1

D

2

J

3

N

4

R

5

85°

C

80°

D

55°

E

75°

H

120°

K

55°

L

90°

M

86°

O

135°

P

108°

R

360°

S

90°

T

60°

V

35°

W

80°

82°

B

90˚

75˚

90˚

45˚

60˚

90˚

METRIC

A

B

C

D

E

F

K

L

M

N

63˚

75˚

95˚

50˚

G

H

J

90˚

107˚ 30’

93˚

3°

5°

7°

15°

20°

25°

30°

0°

11°

B C D

E

F G N

P

A

P 117˚30’

Q 117˚30’

R 75˚

S 45˚

T 60˚

U 93˚

V 72˚30’

W 60˚

Y 85˚

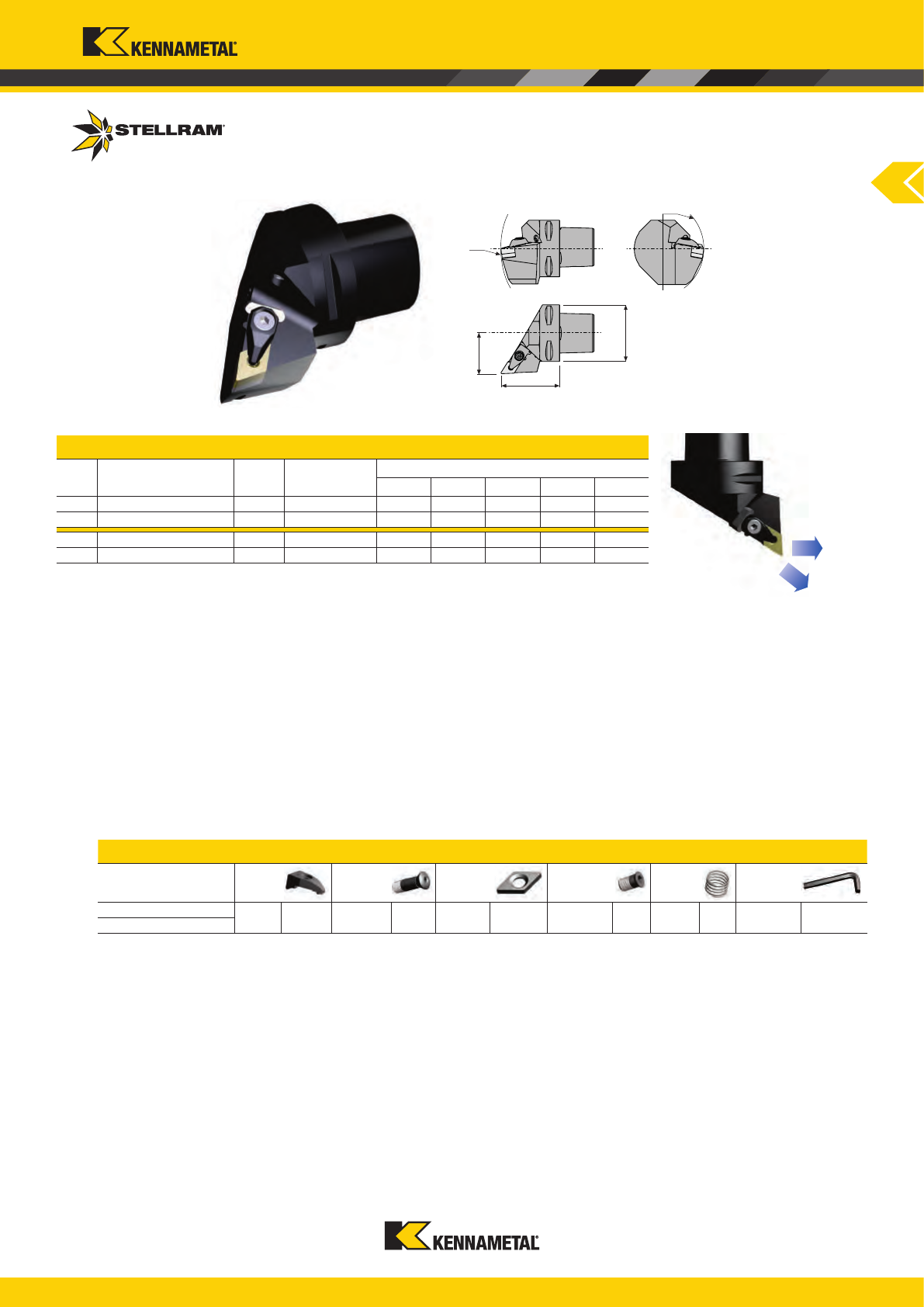

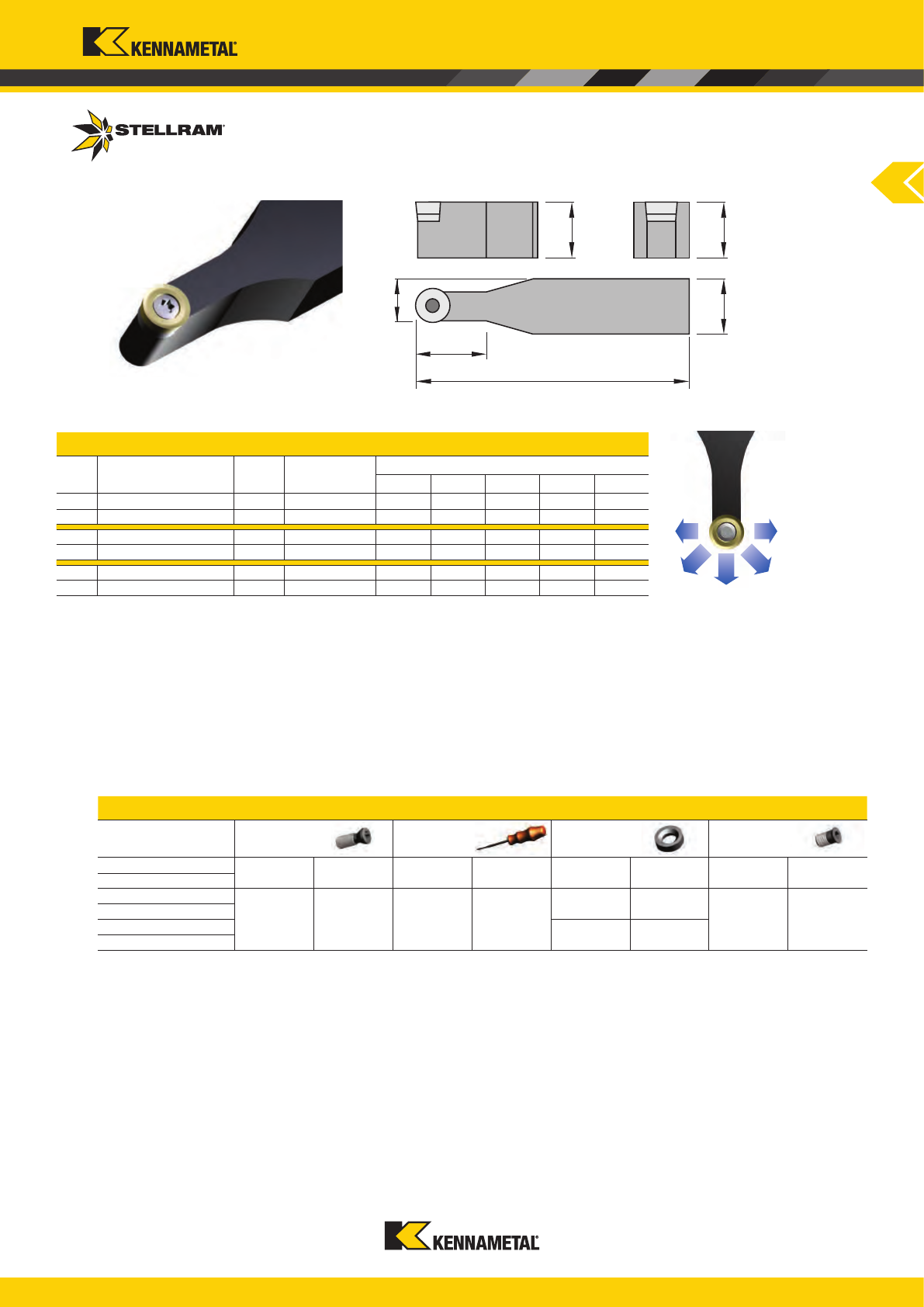

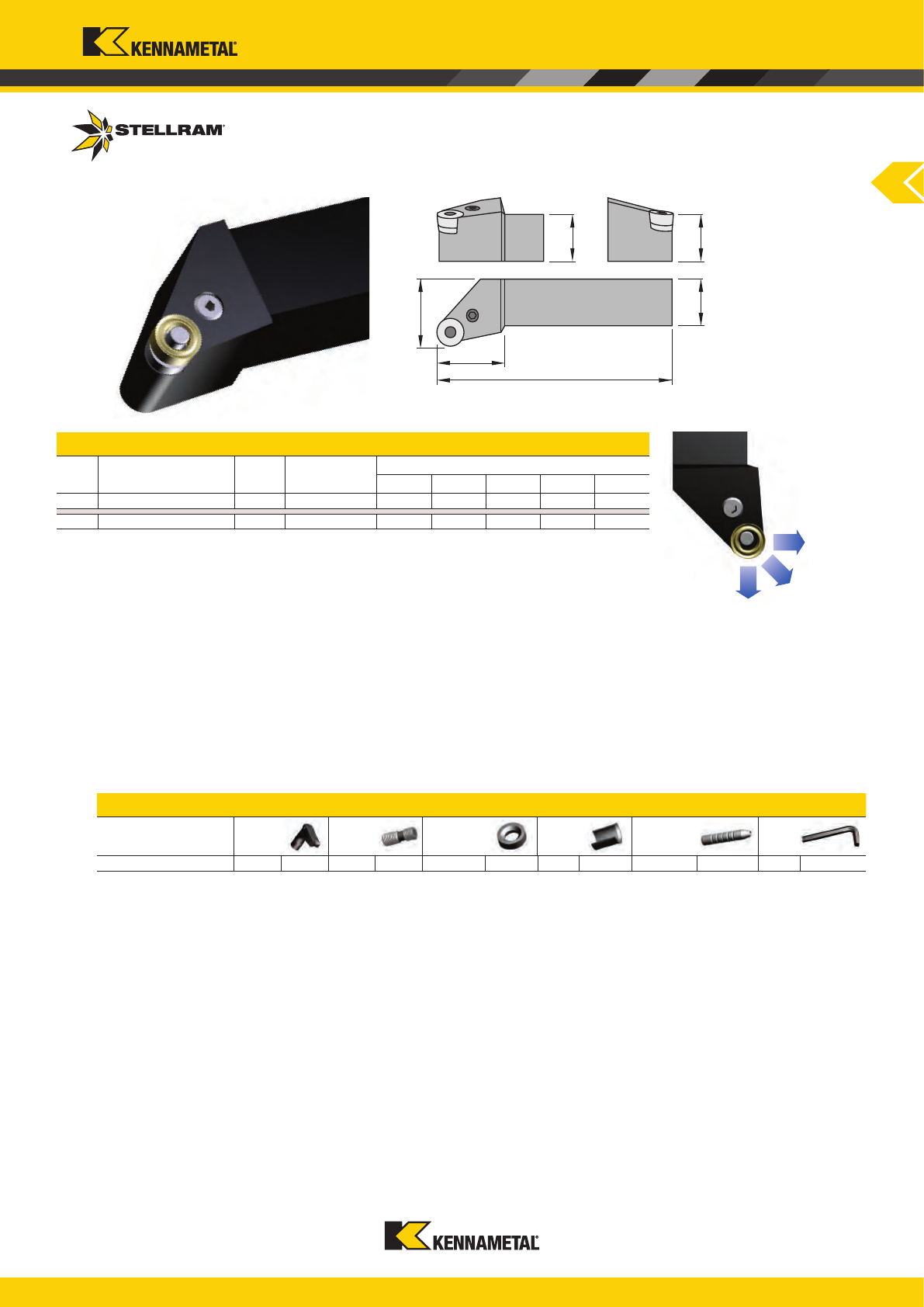

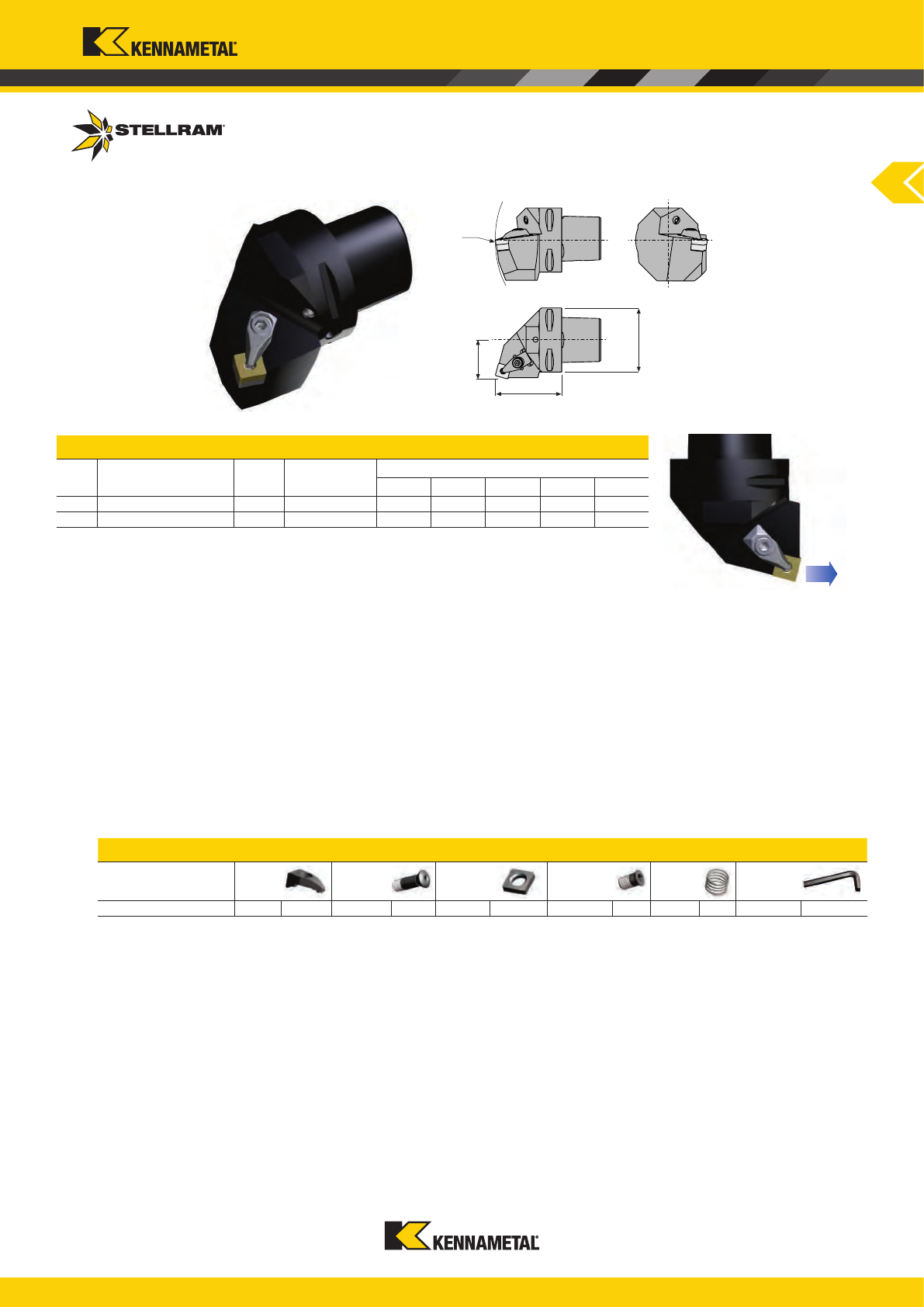

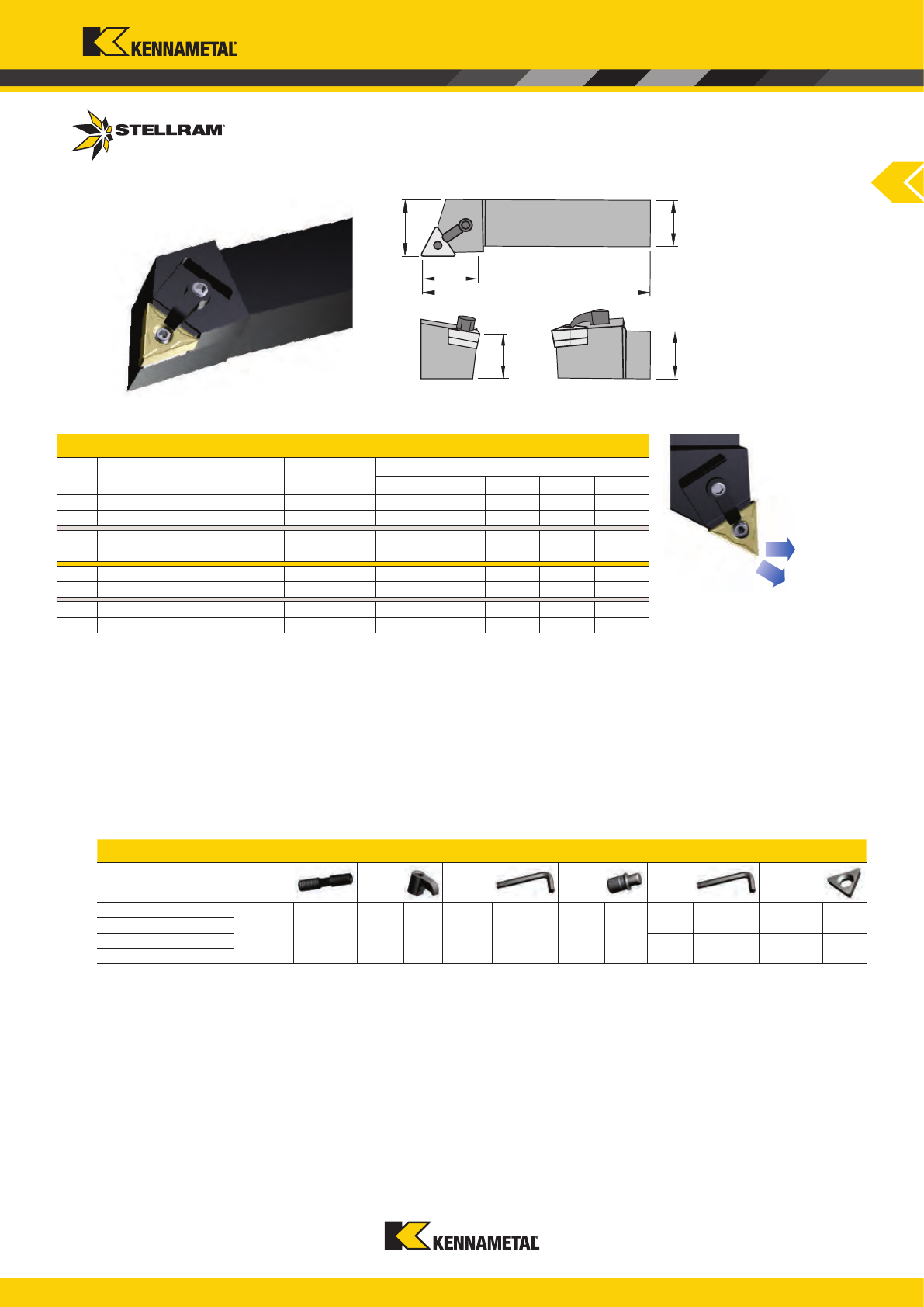

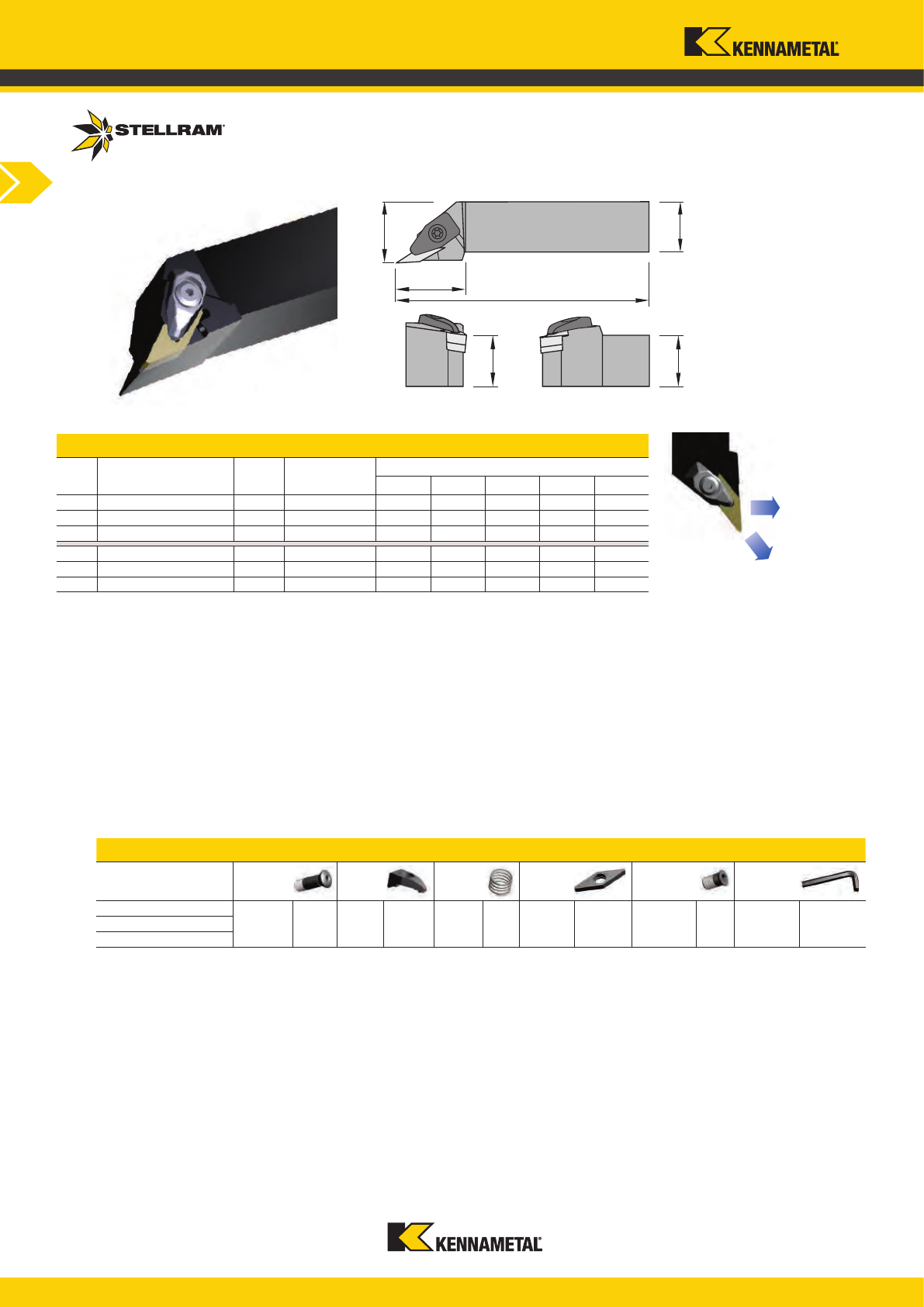

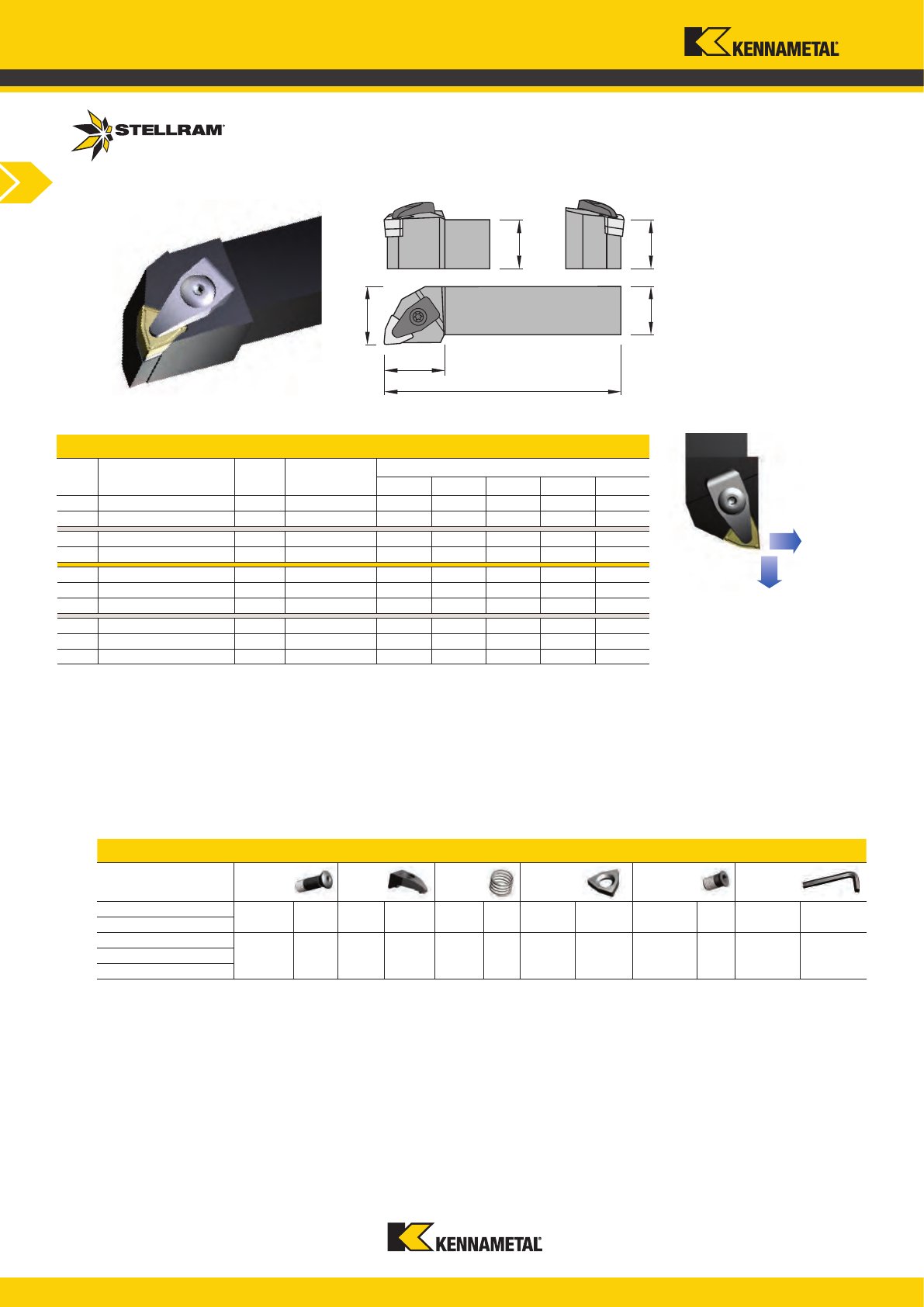

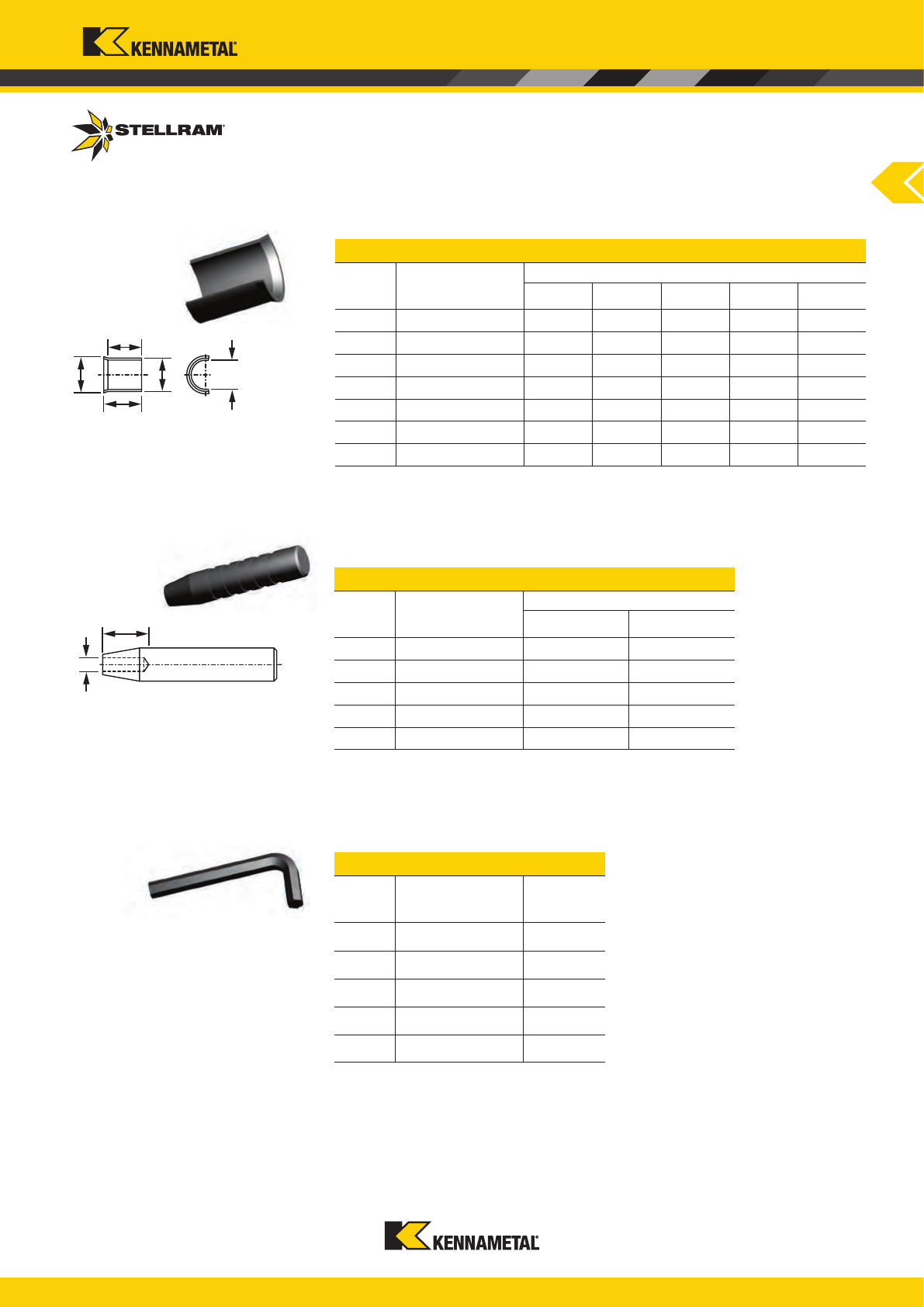

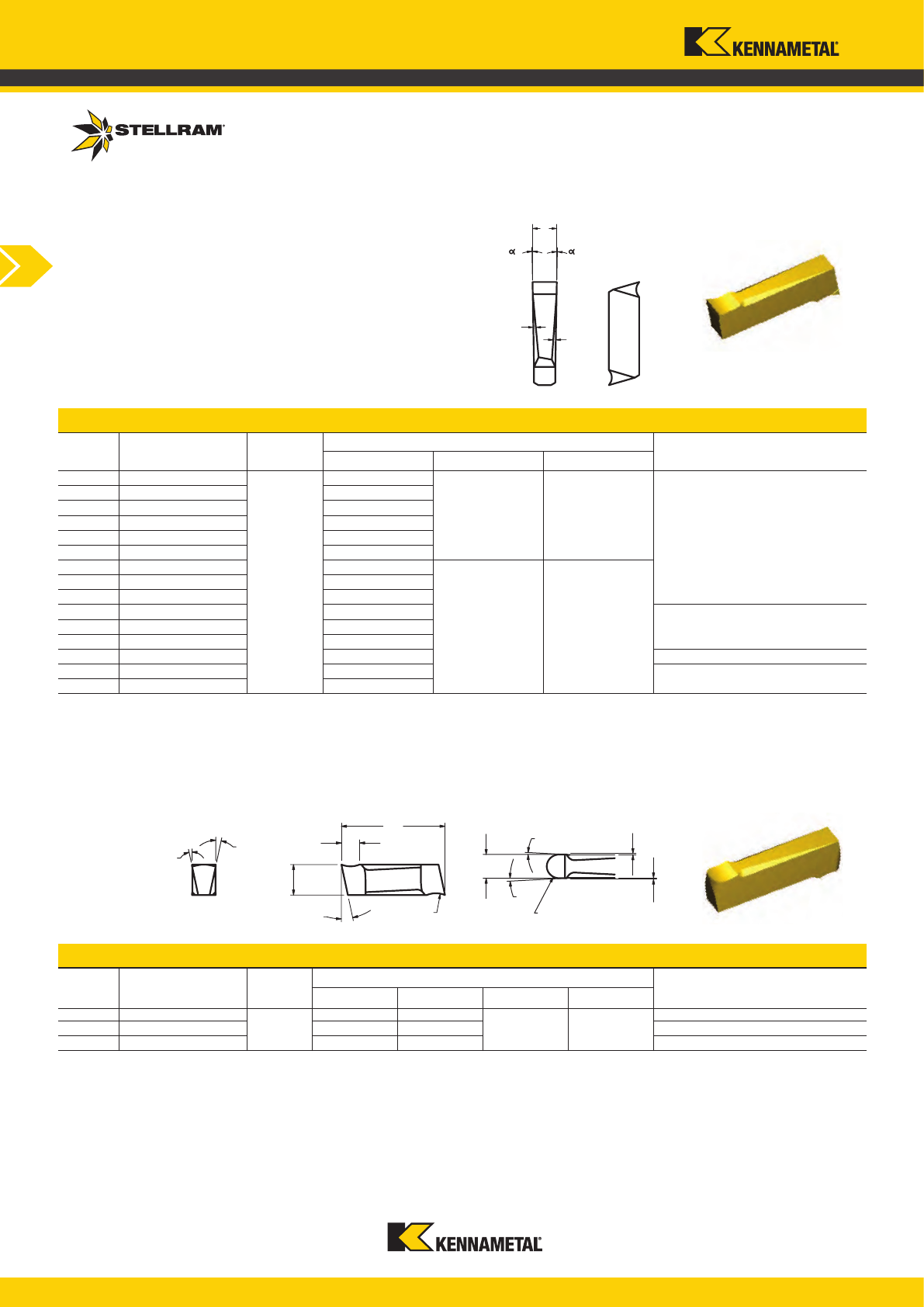

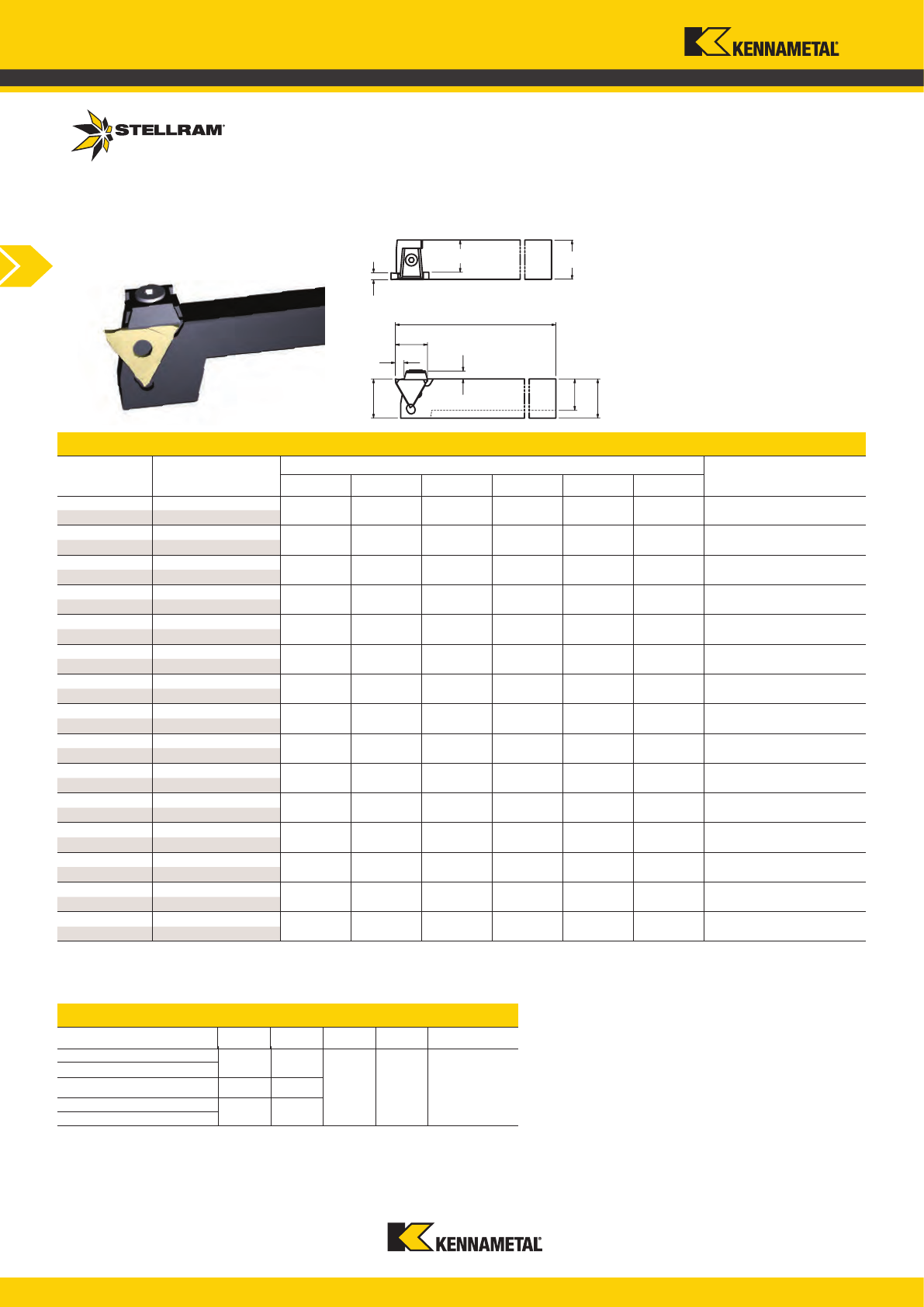

Turning Inserts

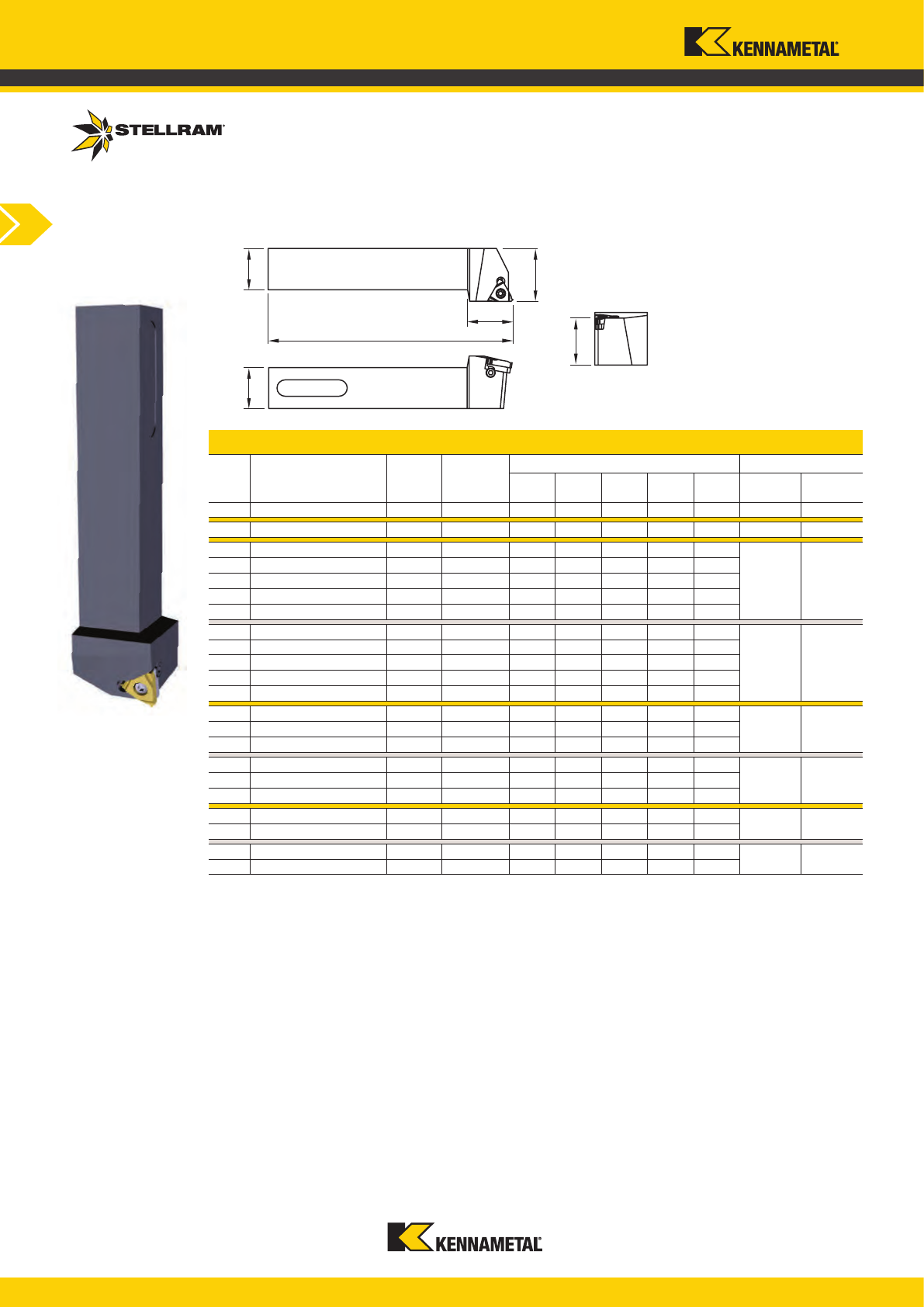

Other normal clearances requiring

SPECIAL specification Symbol O.

S

Posicut

®

P

Lever

Lock

M

Clamp

Lock

5 Hand

4 Clearance

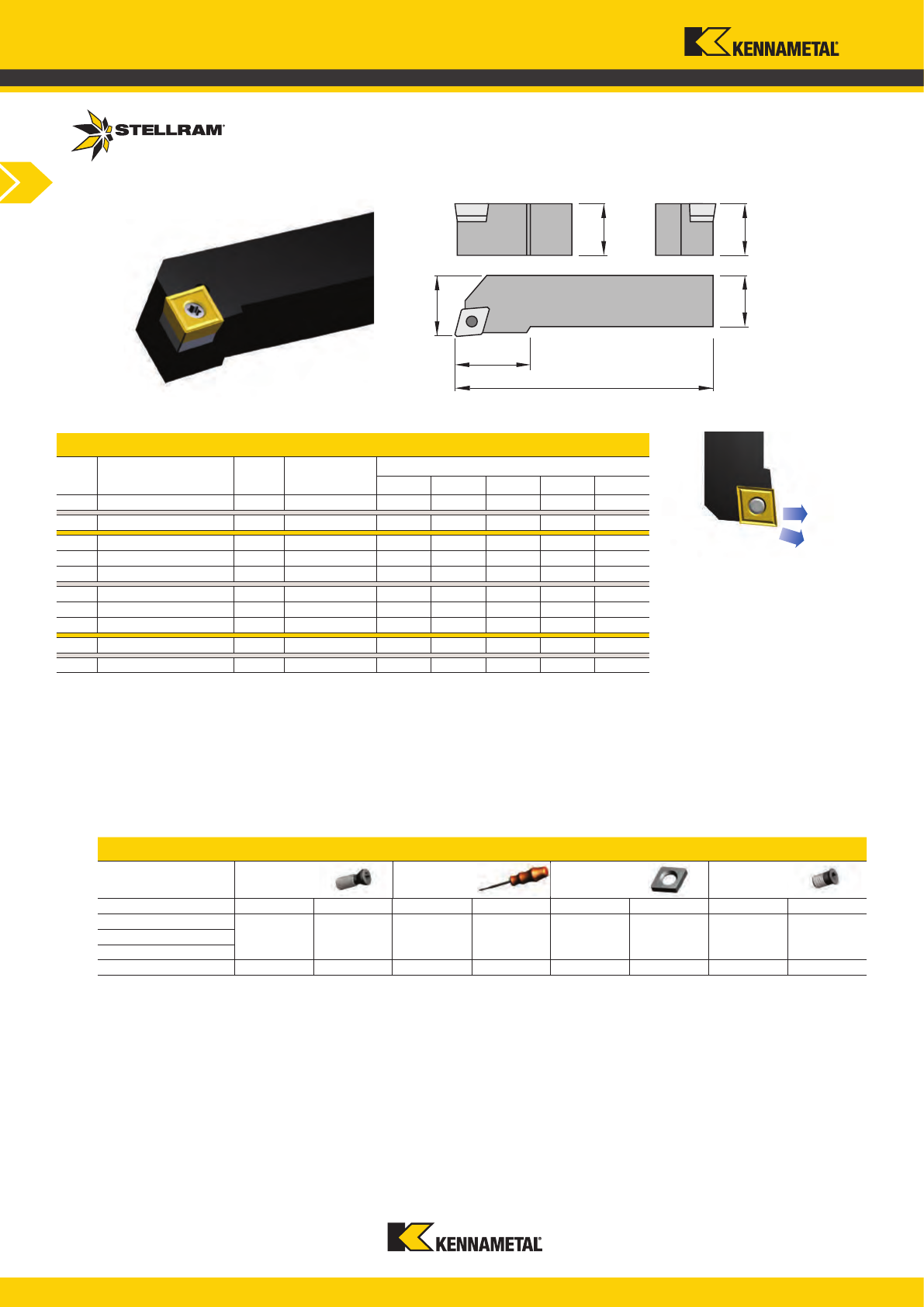

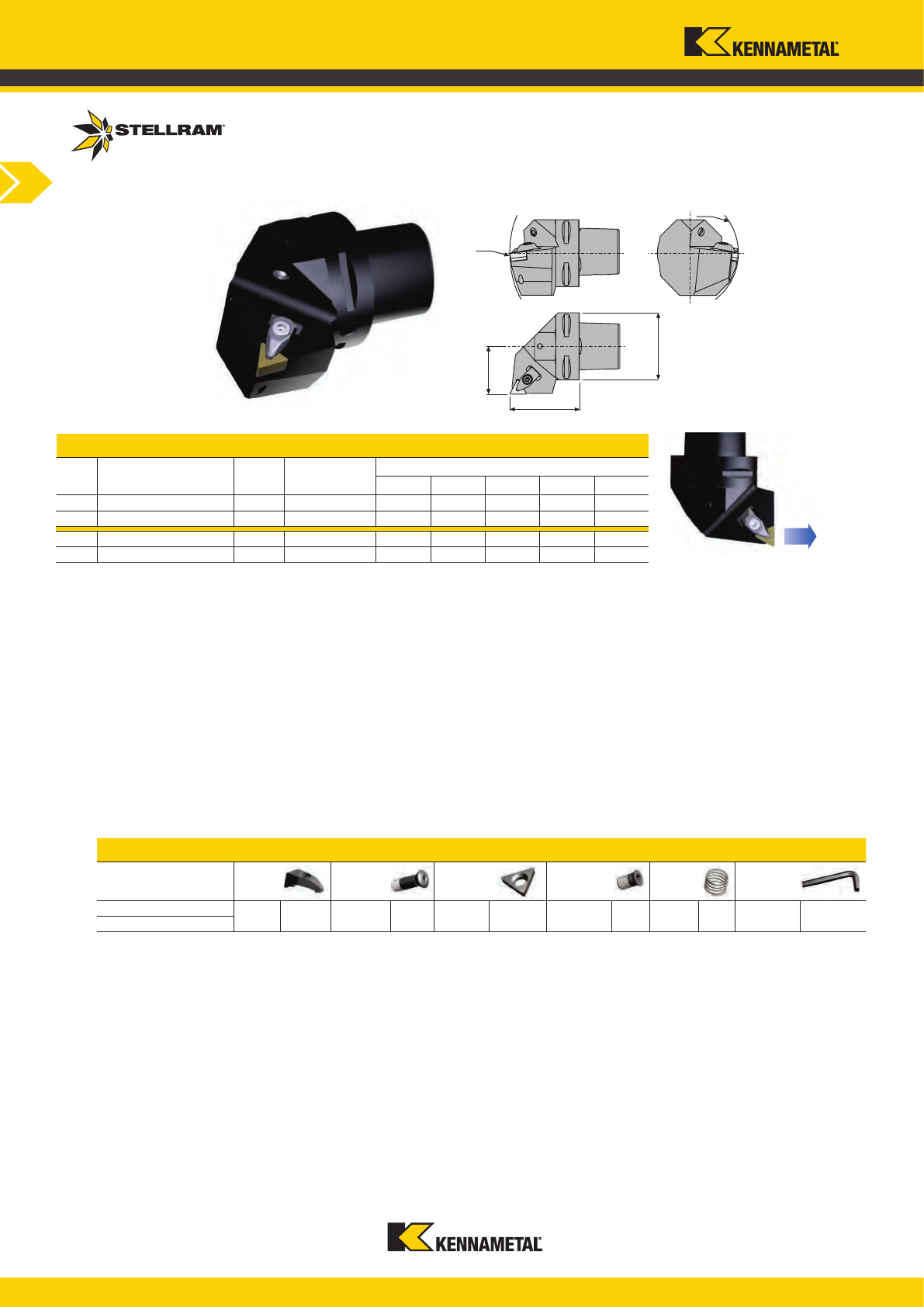

3 Tool Style

2 Insert Shape

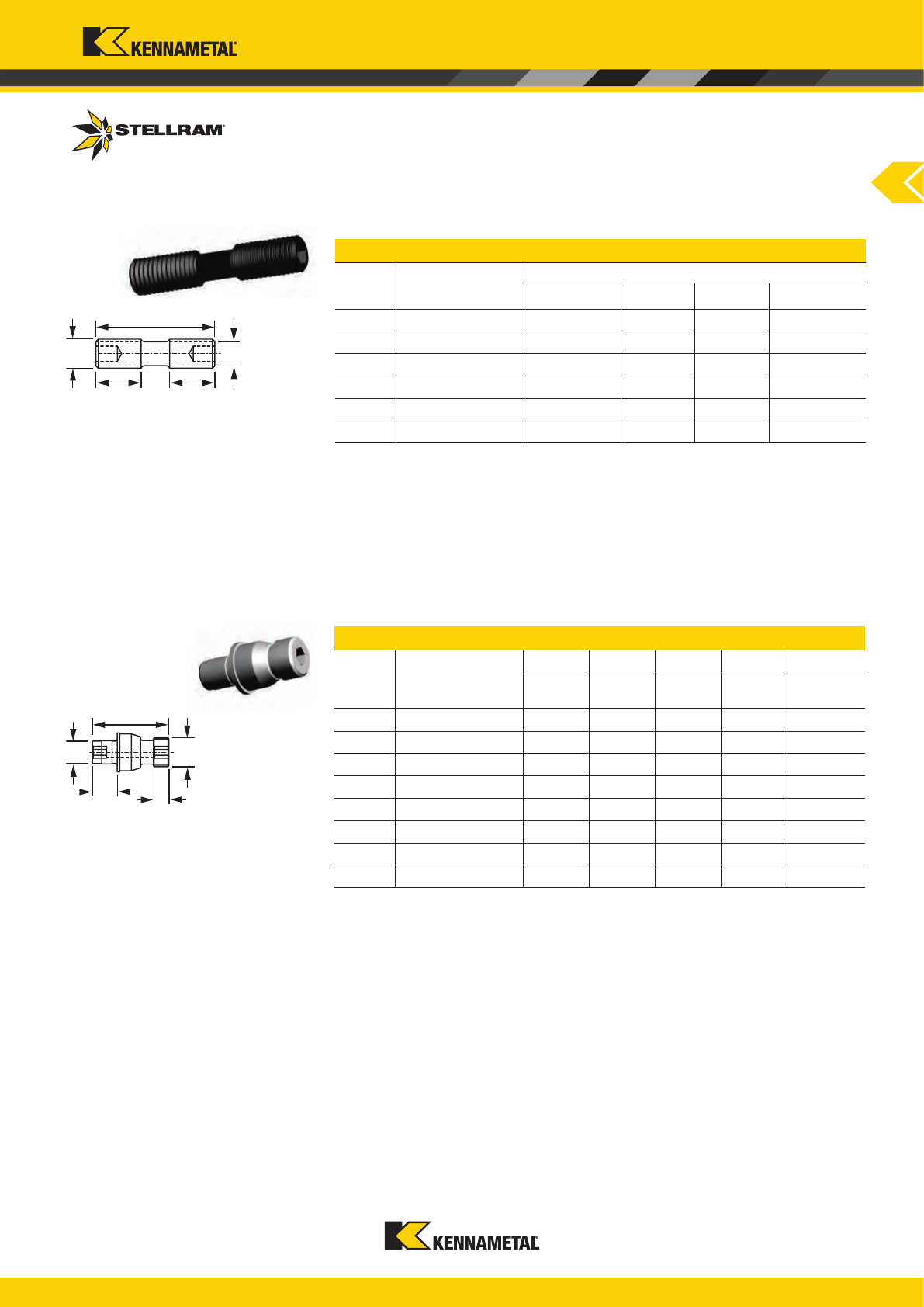

1 Assembly

N

Neutral

L

Left

Hand

R

Right

Hand

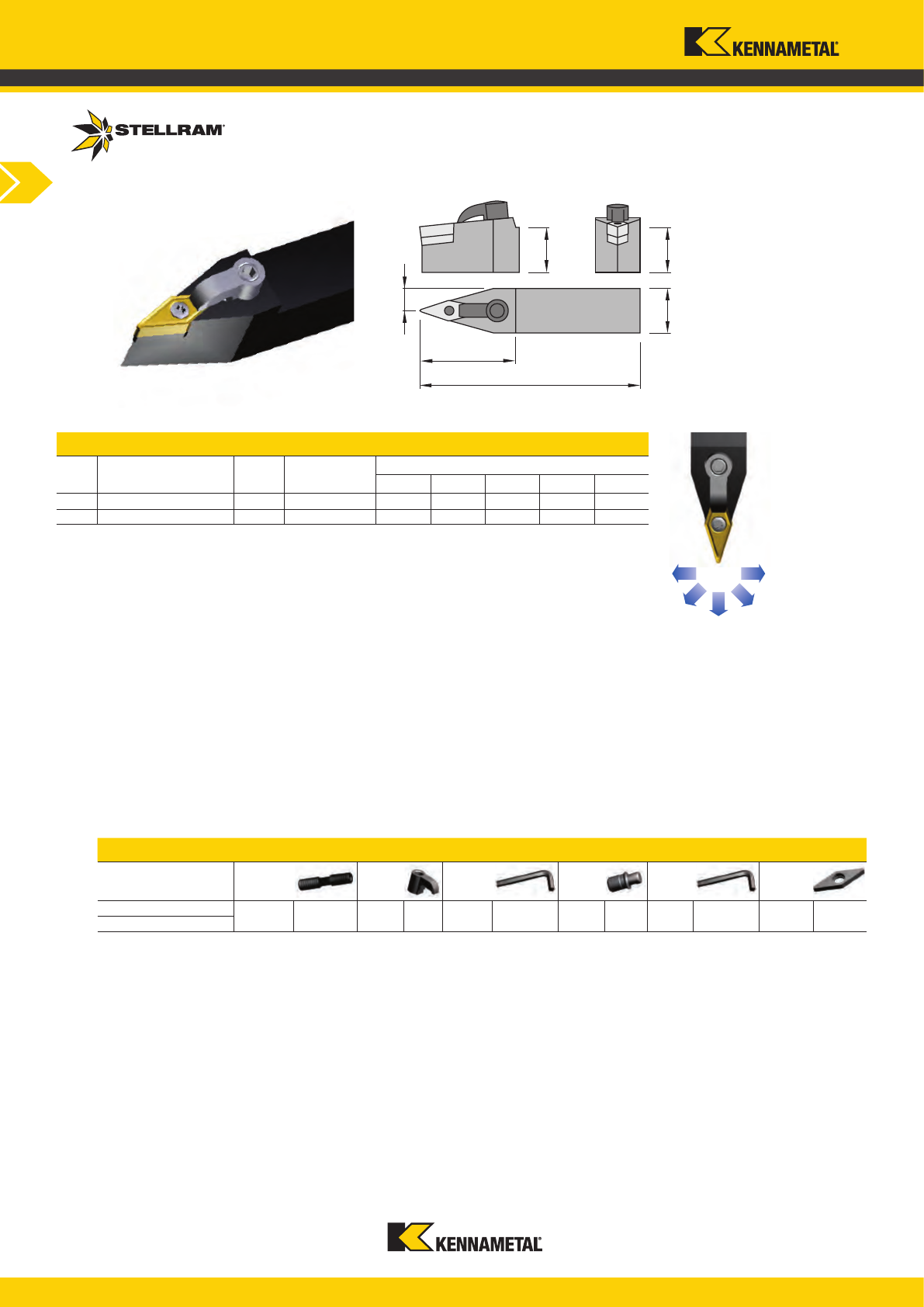

External Toolholders

ISO Designation (ISO 5608)

www.kennametal.com

C39

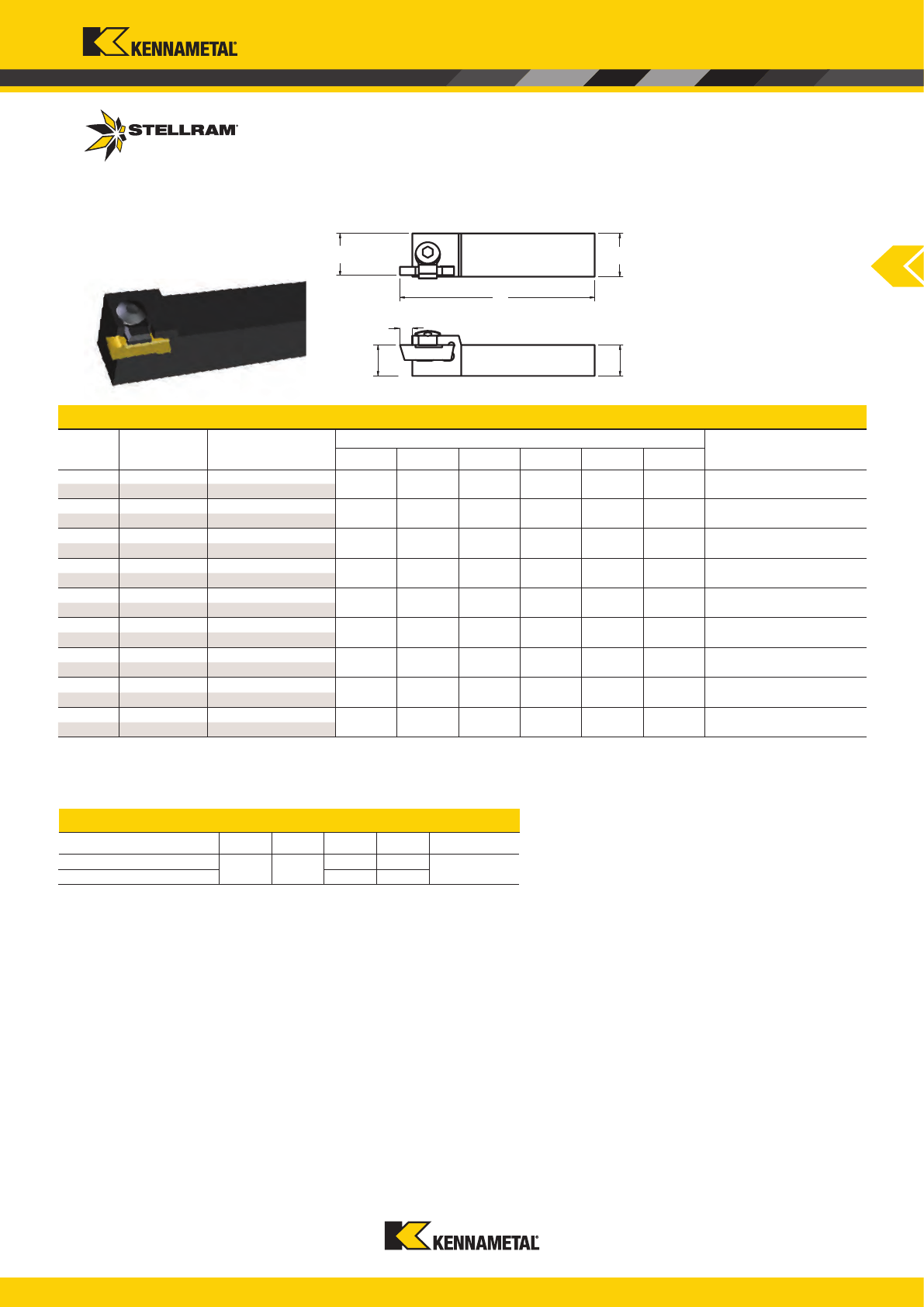

20

6

20

7

K

8

-

10

12

9

-

11

06

= 6

08

= 8

10

= 10

12

= 12

14

= 14

16

= 16

20

= 20

25

= 25

32

= 32

40

= 40

50

= 50

h

b

06

= 6

08

= 8

10

= 10

12

= 12

14

= 14

16

= 16

20

= 20

25

= 25

32

= 32

40

= 40

50

= 50

l

1

A

= 32

B

= 40

C

= 50

D

= 60

E

= 70

F

= 80

G

= 90

H

= 100

J

= 110

K

= 125

L

= 140

M

= 150

N

= 160

P

= 170

Q

= 180

R

= 200

S

= 250

T

= 300

U

= 350

V

= 400

W

= 450

Y

= 500

X

=

L

I

O

I

P

I

C, D,

E, M,

V

I

H

I

A, B,

K

I

R

I

S

I

T

I

W

I

B

60,08

60,08

6

0,08

F

60,08

6

0,08

Q

60,08

6

0,08

Turning Inserts

SPECIAL

11 Optional

Supplementary optional symbol (numbers or letters) added

by the manufacturer.

Must be separated from the standardised designation by a

dash (-).

Qualified tools.

10 Optional

Integers to be preceded by a 0 (zero).

Disregard any decimals. e.g. 9,525 = 09

9 Insert Size

7 Tool Width

8 Tool Length

6 Tool Height

External Toolholders

ISO Designation (ISO 5608)

www.kennametal.com

C40

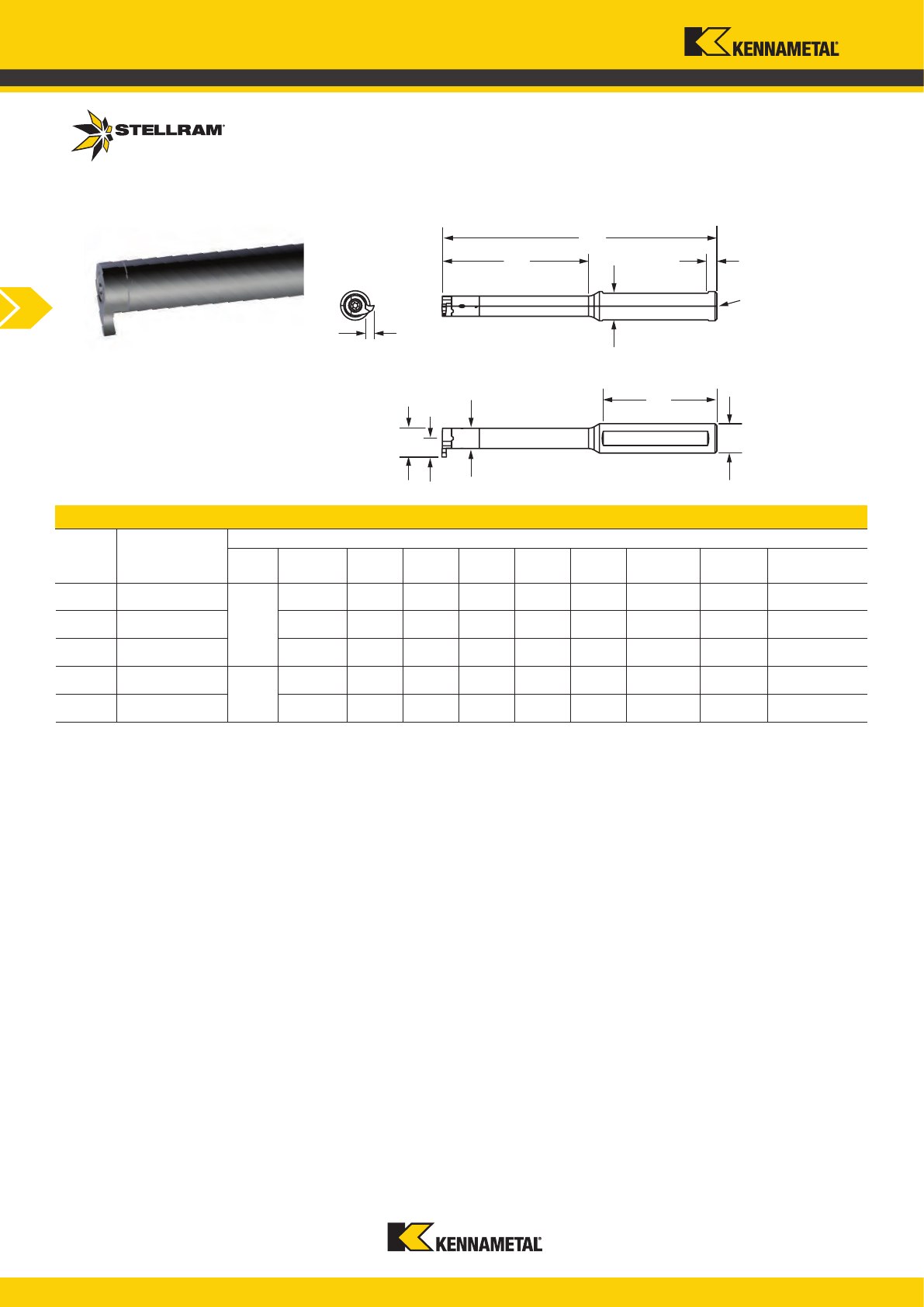

A

1

25

2

R

3

P

4

C

5

A

85°

C

80°

D

55°

E

75°

H

120°

K

55°

L

90°

M

86°

O

P

108°

360°

90°

60°

V

35°

W

80°

82°

B

A

B

C

D

E

F

G

H

J

S

d

06

= 6

08

= 8

10

= 10

12

= 12

16

= 16

20

= 20

25

= 25

32

= 32

40

= 40

50

= 50

l

1

F

= 80

H

= 100

K

= 125

M

= 150

P

= 170

Q

= 180

R

= 200

S

= 250

T

= 300

U

= 350

V

= 400

W

= 450

Y

= 500

X

=

-

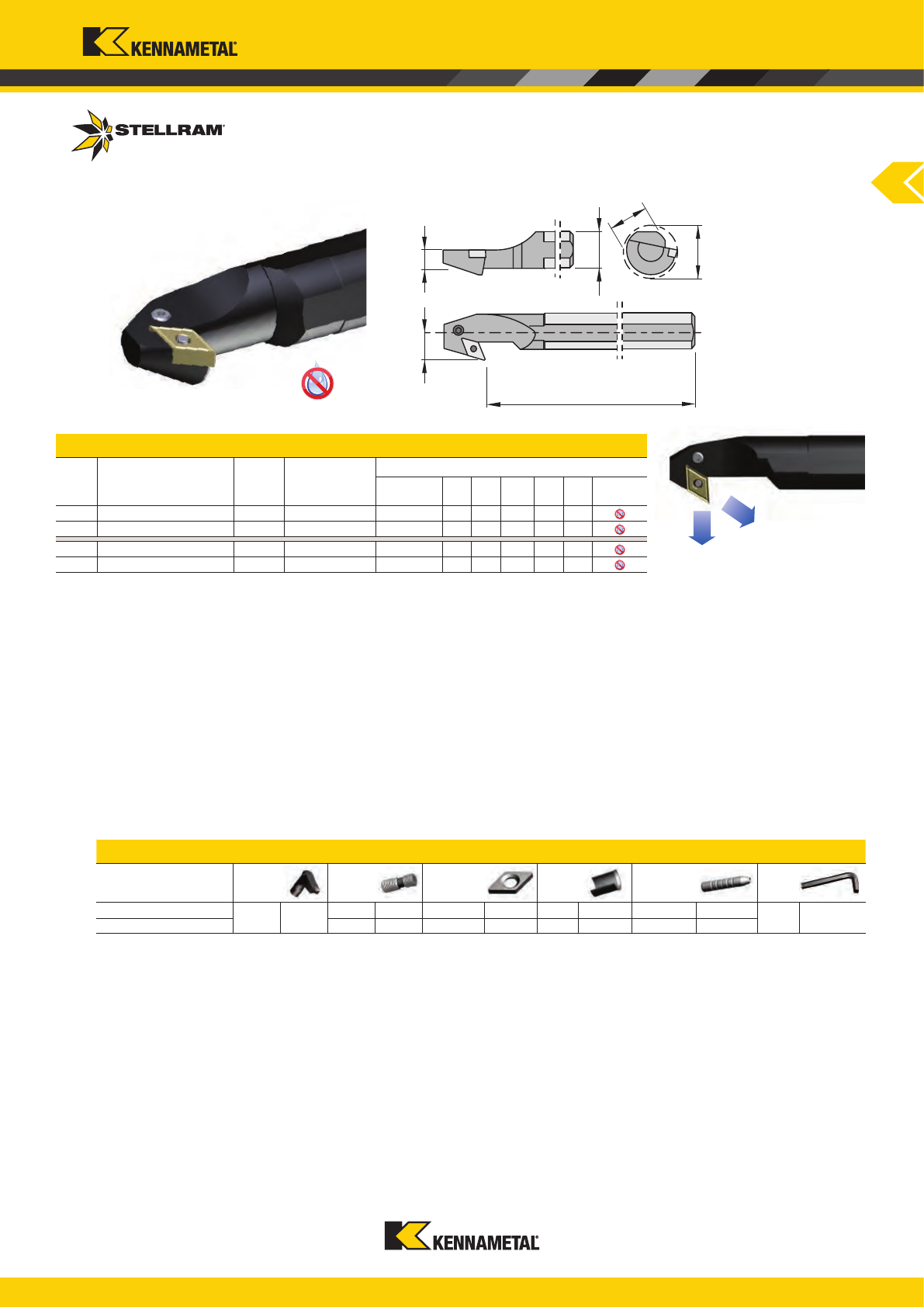

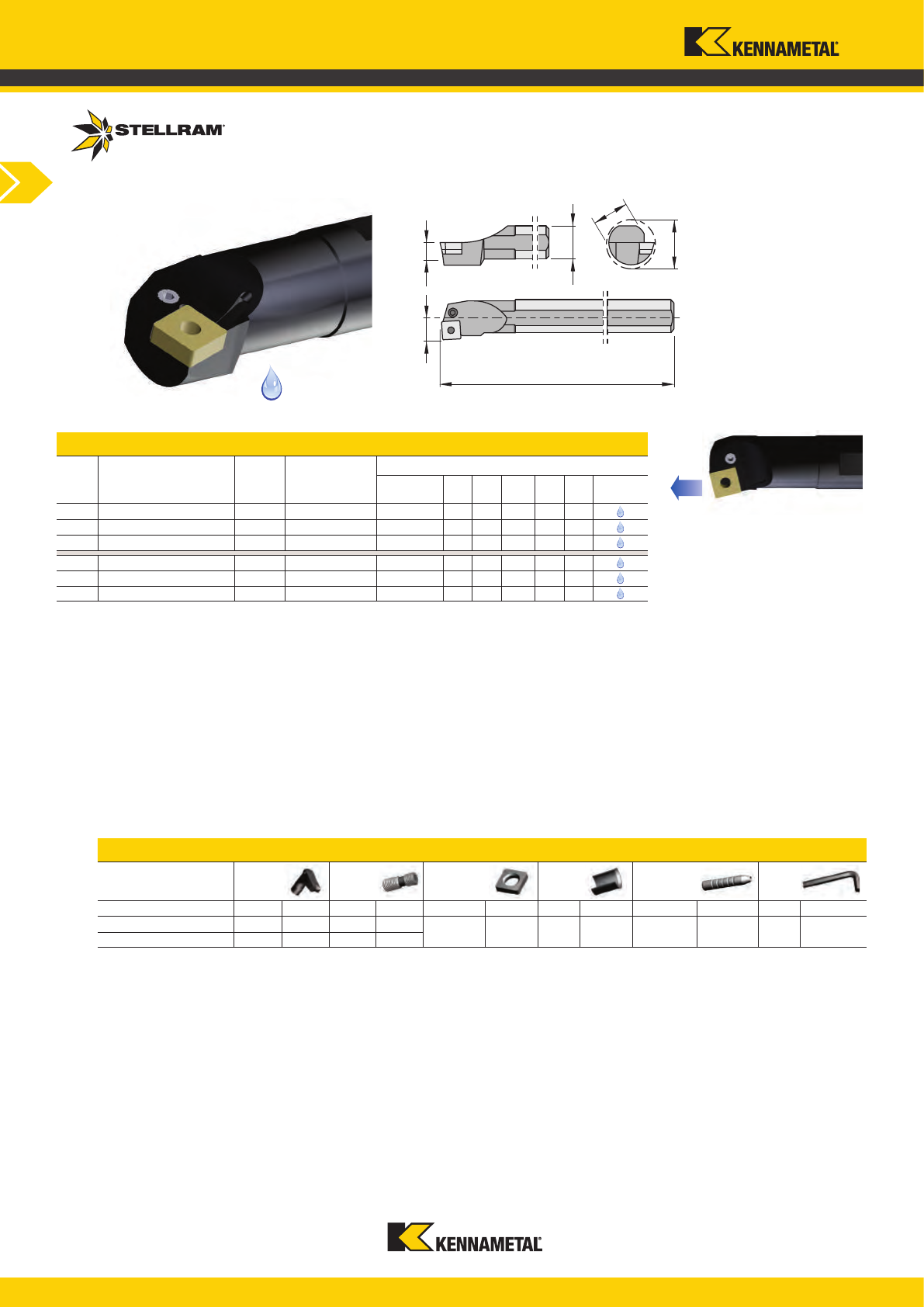

Turning Inserts

SPECIAL

METRIC

S

Posicut

®

P

Lever

Lock

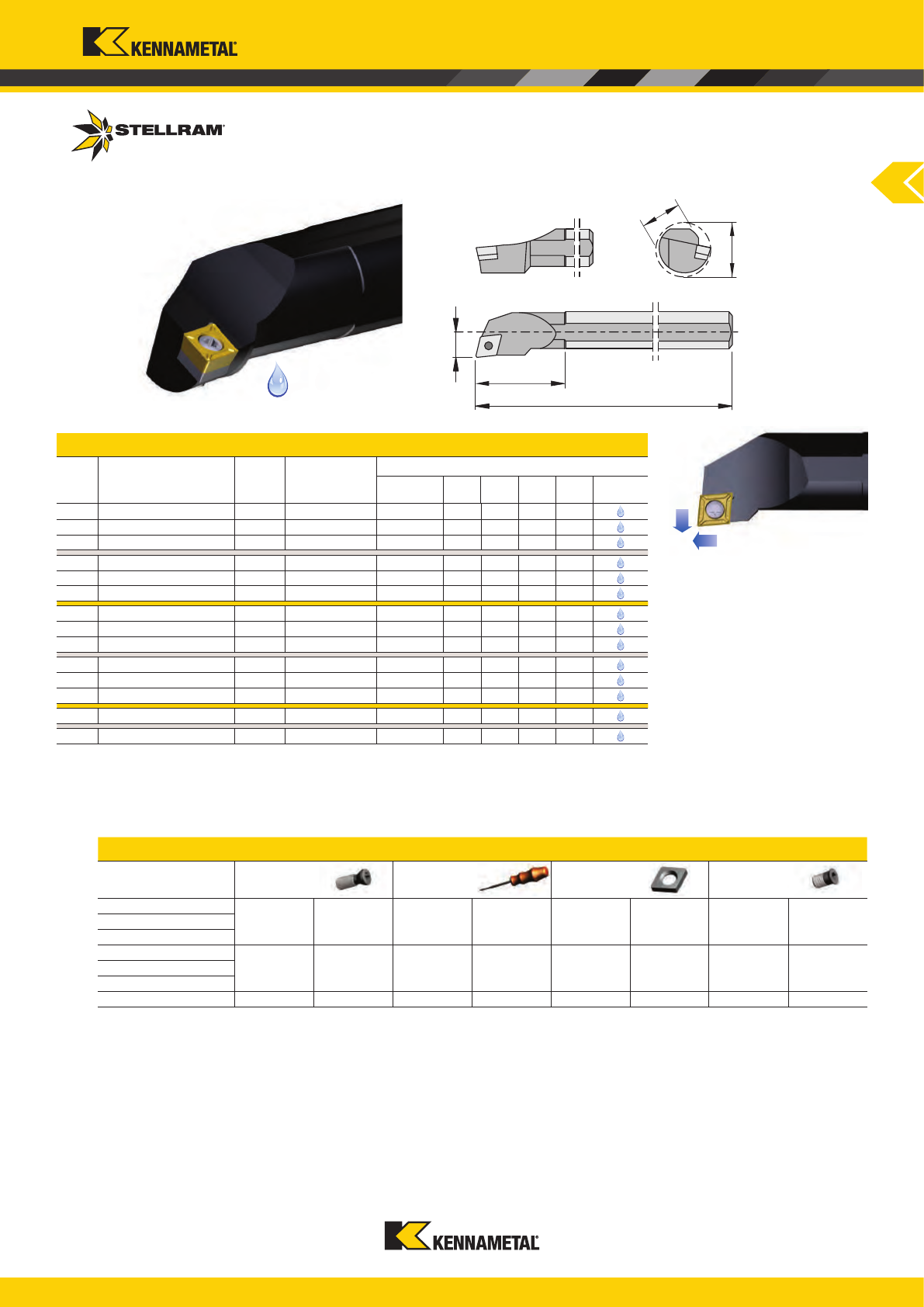

M

Clamp

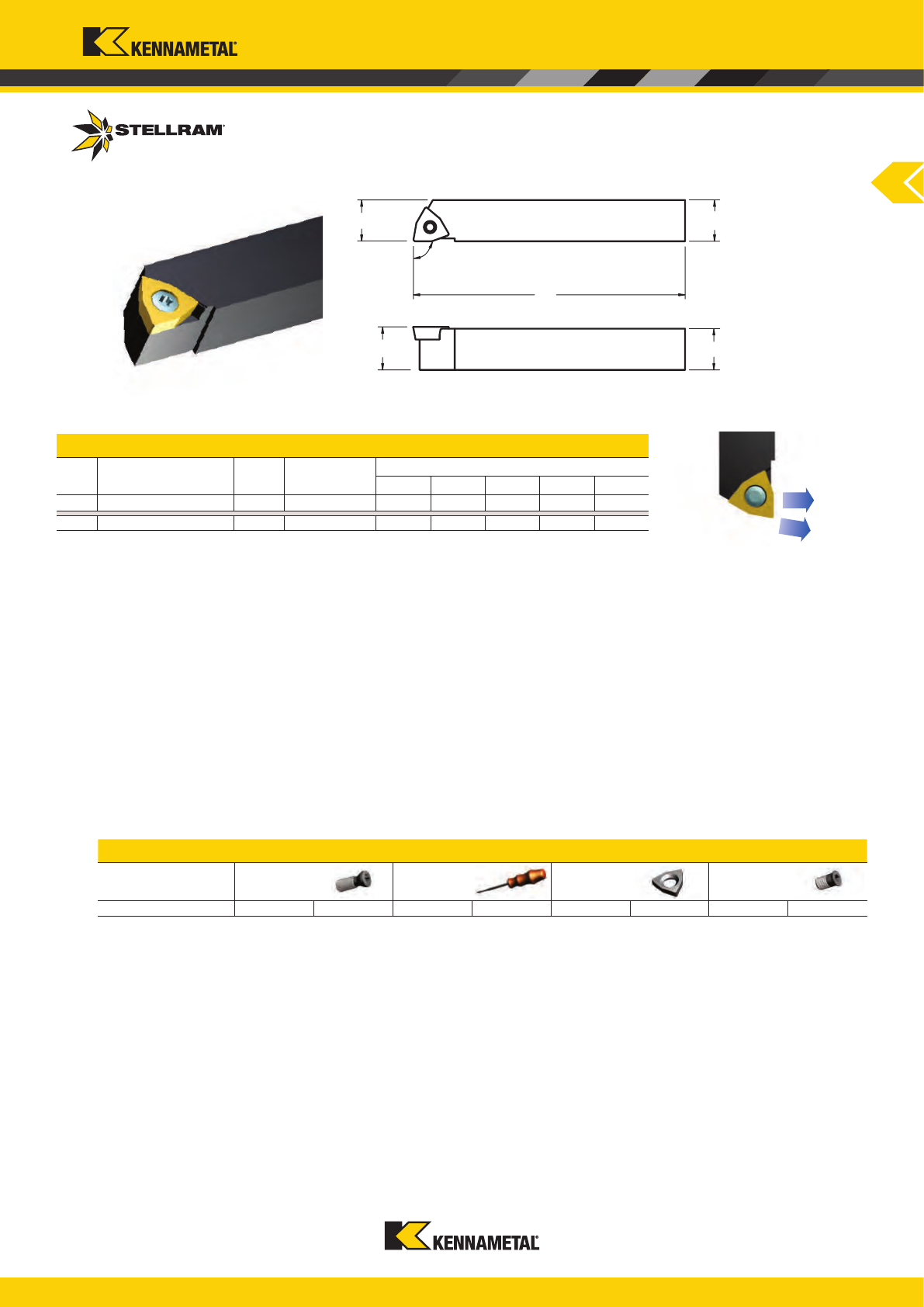

Lock

METRIC

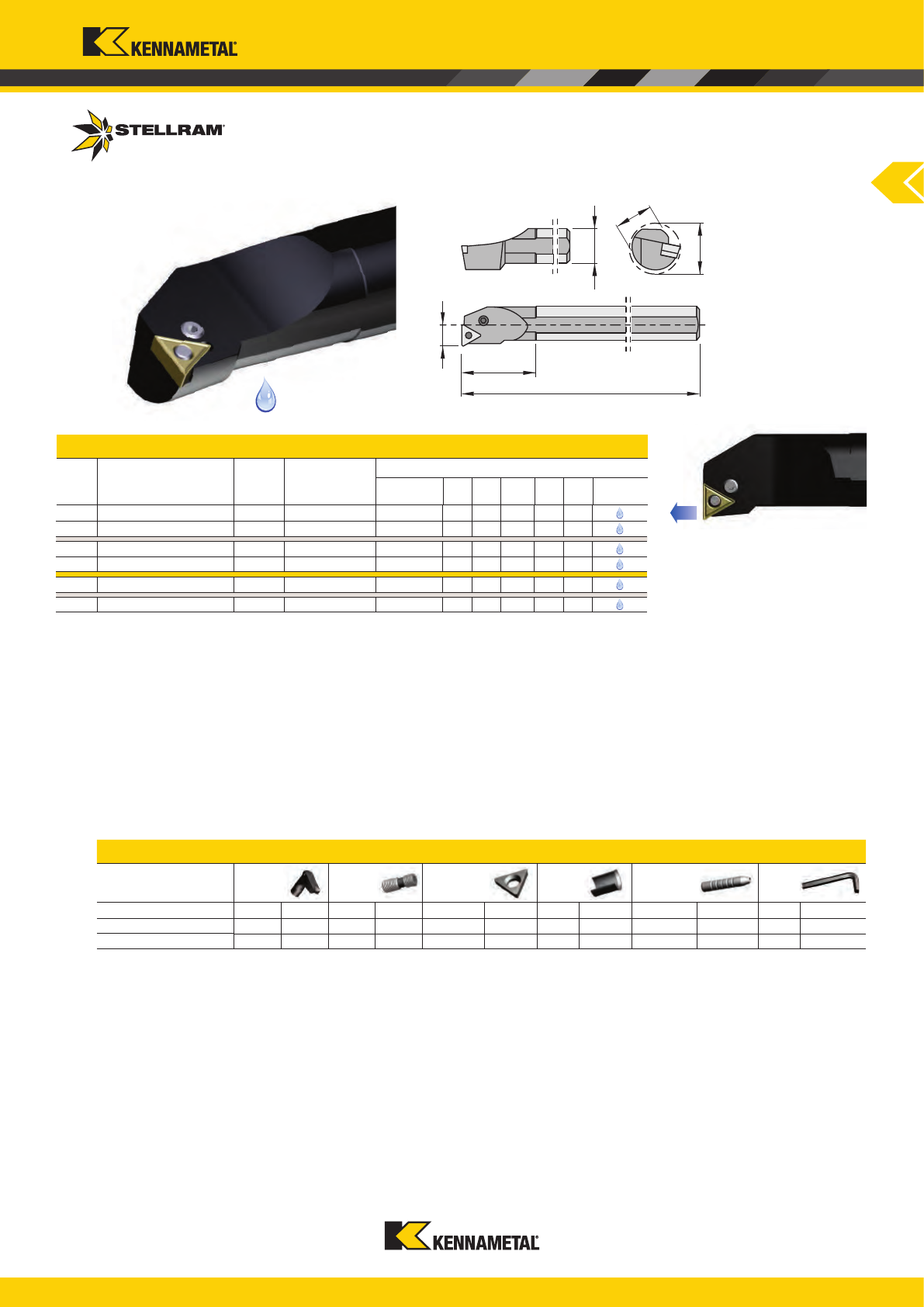

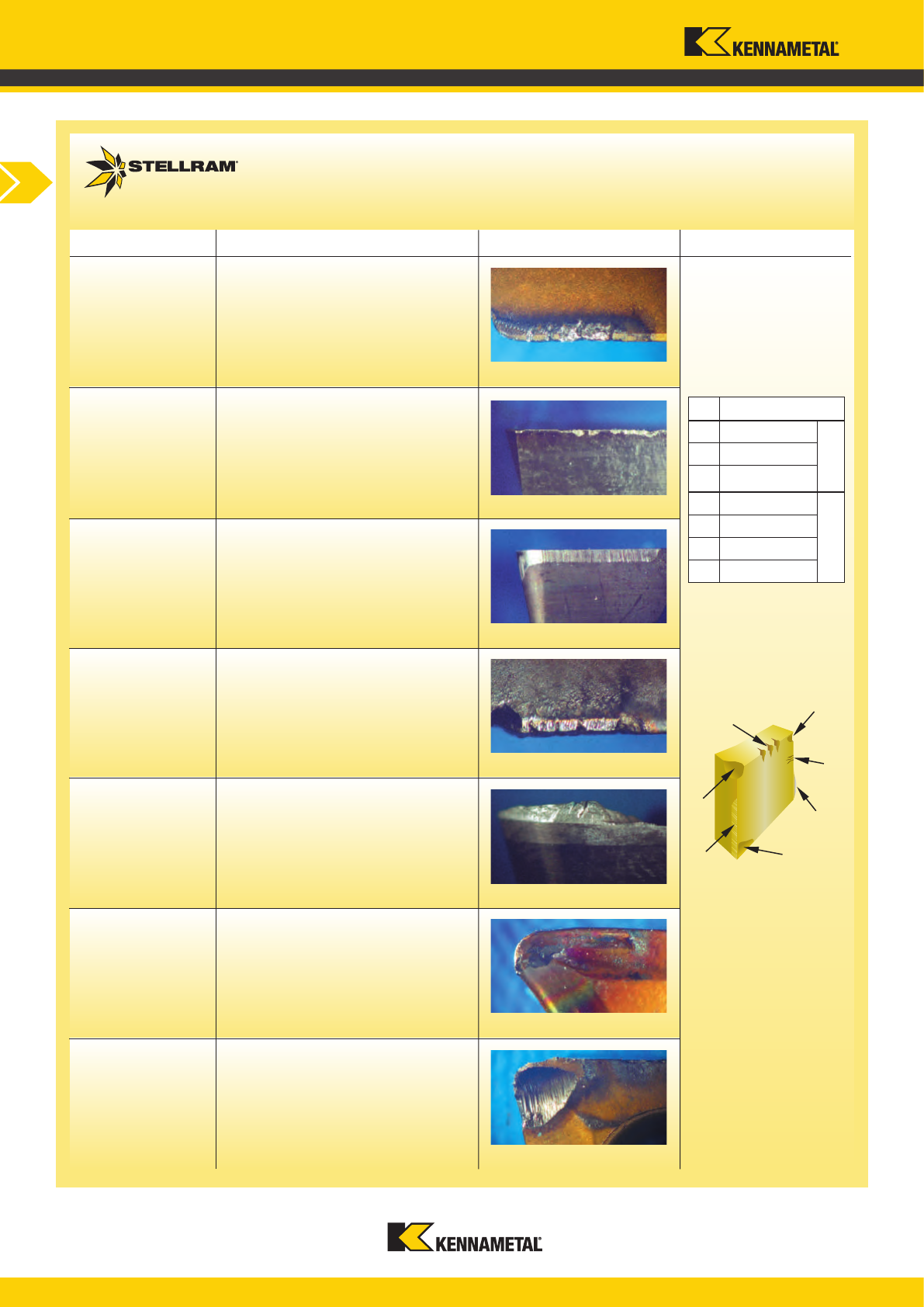

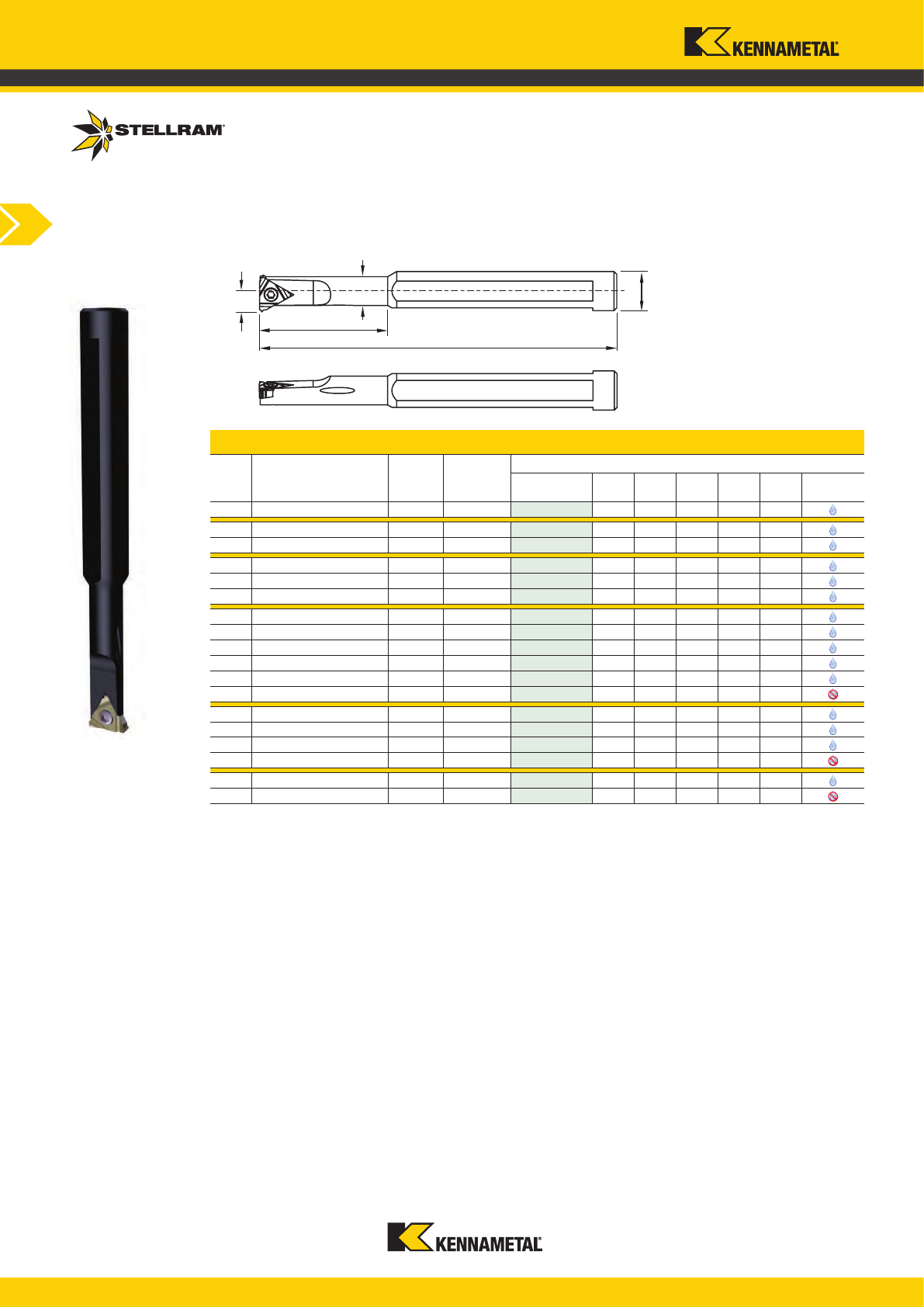

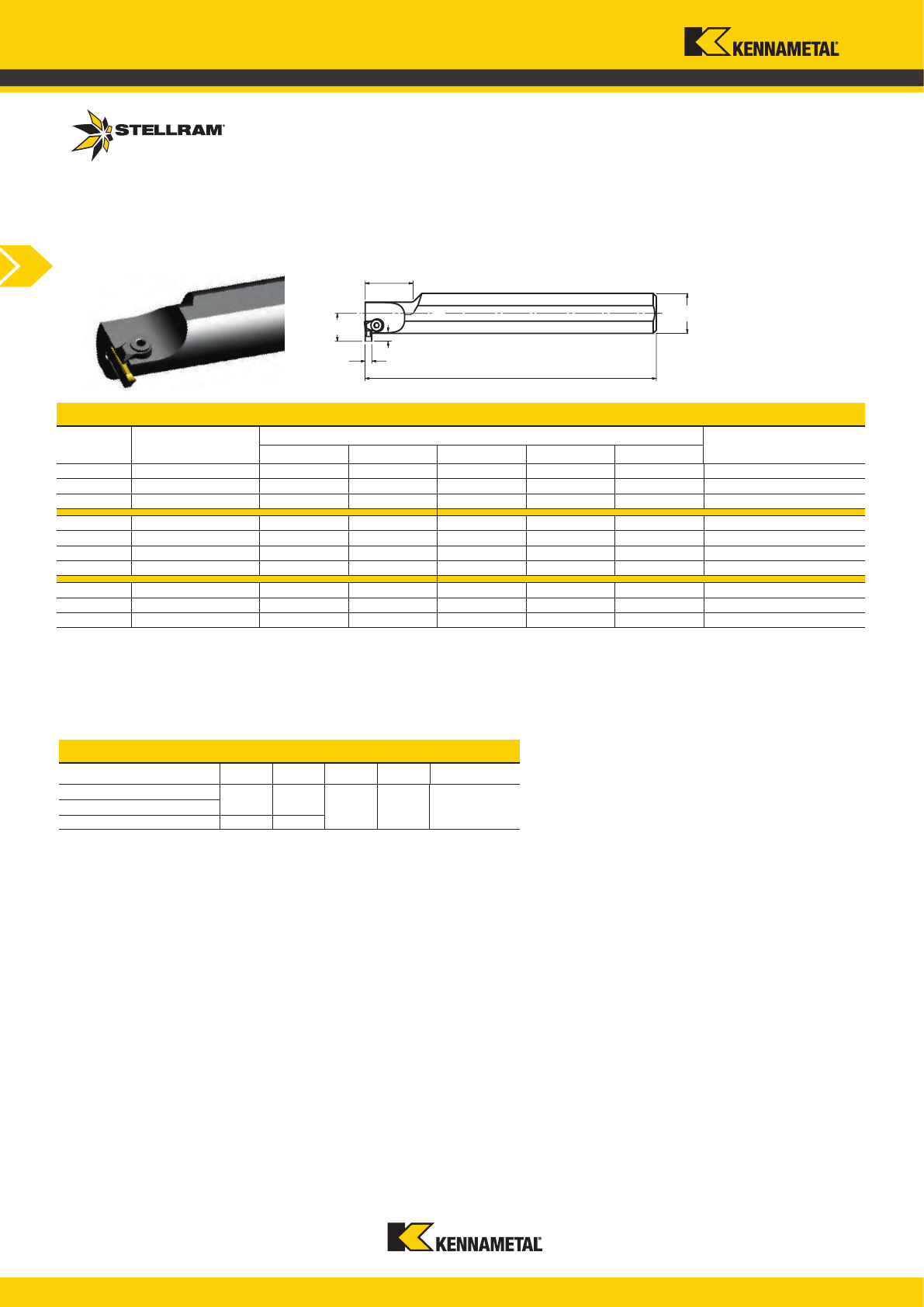

Cemented carbide

shank with

steel head and

anti-vibration device.

Cemented carbide

shank with steel

head, coolant hole

and anti-vibration

device.

Heavy metal shank.

Heavy metal shank

and coolant hole.

Steel shank.

Steel shank and

coolant hole.

Steel shank and anti-

vibration device.

Cemented carbide

shank with steel

head.

Steel shank,

anti-vibration device

and coolant hole.

Cemented carbide

shank with steel

head and coolant

hole.

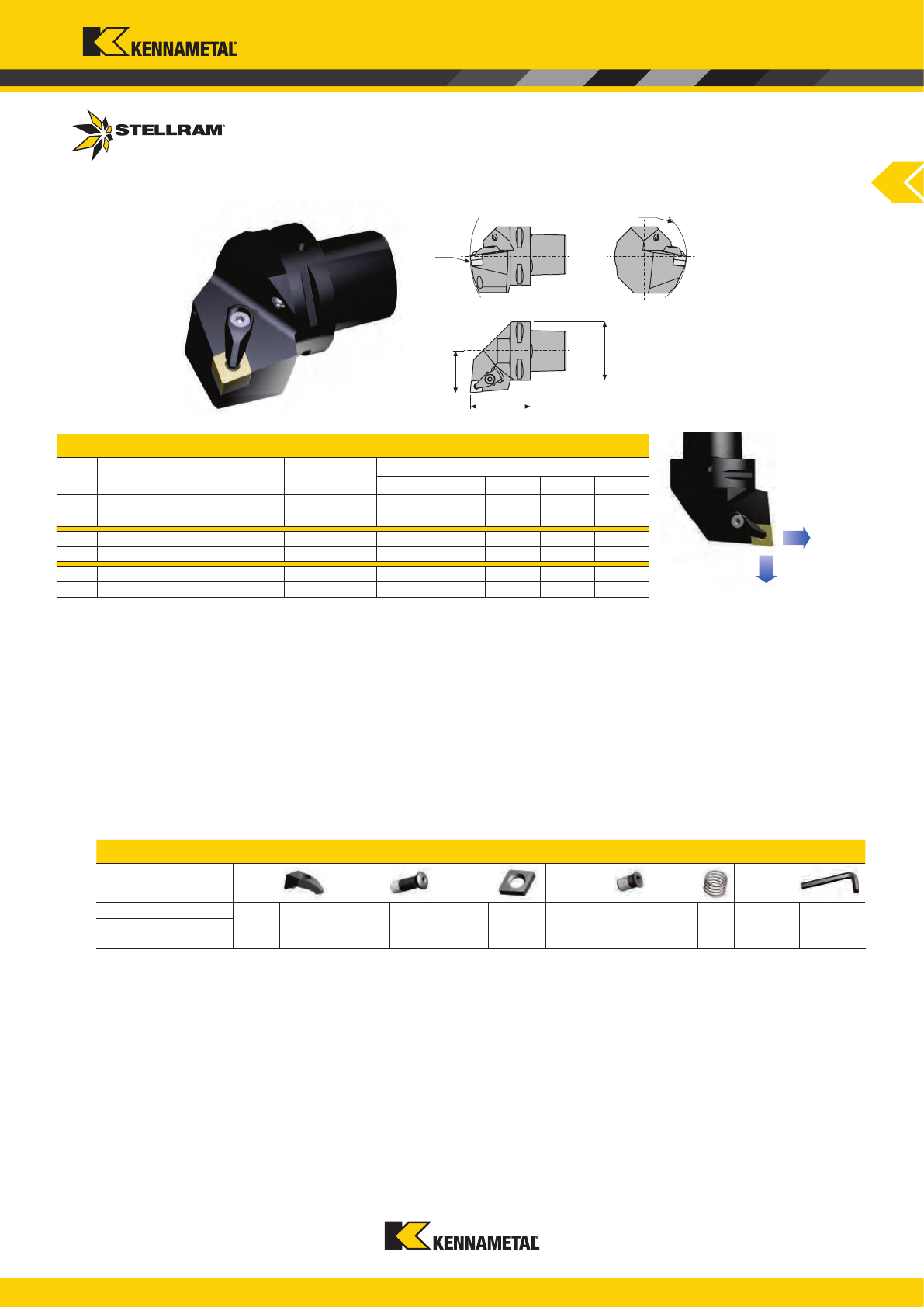

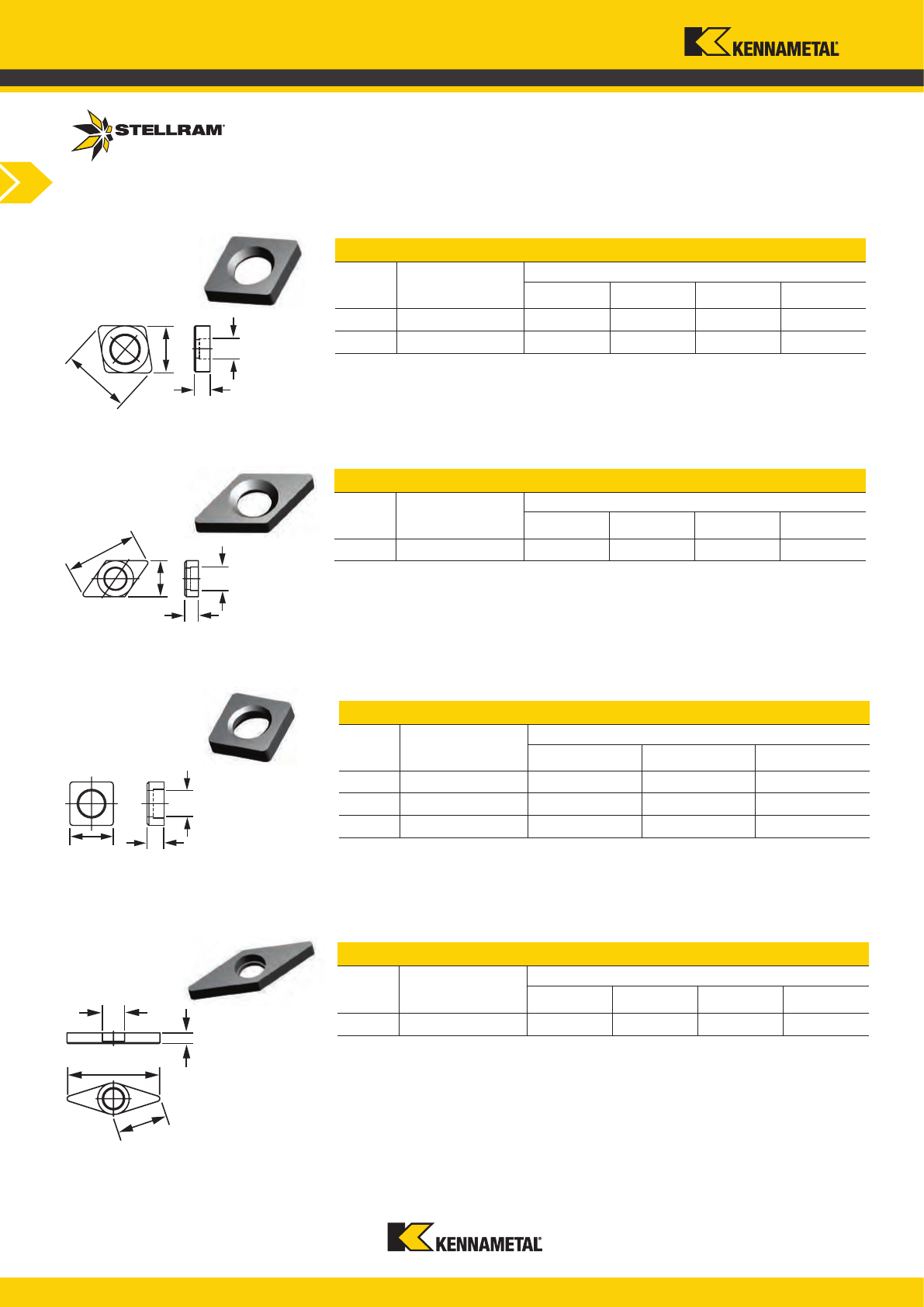

4 Assembly

2 Bar Ø

5 Insert Shape

3 Bar Length

1 Bar Type

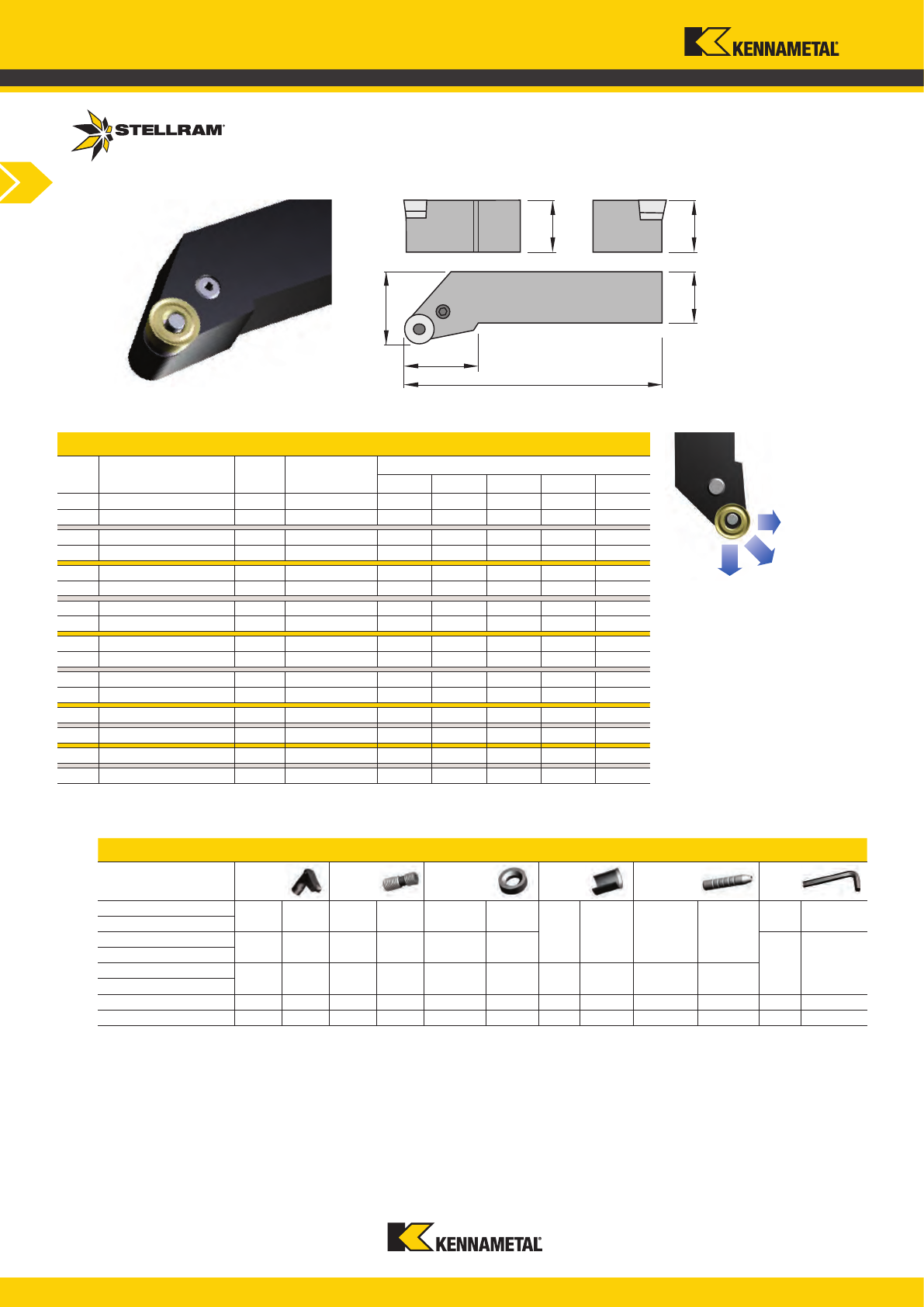

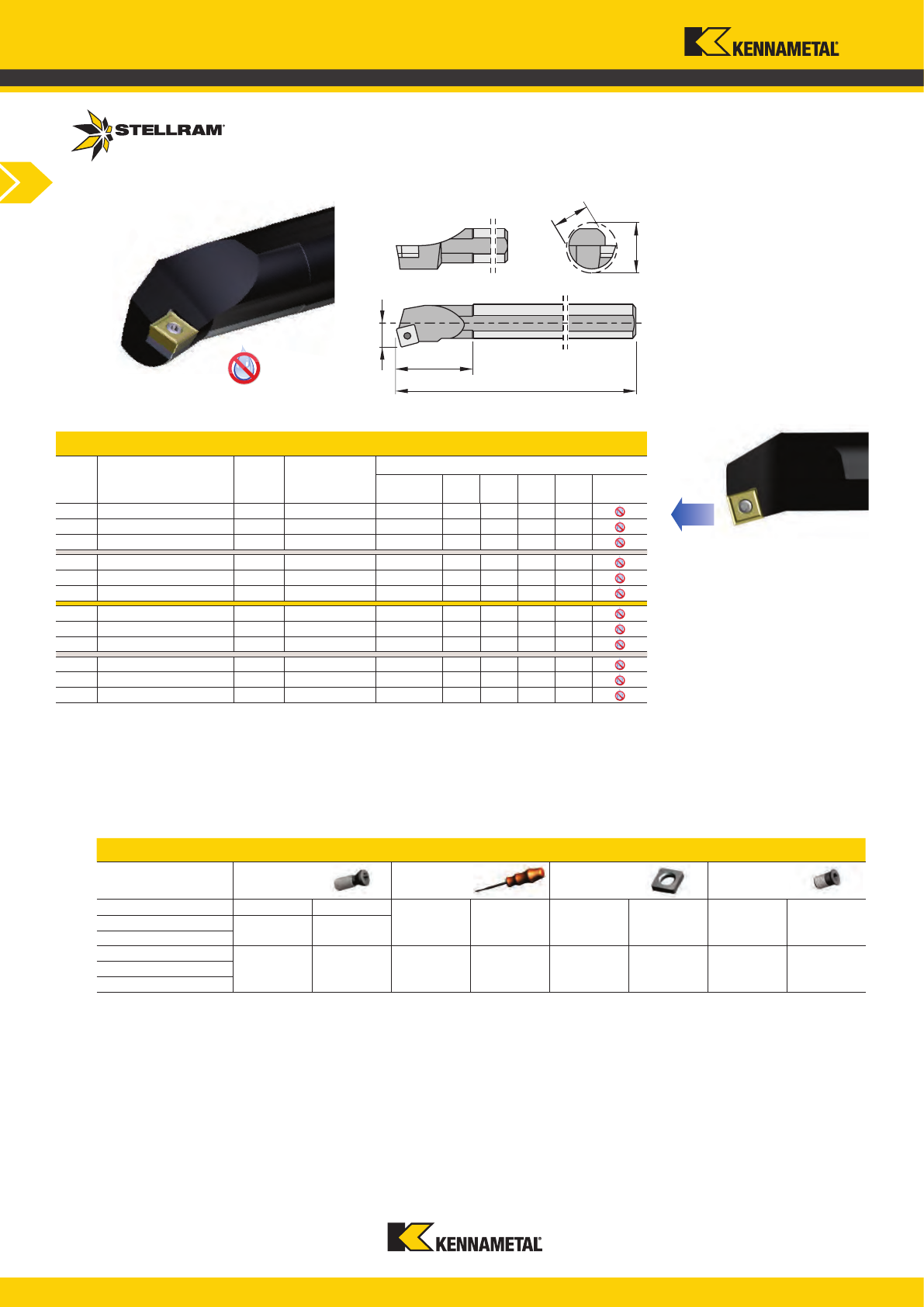

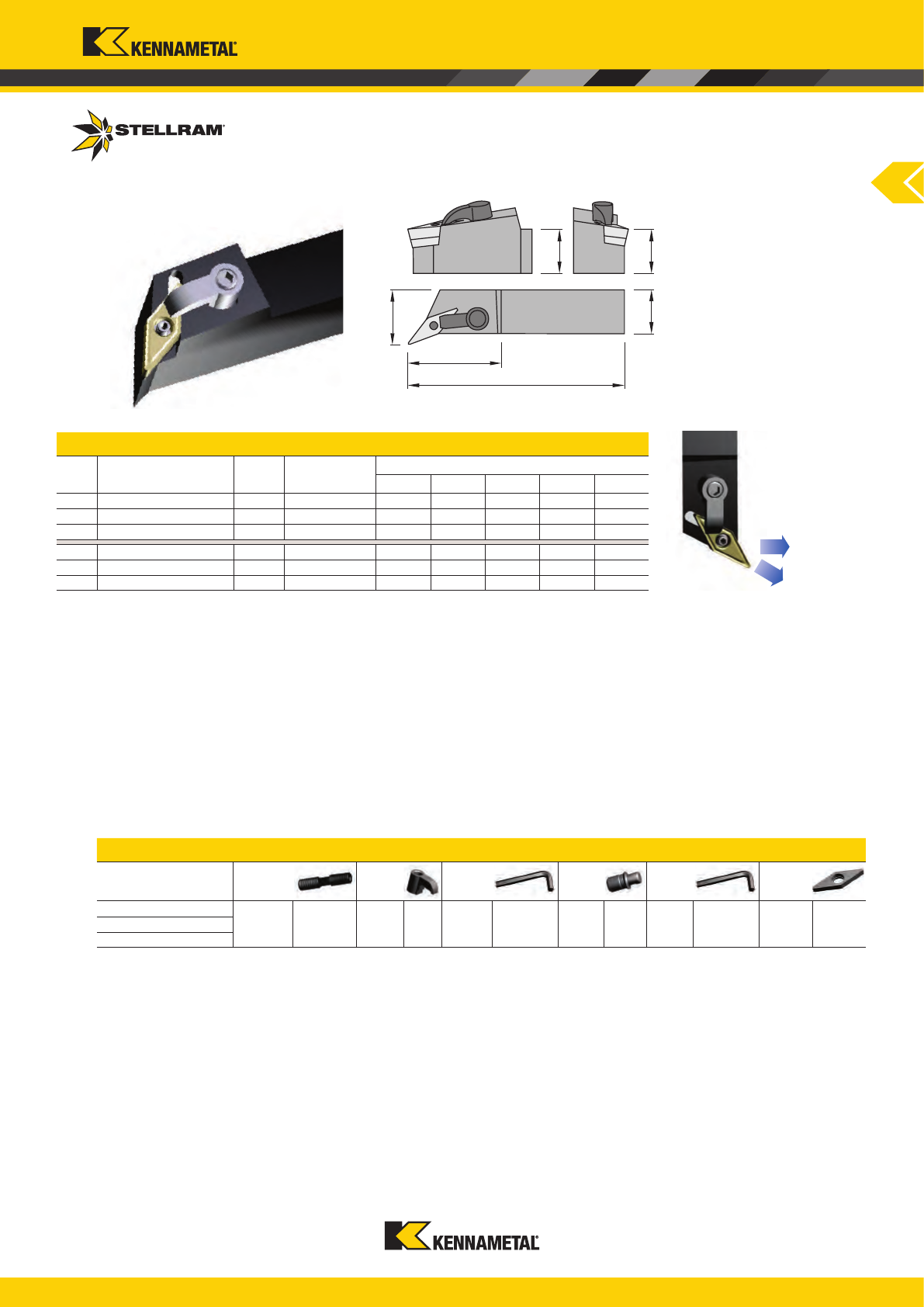

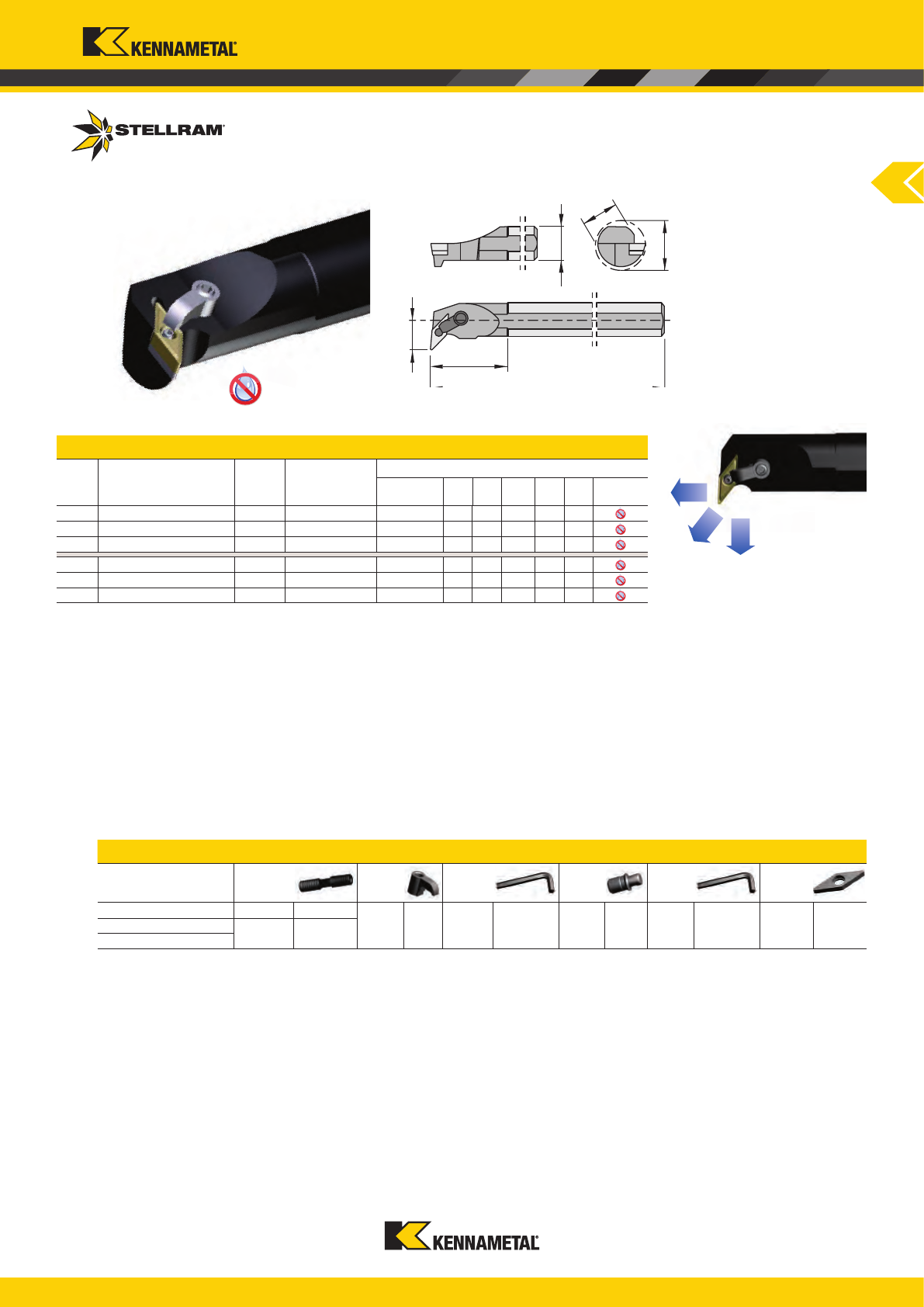

Internal Boring Bars

Clamp Lock Designation

www.kennametal.com

C41

L

N

7

R

8

-

10

12

9

90˚

75˚

95˚

117° 30’

107˚30’

F

K

L

P

Q

45˚

93˚

60˚

85˚

S

U

W

Y

A

3°

B

5°

C

7°

D

15°

E

20°

F

25°

G

30°

N

0°

P

11°

L

O

P

I

C, D,

E, M,

V

I

H

I

A, B,

K

I

R

I

S

I

T

I

W

I

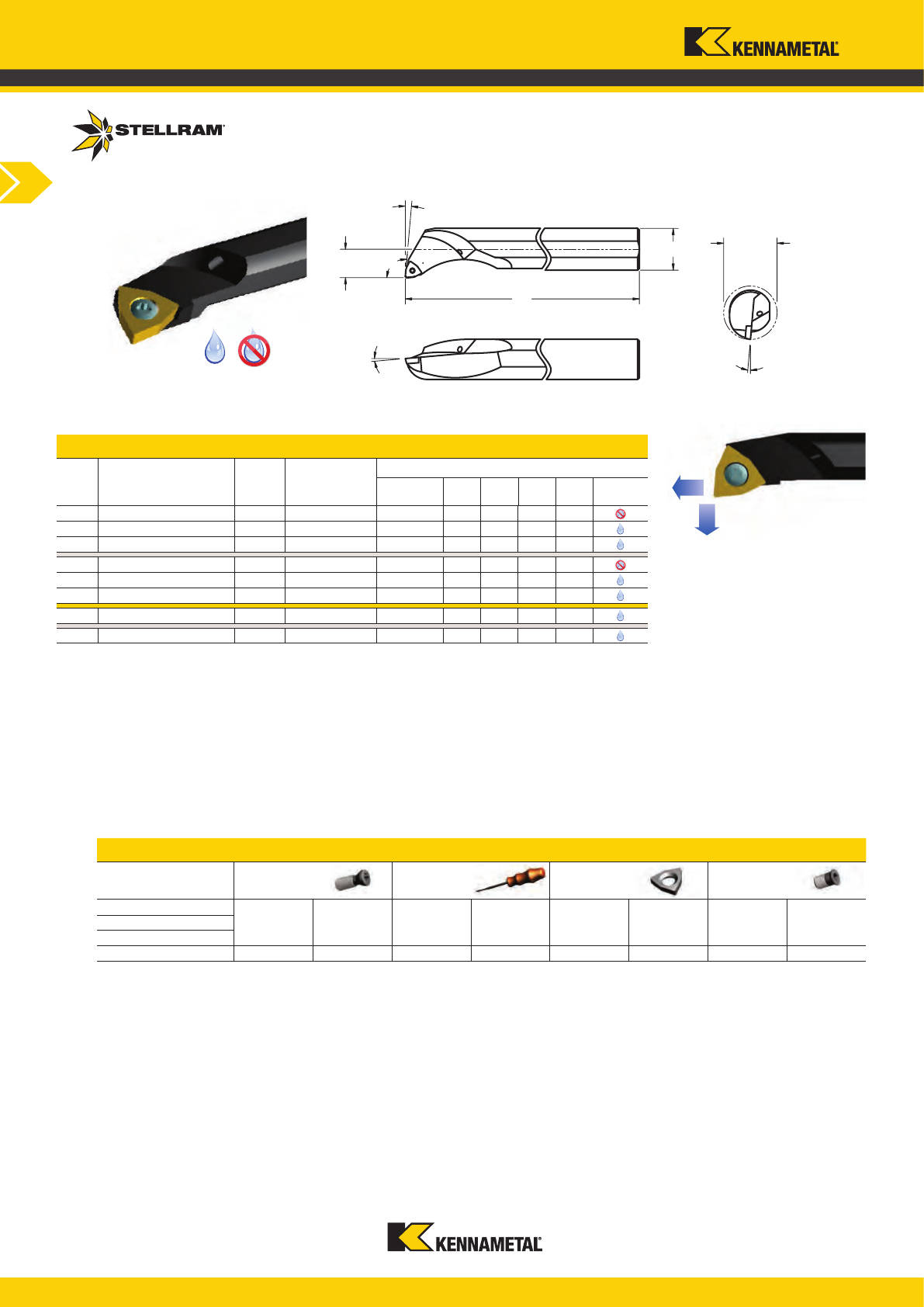

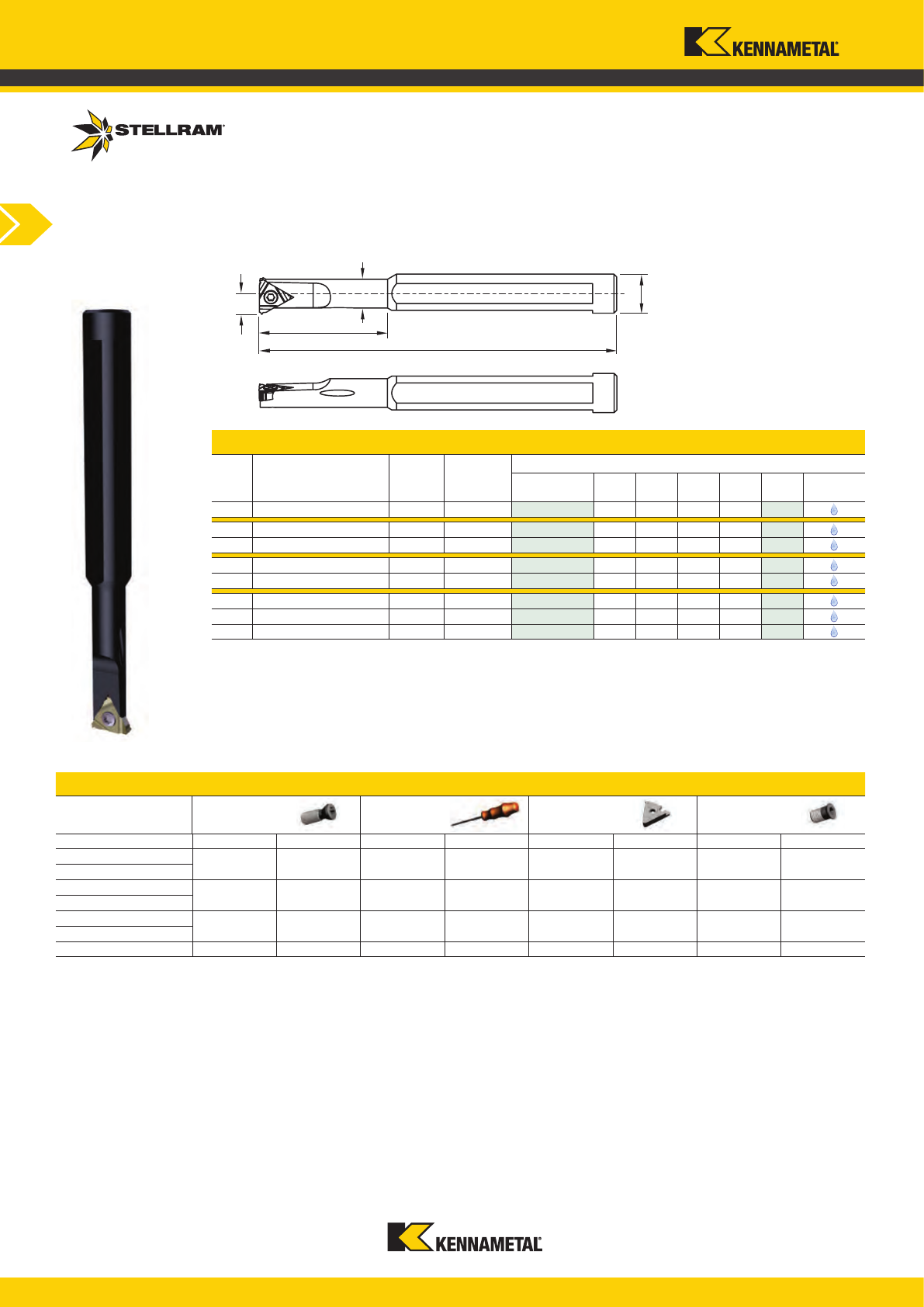

Turning Inserts

10 Optional

Supplementary optional symbol (numbers or letters) added

by the manufacturer.

Must be separated from the standardised designation by a

dash (-).

Integers to be preceded by a 0 (zero).

Disregard any decimals. e.g. 9,525 = 09

9 Insert Size

L

Left

Hand

R

Right

Hand

8 Hand

Other normal clearances requiring

SPECIAL specification Symbol O.

7 Clearance

6 Tool Style

Internal Boring Bars

Clamp Lock Designation

www.kennametal.com

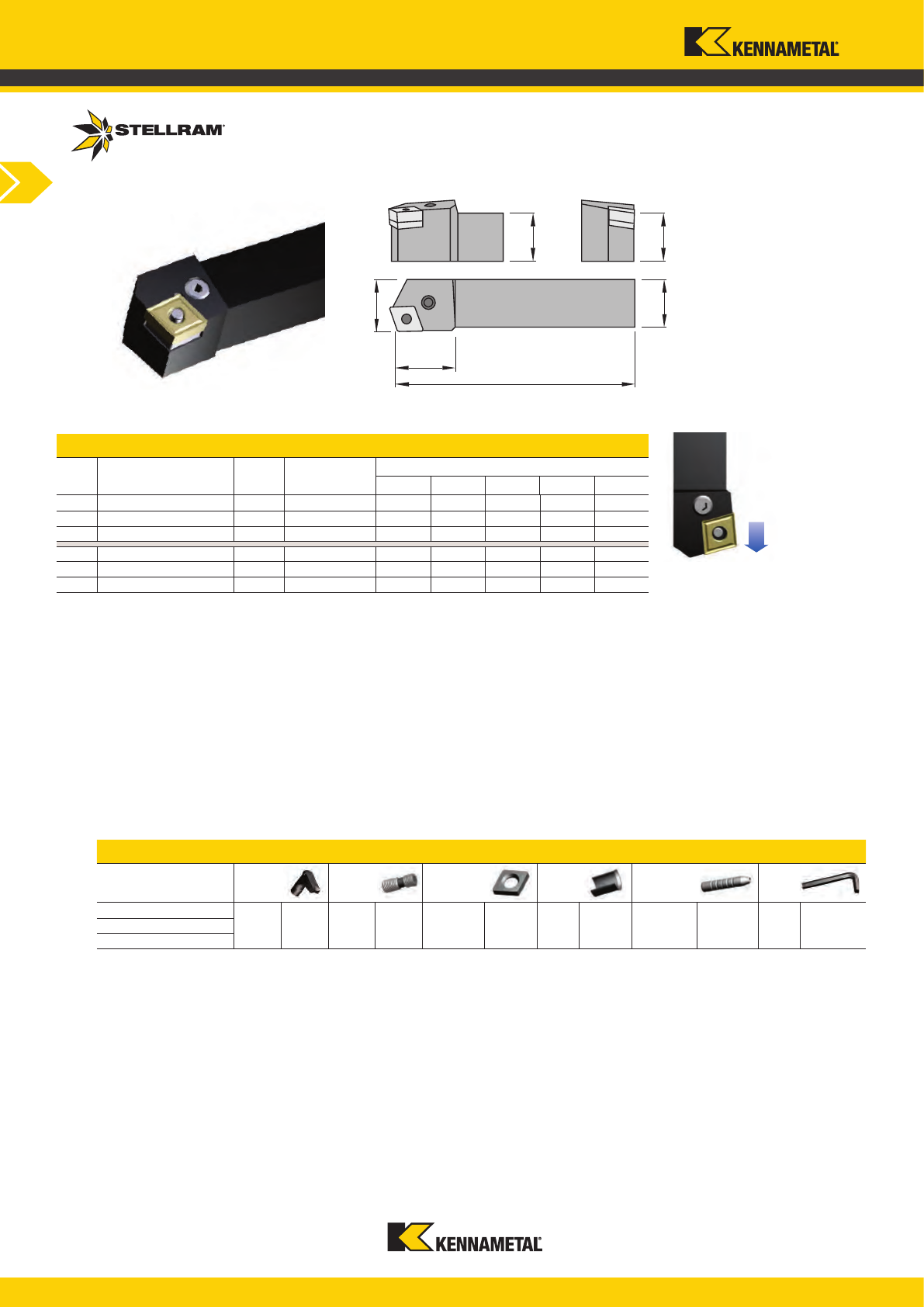

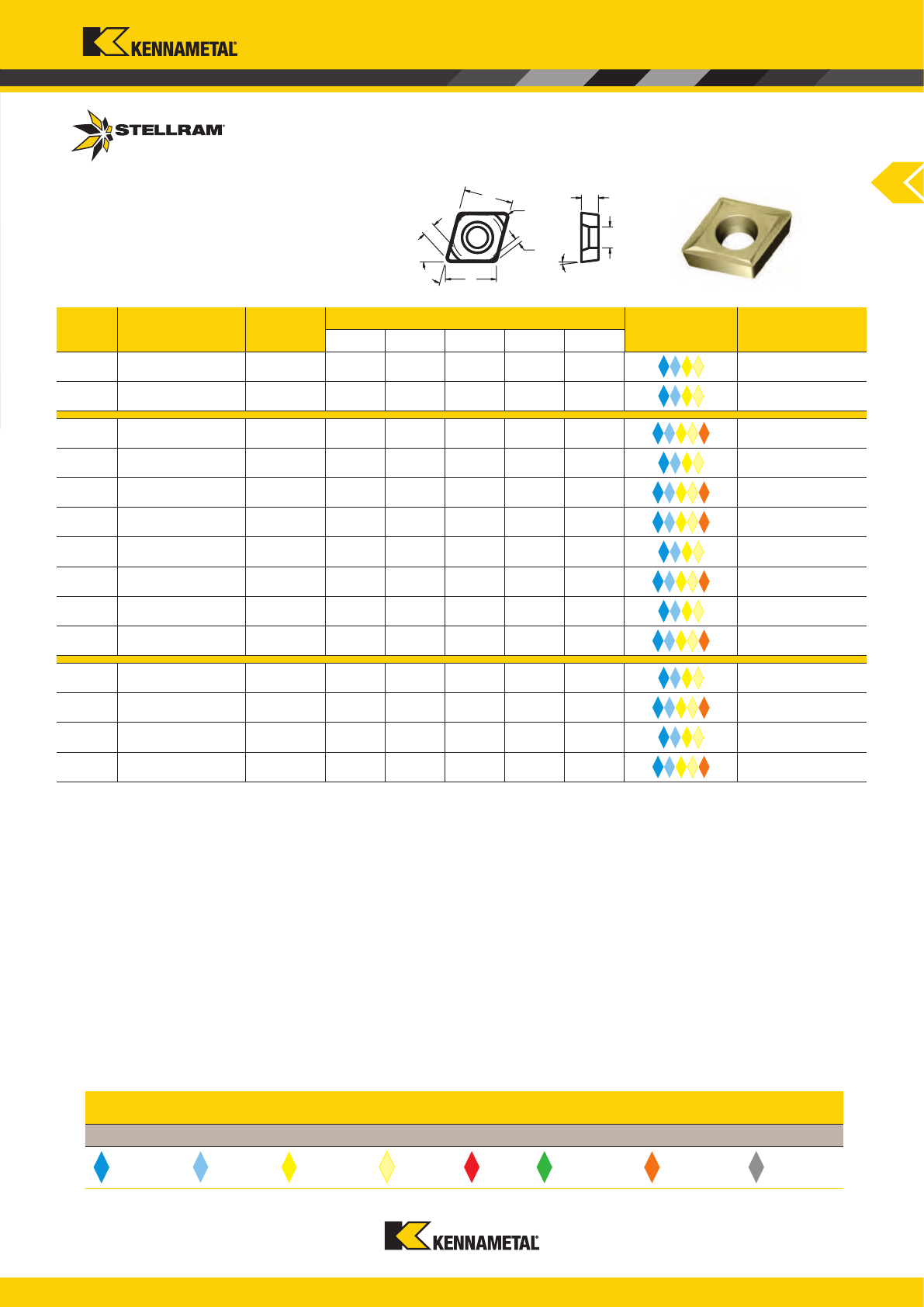

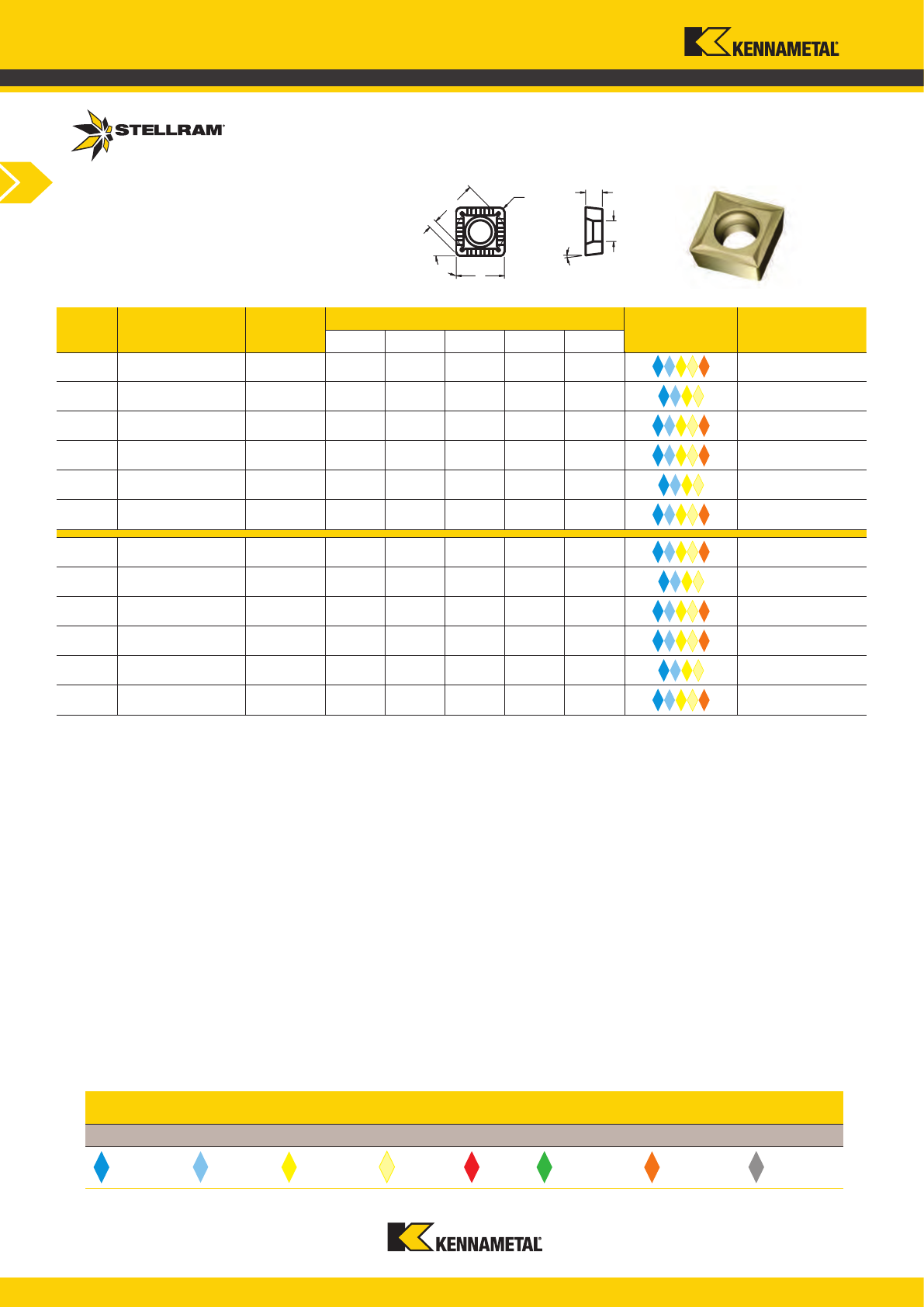

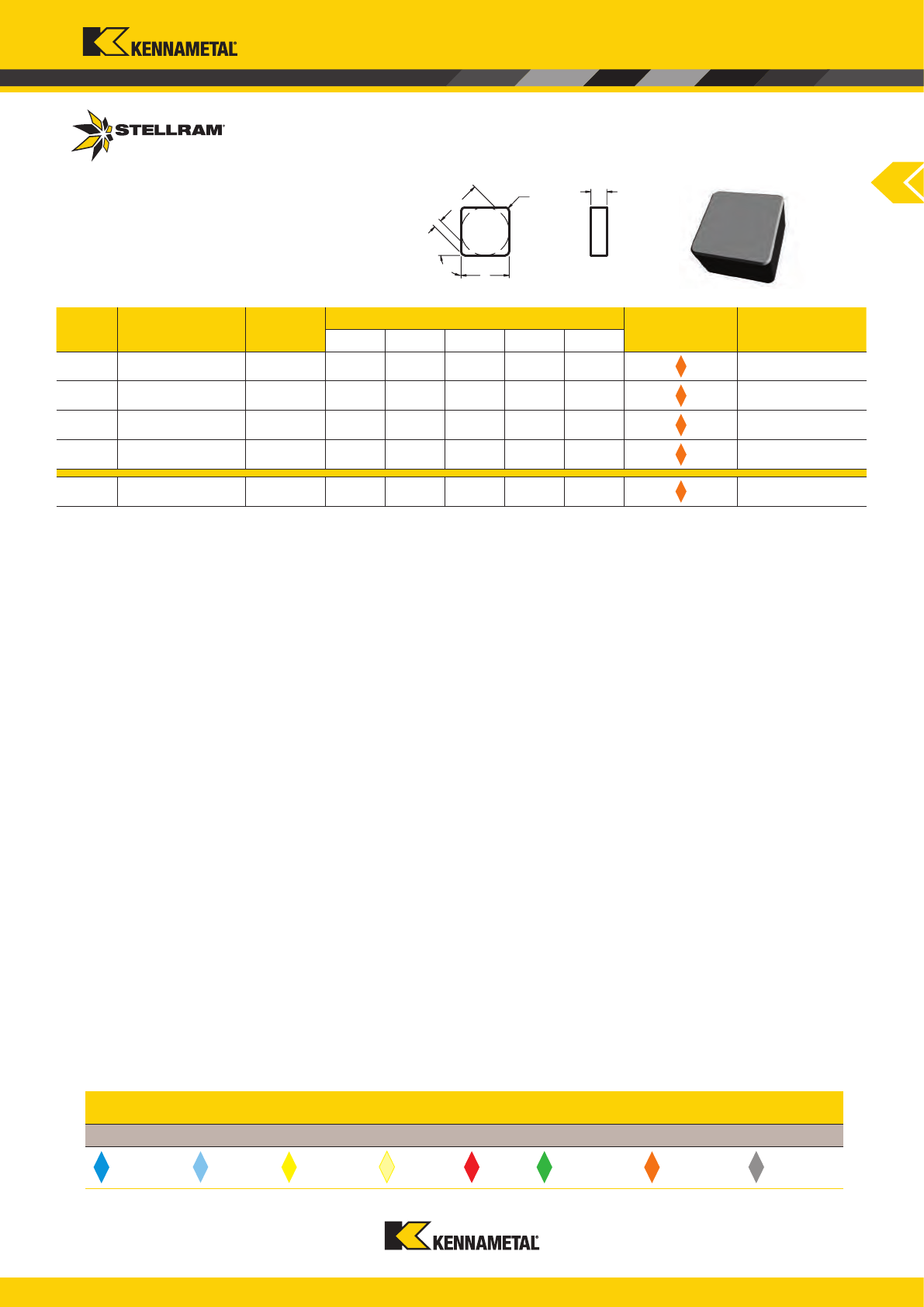

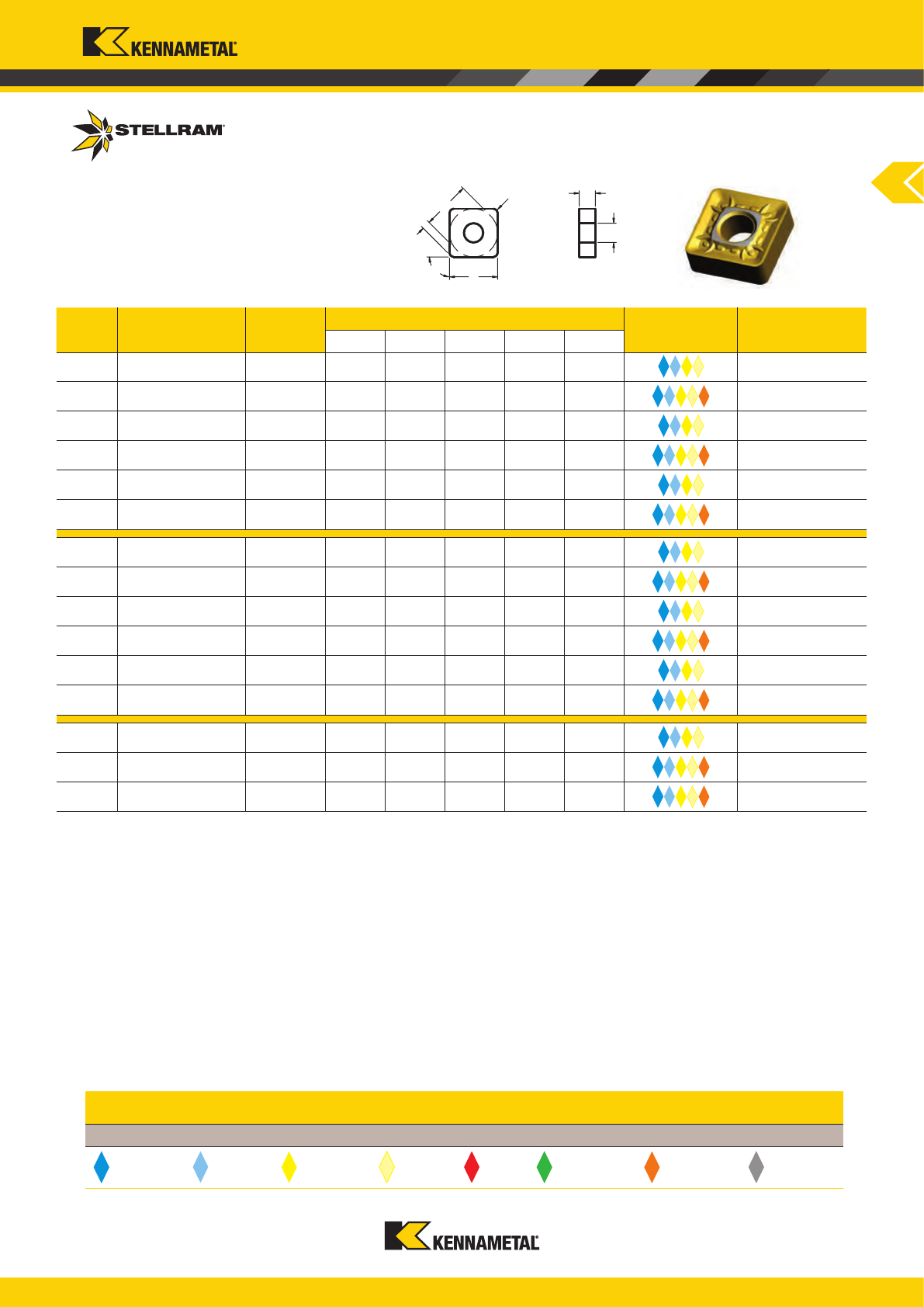

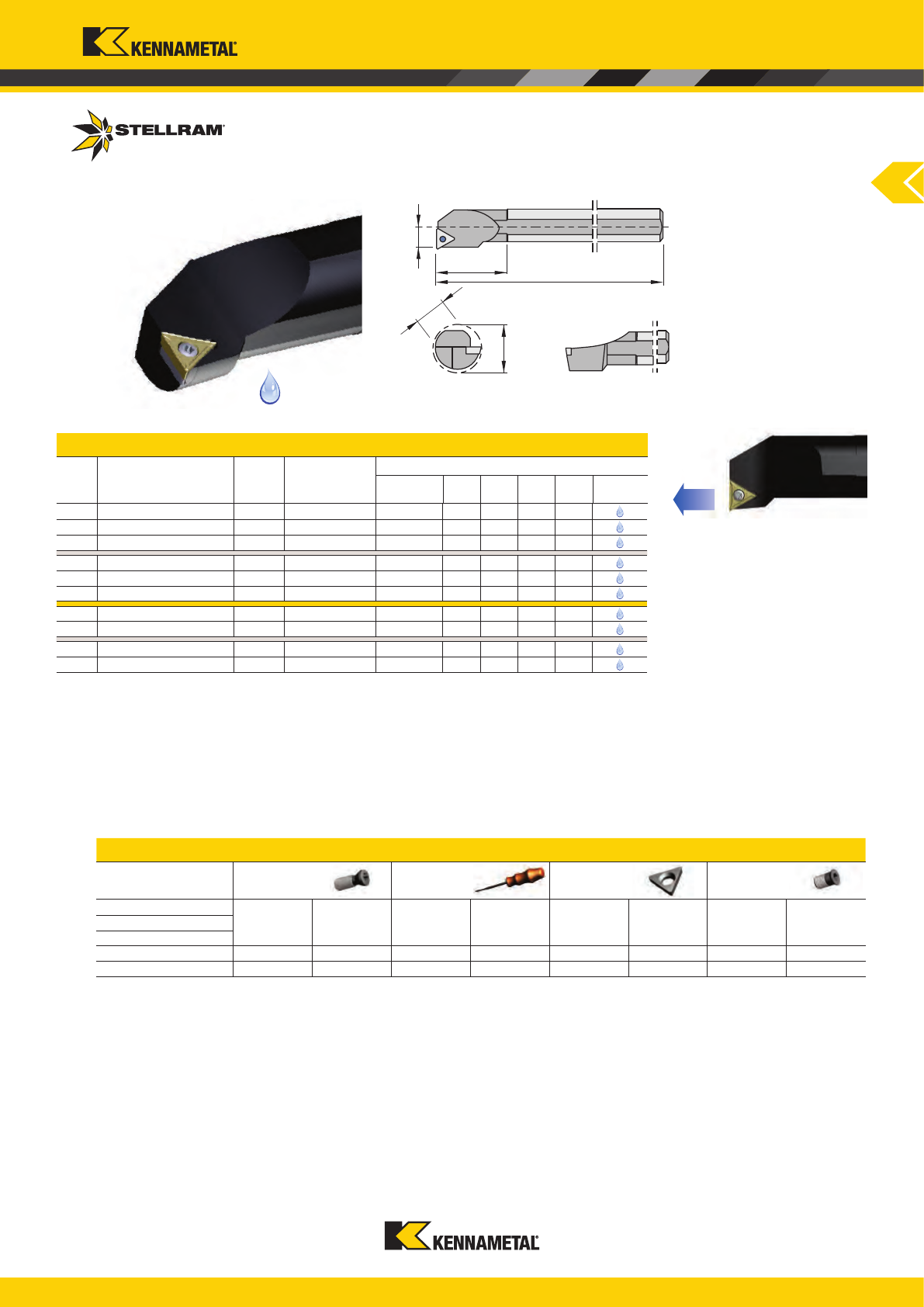

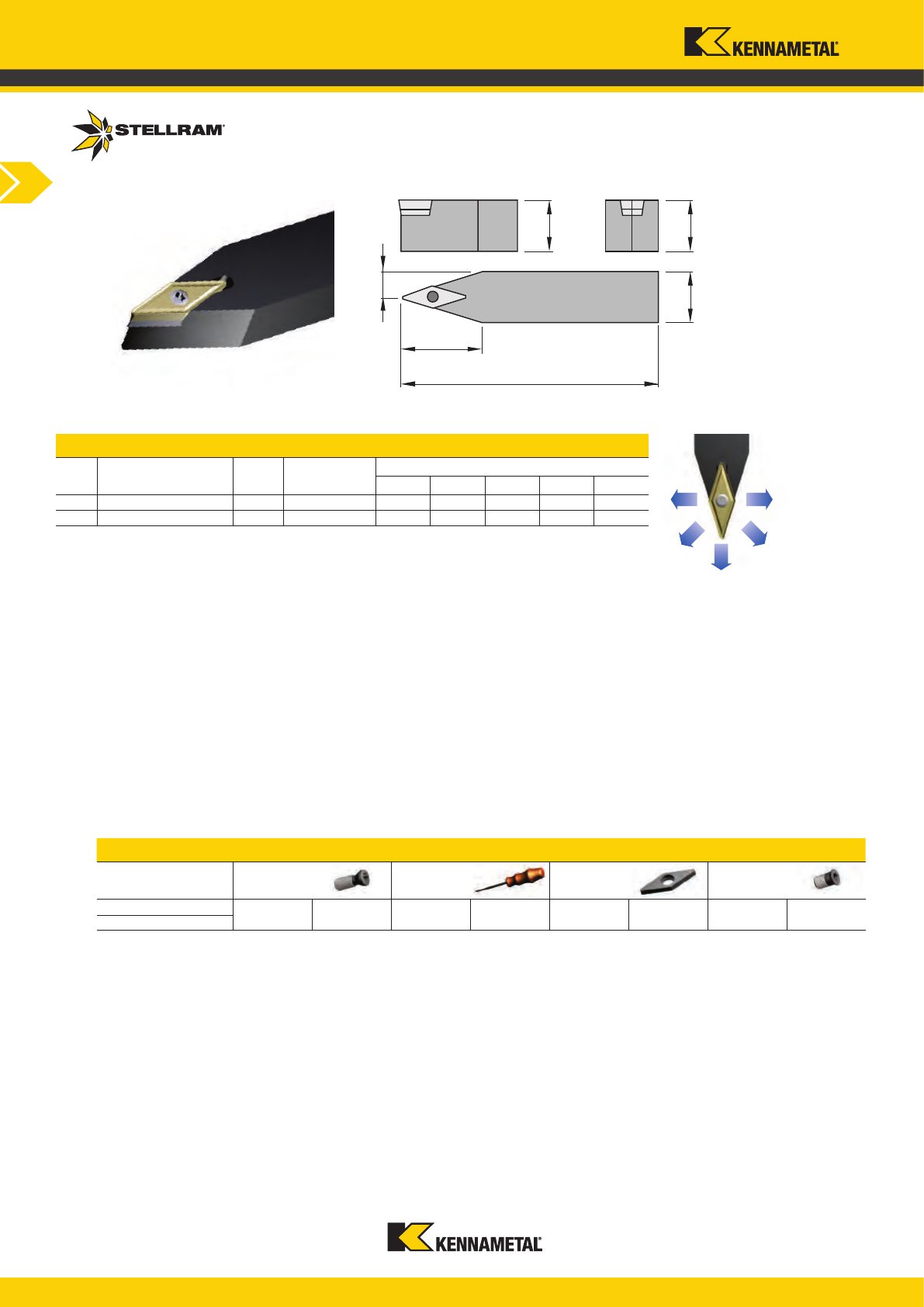

C42

P

P

M

M

K N

S

H

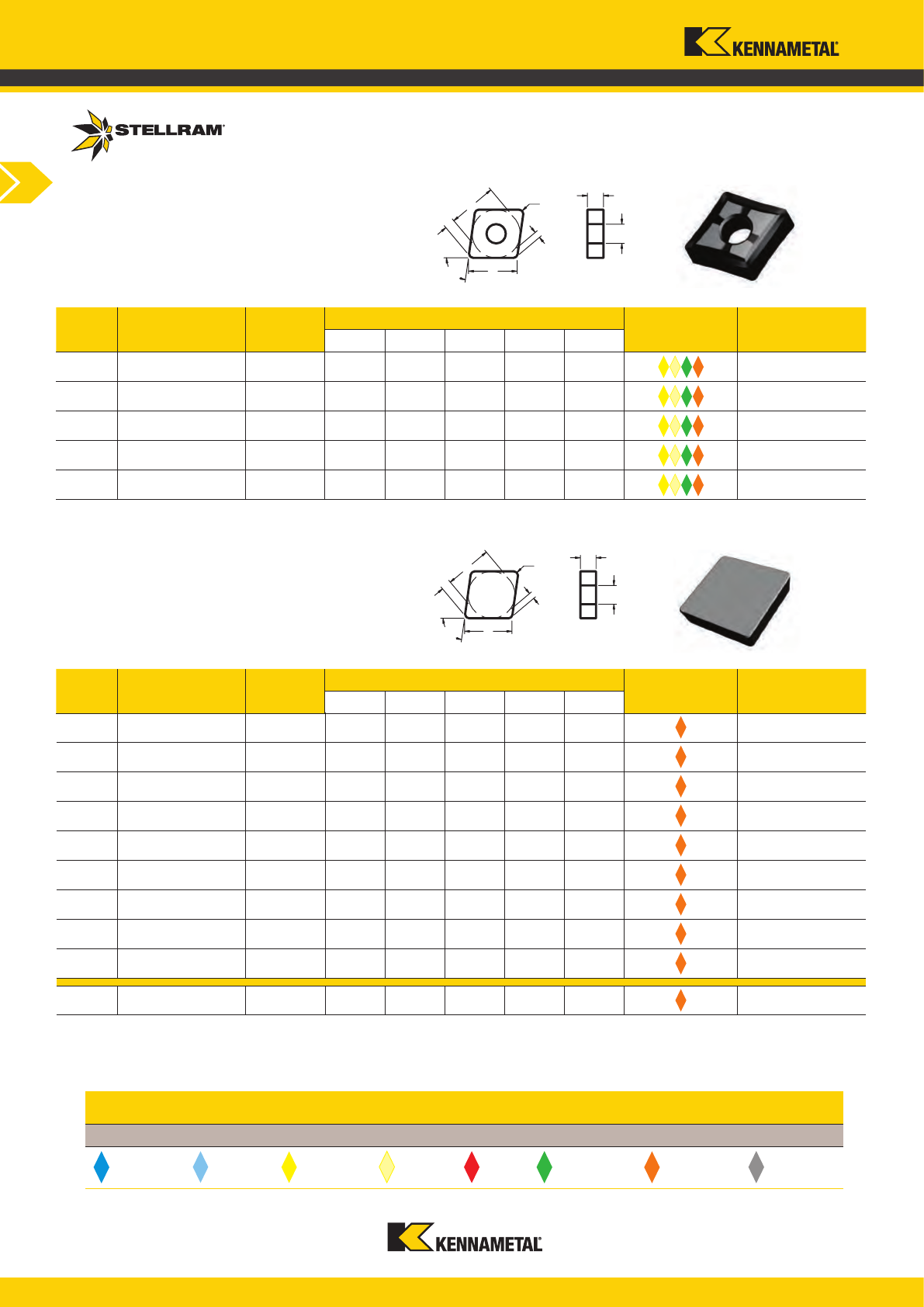

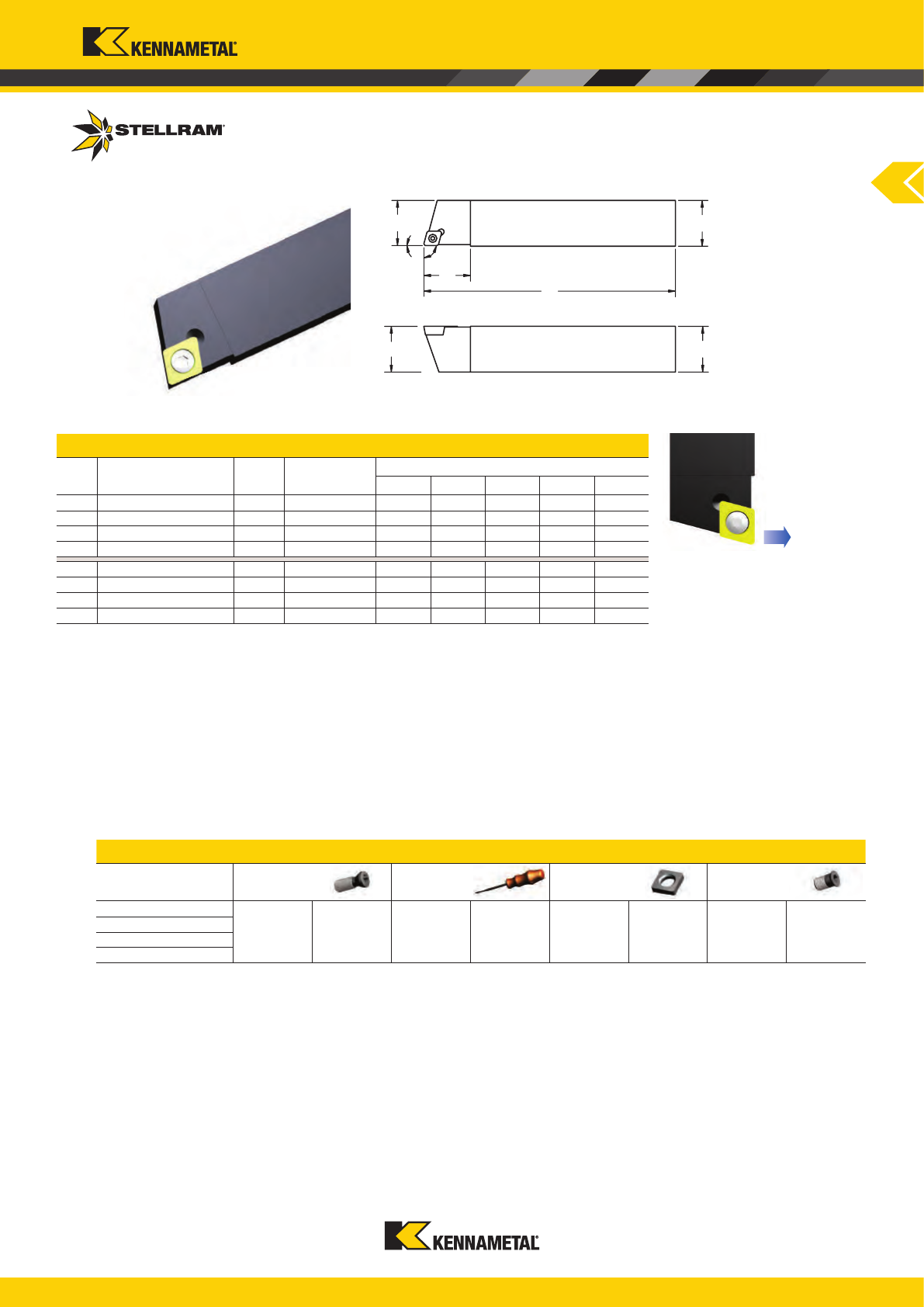

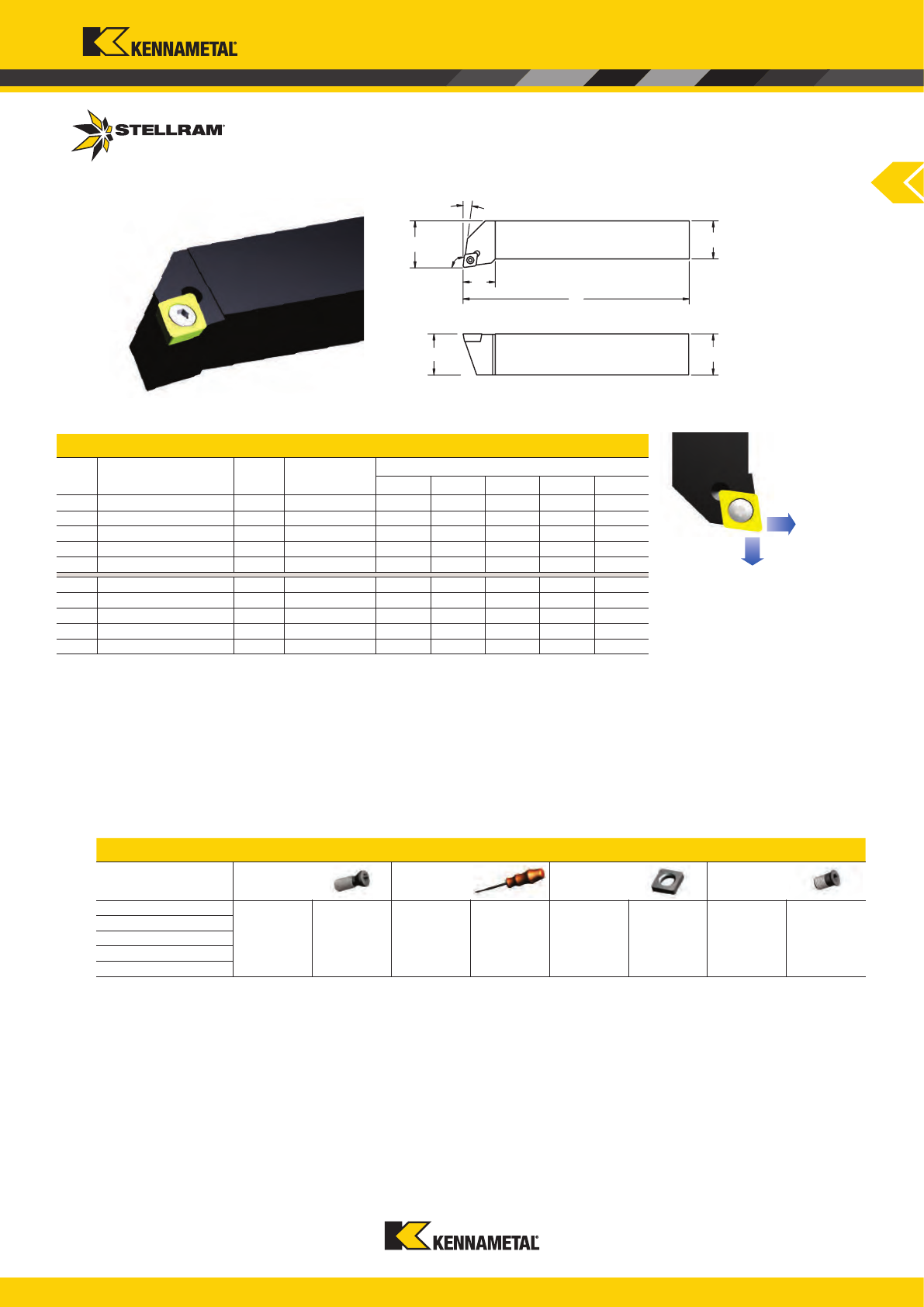

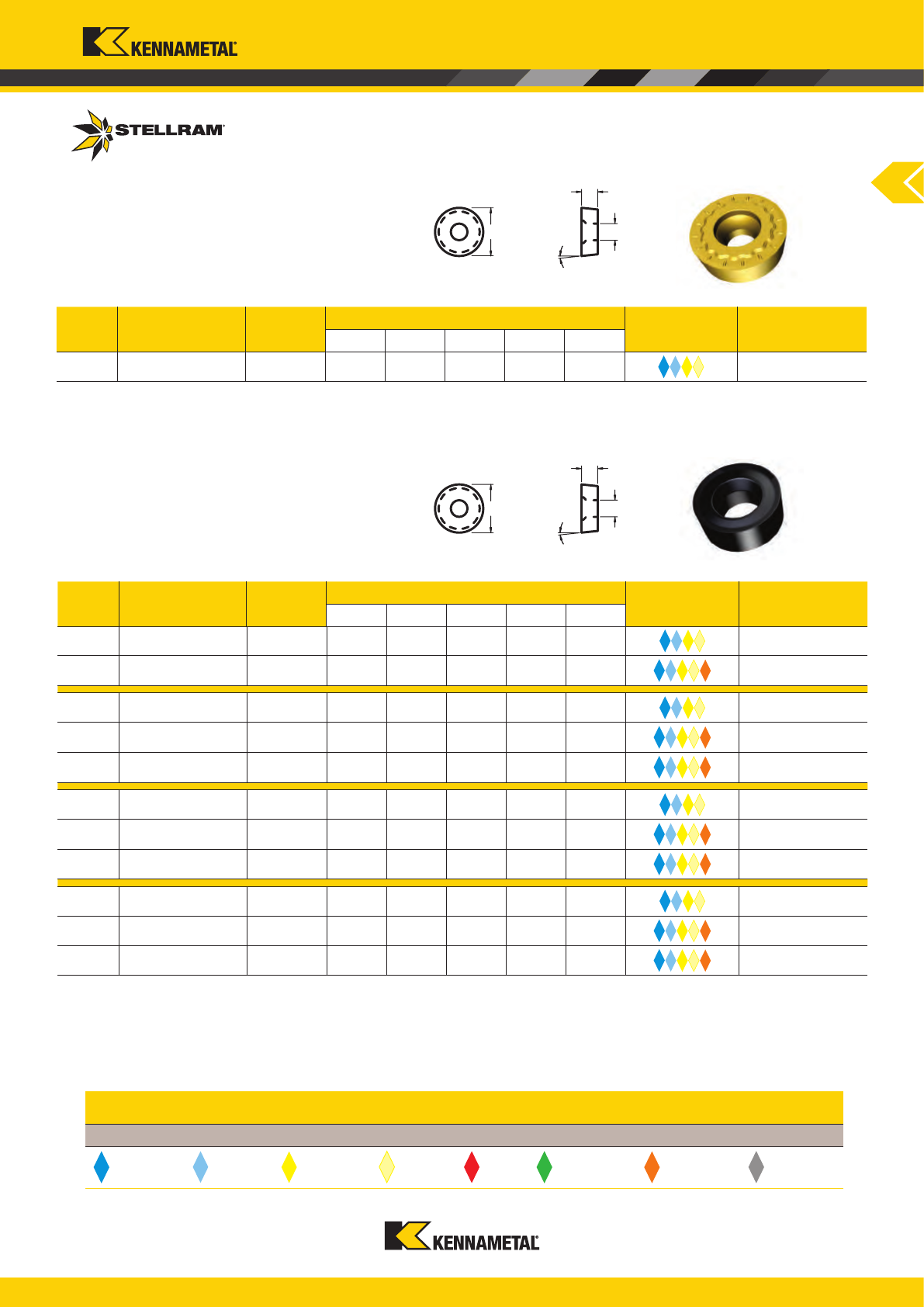

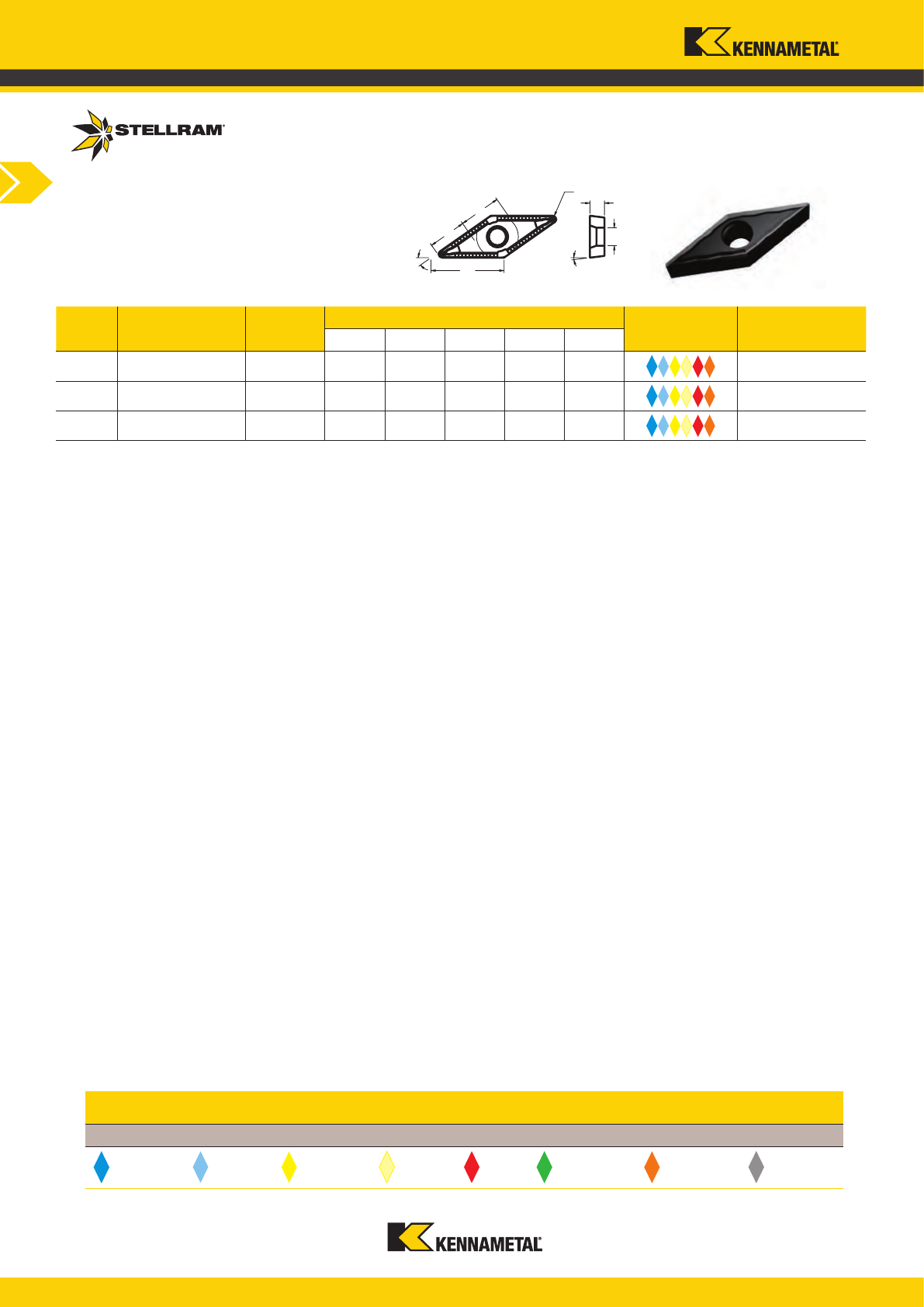

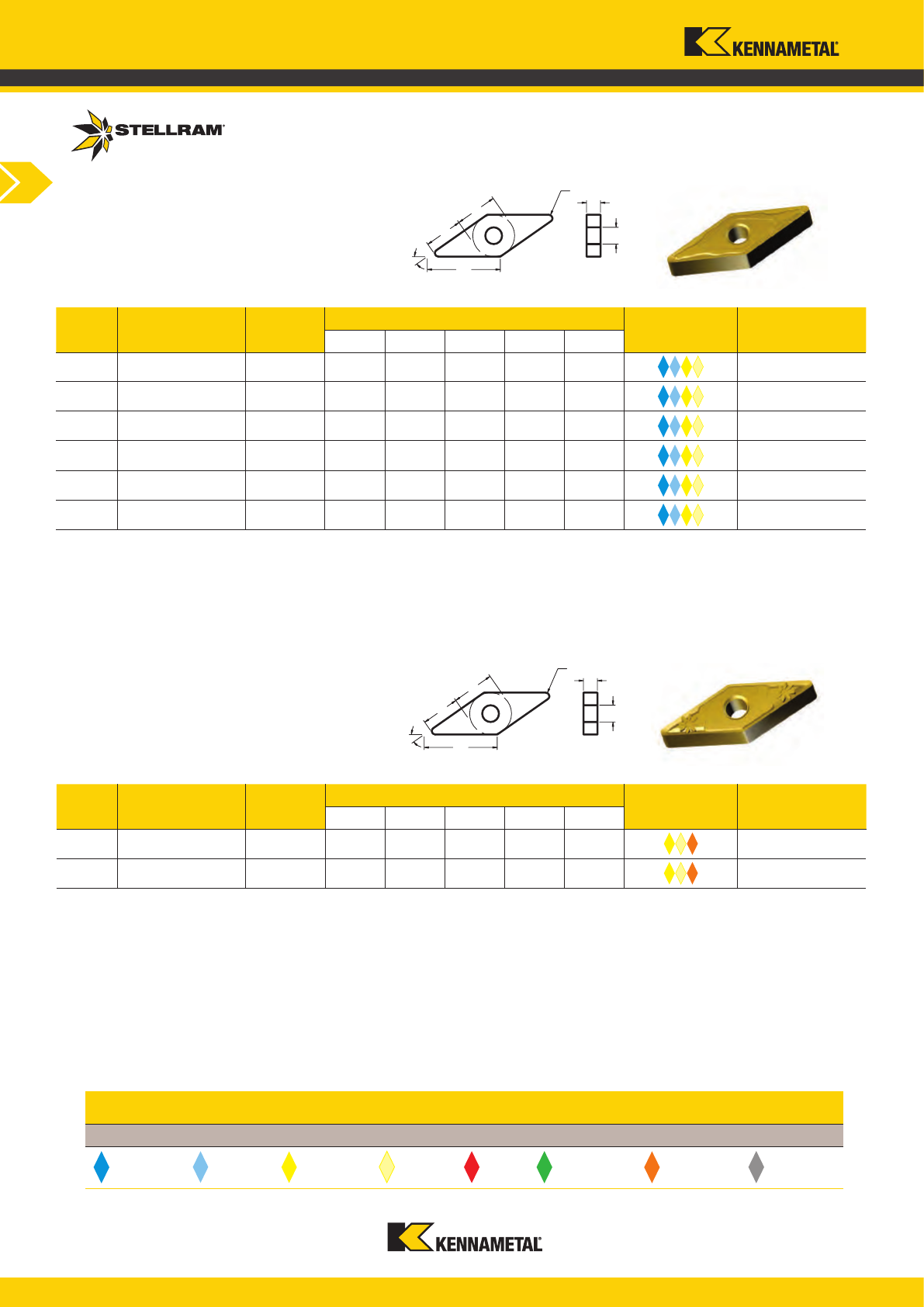

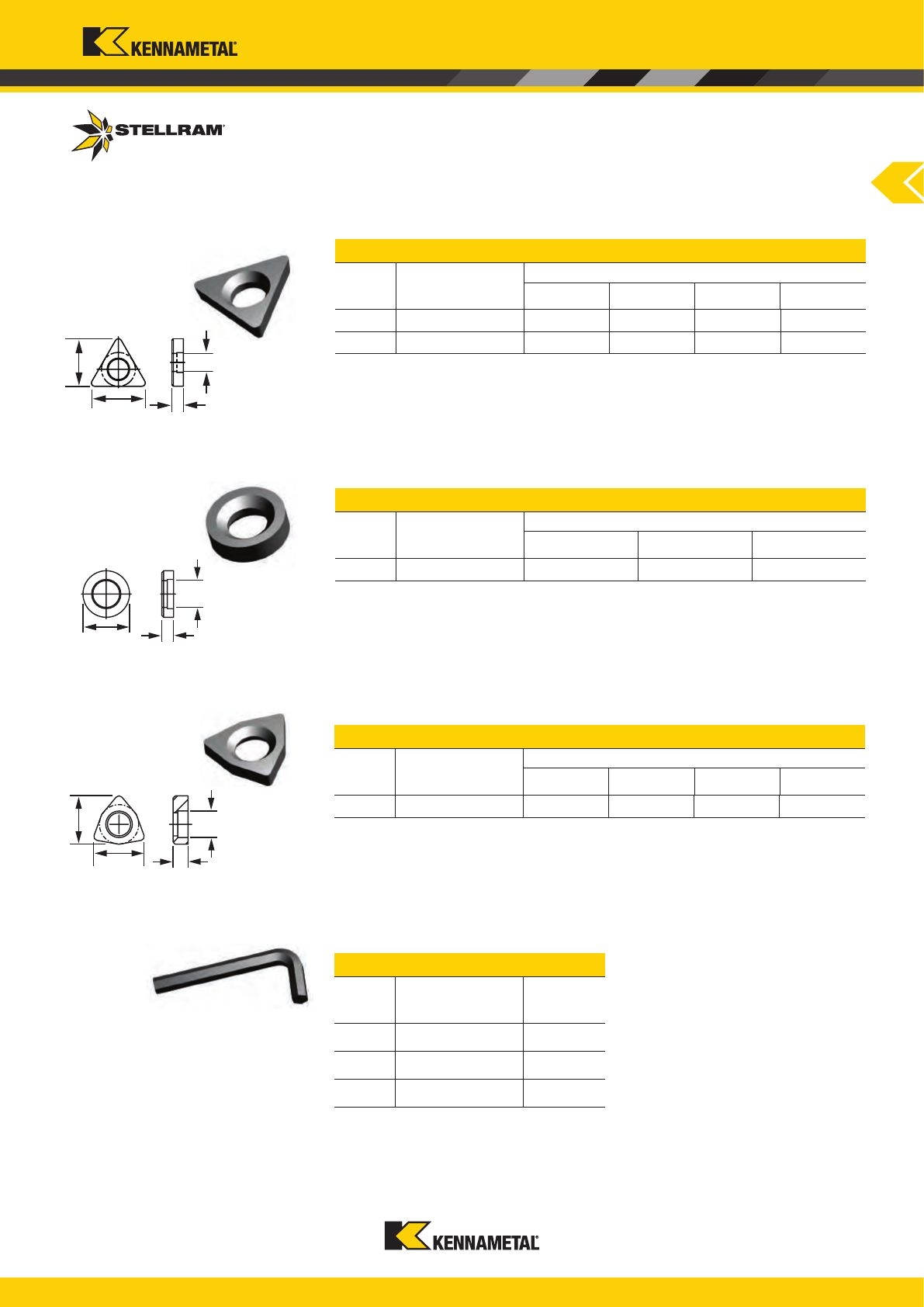

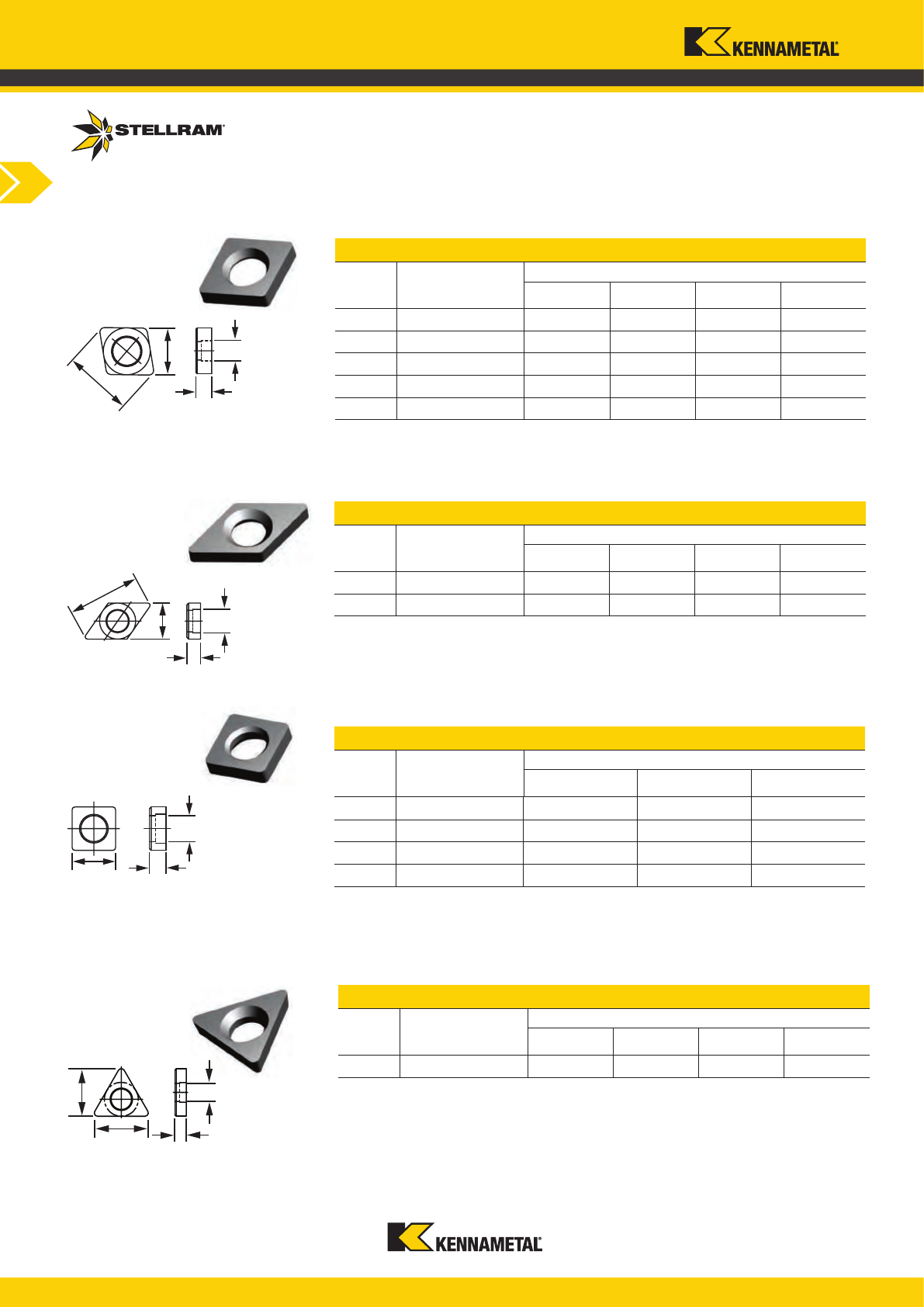

031243 CCGT060200E-62 SP4019 6,35 6,45 2,38 0,00 2,80

030568 CCGT060201E-62 SP4019 6,35 6,45 2,38 0,10 2,80

030569 CCGT060202E-62 SP4019 6,35 6,45 2,38 0,20 2,80

030570 CCGT060204E-62 SP4019 6,35 6,45 2,38 0,40 2,80

030571 CCGT09T300E-62 SP4019 9,52 9,57 3,97 0,00 4,40

030572 CCGT09T301E-62 SP4019 9,52 9,57 3,97 0,10 4,40

030573 CCGT09T302E-62 SP4019 9,52 9,57 3,97 0,20 4,40

030574 CCGT09T304E-62 SP4019 9,52 9,57 3,97 0,40 4,40

030575 CCGT09T308E-62 SP4019 9,52 9,57 3,97 0,80 4,40

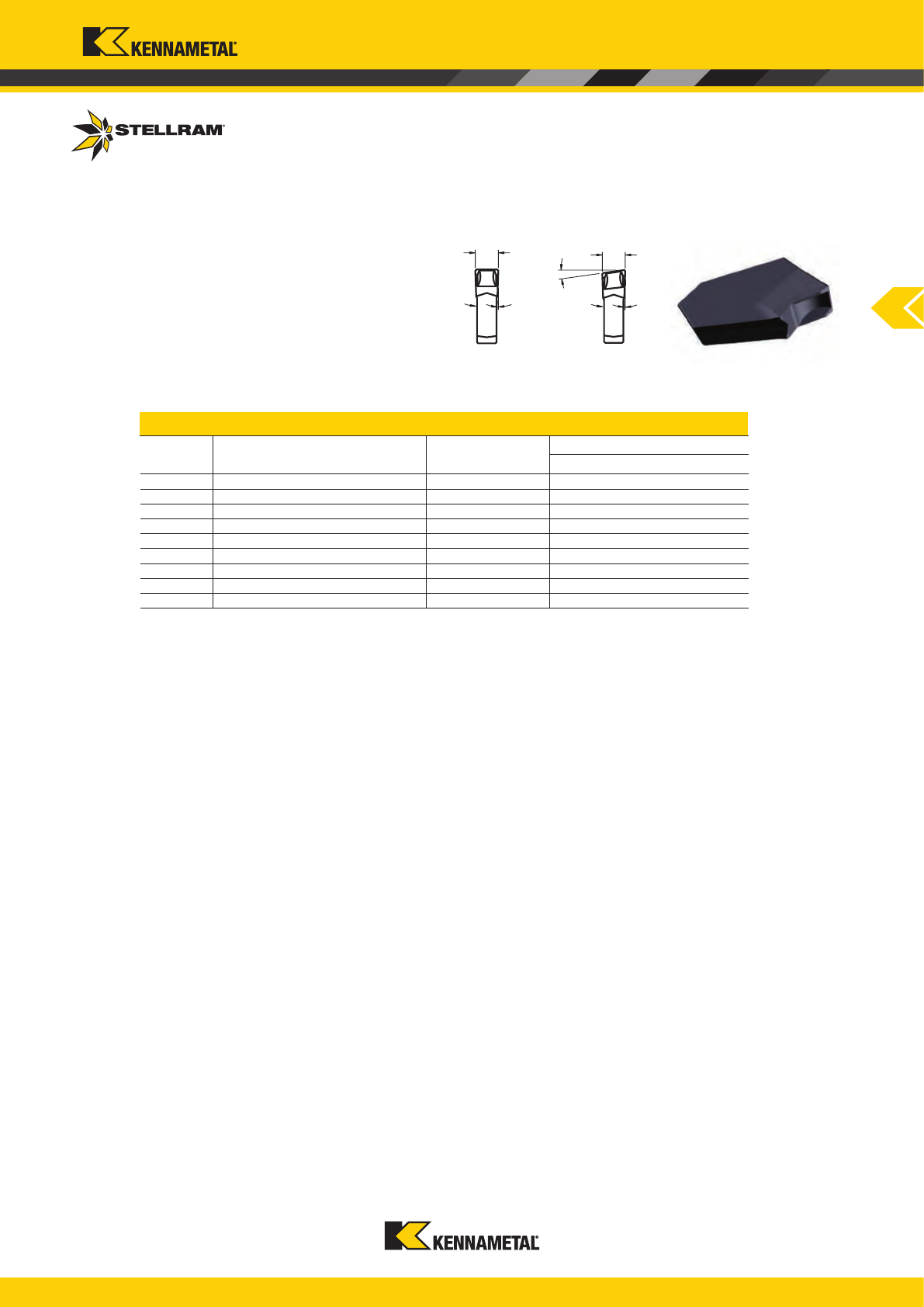

80°

7°

m

d

r

m

1

I

s

h

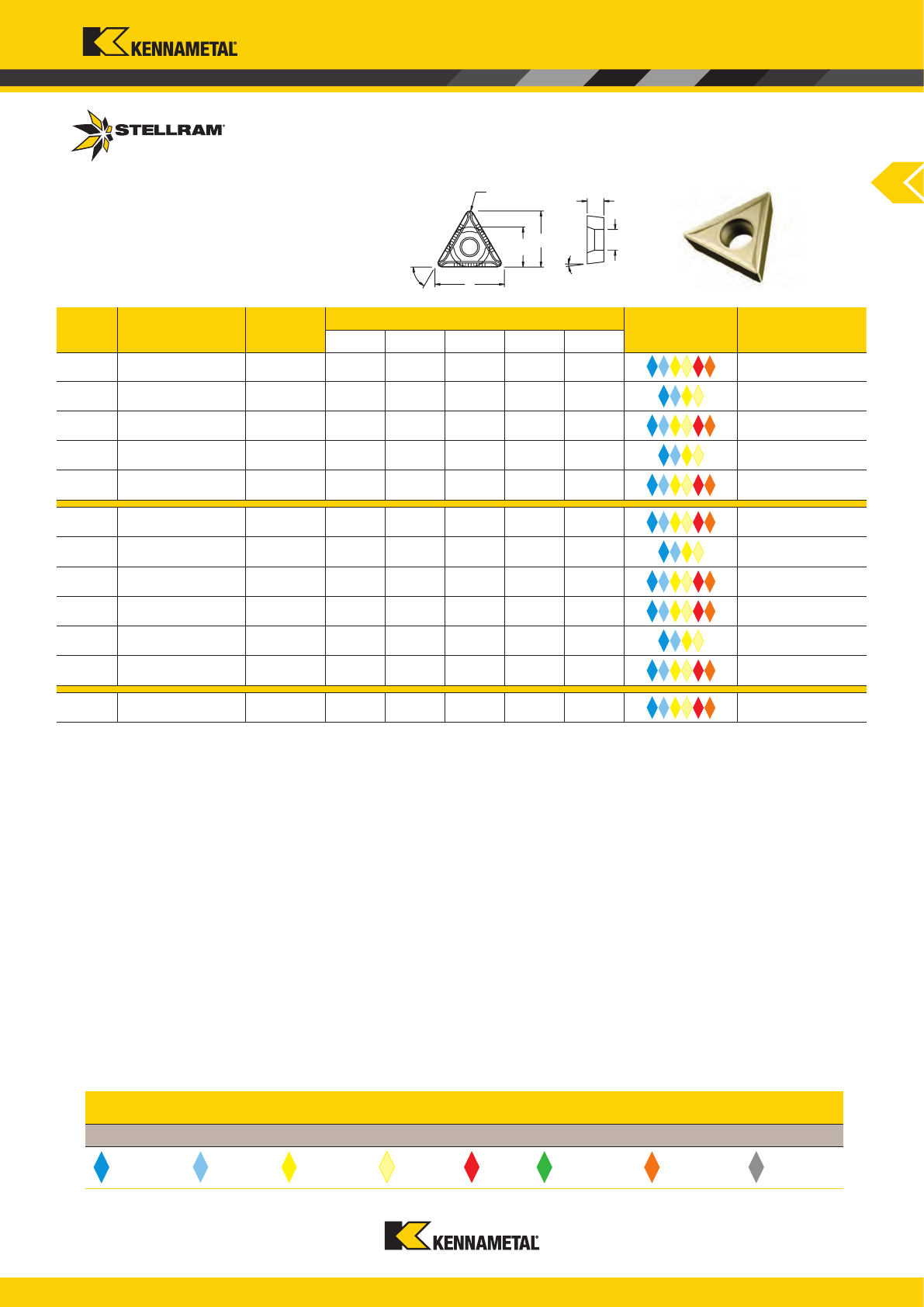

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

Turning Inserts

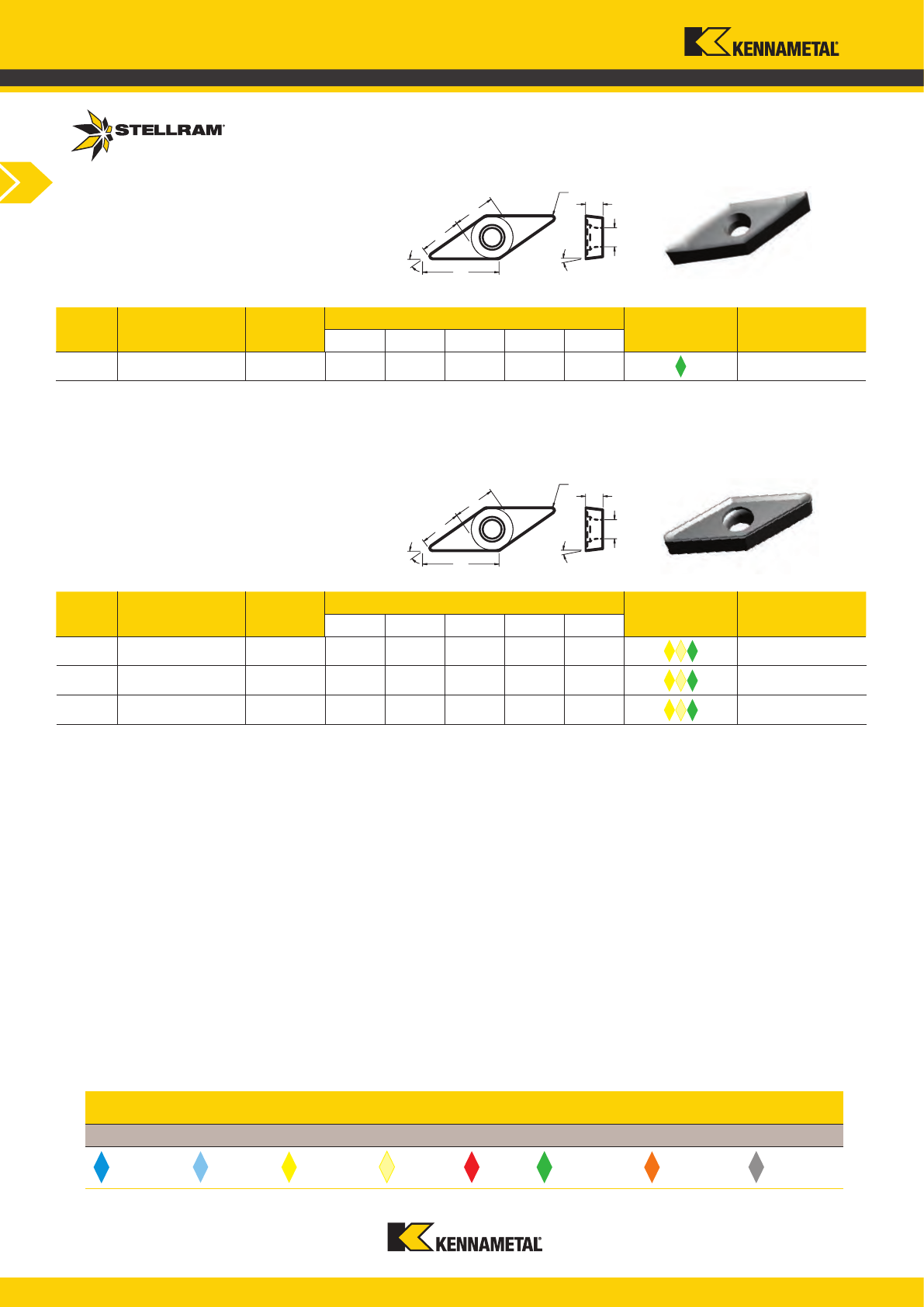

Finishing

Finishing

Finishing

Finishing

Finishing

Finishing

Finishing

Finishing

Finishing

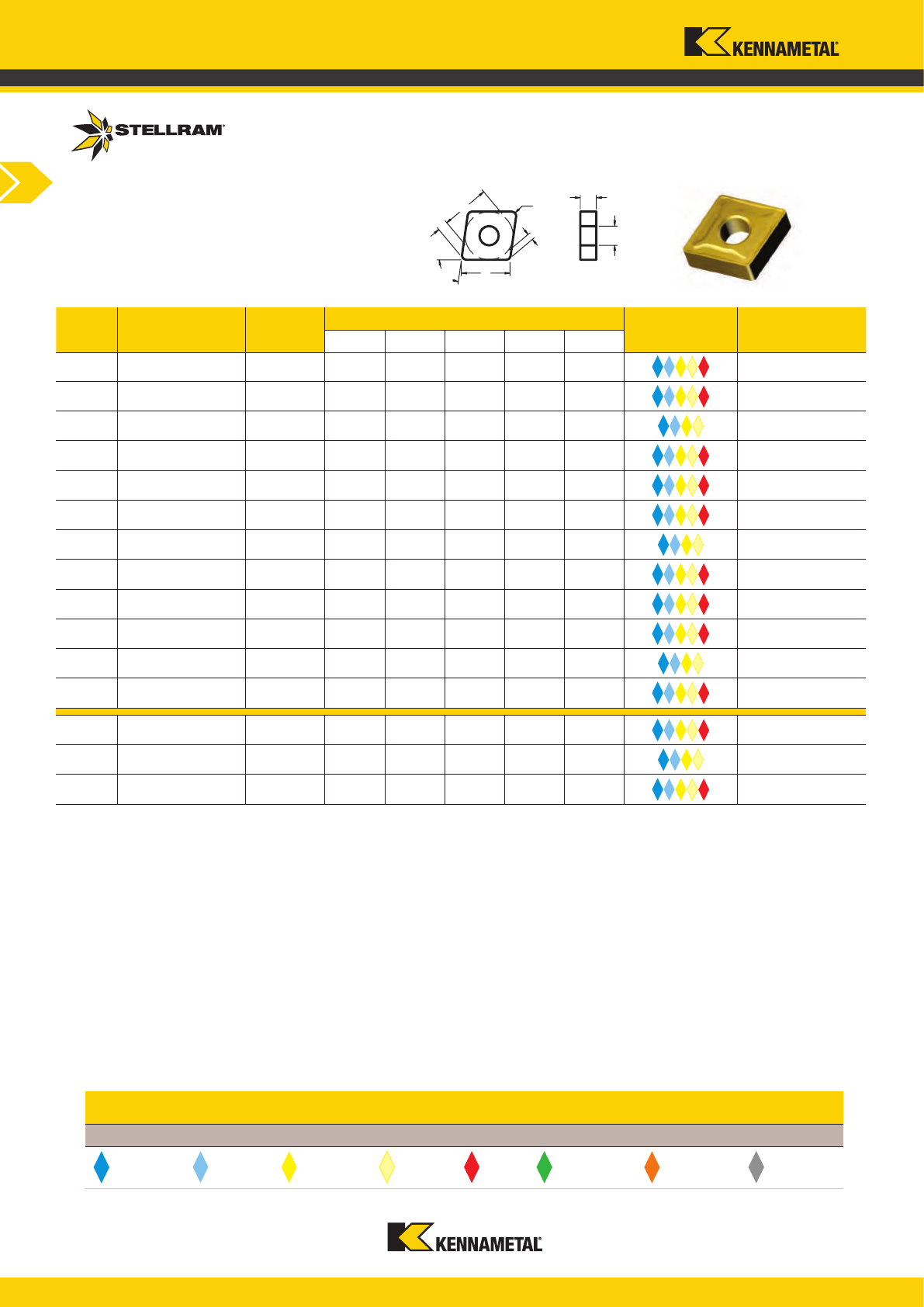

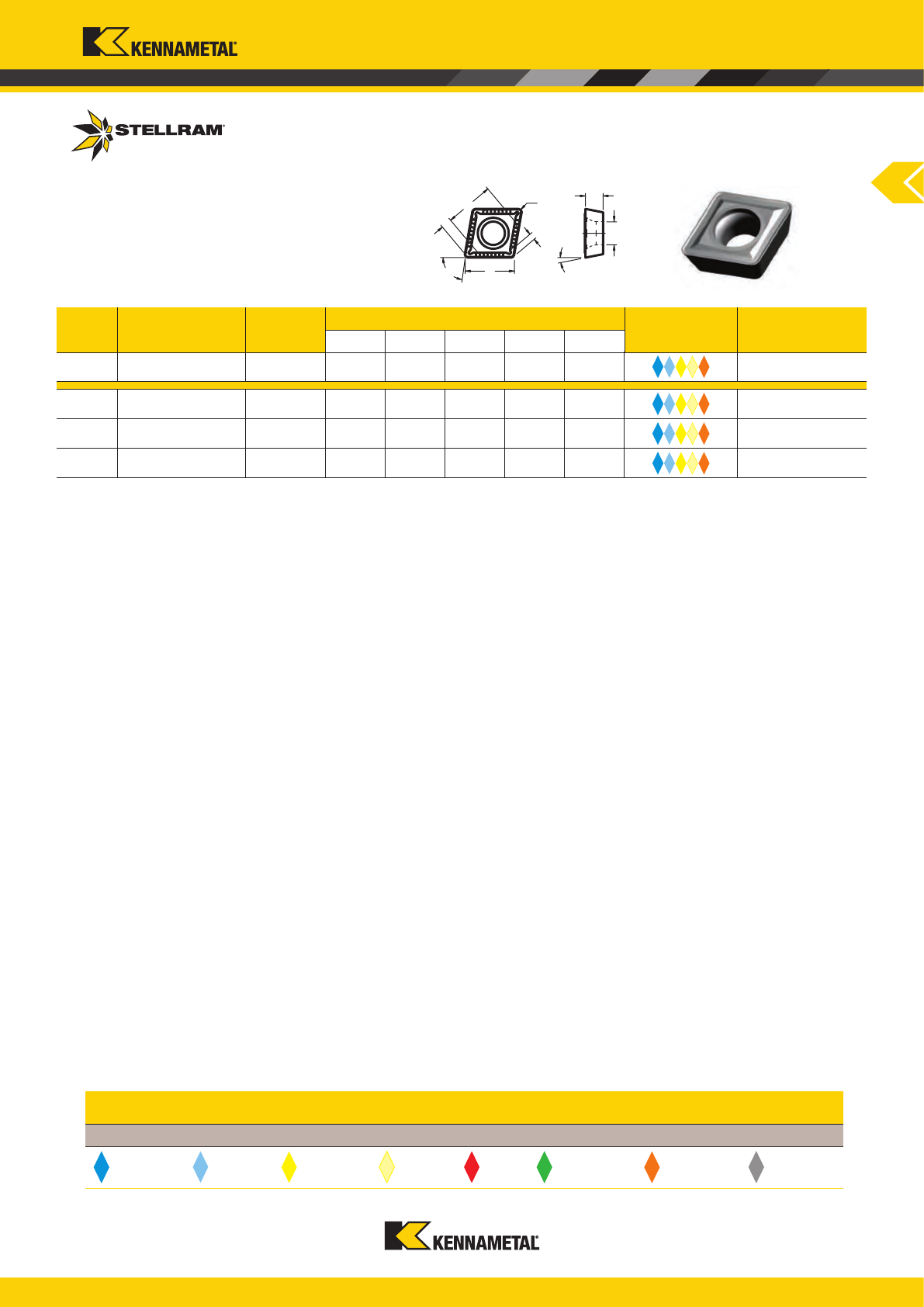

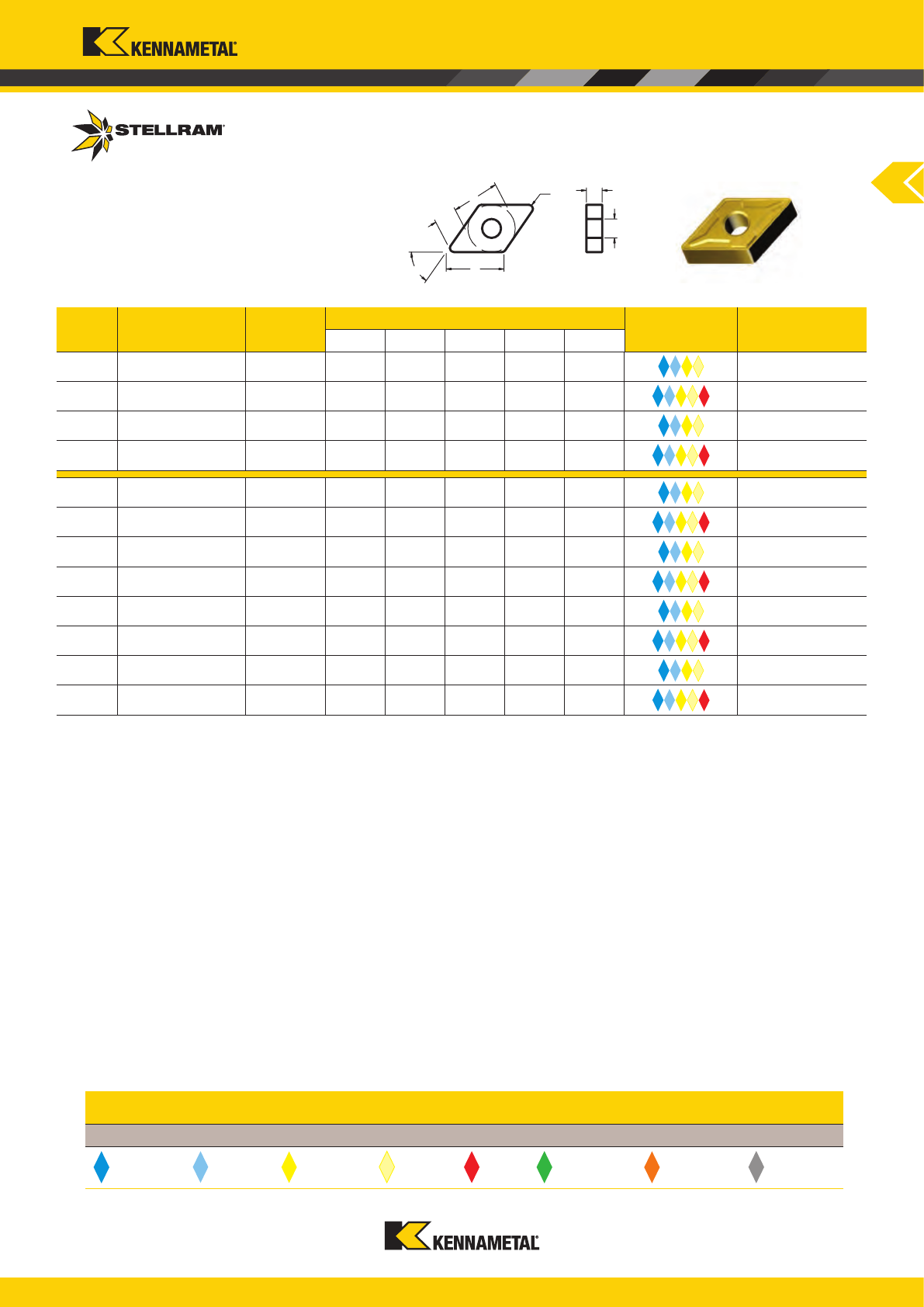

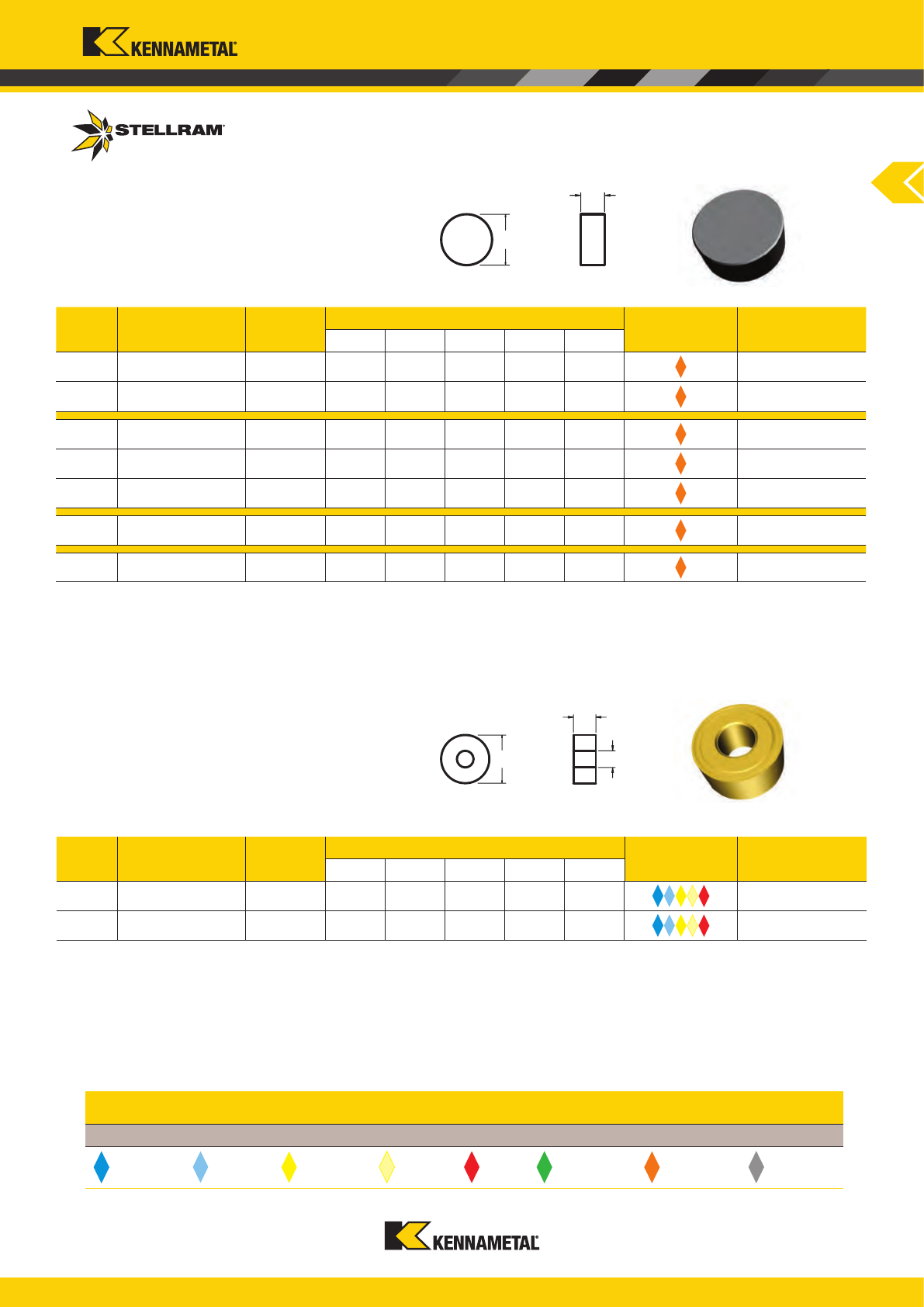

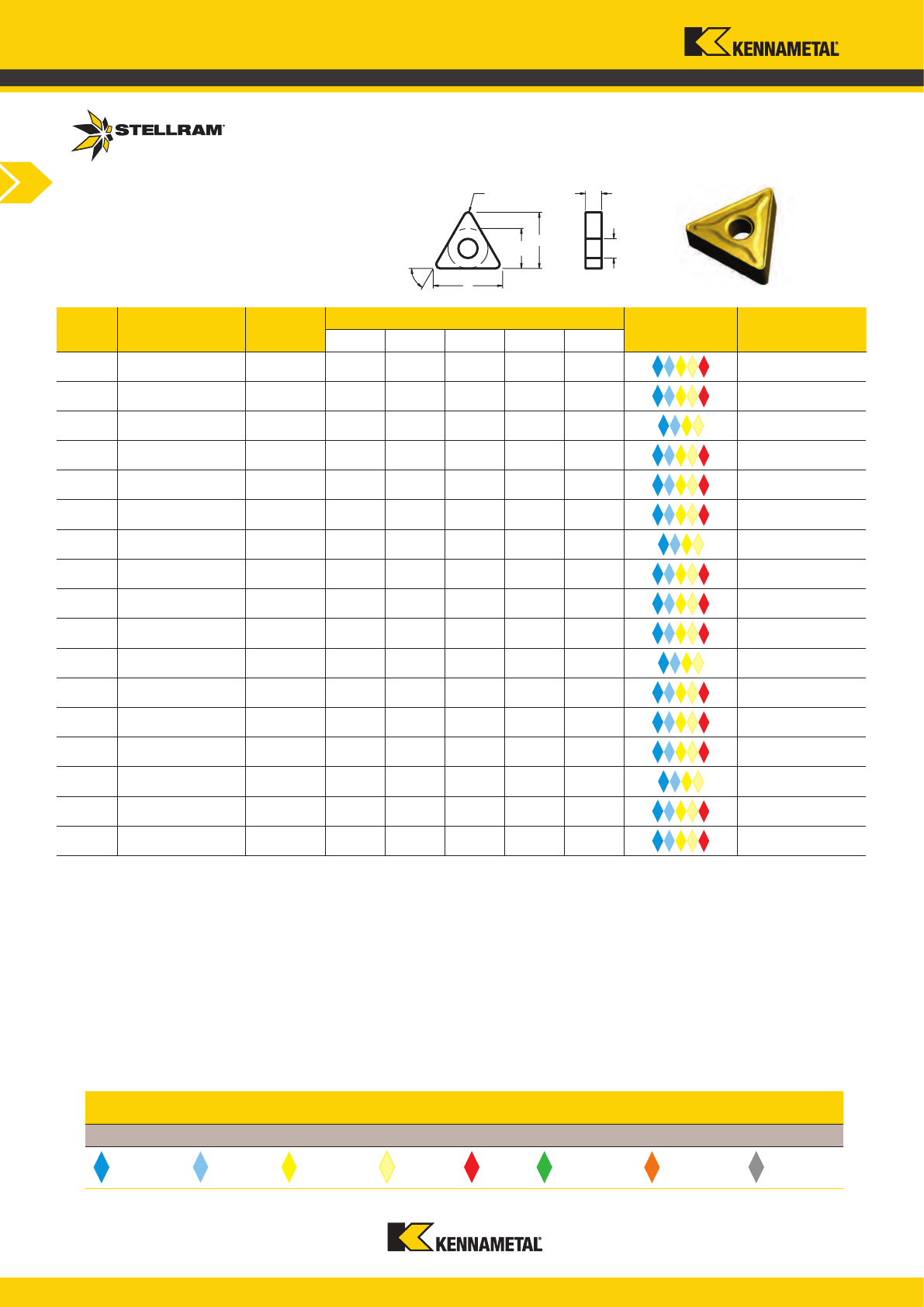

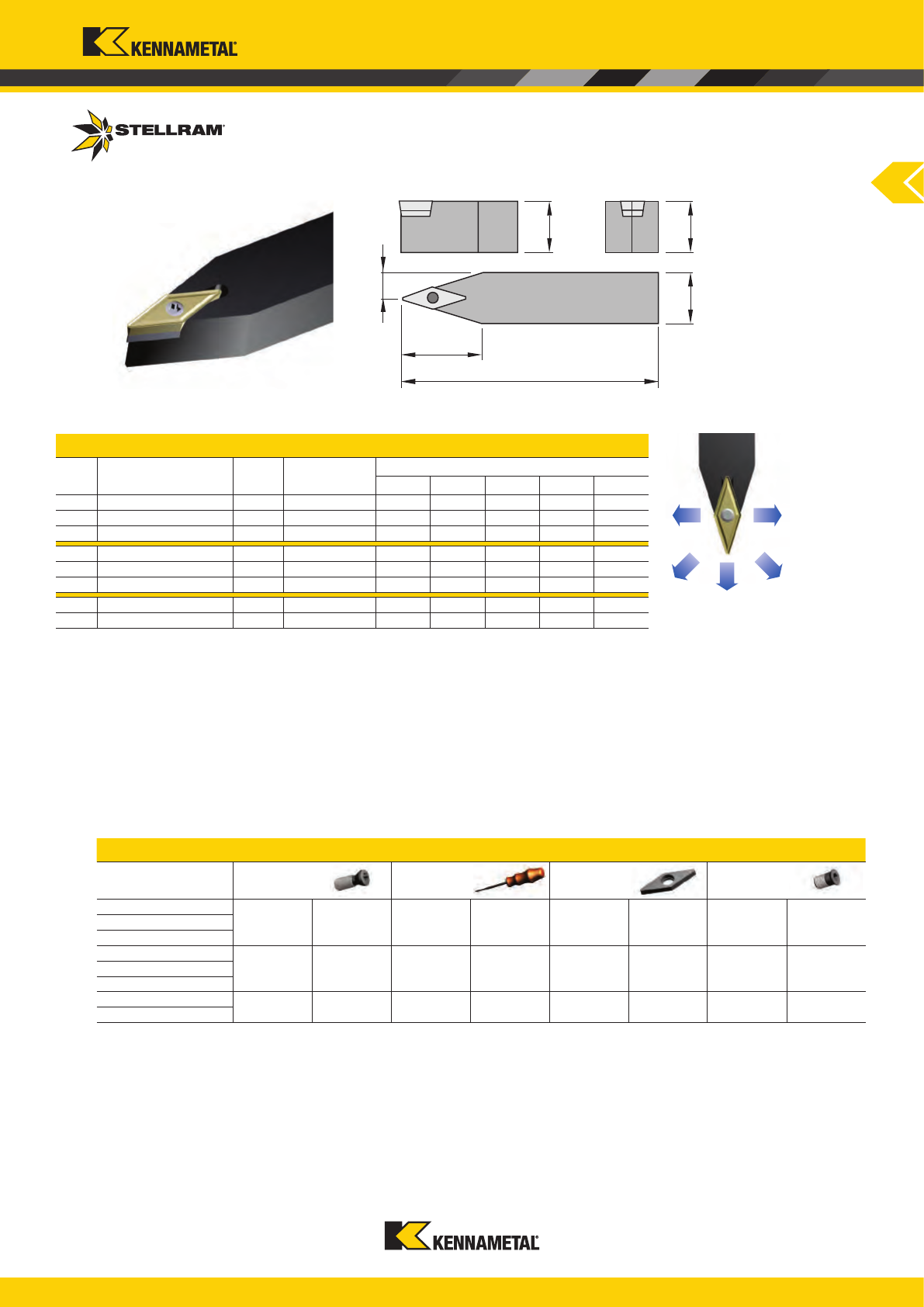

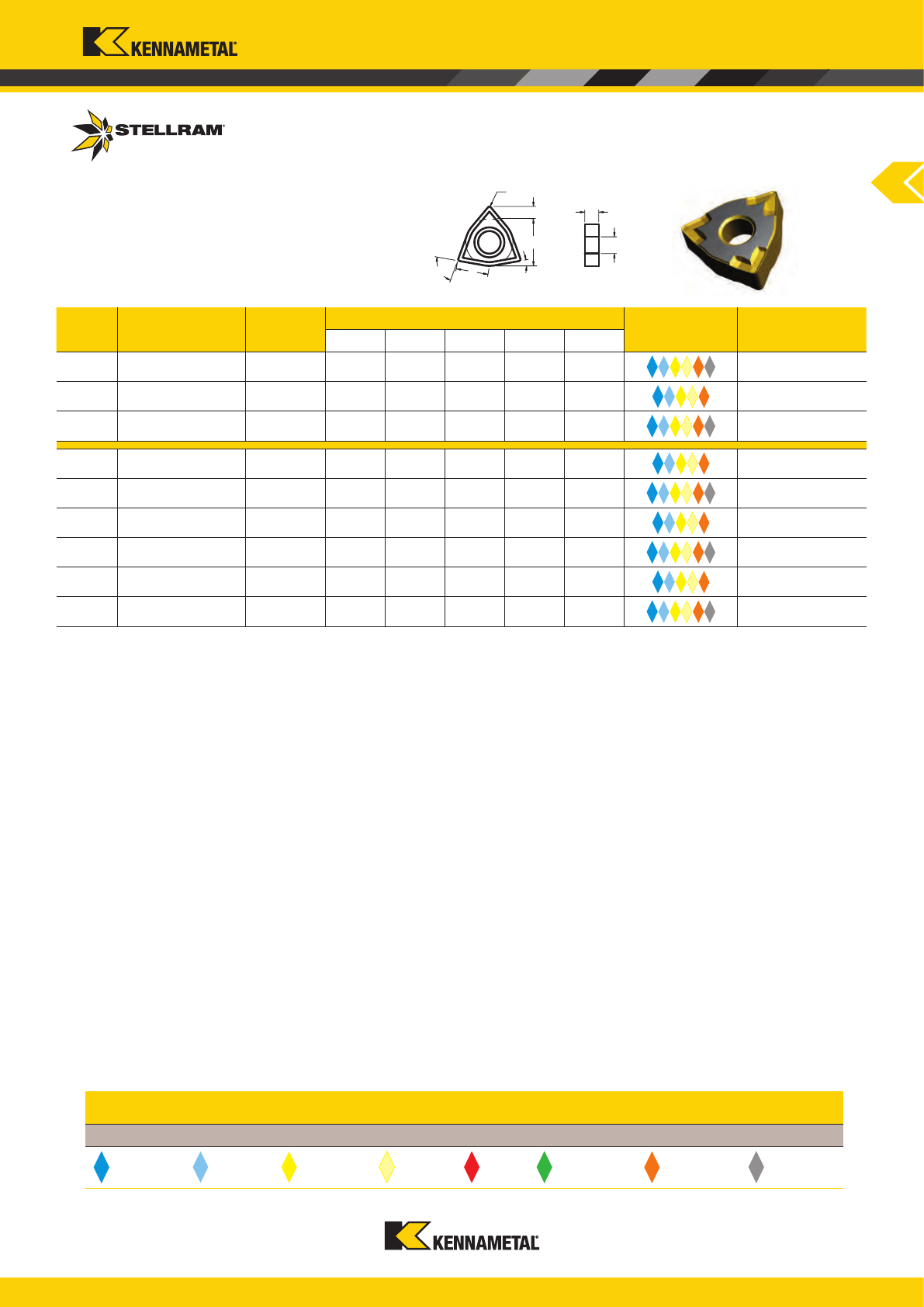

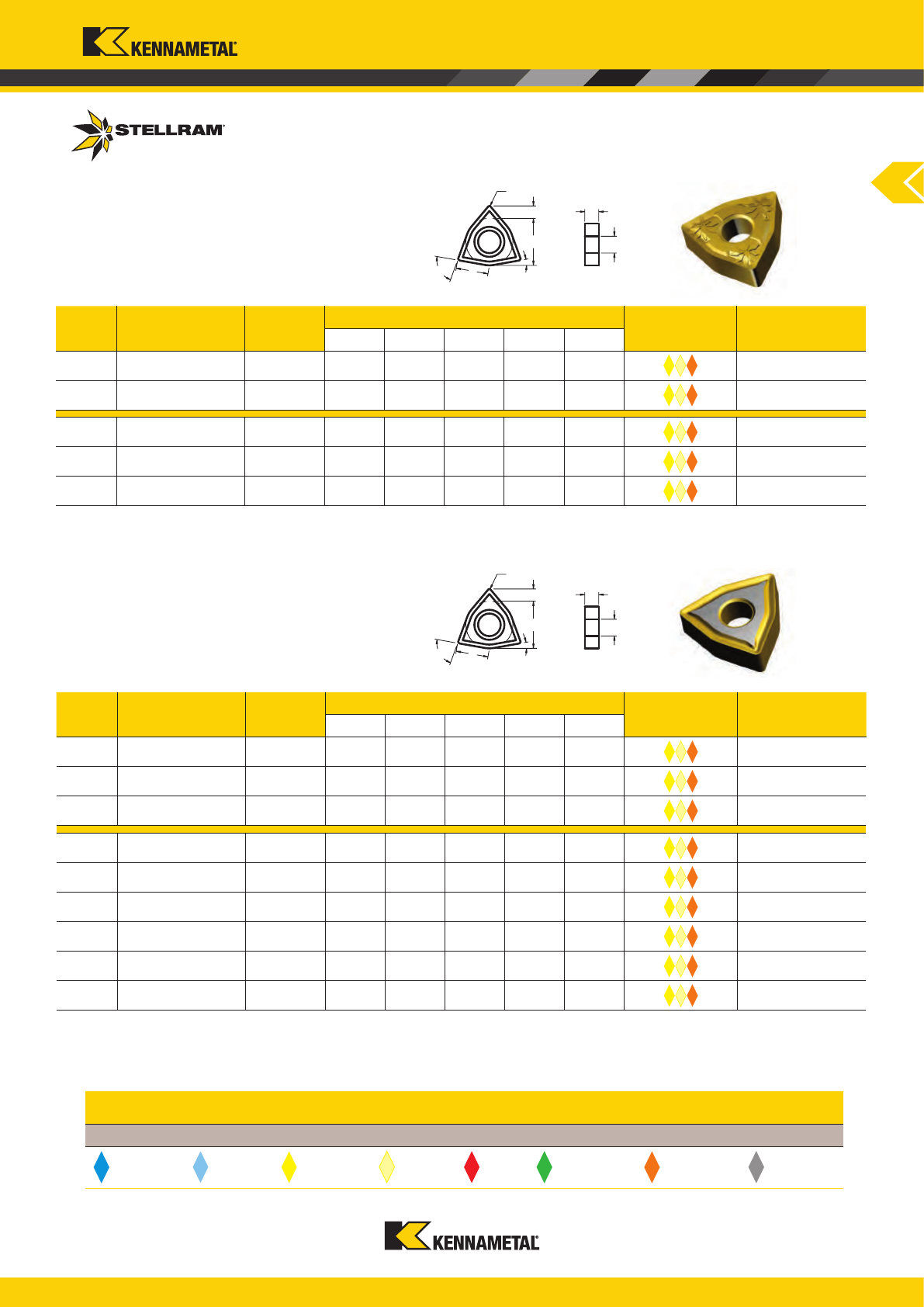

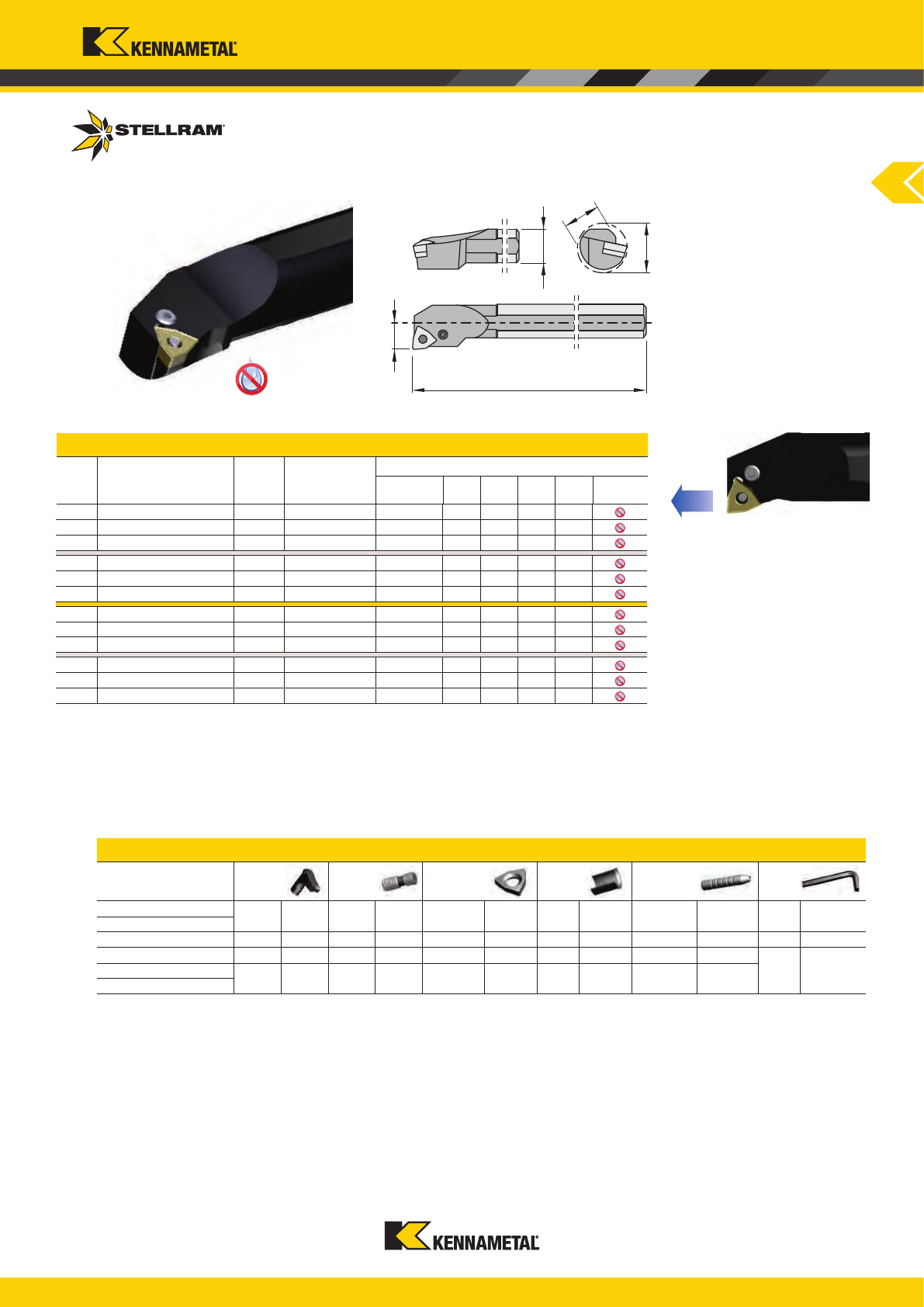

EDP ISO Description Grade

Dimensions (mm)

Material Application

d I s r

h

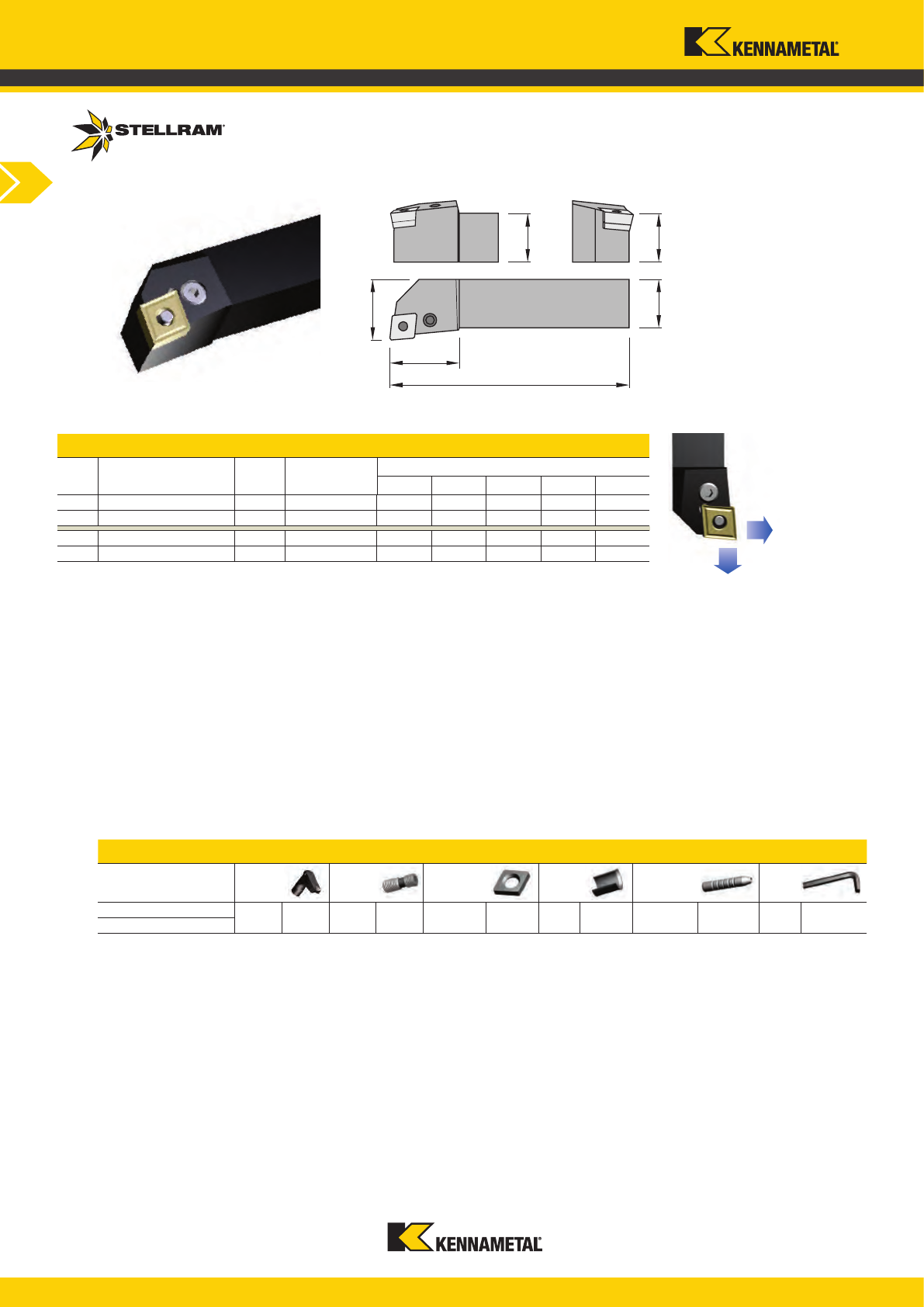

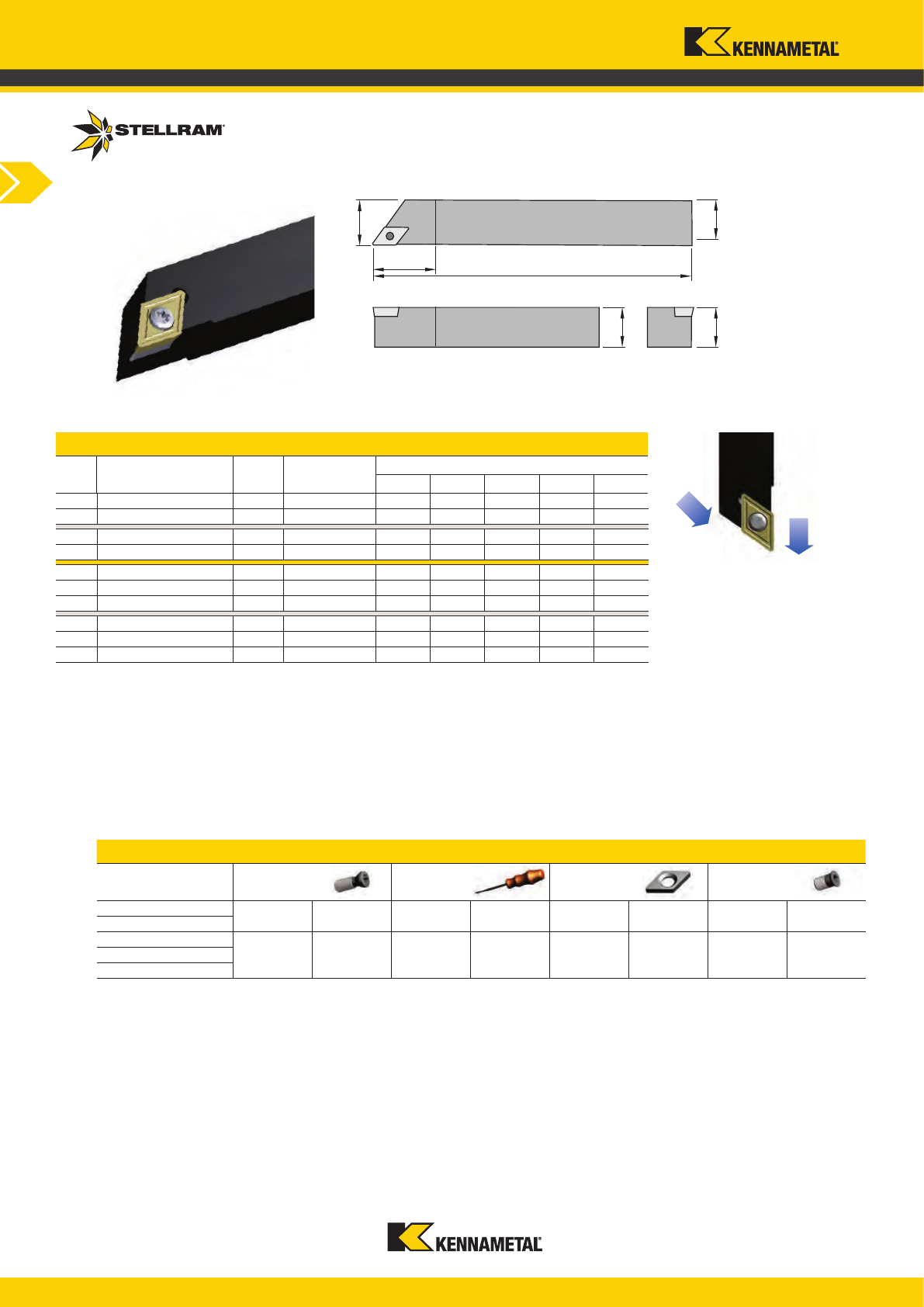

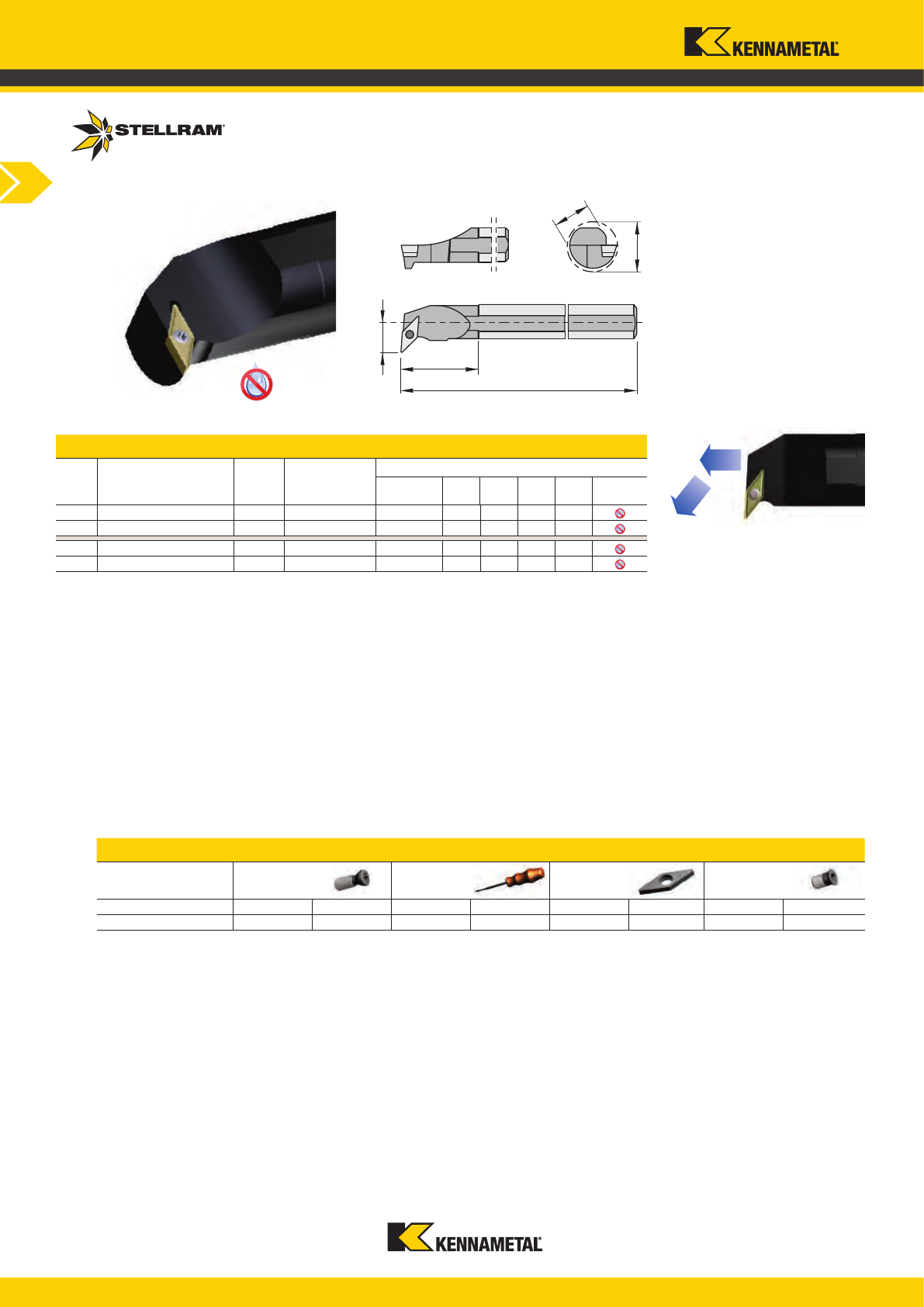

For Toolholders External: see page C44 | Internal: see page C45

C Style

Turning Inserts

CCGT

-62 Geometry

P

P

M

M

K N

S

H

www.kennametal.com

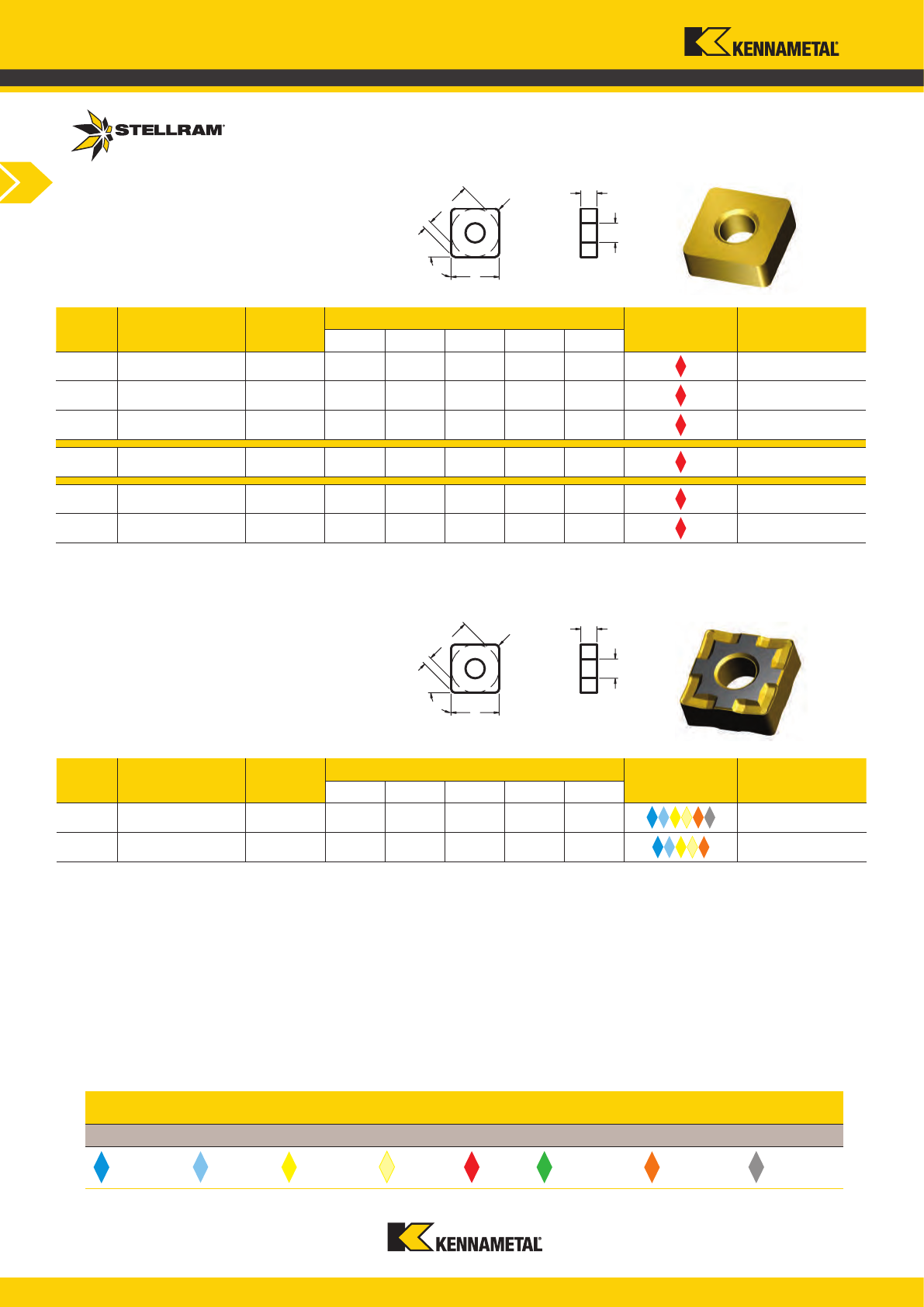

C43

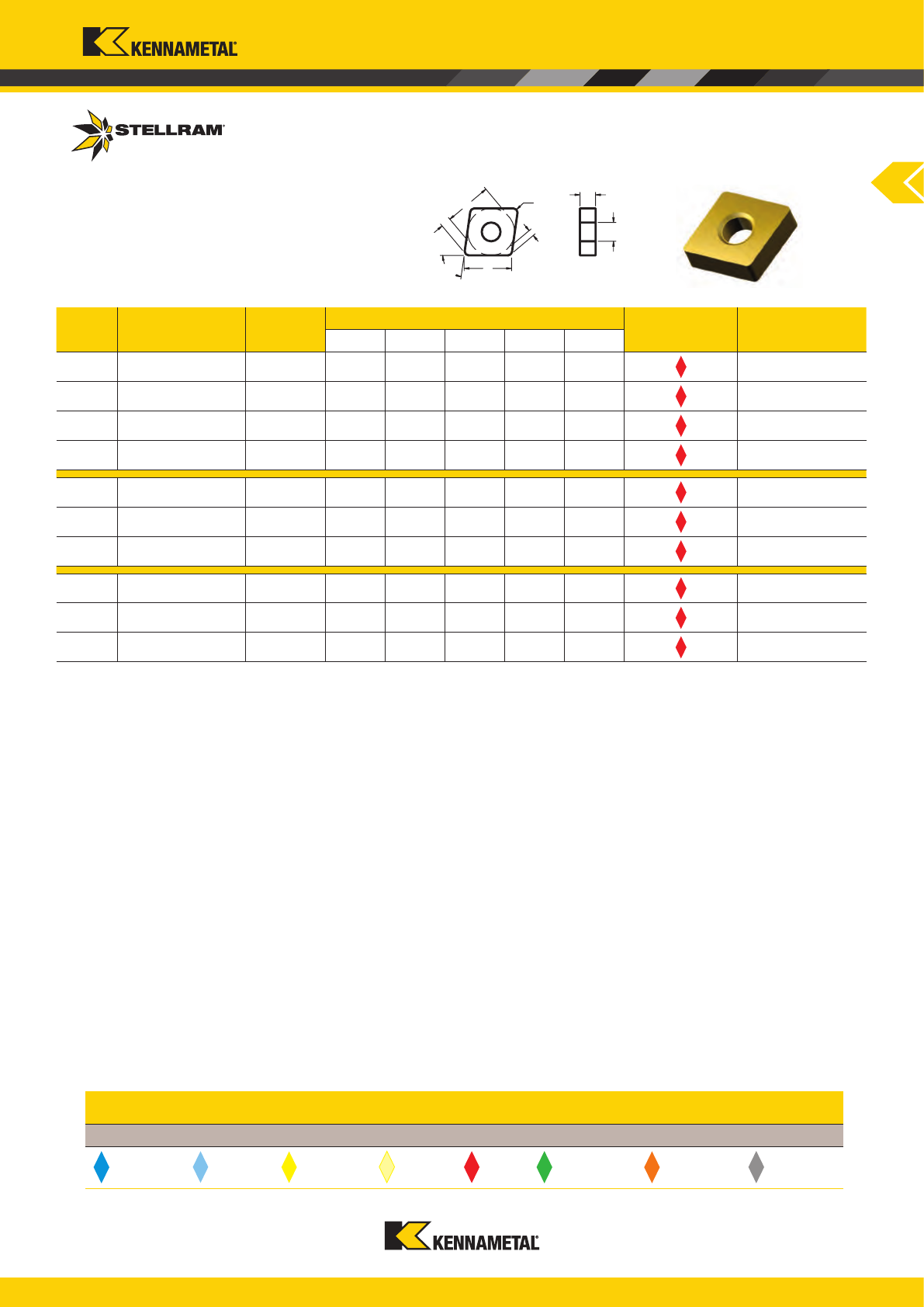

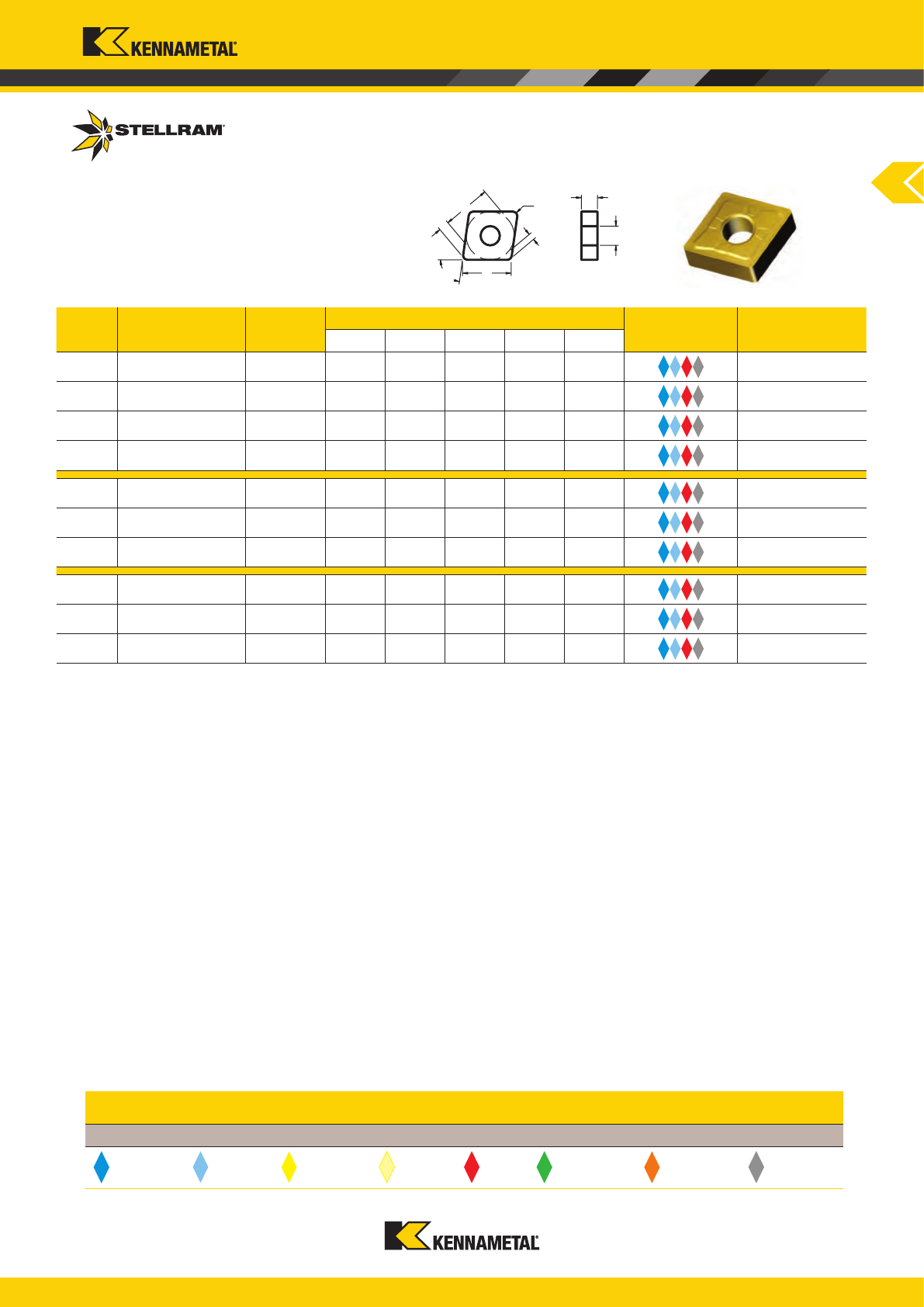

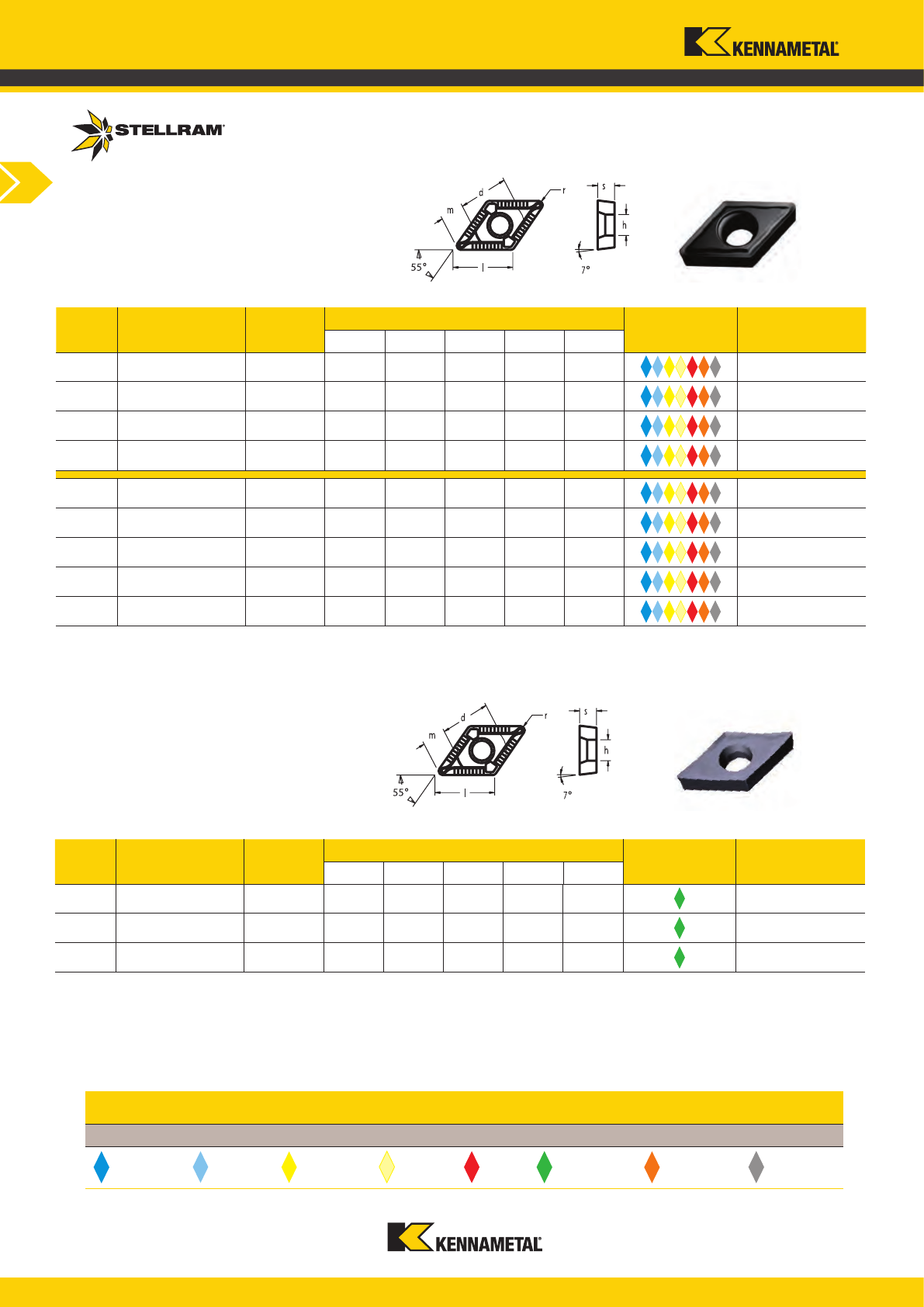

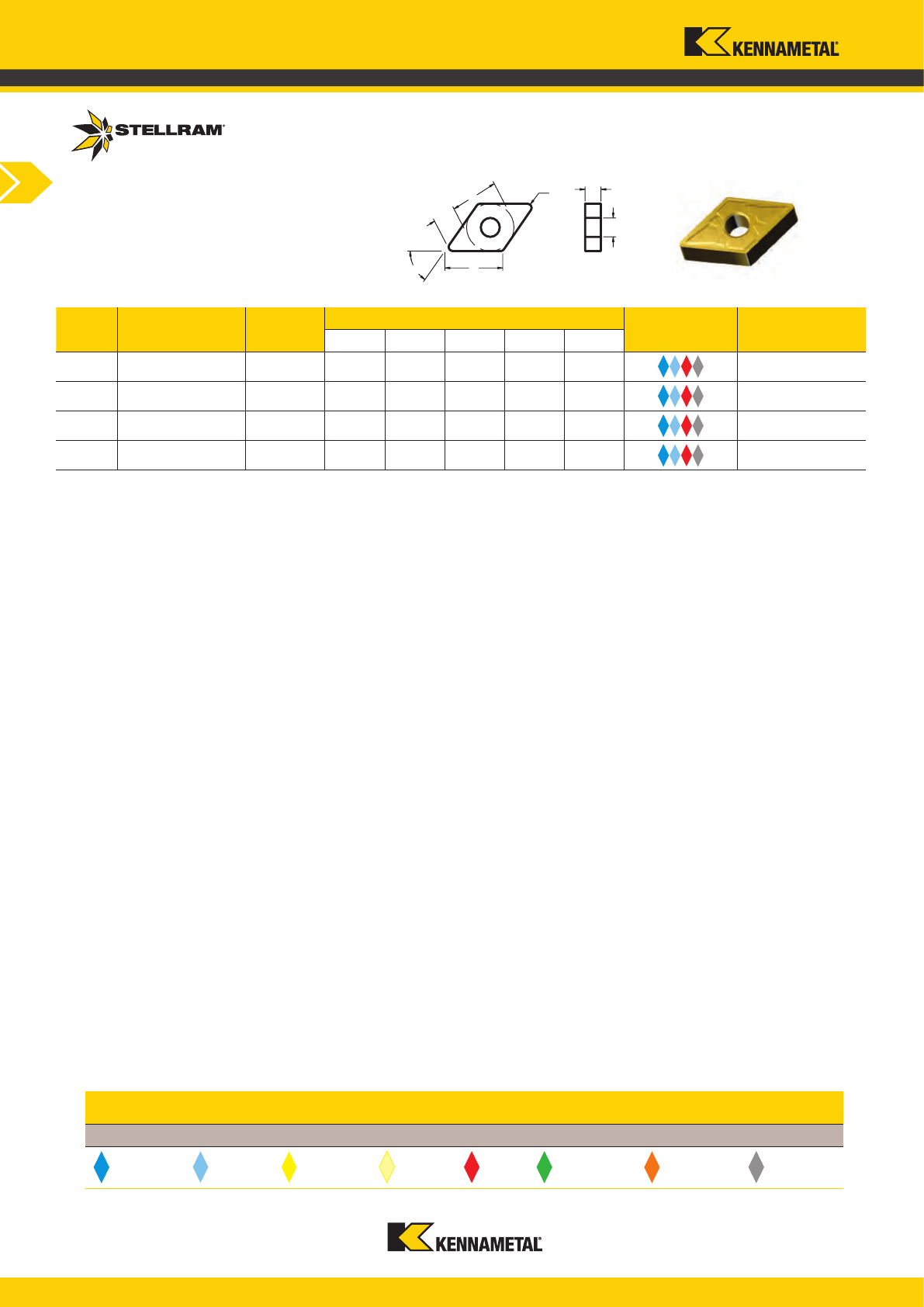

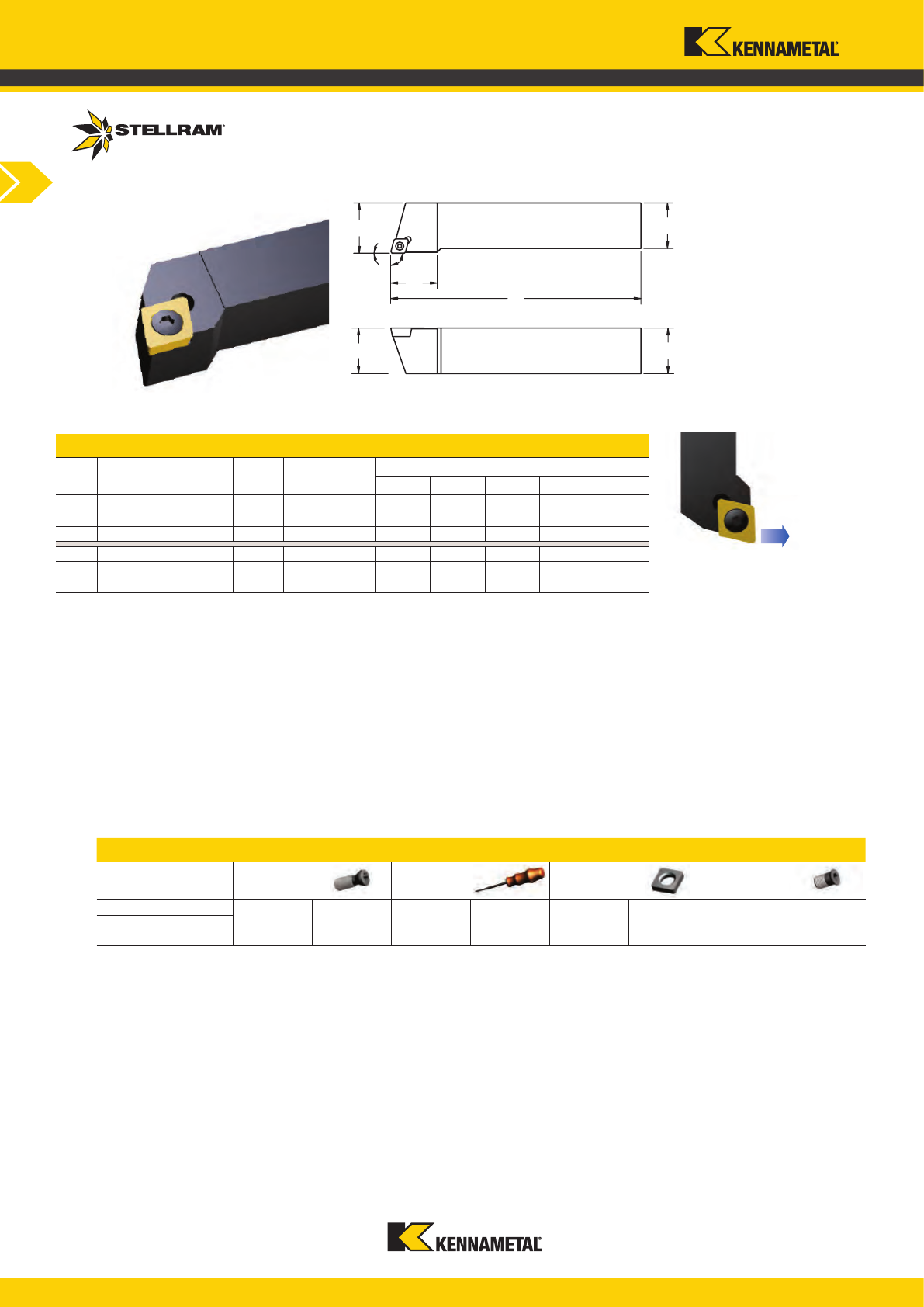

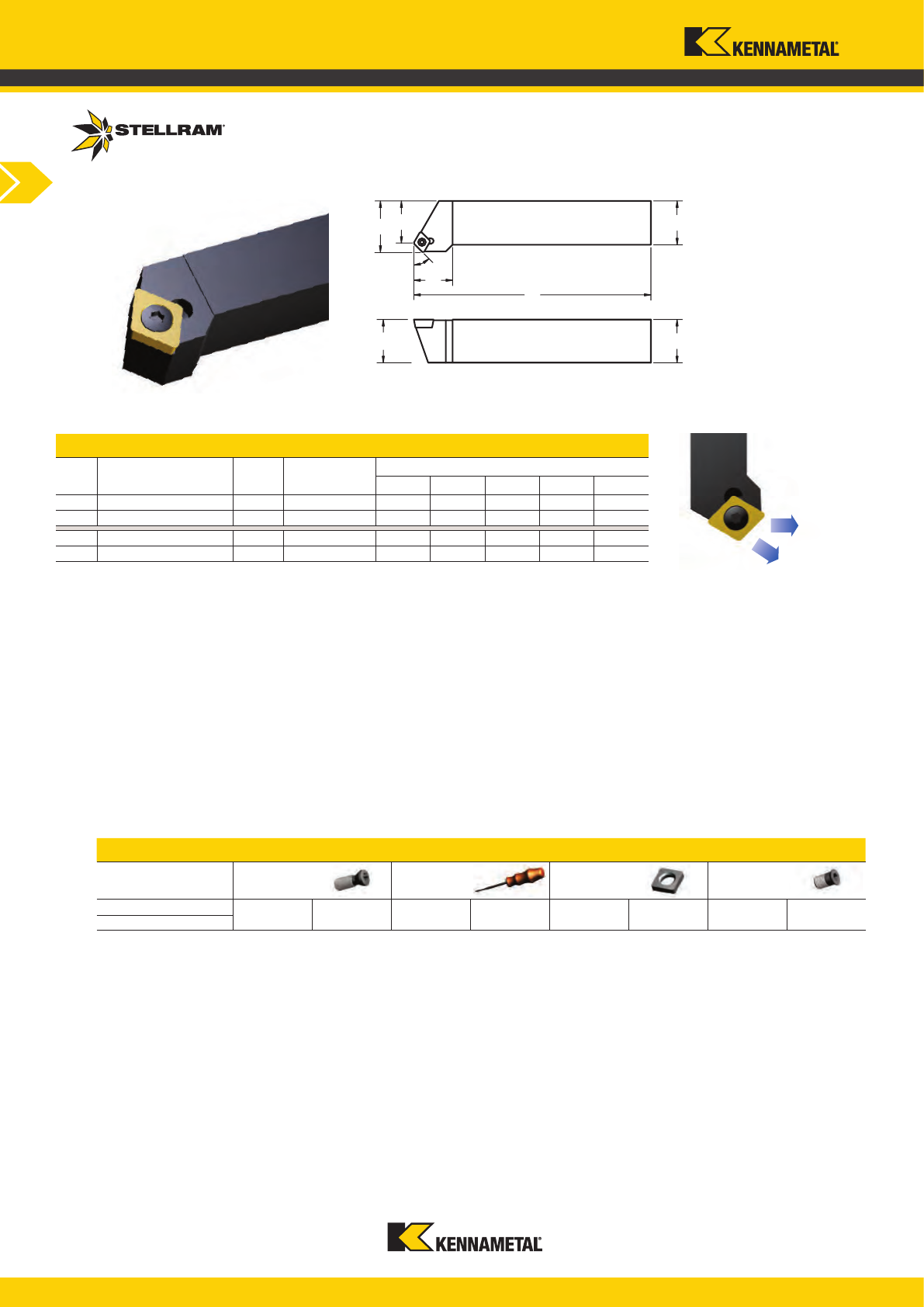

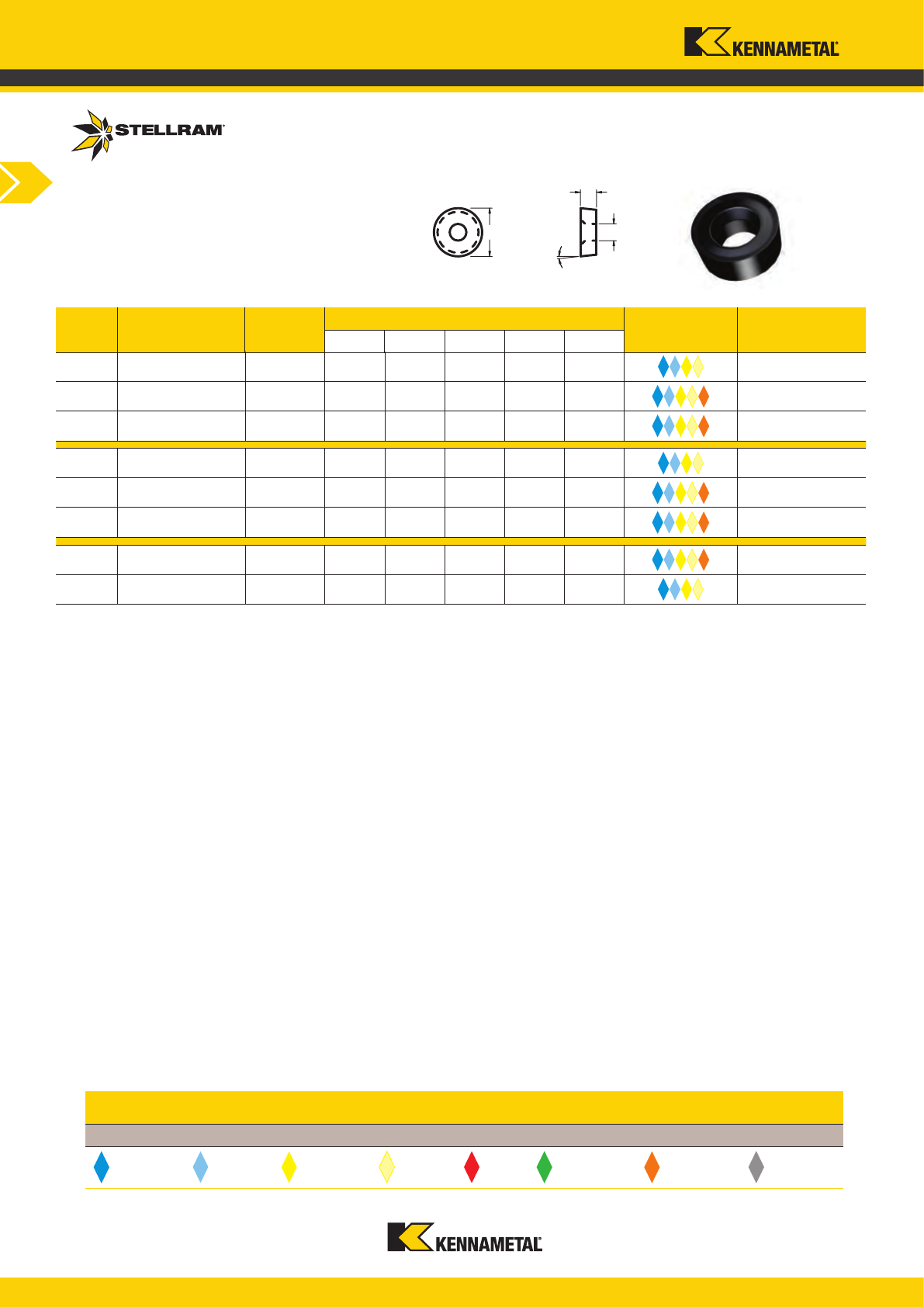

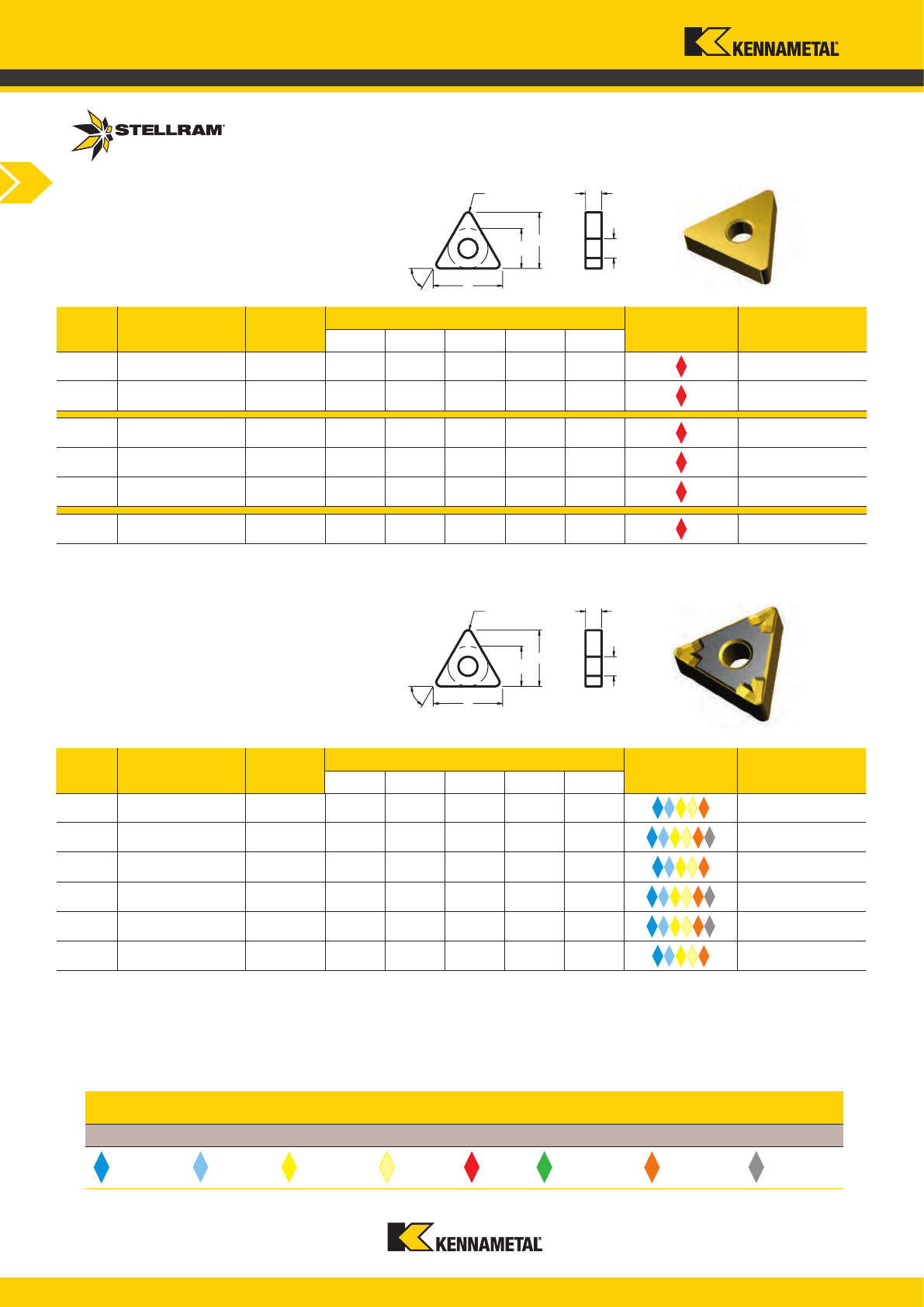

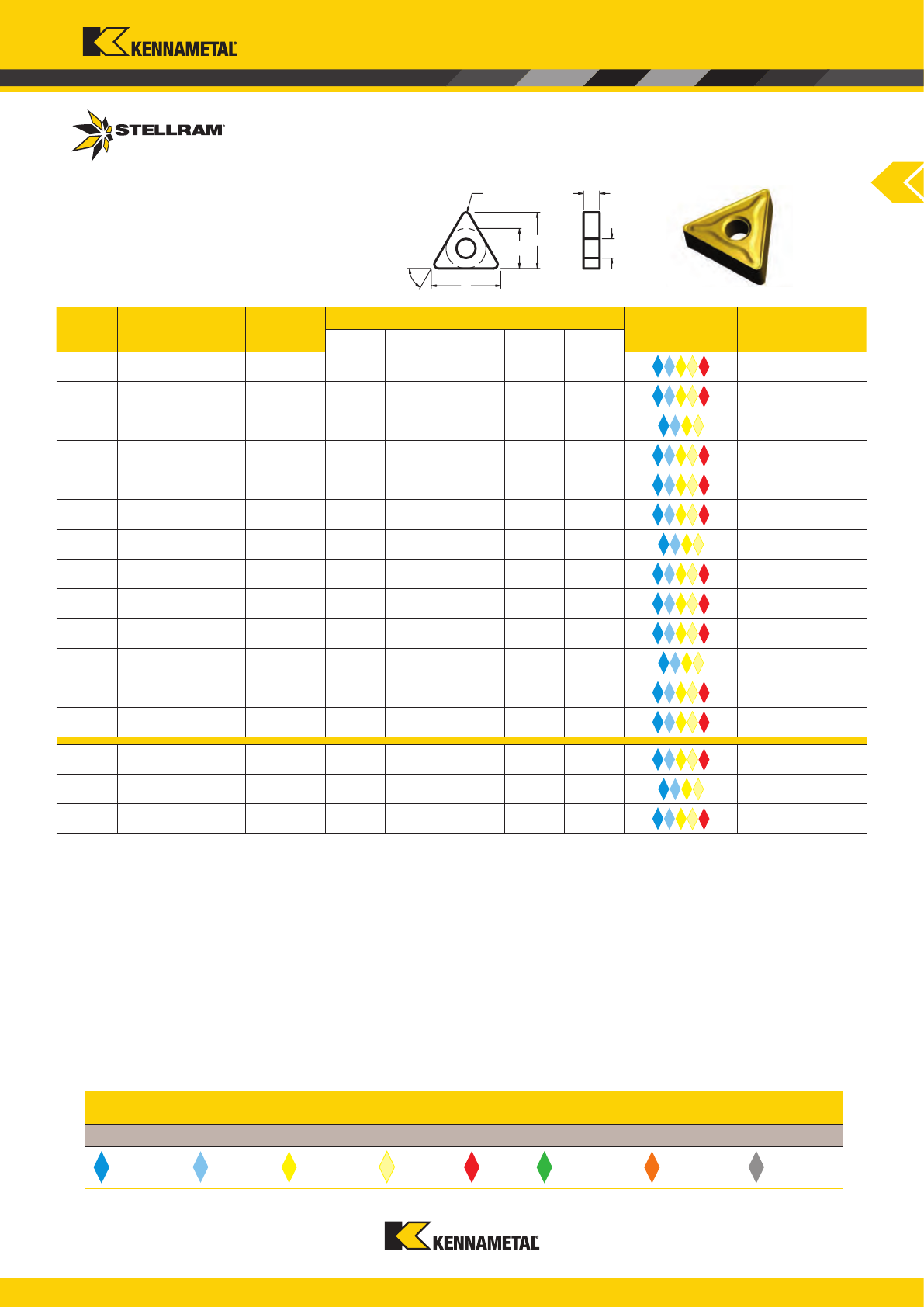

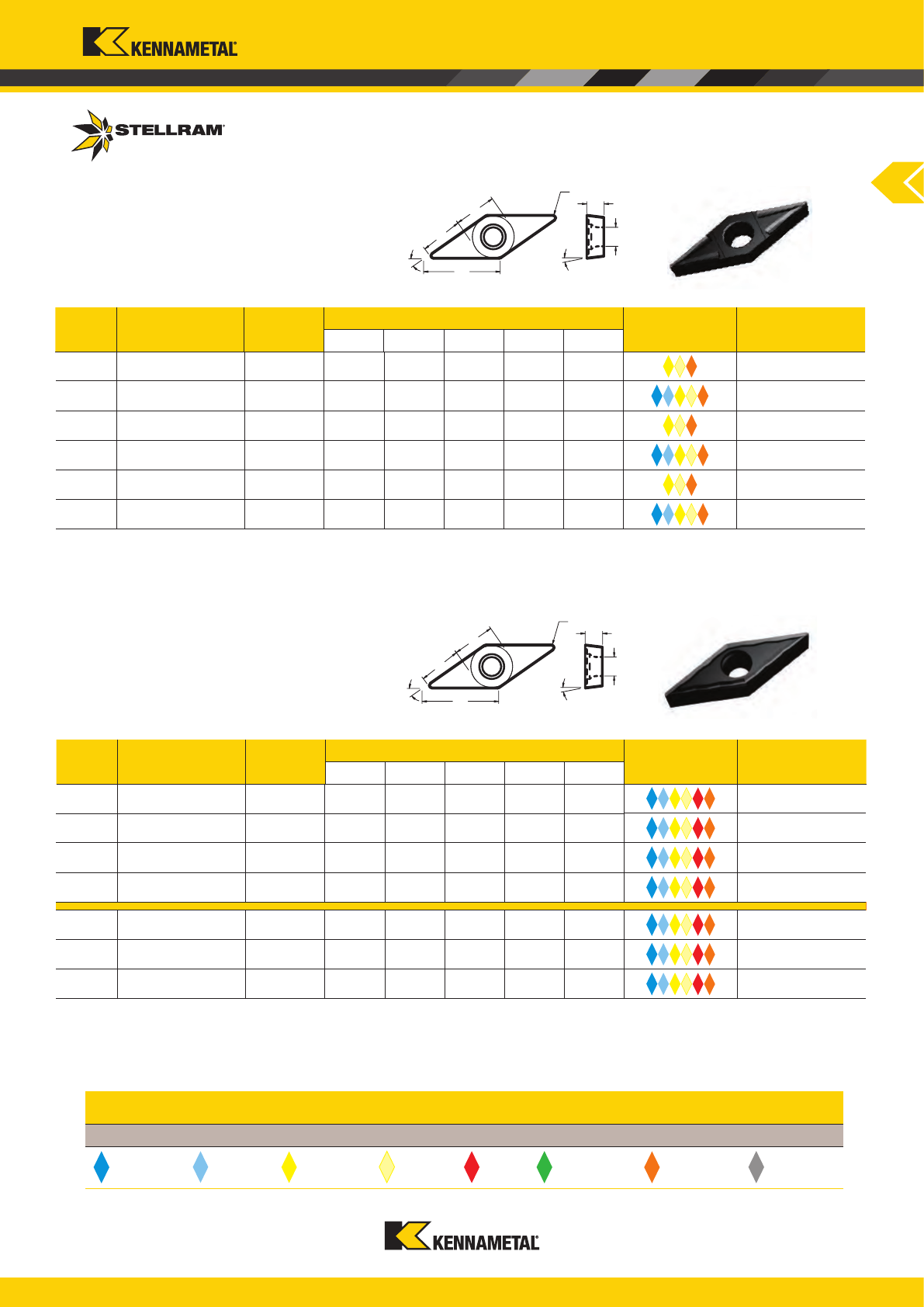

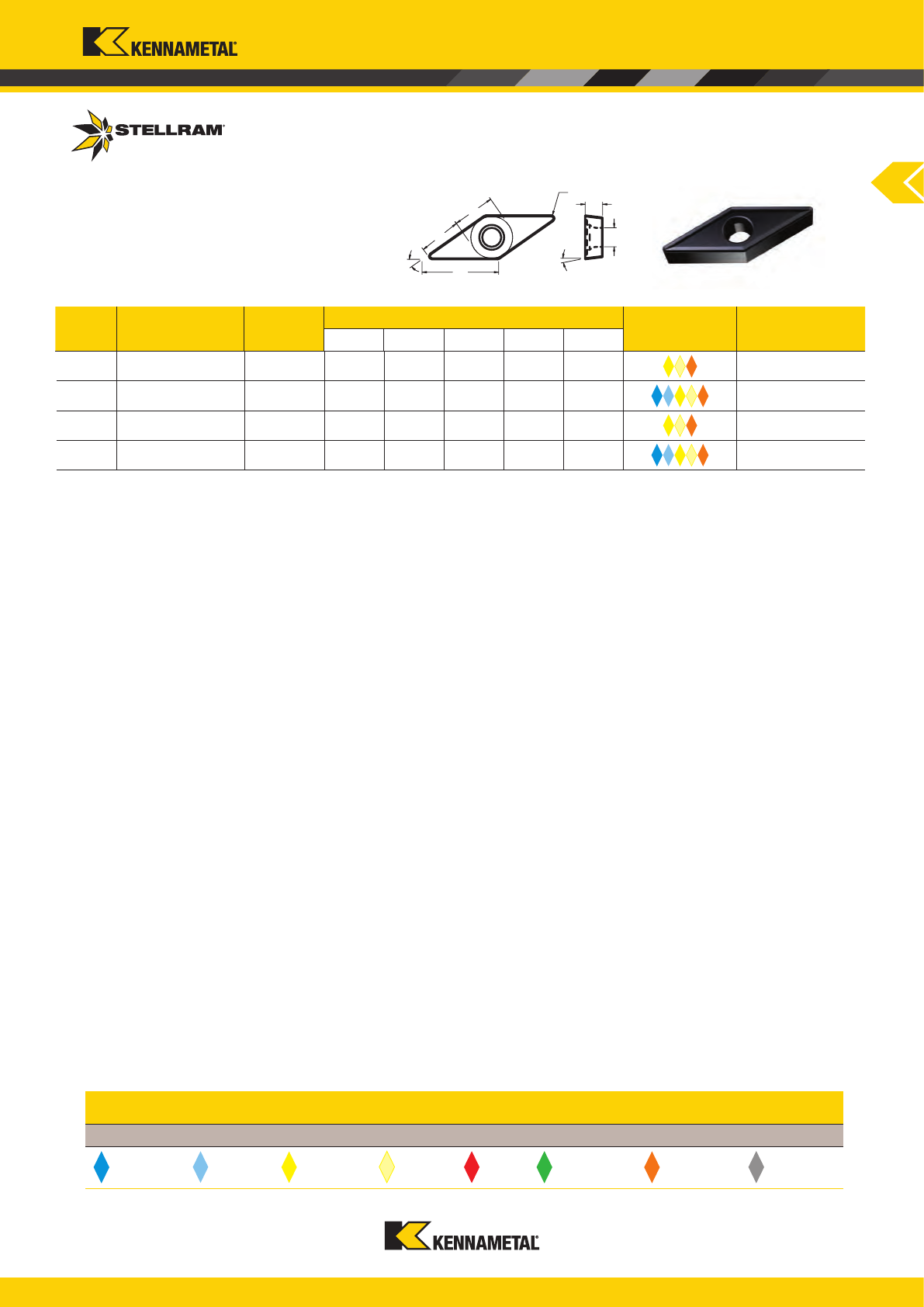

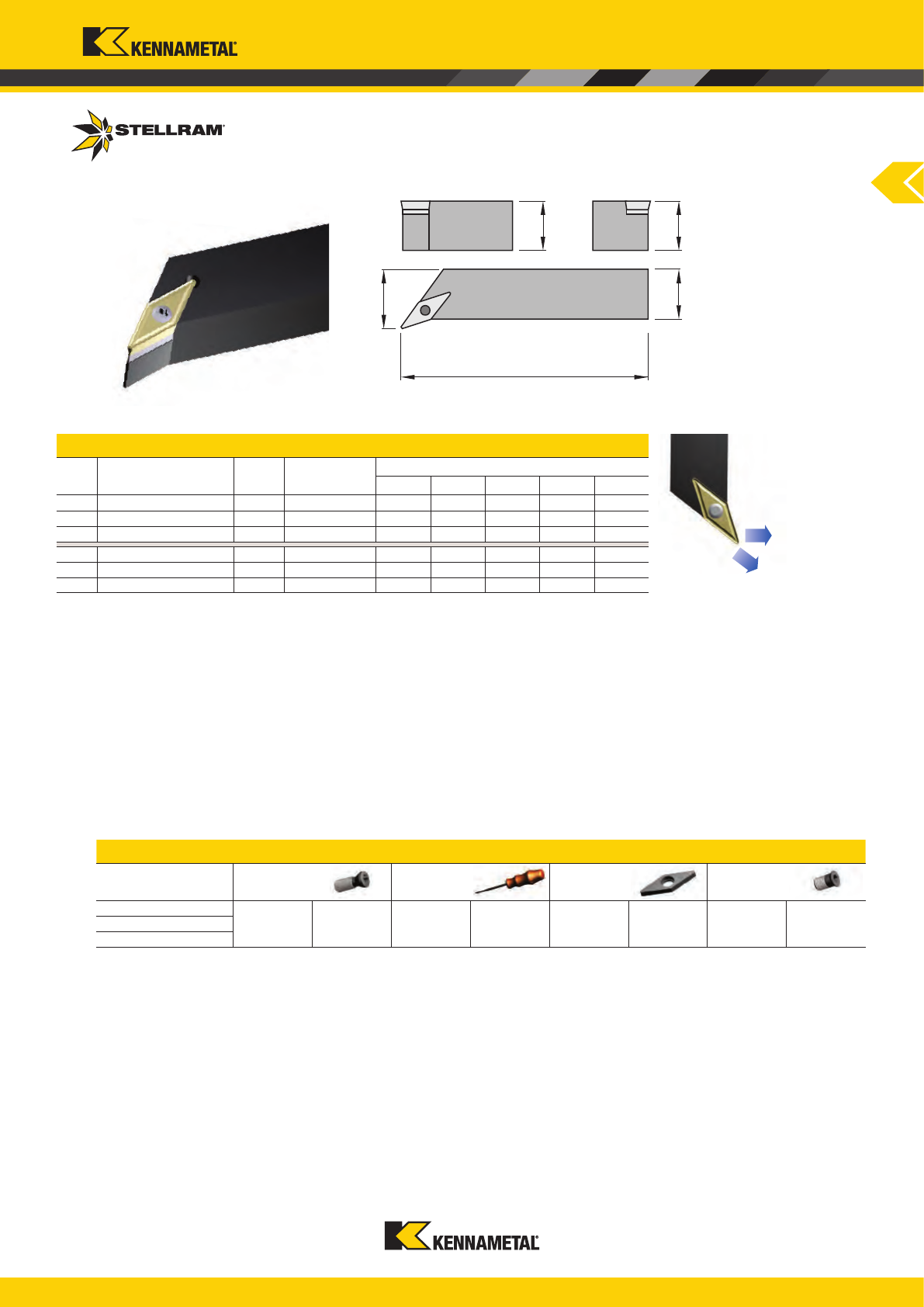

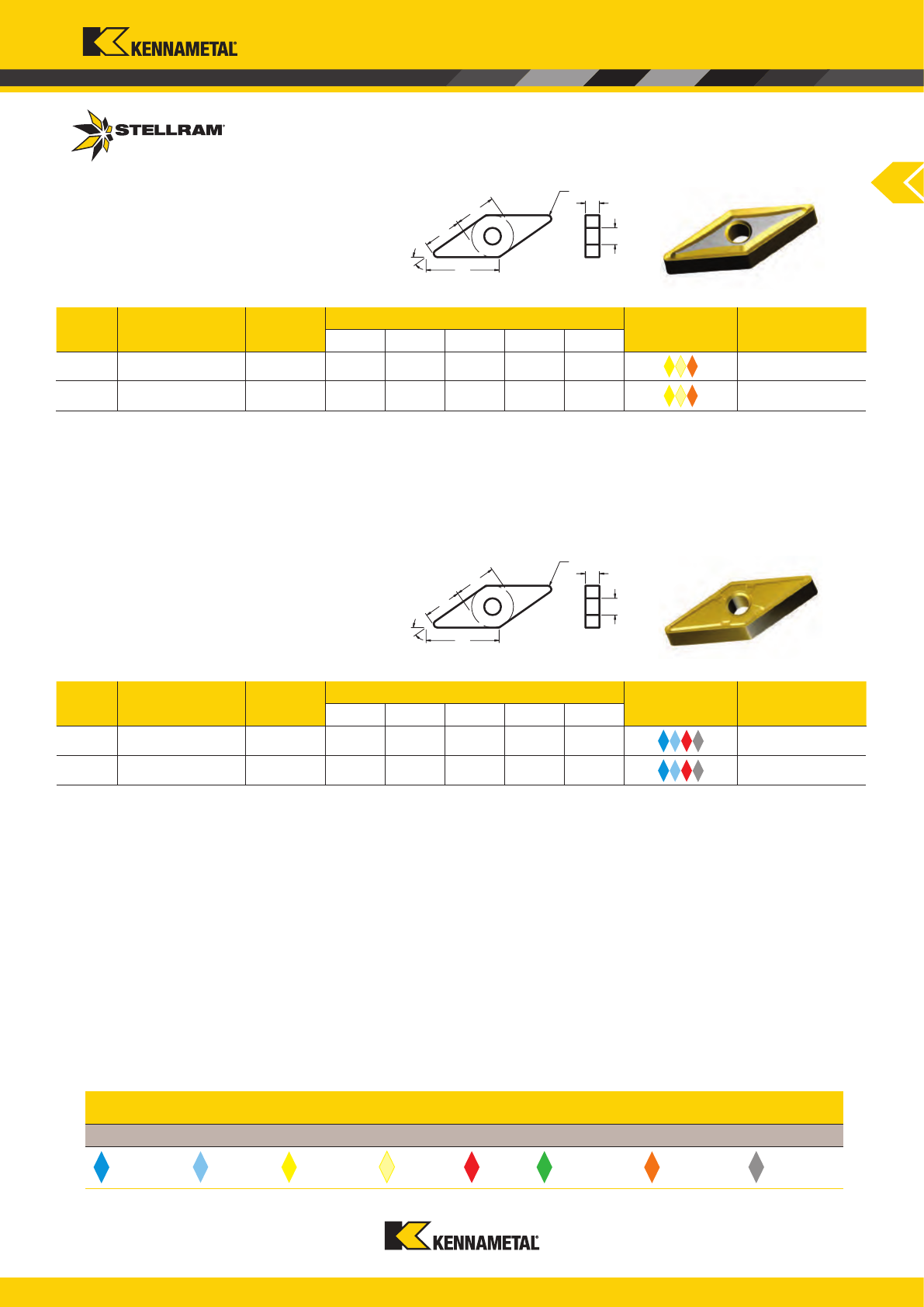

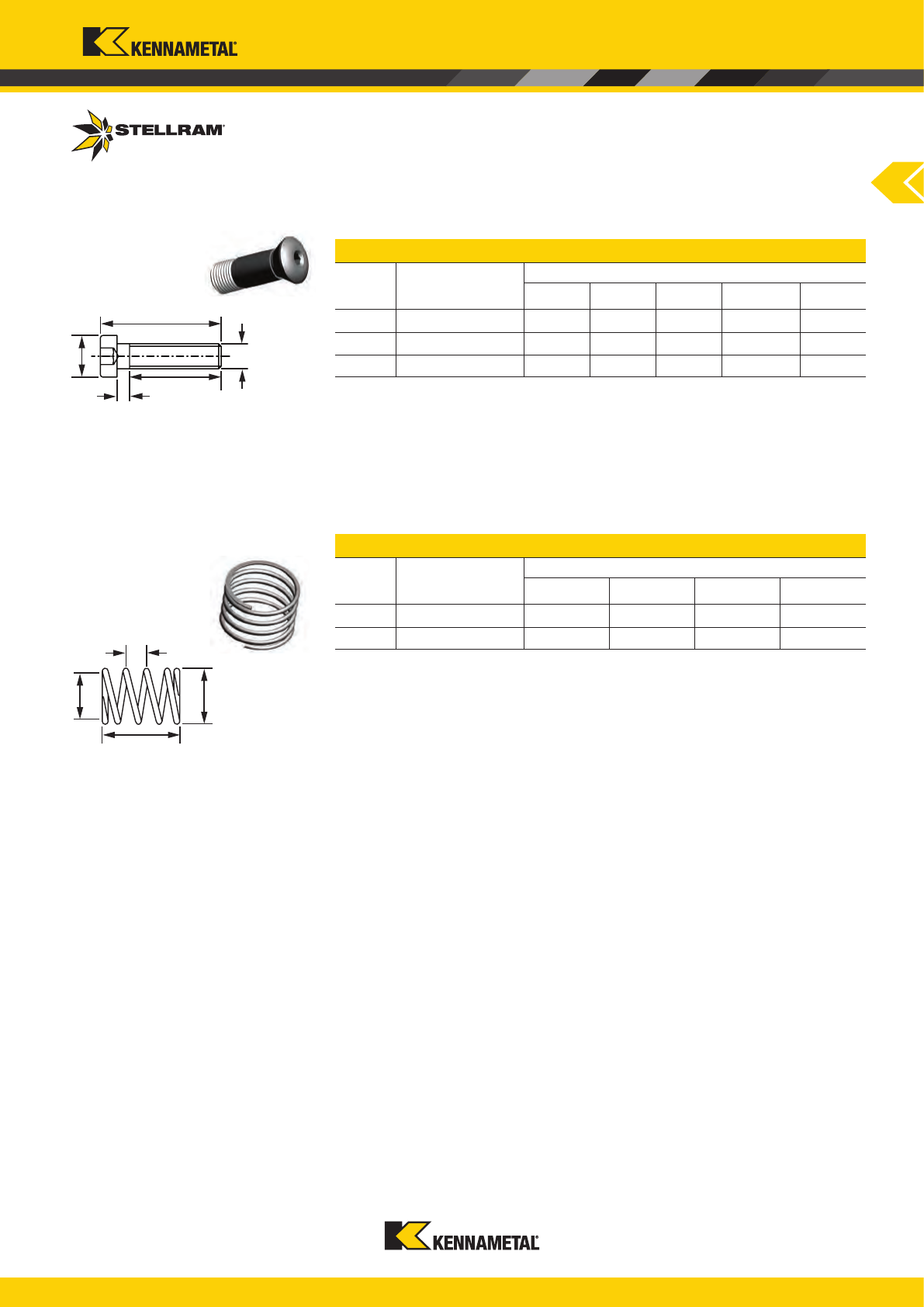

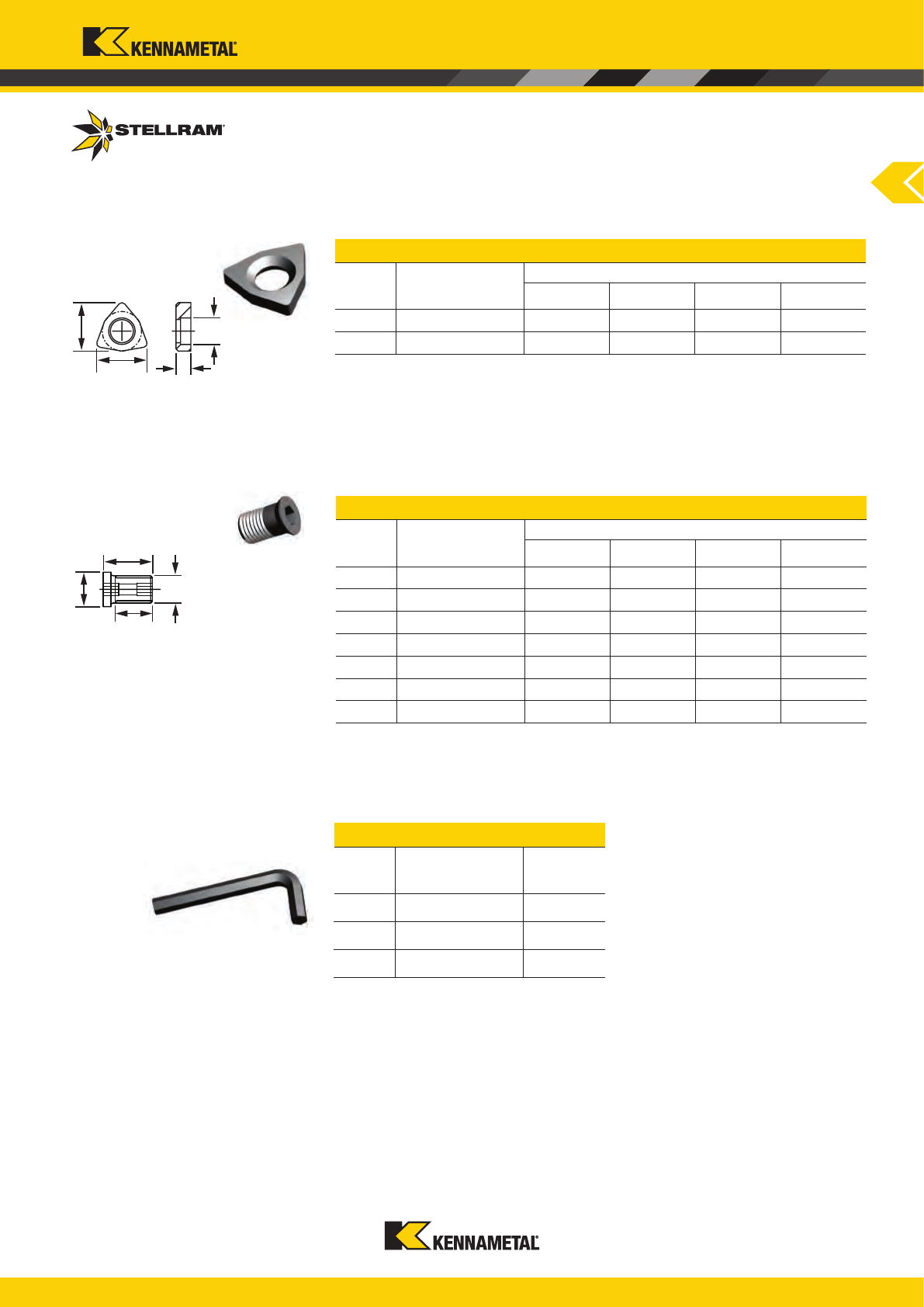

032365 CCMT060202E-73 SP4019 6,35 6,45 2,38 0,20 2,80

032366 CCMT060204E-73 SP4019 6,35 6,45 2,38 0,40 2,80

032367 CCMT060204E-73 NL300 6,35 6,45 2,38 0,40 2,80

032368 CCMT060208E-73 SP4019 6,35 6,45 2,38 0,80 2,80

032369 CCMT060208E-73 NL300 6,35 6,45 2,38 0,80 2,80

032370 CCMT09T304E-73 SP4019 9,52 9,57 3,97 0,40 4,40

032371 CCMT09T304E-73 NL300 9,52 9,57 3,97 0,40 4,40

032372 CCMT09T304E-73 NL920 9,52 9,57 3,97 0,40 4,40

032373 CCMT09T308E-73 SP4019 9,52 9,57 3,97 0,80 4,40

032374 CCMT09T308E-73 NL300 9,52 9,57 3,97 0,80 4,40

032375 CCMT09T308E-73 NL920 9,52 9,57 3,97 0,80 4,40

032376 CCMT120404E-73 SP4019 12,70 12,90 2,38 0,40 5,16

032377 CCMT120404E-73 NL300 12,70 12,90 2,38 0,40 5,16

032378 CCMT120404E-73 NL920 12,70 12,90 2,38 0,40 5,16

032379 CCMT120408E-73 SP4019 12,70 12,90 4,76 0,80 5,16

032380 CCMT120408E-73 NL300 12,70 12,90 4,76 0,80 5,16

032381 CCMT120408E-73 NL920 12,70 12,90 4,76 0,80 5,16

032382 CCMT120412E-73 SP4019 12,70 12,90 4,76 1,20 5,16

032383 CCMT120412E-73 NL300 12,70 12,90 4,76 1,20 5,16

032384 CCMT120412E-73 NL920 12,70 12,90 4,76 1,20 5,16

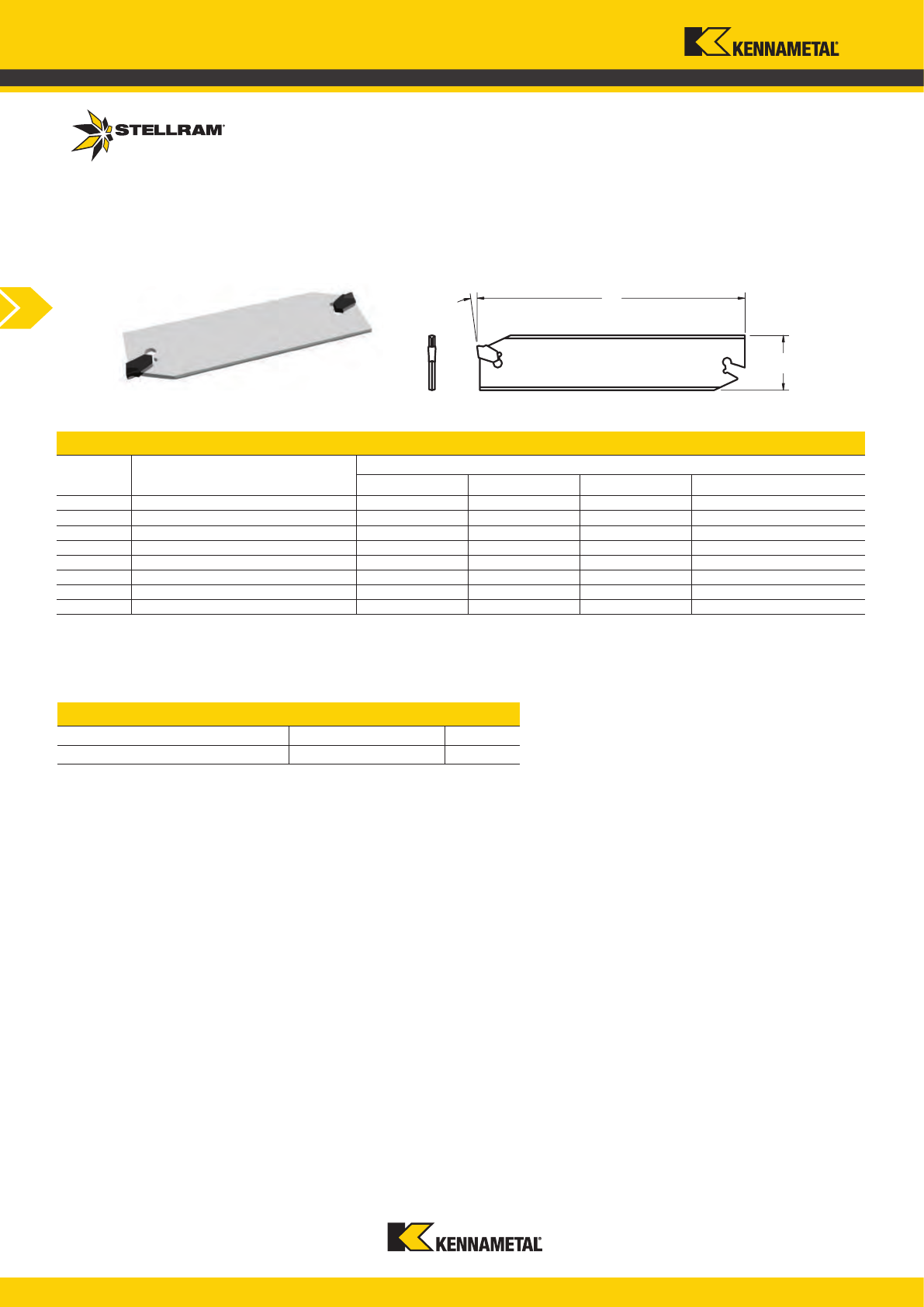

80°

7°

m

d

r

m

1

I

s

h

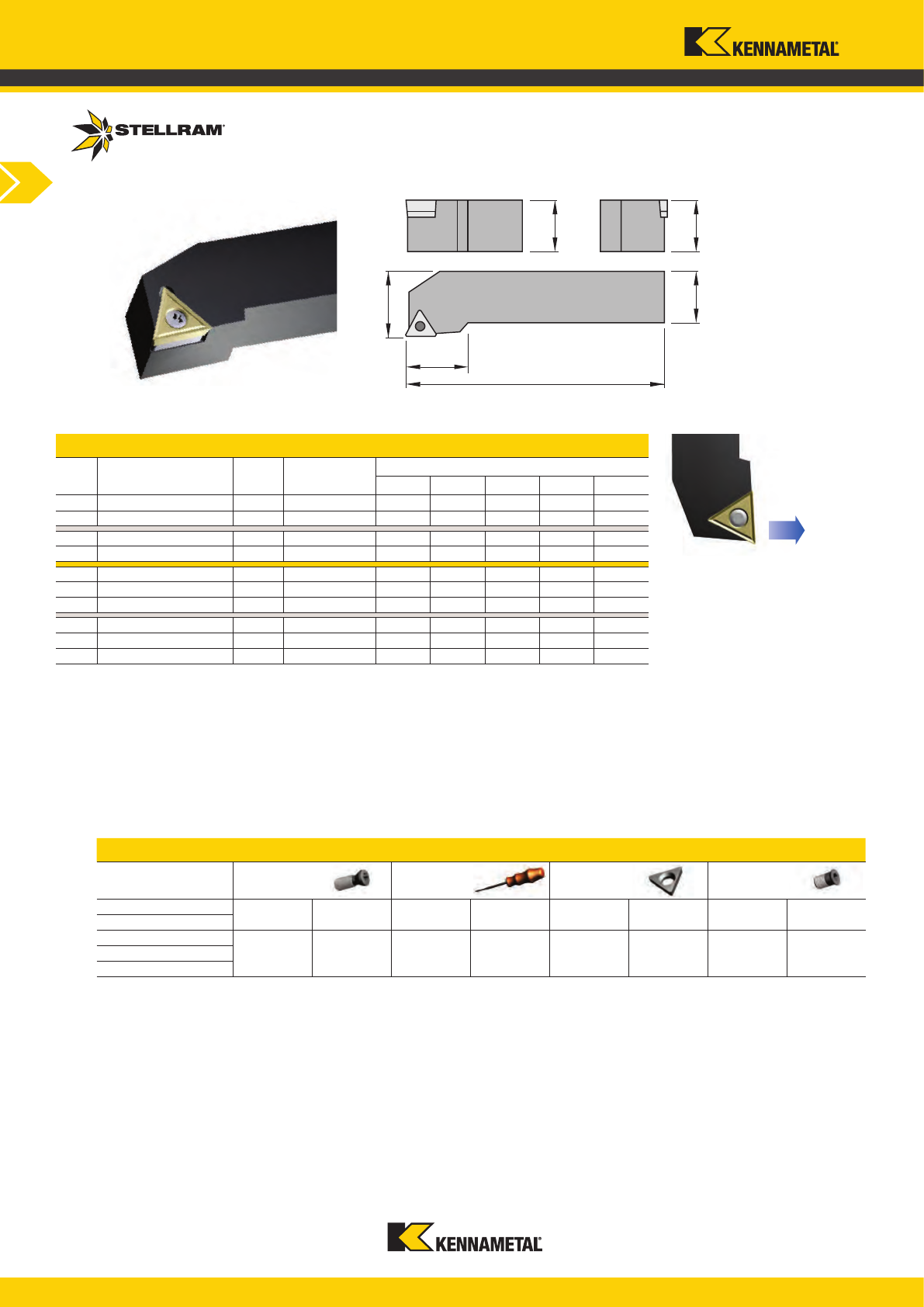

Material Guide – Key to Recommended Inserts

Material Designation

Alloyed Steels PH Stainless Aluminum & Alloys High Temp. Alloys Hard MaterialsUnalloyed Steels Stainless Steels Cast Irons

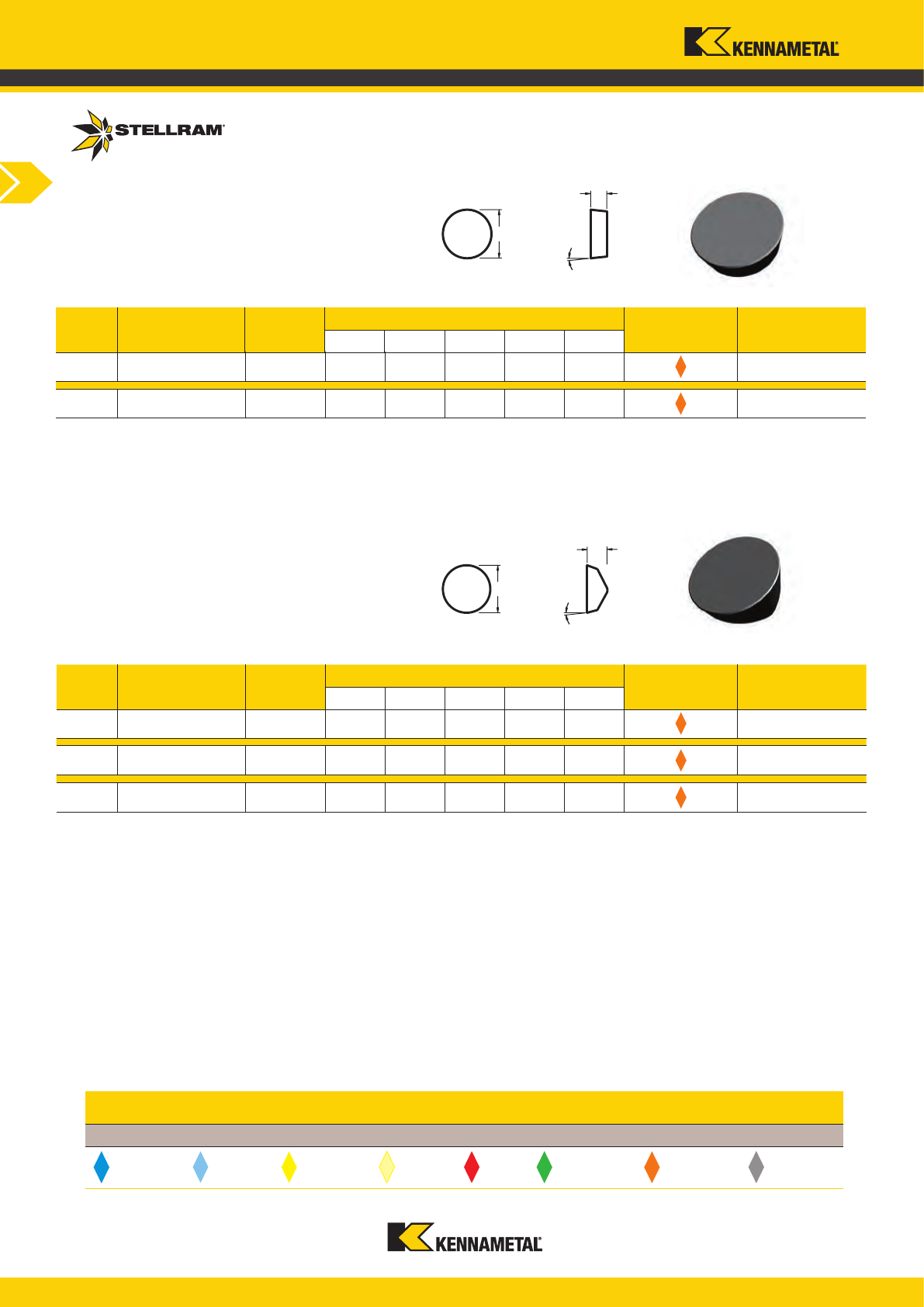

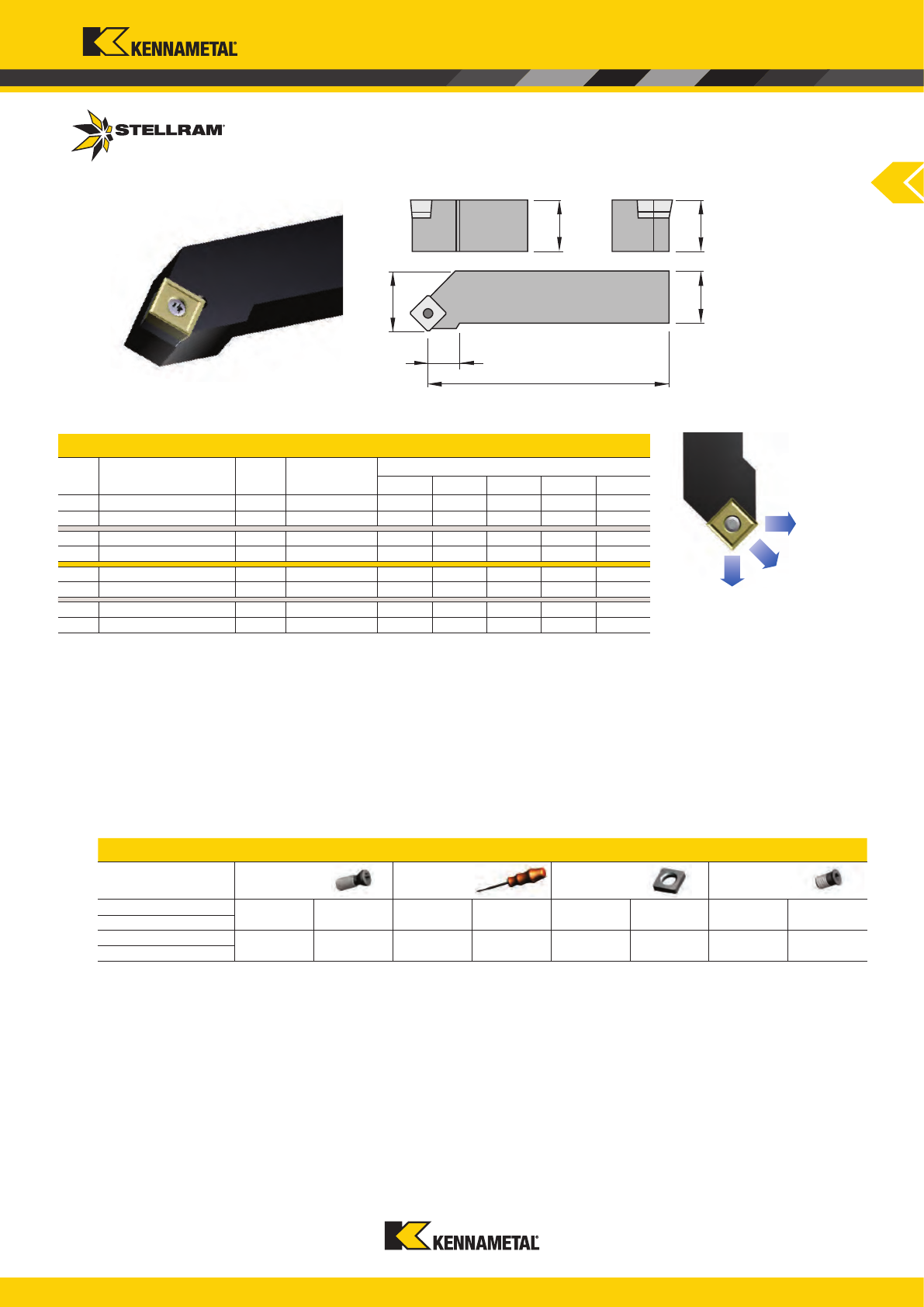

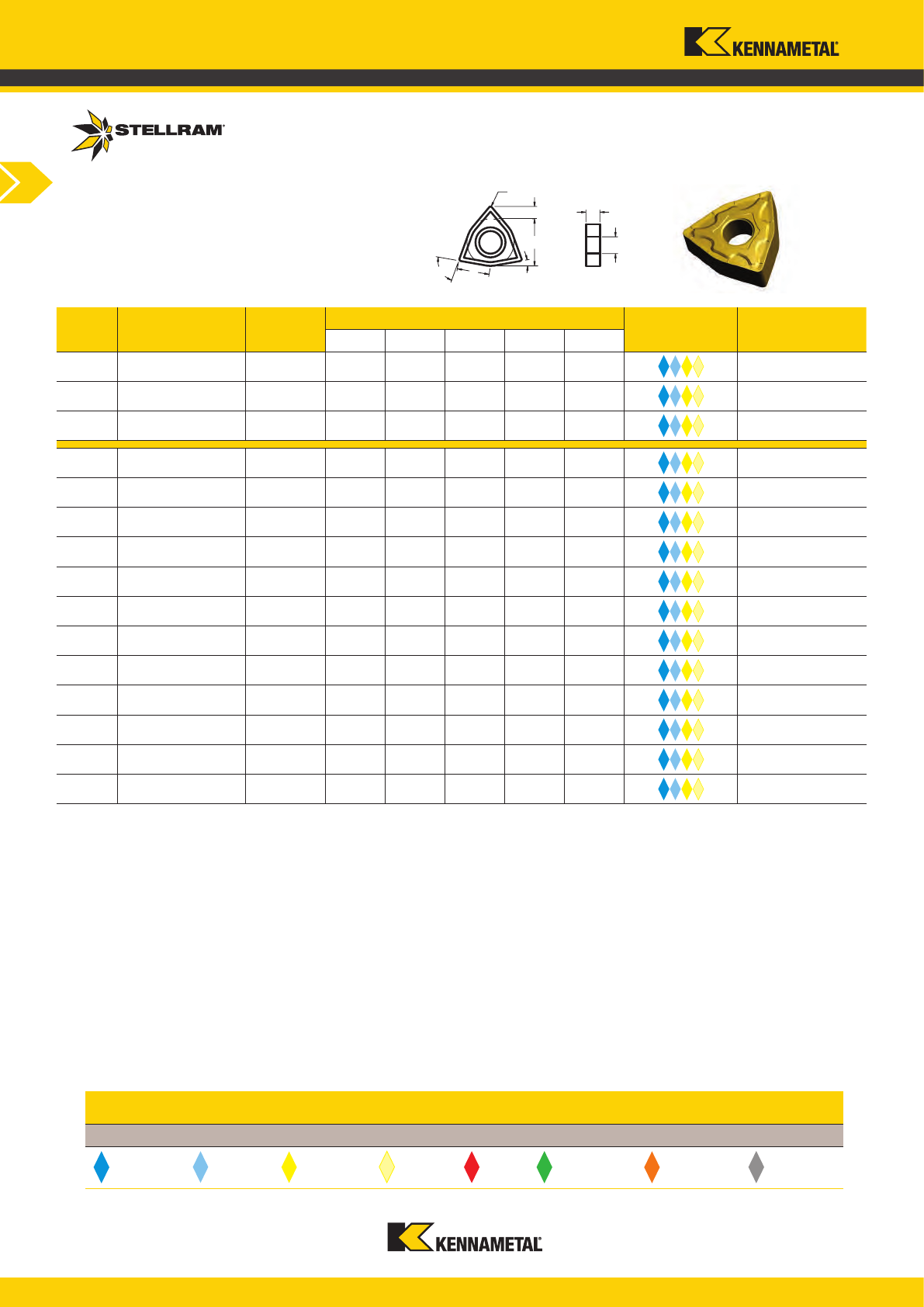

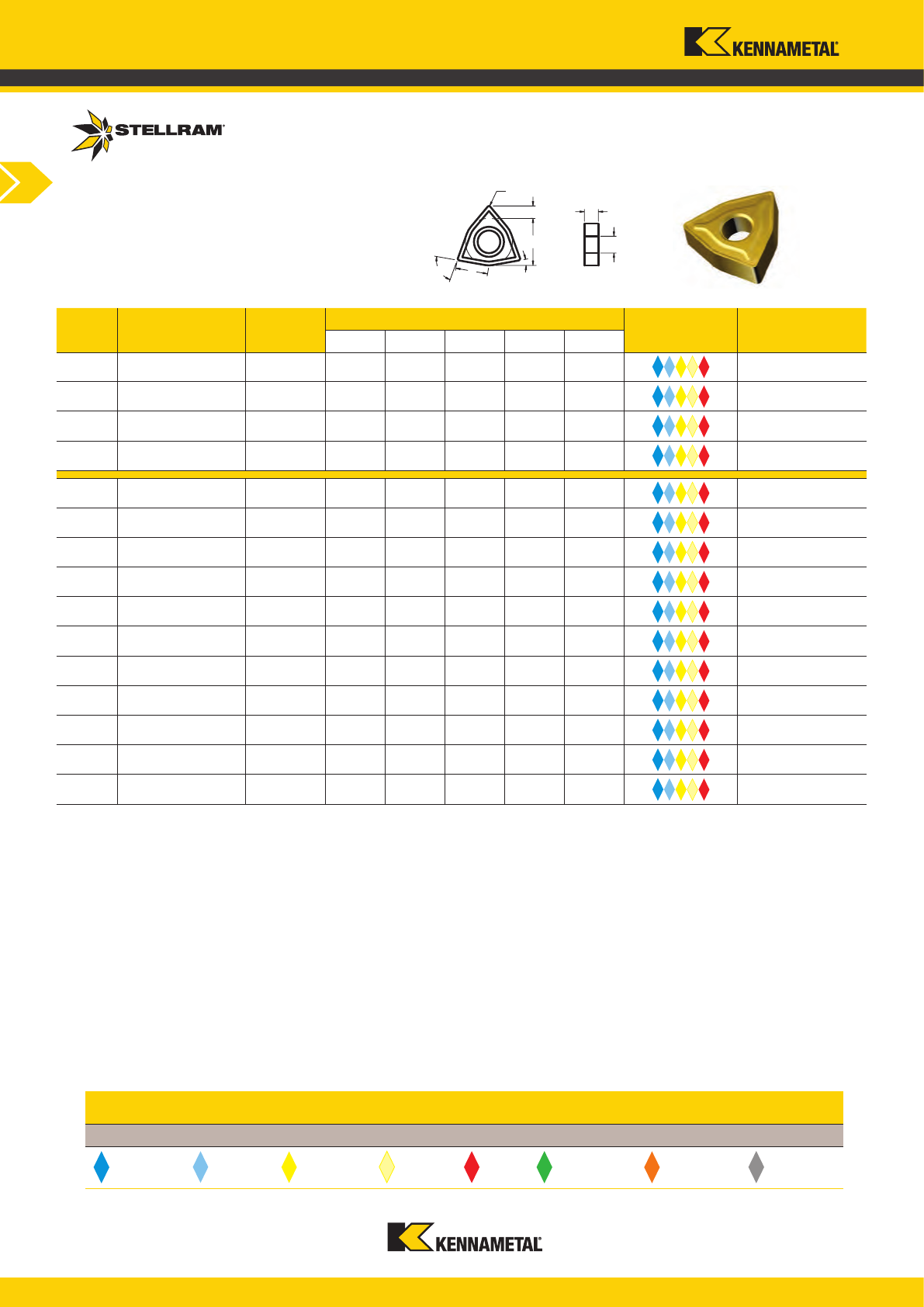

Turning Inserts

EDP ISO Description Grade

Dimensions (mm)

Material Application

d I s r

h

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

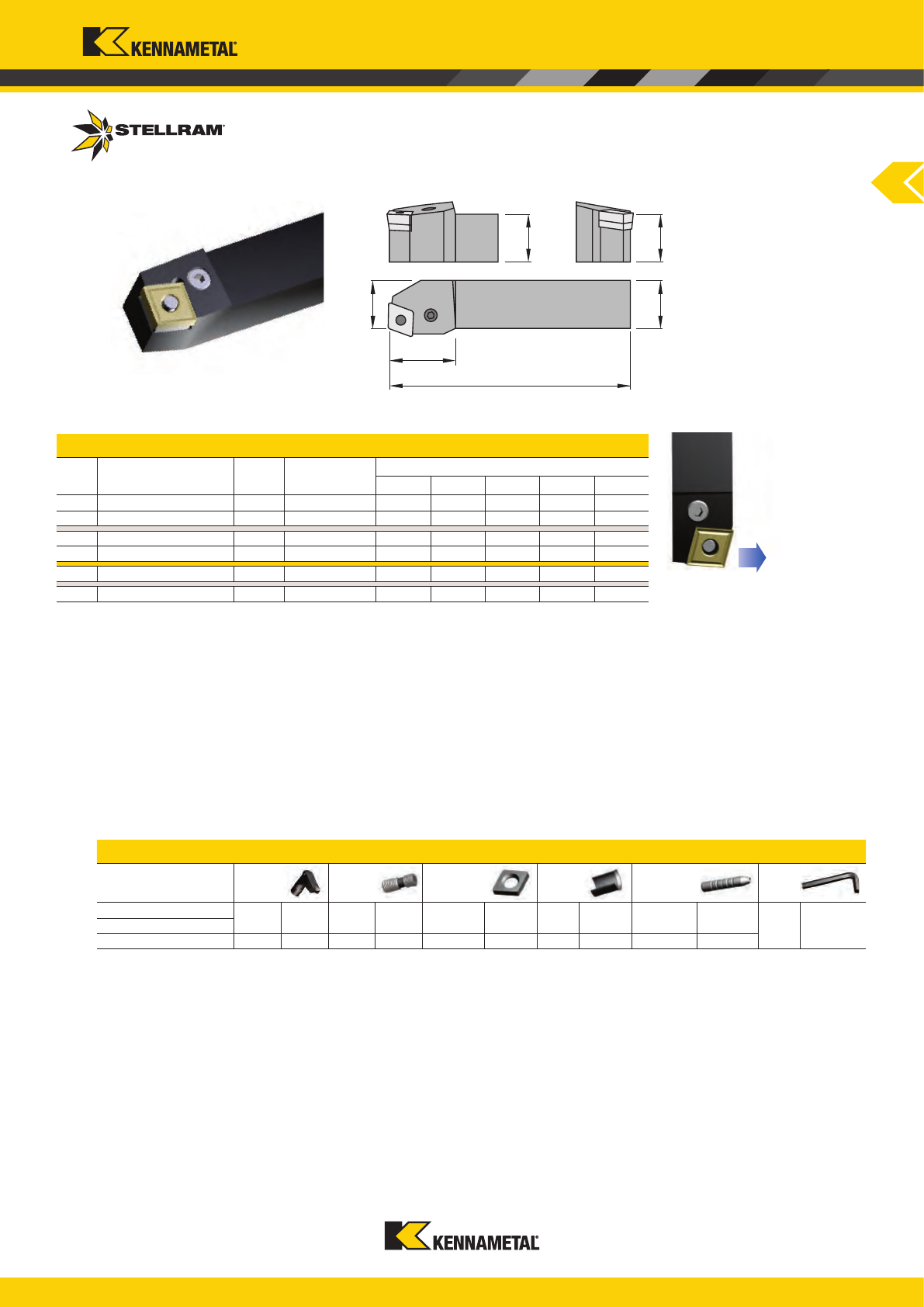

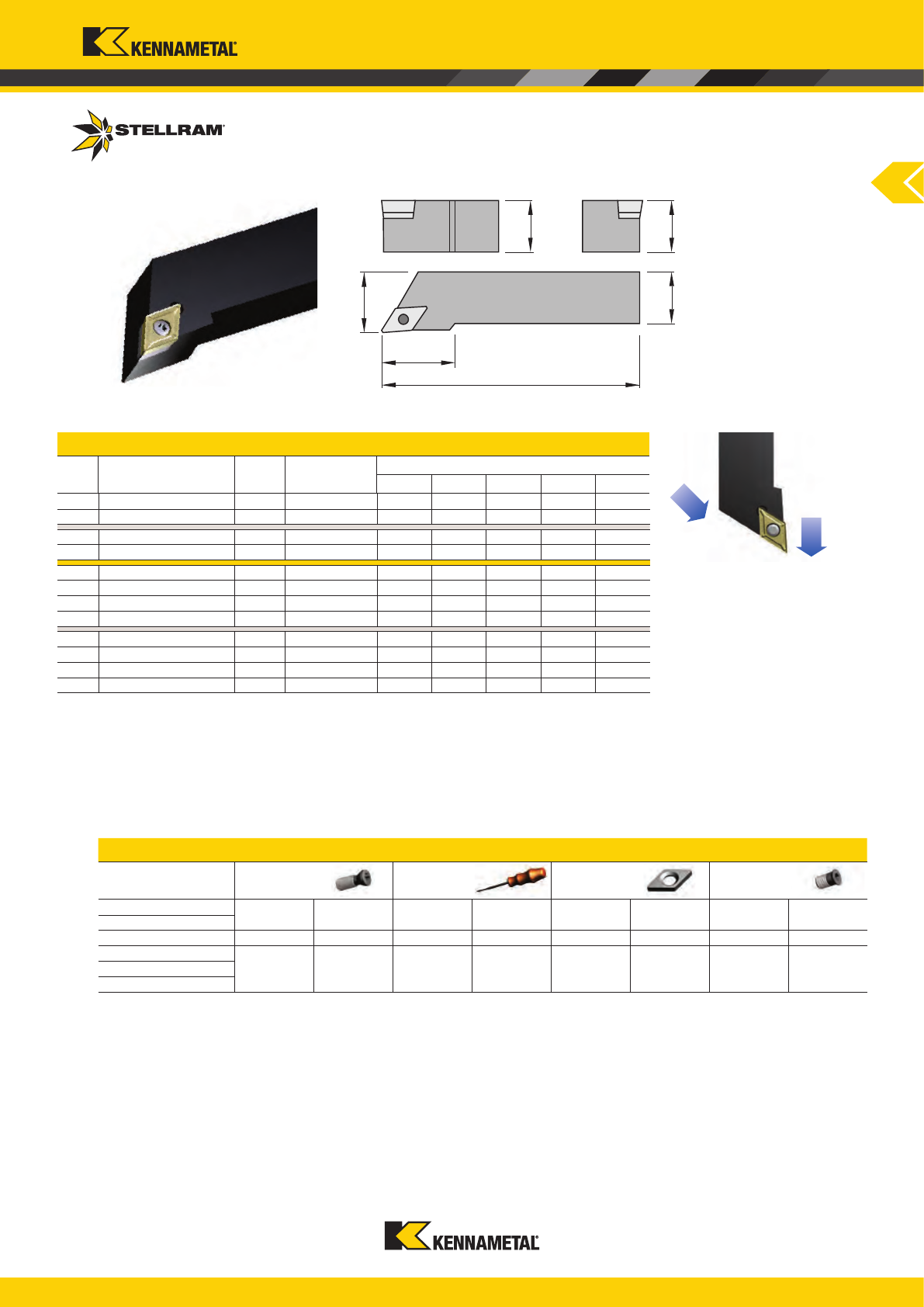

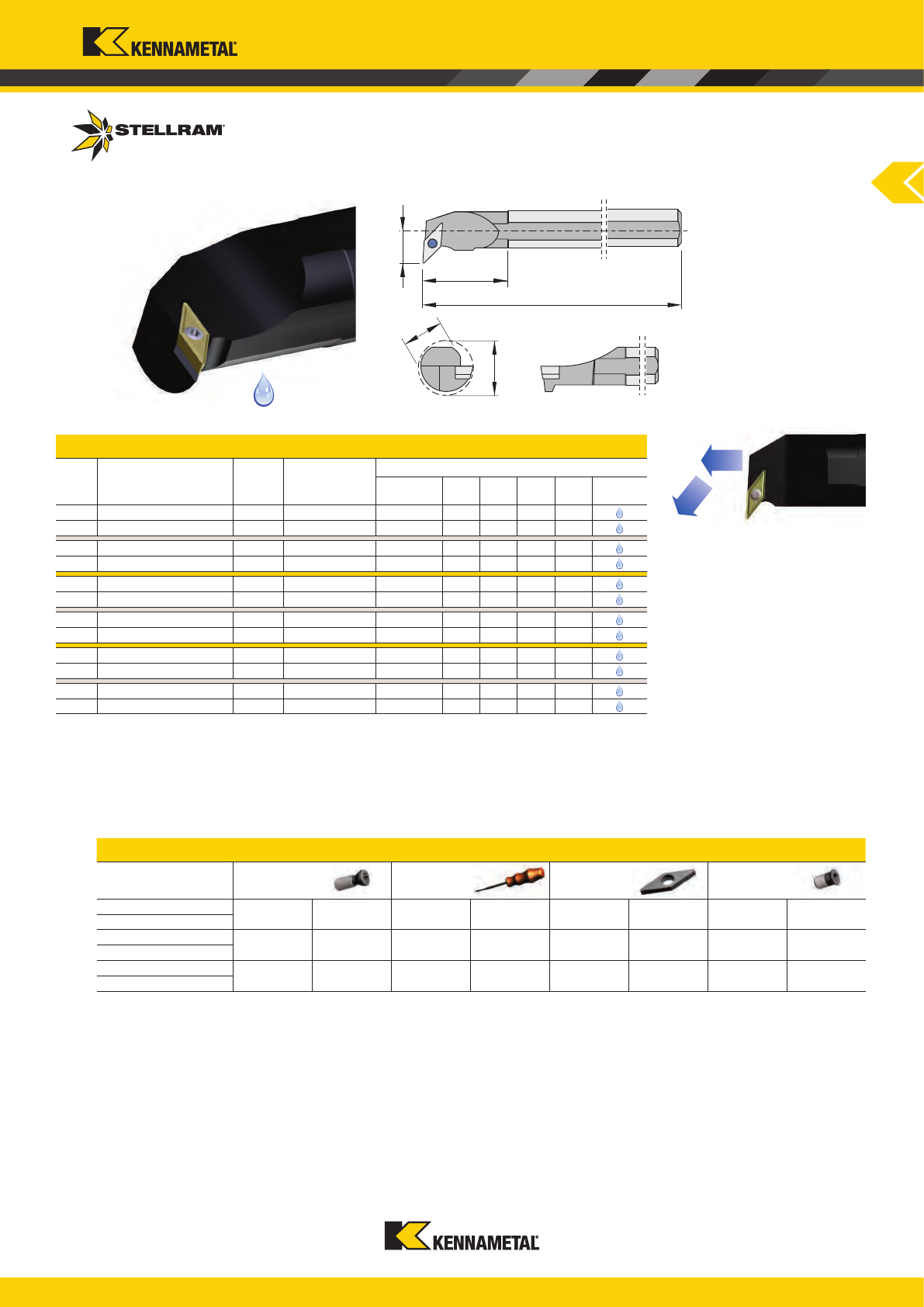

For Toolholders External: see page C44 | Internal: see page C45

C Style

Turning Inserts

CCMT

-73 Geometry

www.kennametal.com

C44

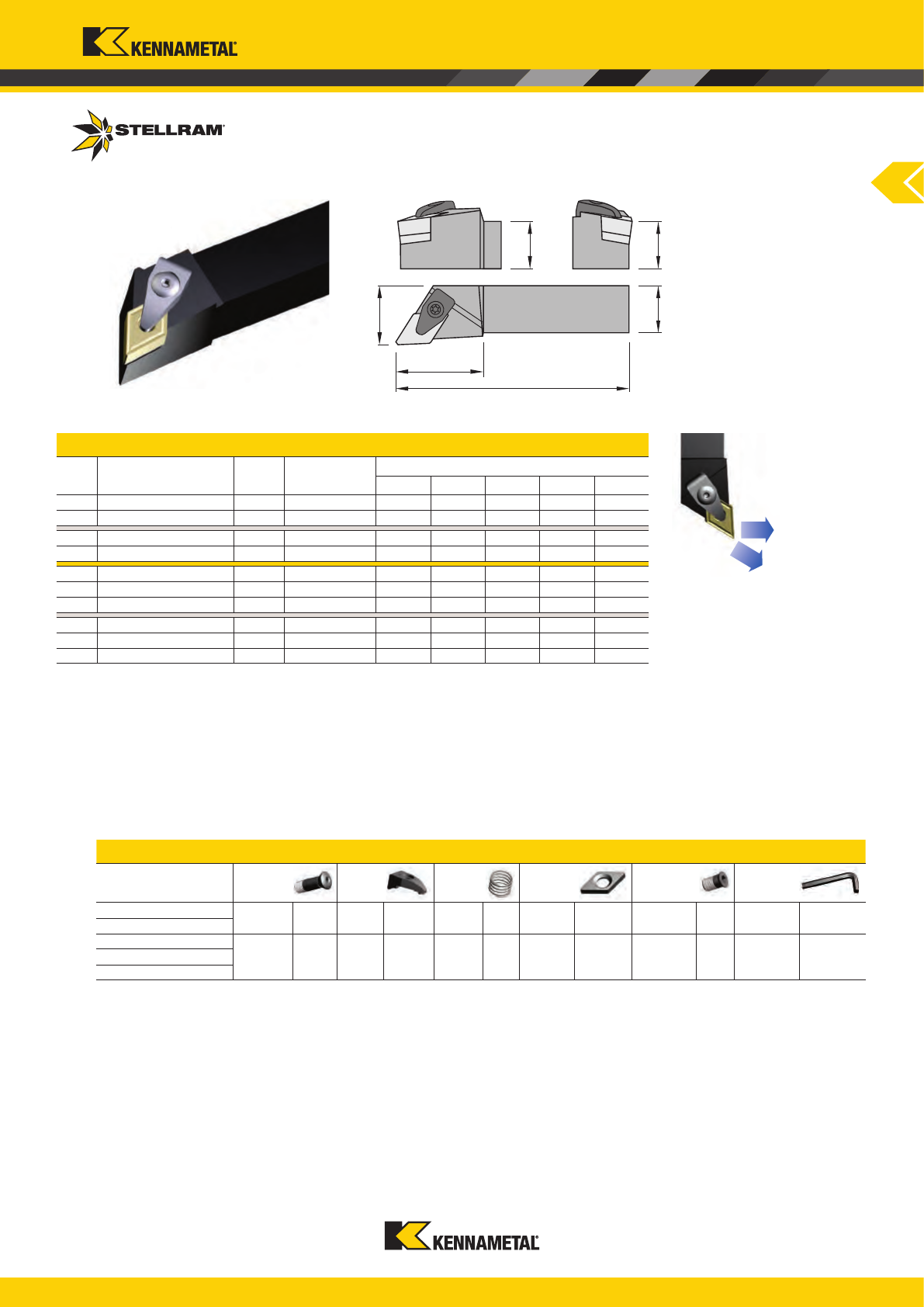

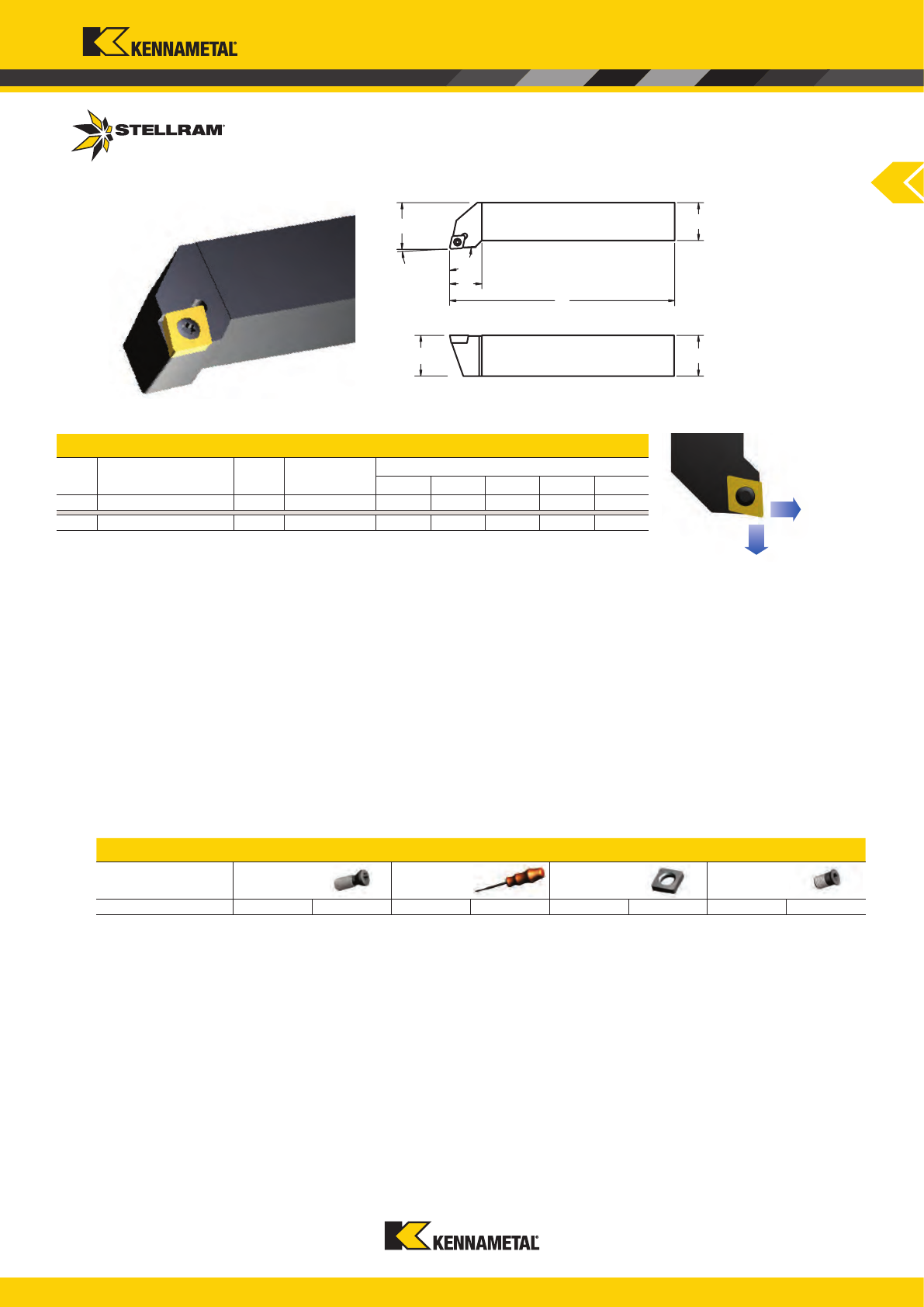

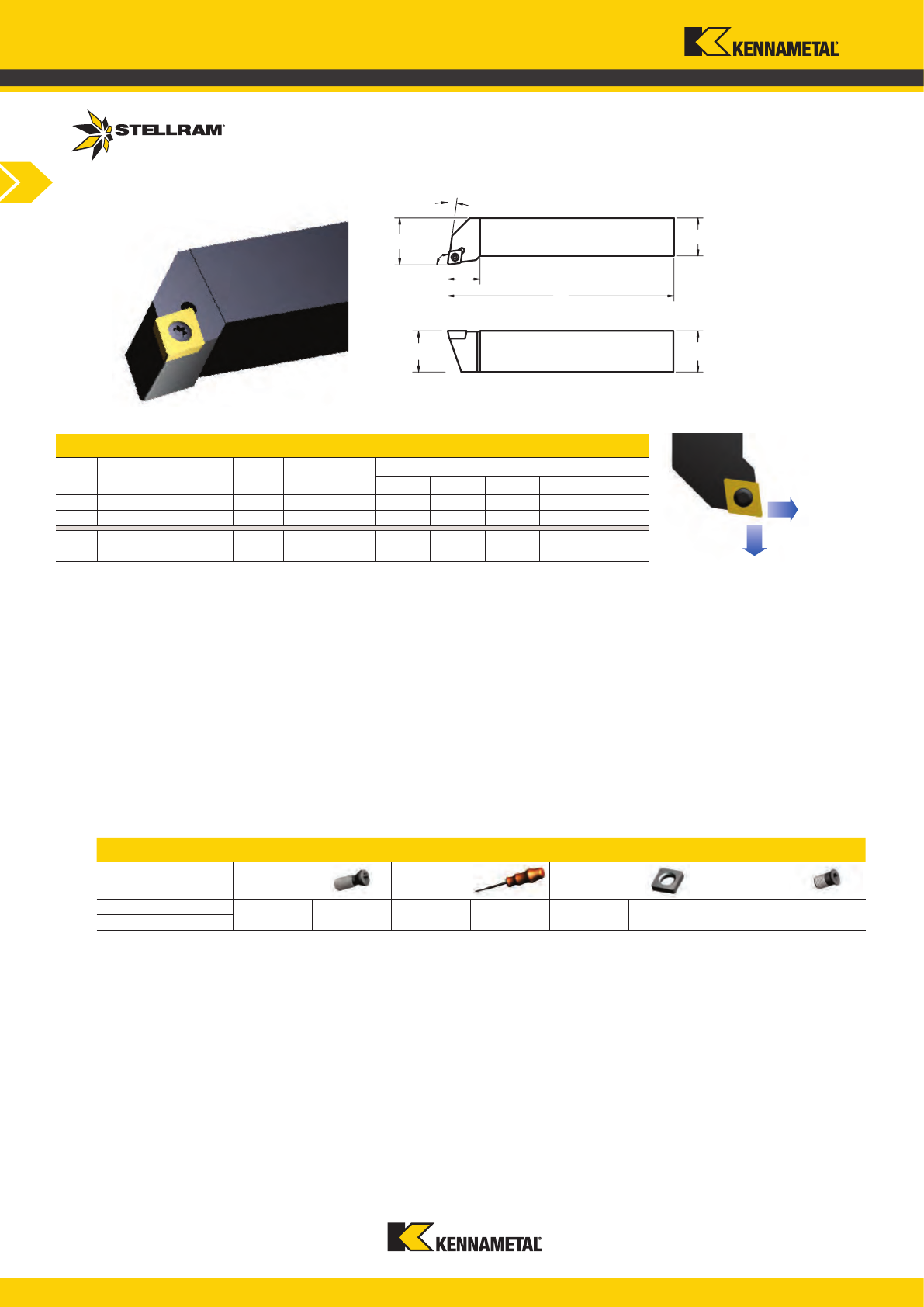

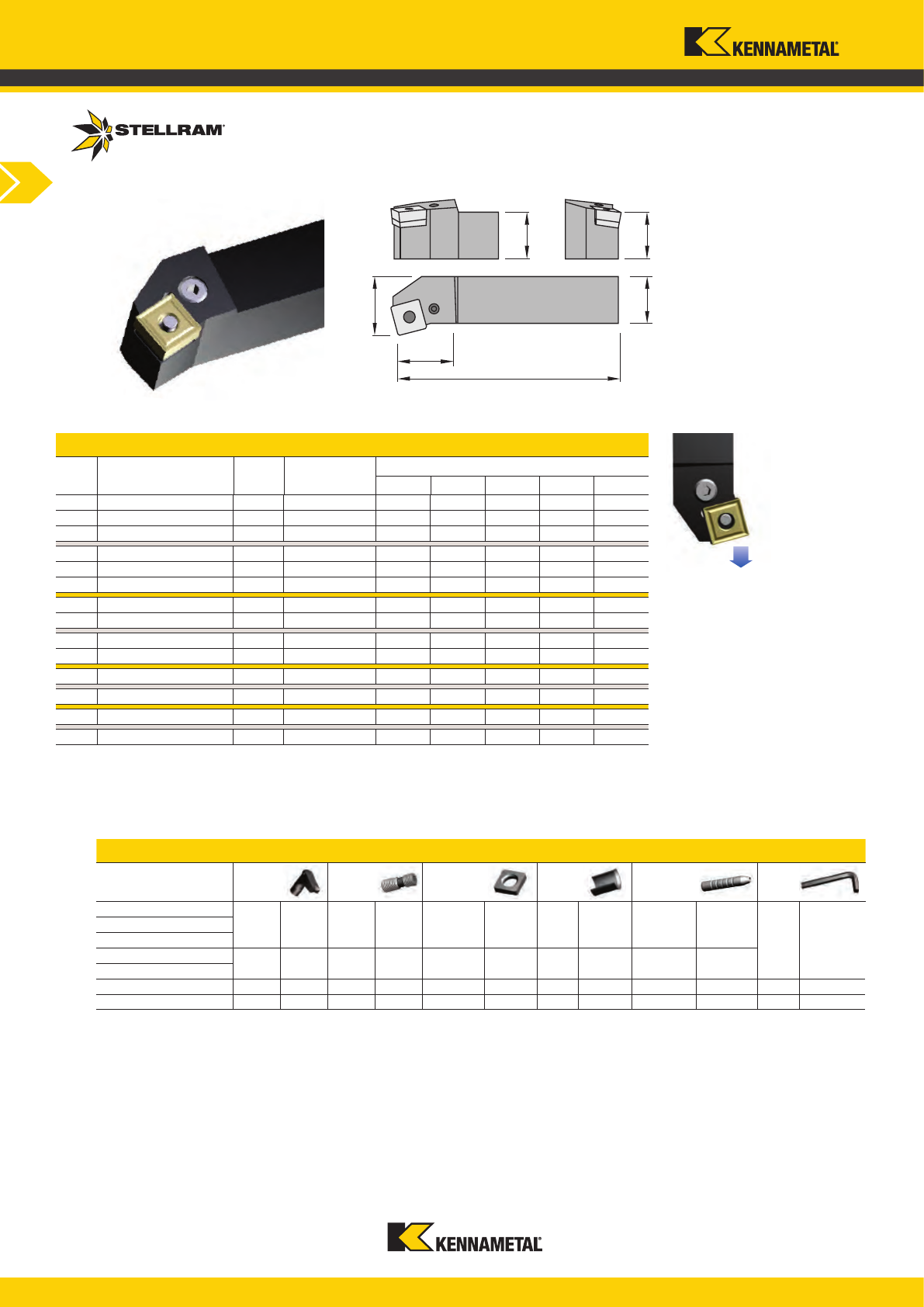

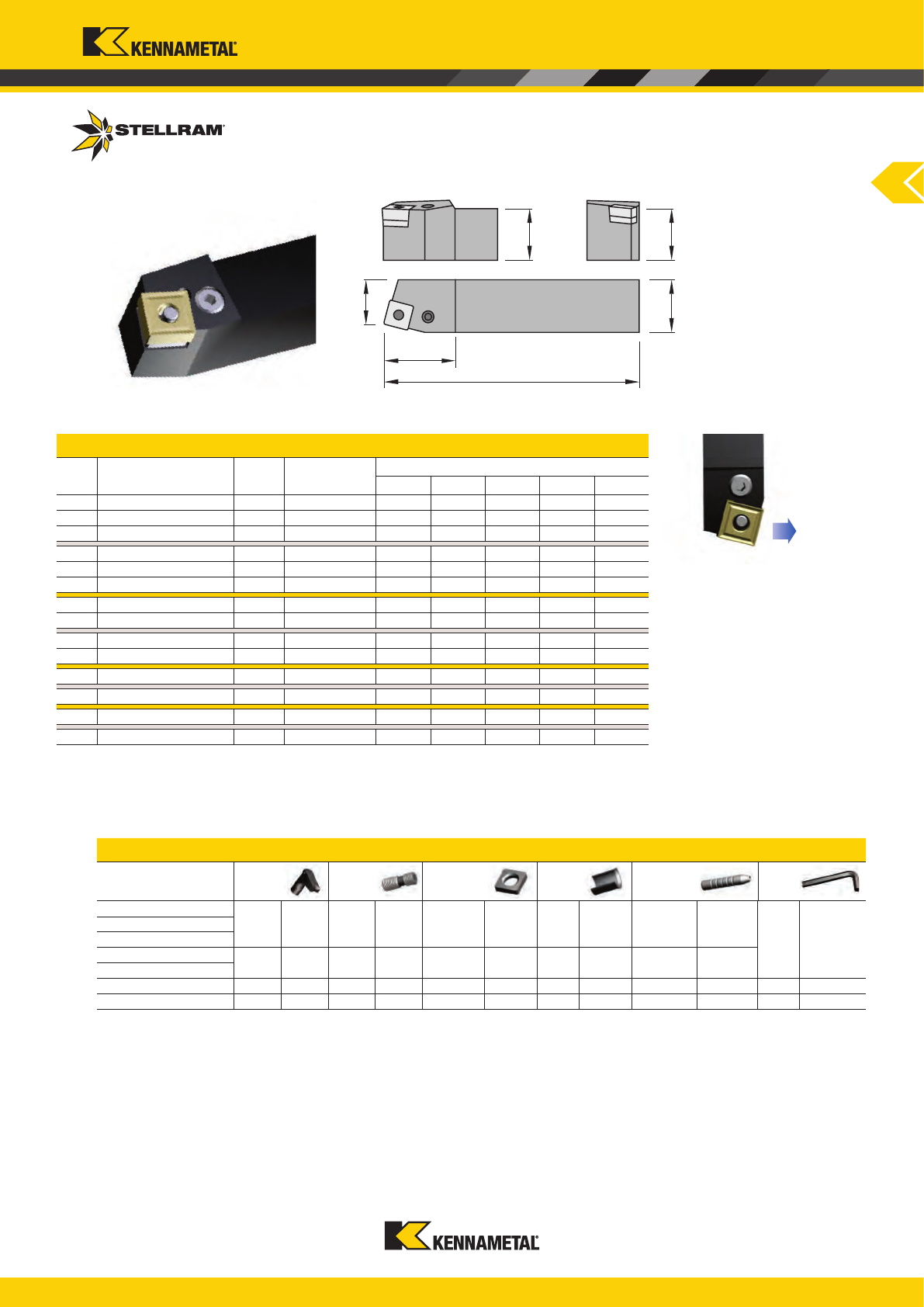

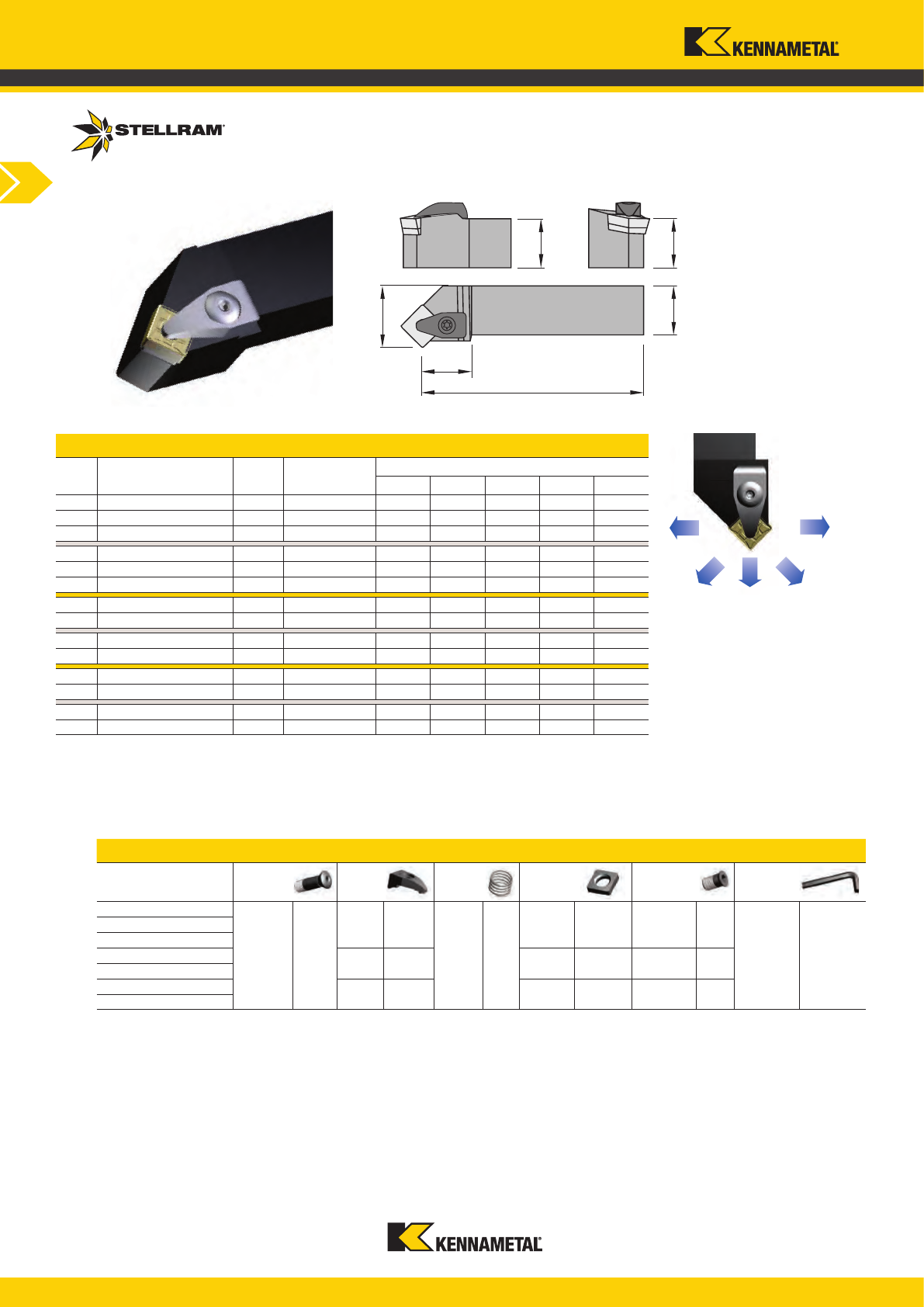

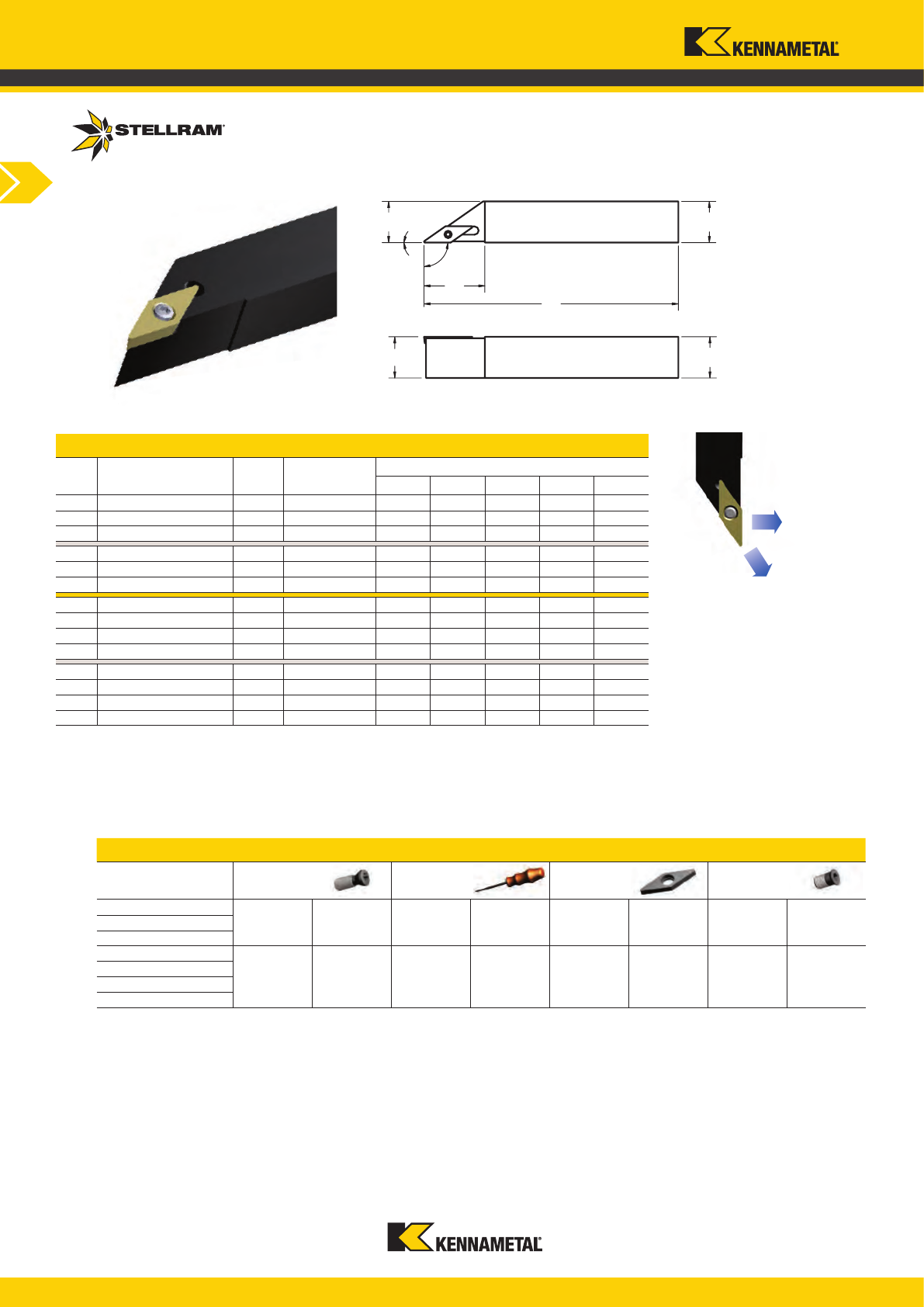

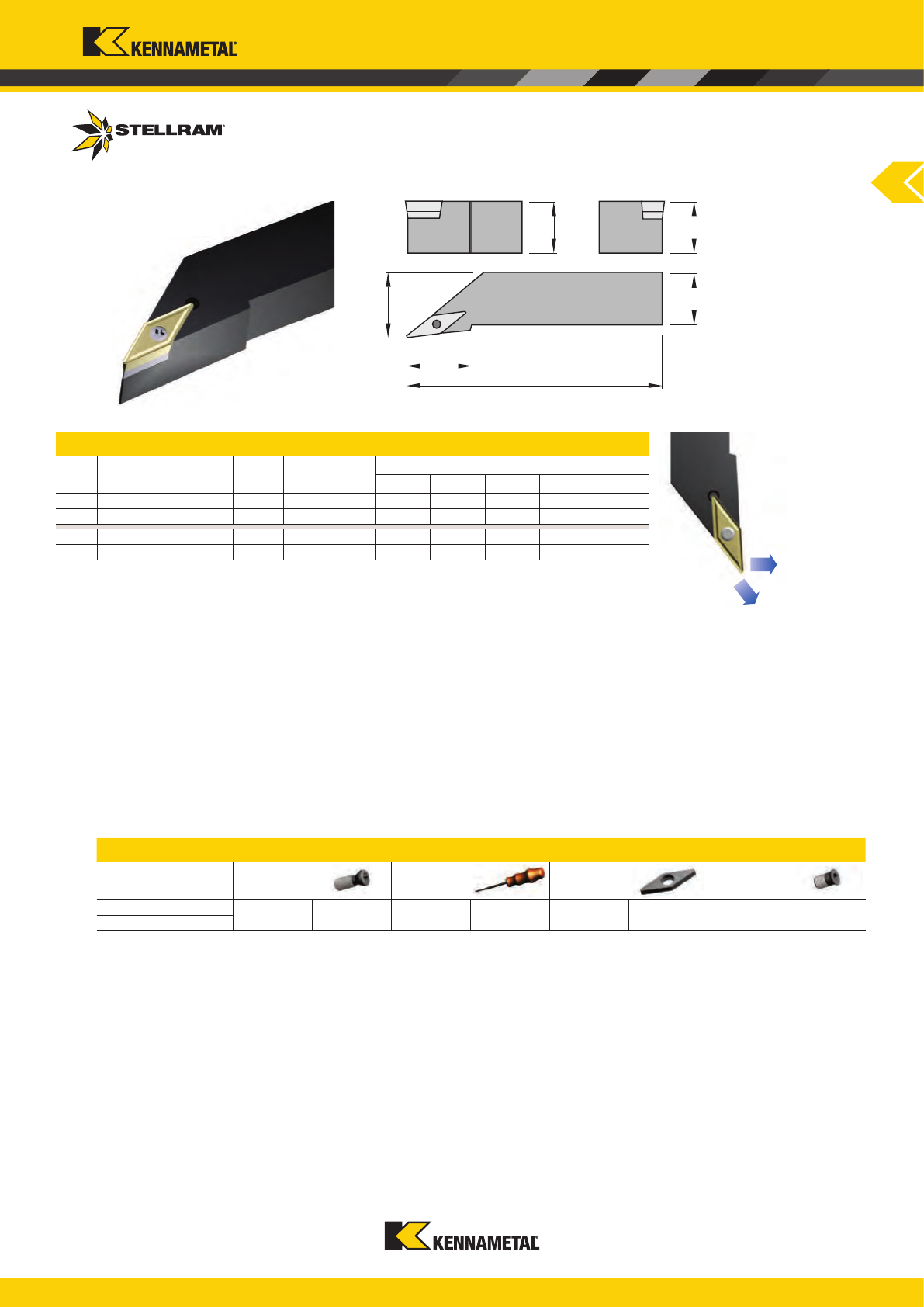

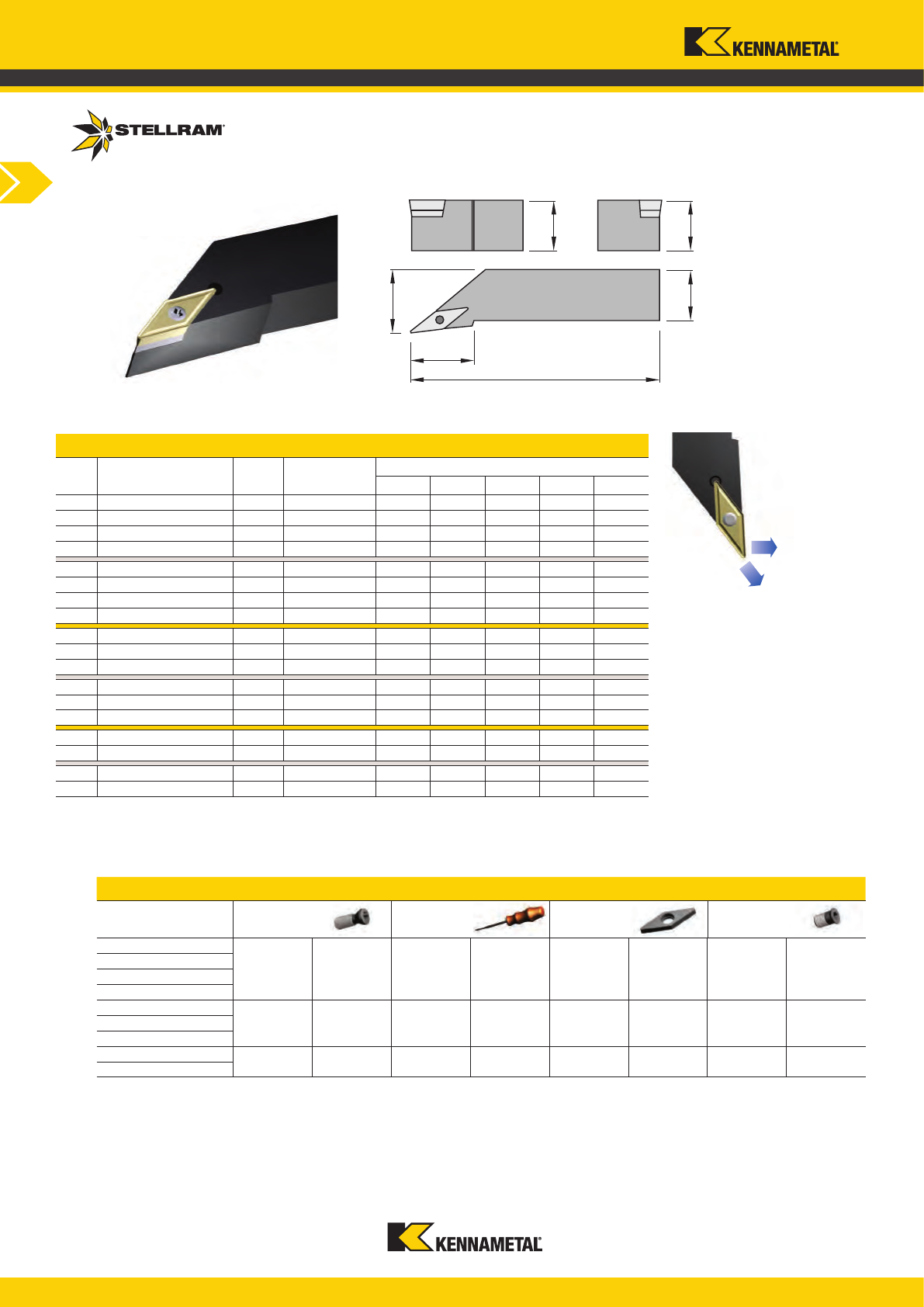

SCLCL/R 1010 E06 015061 F2507T 018488 T7 - - - -

SCLCL/R 1212 F09

015262 D4010T 015240 T15 - - - -SCLCL/R 1616 H09

SCLCL/R 2020 K09